Abstract

To meet the requirements of amphibious exploration, ocean exploration, and military reconnaissance tasks, a pneumatic amphibious soft bionic robot was developed by taking advantage of the structural characteristics, motion forms, and propulsion mechanisms of the sea lion fore-flippers, inchworms, Carangidae tails, and dolphin tails. Using silicone rubber as the main material of the robot, combined with the driving mechanism of the pneumatic soft bionic actuator, and based on the theory of mechanism design, a systematic structural design of the pneumatic amphibious soft bionic robot was carried out from the aspects of flippers, tail, head–neck, and trunk. Then, a numerical simulation algorithm was used to analyze the main executing mechanisms and their coordinated motion performance of the soft bionic robot and to verify the rationality and feasibility of the robot structure design and motion forms. With the use of rapid prototyping technology to complete the construction of the robot prototype body, based on the motion amplitude, frequency, and phase of the bionic prototype, the main execution mechanisms of the robot were controlled through a pneumatic system to carry out experimental testing. The results show that the performance of the robot is consistent with the original design and numerical simulation predictions, and it can achieve certain maneuverability, flexibility, and environmental adaptability. The significance of this work is the development of a pneumatic soft bionic robot suitable for amphibious environments, which provides a new idea for the bionic design and application of pneumatic soft robots.

1. Introduction

With the rapid development of bionic robot technology, material technology, rapid prototyping technology, and artificial intelligence, soft robots have become a research hotspot in the field of robotics. They are based on natural organisms, mainly composed of soft elastic materials or malleable materials, with high degrees of freedom, and obtain a large amount of energy through large-amplitude and high-curvature bending and torsion [1,2]. Soft robots can arbitrarily change their shape and size in a limited space and can well imitate biological prototypes to complete crawling, jumping, swimming, grasping, and other movement patterns [3,4]. They have the advantages of high safety in human–machine interaction, strong adaptability to unstructured environments, good maneuverability, and low maintenance costs and can meet the operational requirements in various complex and changing environments [5,6,7].

In the field of research on crawling soft robots, these robots can be specifically divided into peristaltic, “”-shaped motion, and serpentine-shaped motion [8,9]. The peristaltic crawling robots are mainly based on the peristaltic mechanism of worms. The worm’s body belongs to a hydrostatic skeletal structure, and by controlling the contraction of the longitudinal or circular muscles between various segments of the body, the length and diameter of each segment can be changed, generating traveling waves. Seok S. et al. [10] from the Massachusetts Institute of Technology developed a crawling robot, Meshworm, using shape memory alloys (SMAs), which is not only capable of effective crawling but also has anti-interference capabilities. Jiang C. et al. [11] from Donghua University developed a pipeline crawling robot based on paper–fabric composite materials that can achieve a peristaltic crawling through the anchoring effect of Kresling fold modes. The “”-shaped crawling robots are mainly based on the bending crawling mechanism of inchworms and caterpillars. The bodies of inchworms and caterpillars are also hydrostatic skeletal structures, which can achieve “”-shaped crawling by utilizing the pressure between the feet and the base, combined with body tension. Lin H.T. et al. [12] from Tufts University developed an SMA-driven caterpillar-like robot, GoQBot, which can achieve crawling, rolling, and obstacle-surmounting motions. Han F.L. et al. [13] from Central South University designed an inchworm-like crawling robot that can move forward and climb slopes by adjusting the inflation and deflation of the deformation cavity and alternating adsorption of the adsorption cavity. Serpentine crawling robots are mainly based on the serpentine crawling mechanism of snakes. A snake’s body generates multiple alternating peaks and valleys from front to back, generating unbalanced forces to achieve crawling. Onal C.D. et al. [14] from the Massachusetts Institute of Technology developed a bi-directional fluidic elastomer-driven robotic snake by controlling the inflation and deflation of the actuators in different directions, achieving a maximum crawling speed of 19 mm/s. Qin Y. et al. [15] from the Worcester Polytechnic Institute developed a robotic snake based on silicone rubber material that mimics the snake serpentine motion, with a maximum crawling speed of 131.6 mm/s. Although existing crawling soft robots have relatively limited movement functions and working environments, their crawling speed has been significantly improved.

With the continuous deepening of research on soft robots, they have achieved further rapid development [16]. In the field of research on underwater soft robots, they can be specifically divided into trunk-swinging type, trunk-undulating type, wing (fin)-flapping type, wing (fin)-undulating type, and jet propulsion type [17,18]. Trunk-swinging-type robots are mainly based on the tail-swinging mechanism of Carangidae. Carangidae achieve propulsion by alternating the asymmetrical contraction and extension of the muscles on both sides of the trunk, combined with the periodic swinging of the tail fin, which achieves high stability. Marchese A.D. et al. [19,20] from the Massachusetts Institute of Technology developed a pneumatic- and hydraulic-driven robotic fish capable of autonomous maneuvering underwater with functions such as rapid tracking, escape, and hydrological observation. Liu S.J. et al. [21] from Jilin University developed a tuna-like robot based on simulating fish muscle bundles, with a maximum swing angle of 20° and a maximum thrust of 0.185 N at the optimal frequency of 3.5 Hz. This type of robot has high flexibility and fast swimming speed, but poor stability. Trunk-undulating underwater robots are mainly based on the trunk undulation mechanism of hairtails and eels. Hairtails and eels can shuttle through complex environments such as undersea reefs and coral clumps by utilizing the asymmetric fluctuation of the trunk. Low K.H. et al. [22] from Nanyang Technological University developed a multiple-segment robot driven by SMA based on polyurethane elastomer, and it completed undulating movements through SMA driving of each segment of the robot. Shen Q. et al. [23] from Beihang University designed a whale-like robot based on IPMC driving, which could drive the trunk of the robot for undulating movements. This type of robot has strong adaptability to unstructured environments and good flexibility, but low movement speed. Wing (fin)-flapping underwater robots are mainly based on the flapping mechanism of manta rays. Manta rays can output a large torque by flapping their pectoral fins periodically. Cai Y. et al. [24] from Beihang University developed a manta-ray-like robotic fish that can imitate muscle contraction movement and achieve pectoral fin flapping swimming by inflating and deflating elastic tubes on both sides of the robot fish. Li T. et al. [25] from Zhejiang University developed a flapping-type robotic fish that can swim by flapping its fins using a dielectric elastomer in the middle of the robotic fish. This type of robot has high motion stability and strong power. Wing (fin)-undulating underwater robots are based on the undulating mechanism of cuttlefish. Cuttlefish use the different frequencies, phases, and amplitudes of their fins on both sides to swim. Kim H.S. et al. [26] from Seoul National University developed an SMA-driven underwater robot based on the driving principle of the manta ray, and the underwater propulsion and swimming speed of the robot can be changed through different execution sequences of the actuators, with a maximum speed of 0.25 bodies per second. Yurugi M. et al. [27] from Meijo University developed a wing (fin)-undulating-type underwater robot based on the swimming pattern of a stingray. By adjusting the cartilage structure inside the robot’s biomimetic fins, the swimming performance of the robot is improved. Although this type of soft robot swims relatively smoothly, this type of soft robot often requires multiple actuators to achieve periodic undulation, leading to a larger size and more complex control system. Jet-propelled underwater robots are mainly based on the propulsion mechanism of jellyfish and cuttlefish. Jellyfish and cuttlefish can swim by using the recoil force generated by muscle pumping. Du W. et al. [28] from the Harbin Institute of Technology designed an SMA-driven squid-like spray robot. The robot swims by the pulse propulsion principle, with fast swimming speed and no noise. Christianson C.M. et al. [29] from the University of California, San Diego, were inspired by cephalopods and proposed an electric-motor-driven jet propulsion underwater robot that can achieve repeatable jet propulsion, with a maximum thrust of 0.19 N and a maximum speed of 32.1 cm/s. This type of robot has good directional motion and high acceleration, but the smoothness of swimming often needs to be improved. The propulsion of underwater soft robots is currently a research hotspot, and researchers, based on the principle of fishtail tendon drive, have achieved the maximum underwater propulsion force by changing the flapping frequency and tail amplitude of an underwater soft robot [30,31,32].

The working environment for land crawling and underwater swimming soft robots mentioned above is relatively limited. With the increasing demand for robot operations towards diversity and complexity, soft robots suitable for amphibious operations are receiving increasing attention [33]. Soomro A.M. et al. [34] from Jeju National University systematically studied an amphibious soft bio-inspired frog robot based on SMA. The motion characteristics of the robot can be consistent with those of a real frog, and it has superior maneuverability and excellent weight balance. However, few researchers have studied the amphibious operation of pneumatic soft bionic robots, resulting in a relatively single movement function and a need to improve the environmental adaptability of pneumatic soft robots, making it difficult to achieve more complex amphibious environment operations. In this article, on the basis of original research results for an imitation sea lion fore-flipper, we deeply analyze the structural characteristics, movement form, and propulsion mechanism of inchworms, Carangidae tails, and dolphin tails through the bionics theory, combined with the driving mechanism of a pneumatic soft bionic actuator, taking full advantage of the large deformation and superelasticity characteristics of the silicone rubber material, to carry out the structural design and the movement form and functional analysis of a pneumatic amphibious soft bionic robot. Then, motion simulation research of the robot 3D digital model structure is performed through numerical simulation algorithms, which provide the qualitative and quantitative motion performance of the main executing mechanisms of the robot and verify the rationality and feasibility of the structural design and the motion form of the soft bionic robot. In the end, the maneuverability, flexibility, and environmental adaptability of the robot are evaluated in various environments, both water and land, and the performance indices are quantified.

2. Research on Propulsion Mechanism of Biological Prototype

This article deeply studies the structural characteristics and propulsion mechanisms of natural organisms, providing a research basis for the structural design and motion function realization of soft robots. The fore-flippers of sea lions have characteristics such as strong underwater maneuverability, high flexibility, and low tail vortex disturbances [35]. Due to the superior motion performance of California sea lions compared to other types of sea lions, with faster movement speed and more flexible movements, their fore-flippers are used as bionic objects for the study of biological prototype propulsion mechanisms. The motion and power output mechanisms of the actuator of the pneumatic soft bionic robot have similarities with the inchworm “”-type motion mechanism. Therefore, the biological prototype propulsion mechanism of inchworms is studied. The left–right-swinging fishtail and the dorsal–ventral motion dolphin tail have excellent propulsion performance in underwater swimming. To comprehensively improve the motion performance of the robot, the left–right swinging and dorsal–ventral motion functions are incorporated into the structural design of the robot, and the biological prototype propulsion mechanism of both types of tail movement is studied. It should be noted that this article is a continuation of our previous research findings, and we will not provide specific research on the biomimetic principle of the fore-flippers of the robot here [36].

2.1. Inchworm

As an invertebrate, the inchworm mainly exerts pressure on soft tissues through its body fluids to obtain the necessary power for crawling. In addition, since the body fluids are not compressible and are always under pressure, the inchworm can maintain a certain rigidity during crawling, and its flexible movements can take on a stretchable “” shape. Moreover, it has a strong climbing ability [37].

2.1.1. Structure Characteristics

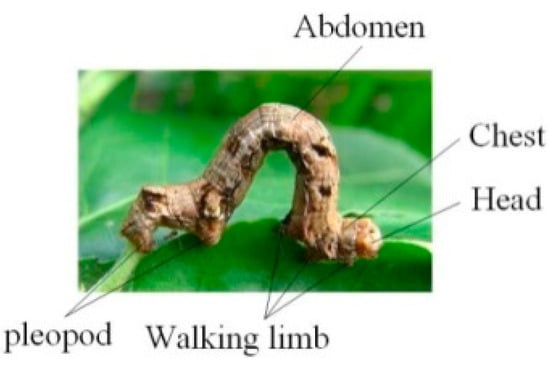

The inchworm is an invertebrate, mainly consisting of a head, trunk, and pleopods; the trunk consists of the chest and pleopods. The chest contains three segments adjacent to the head, which have walking limbs. The structure of the inchworm is shown in Figure 1 [38].

Figure 1.

Schematic diagram of inchworm structure.

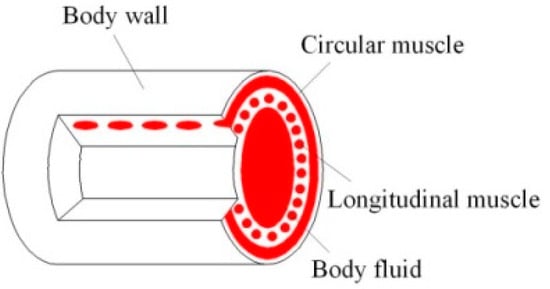

The tissue structure of an inchworm is mainly composed of the body walls, muscles, and body fluids. The body wall layer is thick and hard, equivalent to the skeletal system. The muscles consist of longitudinal and circular muscles that are orthogonally arranged and can form a closed space with body fluids inside, and both elements form a hydrostatic skeleton; the anatomy of the tissue structure of the inchworm is shown in Figure 2. In addition, the inchworm muscles are mainly connected through connective tissue, which provides high strength. When the muscle contracts or relaxes, a deformation is generated in one direction of the hydrostatic skeleton, causing other directions to deform. Therefore, the joint action of body fluids, muscles, and their connective tissues can adjust the stiffness of the inchworm body and ensure morphological changes.

Figure 2.

Schematic diagram of inchworm tissue structure.

2.1.2. Motion Mechanism Analysis

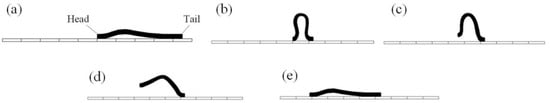

The inchworm can cause bending and straightening of body segments or appendage internodes through muscle contraction and relaxation, as well as alternation of head and tail, driving the head, trunk, and pleopods to cooperate and complete the “”-shaped crawling, which can provide a reference for the robot to achieve crawling motion. The specific process is as follows: When the inchworm moves forward, the body extends forward, causing the chest walking limbs to move to a suitable position, anchoring the base, and then following up with the pleopods, making the body bend into an “” shape, as shown in Figure 3a,b. At the same time, the pleopods anchor the base, and the chest walking limbs lift, allowing for forward movement of the body through hydrostatic skeletal action, as shown in Figure 3c. The inchworm then extends its body segments, raises its head, and moves towards a new foothold to complete a gait cycle, as shown in Figure 3d,e.

Figure 3.

Schematic diagram of inchworm movement state. (a) gait 1, (b) gait 2, (c) gait 3, (d) gait 4, (e) gait 5.

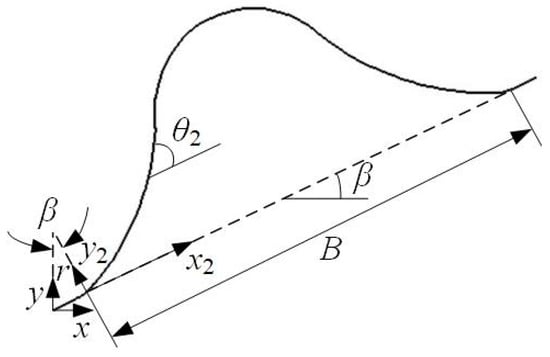

2.1.3. Propulsion Mechanism Analysis

The shape of the centerline of the inchworm in motion is extracted and assumed to be a dimensionless form [39]. Here, the initial rising part (near the tail section) is assumed to be 1/4 arc, the radius of curvature is , and the diagonal is , and then the arc length is . The middle part is assumed to be “”-shaped, connected by a line (chord) and at an angle to the horizontal plane. The basic length along this line is expressed as , the axes are and , the rotation angle of the chord is , and the total arc length is . The head part is at an angle with the horizontal plane. For the circular part, the rotation from the horizontal direction is to , as shown in Figure 4.

Figure 4.

Analysis diagram of inchworm propulsion mechanism.

According to Figure 4, the expressions of , and are

According to the corresponding relationship, the expressions of coordinates and can be further obtained as follows:

When the angle increases gradually until it reaches , the length of the inclined base can be expressed as

where , .

Therefore, based on the above derivation, the step size variation of the inchworm can be determined, which can provide a theoretical basis for the crawling motion state and performance of the robot. A force analysis of the crawling process of the inchworm can be performed, as shown in Figure 5.

Figure 5.

Force analysis diagram of inchworm.

According to Figure 5, suppose that the walking limbs of the inchworm are anchored to the base, and under the action of the hydrostatic skeletal structure, the pleopods follow up, making the body bend into a “” shape. Here, is the pressure generated by the hydrostatic skeletal structure during inchworm movement.

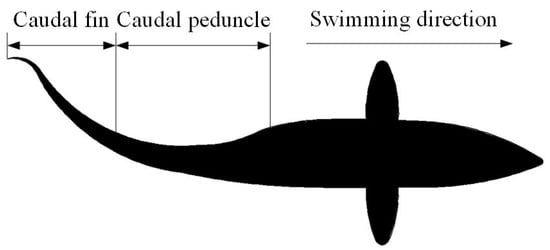

2.2. Left–Right-Swinging Tail

In fish swimming, the most common propulsion method is the left–right swinging of the tail, which is a compound movement that includes the secondary swing and main swing [40]. The swimming of Carangidae is relatively representative. It mainly relies on the rear one-third of the body for left–right-swinging propulsion and directional adjustment, and the caudal peduncle between the body and the caudal fin can assist in coordination [41]. The left–right-swinging propulsion of the Carangidae tail is shown in Figure 6.

Figure 6.

Schematic diagram of the left–right-swinging movement of the tail.

2.2.1. Tail Secondary Swing

The secondary swing of the tail is generated by the cooperative action of the fish body and the rear neck, and the connection position between the caudal peduncle and the caudal fin is the maximum lateral displacement. Taking the center line of the fish body as the x-axis, the fish head orientation as the negative direction, and the center line of the pectoral fin as the y-axis, the swing amplitude of each point can be represented. According to the intersection of the two center lines, a motion coordinate system is established, as shown in Figure 7.

Figure 7.

Trajectory diagram of the left–right swinging of the tail.

The amplitude envelope can be seen as a sine wave with gradually increasing amplitude, and Equation (4) is

where is the horizontal displacement of fish body wave, and are the parameters of the amplitude envelope, is the number of fish body waves, and is the fish body wave frequency.

Furthermore, it can be seen from Equation (4) that the characteristics of the rear half of the fish body and the fishtail can determine the thrust during swimming. Therefore, based on the mathematical model of fish body waves, the structural characteristic parameters of the bionic robot can be adjusted to improve its maneuverability. Therefore, the mathematical model of fish body waves can be used as a theoretical basis to optimize the structural design of the robot, adjust the structural feature parameters, and improve its mobility.

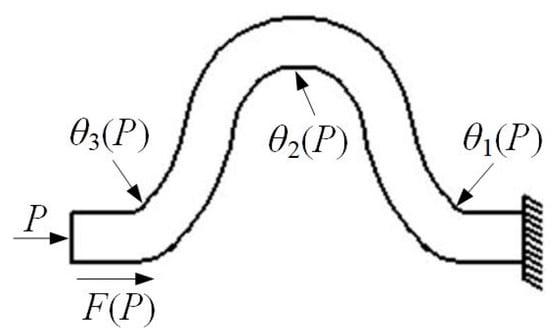

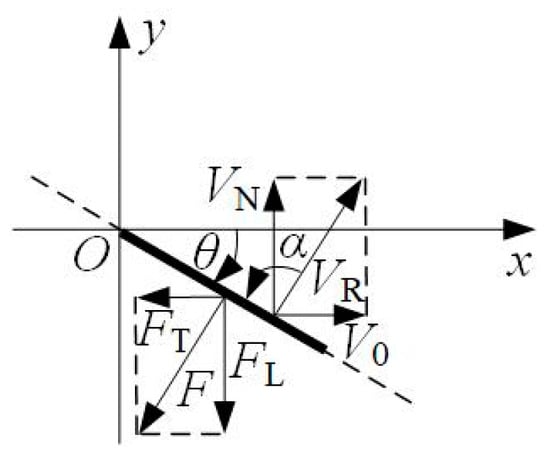

2.2.2. Tail Main Swing

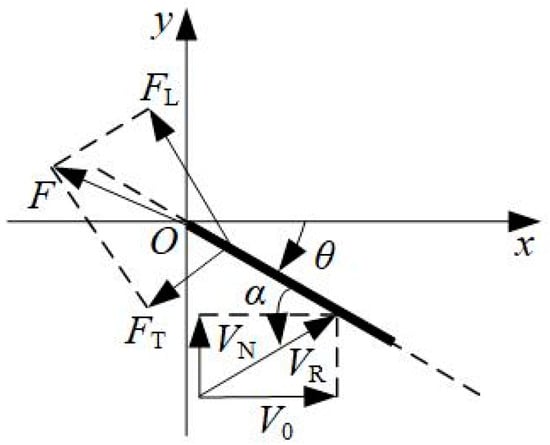

The main swing of the tail is an important source of propulsion, which can be adjusted by changing the swing phase difference and the water striking angle , providing a theoretical basis for the left–right swing propulsion of the robot, and optimizing the design and arrangement of the actuators to enhance the propulsion force of the underwater motion of the robot. According to the theory of fluid mechanics, the tail is approximately simplified as a regular rigid plate, and the swing process is ideally performed in a viscous flow field. The stress analysis can be obtained by decomposing the fluid pressure outside the tail, as shown in Figure 8.

Figure 8.

Force analysis of the left–right swinging of the tail.

According to Figure 8, is the velocity relative to the tail center of gravity, is the flow velocity of the flow field, is the vertical upward velocity of the relative flow field, the hydrodynamic force can be decomposed into lift force and thrust force , is the instantaneous swing angle of the tail, and is instantaneous relative water striking angle at the tail.

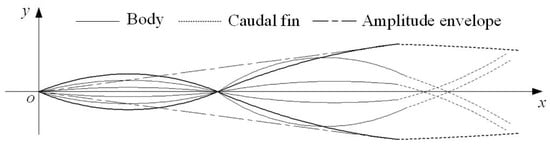

2.3. Dorsal–Ventral Movement Tail

Dorsal–ventral movement has excellent propulsion performance, which can provide a theoretical basis for the dorsal–ventral movement propulsion of the tail and head–neck of the robot and optimize the actuator design and layout. The style of dolphins swimming is a typical representative, as they can generate large swings through their dorsal–ventral movements during swimming, which can be seen as a composite motion formed by the combined effects of buoyancy and pitch [40]. The buoyancy movement is a large swing motion of the tail, which can generate the main thrust force. The pitch motion is adjusted for the tail angle of attack, which can improve propulsion efficiency. The trajectory of dorsal–ventral movement is approximated as a sine wave curve, as shown in Figure 9.

Figure 9.

Schematic diagram of the dorsal–ventral movement of the tail.

To study the motion characteristics and force situation of the tail in fluid, the approximate trajectory equation of the variation of the body centerline of dolphins during motion is extracted, and its Equation (5) is [42]

where is the trajectory function of the body centerline; is the ratio of the abscissa of different points to the length of the body, ; is the tail motion amplitude; and is the motion frequency.

During the swimming process of dolphins, their tail swing amplitude and water striking angle are key parameters that affect motion. The Equation (6) for tail motion and center point displacement can be obtained as follows:

where is the distance from the starting point of the motion position to the center of the tail.

Dolphin dorsal–ventral movement is relatively complex, and the force analysis requires appropriate simplification and assumptions. The body and tail deformation is ignored and seen as a regular rigid plate, the movement is only swinging in the vertical coordinate plane and swimming forward without lateral flipping or moving, and the main force generated is thrust force and lift force . The force is decomposed as shown in Figure 10.

Figure 10.

Force analysis diagram of the dorsal–ventral movement of the tail.

According to Figure 10, is the velocity relative to the tail center of gravity, is the flow velocity of the flow field, is the vertical upward velocity of the relative flow field, hydrodynamic force can be decomposed into lift force and thrust force , is the instantaneous movement angle of the tail, and is the instantaneous relative water striking angle at the tail.

3. Structural Design and Analysis of the Pneumatic Amphibious Soft Bionic Robot

By studying the structural characteristics, motion forms, and propulsion mechanisms of the biomimetic prototype mentioned above, important theoretical guidance and design basis can be provided for the structural design and motion function implementation of the pneumatic amphibious soft bionic robot. It should be noted that before designing the robot structure, the design principles of bending and torsion actuators need to be analyzed. The bending actuator is composed of multiple air cavities that are equally arranged. During inflation, to ensure that the interaction between the air cavity structure can be achieved through expansion and compression, the remaining wall thickness of the air cavities must be greater than that of the expanding wall. This driving mechanism is also applicable to the torsional actuator, which requires ensuring that the expansion of the torsional outer wall of the torsional actuator has the thinnest wall thickness. It should be noted that when the actuator air cavity structure is inflated and expanded, the driving performance mainly depends on the expansion effect of the expansion wall. Therefore, if the shape of the actuator structure has a small impact on its motion and dynamic characteristics, the impact of the actuator structure shape on its driving performance can be approximately ignored.

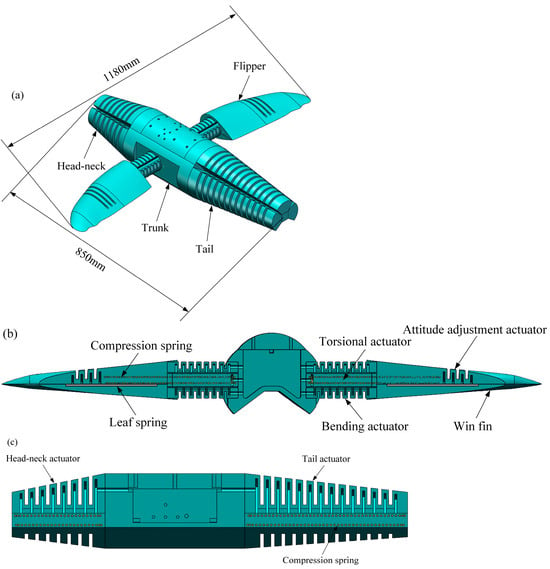

In the structural design of the pneumatic amphibious soft bionic robot, the various executing mechanisms that make up the robot are designed first, including the flippers, tail, head–neck, and trunk, and then assembled into the overall structure. It should be noted that the research focus of the robot is on simulating the motion performance of a California sea lion. Therefore, the proportion of each executing mechanism of the robot to the body of the sea lion needs to roughly correspond to the proportion of each limb to the body of the sea lion, and the overall design dimensions of the robot are also proportionally scaled according to the entire body size of the sea lion. In addition, in the structural design of the tail and head–neck, due to the need to consider the hydrodynamic performance of the robot, the shape design is a streamline spindle.

Finally, the structure of the pneumatic amphibious soft bionic robot is obtained, as shown in Figure 11.

Figure 11.

Structure diagram of pneumatic amphibious soft bionic robot. (a) Pneumatic amphibious soft bionic robot, (b) cross-sectional view along the flipper of the robot, (c) longitudinal-sectional view along the robot.

The flipper of the pneumatic soft bionic robot can achieve the main movements in various directions, including upward, downward, leftward, rightward, upward to left, upward to right, downward to left, and downward to right, and can also complete overall twisting and spanwise attitude adjustment; The tail and head–neck of the robot can provide main power in various directions, including leftward, rightward, and downward, and due to the placement of compression springs inside, a certain amount of restoring force can also be provided during upward movement. The trunk can integrate various execution mechanisms of the robot and inflate and deflate from the central air hole of the trunk sealing cover, changing the volume density of the trunk. This can assist a soft bionic robot in floating and diving, and its design inspiration comes from the principle of imitating a fish swim bladder [43].

In underwater environments, according to the maneuvering requirements, compressed air is injected into the actuators of the flippers, tail, and head–neck in a certain sequence and size, which can enable the pneumatic amphibious soft bionic robot to maneuver in various complex and changing underwater environments. The compressed air injected into the actuators of the flippers can achieve up–down flapping, front–back swinging, coupled flapping and swinging, angle torsion, and attitude adjustment, imitating the movement patterns of the fore-flippers of the sea lion. The injection of compressed air into the actuators of the tail can achieve left–right swinging and dorsal–ventral motion, imitating the movements of left–right-swinging fishtail and dorsal–ventral-moving dolphin tail, respectively. Similarly, the compressed air injected into the actuators of the head–neck area can achieve left–right-swinging and dorsal–ventral motion, mainly to coordinate with flippers and the tail for turning and maintaining movement stability. In addition, inflating or extracting air into the interior of the trunk can adjust the volume density of the trunk, mainly to coordinate with flippers and the tail for upward floating and diving to improve the snorkeling efficiency of the robot.

In a terrestrial environment, according to the mobility requirements, compressed air is injected into the actuators of the flippers, tail, and head–neck in a certain sequence and size to enable the pneumatic amphibious soft bionic robot to crawl on land. The middle actuators of the head–neck and tail are successively filled with compressed air, which can achieve “”-type bending motion of the head–neck and tail of the robot and can imitate the forms of inchworm motion, enabling the robot to complete forward crawling. Injecting compressed air to the left and right actuators of the head–neck and tail respectively allows the actuators to achieve left and right bending motion, enabling the robot to complete left and right turning and crawling. Injecting compressed air into the actuators of the flippers can help the robot maintain motion balance and adjust its posture and orientation in a specific environment to complete obstacle crossing and small space crossing.

4. Research on Simulation of Robot Motion Performance

Numerical simulation algorithms were used to analyze the structure and motion forms of the main execution mechanism and the pneumatic amphibious soft bionic robot designed above. It should be noted that during the motion of the robot, it must have good large deformation and hyperelastic characteristics under a certain stiffness and strength, and it also needs to withstand the repeated bending and torsional expansion effects caused by inflating and deflating, as well as adapt to complex and changing environments. After solidification, silicone rubber has good hydrophobicity, chemical inertness, safety, flexibility, extensibility, and the ability to withstand extreme temperatures, and it can be used as the main material for research and development of production, medical, and military-related types of equipment [44]. Due to the ease of mixing, stirring, and deflating, the curing of Ecoflex-0030 silicone rubber produced by Smooth-On company based on Dragon Skin technology is considered. After solidification, it has moderate softness and hardness, excellent wear resistance, tensile strength, and safe stability, and can be stretched several times without tearing or deforming, while maintaining its original size. Therefore, Ecoflex-0030 silicone rubber material is chosen as the main body material for numerical simulation calculations and subsequent experimental research of the pneumatic amphibious soft bionic robot. Based on uniaxial, biaxial, and shear tests, stress and strain parameters of the silicone rubber material can be obtained, which are used to complete robot modeling, simulation, and testing. The Ecoflex 0030 silicone rubber material is shown in Table 1.

Table 1.

Ecoflex 0030 silicone rubber material properties.

The selected silicone rubber constitutive model is Yeoh, and the specific coefficients are shown in the Table 2.

Table 2.

Coefficients of constitutive model of Yeoh silicone rubber.

It should be noted that in the numerical simulation environment, it is necessary to define the inflation pressure for each actuation unit of the robot according to the actual situation, and the passive bending side actuation units are not inflated, while the active bending side actuation units are inflated. The flipper has six actuation units, and the tail and head–neck each have three actuation units. The inflation of the flipper is 100 kPa, and the inflation of the tail and head–neck is 120 kPa. In addition, it is necessary to verify the independence of the grid.

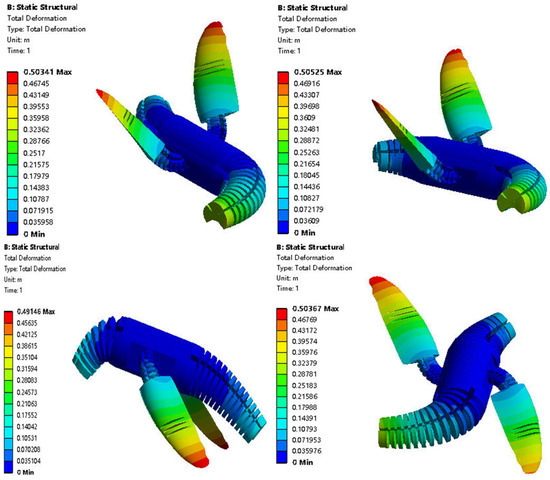

Finally, numerical simulation calculations were conducted on the pneumatic amphibious soft bionic robot, and the collaborative motion simulation results of various executing mechanisms of the robot were obtained, as shown in Figure 12.

Figure 12.

Movement form analysis of pneumatic amphibious soft bionic robot.

According to Figure 12, it can be seen that the main execution mechanisms of the pneumatic amphibious soft bionic robot cooperate reasonably and have flexible pose changes that conform to the expected motion form analysis results and can meet the expected motion functions, and the deformation of each execution mechanism also conforms to the actual deformation law of the silicone rubber material after inflation. Therefore, the deformation law of cloud images in the calculation results can verify that the structural design and motion forms of the robot are reasonable and feasible. The flipper achieves upward and downward flapping, forward and backward swinging, coupled flapping and swinging, torsional, and attitude adjustment motions. The maximum bending angles of the upward and downward flapping are 1.45 rad and 1.54 rad, respectively. The maximum bending angles of the forward and backward swinging are 1.43 rad and 1.46 rad, respectively. The maximum bending angles of the couple upward and downward flapping and swinging are 1.51 rad and 1.56 rad, respectively. The maximum torsional angle is 0.98 rad. The tail and head–neck have achieved left–right swinging and dorsal–ventral movement, respectively; the maximum bending angle of the tail swinging to the left is 2.09 rad, the maximum bending angle of the swinging to the right is 2.11 rad, and the maximum bending angle of the dorsal–ventral movement is 2.62 rad. The maximum bending angle of the head–neck swinging to the left is 1.16 rad, the maximum bending angle of the swinging to the right is 1.19 rad, and the maximum bending angle of the dorsal–ventral movement is 1.72 rad.

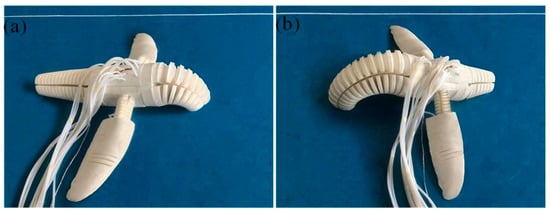

5. Robot Prototype Development and Experimental Research

In the construction of the prototype structure, since the main material of the soft bionic robot is soft elastic silicone rubber, with multiple air cavity channels with complex structures inside, and embedded with bending sensors, compression springs, and other parts, rapid prototyping technologies such as 3D printing, replica process, shape deposition, and soft lithography are required [45,46]. In the prototype experimental research, different experimental environments of the soft bionic robot on water and land were constructed, and a series of prototype static pool swimming and land crawling studies were conducted. The performance of various motion modes of the main executing mechanisms of the robot under different motion frequencies, amplitudes, phase differences, and offsets was evaluated to verify the feasibility and rationality of the prototype design scheme.

5.1. Prototype System Construction

5.1.1. Mold Making

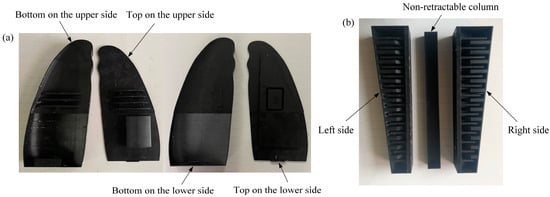

A mold is a prerequisite for producing prototypes of the pneumatic amphibious soft bionic robot. The mold is designed in three dimensions based on the actual structural characteristics of the robot, and the physical mold was obtained through 3D printing technology. PLA materials were selected as the printing consumable due to their advantages of strong stability, good flatness, and non-toxicity. Due to the fact that each execution mechanism of the robot is made of silicone rubber material poured into different structural molds, there are many types and quantities of molds involved. Therefore, only the molds of the flipper wing fin and the tail actuator are shown here as examples (Figure 13).

Figure 13.

Mold structure. (a) Flipper wing fin, (b) tail actuator.

5.1.2. Physical Preparation

Silicone rubber pouring, static molding, and demolding were carried out based on the replica process, and then the prepared objects were bonded using soft lithography. The specific process was as follows: First, take two parts of Ecoflex-0030 silicone rubber A and B with a mass ratio of 1:1, stir them evenly until they are completely mixed, place them in a vacuum defoamer for the first degassing, and then pour the silicone rubber into a mold with a surface coated with Vaseline silicone rubber release agent. When the pouring depth reaches about half of the mold depth, perform the second degassing, and when the silicone rubber is filled, perform the third degassing. Place the mold that has already been filled with silicone rubber into the heater box for heating. Once the silicone rubber solution is fully cured, the mold can be removed from the heater box and the silicone rubber can be de-molded to obtain the basic components that make up the soft bionic robot. Finally, the joint surfaces of each basic component unit are immersed in uncured silicone rubber through soft lithography, and the joint surfaces of each basic component unit are bonded to form a whole. For the connection between silicone rubber and air ducts, it is necessary to use products that specifically adhere to silicone rubber to connect the air ducts and air vents. It should be noted that due to the relatively complex structure and high structural strength requirements of the robot, it is difficult to complete the prototype production solely by using soft lithography. Therefore, it is necessary to use wax loss casting technology that is conducive to the production of complex cavity structures. Firstly, make a wax core, assemble the bottom mold, core mold, and baffle, pour the evenly mixed silicone rubber into the mold, and remove the air. After the silicone rubber is formed, take out the core mold and pour in pre-melted, low-melting-point, and volatile paraffin material. Pour it in and let it stand for about 1 h; after the paraffin has solidified, remove the wax core. Then, assemble the mold and the prepared wax core, pour in the evenly mixed silicone rubber solution, and remove air. After the silicone rubber has solidified, remove the soft air cavity with the wax core. Heat the air cavity in water and use tools to compress it to accelerate the cleaning speed of paraffin material. Residual paraffin on the inner wall of the cavity can be discharged from the circular hole after solidification. The wax loss casting technology can integrate the execution part and the limiting part, greatly improving the strength and sealing of the soft bionic robot.

The bending sensors and compression springs required for the soft bionic robot were embedded using a shape deposition manufacturing method. Specifically, the process involved multi-layer deposition, where after the bottom layer was solidified, the silicone rubber solution was poured to form the middle layer, and electronic components and compression springs were placed. After the middle layer was solidified, a silicone rubber solution was poured to form the top layer for final shaping, enabling highly integrated manufacturing, sensing, and driving for soft robotics. It should be noted that to avoid the embedded electronic components and compression springs being misaligned or tilted, it was necessary to manually adjust them promptly.

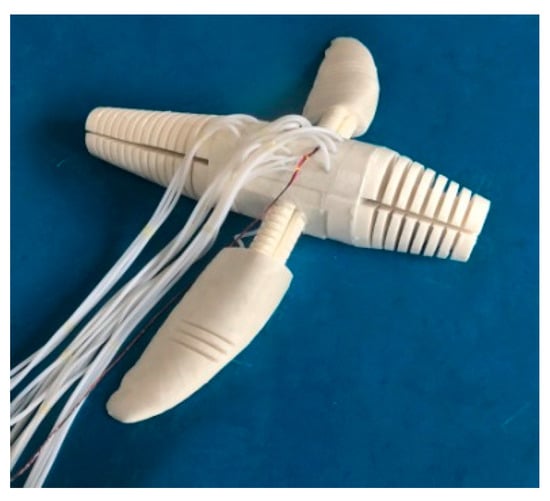

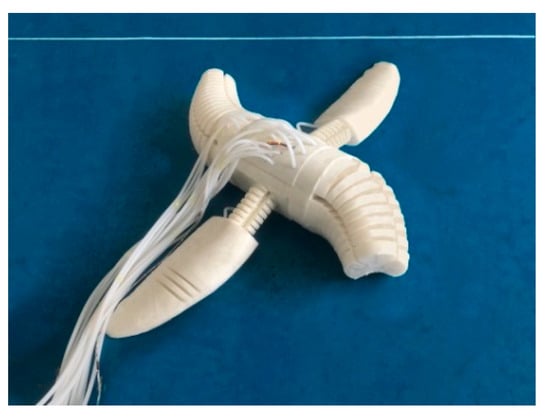

Finally, the prototype model of the pneumatic amphibious soft robot was obtained, as shown in Figure 14.

Figure 14.

Prototype of the pneumatic amphibious soft bionic robot.

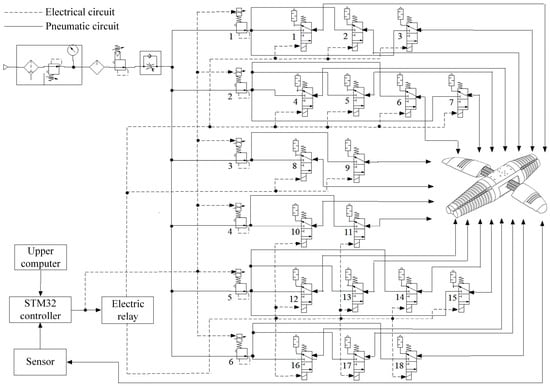

5.1.3. Construction of Control System

We built a pneumatic soft bionic robot control system, based on the pneumatic drive system, using an STM32 microcontroller as the main controller, and sent commands to the electrical proportional valves and relays to control the pressure and on/off timing of the actuators in the robot, so that the robot actuators performed coordinated movement, and then, the robot attitude and position information collected by sensors was transferred to the controller to realize the robot motion control. In addition, since the inflation and pumping of the trunk to assist the robot in snorkeling are controlled separately according to the actual conditions, they are not specifically described here. The principle of the robot control system is shown in Figure 15.

Figure 15.

Schematic diagram of the control system.

The list of pneumatic components is shown in Table 3.

Table 3.

The list of pneumatic components.

5.2. Robot Experimental Research

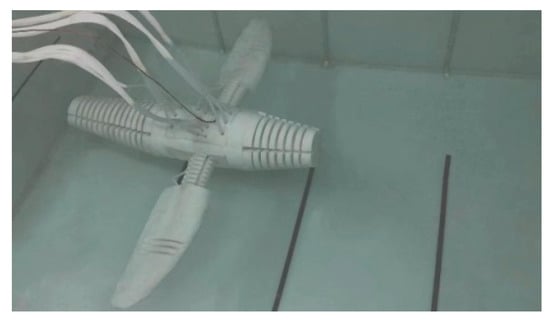

5.2.1. Testing and Analysis of the Underwater Swimming Performance of the Robot

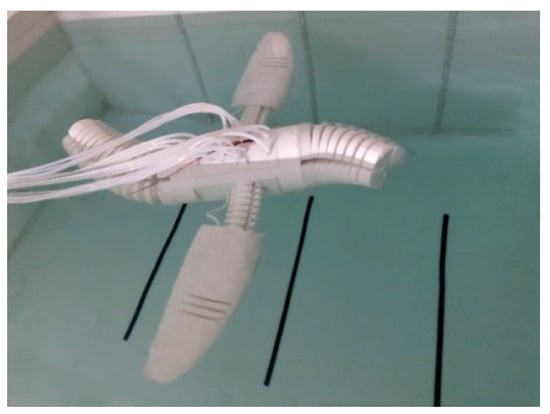

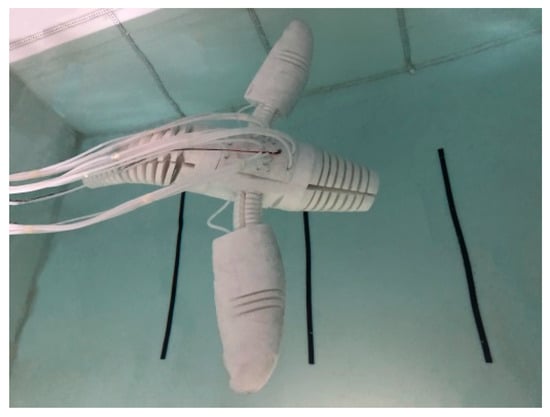

To conduct testing and analysis of various underwater swimming modes of the robot, it was necessary to construct a prototype pool experimental environment. The water storage volume of the pool could enable the prototype to complete a certain range of straight swimming, bow turning, and snorkeling motion functions. The experimental environment for the prototype swimming test was constructed as shown in Figure 16.

Figure 16.

Construction of swimming experimental environment of the soft bionic robot.

According to the motion form and characteristics of the biomimetic prototype, the main executing mechanisms of the pneumatic amphibious soft bionic robot were controlled correspondingly so that the bilateral flippers, tail, and head–neck of the soft robot could coordinate movement and complete straight swimming, bow turning, and snorkeling movements, respectively.

- (1)

- Performance testing and analysis of robot straight swimming

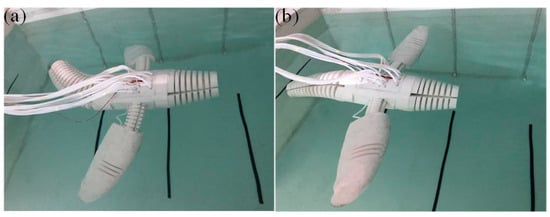

The soft bionic robot swims primarily through the simultaneous, same-frequency, and same-direction flapping and swinging of both sides of the flippers, along with the left–right swinging of the tail, as well as through the simultaneous, same-frequency, and same-direction flapping and swinging of both sides of the flippers, along with the dorsal–ventral movement of the tail. The motion state is shown in Figure 17.

Figure 17.

Straight swimming motion of each execution mechanism coordinated by the robot. (a) Bilateral flippers + tail swinging, (b) bilateral flippers + dorsal–ventral movement.

To systematically and comprehensively study the swimming performance of the soft bionic robot, the straight swimming performance of the robot with flippers, tail, and flippers + tail through coordinated movement was studied in detail.

- (1)

- The variable frequency and amplitude of the robot flippers flapping and swinging

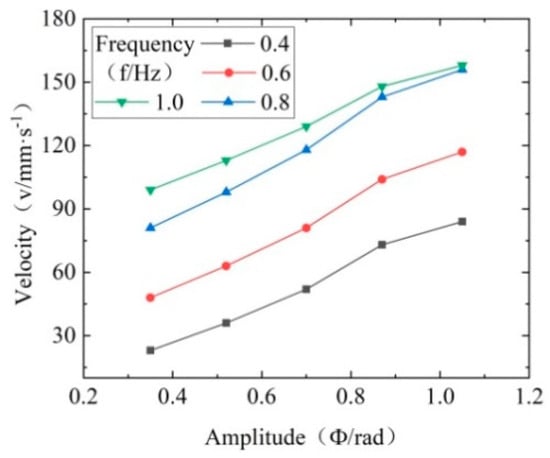

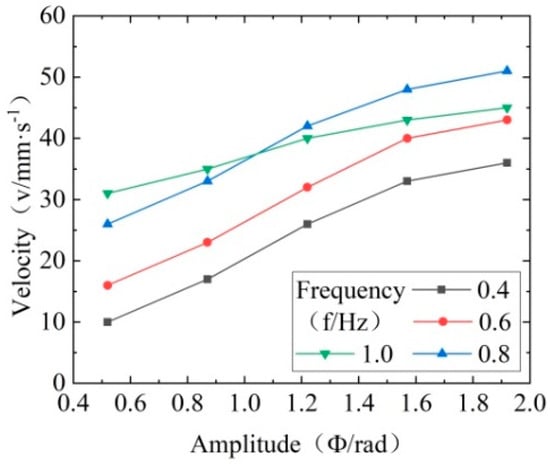

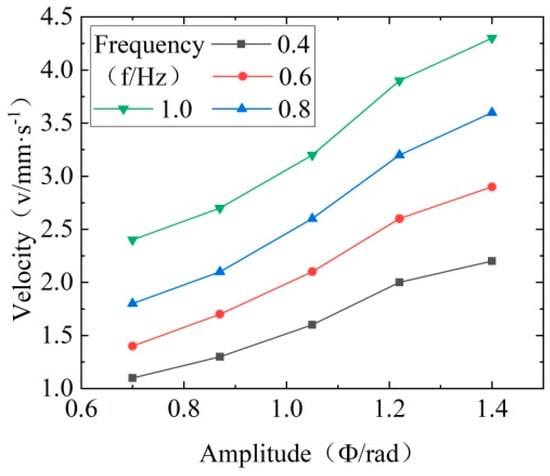

The flapping and swinging frequencies and of the flippers on both sides of the robot are 0.4 Hz, 0.6 Hz, 0.8 Hz, and 1.0 Hz. The flapping and swinging amplitudes and are 1.05 rad, and the positional rotation frequencies and are 0.7 Hz. The positional rotation amplitudes and are 0.87 rad, and the offsets are all 0. The test results were obtained, as shown in Figure 18.

Figure 18.

Test of variable frequency and amplitude of the flippers flapping and swinging in straight swimming.

According to Figure 18, it can be seen that the swimming velocity of the robot increases with the increase in the frequencies and amplitudes of the flipper flapping and swinging, and the frequency has a greater impact on the swimming velocity than the amplitude. For an increase in frequency, when the frequency of the flipper flapping and swinging is 1 Hz, as the amplitude increases, the swimming velocity is close to the frequency of 0.8 Hz. This is because when the frequency and amplitude are large, the body oscillation of the robot during swimming is relatively strong, and the operation is unstable, which greatly affects the swimming velocity. As the amplitude increases, when the flapping and swinging amplitude of the robot increases to a certain extent, the trend of increasing swimming velocity gradually slows down. This is because increasing the amplitude can prolong the swinging motion time, leading to an increase in the longitudinal thrust action time and affecting the swimming velocity. It should be noted that the increase in the flapping and swinging amplitude of the flipper has a relatively greater impact on the acceleration of the robot, which can improve the propulsion efficiency of the robot in variable-velocity operation. Therefore, on the premise of ensuring stable operation of the robot, the higher the flapping and swinging frequency of the flipper is, the more suitable it is for high-velocity cruising of the prototype, while the larger the flapping and swinging amplitude of the flipper is, the more suitable it is for variable-velocity movement and emergency braking of the prototype.

- (2)

- The variable positional rotation frequency and amplitude of the robot flippers

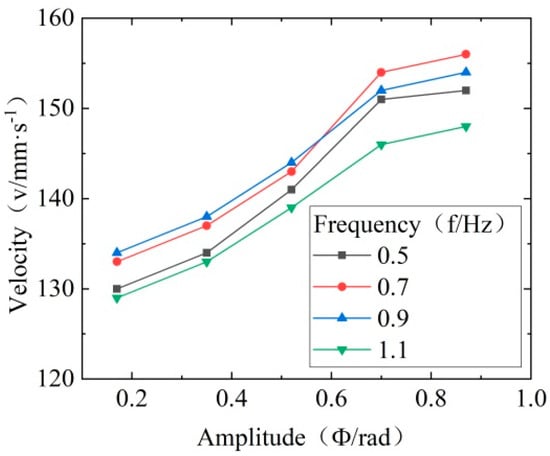

The flapping and swinging frequencies and of the flippers on both sides of the robot are 0.8 Hz. The flapping and swinging amplitudes and are 1.05 rad. The positional rotation frequencies and are 0.5 Hz, 0.7 Hz, 0.9 Hz, and 1.1 Hz. The positional rotation amplitudes and are 0.87 rad, and the offsets are all 0. The test results were obtained, as shown in Figure 19.

Figure 19.

Test of variable position rotation frequency and amplitude of the flippers in straight swimming.

According to Figure 19, it can be seen that the variable positional rotation frequency of the flippers has little effect on the swimming velocity of the robot. When the positional rotation frequency is low, as the frequency increases, the swimming velocity of the robot increases. When the positional rotation frequency is high, the swimming velocity decreases due to significant oscillation of the robot body. The positional rotation amplitude of the flippers gradually increases, and the swimming velocity of the robot also increases. When the amplitude is large, the trend of increasing the swimming velocity slows down. This is because as the amplitude of the positional rotation increases, the difference between the amplitude of the flapping and swinging gradually increases, leading to an increase in the asymmetry of the flipper movement, reducing the velocity of the vortex ring movement on the wing fin surface, increasing the interference, and thus affecting the thrust enhancement. In addition, the setting of the positional rotation amplitude of the flippers is too large, which also affects the swimming stability of the robot.

- (3)

- The variable left–right-swinging frequency and amplitude of the robot tail

The frequencies and of the left–right swinging of the robot tail are 0.4 Hz, 0.6 Hz, 0.8 Hz, and 1.0 Hz. The amplitudes and of the left–right swinging are 1.05 rad. The offsets are all 0. The test results were obtained, as shown in Figure 20.

Figure 20.

Test of variable left–right-swinging frequency and amplitude of the tail in straight swimming.

According to Figure 20, it can be seen that the swimming velocity of the robot gradually increases with the increase in the tail swinging frequency. When the amplitude increases to a certain extent, the swimming velocity decreases, which is caused by strong body oscillation and unstable operation. The swinging amplitude of the robot tail gradually increases, and the trend of increasing the swimming velocity changes from a linear change to a nonlinear change, and the increasing trend slows down. Therefore, the swinging frequency and amplitude setting of the robot tail should not be too high.

- (4)

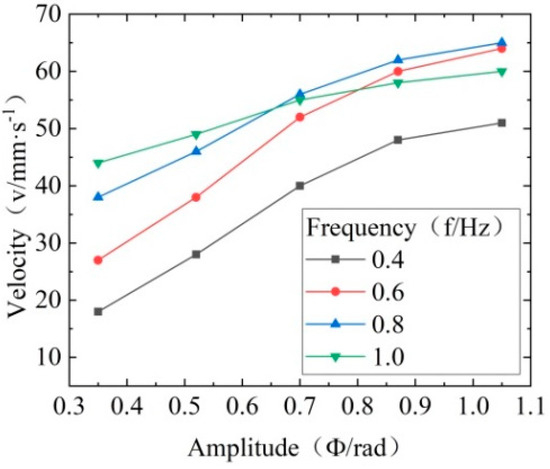

- The variable dorsal–ventral movement frequency and amplitude of the robot tail

The frequencies of the robot tail dorsal–ventral movement are 0.4 Hz, 0.6 Hz, 0.8 Hz, and 1.0 Hz. The motion amplitude is 1.92 rad, with no offsets. The test results were obtained, as shown in Figure 21.

Figure 21.

Test of variable dorsal–ventral movement frequency and amplitude of the tail in straight swimming.

According to Figure 21, it can be seen that the trend of the swimming velocity of the robot with the increase in the frequency and amplitude of the tail dorsal–ventral movement is similar to that of the tail left–right swinging, but the swimming velocity of the robot tail dorsal–ventral movement is lower than that of the tail left–right swinging, which is related to the robot structure. The recovery process of dorsal–ventral movement is not driven by the actuator but is completed by the internal compression spring generating a recovery force, which is relatively low and cannot generate a regular fast response drive like the actuator, thereby affecting the robot’s swimming velocity.

- (5)

- The robot flippers + tail left–right swinging and flippers + tail dorsal–ventral movement

The flapping and swinging frequencies and of the robot flippers on both sides are 0.8 Hz, the flapping and swinging amplitudes and are 1.05 rad, the positional rotation frequencies and are 0.7 Hz, the positional rotation amplitudes and are 0.87 rad, and the offsets are all 0. The tail left–right-swinging frequencies and are 0.6 Hz, and amplitudes and are 0.87 rad. The tail dorsal–ventral movement frequency is 0.8 Hz, with an amplitude of 1.57 rad.

The straight swimming performance data of the robot flippers + tail left–right swinging and flippers + dorsal–ventral movement were collected through multiple experiments, and the average results are shown in Table 4.

Table 4.

Test results of cooperative motion of each actuator of the soft bionic robot in straight swimming.

According to Table 3, under the control of the constructed CPG-ANFIS-PID controller, the swimming velocity of the two straight swimming modes of the pneumatic amphibious soft bionic robot is 196.1 mm/s and 183.8 mm/s, respectively. Therefore, the combination of flippers and tail left–right swinging is more conducive to robot swimming and can correspond to the lower performance of the tail dorsal–ventral movement compared to the tail left–right-swinging motion. It should be noted that the swimming velocity generated by the coordinated movement of the flippers and tail was smaller than the sum of the swimming velocity generated by the flippers and tail moving separately because the cooperative movement of the various execution mechanisms of the robot would produce mutual interference and vortex effects, which would affect the swimming velocity of the robot to a certain extent. In addition, when there is a resonance between the tail motion frequency and the intrinsic frequency of the flipper, the swimming velocity of the tail-driven robot can reach its peak. Therefore, to cooperate with the efficient coordinated movement of the flippers, the frequency of tail movement should not exceed the frequency of flipper movement.

- (2)

- Performance testing and analysis of the robot bow turning

The bow-turning motion modes of the pneumatic amphibious soft bionic robot mainly include differential motion (i.e., asynchronous cooperative motion) of the flippers on both sides and the “C”-shape swinging of the tail. To more effectively complete the experimental research on the bow-turning performance of the robot, it is also necessary to take into account the head–neck motion and collaborate with the flippers and tail to complete the robot bow-turning performance test. In addition, it is specified that the counterclockwise direction of the robot turn bow is positive, meaning that the left turning direction of the robot is positive, while the right turning direction is negative. It should be noted that the frequency and amplitude of the flipper flapping and swinging, as well as the frequency and amplitude of the tail “C”-shaped swinging, have the greatest impact on the bow-turning performance of the robot. Therefore, the study of bow-turning performance should be carried out by changing these factors. The motion state of the soft bionic robot bow-turning experiment is shown in Figure 22.

Figure 22.

Bow-turning motion state diagram of coordinated motion of each execution mechanism of the soft bionic robot.

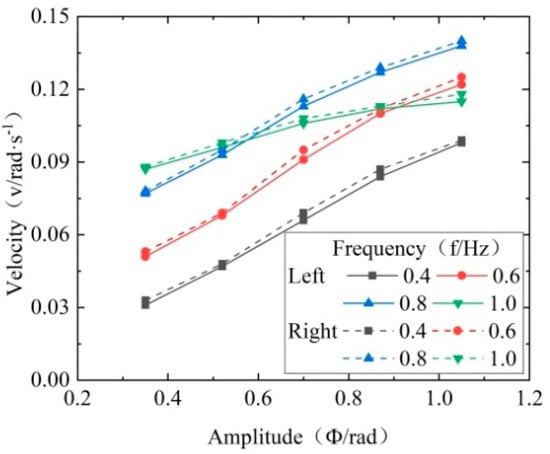

- (1)

- The differential motion of the variable frequency and amplitude of the robot flippers

For the robot turning its bow to the left, the flapping and swinging frequencies of the right flipper are 0.4 Hz, 0.6 Hz, 0.8 Hz, and 1.0 Hz, with the flapping and swinging amplitude of 1.05 rad, positional rotation frequency of 0.7 Hz, and the positional rotation amplitude of 0.87 rad. The left flipper moves in the opposite direction to the right flipper. The head–neck system serves as an auxiliary bow-turning mechanism and swings to the left with a frequency corresponding to the flipper, and the amplitude of the swings is 1.05 rad. For the robot turning its bow to the right, the movements of the flippers and head–neck are reversed, with all other parameters unchanged. The test results were obtained, as shown in Figure 23.

Figure 23.

Test of the differential bow motion of the flippers on both sides in bow turning.

According to Figure 23, as the frequency of the flipper increases and the amplitude remains relatively small, the bow-turning rate of the robot gradually increases. However, when the frequency and amplitude are both large, the bow-turning rate decreases. This is mainly because the large frequency and amplitude cause the turning radius of the robot to gradually decrease. At the same time, the vortex flow generated by the turning motion is constrained by the reduced space for movement, making it difficult to spread outwards, which results in a rapid increase in resistance. The resistance caused by the vortex rapidly increases. In addition, as the amplitude of the flipper increases, both the longitudinal and transverse moments also increase, causing the center of gravity to fluctuate greatly and reducing the stability of the robot, which limits the increase in the bow-turning velocity. Therefore, as the frequency and amplitude of the flipper increase, the differential bow turning of the flippers can increase the turning torque and reduce the turning radius, but the velocity stability decreases.

- (2)

- The variable “C”-shape swinging frequency and amplitude of the robot tail

For the robot turning its bow to the left, the tail swings to the right with the frequencies of 0.4 Hz, 0.6 Hz, 0.9 Hz, and 1.0 Hz respectively, and the swinging amplitude is 1.57 rad. The head–neck swings to the left with the frequency corresponding to the tail, and the swinging amplitude is 1.05 rad. For the robot turning its bow to the right, the movement direction of the tail and head–neck is opposite, and the other parameter values remain unchanged. The test results were obtained, as shown in Figure 24.

Figure 24.

Test of the “C” shape of the tail in bow turning.

According to Figure 24, it can be seen that as the frequency of the tail swinging increases and the amplitude is relatively small, the bow-turning velocity of the robot gradually increases. However, when the frequency and amplitude are large, the robot bow-turning velocity decreases. This is due to the increase in the lateral moment of the robot, which leads to significant spatial fluctuations in the center of gravity of the robot, and the faster swinging response, causing the body to lose stability and affecting the turning velocity. In addition, as the amplitude of the tail swinging increases, the increasing trend of the robot bow-turning velocity also gradually slows down.

- (3)

- The flippers + tail “C”-shape swinging of the robot

For the robot to turn its bow to the left, the right flipper flapping and swinging frequency is 0.8 Hz and amplitude is 1.05 rad, while the positional rotation frequency is 0.7 Hz and the positional rotation amplitude is 0.87 rad. The left flipper moves in the opposite direction with the same parameter settings. The tail swings to the right with a frequency of 0.8 Hz and an amplitude of 1.57 rad, while the head–neck swings to the left with a frequency of 0.8 Hz and an amplitude of 1.05 rad. For the robot to turn its bow to the right, the motion direction for the flippers, tail, and head–neck is opposite to that of turning its bow to the left, the other parameter settings are the same. Test result data for the robot turning its bow to the left and right were collected, and the average of multiple test results was taken. The specific results are shown in Table 5.

Table 5.

Test results of the soft bionic robot in bow turning.

According to Table 4, it can be seen that under the control of the constructed CPG-ANFIS-PID controller, the left and right bow-turning velocities of the pneumatic amphibious soft bionic robot are 0.18 rad/s and 0.19 rad/s, respectively. Therefore, the flipper and tail left–right swinging has a good bow-turning performance. It should be noted that the disturbance generated by the coordinated motion of the various execution mechanisms of the robot during the turning process is more significant compared to the straight swimming of the robot. In addition, there is a certain difference in the velocity of the robot turning left and right, which is mainly due to robot manufacturing errors.

- (3)

- Testing and analysis of the robot snorkeling performance

The snorkeling mode of the robot is based on the premise that both sides of the flippers flap and swing simultaneously, at the same frequency, and with the same offsets, mainly including two modes: positional rotation for simultaneous, same-frequency, and different-offset movements of the flippers, as well as tail left–right swinging/dorsal–ventral movements. It can also be combined with trunk inflation and extraction assistance to complete snorkeling motion, and its motion state is shown in Figure 25.

Figure 25.

Snorkeling state diagram of coordinated motion of each execution mechanism of the robot.

We conducted snorkeling experiments on the depth determination process from 0 to 1200 mm, where the main control chip collected the pressure values measured by the pressure sensor, calculated the depth of the robot, and obtained its snorkeling motion performance. Due to the poor dorsal–ventral movement performance of the robot compared to the tail swinging left–right, only the flipper variable positional rotation offsets + tail left–right-swinging movement is considered for snorkeling performance analysis.

- (1)

- The robot flipper variable position rotation offsets + tail left–right swinging

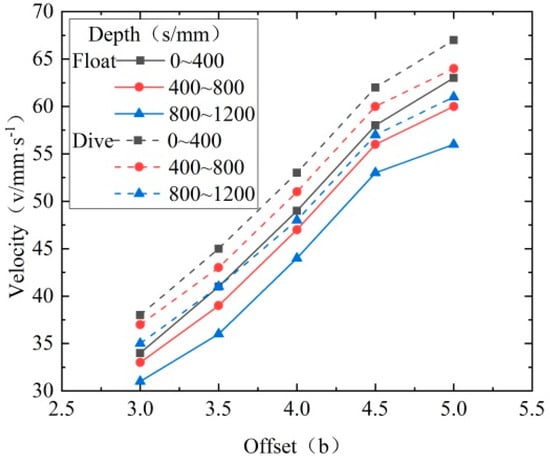

The flapping and swinging frequencies and of the flippers on both sides of the robot are 0.8 Hz, with the flapping and swinging amplitudes and being 1.05 rad. The positional rotation frequencies and are 0.7 Hz, with the positional rotation amplitudes and being 0.87 rad. The tail swing frequencies and on the left–right sides are 0.8 Hz, with the swing amplitudes and being 0.87 rad. For upward floating, the positional rotation offsets of the left flipper are taken as 3, 3.5, 4, 4.5, and 5, and the positional rotation offsets of the right flipper are taken as −3, −3.5, −4, −4.5, and −5. For diving movements, the positional rotation offsets of the left flipper are taken as −3, −3.5, −4, −4.5, and −5, and the positional rotation offsets of the right flipper are taken as 3, 3.5, 4, 4.5, and 5. The test results were obtained, as shown in Figure 26.

Figure 26.

Test of the soft bionic robot in snorkeling.

According to Figure 26, it can be seen that the snorkeling velocity of the robot gradually increases with the increase in the flipper positional rotation offsets. Although the snorkeling velocity is relatively small, the motion process of the robot is relatively stable. It should be noted that robot snorkeling is a composite motion, and its motion velocity is derived from the combination of vertical and horizontal velocities. The vertical velocity is less than the horizontal velocity, while the horizontal velocity is less than the straight swimming velocity of the robot. This is due to the angle of attack generated by the offset of the flipper positional rotation, which affects the horizontal force of the snorkeling motion.

- (2)

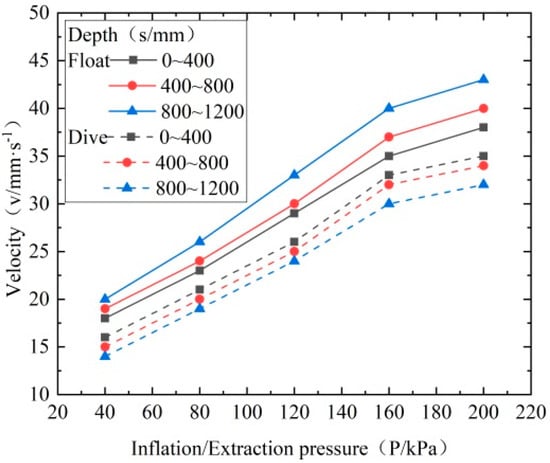

- The variable volume density of the robot trunk

For upward floating, it is necessary to reduce the average density of the trunk volume of the robot. Under the premise of an inflation time of 3 s, the inflation pressures of the trunk are taken as 40 kPa, 80 kPa, 120 kPa, 160 kPa, and 200 kPa. For diving movement, it is necessary to increase the average density of the trunk volume of the robot. Under the premise of a pumping time of 3 s, the pumping pressures of the trunk should be set at 40 kPa, 80 kPa, 120 kPa, 160 kPa, and 200 kPa. The test results were obtained, as shown in Figure 27.

Figure 27.

Test of the soft bionic robot of the trunk coordination in snorkeling.

According to Figure 27, it can be seen that the upward floating velocity of the robot gradually increases with the increase in the trunk inflation pressure, but the increasing trend gradually shows a nonlinear change from the initial linear change. This is because when the inflation pressure is high, the trunk can expand to a certain limit, resulting in a small change in volume density. The variation pattern of the diving velocity of the robot with the increase in extraction pressure is the same as that of the upward floating velocity, but less than the upward floating velocity. This is due to the degree of change in the volume density of the trunk, which is caused by the extraction being less than the inflation. In addition, during the robot’s upward floating phase, the deeper the depth, the faster the upward floating velocity. During the diving phase of the robot, the deeper the depth, the slower the diving velocity.

- (3)

- The flipper variable offsets + tail left–right swinging + trunk variable volume density of the robot

The flapping and swinging frequencies and of the robot flippers on both sides are 0.8 Hz, and flapping and swinging amplitudes and are 1.05 rad. The positional rotation frequencies and are 0.7 Hz, and the positional rotation amplitudes and are 0.87 rad. The tail swings left–right with frequencies and of 0.8 Hz and swing amplitudes and of 0.87 rad. For upward floating, the positional rotation offsets and of the left and right flippers are 4.5 and −4.5, respectively, with a body inflation pressure of 160 kpa. For diving movement, the positional rotation offsets and of the left and right flippers are −4.5 and 4.5, respectively, with a body pumping pressure of 160 kpa.

Experimental result data collection was carried out for the upward floating and diving of the soft bionic robot, and the average values of multiple experimental results were taken. The specific results are shown in Table 6.

Table 6.

Test results of the soft bionic robot in snorkeling.

According to Table 5, under the control of the constructed CPG-ANFIS-PID controller, the upward floating and diving velocities of the pneumatic amphibious soft bionic robot are 85.1 mm/s and 78.9 mm/s, respectively. It should be noted that the snorkeling velocity generated by the coordinated movement of the two flippers and trunk is less than the sum of the snorkeling velocity generated by the separate movements of the two flippers and trunk. This is because when the volume density of the trunk changes, the expansion and contraction of the walls on both sides of the trunk interfere with the normal operation of the flippers.

5.2.2. Testing and Analysis of the Land Crawling Performance of the Robot

According to the crawling characteristics of inchworms, the tail and head–neck of the pneumatic amphibious soft bionic robot are controlled to achieve collaborative motion. By relying on the anisotropic friction force that interacts with the contact surface, the robot completes straight crawling and turning movements.

- (1)

- Robot straight crawling

In the straight crawling motion of the soft bionic robot, first, the middle actuator of the head–neck is inflated to make it bend to a certain extent, and then it is deflated until it returns to a straight state. At the same time, inflating the middle actuator at the tail makes it bend to a certain extent, and then it is deflated until it returns to a straight state. Therefore, periodic motion can be achieved by dragging the robot through the middle actuator of the head–neck and tail to achieve straight crawling. The straight crawling motion state of the soft bionic robot is shown in Figure 28.

Figure 28.

Straight crawling motion of the soft bionic robot. (a) Head–neck movement, (b) tail movement.

We conducted an analysis of the straight crawling performance of the head–neck and tail middle actuators of the robot with variable frequency and amplitude. The motion frequencies and of the head–neck and tail middle actuators are 0.4 Hz, 0.6 Hz, 0.8 Hz, and 1.0 Hz. The motion amplitudes and are 1.4 rad, with no offset. The test results were obtained, as shown in Figure 29.

Figure 29.

Test of variable frequency and amplitude of the head–neck and tail in straight crawling.

According to Figure 29, it can be seen that the straight crawling velocity of the soft bionic robot increases with the increase in the motion frequency of the middle actuators of the tail and head–neck. When the motion amplitude of the tail and head–neck is large, the increasing trend of the straight crawling velocity slows down. This is because the bending angle of the actuator is too large, causing the expansion wall of the actuator to come into contact with the crawling contact surface, forming a force between the surfaces that affects the straight crawling velocity. It should be noted that when the expansion wall of the actuator constantly contacts the contact surface, the actuator can be easily damaged. Therefore, under normal motion conditions, the maximum straight crawling velocity of the robot can reach 3.9 mm/s.

- (2)

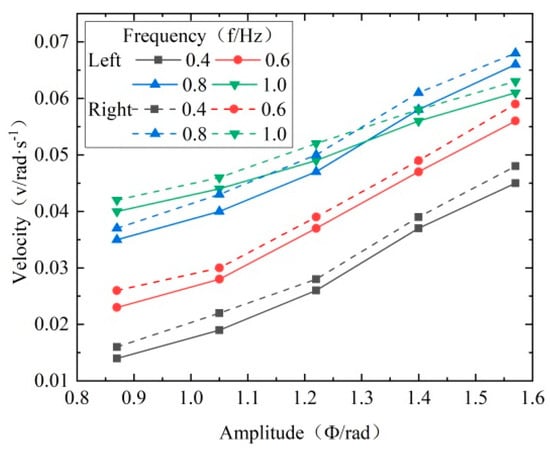

- Robot turning and crawling

In the left turning and crawling of the robot, the actuator on the right side of the head–neck of the robot and the actuator on the left side of the tail are inflated at the same time, bending them to a certain degree, and then deflated until the robot returns to a straight state. During the robot’s right turn, the inflation form is the same, but the direction is opposite. Therefore, by completing periodic movements through the left and right actuators of the head–neck and tail, the robot can be dragged to achieve turning and crawling. The turning and crawling state of the soft bionic robot is shown in Figure 30.

Figure 30.

Turning motion of the soft bionic robot.

In addition, the flippers on both sides can assist the robot in maintaining body balance and changing body posture in specific environments, which can help it cross obstacles or pass through relatively narrow spaces.

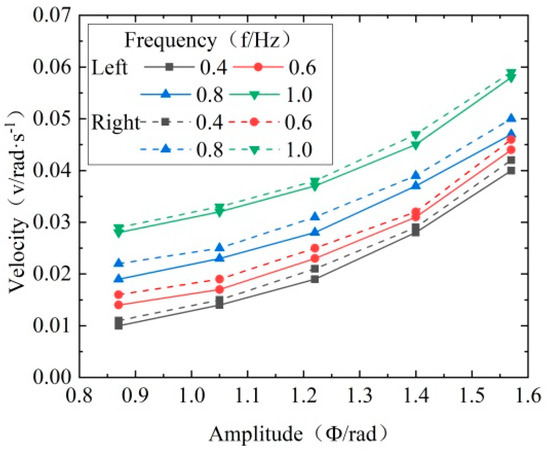

We conducted an analysis of the turning and crawling performance of the left and right actuators on the head–neck and tail of the robot with variable frequency and amplitude. For the robot turning left, the frequencies of the head–neck swinging are 0.4 Hz, 0.6 Hz, 0.8 Hz, and 1.0 Hz, with the motion amplitude of 1.05 rad. The frequencies of the tail swinging are 0.4 Hz, 0.6 Hz, 0.8 Hz, and 1.0 Hz, with the motion amplitude of 1.57 rad. The offset is set to 0. For the robot turning right, the directions of the head–neck and tail movements are reversed, with no changes to the parameter settings. The test results were obtained, as shown in Figure 31.

Figure 31.

Test of variable frequency and amplitude of the head–neck and tail in turning to crawl.

According to Figure 31, it can be seen that the turning and crawling velocity of the soft bionic robot increases with the increase in the frequency and amplitude of motion of the left and right actuators of the head–neck and tail, and the increasing trend is becoming larger and larger. Therefore, with the permission of the robot structure, the motion frequency and amplitude of the head–neck and tail can be further increased, which can be more conducive to the turning and crawling of the robot. The maximum left and right turning velocities of the soft bionic robot are 0.058 rad/s and 0.059 rad/s, respectively.

6. Conclusions

This article develops a pneumatic amphibious soft bionic robot that can provide a new carrier research platform for amphibious reconnaissance, ocean exploration, and military reconnaissance tasks and has a wide range of application prospects.

- (1)

- Based on anatomical and biomechanical theories, the tissue structure, movement gait, and propulsion mechanism of the inchworm were obtained. Through the sine motion equation, the motion trajectories of a left–right-swinging fishtail and a dorsal–ventral movement dolphin tail were described, and then the propulsion mechanism of the tail movement was obtained according to the theories of biomechanics and fluid mechanics.

- (2)

- Based on the research results on the propulsion mechanism of biological prototypes, the structural design of the pneumatic amphibious soft bionic robot was carried out from the aspects of flippers, tail, head–neck, and trunk, and the main motion forms and functions of each executing mechanism of the robot were analyzed. Through numerical simulation algorithms, the motion simulation research of the main executing mechanism and the entire machine of the robot was completed, and the motion performance of the robot was given, indicating that the robot design scheme and motion forms are feasible and reasonable.

- (3)

- A prototype of the pneumatic amphibious soft bionic robot was built, and the motion performance tests of straight swimming, bow turning, snorkeling, and land crawling and turning were completed under the cooperation of various executing mechanisms of the soft bionic robot. This proves that the soft bionic robot has certain maneuverability, flexibility, and environmental adaptability. The straight swimming velocity of the robot can reach 196.1 mm/s, and the left and right bow-turning velocities can reach 0.18 rad/s and 0.19 rad/s, respectively. The upward floating and diving velocities can reach 85.1 mm/s and 78.9 mm/s, respectively. The straight crawling velocity can reach 3.9 mm/s, and the left and right turning velocities can reach 0.058 rad/s and 0.059 rad/s, respectively.

Author Contributions

Conceptualization, W.Z. and Y.Z.; methodology, W.Z.; software, W.Z.; validation, W.Z., Y.Z. and L.Y.; formal analysis, N.W.; investigation, L.P.; resources, Y.Z.; data curation, Y.Z.; writing—original draft preparation, W.Z.; writing—review and editing, Y.Z.; visualization, N.W.; supervision, L.Y.; project administration, Y.Z.; funding acquisition, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the National Natural Science Foundation of China (Grant No. 52005344).

Informed Consent Statement

Informed consent was obtained from all individual participants included in the study.

Data Availability Statement

All code or data generated or analyzed used to support the findings of this study are included within the article.

Acknowledgments

This work was conducted in the Institute of Robotics at Shenyang University of Technology. We would also like to thank the Department of Mechanical Engineering of the National University of Singapore for their support for the successful development of this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rich, S.I.; Wood, R.J.; Majidi, C. Untethered soft robotics. Nat. Electron. 2018, 1, 102–112. [Google Scholar] [CrossRef]

- Hamaya, M.; Matsubara, T.; Teramae, T.; Noda, T.; Morimoto, J. Design of physical user-robot interactions for model identification of soft actuators on exoskeleton robots. Int. J. Robot. Res. 2021, 40, 397–410. [Google Scholar] [CrossRef]

- Pinskier, J.; Howard, D. From bioinspiration to computer generation: Developments in autonomous soft robot design. Adv. Intell. Syst. 2022, 4, 2100086. [Google Scholar] [CrossRef]

- Amal, P.; Nair, A.R.; Arunav, H.; Raj, R.; Akhil, V.M.; Tawk, C.; Shankar, K.V. Bioinspiration and biomimetics in marine robotics: A review on current applications and future trends. Bioinspiration Biomim. 2024, 19, 031002. [Google Scholar]

- Liang, C.; Wang, Y.; Yao, T.; Zhu, B. A shape memory alloy-actuated soft crawling robot based on adaptive differential friction and enhanced antagonistic configuration. J. Intell. Mater. Syst. Struct. 2020, 31, 1920–1934. [Google Scholar] [CrossRef]

- Kim, J.; Lee, G.; Jo, H.; Park, W.; Kim, J.A. wearable soft robot for stroke patients’ finger occupational therapy and quantitative measures on the joint paralysis. Int. J. Precis. Eng. Manuf. 2020, 21, 2419–2426. [Google Scholar] [CrossRef]

- Huo, Q.; Liu, S.; Zhang, Y.; Cheng, G.; Mao, W. Research of three-cavity bionic soft crawling robot. Light Ind. Mach. 2021, 39, 26–30. [Google Scholar]

- Duduta, M.; Clarke, D.R.; Wood, R.J. A high speed soft robot based on dielectric elastomer actuators. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 4346–4351. [Google Scholar]

- Zhang, Z.; Wang, X.; Wang, S.; Meng, D.; Liang, B. Design and modeling of a parallel-pipe-crawling pneumatic soft robot. IEEE Access 2019, 7, 134301–134317. [Google Scholar] [CrossRef]

- Seok, S.; Onal, C.D.; Cho, K.J.; Wood, R.J.; Rus, D.; Kim, S. Meshworm: A peristaltic soft robot with antagonistic nickel titanium coil actuators. IEEE/ASME Trans. Mechatron. 2012, 18, 1485–1497. [Google Scholar] [CrossRef]

- Jiang, C.; Pei, Z. An in-pipe worm robot with pneumatic actuators based on origami paper-fabric composites. Text. Res. J. 2021, 91, 2724–2737. [Google Scholar] [CrossRef]

- Lin, H.T.; Leisk, G.G.; Trimmer, B. GoQBot: A caterpillar inspired soft-bodied rolling robot. Bioinspiration Biomim. 2011, 6, 026007. [Google Scholar] [CrossRef]

- Han, F.; Fei, L.; Liu, W. Design and manufacture of inchworm-like soft robots. J. Mach. Des. 2021, 38, 15–20. [Google Scholar]

- Onal, C.D.; Rus, D. Autonomous undulatory serpentine locomotion utilizing body dynamics of a fluidic soft robot. Bioinspiration Biomim. 2013, 8, 026003. [Google Scholar] [CrossRef]

- Qin, Y.; Wan, Z.; Sun, Y.; Skorina, E.H.; Luo, M.; Onal, C.D. Design, fabrication and experimental analysis of a 3-D soft robotic snake. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 77–82. [Google Scholar]

- Xavier, M.S.; Tawk, C.D.; Zolfagharian, A.; Pinskier, J.; Howard, D.; Young, T.; Lai, J.; Harrison, S.M.; Yong, Y.K.; Bodaghi, M.; et al. Soft pneumatic actuators: A review of design, fabrication, modeling, sensing, control and applications. IEEE Access 2022, 10, 59442–59485. [Google Scholar] [CrossRef]

- Chu, C. Research on Bionic Jellyfish Robot System Based on SMA Flexible Actuator Modules. Master’s Thesis, University of Science and Technology of China, Langfang, China, 2018. [Google Scholar]

- Pfeil, S.; Katzer, K.; Kanan, A.; Mersch, J.; Zimmermann, M.; Kaliske, M. A biomimetic fish fin-like robot based on textile reinforced silicone. Micromachines 2020, 11, 298. [Google Scholar] [CrossRef]

- Marchese, A.D.; Onal, C.D.; Rus, D. Autonomous soft robotic fish capable of escape maneuvers using fluidic elastomer actuators. Soft Robot. 2014, 1, 75–87. [Google Scholar] [CrossRef]

- Katzschmann, R.K.; Marchese, A.D.; Rus, D. Hydraulic autonomous soft robotic fish for 3D swimming. In Experimental Robotics; Springer: Cham, Switzerland, 2016; pp. 405–420. [Google Scholar]

- Liu, S.; Wang, Y.; Li, Z.; Jin, M.; Ren, L.; Liu, C. A fluid-driven soft robotic fish inspired by fish muscle architecture. Bioinspiration Biomim. 2022, 17, 026009. [Google Scholar] [CrossRef]

- Low, K.H.; Yang, J.; Pattathil, A.P.; Zhang, Y. Initial prototype design and investigation of an undulating body SMA. In Proceedings of the 2006 IEEE International Conference on Automation Science and Engineering, Shanghai, China, 8–10 October 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 472–477. [Google Scholar]

- Shen, Q.; Wang, T.; Liang, J.; Wen, L. Hydrodynamic performance of a biomimetic robotic swimmer actuated by ionic polymer-metal composite. Smart Mater. Struct. 2013, 22, 075035. [Google Scholar] [CrossRef]

- Cai, Y.; Bi, S.; Zheng, L. Design and experiments of a robotic fish imitating cow-nosed Ray. J. Bionic Eng. 2010, 7, 120–126. [Google Scholar] [CrossRef]

- Li, T.; Li, G.; Lianb, Y.; Cheng, T.; Jing, D. Fast-moving soft electronic fish. Sci. Adv. 2017, 3, e1602045. [Google Scholar] [CrossRef]

- Kim, H.S.; Heo, J.K.; Choi, I.G.; Ahn, S.H.; Chu, W.S. Shape memory alloy-driven undulatory locomotion of a soft biomimetic ray robot. Bioinspiration Biomim. 2021, 16, 066006. [Google Scholar] [CrossRef]

- Yurugi, M.; Nagai, T.; Shintake, J.; Ikemoto, Y. Cartilage increases swimming efficiency of underwater robots. Sci. Rep. 2021, 11, 11288. [Google Scholar] [CrossRef]

- Du, W. SMA Wire Actuated Squid-like Jet Propeller Prototype. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2008. [Google Scholar]

- Christianson, C.; Cui, Y.; Ishida, M.; Bi, X.; Zhu, Q.; Pawlak, G.; Tolley, M.T. Cephalopod-inspired robot capable of cyclic jet propulsion through shape change. Bioinspiration Biomim. 2020, 16, 016014. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Lueth, T.C. Optimization of stress distribution in tendon-driven continuum robots using fish-tail-inspired method. IEEE Robot. Autom. Lett. 2022, 7, 3380–3387. [Google Scholar] [CrossRef]

- Ge, L.; Ma, W.; Yang, S.; Yu, X.; Sun, T.; Wang, X.; Fa, S.; Wang, Y. Design and analysis of wire-driven tail fin for bionic underwater glider. Ocean Eng. 2023, 286, 115460. [Google Scholar] [CrossRef]

- Xavier, M.S.; Harrison, S.M.; Howard, D.; Yong, Y.K.; Fleming, A.J. Modeling of soft fluidic actuators using fluid–structure interaction simulations with underwater applications. Int. J. Mech. Sci. 2023, 255, 108437. [Google Scholar] [CrossRef]

- Soomro, A.M.; Memon, F.H.; Lee, J.W.; Ahmed, F.; Hussain, K.; Kim, K.H.; Kim, Y.S.; Choi, K.H. Fully 3D printed multi-material soft bio-inspired frog for underwater synchronous swimming. Int. J. Mech. Sci. 2021, 210, 106725. [Google Scholar] [CrossRef]

- Soomro, A.M.; Lee, J.W.; Memon, F.H.; Ahmed, F.; Hussain, K.; Choi, K.H. Bioinspired Multi-material Polyjet-printed Frog Robot for Synchronous and Asynchronous Swimming. J. Bionic Eng. 2023, 20, 923–933. [Google Scholar] [CrossRef]

- Friedman, C.; Joel, B.W.; Schult, A.R.; Leftwich, M.C. Noninvasive 3D geometry extraction of a sea lion foreflipper. J. Aero Aqua Bio-Mech. 2015, 4, 25–31. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, Y.; Lim, K.M.; Luo, J.; Wang, N. Development and performance analysis of pneumatic soft-bodied bionic flipper. Adv. Eng. Mater. 2022, 24, 2101566. [Google Scholar] [CrossRef]

- Antary, T.M.; Sharaf, N.; Allawi, T.; Akkawi, M. General Entomology; China Agricultural University Press: Beijing, China, 2001; Volume 29–31, pp. 95–99. [Google Scholar]