Parameter Identification of Flexible Link Manipulators Using Evolutionary Algorithms

Abstract

1. Introduction

2. Materials and Methods

2.1. Flexible-Link Manipulator Dynamics

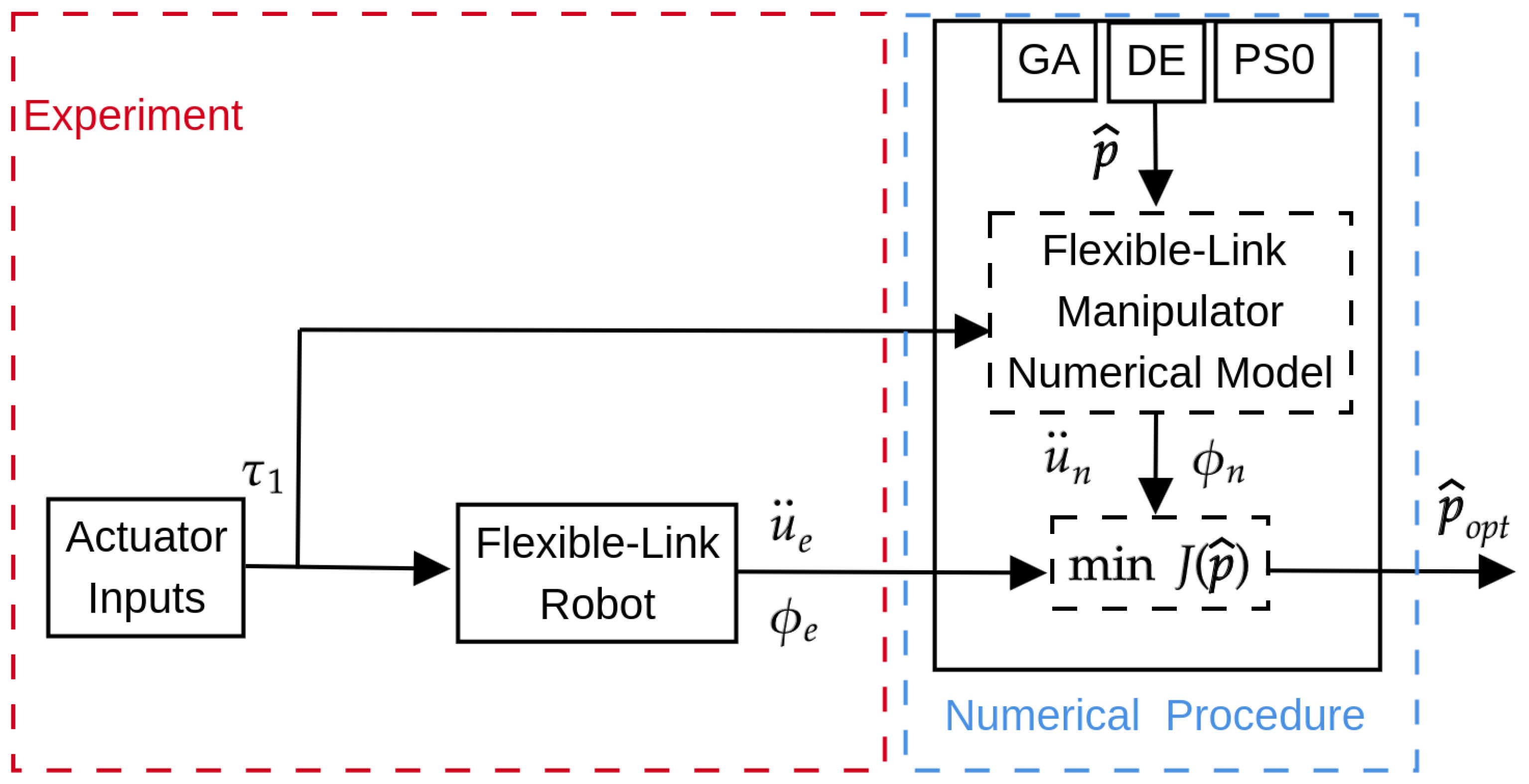

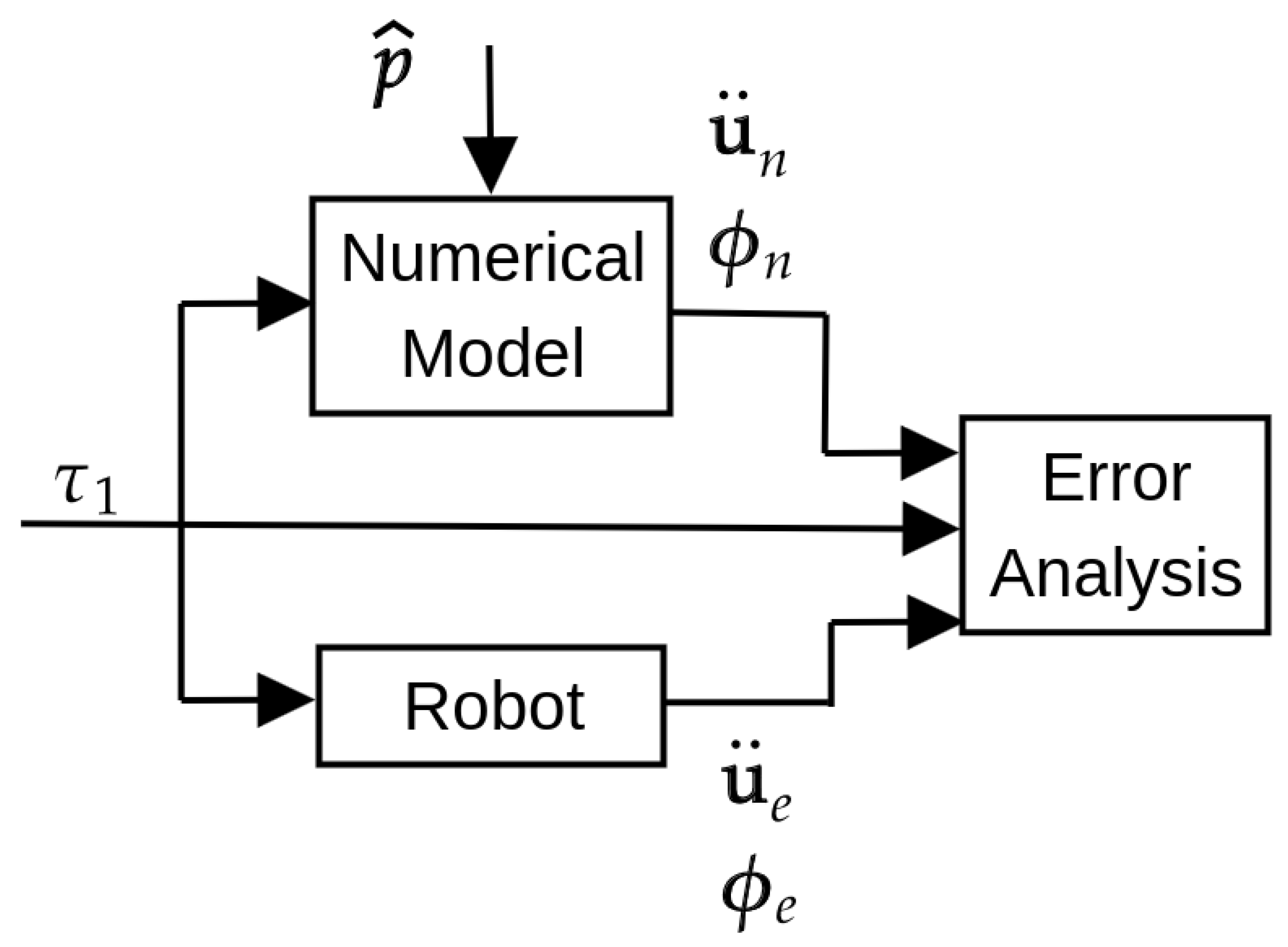

2.2. Parameter Identification Approach

3. Case Study: One-Link Flexible Manipulator

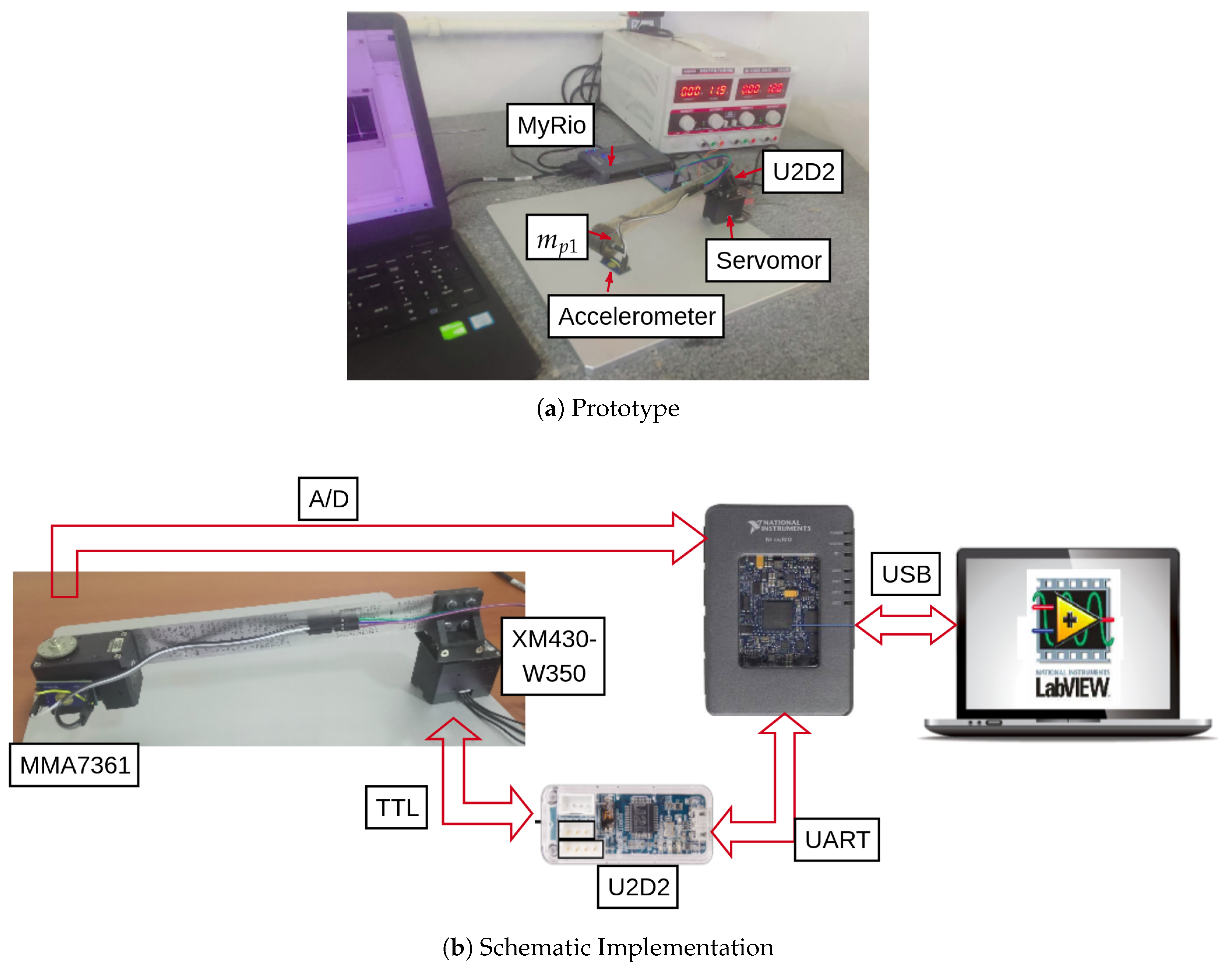

3.1. Testbed

3.2. Numerical Model

4. Results and Discussion

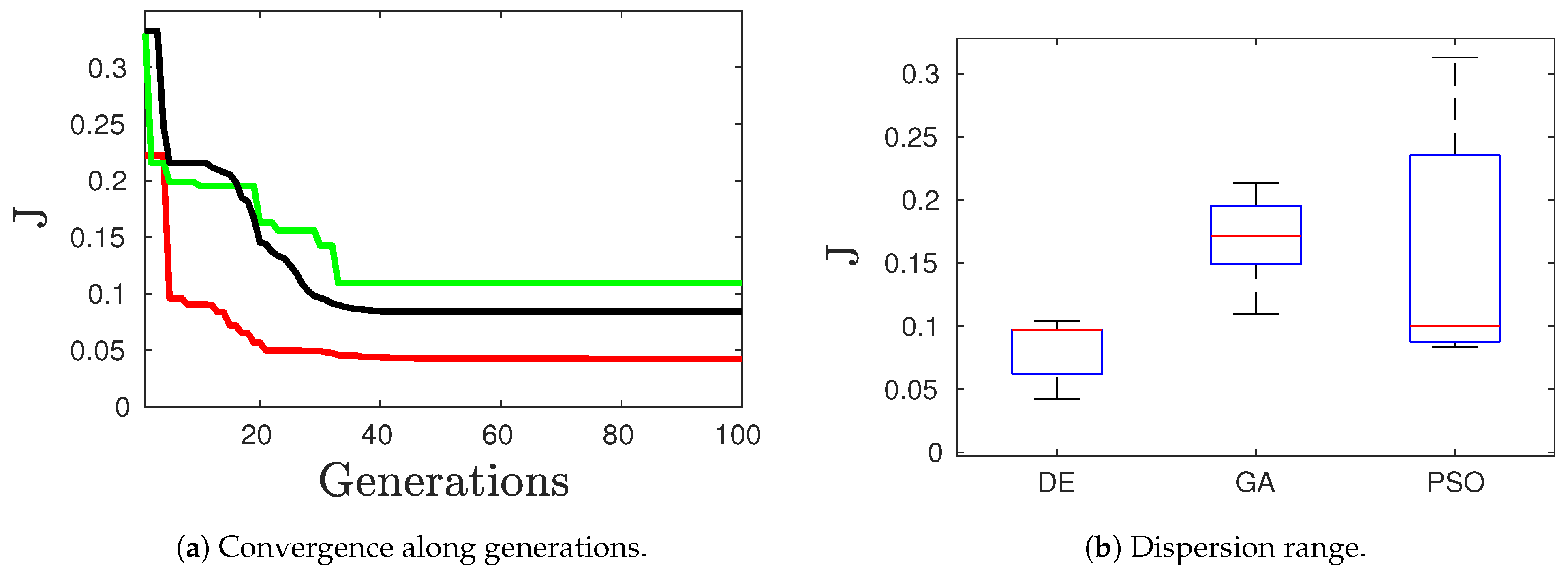

- The parameters used by the DE algorithm [35] are the following: population size = 100, weighting factor F = 0.5, crossover probability = 0.8, 100 generations, and strategy for the generation of candidates.

- The parameters used by the GA algorithm [36] are the following: = 100, selection rate = 0.5, crossover rate = 0.8, mutation rate = 0.2, and 100 generations.

- The parameters used by the PSO algorithm [32] are the following: number of particles = 100, inertia weigth w = 1.4, = 1.5, = 2.5, and 100 iterations.

- The stopping criteria considered was the maximum number of generations/iterations.

- The study cases were run 10 times, and the average values were obtained.

- To establish a fair comparison among the evolutionary algorithms, the seeds 0, 1, 2, …, 9 were used to initialize the random generator for each simulation.

- The aforementioned case studies, using DE, the GA, and PSO, were run 10 times to obtain the upcoming average values.

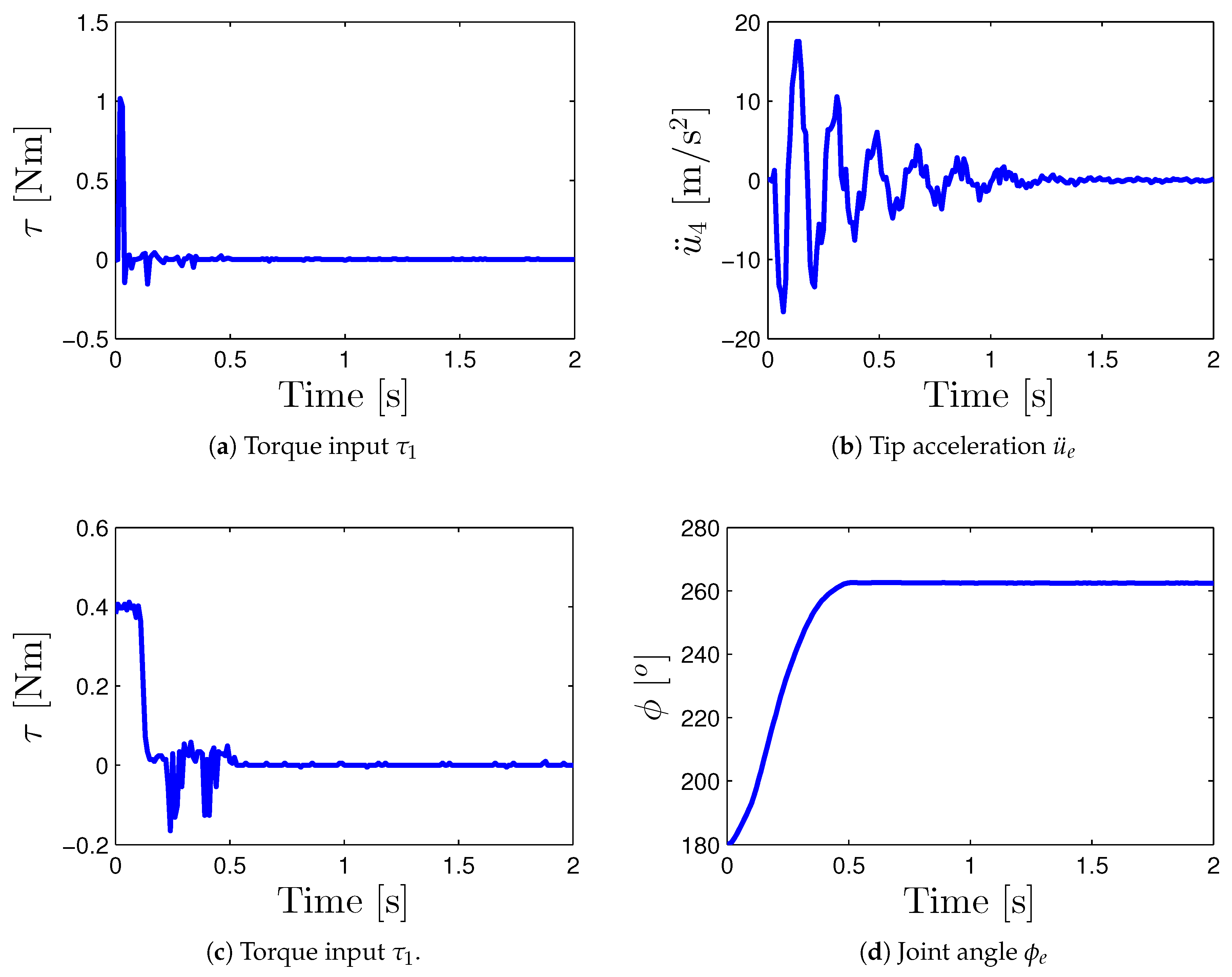

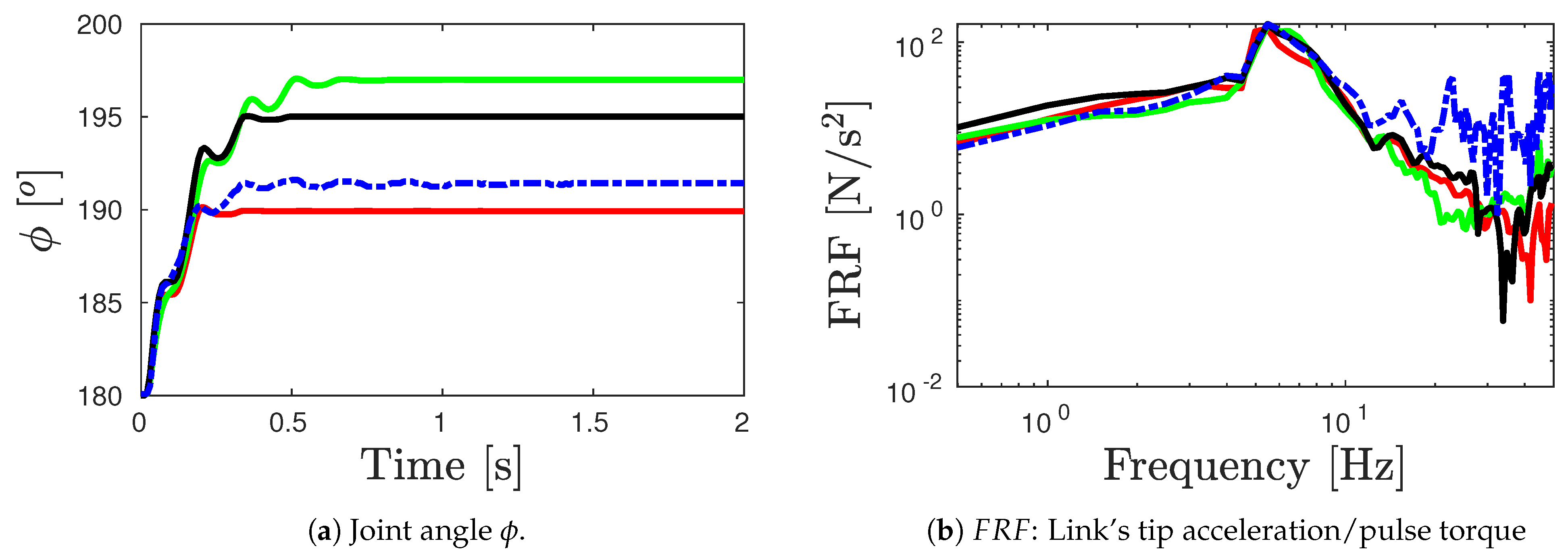

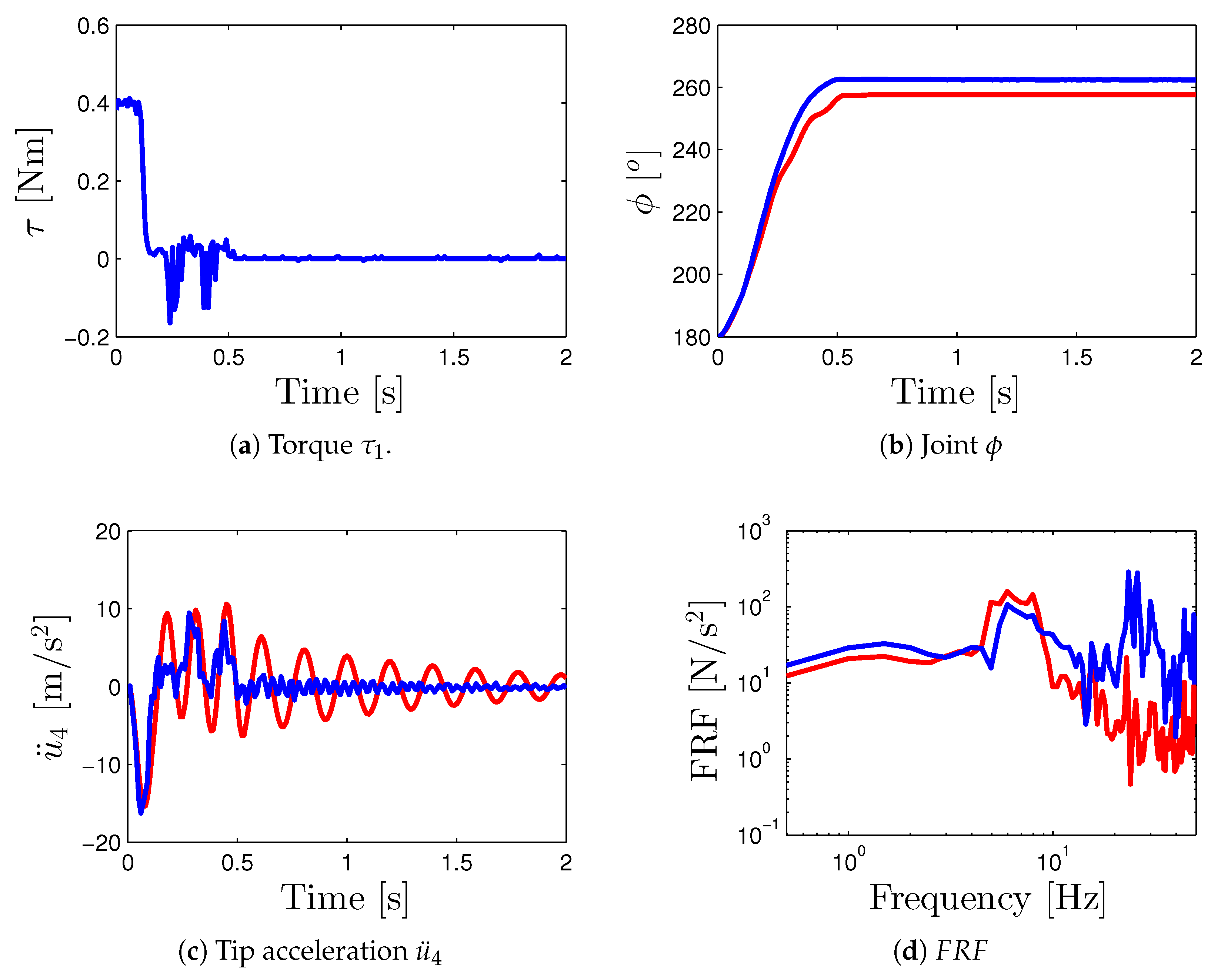

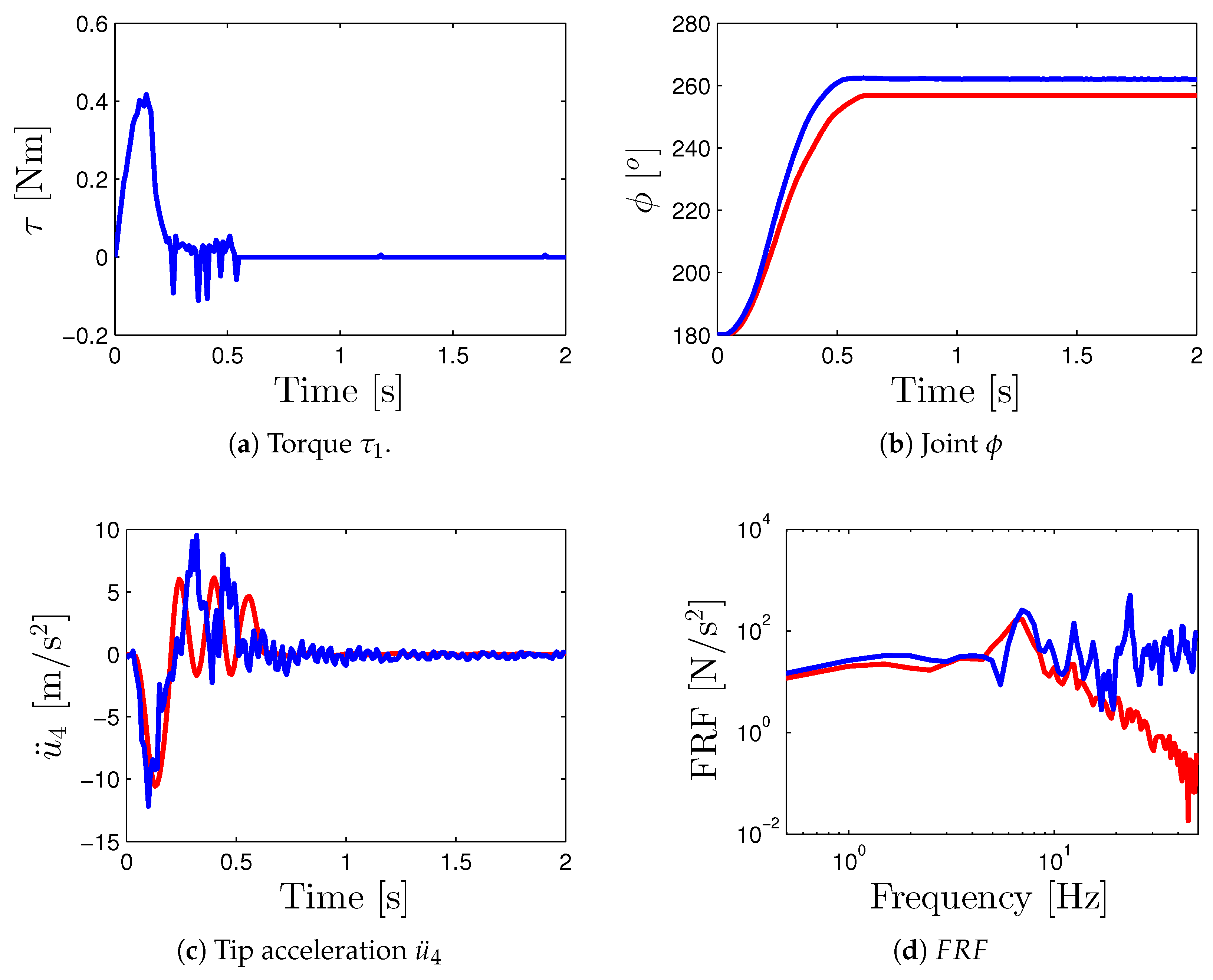

Model Validation

- Three different test inputs were considered for the torque applied by the servomotor that permits assessment of the numerical and experimental dynamic response: triangular (see Figure 8a), pulse (see Figure 9a), and sinusoidal that considers the positive part (see Figure 10a). These inputs are three different signal profiles of torque that produce different angular accelerations at the flexible link. These torques were applied from 0 (seg) to 0.3 (seg) to move the joint angle to a maximum angular displacement of 80 (deg). Figure 8a, Figure 9a and Figure 10a show the torque applied torque that was measured using the current sensor of the servomotor.

- The identified parameters considered in the numerical model were obtained from the best case of DE, and these parameters are presented in Table 2.

- The numerical and experimental outputs of link’s tip acceleration for the corresponding test inputs are presented in Figure 8c, Figure 9c and Figure 10c. Moreover, the frequency response functions (toque input/link’s tip acceleration) for the numerical and experimental outputs are also computed in Figure 8d, Figure 9d and Figure 10d.

- For the error analysis, the error between the numerical model and experimental outputs in terms of the joint angle and the were estimated based on the Normalized Root Mean Square Error () according to the expressions of Equation (7).

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cordier, J.; Friconneau, J.; Gargiulo, L.; Grisolia, C.; Palmer, J.; Perrot, Y.; Samaille, F. Articulated inspection arm for ITER, a demonstration in the Tore Supra tokamak. In Proceedings of the 20th IEEE/NPSS Symposium on Fusion Engineering, San Diego, CA, USA, 14–17 October 2003; IEEE: Piscataway, NJ, USA, 2003; pp. 197–200. [Google Scholar]

- Zhang, Y.; Lu, M. A review of recent advancements in soft and flexible robots for medical applications. Int. J. Med. Robot. Comput. Assist. Surg. 2020, 16, e2096. [Google Scholar] [CrossRef]

- Sąsiadek, J. Space robotics and its challenges. In Aerospace Robotics: Selected Papers from I Conference on Robotics in Aeronautics and Astronautics; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–8. [Google Scholar]

- Li, B.; Li, X.; Gao, H.; Wang, F.Y. Advances in Flexible Robotic Manipulator Systems—Part I: Overview and Dynamics Modeling Methods. IEEE/ASME Trans. Mechatron. 2024, 29, 1100–1110. [Google Scholar] [CrossRef]

- Lara-Molina, F.A.; Gonçalves, R.S. Reliability-based optimization of flexible manipulators. J. Vib. Eng. Technol. 2023, 11, 3147–3162. [Google Scholar] [CrossRef]

- Lismonde, A.; Sonneville, V.; Brüls, O. A geometric optimization method for the trajectory planning of flexible manipulators. Multibody Syst. Dyn. 2019, 47, 347–362. [Google Scholar] [CrossRef]

- Lara-Molina, F.A.; Dumur, D.; Assolari Takano, K. Multi-objective optimal design of flexible-joint parallel robot. Eng. Comput. 2018, 35, 2775–2801. [Google Scholar] [CrossRef]

- Sayahkarajy, M.; Mohamed, Z.; Mohd Faudzi, A.A. Review of modelling and control of flexible-link manipulators. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2016, 230, 861–873. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; You, Z. An overview of dynamic parameter identification of robots. Robot. Comput.-Integr. Manuf. 2010, 26, 414–419. [Google Scholar] [CrossRef]

- Cammarata, A.; Sinatra, R.; Rigano, A.; Lombardo, M.; Maddio, P.D. Design of a large deployable reflector opening system. Machines 2020, 8, 7. [Google Scholar] [CrossRef]

- Urrea, C.; Pascal, J. Design, simulation, comparison and evaluation of parameter identification methods for an industrial robot. Comput. Electr. Eng. 2018, 67, 791–806. [Google Scholar] [CrossRef]

- Pires, I.; Ayala, H.V.H.; Weber, H.I. Nonlinear ensemble gray and black-box system identification of friction induced vibrations in slender rotating structures. Mech. Syst. Signal Process. 2023, 186, 109815. [Google Scholar] [CrossRef]

- Yazdizadeh, A.; Khorasani, K.; Patel, R.V. Identification of a two-link flexible manipulator using adaptive time delay neural networks. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 2000, 30, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Sun, X. System identification and model reduction for a single-link flexible manipulator. J. Sound Vib. 2001, 242, 867–891. [Google Scholar] [CrossRef]

- Ziaei, K.; Wang, D.W. Application of orthonormal basis functions for identification of flexible-link manipulators. Control Eng. Pract. 2006, 14, 99–106. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, J.; Chen, Z.; Liu, B. Dynamic characteristic parameters identification analysis of a parallel manipulator with flexible links. J. Mech. Sci. Technol. 2014, 28, 4833–4840. [Google Scholar] [CrossRef]

- Pappalardo, C.M.; Lök, Ş.İ.; Malgaca, L.; Guida, D. Experimental modal analysis of a single-link flexible robotic manipulator with curved geometry using applied system identification methods. Mech. Syst. Signal Process. 2023, 200, 110629. [Google Scholar] [CrossRef]

- Lara-Molina, F.A. Modeling of Flexible-Link Manipulators Under Uncertain Parameters Based on Stochastic Finite Element Method. J. Mech. Robot. 2022, 14, 061002. [Google Scholar] [CrossRef]

- Meng, D.; She, Y.; Xu, W.; Lu, W.; Liang, B. Dynamic modeling and vibration characteristics analysis of flexible-link and flexible-joint space manipulator. Multibody Syst. Dyn. 2018, 43, 321–347. [Google Scholar] [CrossRef]

- Mehrjooee, O.; Fathollahi Dehkordi, S.; Habibnejad Korayem, M. Dynamic modeling and extended bifurcation analysis of flexible-link manipulator. Mech. Based Des. Struct. Mach. 2020, 48, 87–110. [Google Scholar] [CrossRef]

- Perry, M.; Koh, C.; Choo, Y. Modified genetic algorithm strategy for structural identification. Comput. Struct. 2006, 84, 529–540. [Google Scholar] [CrossRef]

- Trinh, T.N.; Koh, C.G. An improved substructural identification strategy for large structural systems. Struct. Control Health Monit. 2012, 19, 686–700. [Google Scholar] [CrossRef]

- Tam, J.H.; Ong, Z.C.; Ismail, Z.; Ang, B.C.; Khoo, S.Y.; Li, W.L. Inverse identification of elastic properties of composite materials using hybrid GA-ACO-PSO algorithm. Inverse Probl. Sci. Eng. 2018, 26, 1432–1463. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Wang, X.; Ni, P. Output-only structural parameter identification with evolutionary algorithms and correlation functions. Smart Mater. Struct. 2020, 29, 035018. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, G.; Wang, X.; Ni, P.; Zhang, J. A hybrid identification method on butterfly optimization and differential evolution algorithm. Smart Struct. Syst. Int. J. 2020, 26, 345–360. [Google Scholar]

- Xu, X.; Lin, P. Parameter identification of sound absorption model of porous materials based on modified particle swarm optimization algorithm. PLoS ONE 2021, 16, e0250950. [Google Scholar] [CrossRef] [PubMed]

- Yoshikawa, T.; Hosoda, K. Modeling of flexible manipulators using virtual rigid links and passive joints. Int. J. Robot. Res. 1996, 15, 290–299. [Google Scholar] [CrossRef]

- Theodore, R.J.; Ghosal, A. Comparison of the assumed modes and finite element models for flexible multilink manipulators. Int. J. Robot. Res. 1995, 14, 91–111. [Google Scholar] [CrossRef]

- Jonker, J.B.; Aarts, R.G. A perturbation method for dynamic analysis and simulation of flexible manipulators. Multibody Syst. Dyn. 2001, 6, 245–266. [Google Scholar] [CrossRef]

- Usoro, P.B.; Nadira, R.; Mahil, S.S. A Finite Element/Lagrange Approach to Modeling Lightweight Flexible Manipulators. J. Dyn. Syst. Meas. Control 1986, 108, 198–205. [Google Scholar] [CrossRef]

- Inman, D.J.; Singh, R.C. Engineering Vibration; Prentice Hall: Englewood Cliffs, NJ, USA, 1994; Volume 3. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; IEEE: Piscataway, NJ, USA, 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Lara-Molina, F.A.; Dumur, D. A fuzzy approach for the kinematic reliability assessment of robotic manipulators. Robotica 2021, 39, 2095–2109. [Google Scholar] [CrossRef]

- Lara-Molina, F.A.; Dumur, D. Robust multi-objective optimization of parallel manipulators. Meccanica 2021, 56, 2843–2860. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution—A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Holland, J.H. Genetic algorithms. Sci. Am. 1992, 267, 66–73. [Google Scholar] [CrossRef]

| Parameter | Units | Lower Limit () | Upper Limit () |

|---|---|---|---|

| E | Pa | 20 × 109 | 100 × 109 |

| kg m2 | 1 × 10−3 | 0.2 | |

| v | Nm/(rad/s) | 1 × 10−5 | 0.3 |

| N m | 1 × 10−3 | 0.2 | |

| - | 1 × 10−3 | 4 | |

| - | 1 × 10−7 | 2 × 10−4 |

| Parameter | DE | GA | PSO |

|---|---|---|---|

| E [Pa] | |||

| [kg m2] | 0.0053 | 0.0073 | 0.0048 |

| v [Nm/(rad/s)] | |||

| [N m] | 0.1071 | 0.0589 | 0.0902 |

| 1.8240 | 0.2020 | 0.8055 | |

| Parameter | ||

|---|---|---|

| E [Pa] | ||

| [kg m2] | 0.0045 | |

| v [Nm/(rad/s)] | 0.0069 | 0.0036 |

| [N m] | 0.0804 | 0.0194 |

| 0.9860 | 0.5927 | |

| Torque Input () | ||

|---|---|---|

| Triangular | 2.8556 | 1.7092 |

| Rectangular | 5.0235 | 1.5390 |

| Sinusoidal | 6.0896 | 1.5093 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lara-Molina, F.A. Parameter Identification of Flexible Link Manipulators Using Evolutionary Algorithms. Machines 2024, 12, 409. https://doi.org/10.3390/machines12060409

Lara-Molina FA. Parameter Identification of Flexible Link Manipulators Using Evolutionary Algorithms. Machines. 2024; 12(6):409. https://doi.org/10.3390/machines12060409

Chicago/Turabian StyleLara-Molina, Fabian Andres. 2024. "Parameter Identification of Flexible Link Manipulators Using Evolutionary Algorithms" Machines 12, no. 6: 409. https://doi.org/10.3390/machines12060409

APA StyleLara-Molina, F. A. (2024). Parameter Identification of Flexible Link Manipulators Using Evolutionary Algorithms. Machines, 12(6), 409. https://doi.org/10.3390/machines12060409