Vibration Principles Research of Novel Power Electronic Module as Dynamic Vibration Absorber for Chassis-By-Wire

Abstract

1. Introduction

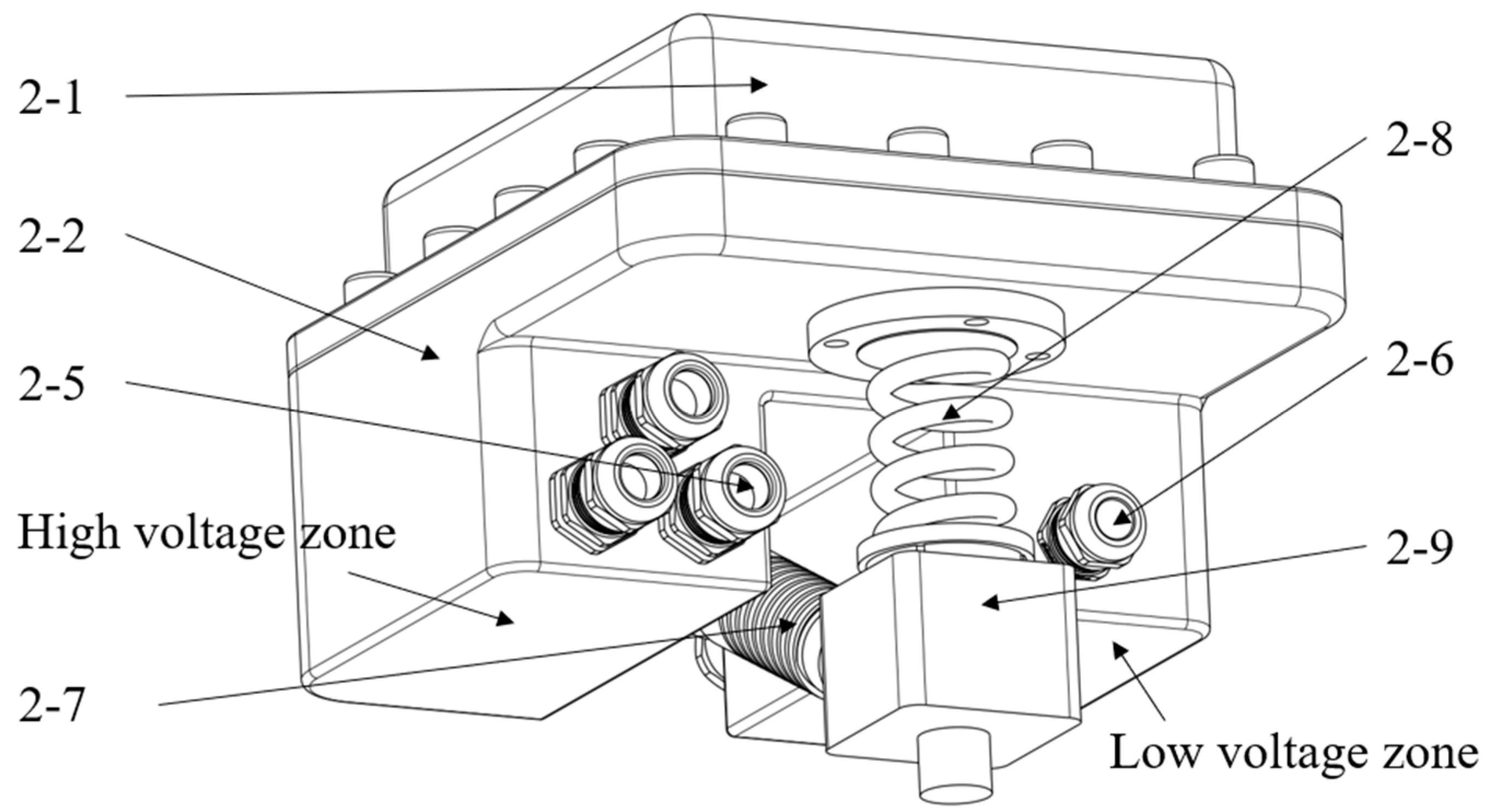

2. Research Objective

3. Research Method

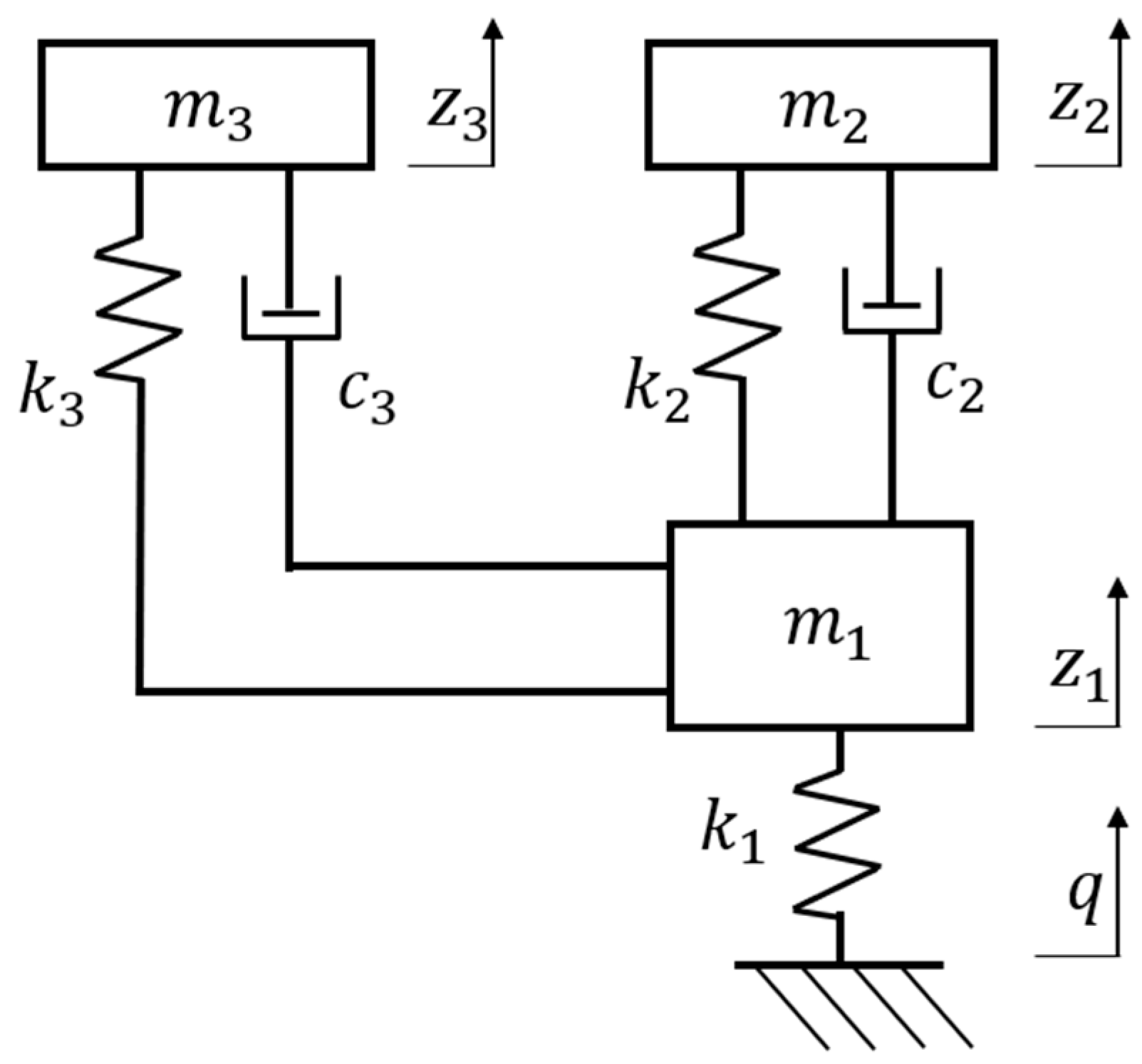

3.1. Dynamic Modeling

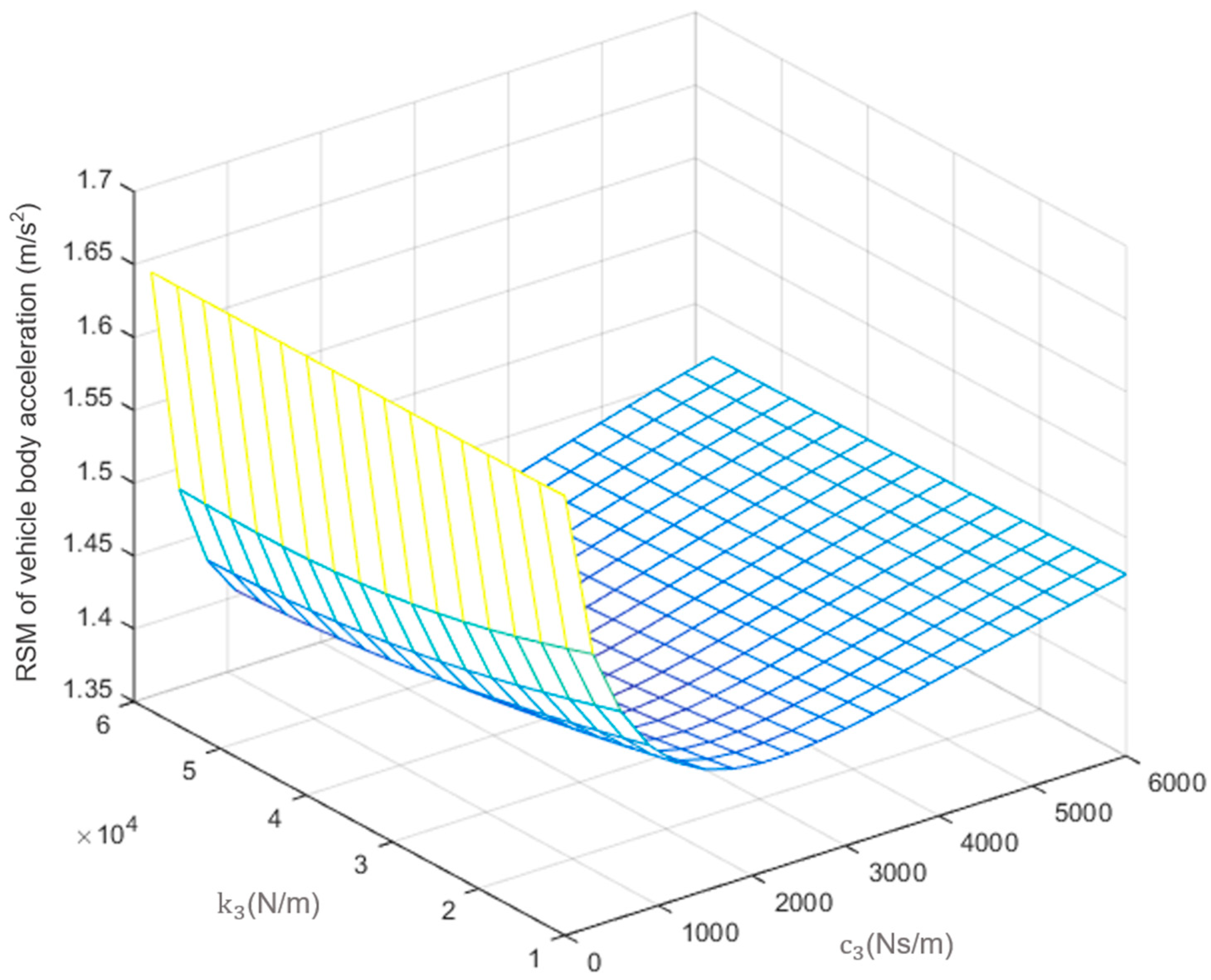

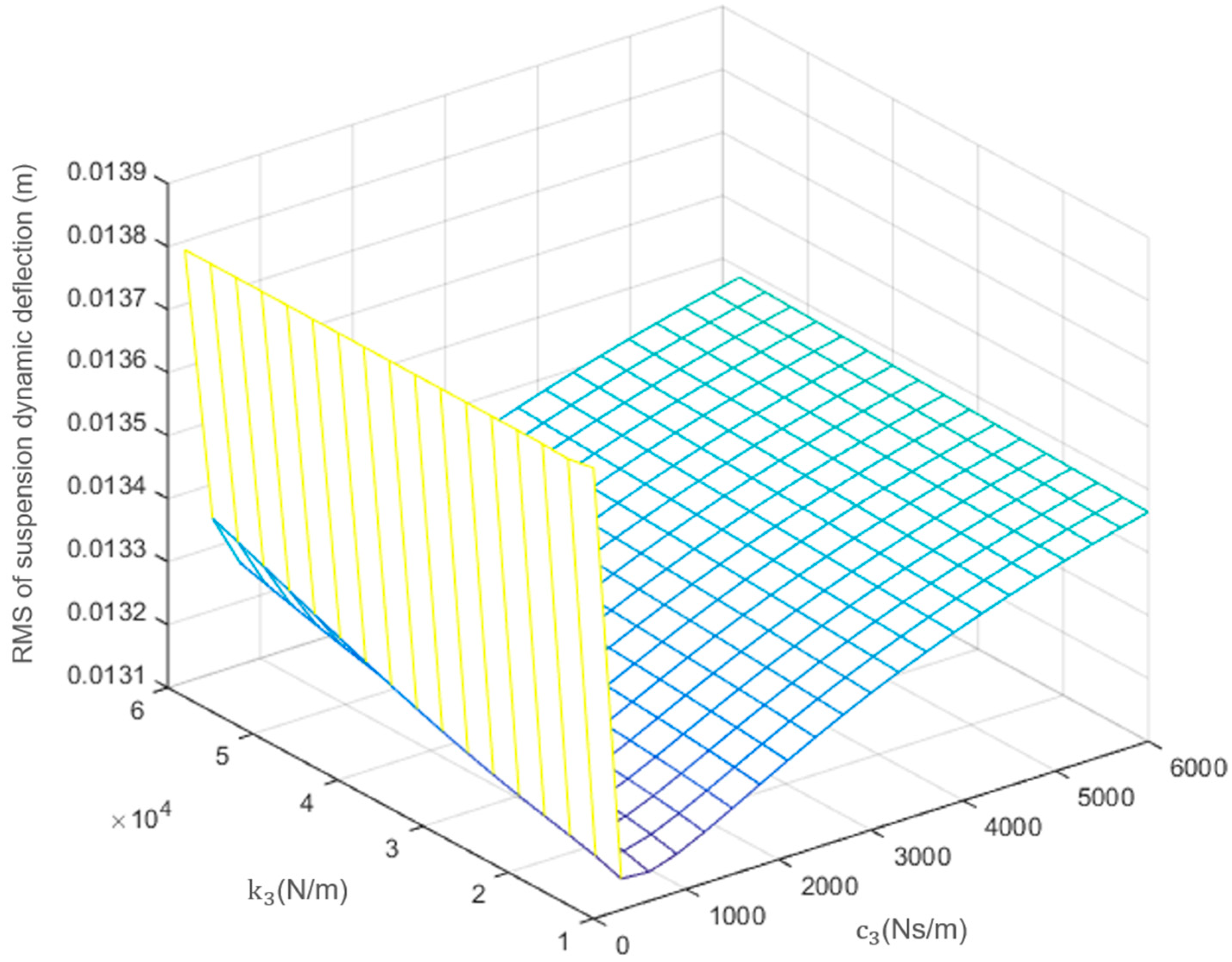

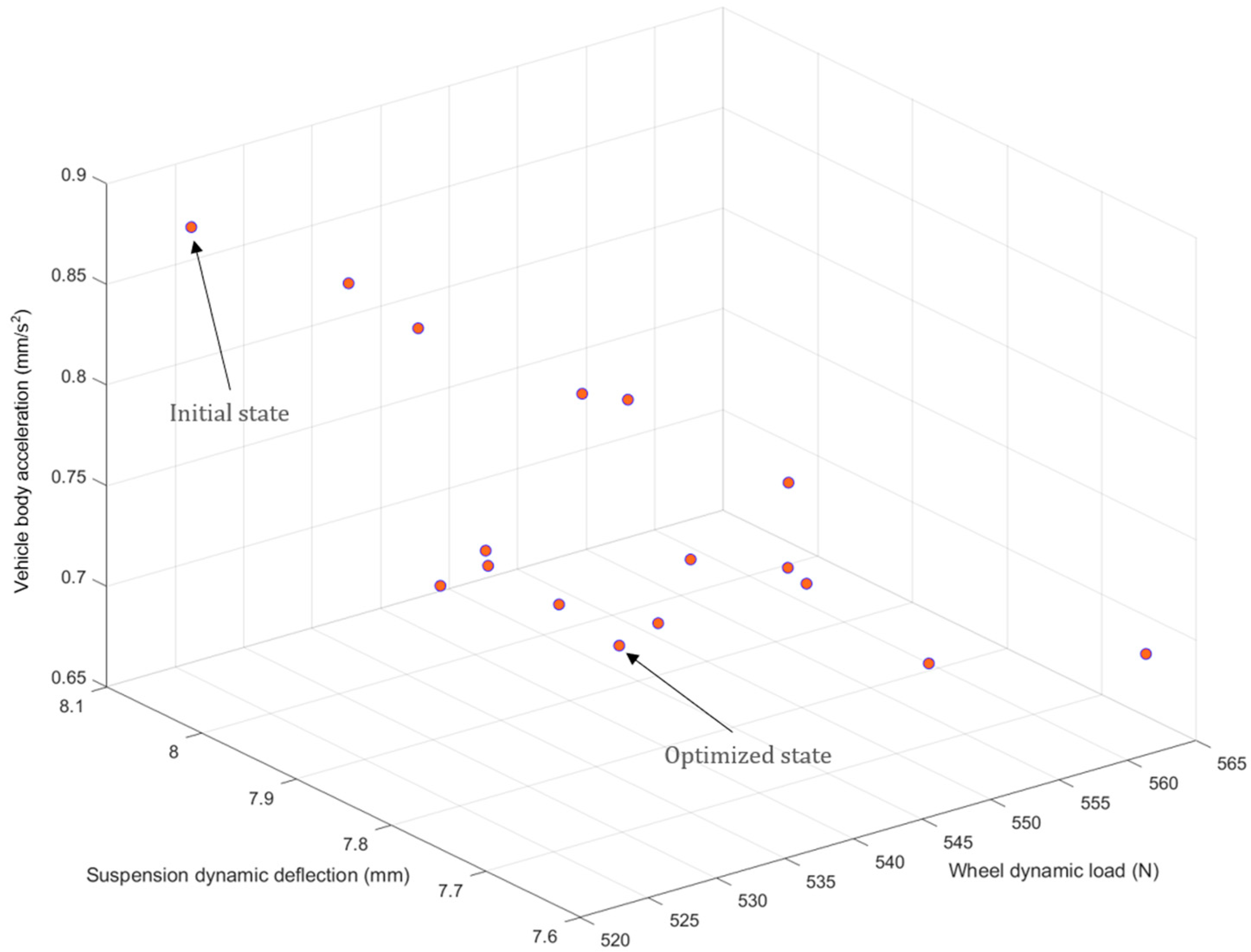

3.2. Parameter Optimization

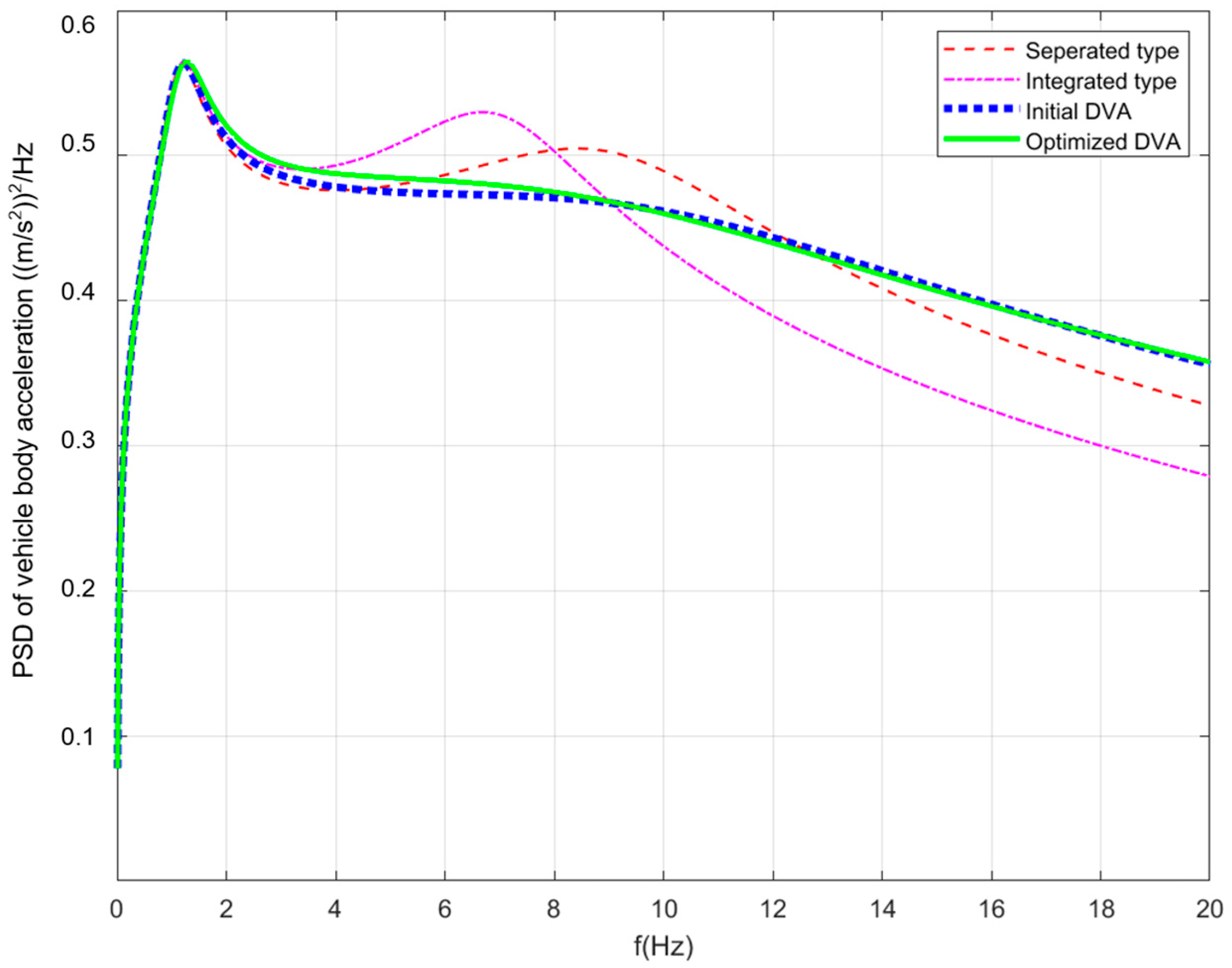

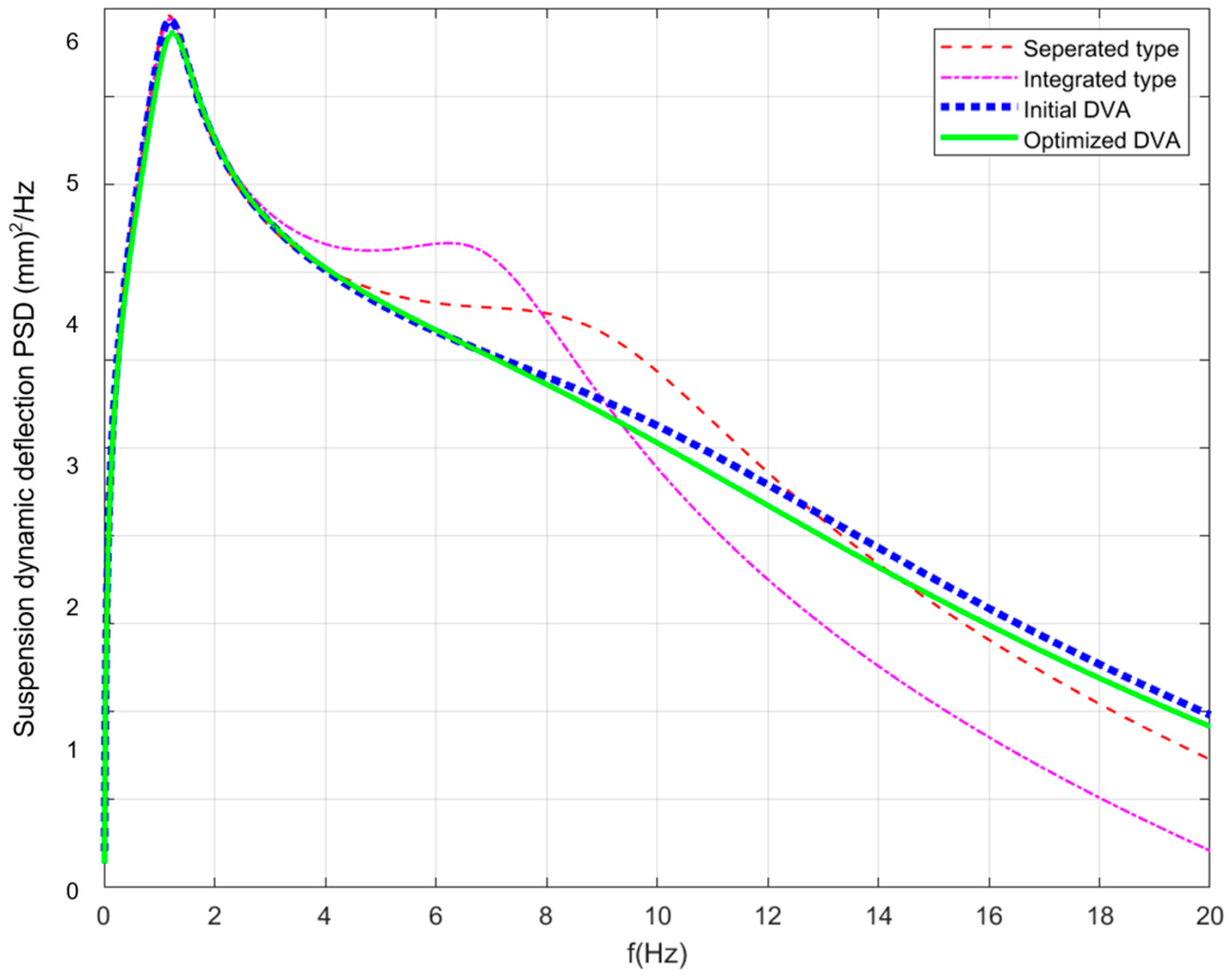

3.3. Comparison and Discussion

4. Simulation Performance

5. Conclusions

- (1)

- The DVA stiffness and damping have a direct impact on ride comfort performance, which can be calculated and optimized mathematically as a typical multi-objective optimization model.

- (2)

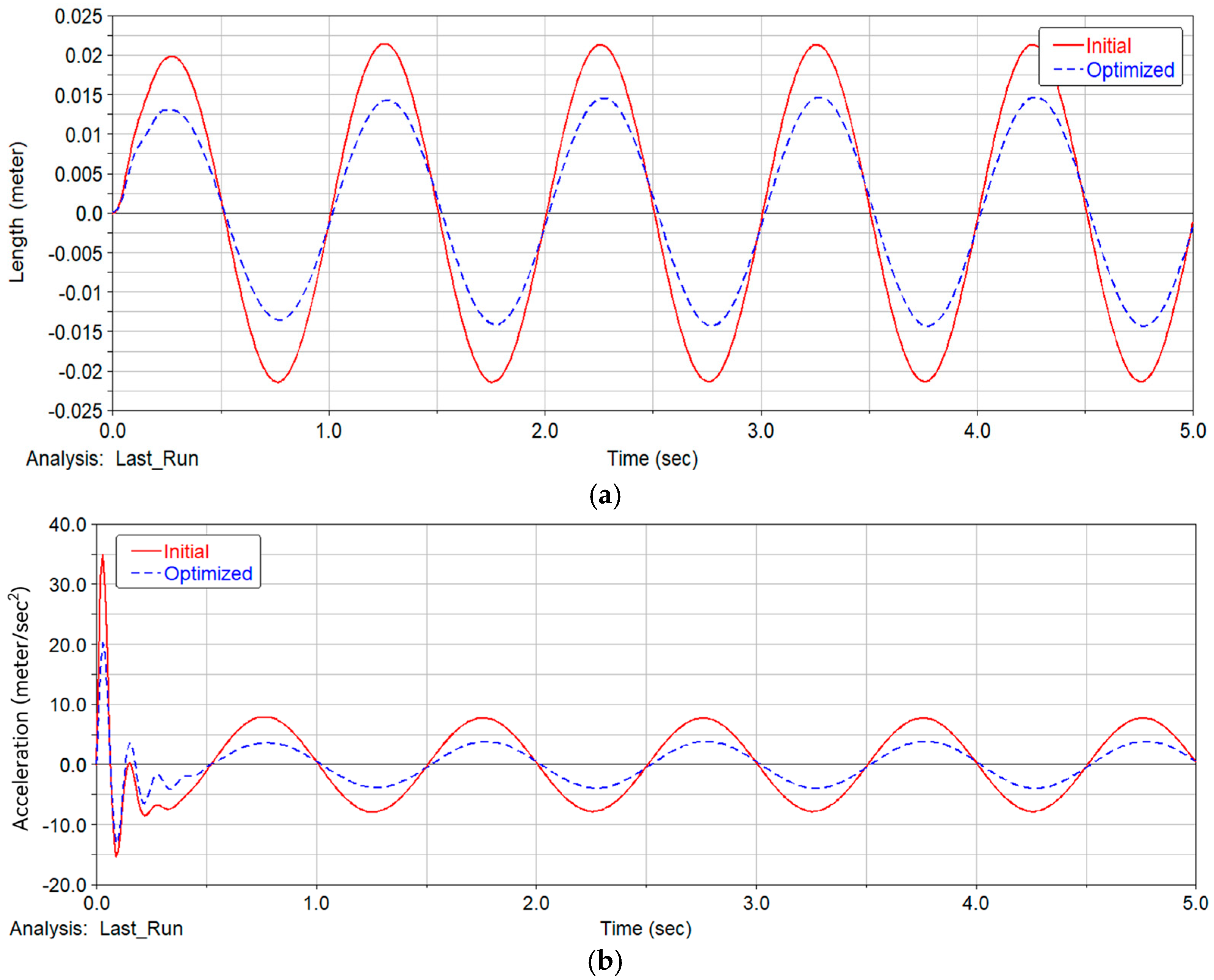

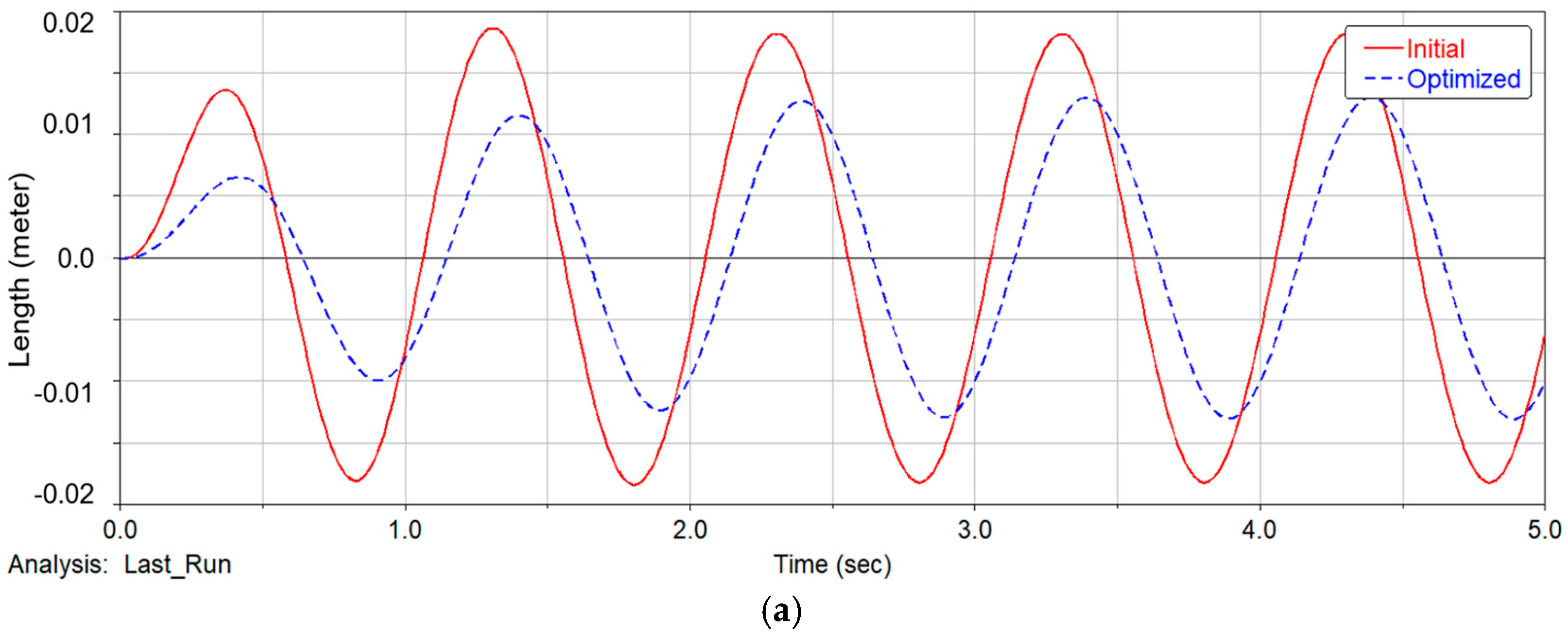

- As a comparison, we take four configuration schemes in this study, namely, a separated type configuration, integrated type configuration, initial DVA configuration, and optimized DVA configuration. We take the condition of a vehicle driving at a speed of 15 m/s on a C-class road, with the simulation results showing the expected advantage of the optimized DVA configuration in ride comfort.

- (3)

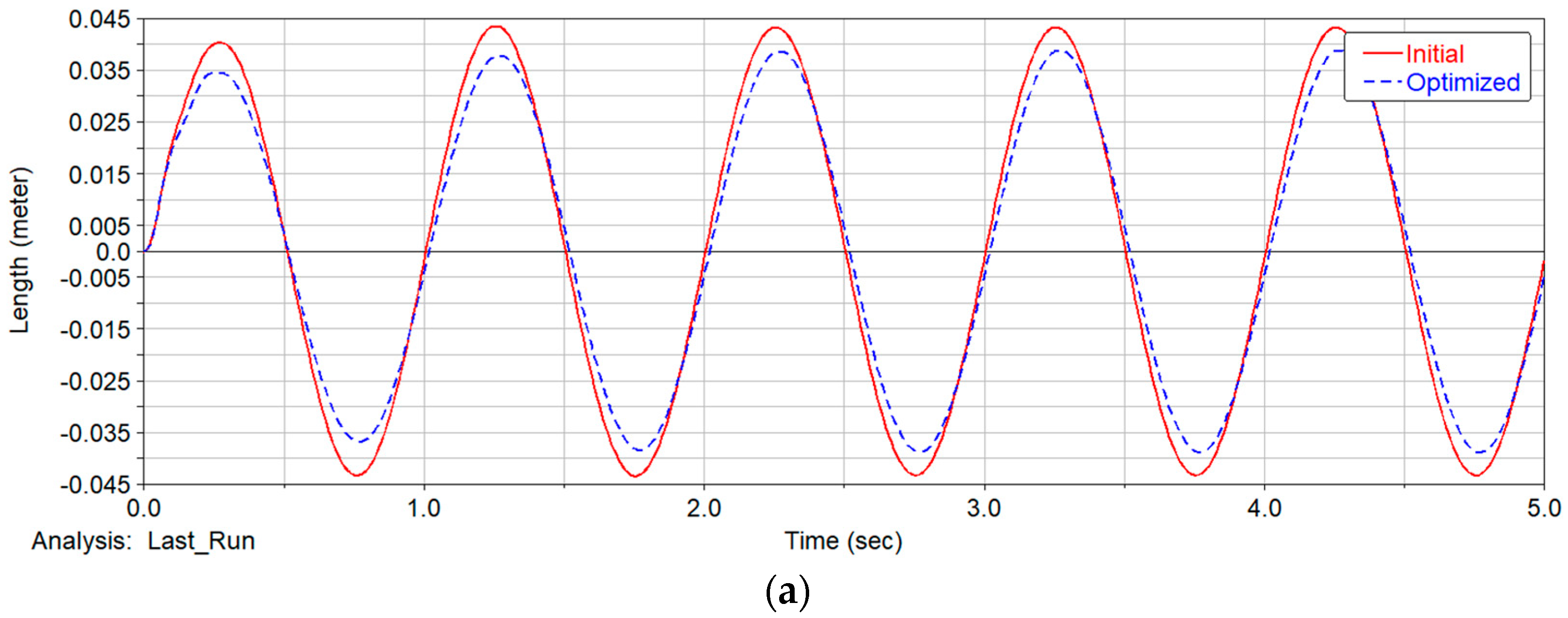

- We built a digital virtual prototype for detailed engineering design. The simulation results show that the optimized DVA configuration shows obvious suppression in component vibration compared to the initial state, including the vehicle body, the IWM, and the PEM. The negative effect of un-sprung mass is effectively mitigated, and ride comfort is obviously improved. At the same time, a frequency sweep analysis of the PEM shows a robust result, which ensures a reliable connection for the chassis-by-wire system.

- (4)

- In the future, we have more work to do in the active control of DVAs. When the elastic element is upgraded with active actuators, the chassis-by-wire system can have a better performance in various road conditions. This technical route is especially suitable for autonomous driving technology, for the sensing information in the VCU can benefit the DVA system in mode recognition and active control strategy. The fundamental principles of vibration revealed in this paper can be a useful reference for the study of active DVA systems in the future.

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| PEM | Power electronic module |

| DVA | Dynamic vibration absorber |

| VCU | Vehicle control unit |

| IWM | In-wheel motor |

| MCU | Motor control unit |

| IGBT | Insulate-gate bipolar transistor |

| RMS | Root mean square |

| PSD | Power spectrum density |

References

- Arango, J.F.; Bergasa, L.M.; Revenga, P.A.; Barea, R.; López-Guillén, E.; Gómez-Huélamo, C.; Araluce, J.; Gutiérrez, R. Drive-by-wire development process based on ROS for an autonomous electric vehicle. Sensors 2020, 20, 6121. [Google Scholar] [CrossRef]

- Ahmad, I.; Ge, X.; Han, Q.L. Decentralized dynamic event-triggered communication and active suspension control of IWM. IEEE/CAA J. Autom. Sin. 2022, 8, 971–986. [Google Scholar] [CrossRef]

- Jung, H.S.; Sul, S.K. Decomposed current controller for a paralleled inverter with a small interfaced inductor. IEEE Trans. Power Electron. 2018, 34, 9316–9328. [Google Scholar] [CrossRef]

- Couture, P.; Francoeur, B.; Simard, J.; Bourgeois, F.X.; Harbec, G.; Hydro Quebec. Electrically motorized wheel assembly. U.S. Patent 5438228, 1 October 1995. [Google Scholar]

- Pedro, J.; Weinholtz, J.; Sousa, L.; Reis, L. A New Concept for a Wheel-Embedded Assembly for Electric Vehicles. J. Mech. Des. 2013, 135, 124502. [Google Scholar] [CrossRef]

- Xing, C.; Zhu, Y.; Wang, J.; Lin, Y. Braking torque distribution reconfiguration strategy of vehicle with faults of in-wheel motor drive system. IEEE Trans. Intell. Transp. Syst. 2024, 25, 14476–14485. [Google Scholar] [CrossRef]

- Perovic, D.K. Making the impossible, possible—Overcoming the design challenges of In-Wheel Motors. World Electr. Veh. J. 2012, 5, 514–519. [Google Scholar] [CrossRef]

- Drexler, D.; Hou, Z. Simulation analysis on vertical vehicle dynamics of three in-wheel motor drive configurations. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 238, 2105–2119. [Google Scholar] [CrossRef]

- Nagaya, G.; Wakao, Y.; Abe, A. Development of an in-wheel drive with advanced dynamic-damper mechanism. JSAE Rev. 2003, 24, 477–481. [Google Scholar] [CrossRef]

- Gashi, R. Electric Steering System for Vehicle. WO Patent 006776A1, 26 August 2007. [Google Scholar]

- Trancossi, M.; Pascoa, J.C. Optimized modular design for energy efficiency: The case of an innovative electric hybrid vehicle design. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Höfer, A. Methodical conception and development of innovative lightweight chassis systems illustrated by the example of the “LEICHT” concept. In 5th International Munich Chassis Symposium 2014: Chassis. Tech Plus; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014. [Google Scholar] [CrossRef]

- Chen, X.; Yin, J.; Wang, W.; Wu, L.; Tang, F. Approaches to diminish large unsprung mass negative effects of wheel side drive electric vehicles. J. Adv. Mech. Des. Syst. Manuf. 2016, 10, JAMDSM0064. [Google Scholar] [CrossRef]

- Ding, X.; Chen, X. A power Electronic Module with Dynamic Vibration Absorption Function, Electric Drive System, and Vehicle. China Patent CN117799372A, 11 January 2024. [Google Scholar]

- Heintzel, A. Developing innovations: Chassis from steer-by-wire to AI. In Proceedings of the 5th International Munich Chassis Symposium, Munich, Germany/Virtually, 4–5 June 2024. [Google Scholar]

- Tavella, D.; Tolkacz, J.; Wasacz, B.; Peraboni, D.; Corradi, R. Cross-Domain Control Architecture—Single Master Controller for Propulsion and Chassis Automotive Domains; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Joseph, J.; Joseph, J.; Rajendran, K.S.; Anoop, M.S. Structural design of ultimate terrain electric vehicle suspension system. In Applications of Computation in Mechanical Engineering: Select Proceedings of 3rd International Conference on Computing in Mechanical Engineering (ICCME 2021), Cochin, India, 22–24 September 2021; Springer Nature: Singapore, 2022. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Z.; Yuan, K.; Zhang, Y. Comprehensive analysis and optimization of dynamic vibration-absorbing structures for electric vehicles driven by In-Wheel Motors. Automot. Innov. 2020, 3, 254–262. [Google Scholar] [CrossRef]

| Parameter Definition | Abbreviation | Unit | Value |

|---|---|---|---|

| Un-sprung mass | m1 | kg | 65 |

| Sprung mass | m2 | kg | 410 |

| DVA mass | m3 | kg | 16 |

| Tire stiffness | k1 | N/m | 225,000 |

| Suspension stiffness | k2 | N/m | 25,000 |

| Suspension damping | c2 | Ns/m | 1800 |

| k2 (N/m) | c2 (Ns/m) | K3 (N/m) | c3 (Ns/m) | |

|---|---|---|---|---|

| Initial state | 25,000 | 1800 | 15,000 | 1000 |

| Optimized state | 22,825 | 2258 | 13,852 | 1668 |

| x-axis direction loading with acceleration of 15 m/s2 | ||||||||||||||||

| Frequency (Hz) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| Amplitude (MPa) | 23.8 | 28.2 | 31.3 | 33.5 | 36.3 | 38.3 | 39.5 | 42.4 | 45.8 | 46.3 | 47.5 | 45.1 | 41.8 | 38.3 | 39.5 | 40.4 |

| y-axis direction loading with acceleration of 15 m/s2 | ||||||||||||||||

| Frequency (Hz) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| Amplitude (MPa) | 20.5 | 25.2 | 28.6 | 30.3 | 33.4 | 35.2 | 36.6 | 38.4 | 42.1 | 44.5 | 43.8 | 41.7 | 38.3 | 33.9 | 35.7 | 36.3 |

| z-axis direction loading with acceleration of 30 m/s2 | ||||||||||||||||

| Frequency (Hz) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| Amplitude (MPa) | 30.2 | 37.4 | 42.3 | 45.4 | 49.5 | 52.8 | 55.4 | 57.7 | 63.6 | 61.9 | 57.5 | 52.8 | 53.9 | 55.6 | 58.5 | 59.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Wang, W.; Chen, X. Vibration Principles Research of Novel Power Electronic Module as Dynamic Vibration Absorber for Chassis-By-Wire. Machines 2024, 12, 932. https://doi.org/10.3390/machines12120932

Ding X, Wang W, Chen X. Vibration Principles Research of Novel Power Electronic Module as Dynamic Vibration Absorber for Chassis-By-Wire. Machines. 2024; 12(12):932. https://doi.org/10.3390/machines12120932

Chicago/Turabian StyleDing, Xiaoyu, Wei Wang, and Xinbo Chen. 2024. "Vibration Principles Research of Novel Power Electronic Module as Dynamic Vibration Absorber for Chassis-By-Wire" Machines 12, no. 12: 932. https://doi.org/10.3390/machines12120932

APA StyleDing, X., Wang, W., & Chen, X. (2024). Vibration Principles Research of Novel Power Electronic Module as Dynamic Vibration Absorber for Chassis-By-Wire. Machines, 12(12), 932. https://doi.org/10.3390/machines12120932