A Review of Physics-Based, Data-Driven, and Hybrid Models for Tool Wear Monitoring

Abstract

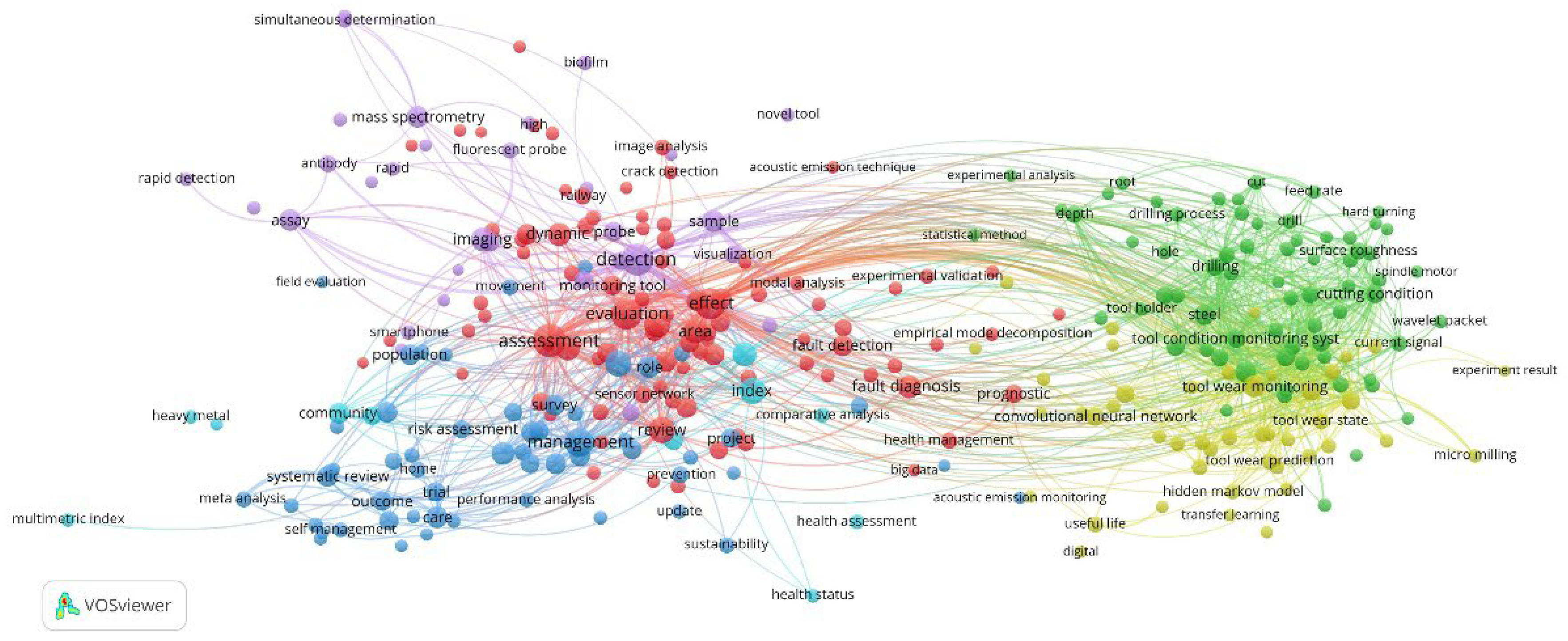

1. Introduction

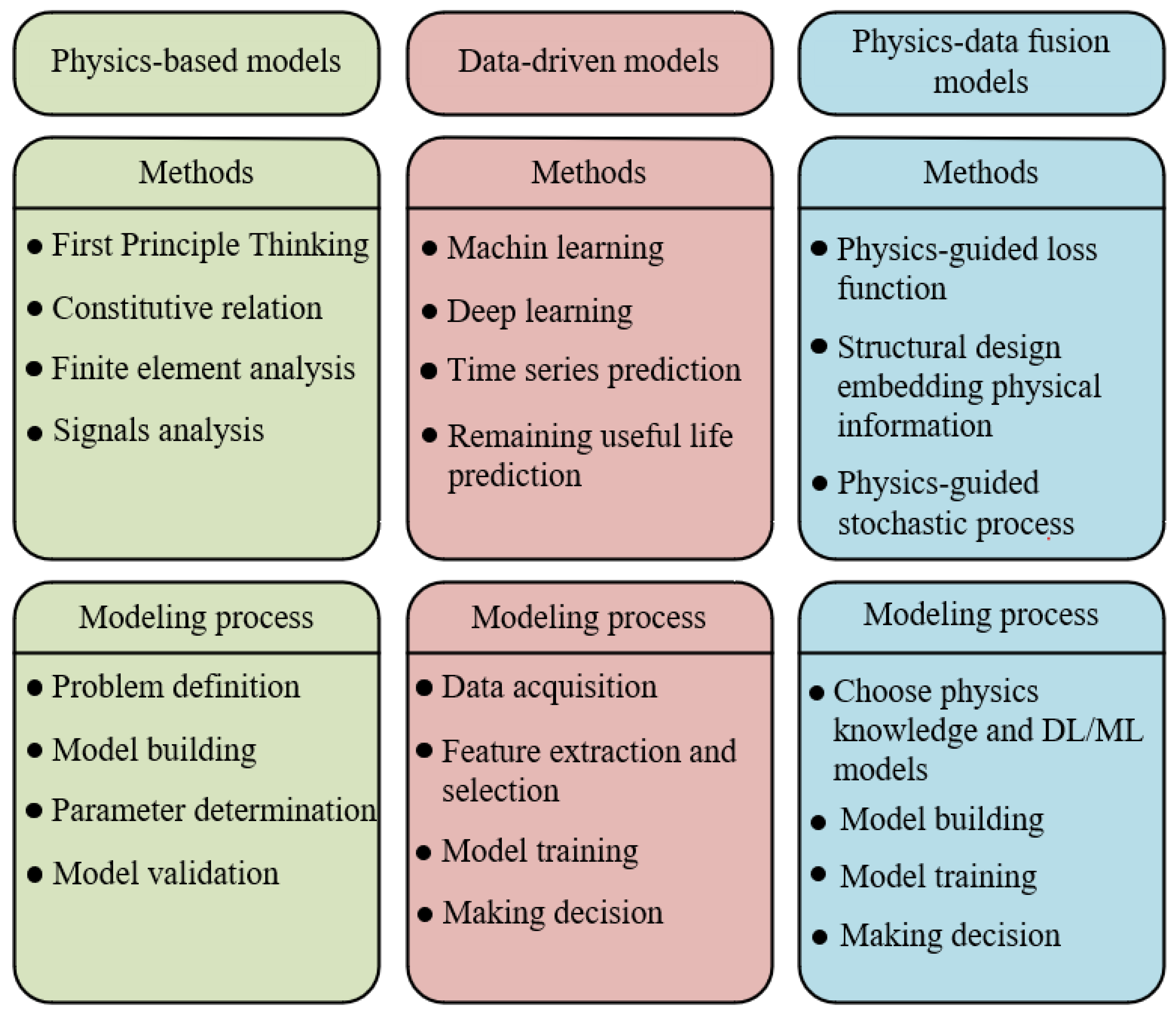

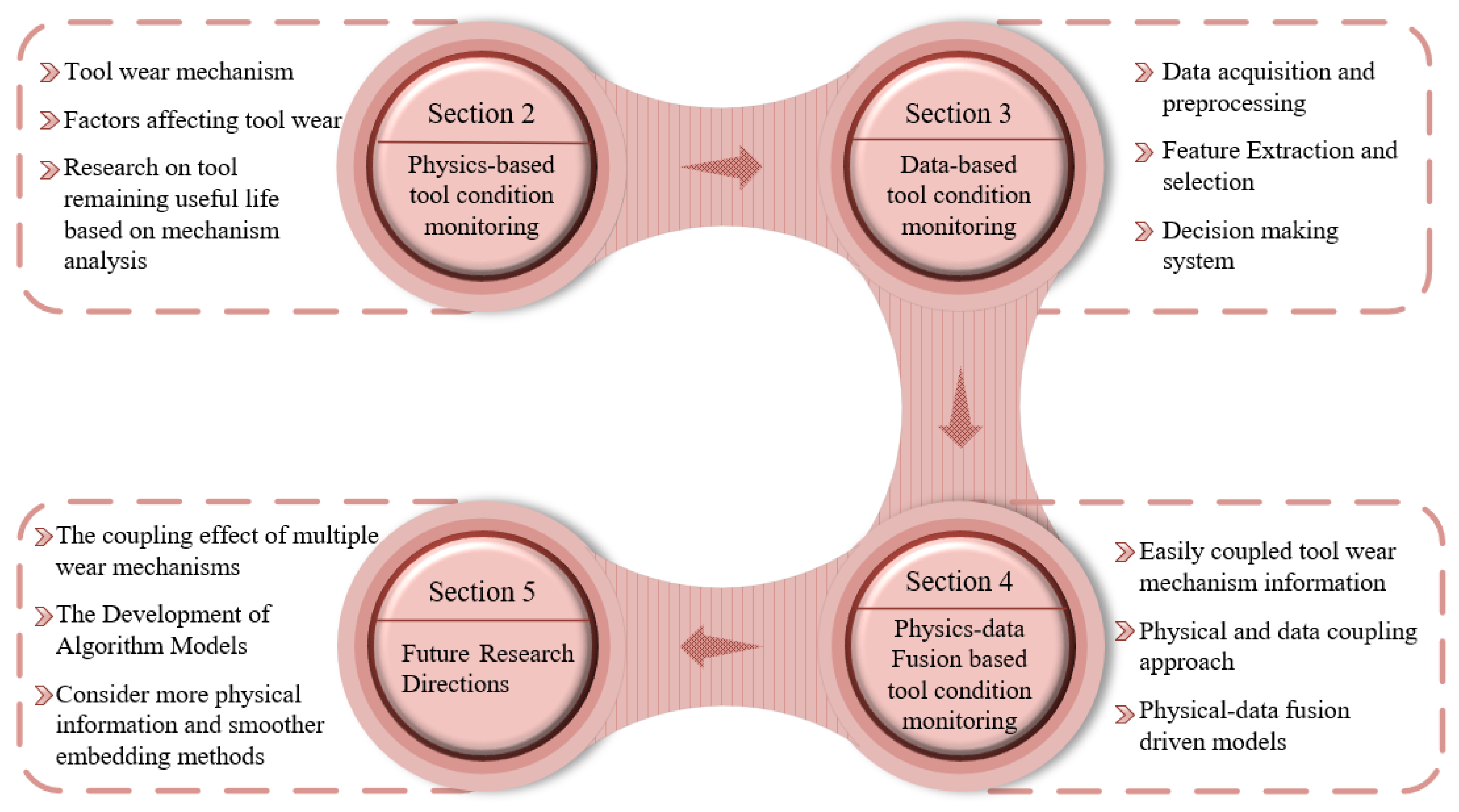

2. Physics-Based TWM

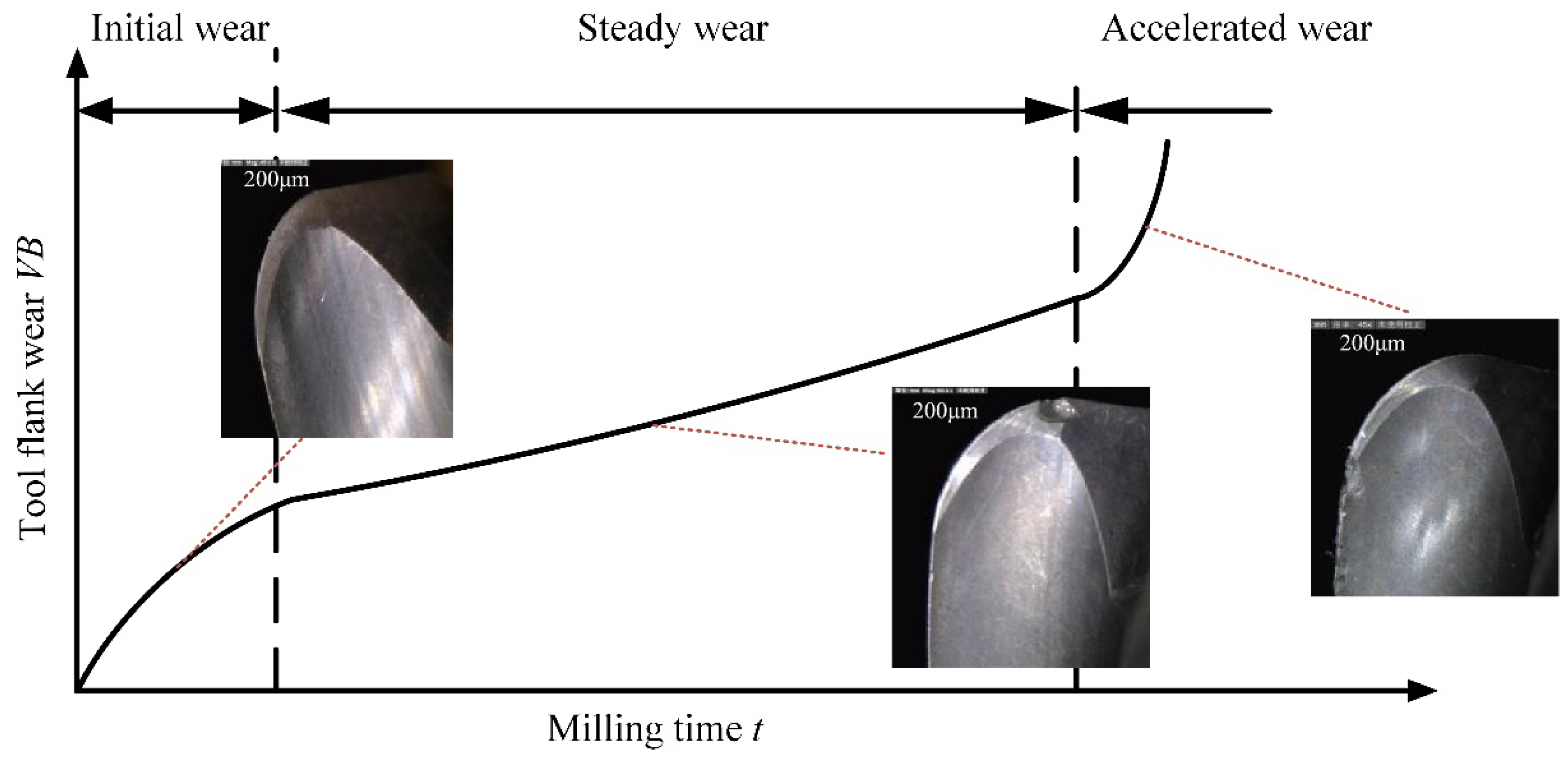

2.1. Tool Wear Mechanism

2.2. Factors Affecting Tool Wear

2.2.1. Machining Parameters

2.2.2. Tool Coatings

2.2.3. Cooling and Lubrication Methods

2.2.4. Workpiece Materials

2.2.5. Others

2.3. Research on Tool RUL Based on Physics Analysis

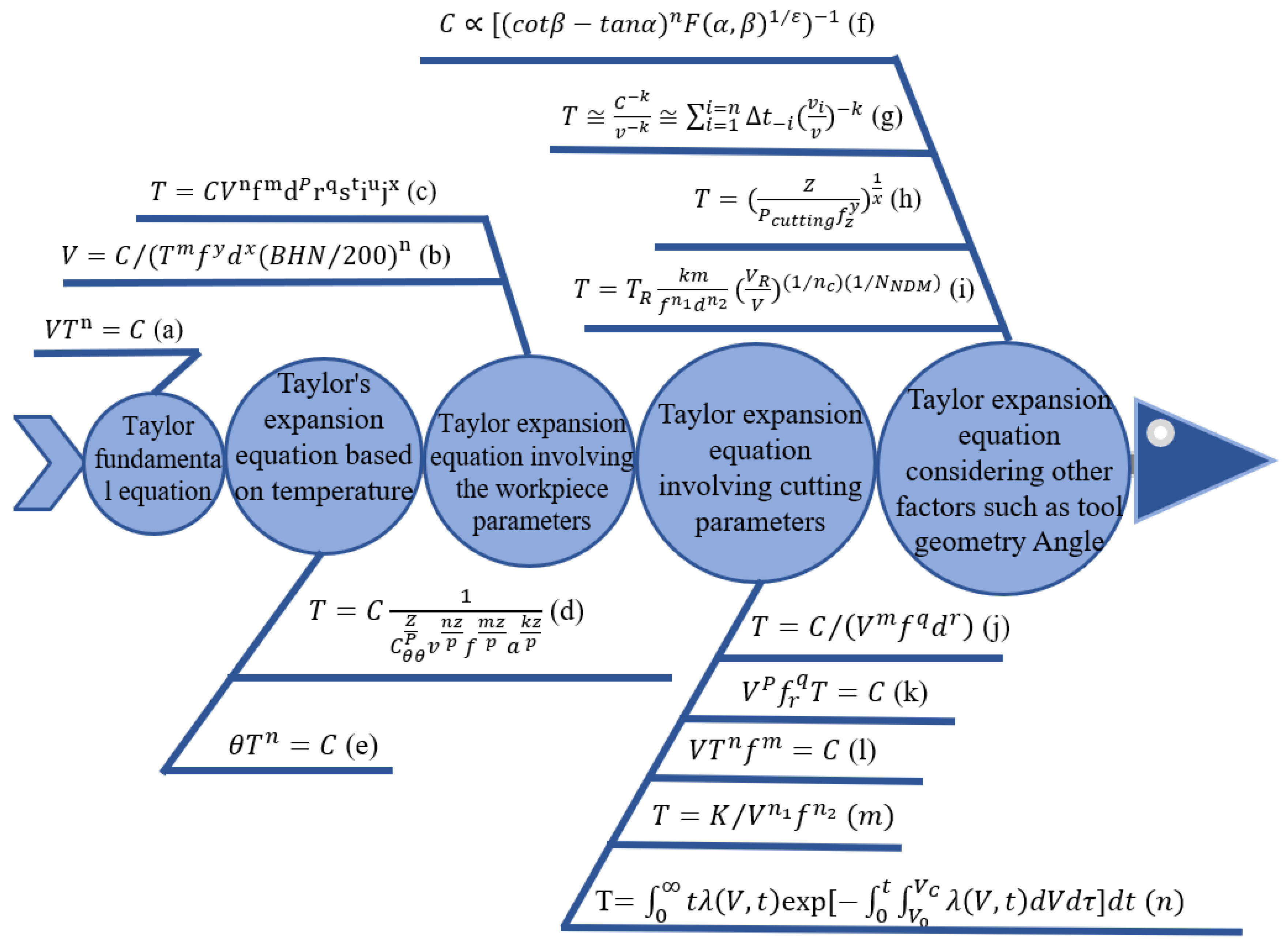

Classical Tool Life Models

3. Data-Driven TWM

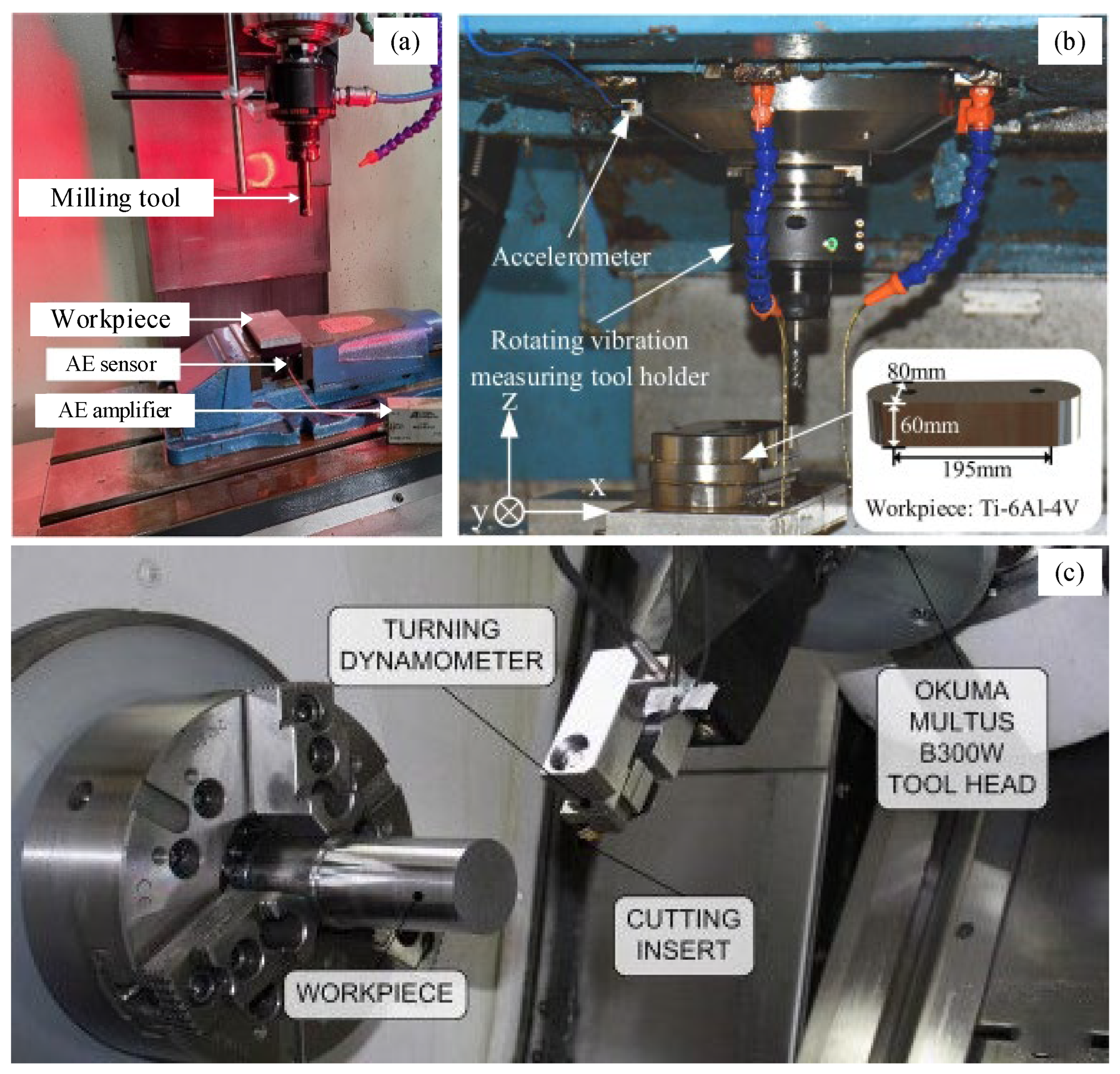

3.1. Signal Acquisition and Preprocessing

3.1.1. Direct Methods

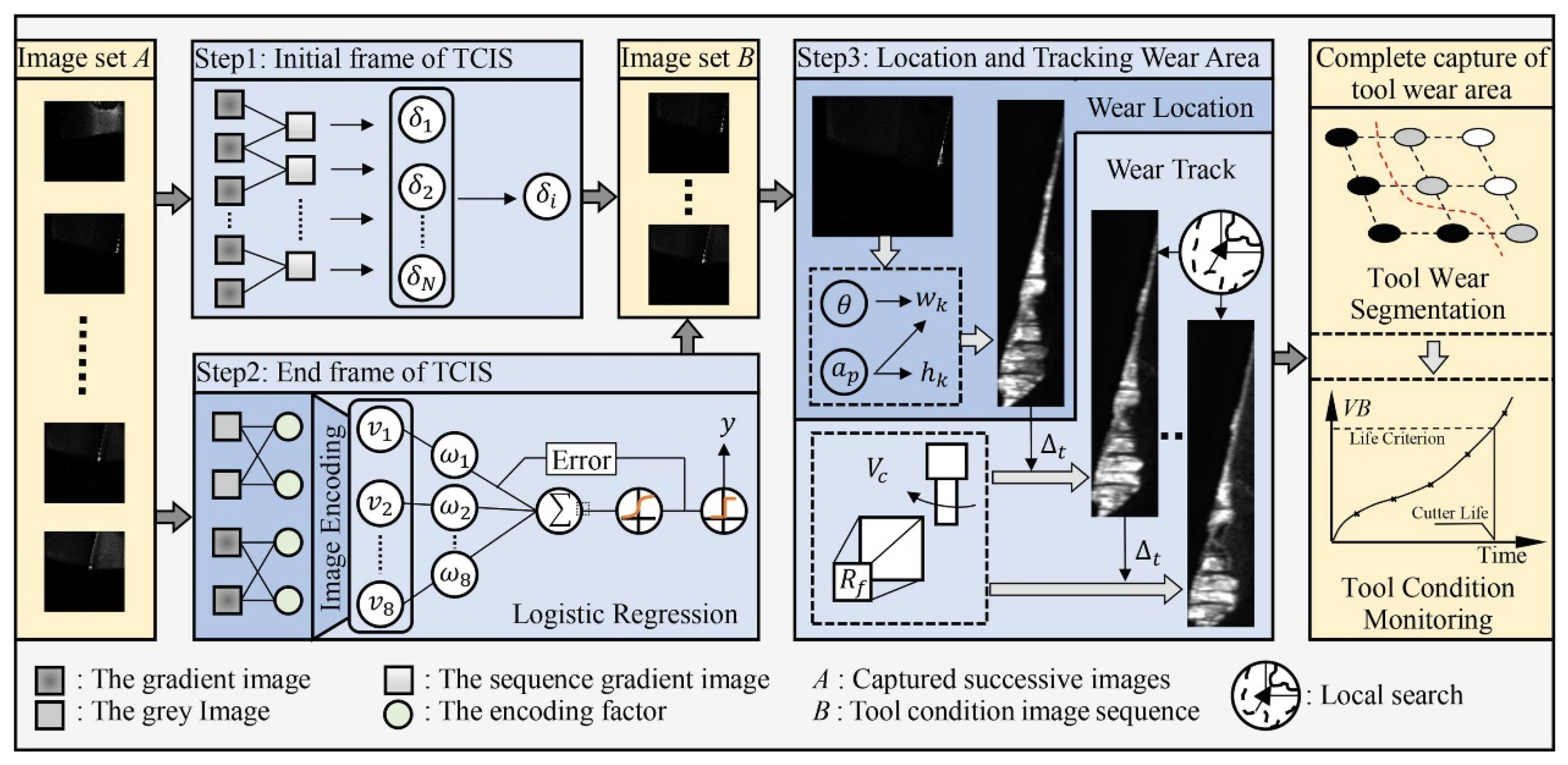

AI-Based Preprocessing Models in Direct Methods

3.1.2. Indirect Methods

AI-Based Preprocessing Models in Indirect Methods

3.2. Feature Extraction and Selection

3.2.1. Digital Image

3.2.2. Physical Signals

3.3. Data-Driven TWM Decision-Making System

3.3.1. ML

3.3.2. Deep Learning

4. Physics–Data Fusion TWM

4.1. Physical Information

4.2. Physics–Data Fusion Methods for TWM

4.2.1. Physics-Guided Loss Function

4.2.2. Structural Design Embedding Physical Information

4.2.3. Physics-Guided Stochastic Processes

4.3. Fusion Strategies for Making Decisions

4.3.1. Outputs of Physical Model as Inputs of Data-Driven Model

4.3.2. Integrating Outputs of Physical Model and Data-Driven Model

4.3.3. Improving Physical Model by the Outputs of Data-Driven Model

5. Trends and Future Challenges

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| TWM | tool wear monitoring |

| RUL | remaining useful life |

| IoT | Internet of Things |

| AI | artificial intelligence |

| ML | machine learning |

| VB | Average wear of flank |

| CNT | coated carbon nanotube |

| DLC | diamond-like carbon |

| MQL | minimum quantity lubrication |

| LN2 | cryogenic cooling |

| CCD | charge coupled devices |

| CMOS | complementary metal oxide semiconductors |

| ORS | on-rotor sensing system |

| LSTMs | long short-term memory networks |

| KPCA | kernel-principal component analysis |

| GPR | gaussian process regression |

| GLCM | gray level co-occurrence matrix |

| LBP | local binary patterns |

| AR | autoregressive process |

| SSA | singular spectrum analysis |

| EMD | empirical mode decomposition |

| WT | wavelet transform |

| EEMD | ensemble empirical mode decomposition |

| CWT | continuous wavelet transform |

| WPD | wavelet packet decomposition |

| DWT | discrete wavelet transform |

| CNN | convolutional neural networks |

| DL | deep learning |

| HMM | hidden Markov model |

| SVM | support vector machine |

| RF | random forest |

| LS-SVM | least squares-support vector machine |

| RNN | recurrent neural networks |

| GRU | gated recurrent unit |

| LSTM | long-short term memory |

| SLSTMs | Siamese long short-term memory networks |

| BCBN | binder-free cubic boron nitride |

| BPN | back propagation neural network |

| CVD | chemical vapor deposition |

| PVD | physical vapor deposition |

| XEDS | X-ray energy-dispersive spectrometry |

| CFRC | carbon fiber reinforced composites |

| SEM | scanning electron microscopy |

| EDS | energy dispersive spectroscopy |

| DTAE | denoising transformer autoencoder |

| MSCAN | multiscale convolutional attention network |

| DCRBM | deep coupled restricted Boltzmann machine |

| UKF | unscented Kalman filter |

| XEDS | X-ray energy-dispersive spectrometry |

| PITL | physics-informed transfer learning |

| CAHSMM | condition-adaptive hidden semi-Markov model |

| MFB-DCNN | multi-band deep convolutional neural network |

| CycleGAN | cycle generative adversarial networks |

| Symbols | |

| β | clearance angle |

| V | cutting speed |

| T | tool life |

| f | feed rate |

| θf | related to it by the equation θf = Vε |

| BHN | material hardness |

| d | depth of cut |

| nc | coating effect factor |

| m, x, y, n, C, k, Z, n1, n2, j | equation parameters |

| NNDM | NDM effect factor |

| Cθ | constant |

| α | rake angle |

| Vc, V0 | speed of operation |

| SC | silicon content |

| AR | aspect ratio |

| R2 | coefficient of determination |

| fZ | tooth feed |

| αα | axial depth of cut |

| fr | feed in turning |

| r | nose radius |

| F (α, β) | α suitable function of α and β |

| ε | the index of cutting speed V when considering the mean flank temperature |

| vi | different cutting speeds |

| Δti | cutting is performed at various vi speeds for Δti time |

| Ti | tool life pertaining to a continuous vi speed |

| Pcutting | power consumed in material removal |

References

- Pimenova, D.Y.; da Silva, L.R.R.; Machado, A.R.; Franca, P.H.P.; Pintaude, G.; Unune, D.R.; Kuntoglu, M.; Krolczyk, G.M. A Comprehensive Review of Machinability of Difficult-to-Machine Alloys with Advanced Lubricating and Cooling Techniques. Tribol. Int. 2024, 196, 109677. [Google Scholar] [CrossRef]

- Guo, Q.; Liu, Z.; Yang, Z.; Jiang, Y.; Sun, Y.; Xu, J.; Zhao, W.; Wang, W.; Wang, W.; Ren, Q.; et al. Development, Challenges and Future Trends on the Fabrication of Micro-Textured Surfaces Using Milling Technology. J. Manuf. Process. 2024, 126, 285–331. [Google Scholar] [CrossRef]

- Javed, K.; Gouriveau, R.; Li, X.; Zerhouni, N. Tool Wear Monitoring and Prognostics Challenges: A Comparison of Connectionist Methods toward an Adaptive Ensemble Model. J. Intell. Manuf. 2018, 29, 1873–1890. [Google Scholar] [CrossRef]

- Sun, Y.; Jia, J.; Xu, J.; Chen, M.; Niu, J. Path, Feedrate and Trajectory Planning for Free-Form Surface Machining: A State-of-the-Art Review. Chin. J. Aeronaut. 2022, 35, 12–29. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Wojciechowski, S.; Powalka, B.; Klos, S.; Szczotkarz, N.; Matuszak, M.; Khanna, N. Evaluation of Turning with Different Cooling-Lubricating Techniques in Terms of Surface Integrity and Tribologic Properties. Tribol. Int. 2020, 148, 106334. [Google Scholar] [CrossRef]

- Gunay, M.; Korkmaz, M.E.; Yasar, N. Performance Analysis of Coated Carbide Tool in Turning of Nimonic 80A Superalloy under Different Cutting Environments. J. Manuf. Process. 2020, 56, 678–687. [Google Scholar] [CrossRef]

- Majstorovic, V.; Jankovic, G.; Zivkov, S.; Stojadinovic, S. Digital Manufacturing in SMEs Based on the Context of the Industry 4.0 Framework—One Approach. In Proceedings of the 10th Cirp Sponsored Conference on Digital Enterprise Technologies (Det 2020)—Digital Technologies as Enablers of Industrial Competitiveness and Sustainability, Budapest, Hungary, 11–13 October 2021; Vancza, J., Maropoulos, P., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2021; Volume 54, pp. 52–57. [Google Scholar]

- Cai, G.; Chen, X.; Li, B.; Chen, B.; He, Z. Operation Reliability Assessment for Cutting Tools by Applying a Proportional Covariate Model to Condition Monitoring Information. Sensors 2012, 12, 12964–12987. [Google Scholar] [CrossRef]

- Dou, J.; Jiao, S.; Xu, C.; Luo, F.; Tang, L.; Xu, X. Unsupervised Online Prediction of Tool Wear Values Using Force Model Coefficients in Milling. Int. J. Adv. Manuf. Technol. 2020, 109, 1153–1166. [Google Scholar] [CrossRef]

- Liu, C.; Wang, G.F.; Li, Z.M. Incremental Learning for Online Tool Condition Monitoring Using Ellipsoid ARTMAP Network Model. Appl. Soft Comput. 2015, 35, 186–198. [Google Scholar] [CrossRef]

- Aliustaoglu, C.; Ertunc, H.M.; Ocak, H. Tool Wear Condition Monitoring Using a Sensor Fusion Model Based on Fuzzy Inference System. Mech. Syst. Signal Process. 2009, 23, 539–546. [Google Scholar] [CrossRef]

- Zhang, C.; Yao, X.; Zhang, J.; Jin, H. Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations. Sensors 2016, 16, 795. [Google Scholar] [CrossRef] [PubMed]

- Siddhpura, A.; Paurobally, R. A Review of Flank Wear Prediction Methods for Tool Condition Monitoring in a Turning Process. Int. J. Adv. Manuf. Technol. 2013, 65, 371–393. [Google Scholar] [CrossRef]

- Kusiak, A. Smart Manufacturing Must Embrace Big Data. Nature 2017, 544, 23–25. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Pan, J.; Pei, R.; Yang, G.; Yi, B. A Framework for Assessing Green Capacity Utilization Considering CO2 Emissions in China’s High-Tech Manufacturing Industry. Sustainability 2020, 12, 4424. [Google Scholar] [CrossRef]

- Sharma, A.K.; Bhandari, R.; Pinca-Bretotean, C.; Sharma, C.; Dhakad, S.K.; Mathur, A. A Study of Trends and Industrial Prospects of Industry 4.0. Mater. Today Proc. 2021, 47, 2364–2369. [Google Scholar] [CrossRef]

- Azeem, M.; Haleem, A.; Javaid, M. Symbiotic Relationship Between Machine Learning and Industry 4.0: A Review. J. Ind. Integr. Manag. 2022, 07, 401–433. [Google Scholar] [CrossRef]

- Johansson, D.; Hägglund, S.; Bushlya, V.; Ståhl, J.-E. Assessment of Commonly Used Tool Life Models in Metal Cutting. Procedia Manuf. 2017, 11, 602–609. [Google Scholar] [CrossRef]

- Li, B. A Review of Tool Wear Estimation Using Theoretical Analysis and Numerical Simulation Technologies. Int. J. Refract. Met. Hard Mater. 2012, 35, 143–151. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Z.; Wang, B. Multi-Pattern Failure Modes and Wear Mechanisms of WC-Co Tools in Dry Turning Ti-6Al-4V. Ceram. Int. 2020, 46, 24512–24525. [Google Scholar] [CrossRef]

- Cui, Z.; Zhang, C.; Zhang, H.; Li, G.; Wu, L.; Zong, W.; Du, K. Wear Characteristics of the Pointed Diamond Tool in Ultraprecision and Micro Cutting of Al 6061 V-Grooves. J. Mater. Process. Technol. 2022, 300, 117414. [Google Scholar] [CrossRef]

- Cui, Z.P.; Li, G.; Liu, H.Z.; Zong, W.J.; Zhang, H.J.; Zhang, C.Y.; Du, K. Tool Anisotropic Wear Prediction and Its Influence on Surface Topography in Diamond Turning of Oxygen-Free Copper. J. Mater. Process. Technol. 2023, 318, 118042. [Google Scholar] [CrossRef]

- Liu, D.; Liu, Z.; Zhao, J.; Song, Q.; Ren, X.; Ma, H. Tool Wear Monitoring through Online Measured Cutting Force and Cutting Temperature during Face Milling Inconel 718. Int. J. Adv. Manuf. Technol. 2022, 122, 729–740. [Google Scholar] [CrossRef]

- Chang, H.; Gao, F.; Li, Y.; Wei, X.; Gao, C.; Chang, L. An Optimized VMD Method for Predicting Milling Cutter Wear Using Vibration Signal. Machines 2022, 10, 548. [Google Scholar] [CrossRef]

- Hoier, P.; Malakizadi, A.; Friebe, S.; Klement, U.; Krajnik, P. Microstructural Variations in 316L Austenitic Stainless Steel and Their Influence on Tool Wear in Machining. Wear 2019, 428, 315–327. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Wojciechowski, S.; Sharma, V.S.; Gupta, M.K.; Kuntoğlu, M. Artificial Intelligence Systems for Tool Condition Monitoring in Machining: Analysis and Critical Review. J. Intell. Manuf. 2023, 34, 2079–2121. [Google Scholar] [CrossRef]

- Cheng, Y.; Guan, R.; Jin, Y.; Gai, X.; Lu, M.; Ding, Y. Research on Intelligent Tool Condition Monitoring Based on Data-Driven: A Review. J. Mech. Sci. Technol. 2023, 37, 3721–3738. [Google Scholar] [CrossRef]

- Lukyanov, A.A.; Grigoriev, S.N.; Bobrovskij, I.N.; Melnikov, P.A.; Bobrovskij, N.M. Optical Method for Monitoring Tool Control for Green Burnishing with Using of Algorithms with Adaptive Settings. In Proceedings of the All-Russian Research-to-Practice Conference Ecology and Safety in the Technosphere, Yurga, Russia, 6–7 March 2017; IoP Publishing Ltd.: Bristol, UK, 2017; Volume 66, p. 012020. [Google Scholar]

- Dutta, S.; Kanwat, A.; Pal, S.K.; Sen, R. Correlation Study of Tool Flank Wear with Machined Surface Texture in End Milling. Measurement 2013, 46, 4249–4260. [Google Scholar] [CrossRef]

- Qin, A.; Guo, L.; You, Z.; Gao, H.; Wu, X.; Xiang, S. Research on Automatic Monitoring Method of Face Milling Cutter Wear Based on Dynamic Image Sequence. Int. J. Adv. Manuf. Technol. 2020, 110, 3365–3376. [Google Scholar] [CrossRef]

- Cheng, Y.; Gai, X.; Guan, R.; Jin, Y.; Lu, M.; Ding, Y. Tool Wear Intelligent Monitoring Techniques in Cutting: A Review. J. Mech. Sci. Technol. 2023, 37, 289–303. [Google Scholar] [CrossRef]

- Dutta, S.; Pal, S.K.; Mukhopadhyay, S.; Sen, R. Application of Digital Image Processing in Tool Condition Monitoring: A Review. CIRP J. Manuf. Sci. Technol. 2013, 6, 212–232. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Yue, C.; Liang, S.Y.; Wang, L. Systematic Review on Tool Breakage Monitoring Techniques in Machining Operations. Int. J. Mach. Tools Manuf. 2022, 176, 103882. [Google Scholar] [CrossRef]

- Kuram, E.; Ozcelik, B. Micro-Milling Performance of AISI 304 Stainless Steel Using Taguchi Method and Fuzzy Logic Modelling. J. Intell. Manuf. 2016, 27, 817–830. [Google Scholar] [CrossRef]

- Wang, G.; Guo, Z.; Qian, L. Tool Wear Prediction Considering Uncovered Data Based on Partial Least Square Regression. J. Mech. Sci. Technol. 2014, 28, 317–322. [Google Scholar] [CrossRef]

- Zhang, B.; Shin, Y.C. A Multimodal Intelligent Monitoring System for Turning Processes. J. Manuf. Process. 2018, 35, 547–558. [Google Scholar] [CrossRef]

- Caggiano, A. Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition. Sensors 2018, 18, 823. [Google Scholar] [CrossRef]

- Zhu, K.; Mei, T.; Ye, D. Online Condition Monitoring in Micromilling: A Force Waveform Shape Analysis Approach. IEEE Trans. Ind. Electron. 2015, 62, 3806–3813. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of Machine Learning to Machine Fault Diagnosis: A Review and Roadmap. Mech. Syst. Signal Process. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Karpatne, A.; Atluri, G.; Faghmous, J.H.; Steinbach, M.; Banerjee, A.; Ganguly, A.; Shekhar, S.; Samatova, N.; Kumar, V. Theory-Guided Data Science: A New Paradigm for Scientific Discovery from Data. IEEE Trans. Knowl. Data Eng. 2017, 29, 2318–2331. [Google Scholar] [CrossRef]

- Muther, T.; Dahaghi, A.K.; Syed, F.I.; Van Pham, V. Physical Laws Meet Machine Intelligence: Current Developments and Future Directions. Artif. Intell. Rev. 2023, 56, 6947–7013. [Google Scholar] [CrossRef]

- Willard, J.; Jia, X.; Xu, S.; Steinbach, M.; Kumar, V. Integrating Scientific Knowledge with Machine Learning for Engineering and Environmental Systems. ACM Comput. Surv. 2023, 55, 66. [Google Scholar] [CrossRef]

- de Leon, M.A.L.; Kolarik, J.; Byrtus, R.; Koziorek, J.; Zmij, P.; Martinek, R. Tool Condition Monitoring Methods Applicable in the Metalworking Process. Arch. Comput. Methods Eng. 2024, 31, 221–242. [Google Scholar] [CrossRef]

- Kramer, B. Tribological Aspects of Metal-Cutting. J. Eng. Ind.-Trans. ASME 1993, 115, 372–376. [Google Scholar] [CrossRef]

- Yang, B.; Wang, M.; Liu, Z.; Che, C.; Zan, T.; Gao, X.; Gao, P. Tool Wear Process Monitoring by Damping Behavior of Cutting Vibration for Milling Process. J. Manuf. Process. 2023, 102, 1069–1084. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, L. Tool Wear and Its Effect on the Surface Integrity in the Machining of Fibre-Reinforced Polymer Composites. Compos. Struct. 2018, 188, 257–265. [Google Scholar] [CrossRef]

- Deng, B.; Peng, F.; Zhou, L.; Wang, H.; Yang, M.; Yan, R. A Comprehensive Study on Flank Wear Progression of Polycrystalline Diamond Micro-Tool during Micro End-Milling of SiCp/Al Composites. Wear 2020, 456, 203291. [Google Scholar] [CrossRef]

- Liu, G.-J.; Zhou, Z.-C.; Qian, X.; Pang, W.-H.; Li, G.-H.; Tan, G.-Y. Wear Mechanism of Cemented Carbide Tool in High Speed Milling of Stainless Steel. Chin. J. Mech. Eng. 2018, 31, 98. [Google Scholar] [CrossRef]

- Gubbels, G.P.H.; van der Beek, G.; Hoep, A.L.; Delbressine, F.L.M.; van Halewijn, H. Diamond Tool Wear When Cutting Amorphous Polymers. CIRP Ann.-Manuf. Technol. 2004, 53, 447–450. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, G.; Cheng, X.; Xu, R.; Zhao, G.; Tian, Y. Fractal Characteristics of Chip Morphology and Tool Wear in High-Speed Turning of Iron-Based Super Alloy. Materials 2020, 13, 1020. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, J.; Chen, H.; Xiao, G.; Chen, Z.; Yi, M.; Xu, C.; Fan, L.; Li, G. Analysis of Tool Wear of TiAlN Coated Tool, Machined Surface Morphology and Chip during Titanium Alloy Milling. Tribol. Int. 2024, 197, 109751. [Google Scholar] [CrossRef]

- Shukla, B.; Singhal, S.; Singh, D. Wear Study Under Plastic-Deformation Conditions. Wear 1994, 172, 185–190. [Google Scholar] [CrossRef]

- Zhang, J.; Li, R.; Yang, H.; Qing, Z.; Chen, S. Tool Wear Characteristics of Interrupted-Cutting Zr-Based Bulk Metallic Glasses with Cemented Carbide Tool. Int. J. Adv. Manuf. Technol. 2024, 133, 2623–2637. [Google Scholar] [CrossRef]

- Stephenson, D.A.; Agapiou, J.S. Metal Cutting Theory and Practice. J. Pet. Sci. Eng. 2006, 16, 315–316. [Google Scholar] [CrossRef]

- Haber, R.E.; Jiménez, J.E.; Peres, C.R.; Alique, J.R. An Investigation of Tool-Wear Monitoring in a High-Speed Machining Process. Sens. Actuators Phys. 2004, 116, 539–545. [Google Scholar] [CrossRef]

- Wright, P.K.; Bagchi, A. Wear Mechanisms That Dominate Tool-Life in Machining. J. Appl. Metalwork. 2008, 1, 15–23. [Google Scholar] [CrossRef]

- Wang, R.; Yang, D.; Wang, W.; Wei, F.; Lu, Y.; Li, Y. Tool Wear in Nickel-Based Superalloy Machining: An Overview. Processes 2022, 10, 2380. [Google Scholar] [CrossRef]

- Suh, N.P. New Theories of Wear and Their Implications for Tool Materials. Wear 1980, 62, 1–20. [Google Scholar] [CrossRef]

- Oyane, M.; Shima, S.; Goto, Y.; Nakayama, T. New Wear Tests of Tool Materials for Metal-Forming. Wear 1984, 100, 119–128. [Google Scholar] [CrossRef]

- Soderberg, S.; Hogmark, S. Wear Mechanisms and Tool Life of High-Speed Steels Related to Microstructure. Wear 1986, 110, 315–329. [Google Scholar] [CrossRef]

- Sakuma, K.; Seto, M. The Relation Between Fiber Orientation and Tool Wear—Tool Wear in Cutting Glass-Fiber-Reinforced Plastics. Bull. JSME-Jpn. Soc. Mech. Eng. 1983, 26, 1420–1427. [Google Scholar] [CrossRef][Green Version]

- Venkatesh, V. Tool Wear Investigations on Some Cutting-Tool Materials. J. Lubr. Technol.-Trans. ASME 1980, 102, 556–559. [Google Scholar] [CrossRef]

- Hao, Z.; Gao, D.; Fan, Y.; Han, R. New Observations on Tool Wear Mechanism in Dry Machining Inconel718. Int. J. Mach. Tools Manuf. 2011, 51, 973–979. [Google Scholar] [CrossRef]

- Liang, J.; Gao, H.; Xiang, S.; Chen, L.; You, Z.; Lei, Y. Research on Tool Wear Morphology and Mechanism during Turning Nickel-Based Alloy GH4169 with PVD-TiAlN Coated Carbide Tool. Wear 2022, 508–509, 204468. [Google Scholar] [CrossRef]

- Wang, Y.; Zou, B.; Huang, C. Tool Wear Mechanisms and Micro-Channels Quality in Micro-Machining of Ti-6Al-4V Alloy Using the Ti(C7N3)-Based Cermet Micro-Mills. Tribol. Int. 2019, 134, 60–76. [Google Scholar] [CrossRef]

- Lindvall, R.; Lenrick, F.; M’Saoubi, R.; Ståhl, J.-E.; Bushlya, V. Performance and Wear Mechanisms of Uncoated Cemented Carbide Cutting Tools in Ti6Al4V Machining. Wear 2021, 477, 203824. [Google Scholar] [CrossRef]

- Cheng, Y.-N.; Ma, C.-J.; Zhang, J.-Y.; Zhou, H. Analysis on Wear Patterns and Mechanisms of Carbide Tool for Face-Hobbing of Spiral Bevel Gear. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2023, 237, 925–936. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, B.; Guo, K.; Liu, J.; Sun, J.; Song, G.; Zhu, S.; Sun, C.; Jiang, Z. Vibration Singularity Analysis for Milling Tool Condition Monitoring. Int. J. Mech. Sci. 2020, 166, 105254. [Google Scholar] [CrossRef]

- Li, X.; Low, I. Evaluation of Advanced Alumina-Based Ceramic Tool Inserts When Machining High-Tensile Steel. J. Mater. Sci. 1994, 29, 3121–3127. [Google Scholar] [CrossRef]

- Tipnis, V.; Joseph, R. Study of Pulnge (or Form) Machining of Low-Carbon Resulfurized Steel on a Multispindle Automatic Screw Machine: Part 2 Influence of Speed, Feed, and Duration of Cutting on Worn Tool Geometry. J. Eng. Ind. 1971, 93, 571–585. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of Signal Behaviors for Sensor Fusion with Tool Condition Monitoring System in Turning. Measurement 2021, 173, 108582. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Sağlam, H.; Pimenov, D.Y.; Giasin, K.; Mikolajczyk, T. Optimization and Analysis of Surface Roughness, Flank Wear and 5 Different Sensorial Data via Tool Condition Monitoring System in Turning of AISI 5140. Sensors 2020, 20, 4377. [Google Scholar] [CrossRef]

- Liu, E.; Wang, R.; Zhang, Y.; An, W. Tool Wear Analysis of Cutting Ti-5553 with Uncoated Carbide Tool under Liquid Nitrogen Cooling Condition Using Tool Wear Maps. J. Manuf. Process. 2021, 68, 877–887. [Google Scholar] [CrossRef]

- Li, W.; Zhou, B.; Xing, L.; He, H.; Ni, X.; Li, M.; Gong, Z. Influence of Cutting Parameters and Tool Nose Radius on the Wear Behavior of Coated Carbide Tool When Turning Austenitic Stainless Steel. Mater. Today Commun. 2023, 37, 107349. [Google Scholar] [CrossRef]

- Palanikumar, K.; Davim, J.P. Mathematical Model to Predict Tool Wear on the Machining of Glass Fibre Reinforced Plastic Composites. Mater. Des. 2007, 28, 2008–2014. [Google Scholar] [CrossRef]

- Hao, Z.-P.; Lu, Y.; Gao, D.; Fan, Y.-H.; Chang, Y.-L. Cutting Parameter Optimization Based on Optimal Cutting Temperature in Machining Inconel718. Mater. Manuf. Process. 2012, 27, 1084–1089. [Google Scholar] [CrossRef]

- Suresh, R.; Joshi, A.G.; Manjaiah, M. Experimental Investigation on Tool Wear in AISI H13 Die Steel Turning Using RSM and ANN Methods. Arab. J. Sci. Eng. 2021, 46, 2311–2325. [Google Scholar] [CrossRef]

- Kadirgama, K.; Abou-El-Hossein, K.A.; Noor, M.M.; Sharma, K.V.; Mohammad, B. Tool Life and Wear Mechanism When Machining Hastelloy C-22HS. Wear 2011, 270, 258–268. [Google Scholar] [CrossRef]

- Malarvannan, R.R.R.; Moorthy, T.V.; Hariharan, P.; Prabhu, P. Investigation on HSS Single Point Cutting Tool Manufactured Using Physical Vapor Deposition Coating Process. Indian J. Eng. Mater. Sci. 2016, 23, 129–133. [Google Scholar]

- Mohanty, A.; Gangopadhyay, S.; Thakur, A. On Applicability of Multilayer Coated Tool in Dry Machining of Aerospace Grade Stainless Steel. Mater. Manuf. Process. 2016, 31, 869–879. [Google Scholar] [CrossRef]

- Bian, R.; Ferraris, E.; Qian, J.; Reynaerts, D.; Li, L.; He, N. Tool Wear Characters in Micro-Milling of Fully Sintered ZrO2 Ceramics by Diamond Coated End Mills. In Proceedings of the High Speed Machining V, Jinan, China, 15–16 August 2012; Liu, Z.Q., Wan, Y., Song, Q.H., Shi, Z.Y., Eds.; Trans Tech Publications Ltd.: Durnten, Switzerland, 2012; Volume 723, pp. 365–370. [Google Scholar]

- Varis, T.; Lagerbom, J.; Suhonen, T.; Raami, L.; Terho, S.; Laurila, J.; Peura, P.; Vuoristo, P. Effect of Heat Treatments on the Wear Resistance of HVAF and HVOF Sprayed Tool Steel Coatings. Surf. Coat. Technol. 2023, 462, 129508. [Google Scholar] [CrossRef]

- Chou, Y.K.; Liu, J. Ion Implantation of Superhard Ceramic Cutting Tools. J. Mater. Eng. Perform. 2004, 13, 398–405. [Google Scholar] [CrossRef]

- Morozow, D.; Siemiatkowski, Z.; Gevorkyan, E.; Rucki, M.; Matijosius, J.; Kilikevicius, A.; Caban, J.; Krzysiak, Z. Effect of Yttrium and Rhenium Ion Implantation on the Performance of Nitride Ceramic Cutting Tools. Materials 2020, 13, 4687. [Google Scholar] [CrossRef] [PubMed]

- Sheleg, V.K.; Levantsevich, M.A.; Maksimchenko, N.N.; Pilipchuk, E.; Yurut, E.L.; Kalach, V.N. Evaluating the Applicability of Electrodeformation Placing Technology by a Flexible Tool for Chromeing Hydrocilindes. J. Frict. Wear 2019, 40, 207–212. [Google Scholar] [CrossRef]

- Santos, S.C.; Sales, W.F.; da Silva, F.J.; Franco, S.D.; da Silva, M.B. Tribological Characterisation of PVD Coatings for Cutting Tools. Surf. Coat. Technol. 2004, 184, 141–148. [Google Scholar] [CrossRef]

- Lewis, D.B.; Bradbury, S.R.; Sarwar, M. The Effect of Substrate Surface Preparation on the Wear and Failure Modes of TiN Coated High Speed Steel Circular Saw Blades. Wear 1996, 197, 82–88. [Google Scholar] [CrossRef]

- Leyendecker, A.; Lemmer, O.; Esser, S. A New Coating Process Integrated in an Innovative Coating System for Production of Well-Adherent Diamond Coatings. Int. J. Refract. Met. Hard Mater. 1998, 16, 187–190. [Google Scholar] [CrossRef]

- Foxrabinovich, G. Structure of Complex Coatings. Wear 1993, 160, 67–76. [Google Scholar] [CrossRef]

- Sokovic, M. Model of Improvement of Cermet Tool Performance by TiN (PVD) Coating. Stroj. Vestn.-J. Mech. Eng. 1997, 43, 129–136. [Google Scholar]

- Lee, M.; Koch, E.F.; Hale, T.E. A Study of the Coating-Substrate Interface Layer of an Al2O3-Coated Cemented Carbide Cutting Tool. Int. J. Refract. Met. Hard Mater. 1996, 14, 335–343. [Google Scholar] [CrossRef]

- Prengel, H.; Heinrich, W.; Roder, G.; Wendt, K. Cvd Coatings Based on Medium-Temperature Cvd Kappa-Al2O3 and Alpha-Al2O3. Surf. Coat. Technol. 1994, 68, 217–220. [Google Scholar] [CrossRef]

- Hao, T.; Du, J.; Su, G.; Zhang, P.; Sun, Y.; Zhang, J. Mechanical and Cutting Performance of Cemented Carbide Tools with Cr/x/DLC Composite Coatings. Int. J. Adv. Manuf. Technol. 2020, 106, 5241–5254. [Google Scholar] [CrossRef]

- Khan, S.A.; Ferreira, F.; Oliveira, J.; Emami, N.; Ramalho, A. A Comparative Study in the Tribological Behaviour of Different DLC Coatings Sliding against Titanium Alloys. Wear 2024, 554, 205468. [Google Scholar] [CrossRef]

- Cakir, F.H.; Yilmaz, A.; Sert, Z. Evaluation of the Performance of DLC Coatings (Ta-C) of WC-Co Tools While Machining Al7075 Alloy. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2024, 238, 09544062241237425. [Google Scholar] [CrossRef]

- Valleti, K.; Miryalkar, P.; Krishna, L.R. Efficacy of TiCrN/DLC Coatings for Service Life Enhancement of Stamping Dies. Vacuum 2023, 217, 112534. [Google Scholar] [CrossRef]

- McMaster, S.J.; Kosarieh, S.; Liskiewicz, T.W.; Neville, A.; Beake, B.D. Utilising H/E to Predict Fretting Wear Performance of DLC Coating Systems. Tribol. Int. 2023, 185, 108524. [Google Scholar] [CrossRef]

- Chenrayan, V.; Manivannan, C.; Shahapurkar, K.; Krishna, A.; Tirth, V.; Algahtani, A.; Alarifi, I.M. Machinability Performance Investigation of TiAlN-, DLC-, and CNT-Coated Tools during Turning of Difficult-to-Cut Materials. J. Nanomater. 2022, 2022, 9664365. [Google Scholar] [CrossRef]

- Li, L.; Xu, J.; Guo, G.; Gupta, M.K.; Chen, M. Wear Behavior of Different Coated Tools in MQL-Assisted Milling of Magnesium-Based Rare-Earth Alloys. J. Mater. Res. Technol.-JMRT 2023, 27, 1665–1682. [Google Scholar] [CrossRef]

- Rakesh, P.R.; Chakradhar, D. Machining Performance Comparison of Inconel 625 Superalloy under Sustainable Machining Environments. J. Manuf. Process. 2023, 85, 742–755. [Google Scholar] [CrossRef]

- Das, A.; Mundu, A.R.S.; Bajpai, V. Enhancing Tribological Performance of Lead Free Brass in High Speed Micro Turning via Hybrid Cryogenic Cooling Technique. Tribol. Int. 2023, 179, 108090. [Google Scholar] [CrossRef]

- Meng, F.; Ding, Z.; Meng, X.; Ai, X.; Zhang, Z.; Ma, W.; Boyjoo, Y.; Wang, K. Research on Different Cooling Methods in the Machining of CGI and GCI. Appl. Nanosci. 2020, 10, 2177–2188. [Google Scholar] [CrossRef]

- Junankar, A.A.; Purohit, J.K.; Sayed, A.R. Minimum Quantity Lubrication System for Metal-Cutting Process: Sustainable Manufacturing Process. Mater. Today Proc. 2019, 18, 5264–5269. [Google Scholar] [CrossRef]

- Jerold, B.D.; Kumar, M.P. Experimental Comparison of Carbon-Dioxide and Liquid Nitrogen Cryogenic Coolants in Turning of AISI 1045 Steel. Cryogenics 2012, 52, 569–574. [Google Scholar] [CrossRef]

- Lin, G.; Shi, H.; Liu, X.; Wang, Z.; Zhang, H.; Zhang, J. Tool Wear on Machining of Difficult-to-Machine Materials: A Review. Int. J. Adv. Manuf. Technol. 2024, 134, 989–1014. [Google Scholar] [CrossRef]

- Marousi, M.; Rimpault, X.; Turenne, S.; Balazinski, M. Initial Tool Wear and Process Monitoring during Titanium Metal Matrix Composite Machining (TiMMC). J. Manuf. Process. 2023, 86, 208–220. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Gläbe, R. Advances in Precision Machining of Steel. CIRP Ann.-Manuf. Technol. 2001, 50, 385–388. [Google Scholar] [CrossRef]

- Liu, C.; Ai, X.; Liu, Z. Experimental Study on Wear Mechanism of Cutting Tool and Cutting Temperature in High Speed Machining Superalloy. In Digital Design and Manufacturing Technology, Pts 1 and 2; Chai, G.Z., Lu, C.D., Wen, D.H., Eds.; Trans Tech Publications Ltd.: Stafa, Switzerland, 2010; Volume 102–104, pp. 525–528. [Google Scholar]

- Wang, Y.; Zou, B.; Yin, G. Wear Mechanisms of Ti(C7N3)-Based Cermet Micro-Drill and Machining Quality during Ultra-High Speed Micro-Drilling Multi-Layered PCB Consisting of Copper Foil and Glass Fiber Reinforced Plastics. Ceram. Int. 2019, 45, 24578–24593. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Han, L.; Wei, Q.; Deng, J.; Gao, Y. Experimental Study on Tool Wear in Milling CFRP/Ti Laminated Materials with Diamond Coated Unit Edge Tool. Ferroelectrics 2022, 594, 166–174. [Google Scholar] [CrossRef]

- Saha, S.; Deb, S.; Bandyopadhyay, P.P. Precise Measurement of Worn-out Tool Diameter Using Cutting Edge Features during Progressive Wear Analysis in Micro-Milling. Wear 2022, 488–489, 204169. [Google Scholar] [CrossRef]

- Wang, X.; Kwona, P.Y.; Sturtevant, C.; Kim, D.; Lantrip, J. Tool Wear of Coated Drills in Drilling CFRP. J. Manuf. Process. 2013, 15, 127–135. [Google Scholar] [CrossRef]

- van der Heide, E.; Burlat, M.; Bolt, P.J.; Schipper, D.J. Wear of Soft Tool Materials in Sliding Contact with Zinc-Coated Steel Sheet. J. Mater. Process. Technol. 2003, 141, 197–201. [Google Scholar] [CrossRef]

- Zhang, B.; Sui, T.; Lin, B.; Zheng, W.; Li, S.; Fang, S.; Huang, Y.; Feng, Y. Drilling Process of Cf/SiC Ceramic Matrix Composites: Cutting Force Modeling, Machining Quality and PCD Tool Wear Analysis. J. Mater. Process. Technol. 2022, 304, 117566. [Google Scholar] [CrossRef]

- Amigo, F.J.; Urbikain, G.; López de Lacalle, L.N.; Pereira, O.; Fernández-Lucio, P.; Fernández-Valdivielso, A. Prediction of Cutting Forces Including Tool Wear in High-Feed Turning of Nimonic® C-263 Superalloy: A Geometric Distortion-Based Model. Measurement 2023, 211, 112580. [Google Scholar] [CrossRef]

- Thornton, A.; Wilks, J. Clean Surface-Reactions Between Diamond and Steel. Nature 1978, 274, 792–793. [Google Scholar] [CrossRef]

- Liu, W.; Li, A.; Wu, H.; Long, Y.; Huang, J.; Deng, X.; Wang, C.; Wang, Q.; Wu, S. Effects of Gas Pressure on Microstructure and Performance of (Ti, Al, Zr) N Coatings Produced by Physical Vapor Deposition. Ceram. Int. 2016, 42, 17436–17441. [Google Scholar] [CrossRef]

- Guan, H.; Zhong, Y.; Zou, W.; Sun, P.; Zhai, J.; Qu, S. Research on the Electric-Pulse-Assisted Turning Behavior of TC27 Alloy. Metals 2023, 13, 702. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, G.; Liu, J.; Wei, H.; Huang, J. Effect of Pulse Current Parameters on Electroplastically Assisted Dry Cutting Performance of W93NiFe Alloy. Int. J. Adv. Manuf. Technol. 2024, 131, 2123–2131. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, M.; Guo, X.; Zhang, K. Improving the Frictional Properties of the Tool/Chip Interface of Micro-Textured Ceramics Tools by Using Electromagnetic-Assisted Nanofluids. Mater. Today Commun. 2024, 39, 109017. [Google Scholar] [CrossRef]

- Taylor, F.W. On the Art of Cutting Metals. J. Fluids Eng. Trans. ASME 1906, 28, 31–58. [Google Scholar] [CrossRef]

- Wang, H.-P.; Wysk, R.A. An Expert System for Machining Data Section. Comput. Ind. Eng. 1986, 10, 99–107. [Google Scholar] [CrossRef]

- Venkatech, V.C. Computerized Machinability Data. In Proceedings of the Automach Australia 86 Conference Proceedings, Sydney, Australia, 26–29 May 1986; pp. 1/59–73. [Google Scholar]

- Kovac, P.; Gostimirovic, M.; Rodic, D.; Savkovic, B. Using the Temperature Method for the Prediction of Tool Life in Sustainable Production. Measurement 2019, 133, 320–327. [Google Scholar] [CrossRef]

- Quinto, D.T. Mechanical Property and Structure Relationships in Hard Coated Carbide Tools. Met. Technol. 1988, 9, 60–75. [Google Scholar]

- Lau, W.S.; Venuvinod, P.K.; Rubenstein, C. The Relation between Tool Geometry and the Taylor Tool Life Constant. Int. J. Mach. Tool Des. Res. 1980, 20, 29–44. [Google Scholar] [CrossRef]

- Palmai, Z. A Model of Non-Linear Cumulative Damage to Tools at Changing Cutting Speeds. Int. J. Adv. Manuf. Technol. 2014, 74, 973–982. [Google Scholar] [CrossRef]

- Lee, Y.J.; Yoon, H.-S. Modeling of Cutting Tool Life with Power Consumption Using Taylor’s Equation. J. Mech. Sci. Technol. 2023, 37, 3077–3085. [Google Scholar] [CrossRef]

- Marksberry, P.W.; Jawahir, I.S. A Comprehensive Tool-Wear/Tool-Life Performance Model in the Evaluation of NDM (near Dry Machining) for Sustainable Manufacturing. Int. J. Mach. Tools Manuf. 2008, 48, 878–886. [Google Scholar] [CrossRef]

- Hoffman, E.G. Fundamentals of Tool Design; Society of Manufacturing Engineers: Southfield, MI, USA, 1984. [Google Scholar]

- Liang, S.Y. Manufacturing Processes and Equipment. Mach. Sci. Technol. 2000, 4, 317–318. [Google Scholar] [CrossRef]

- Galante, G.; Lombardo, A.; Passannanti, A. Tool-Life Modelling as a Stochastic Process. Int. J. Mach. Tools Manuf. 1998, 38, 1361–1369. [Google Scholar] [CrossRef]

- Lin, J.T.; Bhattacharyya, D.; Lane, C. Machinability of a Silicon Carbide Reinforced Aluminium Metal Matrix Composite. Wear 1995, 181, 883–888. [Google Scholar] [CrossRef]

- Iyer, K.S.S.; Ukhidave, V.H. Tool Life with Speed and Time Dependent Failures. Comput. Ind. 1981, 2, 141–145. [Google Scholar] [CrossRef]

- John, R.; Lin, R.; Jayaraman, K.; Bhattacharyya, D. Modified Taylor’s Equation Including the Effects of Fiber Characteristics on Tool Wear When Machining Natural Fiber Composites. Wear 2021, 468–469, 203606. [Google Scholar] [CrossRef]

- Timata, M.; Saikaew, C. Experimental and Simulation Study on Tool Life Models in Drilling of Forging Brass Using Uncoated-WC and AlCrN Coated-WC Tools. Coatings 2019, 9, 853. [Google Scholar] [CrossRef]

- dos Santos, A.G.; da Silva, M.B.; Jackson, M.J. Tungsten Carbide Micro-Tool Wear When Micro Milling UNS S32205 Duplex Stainless Steel. Wear 2018, 414–415, 109–117. [Google Scholar] [CrossRef]

- Chen, J.; Liu, W.; Deng, X.; Wu, S. Tool Life and Wear Mechanism of WC–5TiC–0.5VC–8Co Cemented Carbides Inserts When Machining HT250 Gray Cast Iron. Ceram. Int. 2016, 42, 10037–10044. [Google Scholar] [CrossRef]

- Songmene, V.; Zaghbani, I.; Kientzy, G. Machining and Machinability of Tool Steels: Effects of Lubrication and Machining Conditions on Tool Wear and Tool Life Data. Procedia CIRP 2018, 77, 505–508. [Google Scholar] [CrossRef]

- Karandikar, J.M.; Abbas, A.E.; Schmitz, T.L. Tool Life Prediction Using Bayesian Updating. Part 2: Turning Tool Life Using a Markov Chain Monte Carlo Approach. Precis. Eng. 2014, 38, 18–27. [Google Scholar] [CrossRef]

- Ginting, A.; Nouari, M. Optimal Cutting Conditions When Dry End Milling the Aeroengine Material Ti–6242S. J. Mater. Process. Technol. 2007, 184, 319–324. [Google Scholar] [CrossRef]

- Poulachon, G.; Moisan, A.; Jawahir, I.S. Tool-Wear Mechanisms in Hard Turning with Polycrystalline Cubic Boron Nitride Tools. Wear 2001, 250, 576–586. [Google Scholar] [CrossRef]

- Lubis, M.S.Y.; Djamil, S.; Steven, D. Andri Tool Life Investigation of Carbide Cutting Tools in the Turning of Cast Iron Material. IOP Conf. Ser. Mater. Sci. Eng. 2020, 725, 012039. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Lee, H.C.; Lee, Y.; Lee, S.Y.; Choi, S.; Lee, D.L.; Im, Y.T. Tool Life Prediction for the Bolt Forming Process Based on High-Cycle Fatigue and Wear. J. Mater. Process. Technol. 2008, 201, 348–353. [Google Scholar] [CrossRef]

- Choudhury, S.K.; Rath, S. In-Process Tool Wear Estimation in Milling Using Cutting Force Model. J. Mater. Process. Technol. 2000, 99, 113–119. [Google Scholar] [CrossRef]

- Shao, H.; Wang, H.L.; Zhao, X.M. A Cutting Power Model for Tool Wear Monitoring in Milling. Int. J. Mach. Tools Manuf. 2004, 44, 1503–1509. [Google Scholar] [CrossRef]

- Dai, X.; Gao, Z. From Model, Signal to Knowledge: A Data-Driven Perspective of Fault Detection and Diagnosis. IEEE Trans. Ind. Inform. 2013, 9, 2226–2238. [Google Scholar] [CrossRef]

- Li, S.; Ling, Z.; Zhu, K. Image Super Resolution by Double Dictionary Learning and Its Application to Tool Wear Monitoring in Micro Milling. Mech. Syst. Signal Process. 2024, 206, 110917. [Google Scholar] [CrossRef]

- Ferrando Chacón, J.L.; Fernández de Barrena, T.; García, A.; Sáez de Buruaga, M.; Badiola, X.; Vicente, J. A Novel Machine Learning-Based Methodology for Tool Wear Prediction Using Acoustic Emission Signals. Sensors 2021, 21, 5984. [Google Scholar] [CrossRef] [PubMed]

- Herwan, J.; Misaka, T.; Furukawa, Y.; Ogura, I.; Komoto, H. A Proposal for Improving Production Efficiency of Existing Machining Line through a Hybrid Monitoring and Optimisation Process. Int. J. Prod. Res. 2023, 61, 5392–5410. [Google Scholar] [CrossRef]

- Gittler, T.; Glasder, M.; Ozturk, E.; Luthi, M.; Weiss, L.; Wegener, K. International Conference on Advanced and Competitive Manufacturing Technologies Milling Tool Wear Prediction Using Unsupervised Machine Learning. Int. J. Adv. Manuf. Technol. 2021, 117, 2213–2226. [Google Scholar] [CrossRef]

- Abdeltawab, A.; Xi, Z.; Zhang, L. Tool Wear Classification Based on Maximal Overlap Discrete Wavelet Transform and Hybrid Deep Learning Model. Int. J. Adv. Manuf. Technol. 2024, 130, 2443–2456. [Google Scholar] [CrossRef]

- Chittam, S.; Gokaraju, B.; Xu, Z.; Sankar, J.; Roy, K. Big Data Mining and Classification of Intelligent Material Science Data Using Machine Learning. Appl. Sci. 2021, 11, 8596. [Google Scholar] [CrossRef]

- Sortino, M. Application of Statistical Filtering for Optical Detection of Tool Wear. Int. J. Mach. Tools Manuf. 2003, 43, 493–497. [Google Scholar] [CrossRef]

- Datta, A.; Dutta, S.; Pal, S.K.; Sen, R. Progressive Cutting Tool Wear Detection from Machined Surface Images Using Voronoi Tessellation Method. J. Mater. Process. Technol. 2013, 213, 2339–2349. [Google Scholar] [CrossRef]

- Sarat Babu, M.; Babu Rao, T. Multi-Sensor Heterogeneous Data-Based Online Tool Health Monitoring in Milling of IN718 Superalloy Using OGM (1, N) Model and SVM. Measurement 2022, 199, 111501. [Google Scholar] [CrossRef]

- Mabe, J.; Zubia, J.; Gorritxategi, E. Photonic Low Cost Micro-Sensor for in-Line Wear Particle Detection in Flowing Lube Oils. Sensors 2017, 17, 586. [Google Scholar] [CrossRef] [PubMed]

- Jywe, W.-Y.; Hsieh, T.-H.; Chen, P.-Y.; Wang, M.-S.; Lin, Y.-T. Evaluation of Tool Scraping Wear Conditions by Image Pattern Recognition System. Int. J. Adv. Manuf. Technol. 2019, 105, 1791–1799. [Google Scholar] [CrossRef]

- Babu, M.S.; Rao, T.B. An in-process tool wear assessment using Bayesian optimized machine learning algorithm. Int. J. Interact. Des. Manuf. 2023, 17, 1823–1845. [Google Scholar] [CrossRef]

- Bagga, P.J.; Makhesana, M.A.; Patel, K.M. A novel approach of combined edge detection and segmentation for tool wear measurement in machining. Prod. Eng. Res. Dev. 2021, 15, 519–533. [Google Scholar] [CrossRef]

- Jang, W.-K.; Kim, D.-W.; Seo, Y.-H.; Kim, B.-H. Tool-Wear-Estimation System in Milling Using Multi-View CNN Based on Reflected Infrared Images. Sensors 2023, 23, 1208. [Google Scholar] [CrossRef]

- Brili, N.; Ficko, M.; Klancnik, S. Tool Condition Monitoring of the Cutting Capability of a Turning Tool Based on Thermography. Sensors 2021, 21, 6687. [Google Scholar] [CrossRef]

- Brili, N.; Ficko, M.; Klancnik, S. Automatic Identification of Tool Wear Based on Thermography and a Convolutional Neural Network during the Turning Process. Sensors 2021, 21, 1917. [Google Scholar] [CrossRef]

- Dai, Y.; Zhu, K. A Machine Vision System for Micro-Milling Tool Condition Monitoring. Precis. Eng. 2018, 52, 183–191. [Google Scholar] [CrossRef]

- Wu, X.; Liu, Y.; Zhou, X.; Mou, A. Automatic Identification of Tool Wear Based on Convolutional Neural Network in Face Milling Process. Sensors 2019, 19, 3817. [Google Scholar] [CrossRef]

- Hou, Q.; Sun, J.; Lv, Z.; Huang, P.; Song, G.; Sun, C. An Online Tool Wear Detection System in Dry Milling Based on Machine Vision. Int. J. Adv. Manuf. Technol. 2019, 105, 1801–1810. [Google Scholar] [CrossRef]

- Loizou, J.; Tian, W.; Robertson, J.; Camelio, J. Automated Wear Characterization for Broaching Tools Based on Machine Vision Systems. J. Manuf. Syst. 2015, 37, 558–563. [Google Scholar] [CrossRef]

- García-Ordás, M.T.; Alegre-Gutiérrez, E.; Alaiz-Rodríguez, R.; González-Castro, V. Tool Wear Monitoring Using an Online, Automatic and Low Cost System Based on Local Texture. Mech. Syst. Signal Process. 2018, 112, 98–112. [Google Scholar] [CrossRef]

- Shahabi, H.H.; Ratnam, M.M. Assessment of Flank Wear and Nose Radius Wear from Workpiece Roughness Profile in Turning Operation Using Machine Vision. Int. J. Adv. Manuf. Technol. 2009, 43, 11–21. [Google Scholar] [CrossRef]

- Liang, Y.-T.; Chiou, Y.-C. An Effective Drilling Wear Measurement Based on Visual Inspection Technique; Atlantis Press: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Bhat, N.N.; Dutta, S.; Vashisth, T.; Pal, S.; Pal, S.K.; Sen, R. Tool Condition Monitoring by SVM Classification of Machined Surface Images in Turning. Int. J. Adv. Manuf. Technol. 2016, 83, 1487–1502. [Google Scholar] [CrossRef]

- Li, L.; An, Q. An In-Depth Study of Tool Wear Monitoring Technique Based on Image Segmentation and Texture Analysis. Measurement 2016, 79, 44–52. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Kumar Gupta, M.; da Silva, L.R.R.; Kiran, M.; Khanna, N.; Krolczyk, G.M. Application of Measurement Systems in Tool Condition Monitoring of Milling: A Review of Measurement Science Approach. Measurement 2022, 199, 111503. [Google Scholar] [CrossRef]

- Szydłowski, M.; Powałka, B.; Matuszak, M.; Kochmański, P. Machine Vision Micro-Milling Tool Wear Inspection by Image Reconstruction and Light Reflectance. Precis. Eng. 2016, 44, 236–244. [Google Scholar] [CrossRef]

- Zhu, K.; Yu, X. The Monitoring of Micro Milling Tool Wear Conditions by Wear Area Estimation. Mech. Syst. Signal Process. 2017, 93, 80–91. [Google Scholar] [CrossRef]

- You, Z.; Gao, H.; Guo, L.; Liu, Y.; Li, J. On-Line Milling Cutter Wear Monitoring in a Wide Field-of-View Camera. Wear 2020, 460–461, 203479. [Google Scholar] [CrossRef]

- Chen, M.; Li, M.; Zhao, L.; Liu, J. Tool Wear Monitoring Based on the Combination of Machine Vision and Acoustic Emission. Int. J. Adv. Manuf. Technol. 2023, 125, 3881–3897. [Google Scholar] [CrossRef]

- Zhou, C.; Guo, K.; Sun, J. An Integrated Wireless Vibration Sensing Tool Holder for Milling Tool Condition Monitoring with Singularity Analysis. Measurement 2021, 174, 109038. [Google Scholar] [CrossRef]

- Totis, G.; Sortino, M. Development of a Modular Dynamometer for Triaxial Cutting Force Measurement in Turning. Int. J. Mach. Tools Manuf. 2011, 51, 34–42. [Google Scholar] [CrossRef]

- Salonitis, K.; Kolios, A. Force-Based Reliability Estimation of Remaining Cutting Tool Life in Titanium Milling. Int. J. Adv. Manuf. Technol. 2020, 106, 3321–3333. [Google Scholar] [CrossRef]

- Dimla, D.E.; Lister, P.M. On-Line Metal Cutting Tool Condition Monitoring.: I: Force and Vibration Analyses. Int. J. Mach. Tools Manuf. 2000, 40, 739–768. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, W. Review of Tool Condition Monitoring Methods in Milling Processes. Int. J. Adv. Manuf. Technol. 2018, 96, 2509–2523. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. ANOVA and Fuzzy Rule Based Evaluation and Estimation of Flank Wear, Temperature and Acoustic Emission in Turning. CIRP J. Manuf. Sci. Technol. 2021, 35, 589–603. [Google Scholar] [CrossRef]

- Akbari, A.; Danesh, M.; Khalili, K. A Method Based on Spindle Motor Current Harmonic Distortion Measurements for Tool Wear Monitoring. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 5049–5055. [Google Scholar] [CrossRef]

- Ma, P.; Lan, X.; Tong, S.; Zheng, X.; Wang, W. The Method of Self-Learning Based Online Tool Wear Monitoring in Semi-Finishing or Finishing Working Step. Int. J. Adv. Manuf. Technol. 2023, 124, 4649–4661. [Google Scholar] [CrossRef]

- Yuan, J.; Liu, L.; Yang, Z.; Bo, J.; Zhang, Y. Tool Wear Condition Monitoring by Combining Spindle Motor Current Signal Analysis and Machined Surface Image Processing. Int. J. Adv. Manuf. Technol. 2021, 116, 2697–2709. [Google Scholar] [CrossRef]

- Schmucker, B.; Wang, C.-P.; Zaeh, M.F.; Erkorkmaz, K. Wide-Bandwidth Cutting Force Monitoring via Motor Current and Accelerometer Signals. CIRP Ann.-Manuf. Technol. 2023, 72, 309–312. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoglu, M.; Gunes, A.; Sahin, O.S. Experimental Study and Analysis of Machinability Characteristics of Metal Matrix Composites during Drilling. Compos. Part B Eng. 2019, 166, 401–413. [Google Scholar] [CrossRef]

- Bacci da Silva, M.; Wallbank, J. Cutting Temperature: Prediction and Measurement Methods—A Review. J. Mater. Process. Technol. 1999, 88, 195–202. [Google Scholar] [CrossRef]

- Wang, H.; Sun, J.; Li, J.; Lu, L.; Li, N. Evaluation of Cutting Force and Cutting Temperature in Milling Carbon Fiber-Reinforced Polymer Composites. Int. J. Adv. Manuf. Technol. 2016, 82, 1517–1525. [Google Scholar] [CrossRef]

- Li, C.; Shi, D.; Li, B.; Wang, H.; Feng, G.; Gu, F.; Ball, A.D. Modelling the Dynamics of a CNC Spindle for Tool Condition Identification Based on On-Rotor Sensing. In Proceedings of the Income-VI and Tepen 2021: Performance Engineering and Maintenance Engineering, Tianjin, China, 20–23 October 2021; Zhang, H., Feng, G., Wang, H., Gu, F., Sinha, J.K., Eds.; Springer International Publishing Ag: Cham, Switzerland, 2023; Volume 117, pp. 1057–1071. [Google Scholar]

- Li, C.; Li, B.; Wang, H.; Shi, D.; Gu, F.; Ball, A.D. Tool Wear Monitoring in CNC Milling Process Based on Vibration Signals from an On-Rotor Sensing Method. In Proceedings of the International Conference on the Efficiency and Performance Engineering Network, Qingdao, China, 29 August–1 September 2023; Zhang, H., Ji, Y., Liu, T., Sun, X., Ball, A.D., Eds.; Springer International Publishing Ag: Cham, Switzerland, 2023; Volume 129, pp. 268–281. [Google Scholar]

- Zhou, C.; Guo, K.; Zhao, Y.; Zan, Z.; Sun, J. Development and Testing of a Wireless Rotating Triaxial Vibration Measuring Tool Holder System for Milling Process. Measurement 2020, 163, 108034. [Google Scholar] [CrossRef]

- Ostasevicius, V.; Karpavicius, P.; Jurenas, V.; Cepenas, M.; Cesnavicius, R.; Eidukynas, D. Development of Universal Wireless Sensor Node for Tool Condition Monitoring in Milling. Int. J. Adv. Manuf. Technol. 2020, 110, 1015–1025. [Google Scholar] [CrossRef]

- Wang, B.; Lei, Y.; Li, N.; Wang, W. Multiscale Convolutional Attention Network for Predicting Remaining Useful Life of Machinery. IEEE Trans. Ind. Electron. 2021, 68, 7496–7504. [Google Scholar] [CrossRef]

- Wang, H.; Wang, S.; Sun, W.; Xiang, J. Multi-Sensor Signal Fusion for Tool Wear Condition Monitoring Using Denoising Transformer Auto-Encoder Resnet. J. Manuf. Process. 2024, 124, 1054–1064. [Google Scholar] [CrossRef]

- Ma, M.; Sun, C.; Chen, X.; Zhang, X.; Yan, R. A Deep Coupled Network for Health State Assessment of Cutting Tools Based on Fusion of Multisensory Signals. IEEE Trans. Ind. Inform. 2019, 15, 6415–6424. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; He, Y.; Wang, Y.; Wang, Y.; Wang, S. Deep Spatial-Temporal Feature Extraction and Lightweight Feature Fusion for Tool Condition Monitoring. IEEE Trans. Ind. Electron. 2022, 69, 7349–7359. [Google Scholar] [CrossRef]

- Gomes, M.C.; Brito, L.C.; Bacci da Silva, M.; Viana Duarte, M.A. Tool Wear Monitoring in Micromilling Using Support Vector Machine with Vibration and Sound Sensors. Precis. Eng. 2021, 67, 137–151. [Google Scholar] [CrossRef]

- Xu, X.; Wang, J.; Zhong, B.; Ming, W.; Chen, M. Deep Learning-Based Tool Wear Prediction and Its Application for Machining Process Using Multi-Scale Feature Fusion and Channel Attention Mechanism. Measurement 2021, 177, 109254. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.H.; Choudhury, I.A.; Dahari, M. Monitoring the Tool Wear, Surface Roughness and Chip Formation Occurrences Using Multiple Sensors in Turning. J. Manuf. Syst. 2014, 33, 476–487. [Google Scholar] [CrossRef]

- Xiang, S.; Qin, Y.; Liu, F.; Gryllias, K. Automatic Multi-Differential Deep Learning and Its Application to Machine Remaining Useful Life Prediction. Reliab. Eng. Syst. Saf. 2022, 223, 108531. [Google Scholar] [CrossRef]

- Ghosh, N.; Ravi, Y.B.; Patra, A.; Mukhopadhyay, S.; Paul, S.; Mohanty, A.R.; Chattopadhyay, A.B. Estimation of Tool Wear during CNC Milling Using Neural Network-Based Sensor Fusion. Mech. Syst. Signal Process. 2007, 21, 466–479. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, E.; Wu, Y.; Guo, B.; Jiang, Z.; Wu, F. A Novel Hybrid Model Integrating Residual Structure and Bi-Directional Long Short-Term Memory Network for Tool Wear Monitoring. Int. J. Adv. Manuf. Technol. 2022, 120, 6707–6722. [Google Scholar] [CrossRef]

- Wei, X.; Liu, X.; Yue, C.; Wang, L.; Liang, S.Y.; Qin, Y. A Multi-Sensor Signals Denoising Framework for Tool State Monitoring Based on UKF-CycleGAN. Mech. Syst. Signal Process. 2023, 200, 110420. [Google Scholar] [CrossRef]

- Song, G.; Zhang, J.; Zhu, K.; Ge, Y.; Yu, L.; Fu, Z. Tool Wear Monitoring Based on Multi-Kernel Gaussian Process Regression and Stacked Multilayer Denoising AutoEncoders. Mech. Syst. Signal Process. 2023, 186, 109851. [Google Scholar] [CrossRef]

- Ambhore, N.; Kamble, D.; Chinchanikar, S.; Wayal, V. Tool Condition Monitoring System: A Review. Mater. Today Proc. 2015, 2, 3419–3428. [Google Scholar] [CrossRef]

- You, Z.; Gao, H.; Guo, L.; Liu, Y.; Li, J.; Li, C. Machine Vision Based Adaptive Online Condition Monitoring for Milling Cutter under Spindle Rotation. Mech. Syst. Signal Process. 2022, 171, 108904. [Google Scholar] [CrossRef]

- Suprock, C.A.; Roth, J.T. Methods for On-Line Directionally Independent Failure Prediction of End Milling Cutting Tools. Mach. Sci. Technol. 2007, 11, 1–43. [Google Scholar] [CrossRef]

- Xi, L.; Wang, W.; Chen, J.; Wu, X. Appending-Inspired Multivariate Time Series Association Fusion for Tool Condition Monitoring. J. Intell. Manuf. 2023, 35, 3259–3272. [Google Scholar] [CrossRef]

- Ko, T.; Cho, D.; Jung, M. Online Monitoring of Tool Breakage in Face Milling Using a Self-Organized Neural-Network. J. Manuf. Syst. 1995, 14, 80–90. [Google Scholar] [CrossRef]

- Zafar, T.; Kamal, K.; Mathavan, S.; Hussain, G.; Alkahtani, M.; Alqahtani, F.M.; Aboudaif, M.K. A Hybrid Approach for Noise Reduction in Acoustic Signal of Machining Process Using Neural Networks and ARMA Model. Sensors 2021, 21, 8023. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhi, G.; Chen, W.; Qian, Q.; He, D.; Sun, B.; Sun, W. A New Tool Wear Condition Monitoring Method Based on Deep Learning under Small Samples. Measurement 2022, 189, 110622. [Google Scholar] [CrossRef]

- Ao, Y.; Qiao, G. Prognostics for Drilling Process with Wavelet Packet Decomposition. Int. J. Adv. Manuf. Technol. 2010, 50, 47–52. [Google Scholar] [CrossRef]

- Vautard, R.; Yiou, P.; Ghil, M. Singular-Spectrum Analysis—A Toolkit for Short, Noisy Chaotic Signals. Phys. D 1992, 58, 95–126. [Google Scholar] [CrossRef]

- Salgado, D.R.; Alonso, F.J. An Approach Based on Current and Sound Signals for In-Process Tool Wear Monitoring. Int. J. Mach. Tools Manuf. 2007, 47, 2140–2152. [Google Scholar] [CrossRef]

- Kilundu, B.; Dehombreux, P.; Chiementin, X. Tool Wear Monitoring by Machine Learning Techniques and Singular Spectrum Analysis. Mech. Syst. Signal Process. 2011, 25, 400–415. [Google Scholar] [CrossRef]

- Samantaray, L.; Dash, M.; Panda, R. A Review on Time-Frequency, Time-Scale and Scale-Frequency Domain Signal Analysis. IETE J. Res. 2005, 51, 287–293. [Google Scholar] [CrossRef]

- Yen, C.-L.; Lu, M.-C.; Chen, J.-L. Applying the Self-Organization Feature Map (SOM) Algorithm to AE-Based Tool Wear Monitoring in Micro-Cutting. Mech. Syst. Signal Process. 2013, 34, 353–366. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Incecik, A.; Gupta, M.K.; Królczyk, G.M.; Gardoni, P. A Novel Ensemble Deep Learning Model for Cutting Tool Wear Monitoring Using Audio Sensors. J. Manuf. Process. 2022, 79, 233–249. [Google Scholar] [CrossRef]

- Li, X.; Guan, X.P. Time-Frequency-Analysis-Based Minor Cutting Edge Fracture Detection during End Milling. Mech. Syst. Signal Process. 2004, 18, 1485–1496. [Google Scholar] [CrossRef]

- Zhu, K.; Wong, Y.S.; Hong, G.S. Wavelet Analysis of Sensor Signals for Tool Condition Monitoring: A Review and Some New Results. Int. J. Mach. Tools Manuf. 2009, 49, 537–553. [Google Scholar] [CrossRef]

- Long, J.; Wang, H.; Li, P.; Fan, H. Applications of Fractional Lower Order Time-Frequency Representation to Machine Bearing Fault Diagnosis. IEEE CAA J. Autom. Sin. 2017, 4, 734–750. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.L.C.; Shih, H.H.; Zheng, Q.N.; Yen, N.C.; Tung, C.C.; Liu, H.H. The Empirical Mode Decomposition and the Hilbert Spectrum for Nonlinear and Non-Stationary Time Series Analysis. Proc. R. Soc.-Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Ben Ali, J.; Fnaiech, N.; Saidi, L.; Chebel-Morello, B.; Fnaiech, F. Application of Empirical Mode Decomposition and Artificial Neural Network for Automatic Bearing Fault Diagnosis Based on Vibration Signals. Appl. Acoust. 2015, 89, 16–27. [Google Scholar] [CrossRef]

- Shi, X.; Wang, R.; Chen, Q.; Shao, H. Cutting Sound Signal Processing for Tool Breakage Detection in Face Milling Based on Empirical Mode Decomposition and Independent Component Analysis. J. Vib. Control 2015, 21, 3348–3358. [Google Scholar] [CrossRef]

- Babouri, M.K.; Ouelaa, N.; Djebala, A. Experimental Study of Tool Life Transition and Wear Monitoring in Turning Operation Using a Hybrid Method Based on Wavelet Multi-Resolution Analysis and Empirical Mode Decomposition. Int. J. Adv. Manuf. Technol. 2016, 82, 2017–2028. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, B.; Yan, X.; Yang, H. An Improved Signal Processing Approach Based on Analysis Mode Decomposition and Empirical Mode Decomposition. Energies 2019, 12, 3077. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble empirical mode decomposition: A noise-assisted data analysis method. Adv. Adapt. Data Anal. 2011, 1, 1–41. [Google Scholar] [CrossRef]

- Dong, D.; Wang, T.; Wang, J.; Niu, J.; Qiao, Y.; Wang, X. Study on Tool Wear State Monitoring Based on EEMD Information Entropy and PSO-SVM. J. Phys. Conf. Ser. 2023, 2566, 012111. [Google Scholar] [CrossRef]

- Barbosh, M.; Sadhu, A.; Vogrig, M. Multisensor-Based Hybrid Empirical Mode Decomposition Method towards System Identification of Structures. Struct. Control Health Monit. 2018, 25, e2147. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, X.; Yue, C.; Liu, S.; Li, X.; Liang, S.Y.; Wang, L. An Imbalanced Data Learning Approach for Tool Wear Monitoring Based on Data Augmentation. J. Intell. Manuf. 2023, 69, 1–22. [Google Scholar] [CrossRef]

- Benkedjouh, T.; Zerhouni, N.; Rechak, S. Tool Wear Condition Monitoring Based on Continuous Wavelet Transform and Blind Source Separation. Int. J. Adv. Manuf. Technol. 2018, 97, 3311–3323. [Google Scholar] [CrossRef]

- Hong, Y.-S.; Yoon, H.-S.; Moon, J.-S.; Cho, Y.-M.; Ahn, S.-H. Tool-Wear Monitoring during Micro-End Milling Using Wavelet Packet Transform and Fisher’s Linear Discriminant. Int. J. Precis. Eng. Manuf. 2016, 17, 845–855. [Google Scholar] [CrossRef]

- Nakano, T.; Koresawa, H.; Narahara, H. Tool Condition Monitoring Method by Anomaly Segmentation of Time-Frequency Images Using Acoustic Emission in Small Hole Drilling. J. Adv. Mech. Des. Syst. Manuf. 2023, 17, 23–00133. [Google Scholar] [CrossRef]

- Paliwal, D.; Choudhur, A.; Govandhan, T. Identification of Faults through Wavelet Transform Vis-à-Vis Fast Fourier Transform of Noisy Vibration Signals Emanated from Defective Rolling Element Bearings. Front. Mech. Eng. 2014, 9, 130–141. [Google Scholar] [CrossRef]

- Cheng, Y.; Lin, M.; Wu, J.; Zhu, H.; Shao, X. Intelligent Fault Diagnosis of Rotating Machinery Based on Continuous Wavelet Transform-Local Binary Convolutional Neural Network. Knowl.-Based Syst. 2021, 216, 106796. [Google Scholar] [CrossRef]

- Sevilla-Camacho, P.Y.; Herrera-Ruiz, G.; Robles-Ocampo, J.B.; Jauregui-Correa, J.C. Tool Breakage Detection in CNC High-Speed Milling Based in Feed-Motor Current Signals. Int. J. Adv. Manuf. Technol. 2011, 53, 1141–1148. [Google Scholar] [CrossRef]

- Dong, W.; Guo, X.; Hu, Y.; Wang, J.; Tian, G. Discrete Wavelet Transformation and Genetic Algorithm—Back Propagation Neural Network Applied in Monitoring Woodworking Tool Wear Conditions in the Milling Operation Spindle Power Signals. Bioresources 2021, 16, 2369–2384. [Google Scholar] [CrossRef]

- Jemielniak, K.; Kossakowska, J.; Urbanski, T. Application of Wavelet Transform of Acoustic Emission and Cutting Force Signals for Tool Condition Monitoring in Rough Turning of Inconel 625. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2011, 225, 123–129. [Google Scholar] [CrossRef]

- Segreto, T.; D’Addona, D.; Teti, R. Tool wear estimation in turning of Inconel 718 based on wavelet sensor signal analysis and machine learning paradigms. Prod. Eng. Res. Dev. 2020, 14, 693–705. [Google Scholar] [CrossRef]

- Duan, J.; Duan, J.; Zhou, H.; Zhan, X.; Li, T.; Shi, T. Multi-Frequency-Band Deep CNN Model for Tool Wear Prediction. Meas. Sci. Technol. 2021, 32, 065009. [Google Scholar] [CrossRef]

- Madhusudana, C.K.; Kumar, H.; Narendranath, S. Face Milling Tool Condition Monitoring Using Sound Signal. Int. J. Syst. Assur. Eng. Manag. 2017, 8, 1643–1653. [Google Scholar] [CrossRef]

- Perez-Salinas, C.; de Lacalle, L.N.L.; del Olmo, A.; Kumar, C.S. The Relationship between the Cutting-Edge, Tool Wear, and Chip Formation during Inconel 718 Dry Cutting. Int. J. Adv. Manuf. Technol. 2024, 132, 6001–6017. [Google Scholar] [CrossRef]

- Lin, C.-J.; Jhang, J.-Y.; Chen, S.-H. Tool Wear Prediction Using a Hybrid of Tool Chip Image and Evolutionary Fuzzy Neural Network. Int. J. Adv. Manuf. Technol. 2022, 118, 921–936. [Google Scholar] [CrossRef]

- Zhang, P.P.; Guo, Y.; Wang, B. Novel Tool Wear Monitoring Method in Milling Difficult-Tomachine Materials Using Cutting Chip Formation. In Proceedings of the 12th International Conference on Damage Assessment of Structures, Kitakyushu, Japan, 10–12 July 2017; IoP Publishing Ltd.: Bristol, UK, 2017; Volume 842, p. 012042. [Google Scholar]

- Chen, S.-H.; Zhang, M.-J. Application of CNN-BP on Inconel-718 Chip Feature and the Influence on Tool Life. Int. J. Adv. Manuf. Technol. 2022, 121, 5913–5930. [Google Scholar] [CrossRef]

- Yeo, S.H.; Khoo, L.P.; Neo, S.S. Tool Condition Monitoring Using Reflectance of Chip Surface and Neural Network. J. Intell. Manuf. 2000, 11, 507–514. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.H.; Choudhury, I.A.; Yusoff, N. A New Approach to Investigate Tool Condition Using Dummy Tool Holder and Sensor Setup. Int. J. Adv. Manuf. Technol. 2012, 61, 465–479. [Google Scholar] [CrossRef]

- Pagani, L.; Parenti, P.; Cataldo, S.; Scott, P.J.; Annoni, M. Indirect Cutting Tool Wear Classification Using Deep Learning and Chip Colour Analysis. Int. J. Adv. Manuf. Technol. 2020, 111, 1099–1114. [Google Scholar] [CrossRef]

- Chen, S.-H.; Luo, Z.-R. Study of Using Cutting Chip Color to the Tool Wear Prediction. Int. J. Adv. Manuf. Technol. 2020, 109, 823–839. [Google Scholar] [CrossRef]

- Guan, R.; Cheng, Y.; Zhou, S.; Gai, X.; Lu, M.; Xue, J. Research on Tool Wear Classification of Milling 508III Steel Based on Chip Spectrum Feature. Int. J. Adv. Manuf. Technol. 2024, 133, 1531–1547. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, J.; Gao, J.; Li, Z.; Li, E. Milling Tool Wear Prediction Method Based on Deep Learning Under Variable Working Conditions. IEEE Access 2020, 8, 140726–140735. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, L.; Wan, X.; Feng, B. Tool Wear Online Monitoring Method Based on DT and SSAE-PHMM. J. Comput. Inf. Sci. Eng. 2021, 21, 034501. [Google Scholar] [CrossRef]

- Sun, J.; Hong, G.S.; Rahman, M.; Wong, Y.S. Improved Performance Evaluation of Tool Condition Identification by Manufacturing Loss Consideration. Int. J. Prod. Res. 2005, 43, 1185–1204. [Google Scholar] [CrossRef]

- Wang, G.; Feng, X. Tool Wear State Recognition Based on Linear Chain Conditional Random Field Model. Eng. Appl. Artif. Intell. 2013, 26, 1421–1427. [Google Scholar] [CrossRef]

- Kasim, N.A.; Nuawi, M.Z.; Ghani, J.A.; Rizal, M.; Ngatiman, N.A.; Haron, C.H.C. Enhancing Clustering Algorithm with Initial Centroids in Tool Wear Region Recognition. Int. J. Precis. Eng. Manuf. 2021, 22, 843–863. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Yue, C.; Liu, S.; Zhang, B.; Li, R.; Liang, S.Y.; Wang, L. A Data-Driven Approach for Tool Wear Recognition and Quantitative Prediction Based on Radar Map Feature Fusion. Measurement 2021, 185, 110072. [Google Scholar] [CrossRef]

- Xu, W.; Miao, H.; Zhao, Z.; Liu, J.; Sun, C.; Yan, R. Multi-Scale Convolutional Gated Recurrent Unit Networks for Tool Wear Prediction in Smart Manufacturing. Chin. J. Mech. Eng. 2021, 34, 53. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, L.; Wang, Y. Event-Driven Tool Condition Monitoring Methodology Considering Tool Life Prediction Based on Industrial Internet. J. Manuf. Syst. 2021, 58, 205–222. [Google Scholar] [CrossRef]

- Gao, Z.; Hu, Q.; Xu, X. Condition Monitoring and Life Prediction of the Turning Tool Based on Extreme Learning Machine and Transfer Learning. Neural Comput. Appl. 2022, 34, 3399–3410. [Google Scholar] [CrossRef]

- Tao, Z.; An, Q.; Liu, G.; Chen, M. A Novel Method for Tool Condition Monitoring Based on Long Short-Term Memory and Hidden Markov Model Hybrid Framework in High-Speed Milling Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 105, 3165–3182. [Google Scholar] [CrossRef]

- Elangovan, M.; Devasenapati, S.B.; Sakthivel, N.R.; Ramachandran, K.I. Evaluation of Expert System for Condition Monitoring of a Single Point Cutting Tool Using Principle Component Analysis and Decision Tree Algorithm. Expert Syst. Appl. 2011, 38, 4450–4459. [Google Scholar] [CrossRef]

- Patange, A.D.; Pardeshi, S.S.; Jegadeeshwaran, R.; Zarkar, A.; Verma, K. Augmentation of Decision Tree Model Through Hyper-Parameters Tuning for Monitoring of Cutting Tool Faults Based on Vibration Signatures. J. Vib. Eng. Technol. 2023, 11, 3759–3777. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; He, J.; Hao, Q.; Yang, H.; Wei, J. Tool Wear State Recognition Based on Gradient Boosting Decision Tree and Hybrid Classification RBM. Int. J. Adv. Manuf. Technol. 2020, 110, 511–522. [Google Scholar] [CrossRef]

- Hsueh, Y.-W.; Yang, C.-Y. Tool Breakage Diagnosis in Face Milling by Support Vector Machine. J. Mater. Process. Technol. 2009, 209, 145–152. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Tan, H.H. In-Process Tool Condition Monitoring in Compliant Abrasive Belt Grinding Process Using Support Vector Machine and Genetic Algorithm. J. Manuf. Process. 2018, 31, 199–213. [Google Scholar] [CrossRef]

- Guo, J.; Li, A.; Zhang, R. Tool Condition Monitoring in Milling Process Using Multifractal Detrended Fluctuation Analysis and Support Vector Machine. Int. J. Adv. Manuf. Technol. 2020, 110, 1445–1456. [Google Scholar] [CrossRef]

- Cardoz, B.; Shaikh, H.N.E.A.; Mulani, S.M.; Kumar, A.; Rajasekharan, S.G. Random Forests Based Classification of Tool Wear Using Vibration Signals and Wear Area Estimation from Tool Image Data. Int. J. Adv. Manuf. Technol. 2023, 126, 3069–3081. [Google Scholar] [CrossRef]

- Jogdeo, A.A.; Patange, A.D.; Atnurkar, A.M.; Sonar, P.R. Robustification of the Random Forest: A Multitude of Decision Trees for Fault Diagnosis of Face Milling Cutter Through Measurement of Spindle Vibrations. J. Vib. Eng. Technol. 2024, 12, 4521–4539. [Google Scholar] [CrossRef]

- Varghese, A.; Kulkarni, V.; Joshi, S.S. Tool Life Stage Prediction in Micro-Milling From Force Signal Analysis Using Machine Learning Methods. J. Manuf. Sci. Eng. 2021, 143, 054501. [Google Scholar] [CrossRef]

- Ertunc, H.M.; Loparo, K.A.; Ocak, H. Tool Wear Condition Monitoring in Drilling Operations Using Hidden Markov Models (HMMs). Int. J. Mach. Tools Manuf. 2001, 41, 1363–1384. [Google Scholar] [CrossRef]

- Li, W.; Liu, T. Time Varying and Condition Adaptive Hidden Markov Model for Tool Wear State Estimation and Remaining Useful Life Prediction in Micro-Milling. Mech. Syst. Signal Process. 2019, 131, 689–702. [Google Scholar] [CrossRef]

- Matsumura, T.; Obikawa, T.; Shirakashi, T.; Usui, E. Autonomous Turning Operation Planning with Adaptive Prediction of Tool Wear and Surface-Roughness. J. Manuf. Syst. 1993, 12, 253–262. [Google Scholar] [CrossRef]

- Dimla, D.E. A Modular Tool Wear Monitoring System in a Metal Cutting Operation Using Mlp Neural Networks and Multivariate Process Parameters. In Proceedings of the UKACC International Conference on Control’98, UNIV WALES UNIV COLL SWANSEA, SWANSEA, Wales, UK, 1–4 September 1998; Vols Iⅈ Inst Electrical Engineers Inspec Inc.: Edison, NJ, USA, 1998; pp. 296–301. [Google Scholar]

- Shi, D.; Gindy, N.N. Tool Wear Predictive Model Based on Least Squares Support Vector Machines. Mech. Syst. Signal Process. 2007, 21, 1799–1814. [Google Scholar] [CrossRef]

- Tao, X.; Tao, W. Cutting Tool Wear Identification Based on Wavelet Package and SVM. In Proceedings of the 2010 8th World Congress on Intelligent Control and Automation (WCICA), Jinan, China, 7–9 July 2010; IEEE: New York, NY, USA, 2010; pp. 5953–5957. [Google Scholar]

- Kalita, D.J.; Singh, S. SVM Hyper-Parameters Optimization Using Quantized Multi-PSO in Dynamic Environment. Soft Comput. 2020, 24, 1225–1241. [Google Scholar] [CrossRef]

- Wang, S.; Li, Z.; Liu, C.; Zhang, X.; Zhang, H. Training Data Reduction to Speed up SVM Training. Appl. Intell. 2014, 41, 405–420. [Google Scholar] [CrossRef]

- Wang, H.; Shao, Y. Sparse and Robust SVM Classifier for Large Scale Classification. Appl. Intell. 2023, 53, 19647–19671. [Google Scholar] [CrossRef]

- Peng, Y.; Dong, M.; Zuo, M.J. Current Status of Machine Prognostics in Condition-Based Maintenance: A Review. Int. J. Adv. Manuf. Technol. 2010, 50, 297–313. [Google Scholar] [CrossRef]

- Yu, J.; Liang, S.; Tang, D.; Liu, H. A Weighted Hidden Markov Model Approach for Continuous-State Tool Wear Monitoring and Tool Life Prediction. Int. J. Adv. Manuf. Technol. 2017, 91, 201–211. [Google Scholar] [CrossRef]

- Lin, X.; Zhou, B.; Zhu, L. Sequential Spindle Current-Based Tool Condition Monitoring with Support Vector Classifier for Milling Process. Int. J. Adv. Manuf. Technol. 2017, 92, 3319–3328. [Google Scholar] [CrossRef]

- Zhu, K.; Liu, T. Online Tool Wear Monitoring Via Hidden Semi-Markov Model with Dependent Durations. IEEE Trans. Ind. Inform. 2018, 14, 69–78. [Google Scholar] [CrossRef]

- Wang, W.H.; Hong, G.S.; Wong, Y.S.; Zhu, K.P. Sensor Fusion for Online Tool Condition Monitoring in Milling. Int. J. Prod. Res. 2007, 45, 5095–5116. [Google Scholar] [CrossRef]

- Scheffer, C.; Heyns, P.S. Wear Monitoring in Turning Operations Using Vibration and Strain Measurements. Mech. Syst. Signal Process. 2001, 15, 1185–1202. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; Xie, Q.; Zhang, Y. Force Based Tool Wear Monitoring System for Milling Process Based on Relevance Vector Machine. Adv. Eng. Softw. 2014, 71, 46–51. [Google Scholar] [CrossRef]

- Brezak, D.; Majetic, D.; Udiljak, T.; Kasac, J. Tool Wear Estimation Using an Analytic Fuzzy Classifier and Support Vector Machines. J. Intell. Manuf. 2012, 23, 797–809. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Pruncu, C.I.; Khan, A.M.; Rahman, M.A.; Jamil, M.; Sharma, V.S. Modeling and Performance Evaluation of Al2O3, MoS2 and Graphite Nanoparticle-Assisted MQL in Turning Titanium Alloy: An Intelligent Approach. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 207. [Google Scholar] [CrossRef]

- Ahmed, Y.S.; Alam, M.S.; Arif, A.F.M.; Veldhuis, S.C. Use of Acoustic Emission and Cutting Force Signals to Monitor Built-up Edge Formation in Stainless Steel Turning. Int. J. Adv. Manuf. Technol. 2019, 103, 2257–2276. [Google Scholar] [CrossRef]

- Xu, L.; Huang, C.; Li, C.; Wang, J.; Liu, H.; Wang, X. Estimation of Tool Wear and Optimization of Cutting Parameters Based on Novel ANFIS-PSO Method toward Intelligent Machining. J. Intell. Manuf. 2021, 32, 77–90. [Google Scholar] [CrossRef]

- Joanes Agung’, O.; James, K.; Samuel, K.; Evan, M. Generative and Self-Supervised Ensemble Modeling for Multivariate Tool Wear Monitoring. Eng. Rep. 2024, 6, e12788. [Google Scholar] [CrossRef]

- Assafo, M.; Langendoerfer, P. Unsupervised and Semisupervised Machine Learning Frameworks for Multiclass Tool Wear Recognition. IEEE Open J. Ind. Electron. Soc. 2024, 5, 993–1010. [Google Scholar] [CrossRef]

- Li, W.; Fu, H.; Zhuo, Y.; Liu, C.; Jin, H. Semi-Supervised Multi-Source Meta-Domain Generalization Method for Tool Wear State Prediction under Varying Cutting Conditions. J. Manuf. Syst. 2023, 71, 323–341. [Google Scholar] [CrossRef]

- Fan, C.; Zhang, Z.; Zhang, D.; Luo, M. Research on Tool Wear Modeling of Superalloy Based on Evolutionary Cluster Analysis. Int. J. Adv. Manuf. Technol. 2023, 129, 143–166. [Google Scholar] [CrossRef]

- Niu, M.; Liu, K.; Wang, Y. A Semi-Supervised Learning Method Combining Tool Wear Laws for Machining Tool Wear States Monitoring. Mech. Syst. Signal Process. 2025, 224, 112032. [Google Scholar] [CrossRef]

- Mathew, M.T.; Pai, P.S.; Rocha, L.A. An Effective Sensor for Tool Wear Monitoring in Face Milling: Acoustic Emission. Sadhana 2008, 33, 227–233. [Google Scholar] [CrossRef]

- Zhu, K.; Vogel-Heuser, B. Sparse Representation and Its Applications in Micro-Milling Condition Monitoring: Noise Separation and Tool Condition Monitoring. Int. J. Adv. Manuf. Technol. 2014, 70, 185–199. [Google Scholar] [CrossRef]

- Ross, N.S.; Sheeba, P.T.T.; Shibi, C.S.; Gupta, M.K.; Korkmaz, M.E.; Sharma, V.S. A Novel Approach of Tool Condition Monitoring in Sustainable Machining of Ni Alloy with Transfer Learning Models. J. Intell. Manuf. 2024, 35, 757–775. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, T.; Wang, G.; Guo, R.; Fu, Y.; Sun, Y.; Chen, M. Tool Wear Classification Based on Convolutional Neural Network and Time Series Images during High Precision Turning of Copper. Wear 2023, 522, 204692. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Hong, D.; Lu, Y.; Wang, Z.; Liao, Z. Intelligent Tool Wear Monitoring Based on Multi-Channel Hybrid Information and Deep Transfer Learning. J. Manuf. Syst. 2023, 69, 31–47. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, X.; Yue, C.; Liang, S.Y.; Wang, L. Meta-Learning-Based Approach for Tool Condition Monitoring in Multi-Condition Small Sample Scenarios. Mech. Syst. Signal Process. 2024, 216, 111444. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, Q.; Peng, Q.; Zhuang, J.; Wu, F.; Zhang, Q. Tool Health Monitoring and Prediction via Attention-Based Encoder-Decoder with a Multi-Step Mechanism. Int. J. Adv. Manuf. Technol. 2022, 122, 685–695. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, B.; Li, X.; Liu, S.; Yue, C.; Liang, S.Y. An Approach for Tool Wear Prediction Using Customized DenseNet and GRU Integrated Model Based on Multi-Sensor Feature Fusion. J. Intell. Manuf. 2023, 34, 885–902. [Google Scholar] [CrossRef]

- Kuo, P.-H.; Lin, C.-Y.; Luan, P.-C.; Yau, H.-T. Dense-Block Structured Convolutional Neural Network-Based Analytical Prediction System of Cutting Tool Wear. IEEE Sens. J. 2022, 22, 20257–20267. [Google Scholar] [CrossRef]

- Venkatesh, S.N.; Balaji, P.A.; Elangovan, M.; Annamalai, K.; Indira, V.; Sugumaran, V.; Mahamuni, V.S. Transfer Learning-Based Condition Monitoring of Single Point Cutting Tool. Comput. Intell. Neurosci. 2022, 2022, 3205960. [Google Scholar] [CrossRef]

- Patil, S.S.; Pardeshi, S.S.; Patange, A.D. Health Monitoring of Milling Tool Inserts Using CNN Architectures Trained by Vibration Spectrograms. CMES-Comput. Model. Eng. Sci. 2023, 136, 177–199. [Google Scholar] [CrossRef]

- Karabacak, Y.E. Deep Learning-Based CNC Milling Tool Wear Stage Estimation with Multi-Signal Analysis. Eksploat. Niezawodn.-Maint. Reliab. 2023, 25, 168082. [Google Scholar] [CrossRef]

- Guo, H.; Lin, X.; Zhu, K. Pyramid LSTM Network for Tool Condition Monitoring. IEEE Trans. Instrum. Meas. 2022, 71, 2509511. [Google Scholar] [CrossRef]

- Qin, B.; Wang, Y.; Liu, K.; Jiang, S.; Luo, Q. A Novel Online Tool Condition Monitoring Method for Milling Titanium Alloy with Consideration of Tool Wear Law. Mech. Syst. Signal Process. 2023, 199, 110467. [Google Scholar] [CrossRef]

- Zhi, G.; He, D.; Sun, W.; Zhou, Y.; Pan, X.; Gao, C. An Edge-Labeling Graph Neural Network Method for Tool Wear Condition Monitoring Using Wear Image with Small Samples. Meas. Sci. Technol. 2021, 32, 064006. [Google Scholar] [CrossRef]

- Huang, Z.; Li, W.; Zhu, J.; Wang, L. Cross-Domain Tool Wear Condition Monitoring via Residual Attention Hybrid Adaptation Network. J. Manuf. Syst. 2024, 72, 406–423. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, R.; Liu, X. A Novel Approach to Tool Condition Monitoring Based on Multi-Sensor Data Fusion Imaging and an Attention Mechanism. Meas. Sci. Technol. 2021, 32, 055601. [Google Scholar] [CrossRef]

- He, J.; Xu, Y.; Pan, Y.; Wang, Y. Adaptive Weighted Generative Adversarial Network with Attention Mechanism: A Transfer Data Augmentation Method for Tool Wear Prediction. Mech. Syst. Signal Process. 2024, 212, 111288. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, B.; Liu, K.; Shen, M.; Niu, M.; Han, L. A New Multitask Learning Method for Tool Wear Condition and Part Surface Quality Prediction. IEEE Trans. Ind. Inform. 2021, 17, 6023–6033. [Google Scholar] [CrossRef]

- Wang, D.; Hong, R.; Lin, X. A Method for Predicting Hobbing Tool Wear Based on CNC Real-Time Monitoring Data and Deep Learning. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2021, 72, 847–857. [Google Scholar] [CrossRef]

- Wang, Y.; Niu, M.; Liu, K.; Liu, H.; Qin, B.; Cui, Y. Deep Transfer Learning for Tool Condition Monitoring under Different Processing Conditions. Int. J. Adv. Manuf. Technol. 2024, 133, 507–519. [Google Scholar] [CrossRef]

- Qin, B.; Liu, K.; Song, L.; Qiao, S.; Jiang, Y.; Niu, M.; Wang, Y. A New Method for Tool Wear Monitoring Based on Small Sample Size. Int. J. Adv. Manuf. Technol. 2023, 129, 4541–4551. [Google Scholar] [CrossRef]

- Wong, S.Y.; Chuah, J.H.; Yap, H.J. Technical Data-Driven Tool Condition Monitoring Challenges for CNC Milling: A Review. Int. J. Adv. Manuf. Technol. 2020, 107, 4837–4857. [Google Scholar] [CrossRef]

- Nasir, V.; Sassani, F. A Review on Deep Learning in Machining and Tool Monitoring: Methods, Opportunities, and Challenges. Int. J. Adv. Manuf. Technol. 2021, 115, 2683–2709. [Google Scholar] [CrossRef]

- Faghmous, J.H.; Kumar, V. A Big Data Guide to Understanding Climate Change: The Case for Theory-Guided Data Science. Big Data 2014, 2, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Krasnopolsky, V.M.; Fox-Rabinovitz, M.S. Complex Hybrid Models Combining Deterministic and Machine Learning Components as a New Synergetic Paradigm in Numerical Climate Modeling and Weather Prediction. In Proceedings of the International Joint Conference on Neural Networks (IJCNN), Montreal, QC, Canada, 31 July–4 August 2005; IEEE: New York, NY, USA, 2005; Volumes 1–5, pp. 1615–1620. [Google Scholar]

- O’Gorman, P.A.; Dwyer, J.G. Using Machine Learning to Parameterize Moist Convection: Potential for Modeling of Climate, Climate Change, and Extreme Events. J. Adv. Model. Earth Syst. 2018, 10, 2548–2563. [Google Scholar] [CrossRef]

- Sadowski, P.; Fooshee, D.; Subrahmanya, N.; Baldi, P. Synergies Between Quantum Mechanics and Machine Learning in Reaction Prediction. J. Chem. Inf. Model. 2016, 56, 2125–2128. [Google Scholar] [CrossRef] [PubMed]

- Schuett, K.; Kindermans, P.-J.; Sauceda, H.; Chmiela, S.; Tkatchenko, A.; Mueller, K.-R. SchNet: A Continuous-Filter Convolutional Neural Network for Modeling Quantum Interactions. arXiv 2018, arXiv:1706.08566. [Google Scholar] [CrossRef]

- Alber, M.; Tepole, A.B.; Cannon, W.R.; De, S.; Dura-Bernal, S.; Garikipati, K.; Karniadakis, G.; Lytton, W.W.; Perdikaris, P.; Petzold, L.; et al. Integrating Machine Learning and Multiscale Modeling-Perspectives, Challenges, and Opportunities in the Biologica Biomedical, and Behavioral Sciences. NPJ Digit. Med. 2019, 2, 115. [Google Scholar] [CrossRef]

- Peng, G.C.Y.; Alber, M.; Tepole, A.B.; Cannon, W.; De, S.; Dura-Bernal, S.; Garikipati, K.; Karniadakis, G.; Lytton, W.W.; Perdikaris, P.; et al. Multiscale Modeling Meets Machine Learning: What Can We Learn? Arch. Comput. Methods Eng. 2021, 28, 1017–1037. [Google Scholar] [CrossRef]

- Yazdani, A.; Lu, L.; Raissi, M.; Karniadakis, G.E. Systems Biology Informed Deep Learning for Inferring Parameters and Hidden Dynamics. PLoS Comput. Biol. 2020, 16, e1007575. [Google Scholar] [CrossRef]

- Tripathy, K.P.; Mishra, A.K. Deep Learning in Hydrology and Water Resources Disciplines: Concepts, Methods, Applications, and Research Directions. J. Hydrol. 2024, 628, 130458. [Google Scholar] [CrossRef]

- Maxwell, R.M.; Condon, L.E.; Melchior, P. A Physics-Informed, Machine Learning Emulator of a 2D Surface Water Model: What Temporal Networks and Simulation-Based Inference Can Help Us Learn about Hydrologic Processes. Water 2021, 13, 3633. [Google Scholar] [CrossRef]