Research on Sintering Machine Axle Fault Detection Based on Wheel Swing Characteristics

Abstract

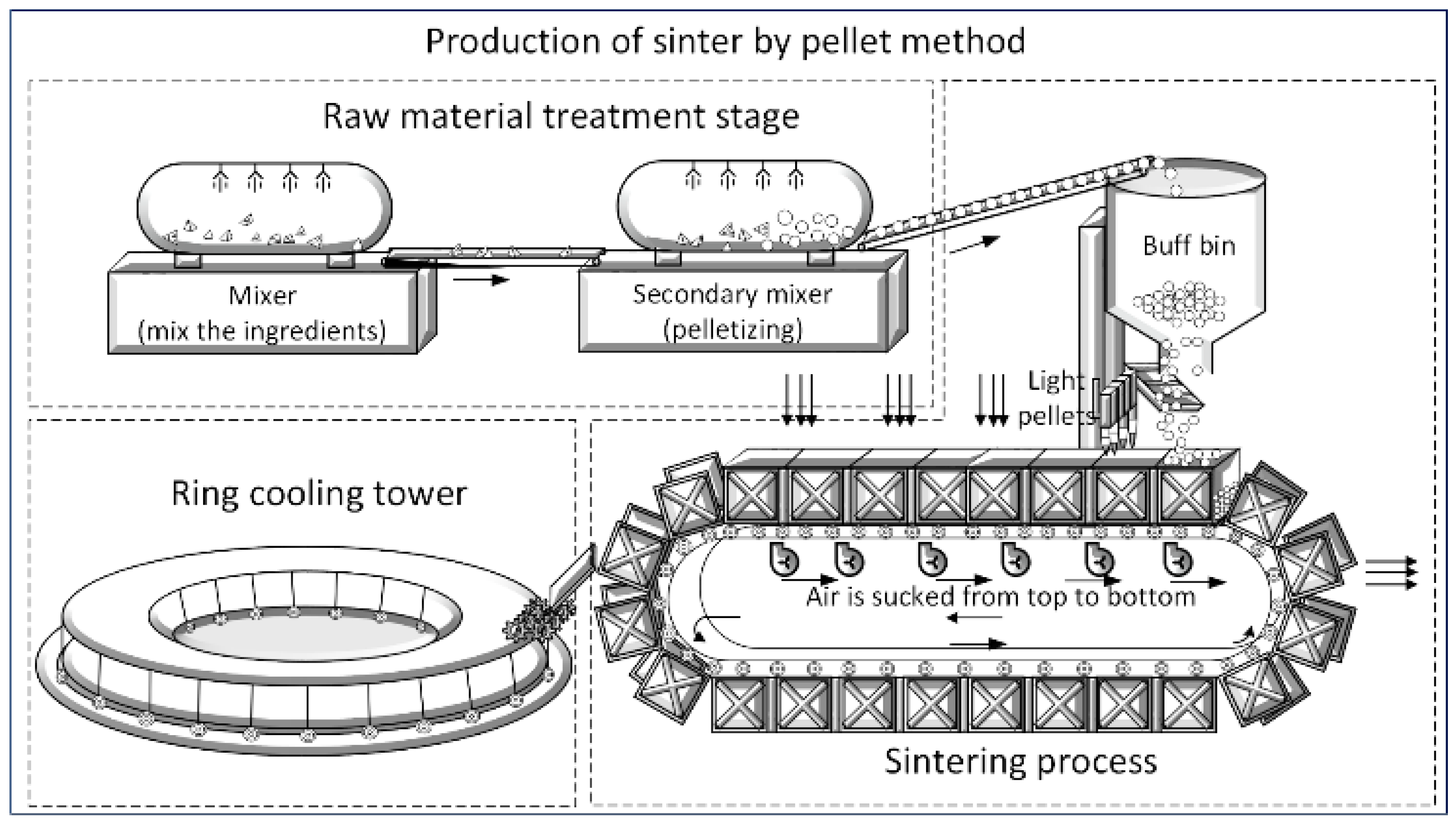

1. Introduction

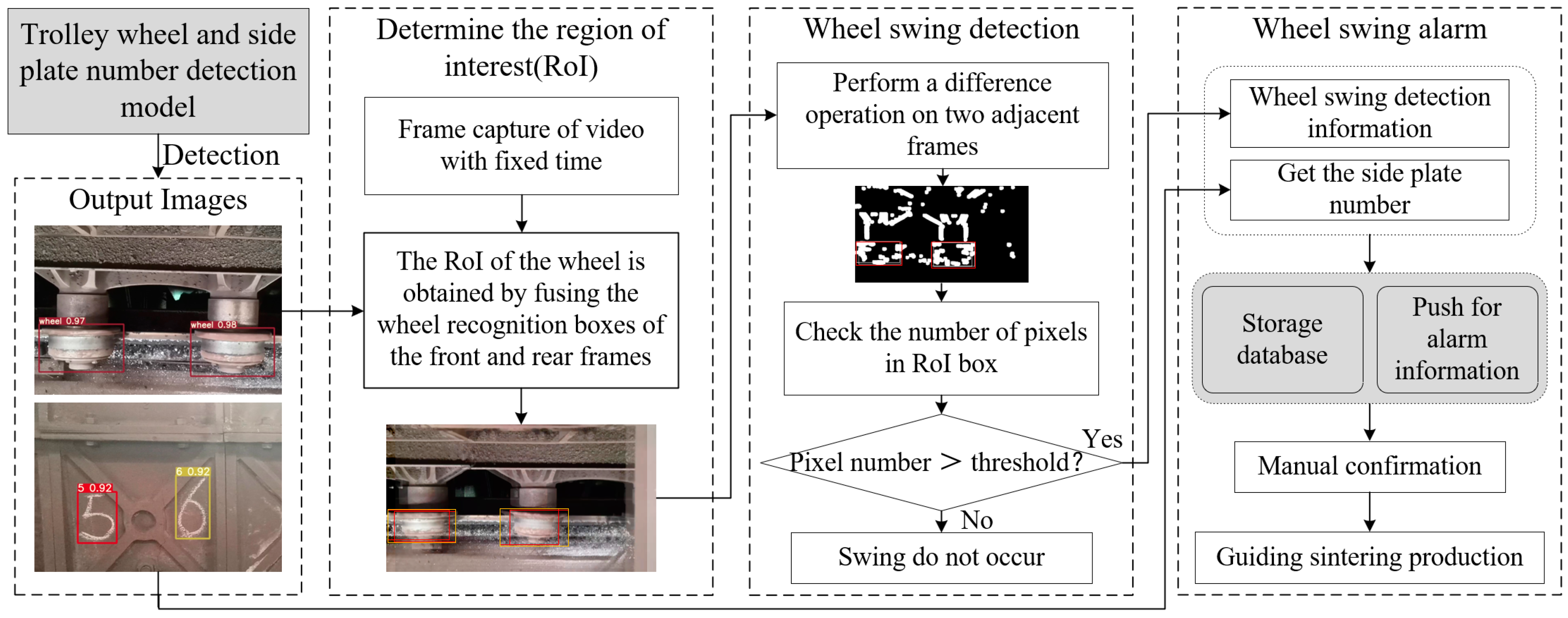

- A computer vision method was combined with an object detection algorithm to determine the region of interest for the wheel, and wheel swing detection was completed in the region;

- This paper proposes a new method for axle fault detection in low-speed and heavy-load vehicles based on wheel swing and realizes a visual detection localization algorithm;

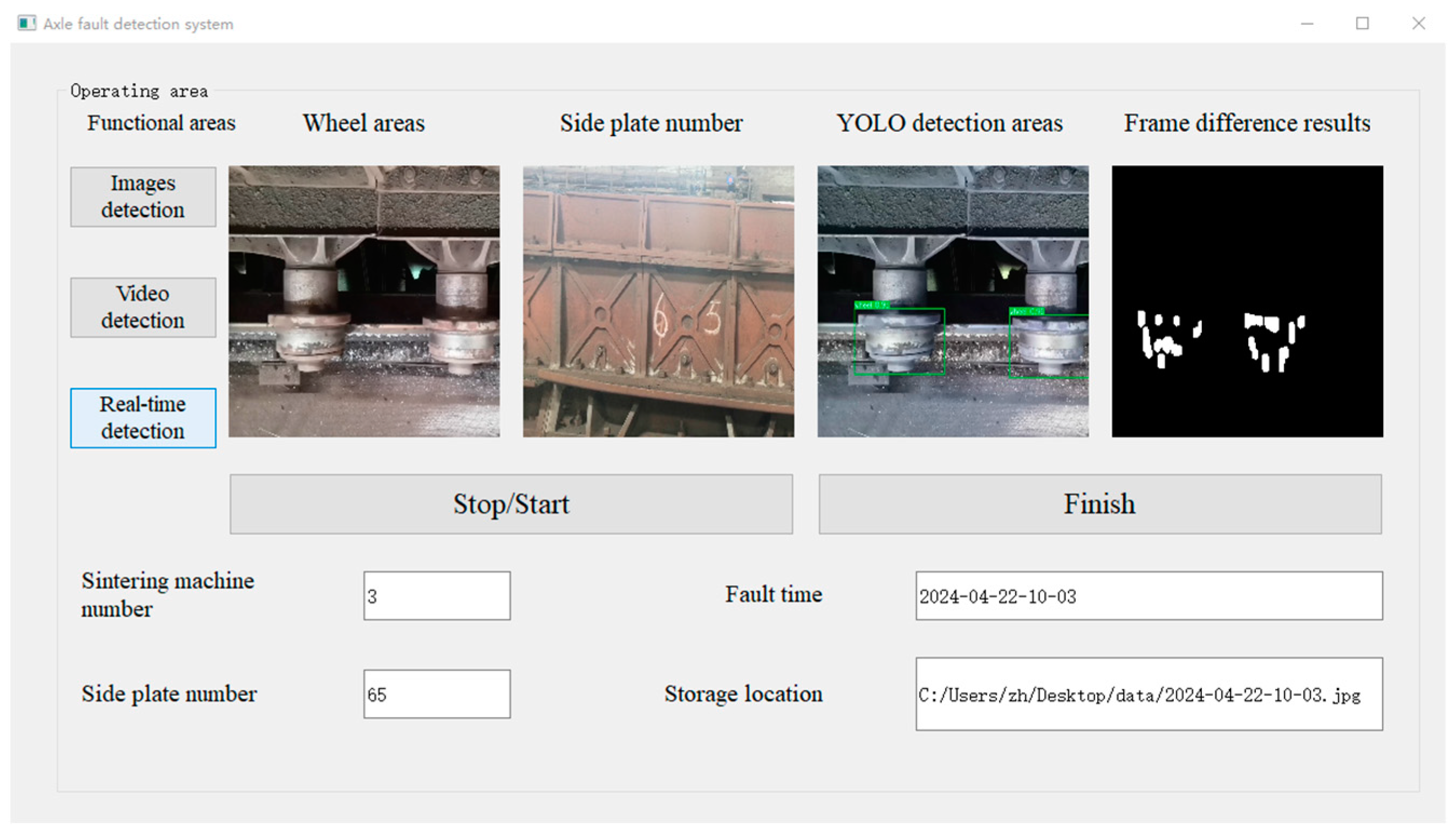

- An axle fault detection and location system was constructed based on the wheel swing detection and location algorithm. Real-time monitoring and early warning of wheel swing faults were realized.

2. Related Work

2.1. Application of Artificial Intelligence and Vision Methods in Axle Fault Detection

2.2. Fault Location Technology

2.3. Current Status of Axle Detection Systems

3. Main Scheme

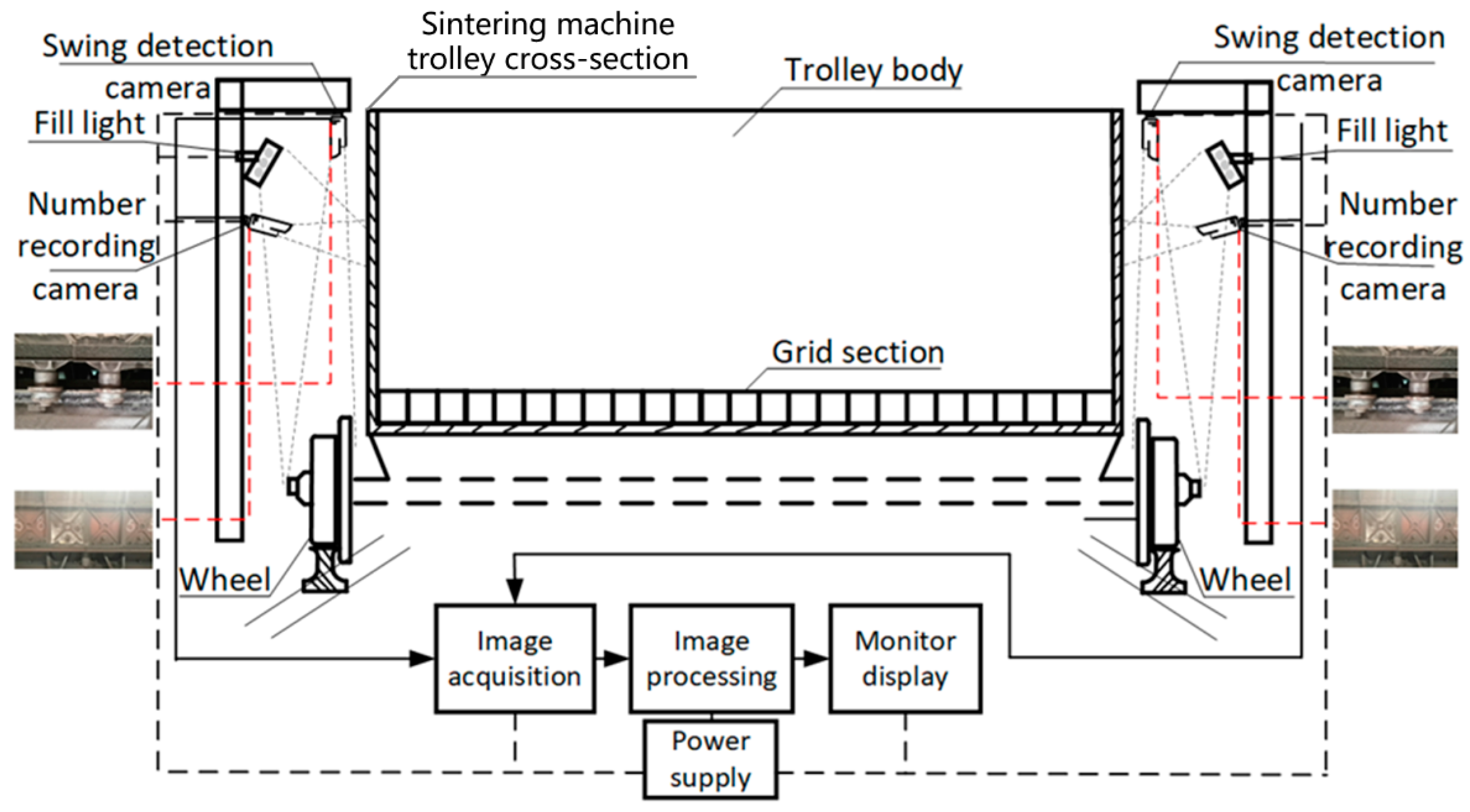

3.1. Hardware Scheme of the Sintering Machine Axle Fault Detection System

3.2. Implementation Scheme

4. Materials and Methods

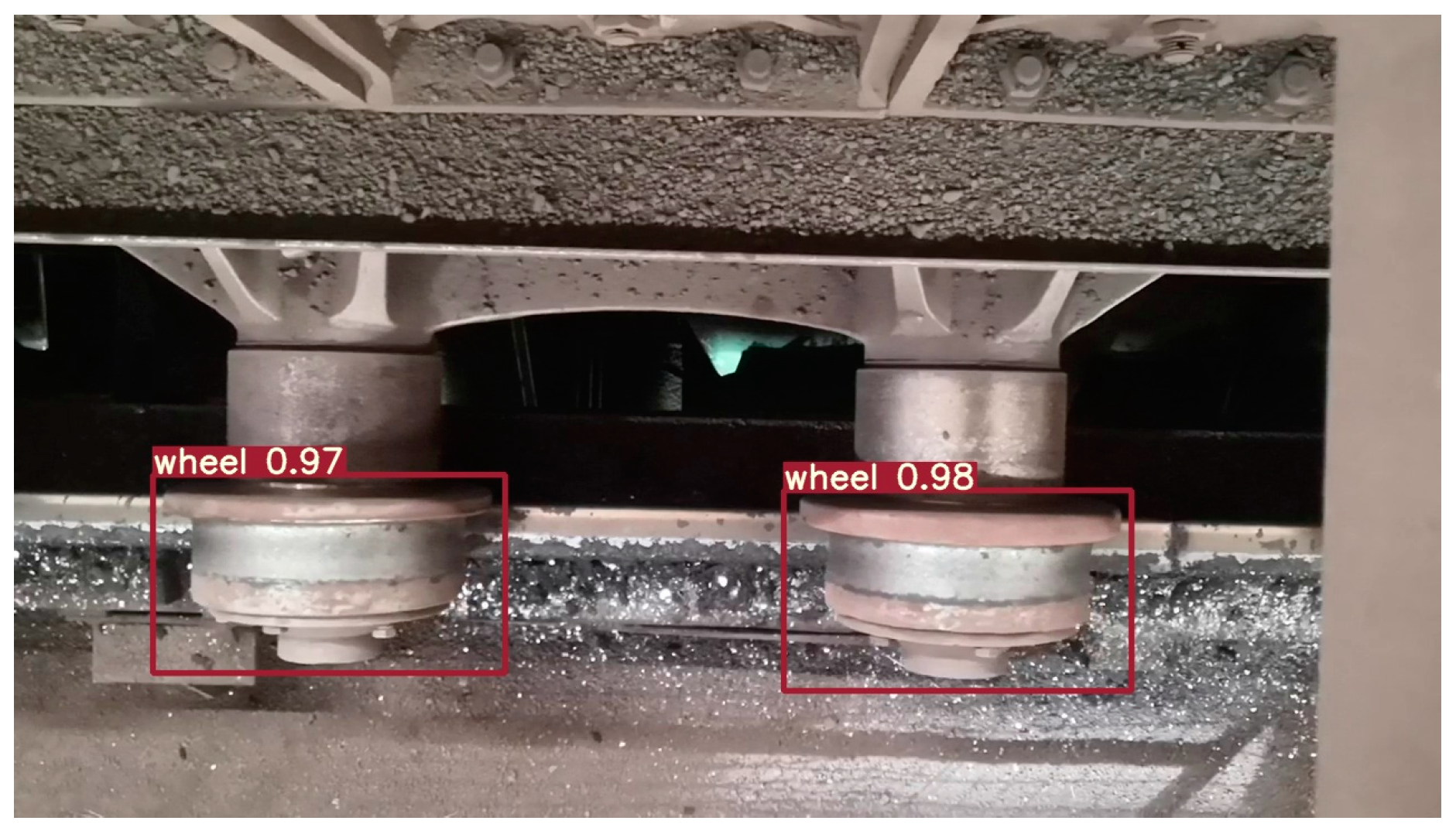

4.1. Wheel Position Detection

4.2. Determining the Wheel Region of Interest

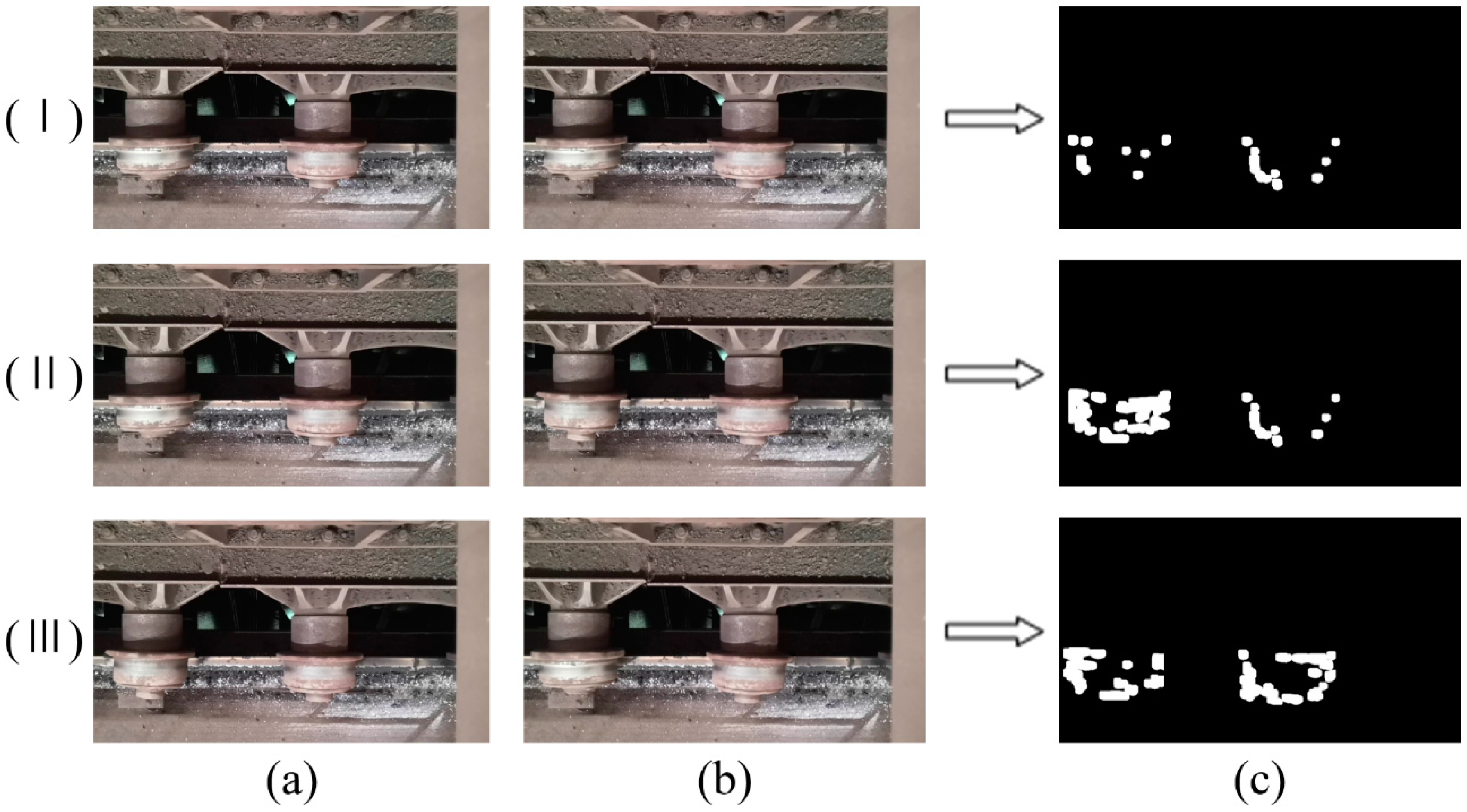

4.3. Wheel Swing Detection

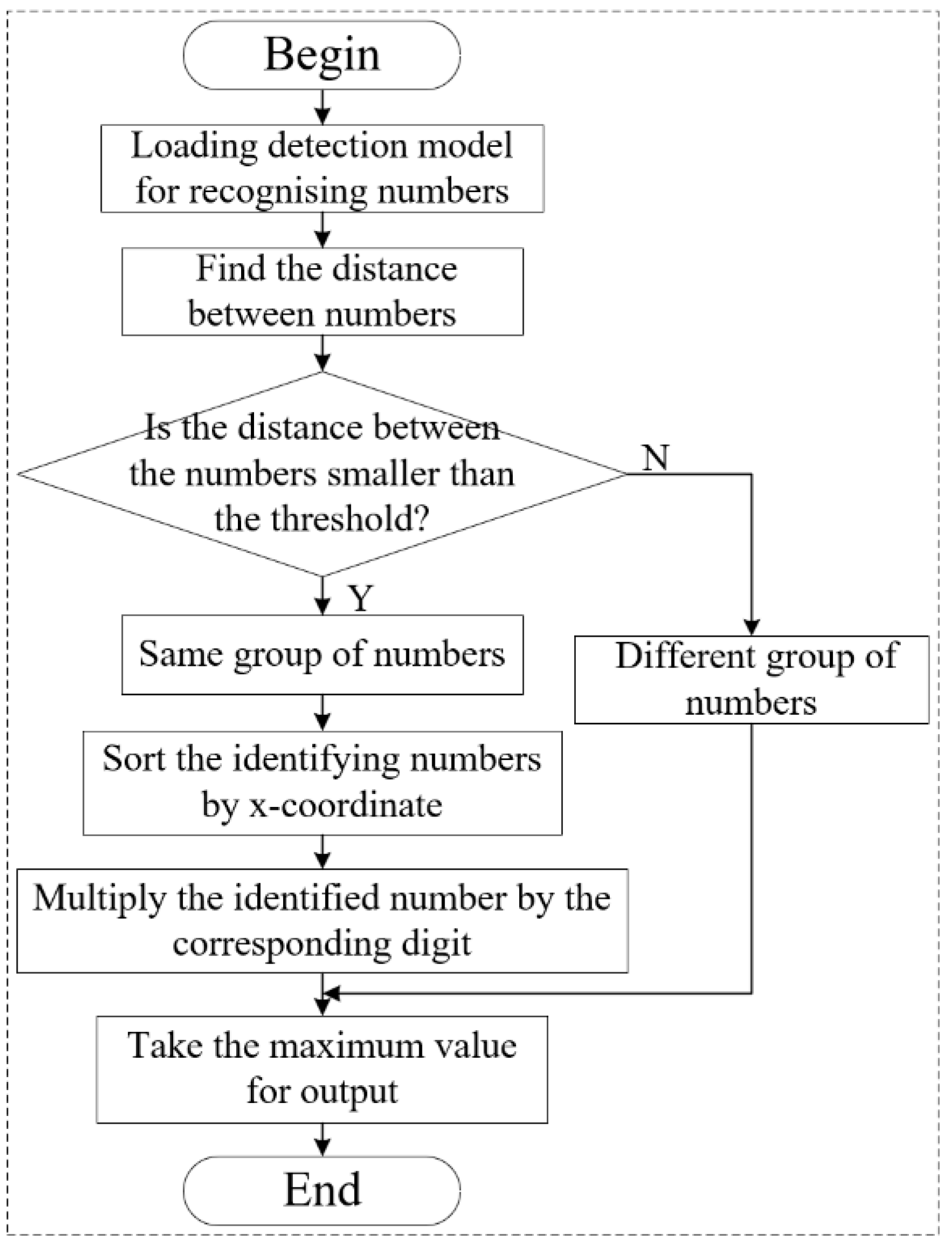

4.4. Swing Fault Location Algorithm

5. Discussion of the Axle Fault Detection Method and System Construction

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gong, Y.H.; Wang, C.H.; Li, J.; Mahyuddin, M.N.; Seman, M.T.A. Application of deep learning in iron ore sintering process: A review. J. Iron Steel Res. Int. 2024, 31, 1033–1049. [Google Scholar] [CrossRef]

- Du, C.; Dutta, S.; Kurup, P.; Yu, T.; Wang, X. A review of railway infrastructure monitoring using fiber optic sensors. Sens. Actuators 2020, 303, 111728. [Google Scholar] [CrossRef]

- Shentsov, A.I.; Odintsov, A.A.; Svirin, E.B. Development of methods and technologies at the sinter plant. Metallurgist 2014, 58, 459–463. [Google Scholar] [CrossRef]

- Fernández-González, D.; Ruiz-Bustinza, Í.; Mochón, J.; González-Gasca, C.; Verdeja, L.F. Iron ore sintering: Process. Miner. Process. Extr. Metall. 2017, 38, 215–227. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Y.; Zhang, B.; Huai, W. Analysis of the temperature characteristics of high-speed train bearings based on a dynamics model and thermal network method. Chin. J. Mech. Eng. 2022, 35, 104. [Google Scholar] [CrossRef]

- Yang, Z.; Wu, B.; Shao, J.; Lu, X.; Zhang, L.; Xu, Y.; Chen, G. Fault detection of high-speed train axle bearings based on a hybridized physical and data-driven temperature model. Mech. Syst. Signal Process. 2024, 208, 111037. [Google Scholar] [CrossRef]

- Yan, G.; Bai, Y.; Yu, C.; Yu, C. A multi-factor driven model for locomotive axle temperature prediction based on multi-stage feature engineering and deep learning framework. Machines 2022, 10, 759. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, S.; Liu, Y. Weak fault feature extraction of axle box bearing based on pre-identification and singular value decomposition. Machines 2022, 10, 1213. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, C.; Kemp, A.H.; Brooks, P. An on-board detection framework for polygon wear of railway wheel based on vibration acceleration of axle-box. Mech. Syst. Signal Process. 2021, 153, 107540. [Google Scholar] [CrossRef]

- Zhao, X.; Qin, Y.; He, C.; Jia, L. Intelligent fault identification for rolling element bearings in impulsive noise environments based on cyclic correntropy spectra and LSSVM. IEEE Access 2020, 8, 40925–40938. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, X.; Zhong, X.; Zhou, H. Fault diagnosis of axle box bearing with acoustic signal based on chirplet transform and support vector machine. Shock Vib. 2022, 2022, 9868999. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Duchesnay, É. Scikit-Learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Zhang, J.M.; Harman, M.; Ma, L.; Liu, Y. Machine learning testing: Survey, landscapes and horizons. IEEE Trans. Softw. Eng. 2022, 48, 1–36. [Google Scholar] [CrossRef]

- Cao, H.; Shao, H.; Zhong, X.; Deng, Q.; Yang, X.; Xuan, J. Unsupervised domain-share CNN for machine fault transfer diagnosis from steady speeds to time-varying speeds. J. Manuf. Syst. 2022, 62, 186–198. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Ding, S.X.; Huang, B. Data-driven fault diagnosis for traction systems in high-speed trains: A survey, challenges, and perspectives. IEEE Trans. Intell. Transp. Syst. 2020, 23, 1700–1716. [Google Scholar] [CrossRef]

- Li, W.; Zhong, X.; Shao, H.; Cai, B.; Yang, X. Multi-mode data augmentation and fault diagnosis of rotating machinery using modified ACGAN designed with new framework. Adv. Eng. Inf. 2022, 52, 101552. [Google Scholar] [CrossRef]

- He, H.; Ma, S.C.; Sun, L. Multi-moving target detection based on the combination of three frame difference algorithm and background difference algorithm. In Proceedings of the 2018 WRC Symposium on Advanced Robotics and Automation 2018, Beijing, China, 16 August 2018; pp. 141–146. [Google Scholar]

- Chen, H.; Jiang, B. A review of fault detection and diagnosis for the traction system in high-speed trains. IEEE Trans. Intell. Transp. Syst. 2019, 21, 450–465. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Fang, L.; Li, Q. Offset detection of grate trolley’s side plate based on YOLOv4. J. Sens. 2021, 2021, 5552206. [Google Scholar] [CrossRef]

- Pham, M.T.; Kim, J.M.; Kim, C.H. Accurate bearing fault diagnosis under variable shaft speed using convolutional neural networks and vibration spectrogram. Appl. Sci. 2020, 10, 6385–6399. [Google Scholar] [CrossRef]

- Dong, Z.; Zhao, D.; Cui, L. An intelligent bearing fault diagnosis framework: One-dimensional improved self-attention-enhanced CNN and empirical wavelet transform. Nonlinear Dyn. 2024, 112, 6439–6459. [Google Scholar] [CrossRef]

- Liu, L.; Song, D.; Geng, Z.; Zheng, Z. A real-time fault early warning method for a high-speed emu axle box bearing. Sensors 2020, 20, 823. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Wen, C.; Wang, Z.; Liu, W.; Chen, G. A novel framework for motor bearing fault diagnosis based on multi-transformation domain and multi-source data. Knowl. -Based Syst. 2024, 283, 111205. [Google Scholar] [CrossRef]

- Dong, Z.; Zhao, D.; Cui, L. Non-negative wavelet matrix factorization-based bearing fault intelligent classification method. Meas. Sci. Technol. 2023, 34, 115013. [Google Scholar] [CrossRef]

- Oh, S.; Han, S.; Jeong, J. Multi-scale convolutional recurrent neural network for bearing fault detection in noisy manufacturing environments. Appl. Sci. 2021, 11, 3963. [Google Scholar] [CrossRef]

- Cui, J.; Qin, Y.; Wu, Y.; Shao, C.; Yang, H. Skip connection YOLO architecture for noise barrier defect detection using UAV-based images in high-speed railway. IEEE Trans. Intell. Transp. Syst. 2023, 24, 12180–12195. [Google Scholar] [CrossRef]

- Sun, W.; Du, H.; Ma, G.; Shi, S.; Zhang, X.; Wu, Y. Moving vehicle video detection combining ViBe and inter-frame difference. Int. J. Embed. Syst. 2020, 12, 371–379. [Google Scholar] [CrossRef]

- Enze, Y.; Miura, Y. Inter-frame differencing in training data for artificial intelligence: Contour processing for inter-frame differencing method. In Proceedings of the 2020 IEEE International Conference on Consumer Electronics—Taiwan 2020, Taiwan, China, 28–30 September 2020; pp. 1–2. [Google Scholar]

- Shi, G.; Suo, J.; Liu, C.; Wan, K.; Lv, X. Moving target detection algorithm in image sequences based on edge detection and frame difference. In Proceedings of the 2017 IEEE 3rd Information Technology and Mechatronics Engineering Conference 2017, Chongqing, China, 3–5 October 2017; pp. 740–744. [Google Scholar]

- Wu, G.; Yan, T.; Yang, G.; Chai, H.; Cao, C. A review on rolling bearing fault signal detection methods based on different sensors. Sensors 2022, 22, 8330. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Luo, S.; Cole, C.; Spiryagin, M.; Sun, Y. A signal-based fault detection and classification method for heavy haul wagons. Veh. Syst. Dyn. 2017, 55, 1807–1822. [Google Scholar] [CrossRef]

- Jana, D.; Patil, J.; Herkal, S.; Nagarajaiah, S.; Duenas-Osorio, L. CNN and Convolutional Autoencoder (CAE) based real-time sensor fault detection, localization, and correction. Mech. Syst. Signal Process. 2022, 169, 108723. [Google Scholar] [CrossRef]

- Vetriselvi, T.; Lydia, E.L.; Mohanty, S.N.; Alabdulkreem, E.; Al-Otaibi, S.; Al-Rasheed, A.; Mansour, R.F. Deep learning based license plate number recognition for smart cities. CMC Comput. Mater Contin. 2022, 70, 2049–2064. [Google Scholar] [CrossRef]

- Marszalek, Z.; Sroka, R.; Zeglen, T. Inductive loop for vehicle axle detection from first concepts to the system based on changes in the sensor impedance components. In Proceedings of the 2015 20th International Conference on Methods and Models in Automation and Robotics 2015, Miedzyzdroje, Poland, 24–27 August 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 765–769. [Google Scholar]

- Jorge, T.; Magalhães, J.; Silva, R.; Guedes, A.; Ribeiro, D.; Vale, C.; Cury, A. Early identification of out-of-roundness damage wheels in railway freight vehicles using a wayside system and a stacked sparse autoencoder. Veh. Syst. Dyn. 2024, 1–26. [Google Scholar] [CrossRef]

- Shah, A.A.; Bhatti, N.A.; Dev, K.; Chowdhry, B.S. MUHAFIZ: IoT-based track recording vehicle for the damage analysis of the railway track. IEEE Internet Things J. 2021, 8, 9397–9406. [Google Scholar] [CrossRef]

- Wang, C.Y.; Yeh, I.H.; Liao, H.Y.M. YOLOv9: Learning What You Want to Learn Using Programmable Gradient Information. arXiv 2024, arXiv:2402.13616. [Google Scholar]

| Swing Degrees | Actual Number | Number Detected | Detection Rate% | Average Detection Rate% |

|---|---|---|---|---|

| 1~2° | 30 | 26 | 86.67 | |

| 2~4° | 30 | 29 | 96.67 | 93.33 |

| >4° | 15 | 15 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Yang, H.; Mei, J.; Wang, Y.; Zhang, H. Research on Sintering Machine Axle Fault Detection Based on Wheel Swing Characteristics. Machines 2024, 12, 498. https://doi.org/10.3390/machines12080498

Chen B, Yang H, Mei J, Wang Y, Zhang H. Research on Sintering Machine Axle Fault Detection Based on Wheel Swing Characteristics. Machines. 2024; 12(8):498. https://doi.org/10.3390/machines12080498

Chicago/Turabian StyleChen, Bo, Husheng Yang, Jiarui Mei, Yueming Wang, and Hao Zhang. 2024. "Research on Sintering Machine Axle Fault Detection Based on Wheel Swing Characteristics" Machines 12, no. 8: 498. https://doi.org/10.3390/machines12080498

APA StyleChen, B., Yang, H., Mei, J., Wang, Y., & Zhang, H. (2024). Research on Sintering Machine Axle Fault Detection Based on Wheel Swing Characteristics. Machines, 12(8), 498. https://doi.org/10.3390/machines12080498