Fault Detection in Harmonic Drive Using Multi-Sensor Data Fusion and Gravitational Search Algorithm

Abstract

1. Introduction

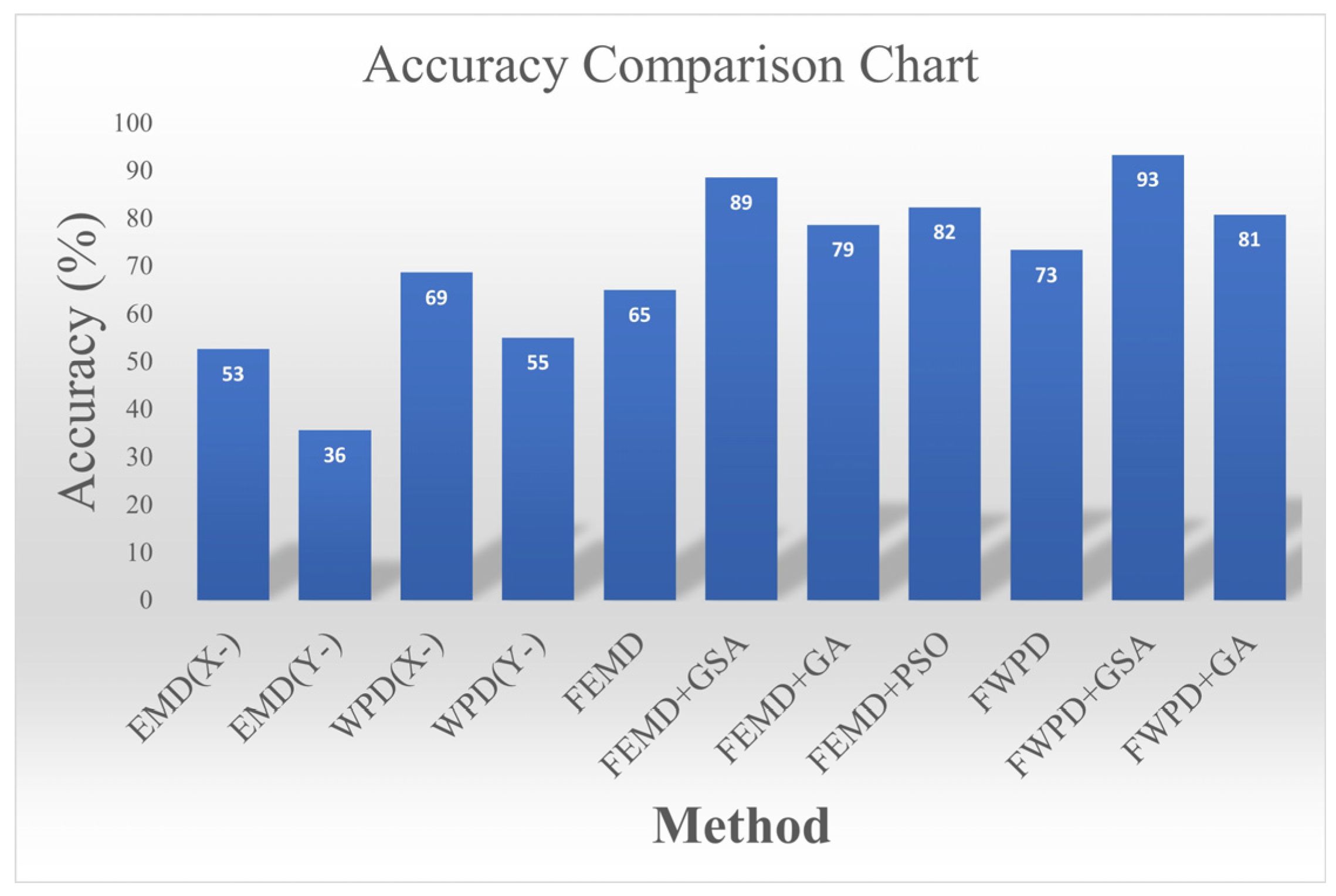

- The proposed method integrates feature fusion with GSA optimization. By fusing decomposed features and applying optimization, we demonstrate through experiments that the method effectively reduces overfitting in high-dimensional data. Furthermore, by optimizing feature selection, it eliminates the interference of redundant features, significantly improving diagnostic accuracy across multiple fault modes.

- Multi-sensor vibration data of harmonic drives were collected under various operating conditions. It was verified that the diagnostic model, after feature fusion and GSA optimization, achieved significantly higher accuracy compared to models using only data fusion.

- The experimental results show that the feature fusion methods FWPD and FEMD improved the accuracy and stability of fault diagnosis. After applying GSA for feature optimization, the FWPD+GSA combination achieved a high diagnostic accuracy.

2. Enhanced Harmonic Drive Fault Diagnosis Framework

- Signal processing stage, where signal decomposition is performed using WPD and EMD.

- Data fusion and optimized feature extraction stage.

- Classifier training stage, where the feature dataset is evaluated using a support vector machine (SVM) combined with K-fold cross-validation

2.1. Signal Processing Stage

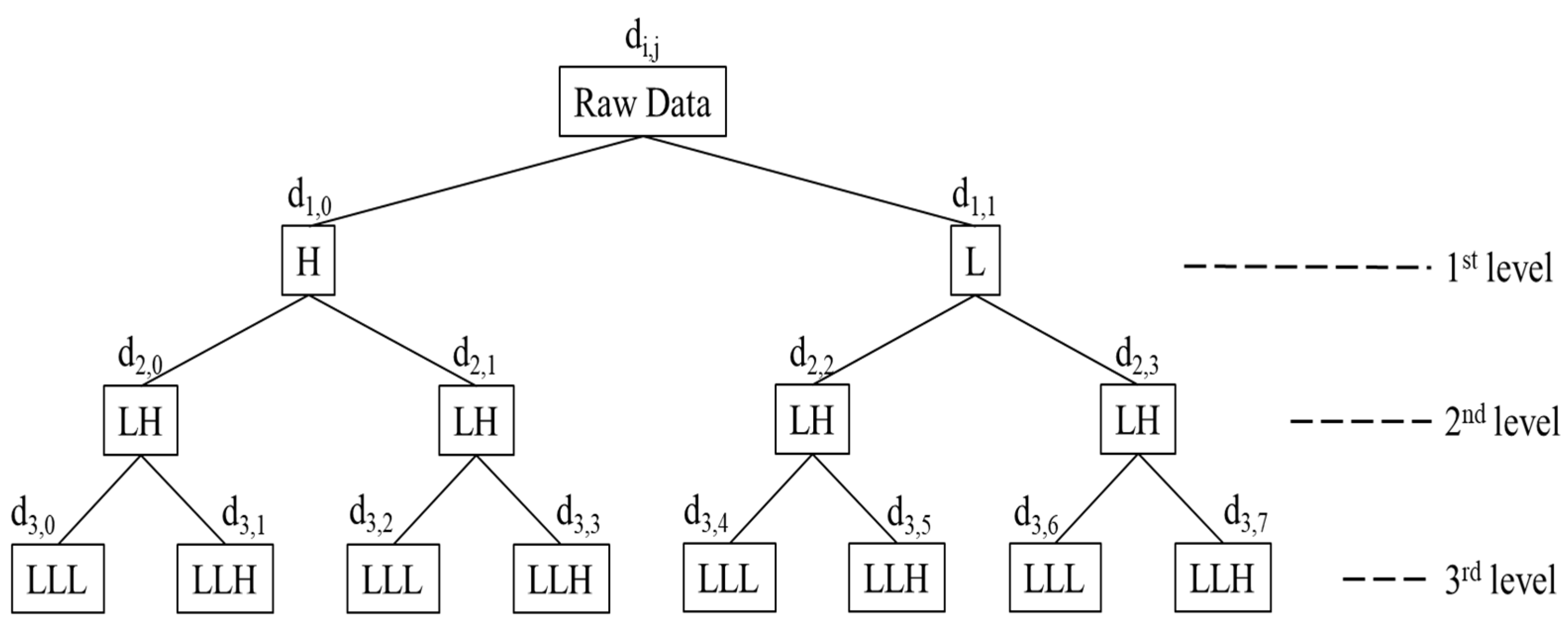

2.1.1. Feature Extraction Using WPD

2.1.2. Feature Extraction Using EMD

2.1.3. Comparison of Time Complexity for Signal Processing Methods

- WPD: The time complexity of WPD is , where is the length of the signal. Since wavelet decomposition involves multi-level frequency decomposition, this method is computationally efficient for processing long-duration signals, making it suitable for multi-scale signal analysis.

- EMD: The time complexity of EMD is , where represents the number of EMD iterations, and represents the signal length. Because EMD relies on repeated interpolation of the signal’s local maxima and minima, the computational load increases significantly as the complexity of the signal rises. This results in EMD having a higher time complexity compared to WPD, particularly when dealing with more intricate signals.

2.2. Feature Signal Enhancement Stage

2.2.1. Data Fusion

2.2.2. Gravitational Search Algorithm

2.2.3. Time Complexity of the Optimization Algorithm

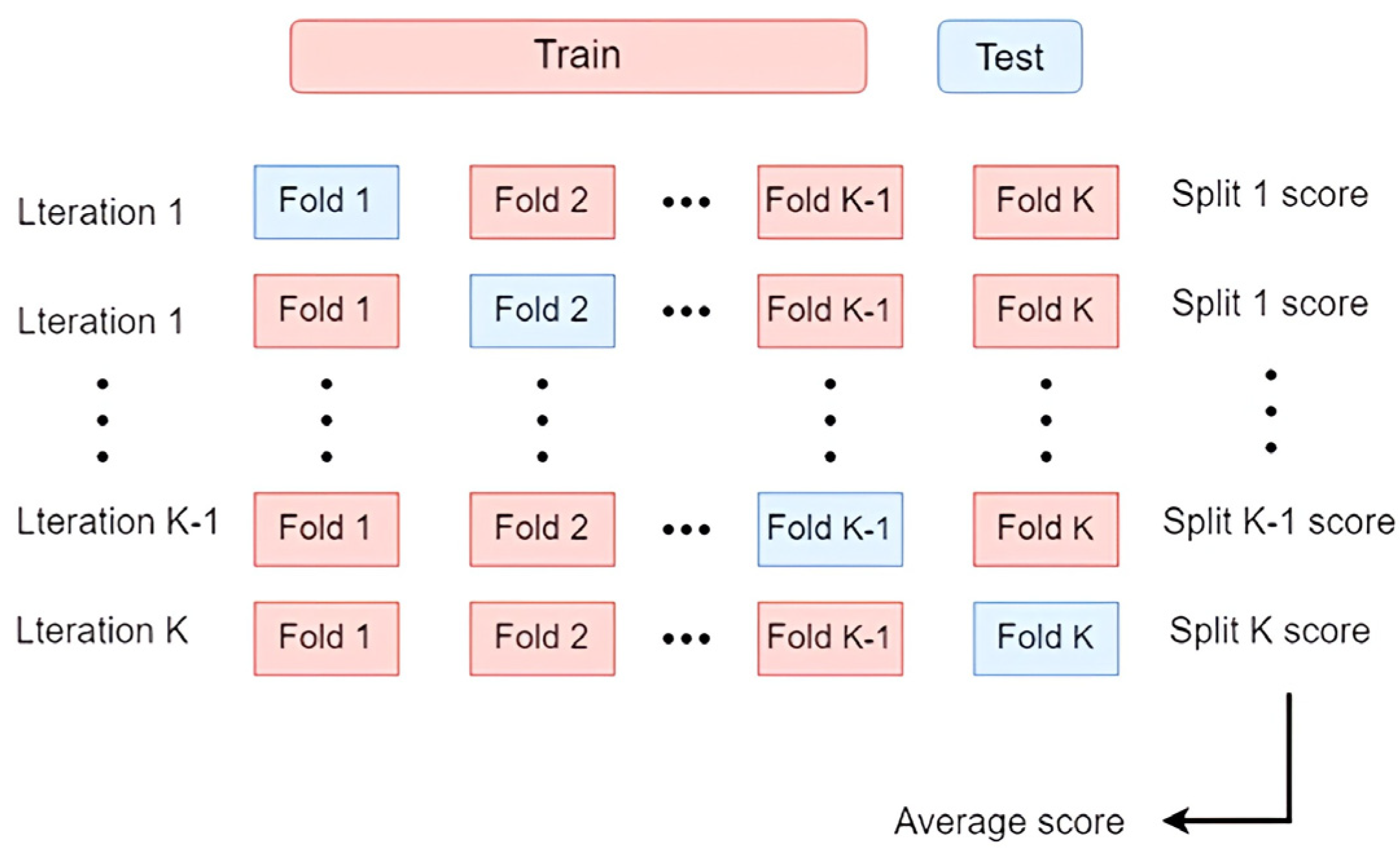

2.3. SVM and K-Fold Cross-Validation

3. Experimental Study

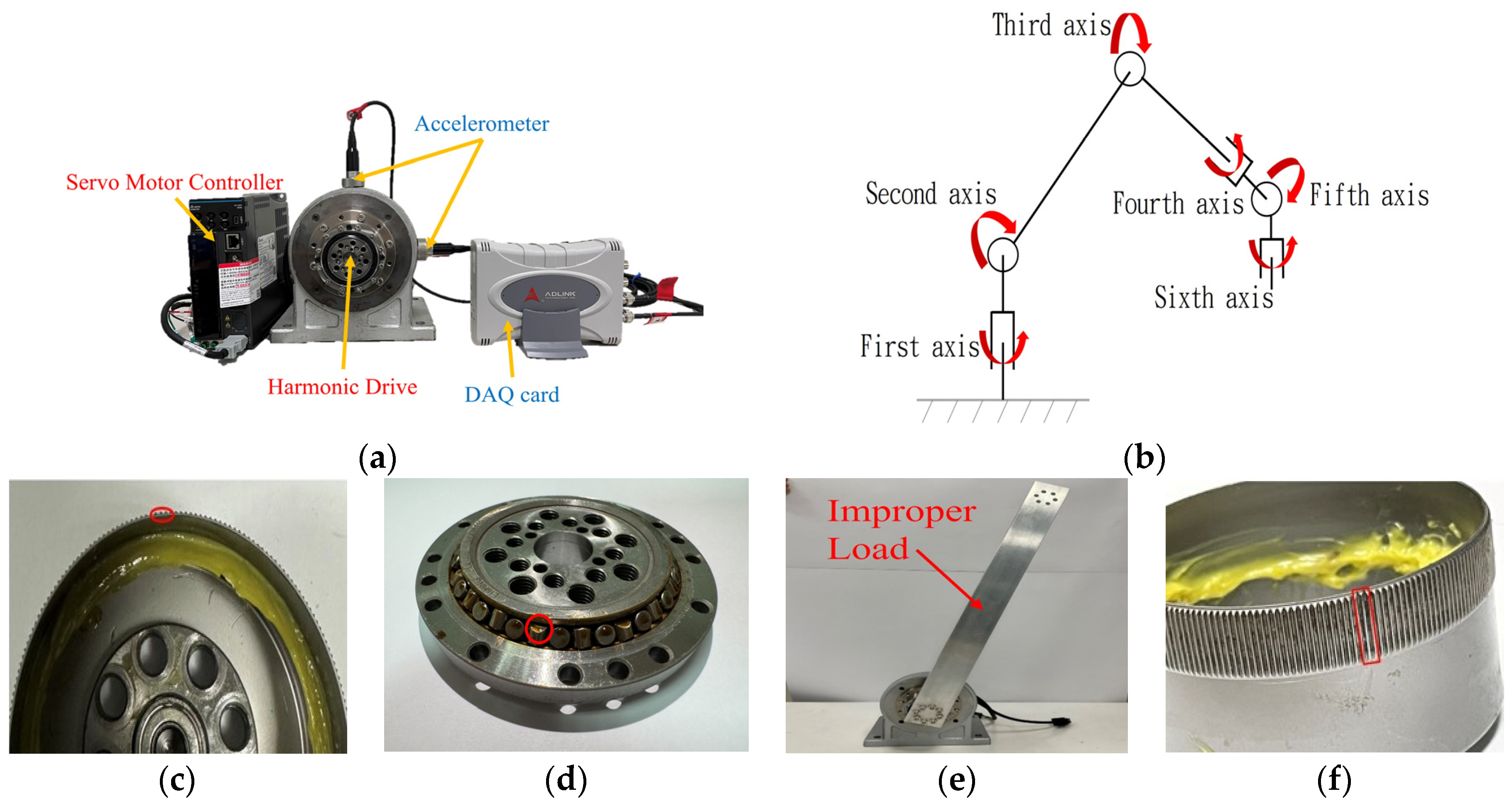

3.1. Experimental Setup

- Harmonic Drive Unit: This unit uses a harmonic drive to mimic the motion of the robotic arm’s sixth axis. It comprises an ECM-B3M-C20604 servo motor and a harmonic drive with a reduction ratio of 100.

- Control Unit: The servo motor is controlled by an ASD-B3-0421-L servo drive controller to manage the motor’s operation.

- Data Acquisition Unit: The ADLink USB-2405 device is employed to collect vibration data from the X- and Y-axes.

3.2. Experimental Procedure

- Step 1: Collect vibration signals from the harmonic drive under six fault models: normal gear, gear wear, gear fracture, less grease, bearing damage, and improper load. The signals are then decomposed using WPD and EMD to obtain decomposition features.

- Step 2: Fuse the decomposition feature matrices from both the X-axis and Y-axis.

- Step 3(a): Perform SVM classification on the fused features, applying 5-fold cross-validation to ensure fairness in training.

- Step 3(b): Optimize the fused features using GSA, PSO, and GA, and compute the computation time performance of each method.

- Step 4: Use the optimized features from step 3(b) for SVM classification, again employing 5-fold cross-validation to ensure fair training.

4. Data Analysis Experiment

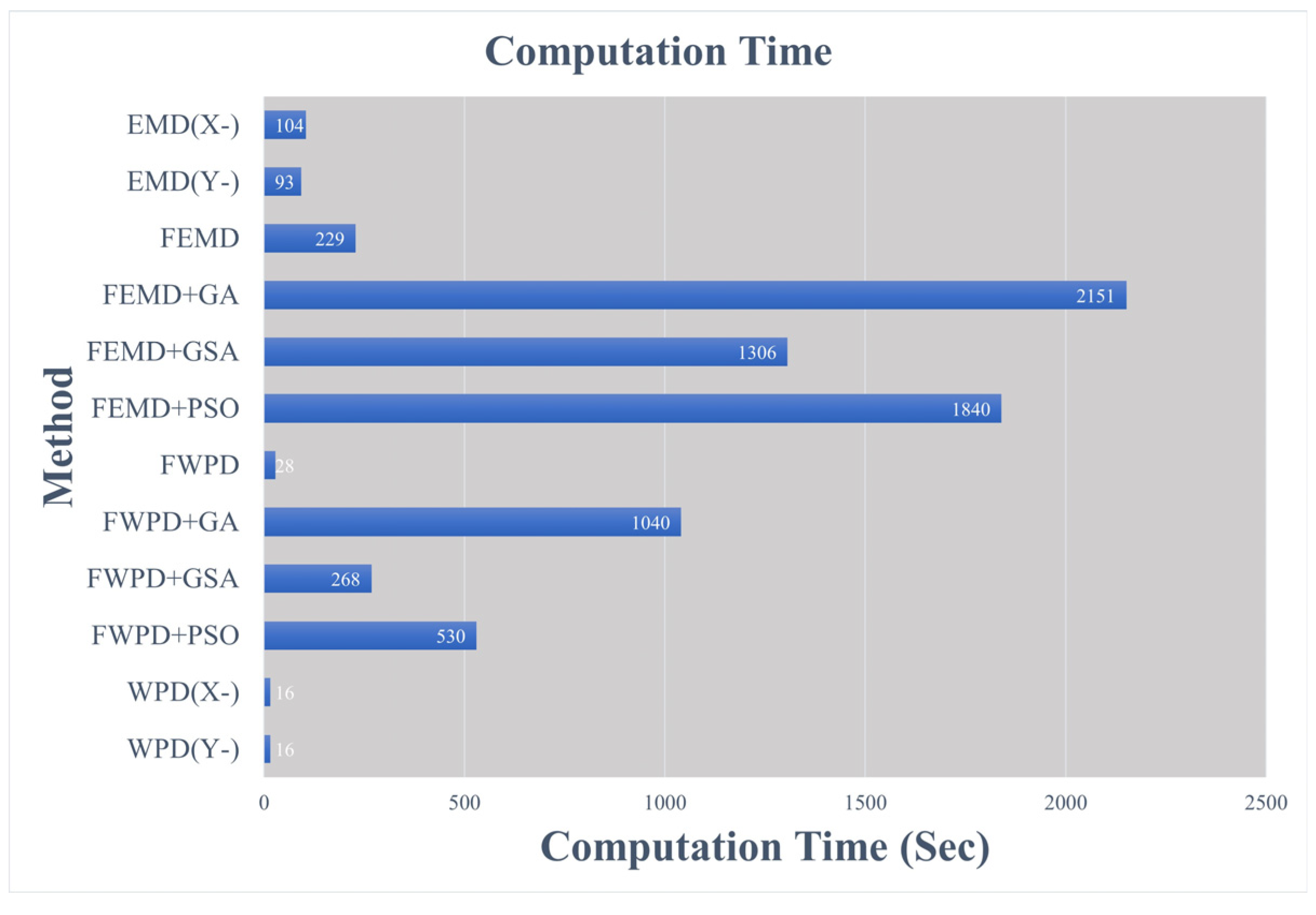

4.1. Computational Complexity Analysis

4.2. Performance Evaluation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IFR International Federation of Robotics. World Robotics 2023 Report: Asia Ahead of Europe and the Americas. Available online: https://ifr.org/ifr-press-releases/news/world-robotics-2023-report-asia-ahead-of-europe-and-the-americas (accessed on 29 November 2023).

- Raviola, A.; De Martin, A.; Guida, R.; Jacazio, G.; Mauro, S.; Sorli, M. Harmonic drive gear failures in industrial robots applications: An overview. In Proceedings of the PHM Society European Conference, Virtual, 28 June–2 July 2021; p. 11. [Google Scholar]

- Li, Q. RUL estimation for rolling bearings using augmented quaternion-based least mean P-power with correntropy induced metric under framework of sparsity. IEEE/ASME Trans. Mechatron. 2022, 28, 976–989. [Google Scholar] [CrossRef]

- Zio, E. Prognostics and Health Management (PHM): Where are we and where do we (need to) go in theory and practice. Reliab. Eng. Syst. Saf. 2022, 218, 108119. [Google Scholar] [CrossRef]

- Medoued, A.; Mordjaoui, M.; Soufi, Y.; Sayad, D. Induction machine bearing fault diagnosis based on the axial vibration analytic signal. Int. J. Hydrogen Energy 2016, 41, 12688–12695. [Google Scholar] [CrossRef]

- Cui, L.; Yan, L.; Zhao, D. Instantaneous Frequency Estimation-Based Order Tracking for Bearing Fault Diagnosis Under Strong Noise. IEEE Sens. J. 2023, 23, 30940–30949. [Google Scholar] [CrossRef]

- Paskalovski, S.; Digalovski, M. Simulation models for induction machine protection analysis. Int. J. Inf. Technol. Secur. 2022, 14, 63–74. [Google Scholar]

- Hou, X.; Du, F.; Huang, K.; Qiu, J.; Zhong, X. A Current-Based Fault Diagnosis Method for Rotating Machinery with Limited Training Samples. IEEE Trans. Instrum. Meas. 2023, 72, 3530414. [Google Scholar] [CrossRef]

- Raouf, I.; Lee, H.; Kim, H.S. Mechanical fault detection based on machine learning for robotic RV reducer using electrical current signature analysis: A data-driven approach. J. Comput. Des. Eng. 2022, 9, 417–433. [Google Scholar] [CrossRef]

- Wang, T.; Liang, M.; Li, J.; Cheng, W.; Li, C. Bearing fault diagnosis under unknown variable speed via gear noise cancellation and rotational order sideband identification. Mech. Syst. Signal Process. 2015, 62, 30–53. [Google Scholar] [CrossRef]

- Visnadi, L.B.; de Castro, H.F. Influence of bearing clearance and oil temperature uncertainties on the stability threshold of cylindrical journal bearings. Mech. Mach. Theory 2019, 134, 57–73. [Google Scholar] [CrossRef]

- Choudhary, A.; Goyal, D.; Letha, S.S. Infrared Thermography-Based Fault Diagnosis of Induction Motor Bearings Using Machine Learning. IEEE Sens. J. 2021, 21, 1727–1734. [Google Scholar] [CrossRef]

- Cui, X.; Wu, Y.; Zhang, X.; Huang, J.; Wong, P.K.; Li, C. A novel fault diagnosis method for rotor-bearing system based on instantaneous orbit fusion feature image and deep convolutional neural network. IEEE/ASME Trans. Mechatron. 2022, 28, 1013–1024. [Google Scholar] [CrossRef]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; De Silva, C.W. Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks. IEEE/ASME Trans. Mechatron. 2017, 23, 101–110. [Google Scholar] [CrossRef]

- Kumar, P.; Raouf, I.; Kim, H.S. Transfer learning for servomotor bearing fault detection in the industrial robot. Adv. Eng. Softw. 2024, 194, 103672. [Google Scholar] [CrossRef]

- Kibrete, F.; Engida Woldemichael, D.; Shimels Gebremedhen, H. Multi-Sensor data fusion in intelligent fault diagnosis of rotating machines: A comprehensive review. Measurement 2024, 232, 114658. [Google Scholar] [CrossRef]

- AlShorman, O.; Irfan, M.; Abdelrahman, R.e.B.; Masadeh, M.; Alshorman, A.; Sheikh, M.A.; Saad, N.; Rahman, S. Advancements in condition monitoring and fault diagnosis of rotating machinery: A comprehensive review of image-based intelligent techniques for induction motors. Eng. Appl. Artif. Intell. 2024, 130, 107724. [Google Scholar] [CrossRef]

- Fang, R.; Liu, Z.; Peng, C.; Yang, Y.; Zhang, S. Fault diagnosis of inter-turn short circuit in turbogenerator rotor windings based on vibration-current signal fusion. Energy Rep. 2023, 9, 316–323. [Google Scholar] [CrossRef]

- Gan, C.; Wu, J.; Yang, S.; Hu, Y.; Cao, W.; Si, J. Fault diagnosis scheme for open-circuit faults in switched reluctance motor drives using fast Fourier transform algorithm with bus current detection. IET Power Electron. 2016, 9, 20–30. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault-tolerant techniques—Part I: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Habbouche, H.; Benkedjouh, T.; Zerhouni, N. Intelligent prognostics of bearings based on bidirectional long short-term memory and wavelet packet decomposition. Int. J. Adv. Manuf. Technol. 2021, 114, 145–157. [Google Scholar] [CrossRef]

- Babu, T.N.; Devendiran, S.; Aravind, A.; Rakesh, A.; Jahzan, M. Fault diagnosis on journal bearing using empirical mode decomposition. Mater. Today Proc. 2018, 5, 12993–13002. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, Y.; Yi, C.; Tsui, K.-L.; Lin, J. Sparsity guided empirical wavelet transform for fault diagnosis of rolling element bearings. Mech. Syst. Signal Process. 2018, 101, 292–308. [Google Scholar] [CrossRef]

- Yan, R.; Shang, Z.; Xu, H.; Wen, J.; Zhao, Z.; Chen, X.; Gao, R.X. Wavelet transform for rotary machine fault diagnosis: 10 years revisited. Mech. Syst. Signal Process. 2023, 200, 110545. [Google Scholar] [CrossRef]

- de Azevedo, H.D.M.; Araújo, A.M.; Bouchonneau, N. A review of wind turbine bearing condition monitoring: State of the art and challenges. Renew. Sustain. Energy Rev. 2016, 56, 368–379. [Google Scholar] [CrossRef]

- Chudzik, A.; Warda, B. Effect of radial internal clearance on the fatigue life of the radial cylindrical roller bearing. Eksploat. I Niezawodn. 2019, 21, 211–219. [Google Scholar] [CrossRef]

- Karabacak, Y.E.; Gürsel Özmen, N.; Gümüşel, L. Intelligent worm gearbox fault diagnosis under various working conditions using vibration, sound and thermal features. Appl. Acoust. 2022, 186, 108463. [Google Scholar] [CrossRef]

- Han, T.; Liu, C.; Yang, W.; Jiang, D. A novel adversarial learning framework in deep convolutional neural network for intelligent diagnosis of mechanical faults. Knowl. -Based Syst. 2019, 165, 474–487. [Google Scholar] [CrossRef]

- Irfan, M.; Althobiani, F.; Alwadie, A.S.; Zaffar, M.; Abbass, A.; Glowacz, A.; Ghonaim, S.M.; Abdushkour, H.; Rahman, S.; Alshorman, O. Condition monitoring of water pump bearings using ensemble classifier. Adv. Mech. Eng. 2022, 14, 16878132221089170. [Google Scholar] [CrossRef]

- Dameshghi, A.; Refan, M.H. Wind turbine gearbox condition monitoring and fault diagnosis based on multi-sensor information fusion of SCADA and DSER-PSO-WRVM method. Int. J. Model. Simul. 2019, 39, 48–72. [Google Scholar] [CrossRef]

- Lei, Y.; Lin, J.; He, Z.; Zuo, M.J. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2013, 35, 108–126. [Google Scholar] [CrossRef]

- Sun, H.; Zi, Y.; He, Z. Wind turbine fault detection using multiwavelet denoising with the data-driven block threshold. Appl. Acoust. 2014, 77, 122–129. [Google Scholar] [CrossRef]

- Rashedi, E.; Nezamabadi-Pour, H.; Saryazdi, S. GSA: A gravitational search algorithm. Inf. Sci. 2009, 179, 2232–2248. [Google Scholar] [CrossRef]

- Rashedi, E.; Rashedi, E.; Nezamabadi-pour, H. A comprehensive survey on gravitational search algorithm. Swarm Evol. Comput. 2018, 41, 141–158. [Google Scholar] [CrossRef]

- Ding, S.; Hao, M.; Cui, Z.; Wang, Y.; Hang, J.; Li, X. Application of multi-SVM classifier and hybrid GSAPSO algorithm for fault diagnosis of electrical machine drive system. ISA Trans. 2023, 133, 529–538. [Google Scholar] [CrossRef] [PubMed]

- Precup, R.-E.; David, R.-C.; Petriu, E.M.; Radac, M.-B.; Preitl, S. Adaptive GSA-based optimal tuning of PI controlled servo systems with reduced process parametric sensitivity, robust stability and controller robustness. IEEE Trans. Cybern. 2014, 44, 1997–2009. [Google Scholar] [CrossRef] [PubMed]

- Eappen, G.; Shankar, T. Hybrid PSO-GSA for energy efficient spectrum sensing in cognitive radio network. Phys. Commun. 2020, 40, 101091. [Google Scholar] [CrossRef]

- Hooda, H.; Verma, O.P. Fuzzy clustering using gravitational search algorithm for brain image segmentation. Multimed. Tools Appl. 2022, 81, 29633–29652. [Google Scholar] [CrossRef]

- Zamfirache, I.A.; Precup, R.-E.; Roman, R.-C.; Petriu, E.M. Reinforcement Learning-based control using Q-learning and gravitational search algorithm with experimental validation on a nonlinear servo system. Inf. Sci. 2022, 583, 99–120. [Google Scholar] [CrossRef]

- Raouf, I.; Lee, H.; Noh, Y.R.; Youn, B.D.; Kim, H.S. Prognostic health management of the robotic strain wave gear reducer based on variable speed of operation: A data-driven via deep learning approach. J. Comput. Des. Eng. 2022, 9, 1775–1788. [Google Scholar] [CrossRef]

- Das, O.; Bagci Das, D.; Birant, D. Machine learning for fault analysis in rotating machinery: A comprehensive review. Heliyon 2023, 9, e17584. [Google Scholar] [CrossRef]

- Raouf, I.; Kumar, P.; Soo Kim, H. Deep learning-based fault diagnosis of servo motor bearing using the attention-guided feature aggregation network. Expert Syst. Appl. 2024, 258, 125137. [Google Scholar] [CrossRef]

- Siddique, M.F.; Ahmad, Z.; Ullah, N.; Kim, J. A Hybrid Deep Learning Approach: Integrating Short-Time Fourier Transform and Continuous Wavelet Transform for Improved Pipeline Leak Detection. Sensors 2023, 23, 8079. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Lei, Y.; Qi, G.; Chai, Y.; Mazur, N.; An, Y.; Huang, X. A review of the application of deep learning in intelligent fault diagnosis of rotating machinery. Measurement 2023, 206, 112346. [Google Scholar] [CrossRef]

- Siddique, M.F.; Ahmad, Z.; Kim, J.-M. Pipeline leak diagnosis based on leak-augmented scalograms and deep learning. Eng. Appl. Comput. Fluid Mech. 2023, 17, 2225577. [Google Scholar] [CrossRef]

- Raouf, I.; Kumar, P.; Lee, H.; Kim, H.S. Transfer Learning-Based Intelligent Fault Detection Approach for the Industrial Robotic System. Mathematics 2023, 11, 945. [Google Scholar] [CrossRef]

| Fault Model | Gear Wear | Less Grease | Gear Fracture | Improper Load | Bearing Damage |

|---|---|---|---|---|---|

| Fault Cause | Excessive shaft misalignment, high surface roughness | Excessive or less grease | Overloading, misuse | Excessive load | Bearing ball wear |

| Model Type | Signal Type | Total |

|---|---|---|

| N, GF, GW, IL, LG, B | Vibration | 170 |

| Methods | Vibration | ||||

|---|---|---|---|---|---|

| ACC | PC | RC | F1 | Computation Time | |

| EMD (X-axis) | 52.6 | 52.2 | 56.6 | 50.6 | 104.11(S) |

| EMD (Y-axis) | 35.6 | 40.5 | 35.6 | 33.7 | 92.66(S) |

| WPD (X-axis) | 68.6 | 69.7 | 68.6 | 88.6 | 15.6(S) |

| WPD (Y-axis) | 55.0 | 55.2 | 55.0 | 54.4 | 15.87(S) |

| FEMD | 65.0 | 75.8 | 65.0 | 64.84 | 228.67(S) |

| FEMD+GSA | 88.5 | 89.7 | 88.5 | 86.9 | 1306.02(S) |

| FEMD+GA | 78.6 | 79.3 | 78.3 | 77.5 | 2151.39(S) |

| FEMD+PSO | 82.3 | 83.7 | 82.5 | 82.5 | 1839.63(S) |

| FWPD | 73.3 | 75.1 | 73.3 | 71.7 | 28.35(S) |

| FWPD+GSA | 93.3 | 94.5 | 93.3 | 92.9 | 267.95(S) |

| FWPD+GA | 80.76 | 82.2 | 80.7 | 80.4 | 1040.46(S) |

| FWPD+PSO | 76.6 | 78.1 | 76.6 | 77.0 | 530.33(S) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsieh, N.-K.; Yu, T.-Y. Fault Detection in Harmonic Drive Using Multi-Sensor Data Fusion and Gravitational Search Algorithm. Machines 2024, 12, 831. https://doi.org/10.3390/machines12120831

Hsieh N-K, Yu T-Y. Fault Detection in Harmonic Drive Using Multi-Sensor Data Fusion and Gravitational Search Algorithm. Machines. 2024; 12(12):831. https://doi.org/10.3390/machines12120831

Chicago/Turabian StyleHsieh, Nan-Kai, and Tsung-Yu Yu. 2024. "Fault Detection in Harmonic Drive Using Multi-Sensor Data Fusion and Gravitational Search Algorithm" Machines 12, no. 12: 831. https://doi.org/10.3390/machines12120831

APA StyleHsieh, N.-K., & Yu, T.-Y. (2024). Fault Detection in Harmonic Drive Using Multi-Sensor Data Fusion and Gravitational Search Algorithm. Machines, 12(12), 831. https://doi.org/10.3390/machines12120831