Implementation and Possibilities of Fuzzy Logic for Optimal Operation and Maintenance of Marine Diesel Engines

Abstract

1. Introduction

- Fuzzy logic is highly adaptable and effective in handling the complexity and ambiguity of diesel engine systems.

- Fuzzy logic in marine diesel engines could extend beyond diagnostics to include performance improvements, offering a dual-purpose tool for engine management.

- Various studies have demonstrated the effectiveness of fuzzy logic in real-world applications, including engine speed control, performance prediction, and emissions management.

- There is a growing trend towards integrating fuzzy logic with other computational techniques like ANNs and ANFIS for enhanced predictive capabilities.

- Fuzzy logic provides a more nuanced and flexible approach than traditional binary systems, making it particularly suitable for marine diesel engine operations’ dynamic and complex nature.

2. Adjustable and Non-Adjustable Parameters in Marine Diesel Engines

- Fuel Injection Timing/Quantity: Adjusting the timing or quantity of fuel injection is crucial for optimizing combustion efficiency and emissions. Precise control over when and how much fuel is injected into the engine allows for better combustion management, directly impacting engine performance and environmental compliance.

- Fuel Injection Rate: This parameter determines the rate at which fuel is delivered to the combustion chamber. Modifying the fuel injection rate influences the atomization and mixing of the fuel with air, essential for efficient combustion and power output.

- Air-to-Fuel Ratio (AFR): Managing the ratio of air to fuel is vital for optimal engine performance. Adjusting the AFR can enhance combustion efficiency and reduce emissions. A well-balanced AFR ensures enough air is available for complete fuel combustion, maximizing efficiency and reducing harmful emissions.

- EGR Rate: The exhaust gas recirculation (EGR) rate affects how much exhaust gas is reintroduced into the engine. Adjusting the EGR rate can help control nitrogen oxide emissions but may also impact overall engine efficiency. This trade-off is crucial for meeting environmental standards while maintaining engine performance.

- Turbocharger Boost Pressure: This parameter adjusts the pressure of air the turbocharger compresses before entering the engine. Changing the turbocharger boost pressure can significantly affect the engine’s power output and efficiency by altering the density of the intake air.

- Engine Bore and Stroke: the cylinders’ diameter and the pistons’ travel distance.

- Compression Ratio: the ratio of the volume inside the cylinder when the piston is at the bottom of its stroke compared to when it is at the top.

- Piston Displacement: the total volume displaced by the pistons within an engine’s cylinders, commonly known as the engine displacement.

3. Predictive Maintenance Using Fuzzy Logic

4. The Investigated Marine Diesel Engine

5. Fuzzy Logic Control for Performance Monitoring of the Investigated Marine Diesel Engine

- Fuel Efficiency: operating the engine at a speed and load where the fuel consumption is minimized for the required power.

- Performance Requirements: running the engine within a range that meets a particular task’s power or torque requirements.

- Emission Standards: adjusting the engine’s operating conditions to reduce emissions while maintaining performance and efficiency. It aims for fuel efficiency and performance and strictly adheres to emission standards, which might require dynamic adjustments based on regulatory changes or operational areas.

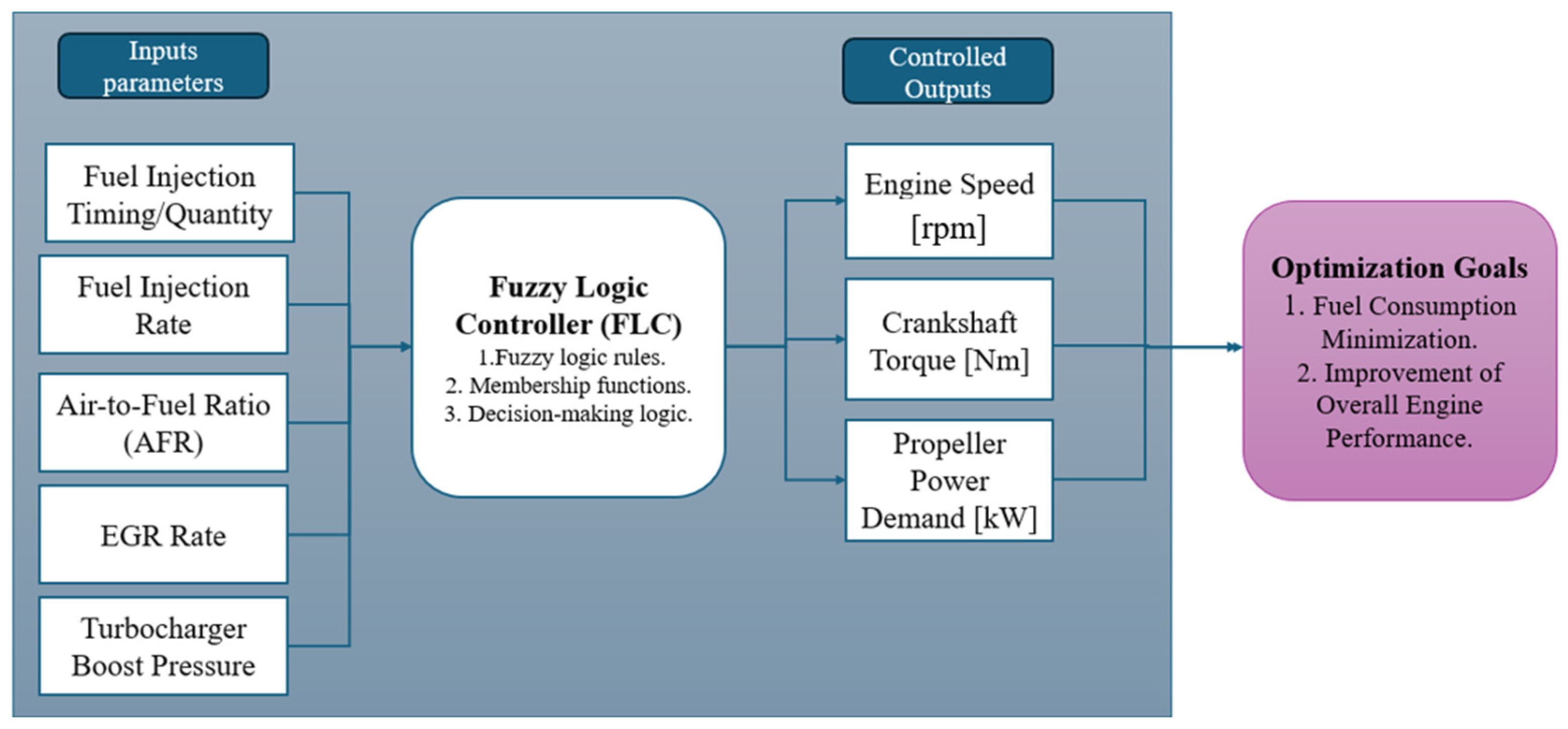

5.1. Define Fuzzy Inputs and Outputs

- Fuel Injection Timing [° crank angle]/Quantity [mg/stroke]: Fuel injection timing is the precise point in the engine cycle at which fuel is injected into the combustion chamber. Fuel injection quantity is the amount of fuel delivered to the combustion chamber per injection cycle.

- Fuel Injection Rate [mg/ms]: the speed at which fuel is injected into the combustion chamber.

- Air-to-Fuel Ratio (AFR) [ratio]: the air mass ratio to the fuel mass entering the combustion chamber.

- EGR Rate [%]: The exhaust gas recirculation (EGR) rate represents the proportion of exhaust gas recirculated back into the engine’s intake air.

- Turbocharger Boost Pressure [kPa]: indicates the pressure of the air supplied to the engine by the turbocharger.

- Engine Speed [rpm]: Continuous variable that indicates the rotational speed of the engine’s crankshaft.

- Crankshaft Torque [Nm]: Continuous variable that indicates the engine’s ability to do work.

- Propeller Power Demand [kW]: The power the propeller requires to propel the vessel, derived from the engine’s power output.

5.2. Digital Analysis of the Performance Curves

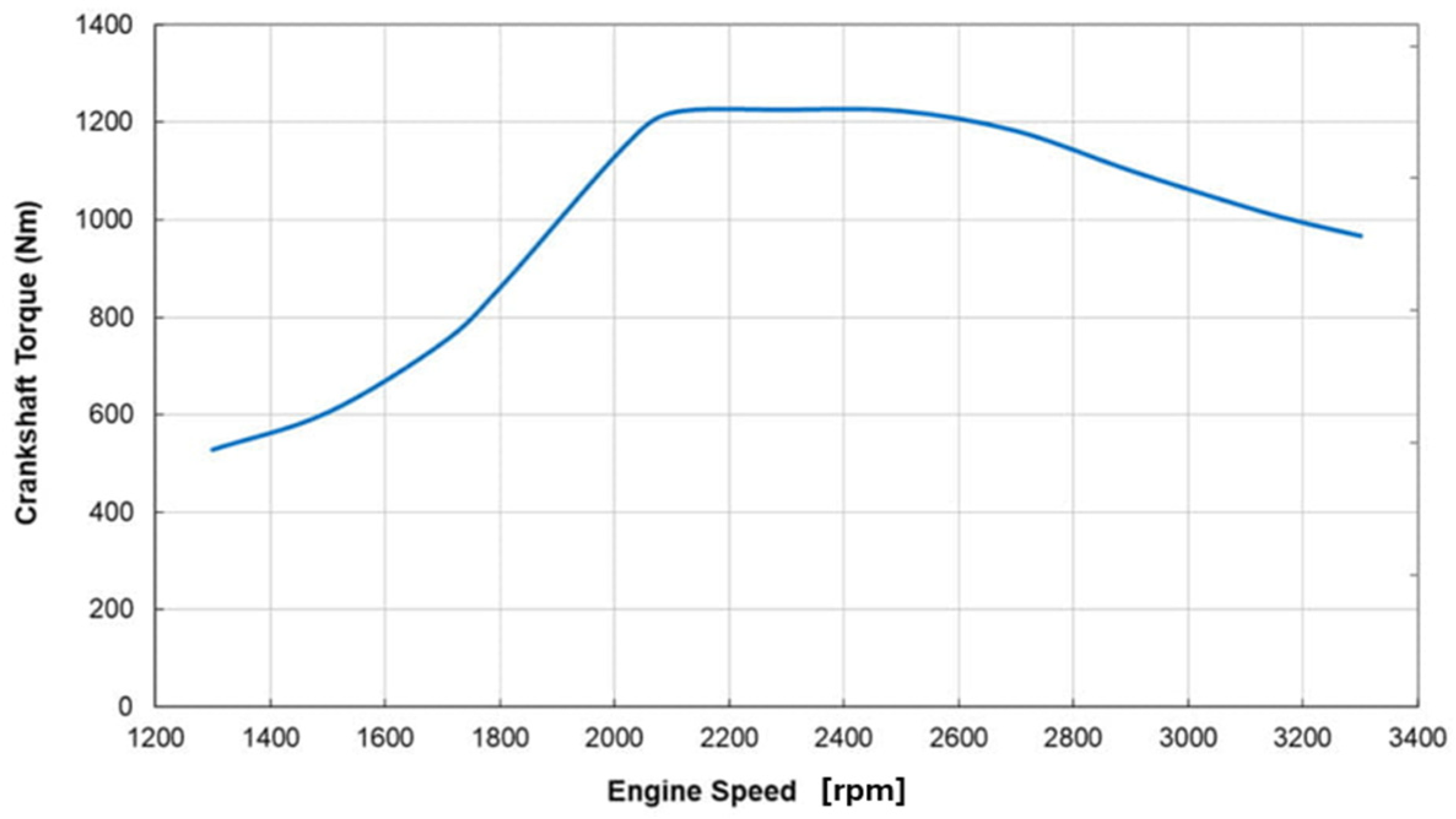

5.2.1. Crankshaft Torque Efficiency Analysis

- Inputs for FLC: fuel injection timing [° crank angle]/quantity [mg/stroke].

- Output for FLC: engine speed [rpm] and crankshaft torque [Nm]

Fuel Injection Timing Impact on Engine Performance

Fuel Injection Quantity Impact on Engine Performance

5.2.2. Propeller Power Output Characteristics

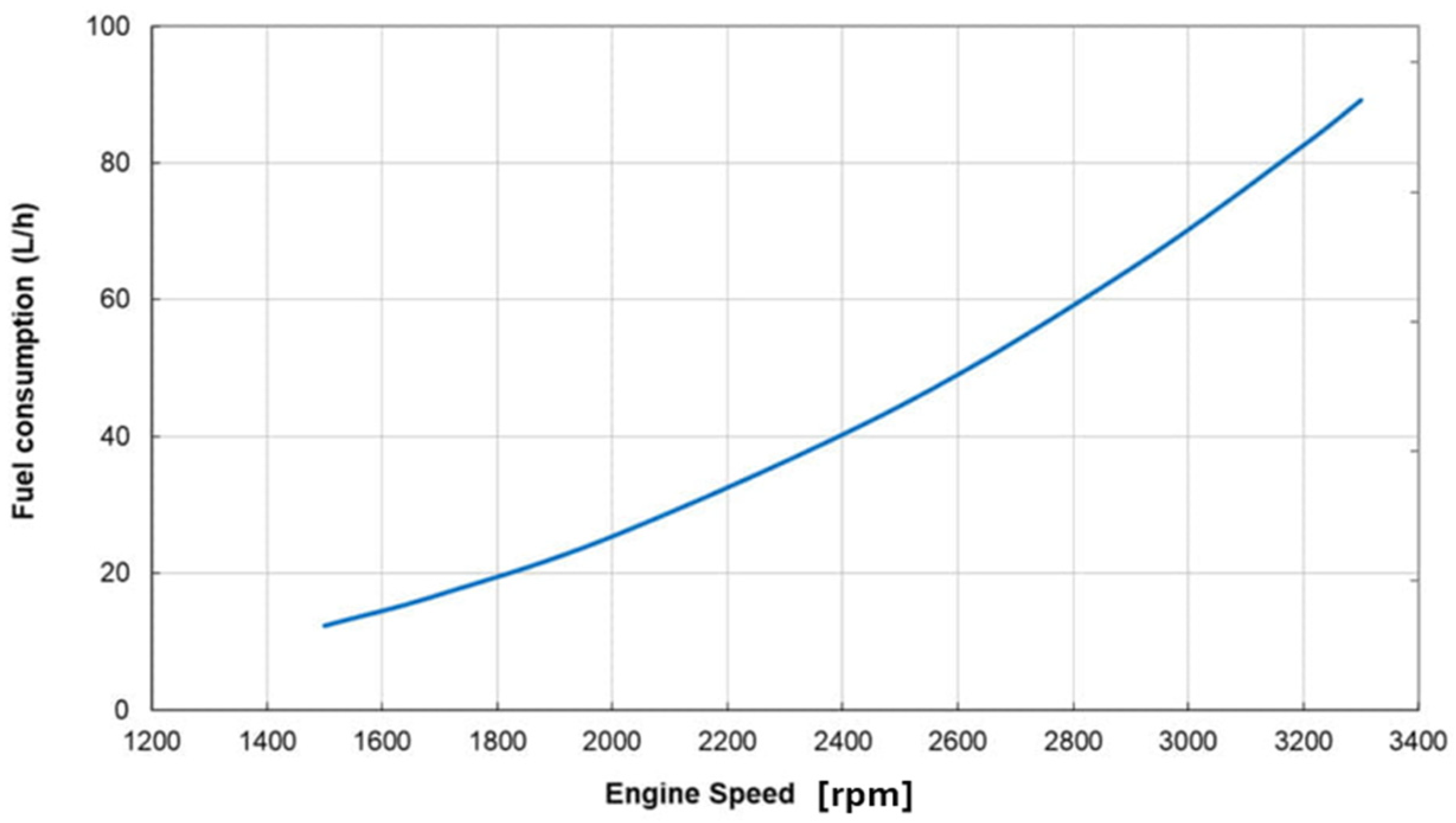

- Inputs for FLC: turbocharger boosts pressure [kPa] and fuel injection rate [mg/ms].

- Output for FLC: engine speed [rpm] and propeller power output [kW].

Turbocharger Boosts Pressure Impact on Engine Performance

Fuel Injection Rate Impact on Engine Performance

Synchronizing Fuel Injection Rate Control with Turbocharger Adjustments

5.3. Optimization of Fuel Consumption

5.4. Fuzzy Logic Control Application in the Tested Marine Engines

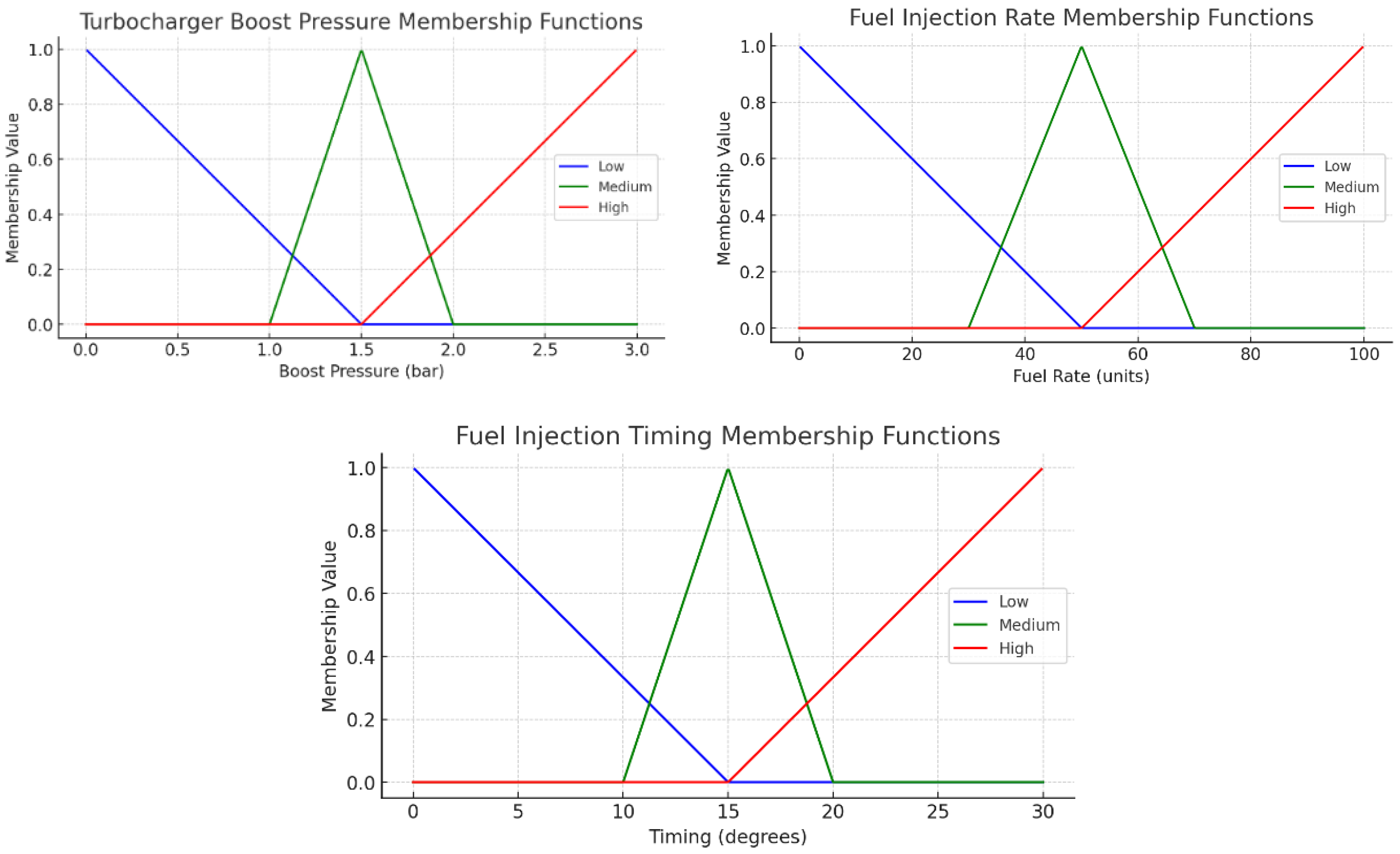

- Fuel injection timing/quantity: [low, medium, high];

- Fuel injection rate: [slow, normal, fast];

- Air-to-fuel ratio (AFR): [low, medium, high];

- EGR rate: [low, medium, high];

- Turbocharger boost pressure: [low, medium, high].

- Fuzzification: Convert the crisp input values (e.g., fuel injection timing, AFR) into fuzzy values using the defined membership functions.

- Rule Base: Develop a set of if–then rules based on expert knowledge and literature. For example: If the fuel injection rate is high and the AFR is rich, then the turbocharger boost pressure is high.

- If the EGR rate is medium and the engine load is high, then the fuel injection timing is advanced.

- Inference Engine: Apply the fuzzy rules to the fuzzified inputs to generate fuzzy outputs. The Mamdani inference method is used, which involves the min–max composition technique.

- Defuzzification: Convert the fuzzy outputs back into crisp values. The centroid method is used for defuzzification, which calculates the center of the area under the fuzzy set curve.

6. Conclusions

- Enhanced Control and Optimization:

- FLC provides a flexible and adaptive approach to engine management, allowing for precise adjustments to key parameters such as fuel injection timing, air-to-fuel ratio, EGR rate, and turbocharger boost pressure. This adaptability leads to smoother engine operations and better performance.

- 2.

- Improved Fuel Efficiency and Reduced Emissions:

- The study establishes that FLC can theoretically improve fuel efficiency and reduce emissions. By managing the inherent complexity and variability in engine operations, FLC offers a robust solution for optimizing engine performance.

- 3.

- Early Fault Detection:

- FLC’s ability to continuously monitor and adjust engine parameters contributes to early fault detection, which can prevent severe malfunctions and extend engine life. This proactive approach enhances the reliability and operational safety of marine diesel engines.

- 4.

- Establishing Empirical Foundations:

- An empirical validation through long-term experiments will be applied. Future studies will focus on collecting performance metrics before and after FLC implementation to quantify the benefits, including fuel consumption, emission levels, and engine speed optimization.

- 5.

- Time and Operation Cost Savings:

- Implementing FLC in marine diesel engines can lead to significant time and cost savings by reducing maintenance needs and improving operational efficiency. The study suggests that adopting FLC could be a transformative step towards more sustainable and efficient marine engine management.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tran, T.A.; Haidara, G. A research on marine diesel engine speed controller by fuzzy logic control theory based on experimental investigation. World 2019, 42, 18–26. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Taniguchi, T.; Eciolaza, L.; Campos, V.; Palhares, R.; Sugeno, M. Fuzzy control systems: Past, present and future. IEEE Comput. Intell. Mag. 2019, 14, 56–68. [Google Scholar] [CrossRef]

- Sakthivel, G.; Snehitkumar, B.; Ilangkumaran, M. Application of fuzzy logic in internal combustion engines to predict the engine performance. Int. J. Ambient Energy 2016, 37, 273–283. [Google Scholar] [CrossRef]

- Ceylan, B.O. Marine diesel engine turbocharger fouling phenomenon risk assessment application by using fuzzy FMEA method. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2023. [Google Scholar] [CrossRef]

- Babichev, S.; Strielkovskaya, L.; Zaitsev, O.; Khamula, O. Development of a fuzzy inference model for the management of a marine engine. In Proceedings of the International Scientific Conference Intellectual Systems of Decision Making and Problem of Computational Intelligence, Zalizniy Port, Ukraine, 26 July 2020. [Google Scholar]

- Yucesan, M.; Bashan, V.; Demirel, H.; Gul, M. An interval type-2 fuzzy enhanced best-worst method for the evaluation of ship diesel generator failures. Ocean Eng. 2022, 138, 106428. [Google Scholar] [CrossRef]

- Ceylan, B.O. Shipboard compressor system risk analysis by using rule-based fuzzy FMEA for preventing major marine accidents. Mar. Syst. Technol. 2023, 272, 113888. [Google Scholar] [CrossRef]

- Engin, O.; Çelik, A.; Kaya, İ. A fuzzy approach to define sample size for attributes control chart in multistage processes: An application in engine valve manufacturing process. Appl. Soft Comp. 2008, 8, 1654–1663. [Google Scholar] [CrossRef]

- Ghaffari, A.; Shamekhi, A.H.; Saki, A.; Kamrani, E. Adaptive fuzzy control for air-fuel ratio of automobile spark ignition engine. World Acad. Sci. Eng. Technol. 2008, 48, 284–292. [Google Scholar]

- García-Nieto, S.; Salcedo, J.; Martínez, M.; Laurí, D. Air management in a diesel engine using fuzzy control techniques. Inf. Sci. 2009, 179, 3392–3409. [Google Scholar] [CrossRef]

- Kekez, M.; Radziszewski, L. A genetic-fuzzy system for modeling of selected processes in diesel engine fuelled by biofuels. In Biofuel Production—Recent Development and Prospects; Marco, A.S.B., Ed.; IntechOpen: Rijeka, Croatia, 2011; pp. 561–576. [Google Scholar]

- Tran, T.A. Effect of ship loading on marine diesel engine fuel consumption for bulk carriers based on the fuzzy clustering method. Ocean Eng. 2020, 207, 107383. [Google Scholar] [CrossRef]

- Piltan, F.; Sulaiman, N.; Talooki, I.A.; Ferdosali, P. Control of IC engine: Design a novel MIMO fuzzy backstepping adaptive based fuzzy estimator variable structure control. Int. J. Robot. Autom. 2011, 2, 360–380. [Google Scholar]

- Gaonkar, R.S.; Pai, S.P. Risk assessment of starting air system of marine diesel engine using fuzzy failure mode and effects analysis. Syst. Assur. 2022, 51–66. [Google Scholar] [CrossRef]

- Rai, A.; Kumar, N.S.; Rao, B.S. Fuzzy logic based prediction of performance and emission parameters of a LPG-diesel dual fuel engine. Procedia Eng. 2012, 38, 280–292. [Google Scholar] [CrossRef]

- Namitha, S.; Shantharama, R. Fuzzy Logic Controller for the Speed Control of an IC engine using MATLAB/SIMULINK. Int. J. Recent Technol. Eng. 2013, 2, 124–127. [Google Scholar]

- Cheng, L.; Dimitriou, P.; Wang, W.; Peng, J.; Aitouche, A. A novel fuzzy logic variable geometry turbocharger and exhaust gas recirculation control scheme for optimizing the performance and emissions of a diesel engine. Int. J. Engine Res. 2020, 21, 1298–1313. [Google Scholar] [CrossRef]

- Tavana, M.; Hajipour, V. A practical review and taxonomy of fuzzy expert systems: Methods and applications. Benchmarking 2020, 27, 81–136. [Google Scholar] [CrossRef]

- Markiewicz, M.; Muślewski, Ł. Survey performance and emission parameters of diesel engine powered by diesel oil and fatty acid methyl esters using fuzzy logic techniques. Fuel 2020, 277, 118179. [Google Scholar] [CrossRef]

- Berber, A.; Tinkir, M.; Gültekin, S.S.; Çelikten, I. Prediction of a diesel engine characteristics by using different modelling techniques. Int. J. Phys. Sci. 2011, 6, 3979–3992. [Google Scholar]

- Xia, M.; Zhang, F. Application of multi-parameter fuzzy optimization to enhance performance of a regulated two-stage turbocharged diesel engine operating at high altitude. Energies 2020, 13, 4278. [Google Scholar] [CrossRef]

- Gao, Z. Active disturbance rejection control: A paradigm shift in feedback control system design. In Proceedings of the American Control Conference IEEE, Minneapolis, MN, USA, 14–16 June 2006. [Google Scholar]

- Yong, S. Identification and Adaptive Neural Network Control of the Speed of Marine Diesel Engine. Int. J. Autom. Power Eng. 2012, 8, 179–185. [Google Scholar]

- García, F.J.Á.; Salgado, D.R. Analysis of the influence of component type and operating condition on the selection of preventive maintenance strategy in multistage industrial machines: A case study. Machines 2022, 10, 385. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, C.; Xu, F.; Wang, Z.; Wang, L. Fault detection for interval type-2 TS fuzzy networked systems via event-triggered control. Machines 2022, 10, 347. [Google Scholar] [CrossRef]

- Straka, M. Design of a computer-aided location expert system based on a mathematical approach. Mathematics 2021, 9, 1052. [Google Scholar] [CrossRef]

- Cazañas, R.D.; Sobrino, D.R.D.; Martínez, E.M.D.L.P.; Koštál, P.; Mudriková, A. Integrating production and maintenance planning as an element of success at the tactical level: A fuzzy control theory approach. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2018, 26, 109–117. [Google Scholar] [CrossRef]

- Yanmar Technical Papers. Available online: https://www.yanmar.com/global/about/technology/technical_review/ (accessed on 3 March 2024).

| Year | Authors | Fuzzy Logic-Based Application |

|---|---|---|

| 2008 | Engin, O. et al. [8] | Engine valve manufacturing process |

| 2008 | Ghaffari, A. et al. [9] | Fuzzy control system to examine the air-fuel ratio of the spark ignition engine |

| 2009 | García-Nieto, S. et al. [10] | Fuzzy controller for air management in diesel engines |

| 2010 | Kekez, M. and Radziszewski, L. [11] | Measurement and modeling of cylinder pressure in diesel engines |

| 2011 | Piltan, F. et al. [13] | Fuzzy estimator variable structure control |

| 2012 | Rai, A. et al. [15] | Prediction of performance and emissions parameters of an LPG diesel dual-fuel engine |

| 2013 | Namitha, S. and Shantharama, R. [16] | Speed control of the IC engine |

| 2016 | Sakthivel, G. et al. [3] | Predicting the internal combustion engine’s performance |

| 2018 | Cheng, L. et al. [17] | Optimizing the performance and emissions of diesel engines |

| 2019 | Tran, T. A. et al. [1] | Speed controller by fuzzy logic control theory |

| 2019 | Nguyen, A.T. et al. [2] | Fuzzy control systems |

| 2023 | Ceylan, B. [4] | Risk assessment of turbocharger fouling using the fuzzy FMEA method |

| 2022 | Yucesan, M. et al. [6] | Evaluation of ship diesel generator failures using fuzzy logic |

| 2023 | Ceylan, B. [7] | Risk analysis of shipboard compressor systems using fuzzy FMEA |

| 2020 | Tran, T. A. [12] | Effect of ship loading on fuel consumption using fuzzy clustering |

| 2020 | Babichev, S. et al. [5] | Fuzzy inference model for the management of a marine engine |

| 2022 | Gaonkar, R.S. et al. [14] | Fuzzy failure mode for the air system of a marine diesel engine |

| Specifications | Value |

|---|---|

| Rated output | 324 kW |

| Rated speed | 3300 rpm |

| Displacement | 5.813 L |

| Number of cylinders | 6 cylinders |

| Aspiration | Turbocharged and intercooled |

| Dimensions | 1440 mm × 748.5 mm × 773.8 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gharib, H.; Kovács, G. Implementation and Possibilities of Fuzzy Logic for Optimal Operation and Maintenance of Marine Diesel Engines. Machines 2024, 12, 425. https://doi.org/10.3390/machines12060425

Gharib H, Kovács G. Implementation and Possibilities of Fuzzy Logic for Optimal Operation and Maintenance of Marine Diesel Engines. Machines. 2024; 12(6):425. https://doi.org/10.3390/machines12060425

Chicago/Turabian StyleGharib, Hla, and György Kovács. 2024. "Implementation and Possibilities of Fuzzy Logic for Optimal Operation and Maintenance of Marine Diesel Engines" Machines 12, no. 6: 425. https://doi.org/10.3390/machines12060425

APA StyleGharib, H., & Kovács, G. (2024). Implementation and Possibilities of Fuzzy Logic for Optimal Operation and Maintenance of Marine Diesel Engines. Machines, 12(6), 425. https://doi.org/10.3390/machines12060425