Accelerated Life Test and Performance Degradation Test of Harmonic Drive with Failure Analysis

Abstract

1. Introduction

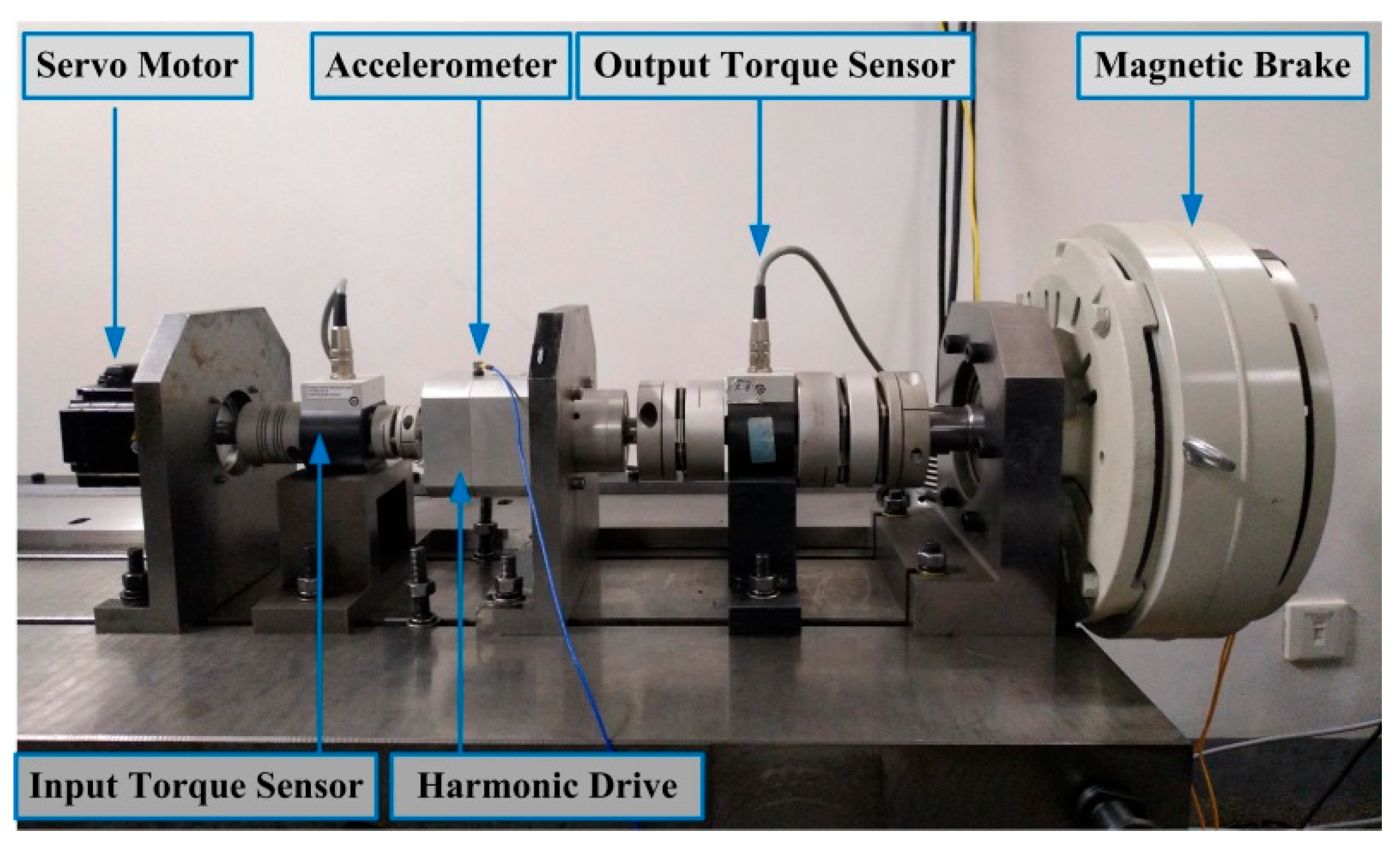

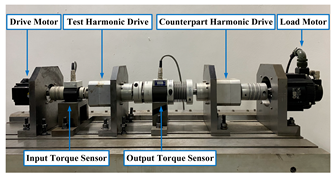

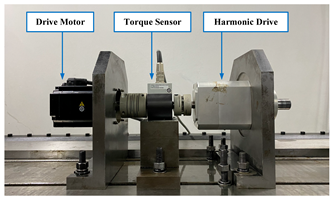

2. Test Rigs of HD Accelerated Life and Performance Degradation

2.1. HD Accelerated Life Test Rig

2.2. HD Performance Degradation Test Rig

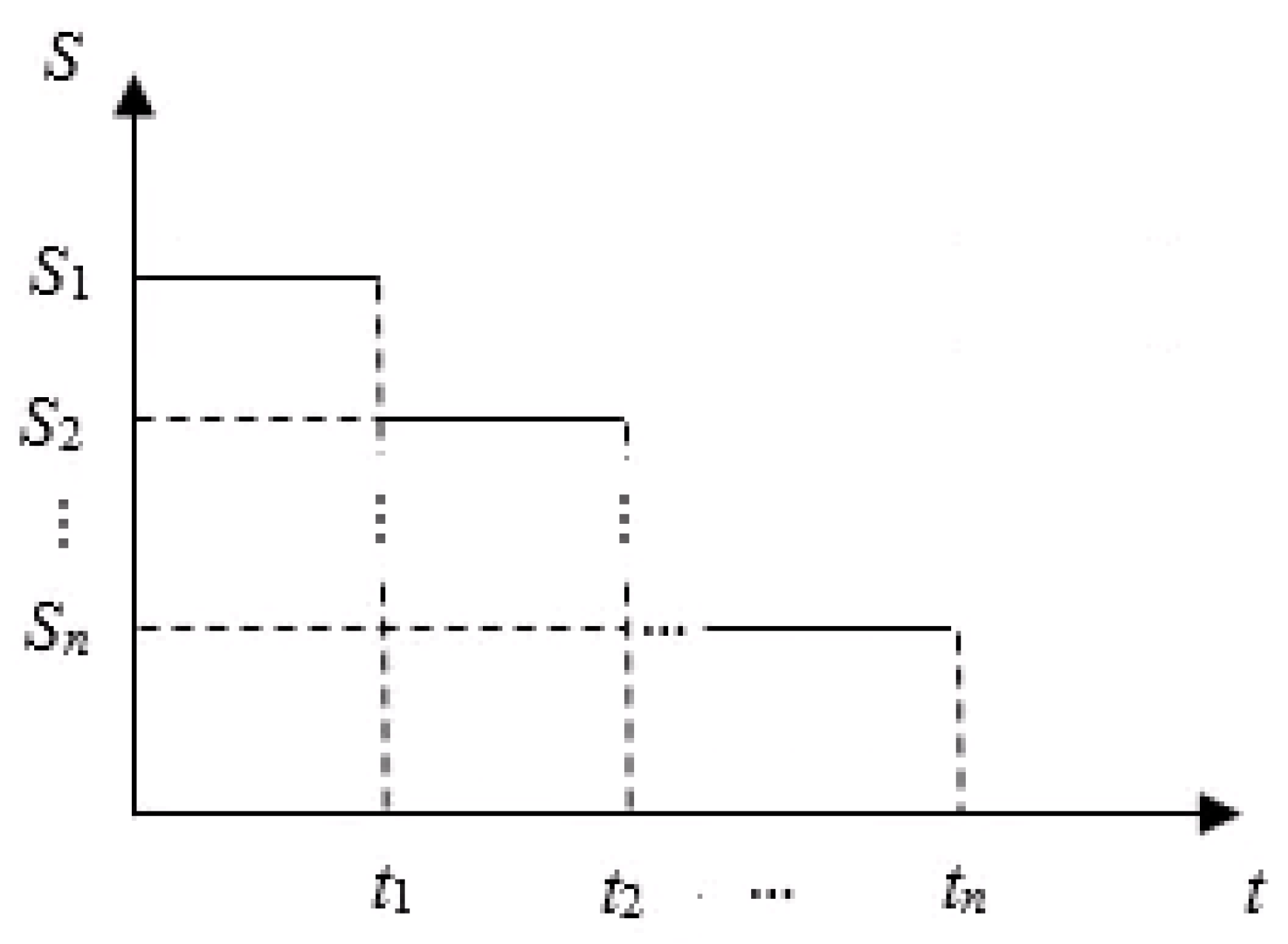

3. Plan of Step-Down Accelerated Life Test and Performance Degradation Test

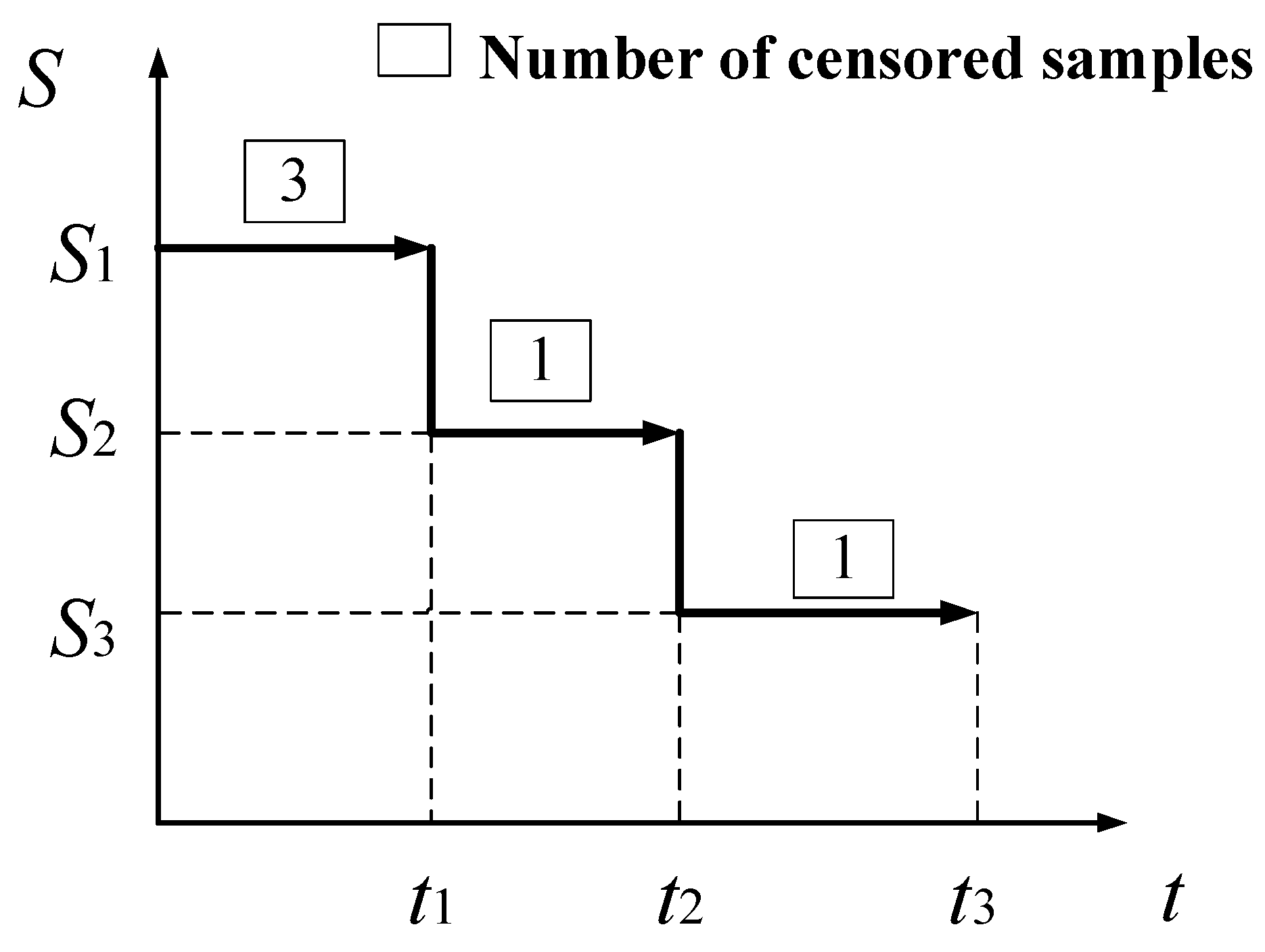

3.1. Stress Level and Sample Number of Step-Down Accelerated Life Test

3.2. Procedure of HD Accelerated Life Test

3.3. Performance Degradation Test

4. Results of Accelerated Life Test and Performance Degradation Test of HD

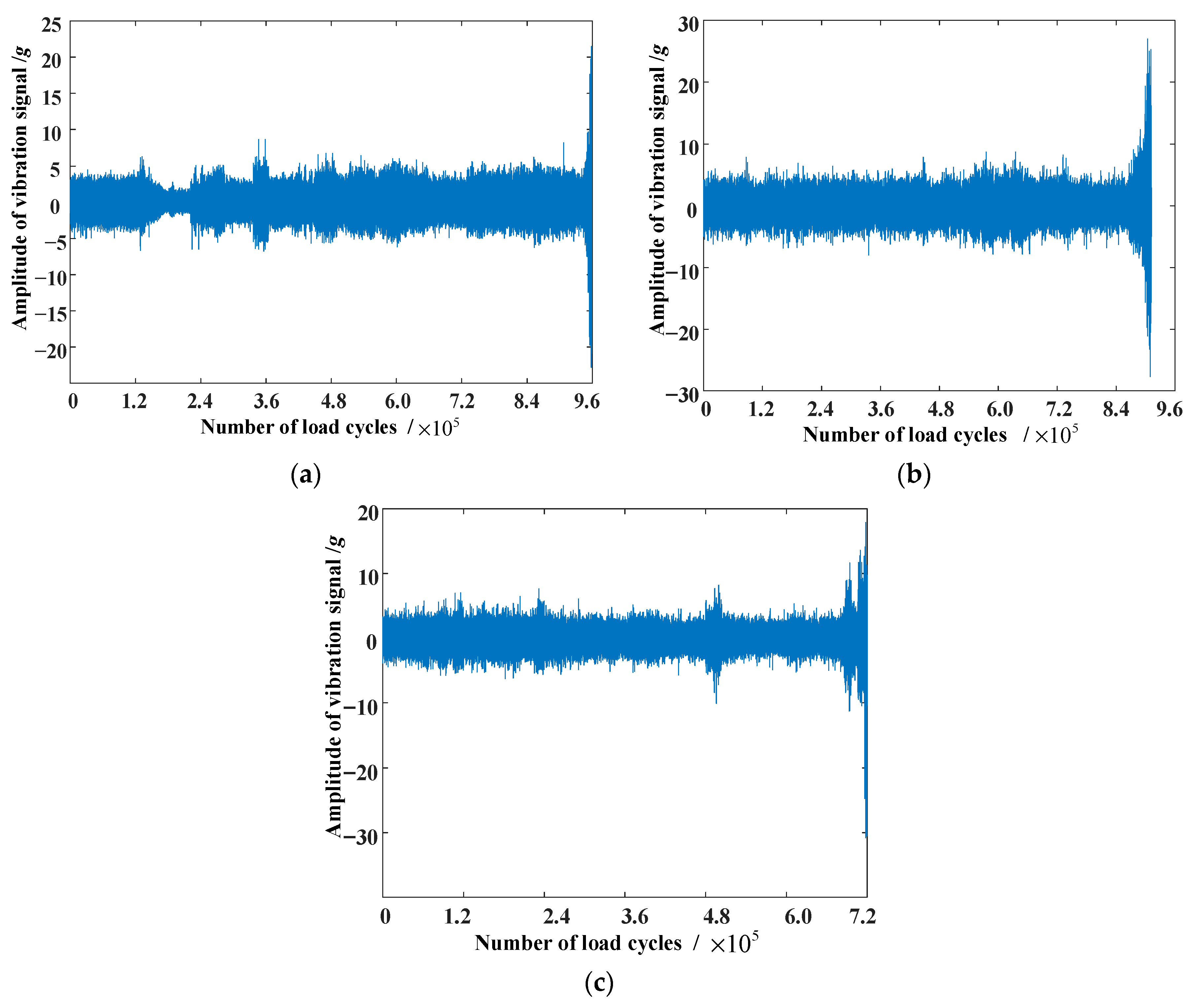

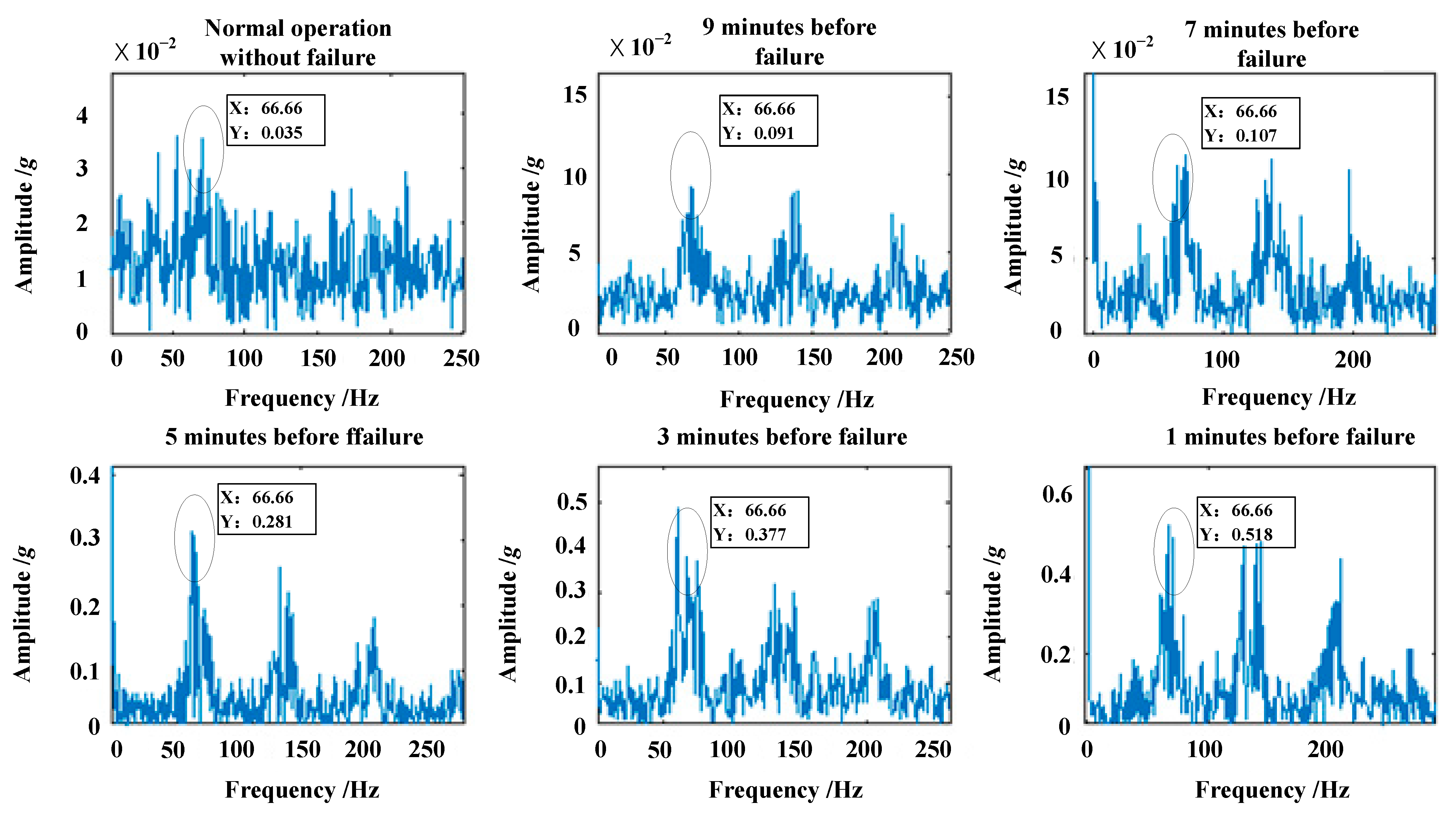

4.1. Step-Down ALT Results Under 100 Nm

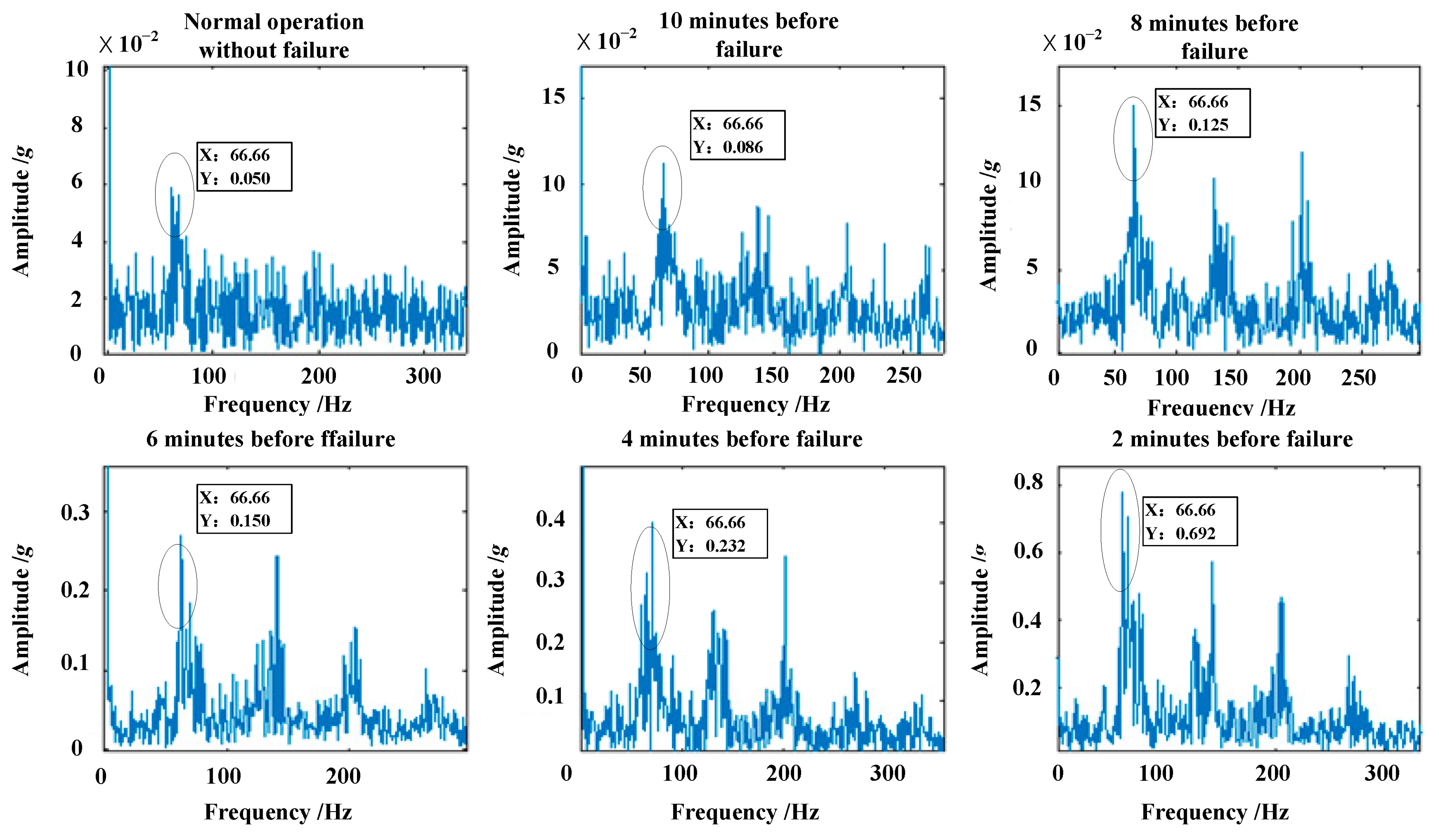

4.2. Two-Stress Step-Down ALT Results Under 100–75 Nm

4.3. Three-Stress Step-Down ALT Results Under 100–75–50 Nm

5. Results Analysis

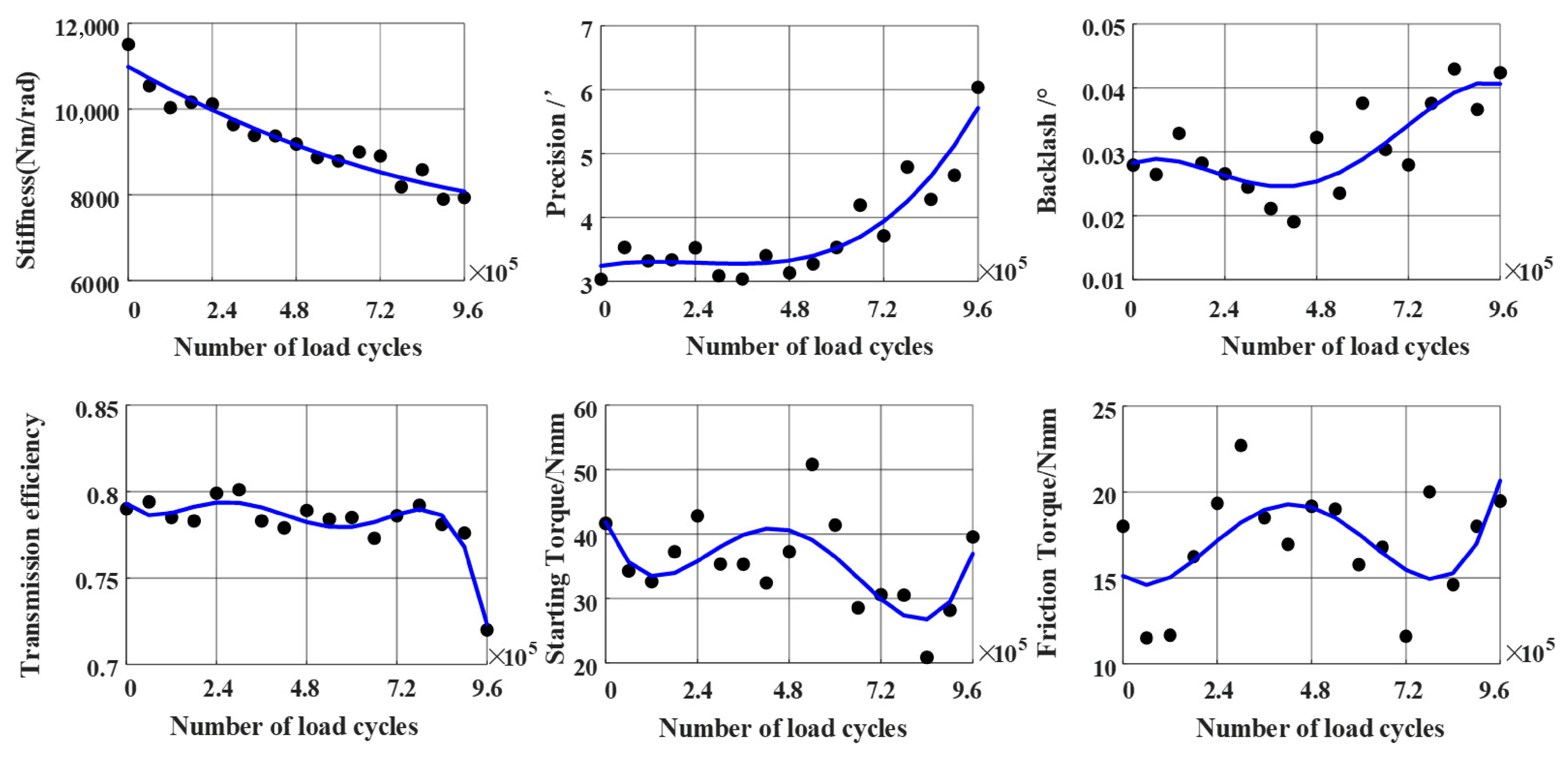

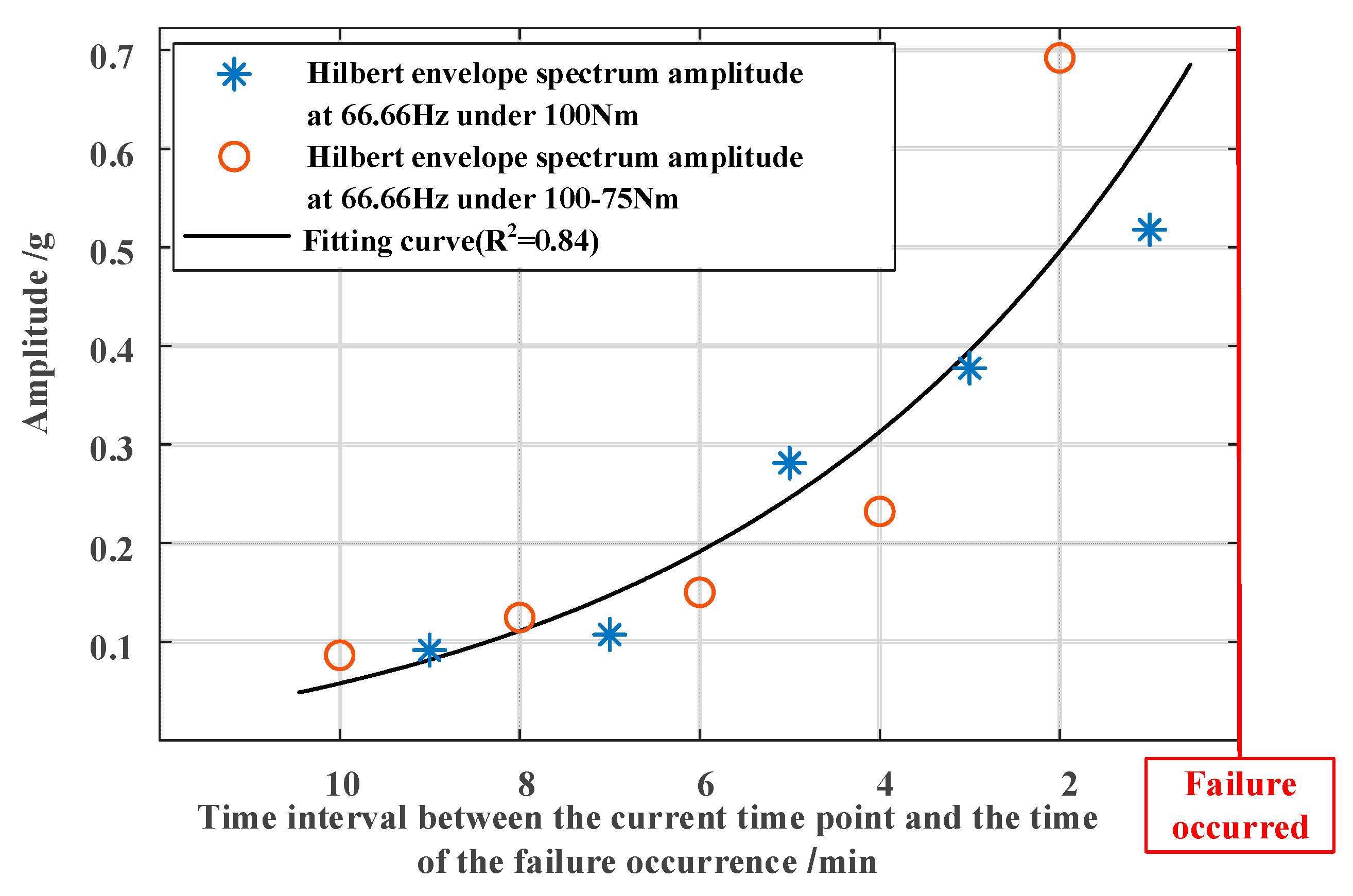

5.1. Performance Degradation Failure Mechanism Analysis

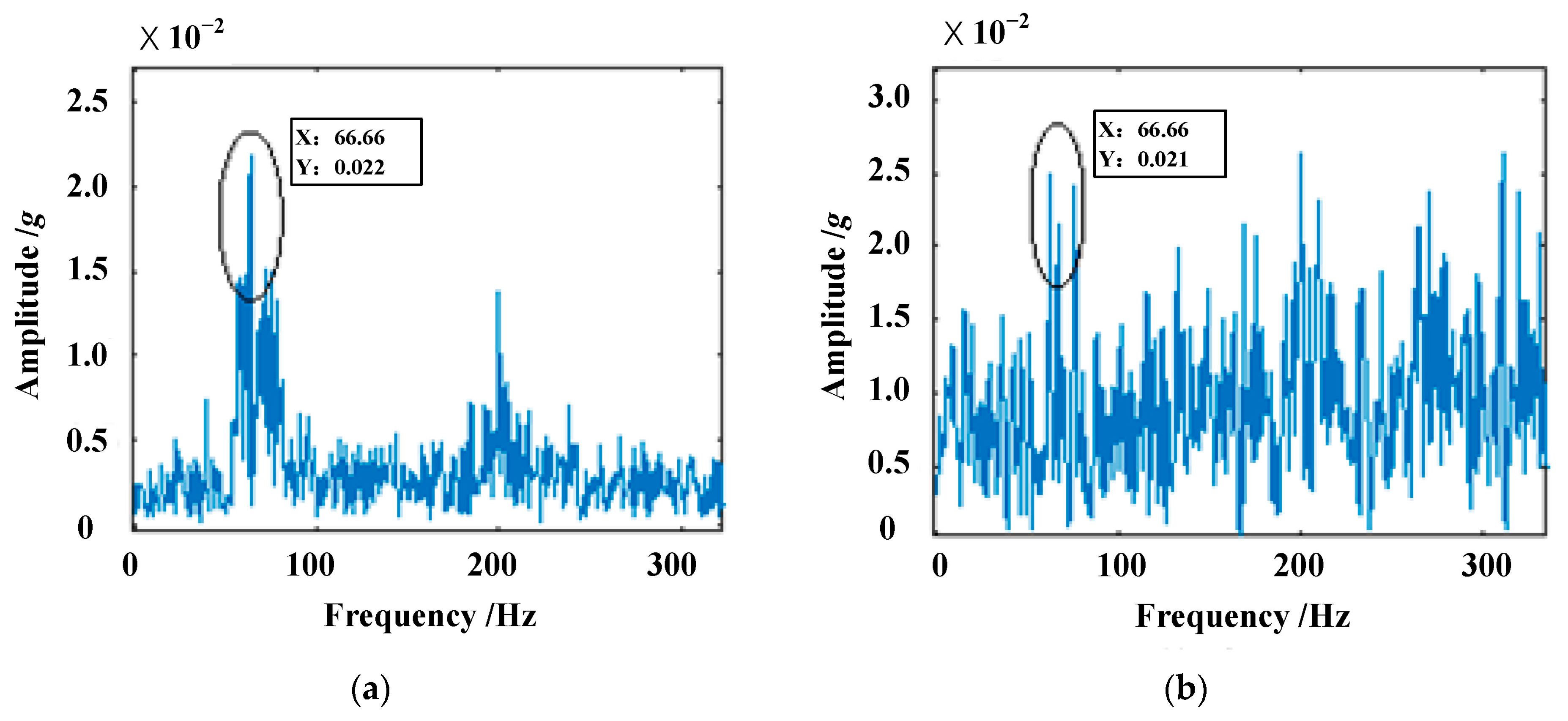

5.2. Mechanism Consistency Analysis of HD Performance Degradation Failure

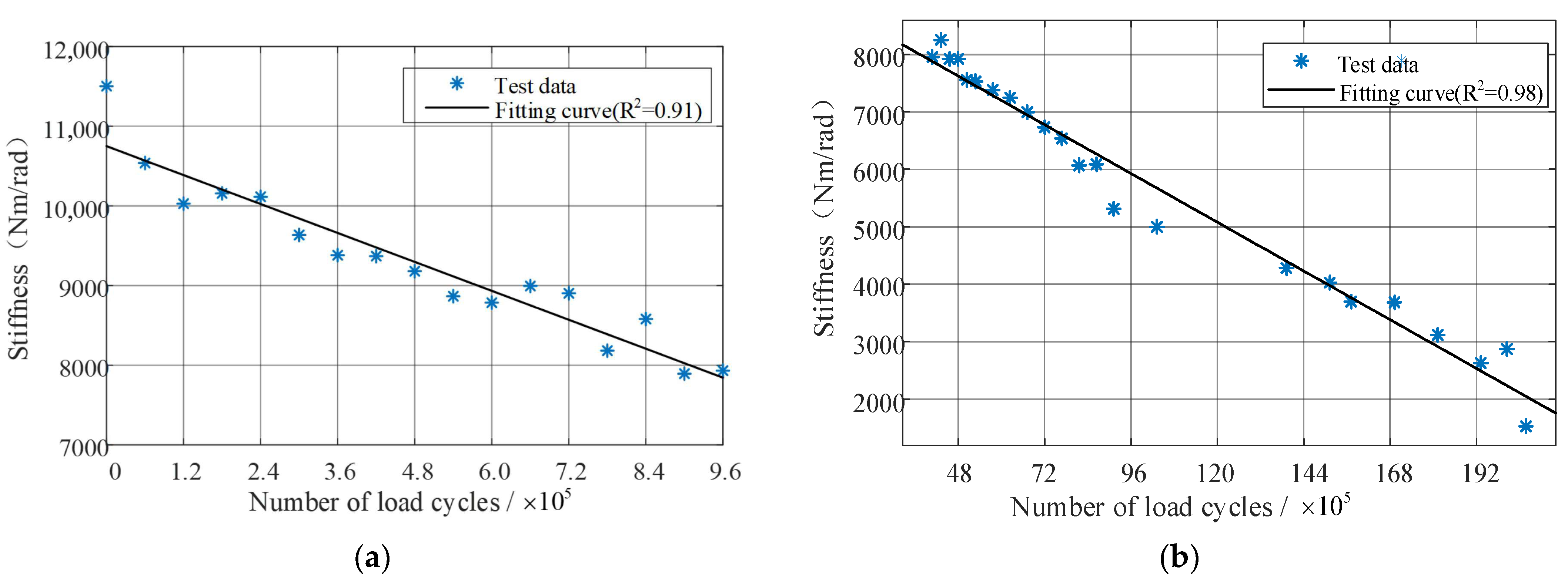

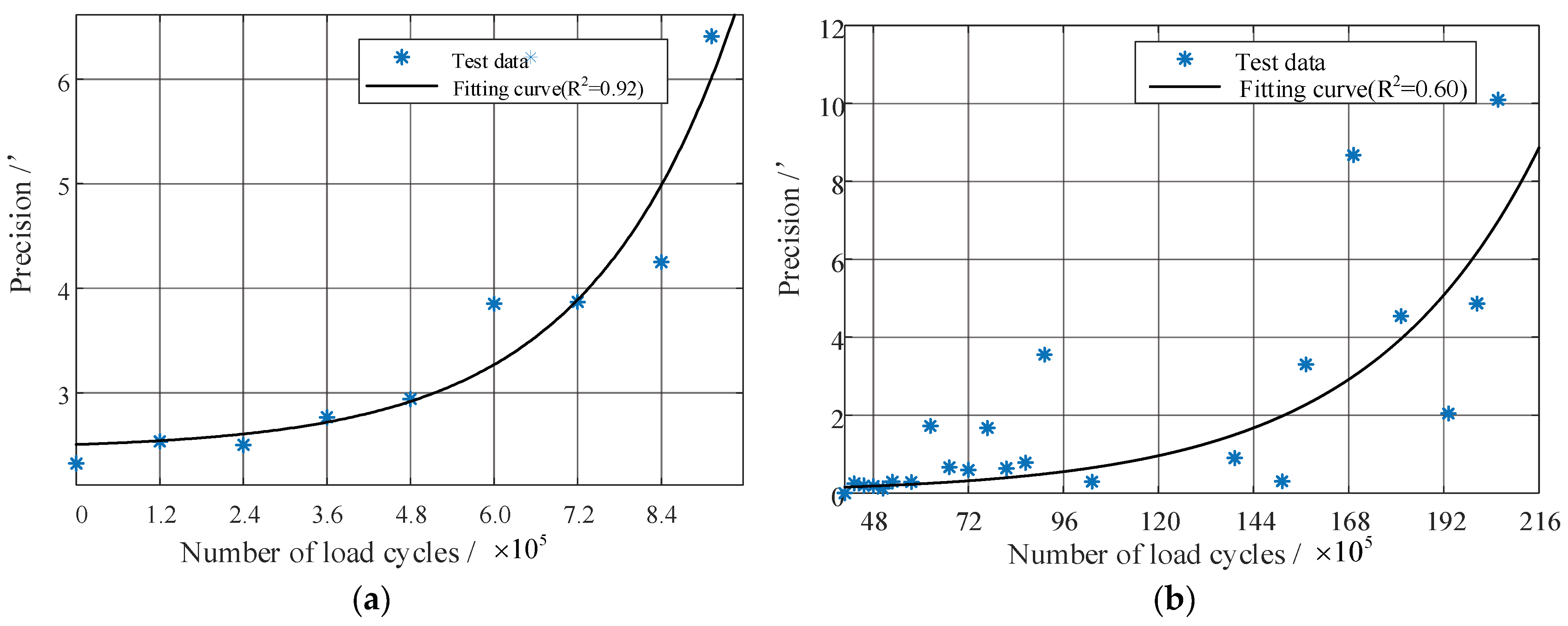

5.2.1. Degradation Trajectory and Accelerated Factor

5.2.2. Verification of Failure Mechanism Consistency

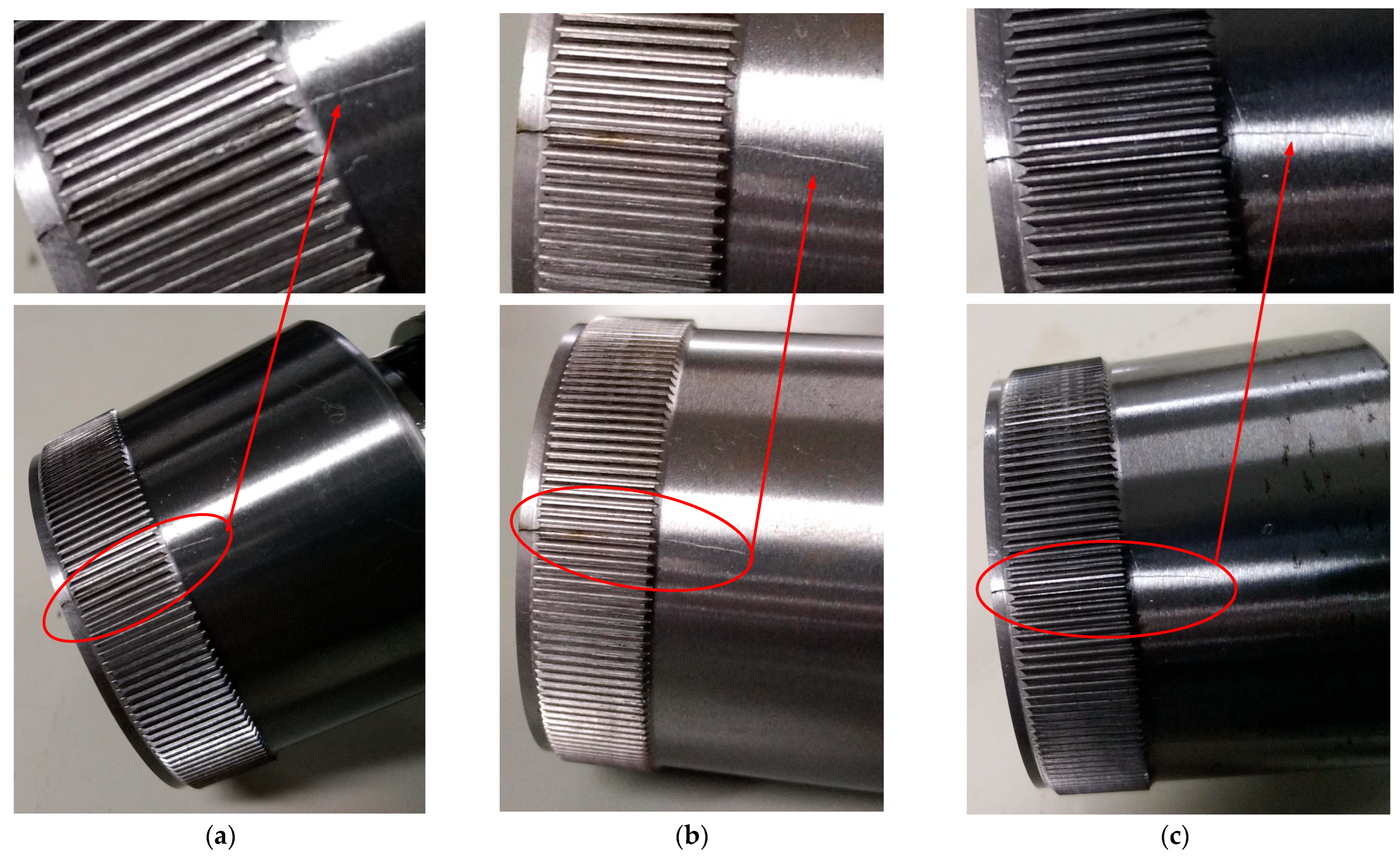

5.3. Strength Failure Mechanism and Its Consistency Analysis

6. Conclusions

- (1)

- An HD life test rig and performance degradation test rig were developed. This platform permits life test under multiple operating conditions with synchronous vibration signal acquisition. Throughout the life tests, periodic assessments are conducted to measure key performance indicators, including stiffness, precision, backlash, transmission efficiency, starting torque, and friction torque.

- (2)

- A comprehensive protocol for HD step-down ALT and performance degradation testing is developed.

- (3)

- An HD ALT under multiple operating conditions is conducted. Testing revealed that strength failure in atmospheric environment manifests as fatigue fracture at the transition zone between the gear ring and cylinder of the flexspline. Life failure data across three different test conditions were obtained.

- (4)

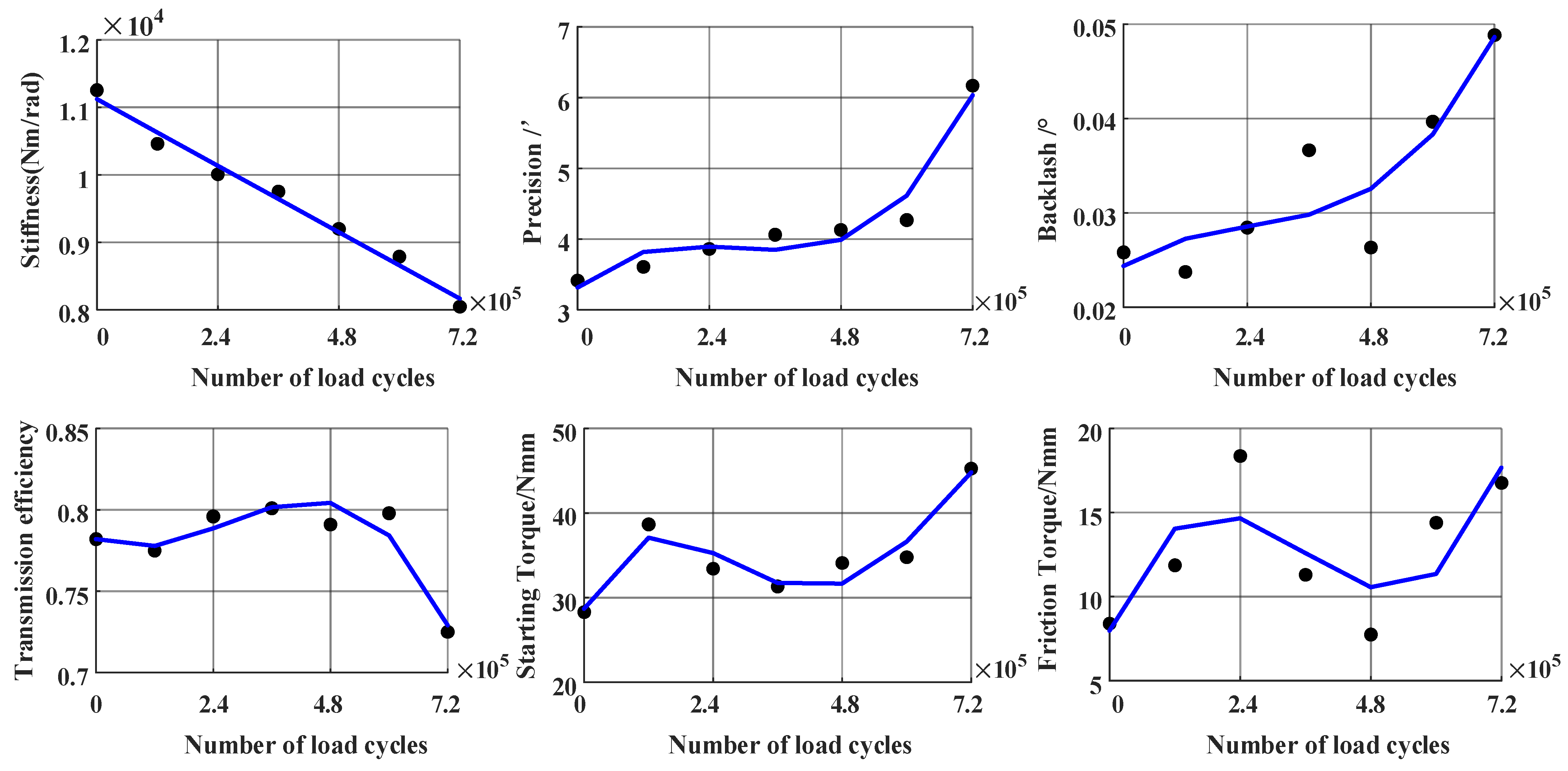

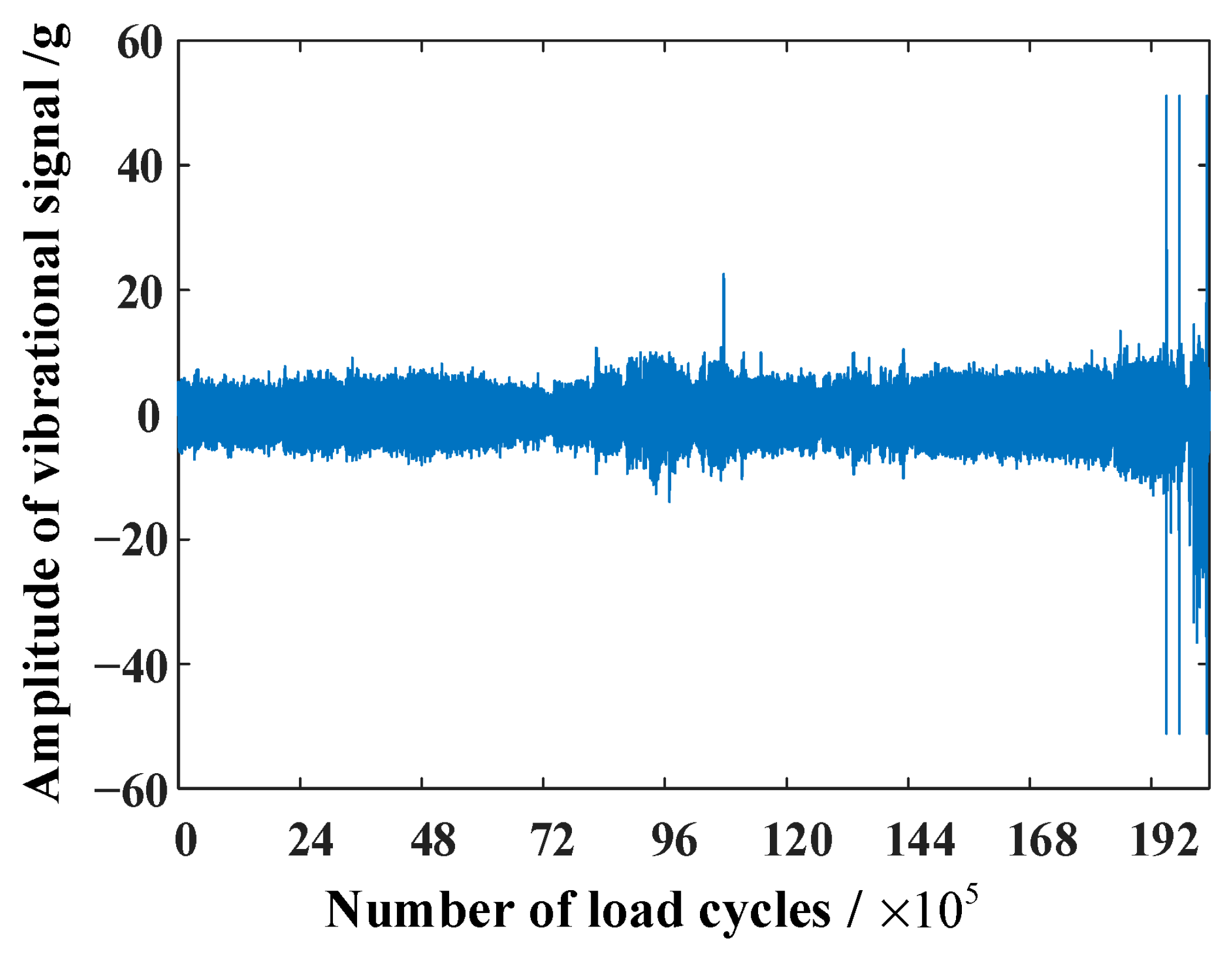

- Performance degradation test during life tests under various conditions is conducted. Key findings include the following: significant degradation in stiffness, precision, and backlash (with pronounced fluctuations in backlash degradation curves), transmission efficiency showing negligible degradation before strength failure but marked decline after strength failure, and starting torque and friction torque exhibiting persistent fluctuation without discernible degradation trends.

- (5)

- Based on ALT and performance degradation data, mechanisms of strength failure and performance degradation failure are analyzed, and the failure mechanism consistency in step-down ALT is verified.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HD | Harmonic Drive |

| ALT | Accelerated Life Test |

| MTBF | Mean Time Between Failures |

| NI | National Instrument |

| DAQ | Data Acquisition |

| FS | Flexspline |

| CS | Circular Spline |

| WG | Wave Generator |

References

- Xiang, Z.L.; Li, T.; Yang, L.; Shang, Y.S. Study on status and problem research of harmonic gear drive. J. Mech. Transm. 2020, 44, 151–162. [Google Scholar]

- Zuo, D.; Chen, D.; Zhu, M. Reliability analysis of harmonic drive with multiple failure modes based on improved calculation model of flexspline stress. Meccanica 2025, 60, 257–269. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, C.; Wang, P.; Yang, F.; Peng, C. Stiffness reliability analysis of harmonic drive considering contact pairs wear. Eng. Comput. 2024, 41, 1327–1352. [Google Scholar] [CrossRef]

- Schafer, I.; Bourlier, P.; Hantschack, F. Space lubrication and performance of harmonic Drive gears. In Proceedings of the 11th ESMATS Symposium, Lucerne, Switzerland, 21–23 September 2005. [Google Scholar]

- Schmidt, J.; Schmid, M. Life test of an industrial standard and of a stainless steel harmonic drive. In Proceedings of the 14th European Space Mechanisms & Tribology Symposium, Constance, Germany, 28–30 September 2011. [Google Scholar]

- Li, J.Y. Failure Mechanism Theory and Accelerated Life Testing Method Research for Space Lubrication Harmonic Drive. Ph.D. Thesis, Chongqing University, Chongqing, China, 2012. [Google Scholar]

- Elsayed, E.A. Overview of reliability testing. IEEE Trans. Reliab. 2012, 61, 282–291. [Google Scholar] [CrossRef]

- Pan, R.; Yang, T.; Seo, K. Planning constant-stress accelerated life tests for acceleration model selection. IEEE Trans. Reliab. 2015, 64, 1356–1366. [Google Scholar] [CrossRef]

- Li, J.Y.; Wang, J.X.; Fan, K.J. Accelerated life model for harmonic drive under adhesive wear. Tribology 2016, 36, 297–303. [Google Scholar]

- Li, J.Y.; Wang, J.X.; Zhou, G.W. Accelerated life testing of harmonic driver in space lubrication. Proc. Inst. Mech. 2015, 229, 1479–1490. [Google Scholar] [CrossRef]

- Li, J.Y.; Wang, J.X.; Zhou, G.W. Failure Mechanism of harmonic drivers for space. Tribology 2013, 33, 44–48. [Google Scholar]

- Ueura, K.; Kiyosawa, Y.; Kurogi, J. Tribological aspects of a strain wave gearing system with specific reference to its space application. Proc. Inst. Mech. 2008, 222, 1051–1061. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, S.; Wang, Z. An accelerated life test model for harmonic drives under a segmental stress history and its parameter optimization. Chin. J. Aeronaut. 2015, 28, 1758–1765. [Google Scholar] [CrossRef]

- Wang, R. Comparison analysis of efficiency for step-down and step-up stress accelerated life testing. IEEE Trans. Reliab. 2012, 61, 590–603. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, Y.H.; Kim, D.S. Lifetime estimation of harmonic reducer for manufacturing robot using accelerated life test. J. Mech. Sci. Technol. 2022, 36, 2879–2887. [Google Scholar] [CrossRef]

- Su, P.F.; Liu, J.H.; Guan, E.G.; Zhao, Y.Z. Torsional stiffness detection and failure analysis of harmonic drive. Mach. Electron. 2020, 38, 41–44+50. [Google Scholar]

- Zhao, Y.Y.; Li, P.X.; Ding, H.L.; Cao, J.B.; Yan, W.X. Harmonic Reducer Performance Prediction Algorithm Based on Multivariate State Estimation and LargeVis Dimensionality Reduction. IEEE Access 2023, 11, 126762–126774. [Google Scholar] [CrossRef]

- Preissner, C.; Royston, T.J.; Shu, D. A high-fidelity harmonic drive model. J. Dyn. Syst. Meas. Control 2012, 134, 011002. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, J.; Sang, R.P. Tungsten containing hydrogenated DLC coatings on grease lubricated harmonic drive gear for space application. In Proceedings of the ESMATS 2011—14th European Space Mechanisms and Tribology Symposium, Constance, Germany, 28–30 September 2011. [Google Scholar]

- Zhang, X.; Jiang, G.D.; Zhang, H.; Yun, X.L.; Mei, X.S. Time-dependent reliability analysis of harmonic drive based on transient FEA and accelerated life test. J. Eng. Comput. 2020, 37, 2293–2317. [Google Scholar] [CrossRef]

- Wang, B.; Lei, Y.G.; Li, N.P. A hybrid prognostics approach for estimating remaining useful life of rolling element bearings. IEEE Trans. Reliab. 2018, 69, 401–412. [Google Scholar] [CrossRef]

- Ivanov, M. Harmonic Gear Drives; Visajas Kola Press: Moscow, Russia, 1981. [Google Scholar]

- Guan, H. Research on Performance Degradation and Life Analysis of Space Harmonic Drive. Master’s Thesis, Chongqing University, Chongqing, China, 2014. [Google Scholar]

- Zou, C.; Tao, T.; Mei, X.S.; Lü, J.W.; Jiang, G.D. Contact analysis for short harmonic reducer in robotic joints. J. Xi’an Jiaotong Univ. 2013, 47, 82–87. [Google Scholar]

- GB/T 14118-1993; Harmonic Drive Reducers. The State Bureau of Quality and Technical Supervision: Beijing, China, 1993.

- GB/T 30819-2014; Harmonic Drive Gear Reducers for Robots. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China: Beijing, China, 2014.

- Feng, J. Consistent test of accelerated storage degradation failure mechanism based on rank correlation coefficient. J. Aerosp. Power 2011, 26, 2439–2444. [Google Scholar]

- Wang, H.W.; Xu, T.X.; Wang, W.Y. Test method of failure mechanism consistency based on degradation model. Acta Aeronaut. Astronaut. Sin. 2015, 36, 889–897. [Google Scholar]

- Liu, W.Z.; Zhang, N.R.; Zhang, C.L.; Zhao, Y.Z. Finite element calculation and analysis on the column-shaped flex spline of harmonic drive. Chin. J. Mech. Eng. 2006, 42, 52–57. [Google Scholar] [CrossRef]

- Ostapski, W. Analysis of the stress state in the harmonic drive generator-flexspline system in relation to selected structural parameters and manufacturing deviations. Bull. Pol. Acad. Sci. Tech. Sci. 2010, 58, 683–698. [Google Scholar] [CrossRef]

- Li, Q.; Zuo, Y.Y. Failure mode analysis of harmonic drive flexspline. Robot. Tech. Appl. 2013, 37–38. [Google Scholar]

- Wang, S.; Jiang, G.D.; Mei, X.S. A rapid stress calculation method for short flexspline harmonic drive. Eng. Comput. 2019, 36, 1852–1867. [Google Scholar] [CrossRef]

| Performance | Test Method | Test Rig |

|---|---|---|

| Stiffness | The drive motor pauses at home position, and the load motor rotates back and forth within rated torque range. Meanwhile, the torsional angle and torque signals of output are acquired synchronously for stiffness calculation |  |

| Precision (transmission error) | HD is operated at a constant speed under no-load, low-speed condition. By having the HD output shaft rotate by at least one revolution, the angular displacement values at both the input and output ends are synchronously acquired by two angular encoders for precision calculation |  |

| Backlash | HD is driven to rotate back and forth. Reversal points within the transmission error signal are extracted, and the transmission error in the forward motion segments and the reverse motion segments are distinguished. The transmission error values for all forward segments and all reverse segments are then averaged separately, and the difference between forward average and reverse average is calculated to determine the backlash | Same as precision |

| Transmission efficiency | Under rated condition, the input and output torque signals of the HD are synchronously acquired for transmission efficiency calculation |  |

| Starting torque | HD is slowly accelerated under no-load condition while the input torque is acquired. The peak torque value occurring during the startup phase is then taken as the starting torque value of HD |  |

| Friction torque | HD is operated under no-load and constant-speed condition, and the motor driving force is solely utilized to overcome friction, neglecting elastic factors within the HD. The input driving torque is the friction torque at that constant speed | Same as starting torque |

| Group Name | Sample Number | Accelerated Stress Level |

|---|---|---|

| Group 1 | 3 | 100 Nm |

| Group 2 (ALTSD1) | 1 | 100 Nm–75 Nm |

| Group 2 (ALTSD2) | 1 | 100 Nm–75 Nm–50 Nm |

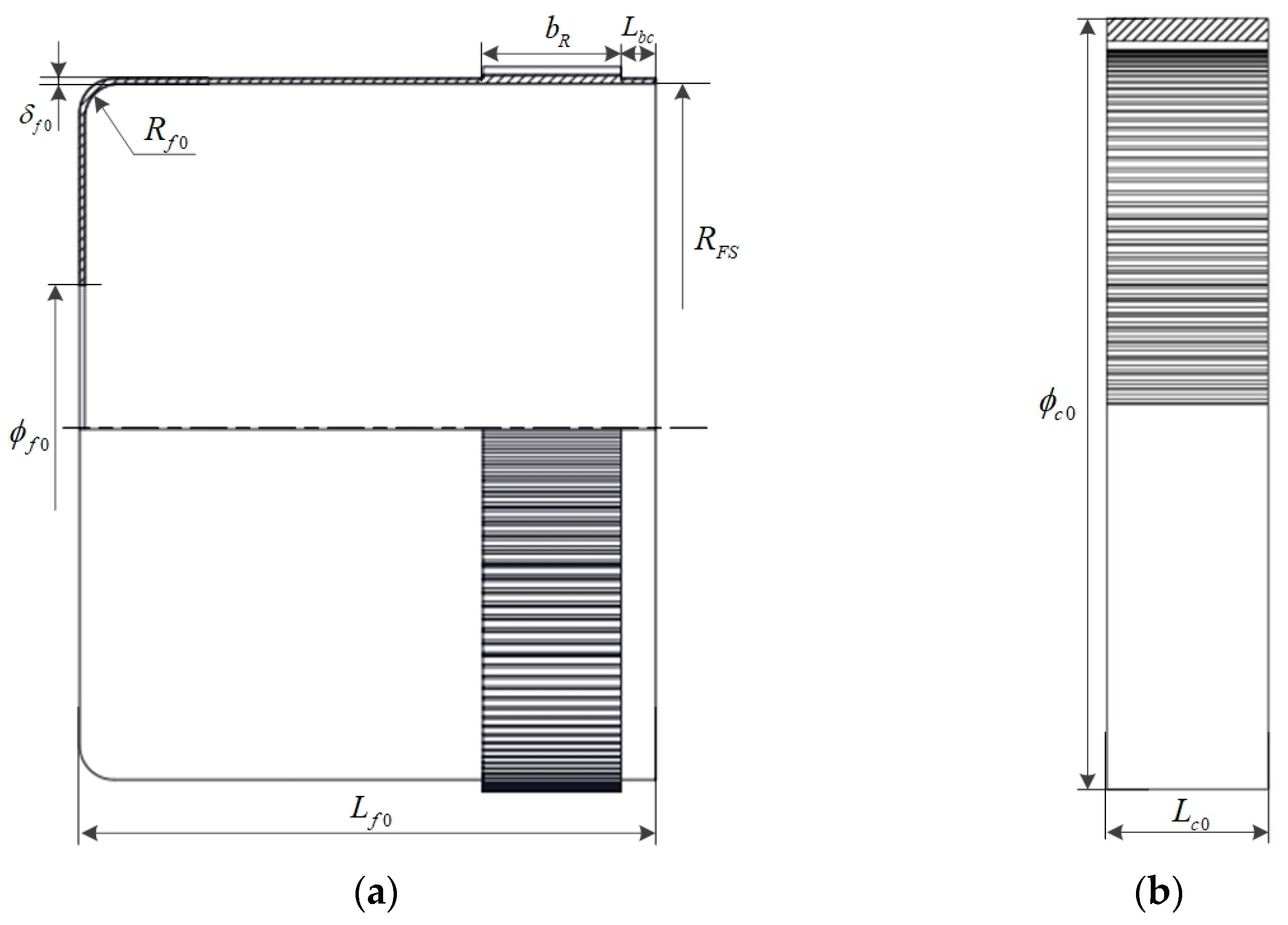

| Geometric Parameter (Unit) | Value | Geometric Parameter (Unit) | Value |

|---|---|---|---|

| Length of FS Lf0 (mm) | 50 | Diameter of CS’s outer circle ϕc0 (mm) | 68 |

| Fillet radius at FS bottom Rf0 (mm) | 3 | Width of CS Lc0 (mm) | 14 |

| Number of FS teeth | 150 | Number of CS teeth | 152 |

| Thickness of FS cylinder δf0 (mm) | 0.45 | Width of FS gear ring bR (mm) | 12 |

| Diameter of inner hole at FS bottom ϕf0 (mm) | 25 | Distance between the gear ring and front end of FS Lbc (mm) | 3 |

| Gear module (mm) | 0.4 | Radius of FS’s dedendum circle (mm) | 30.75 |

| Radius of CS’s dedendum circle (mm) | 32.01 | Radius of FS’s addendum circle (mm) | 31.47 |

| Radius of CS’s addendum circle (mm) | 31.29 | Inner hole diameter of FS’s gear ring RFS (mm) | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, C.; Wang, P.; Yang, F.; Peng, C.; Yun, X. Accelerated Life Test and Performance Degradation Test of Harmonic Drive with Failure Analysis. Machines 2025, 13, 918. https://doi.org/10.3390/machines13100918

Zhang X, Zhang C, Wang P, Yang F, Peng C, Yun X. Accelerated Life Test and Performance Degradation Test of Harmonic Drive with Failure Analysis. Machines. 2025; 13(10):918. https://doi.org/10.3390/machines13100918

Chicago/Turabian StyleZhang, Xian, Changming Zhang, Peng Wang, Fan Yang, Chunlei Peng, and Xialun Yun. 2025. "Accelerated Life Test and Performance Degradation Test of Harmonic Drive with Failure Analysis" Machines 13, no. 10: 918. https://doi.org/10.3390/machines13100918

APA StyleZhang, X., Zhang, C., Wang, P., Yang, F., Peng, C., & Yun, X. (2025). Accelerated Life Test and Performance Degradation Test of Harmonic Drive with Failure Analysis. Machines, 13(10), 918. https://doi.org/10.3390/machines13100918