Methodology and Experimental Verification for Predicting the Remaining Useful Life of Milling Cutters Based on Hybrid CNN-LSTM-Attention-PSA

Abstract

1. Introduction

- (1)

- This paper proposes and validates the application of a CNN-LSTM-Attention deep learning model optimized by the PSA algorithm for CNC milling tool RUL prediction. This model leverages the spatial feature extraction capability of CNN, the temporal sequence data processing capability of LSTM, and the attention mechanism’s ability to identify and utilize key information. This method extracts important features from multi-channel sensor data to precisely assess tool wear. This innovative combination significantly improves the model’s predictive accuracy;

- (2)

- This study introduces a proportional-integral-derivative (PID) theory-based search algorithm (PSA) [22] for model hyperparameter optimization. The PSA algorithm mimics the principles of a PID controller by using differential, integral, and proportional operations to perform fine-tuned searches of model parameters. This aims to minimize prediction errors and quickly and steadily find the optimal model parameters. This method enhances the model’s adaptability to uncertainties and non-linear problems, further improving predictive accuracy and generalization ability;

- (3)

- Through a series of rigorous experiments, the effectiveness of the CNN-LSTM-Attention-PSA model in RUL prediction is validated. Comparisons with other models demonstrate significant improvements in prediction accuracy and computational efficiency, laying the foundation for future research in related fields.

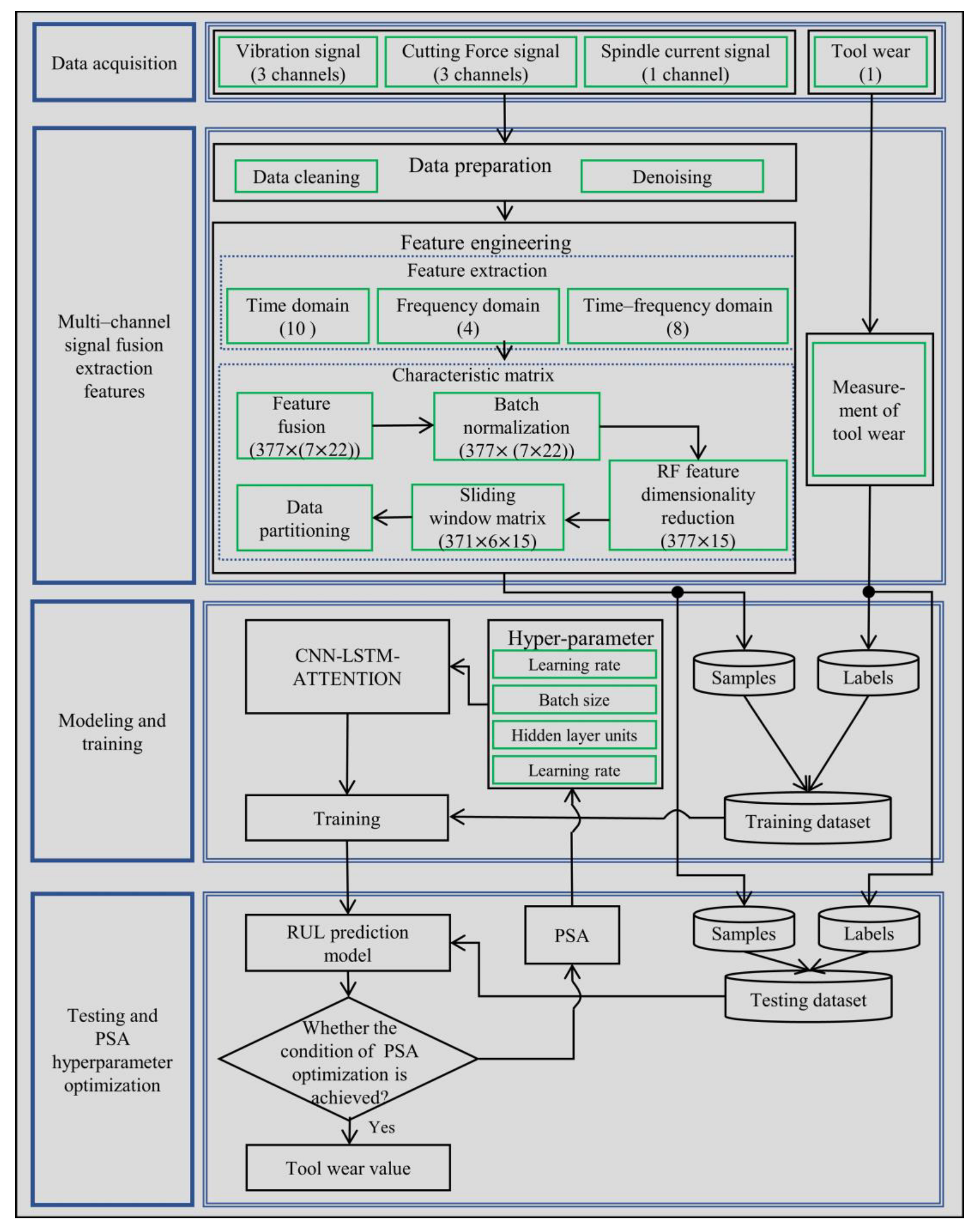

2. Proposed Method

2.1. Deep Learning Model Based on CNN-LSTM-Attention

- (1)

- Extraction of features from multi-channel raw signals that have been cleaned. By integrating, extracting, and reducing the dimensionality of raw signals that have been cleaned, the feature recognition capabilities of the machine learning model are enhanced, providing a richer data foundation for model training and prediction;

- (2)

- This convolutional neural network (CNN) layer performs localized feature extraction through convolution operations, capturing spatial correlations within time-series data. By using filter arrays, the CNN effectively extracts features from the input data, making it suitable for processing complex time-series signals;

- (3)

- To address the temporal nature of the data, the LSTM layer is introduced, which enhances the model’s ability to capture long-term dependencies. The LSTM’s gating mechanism allows it to retain important temporal patterns while mitigating the vanishing gradient problem, thus supporting stable model training;

- (4)

- The self-attention mechanism is used to dynamically assign importance to different parts of the time-series input, enabling the model to focus on the most critical features. This selective attention improves the model’s performance in handling intricate relationships within the data.

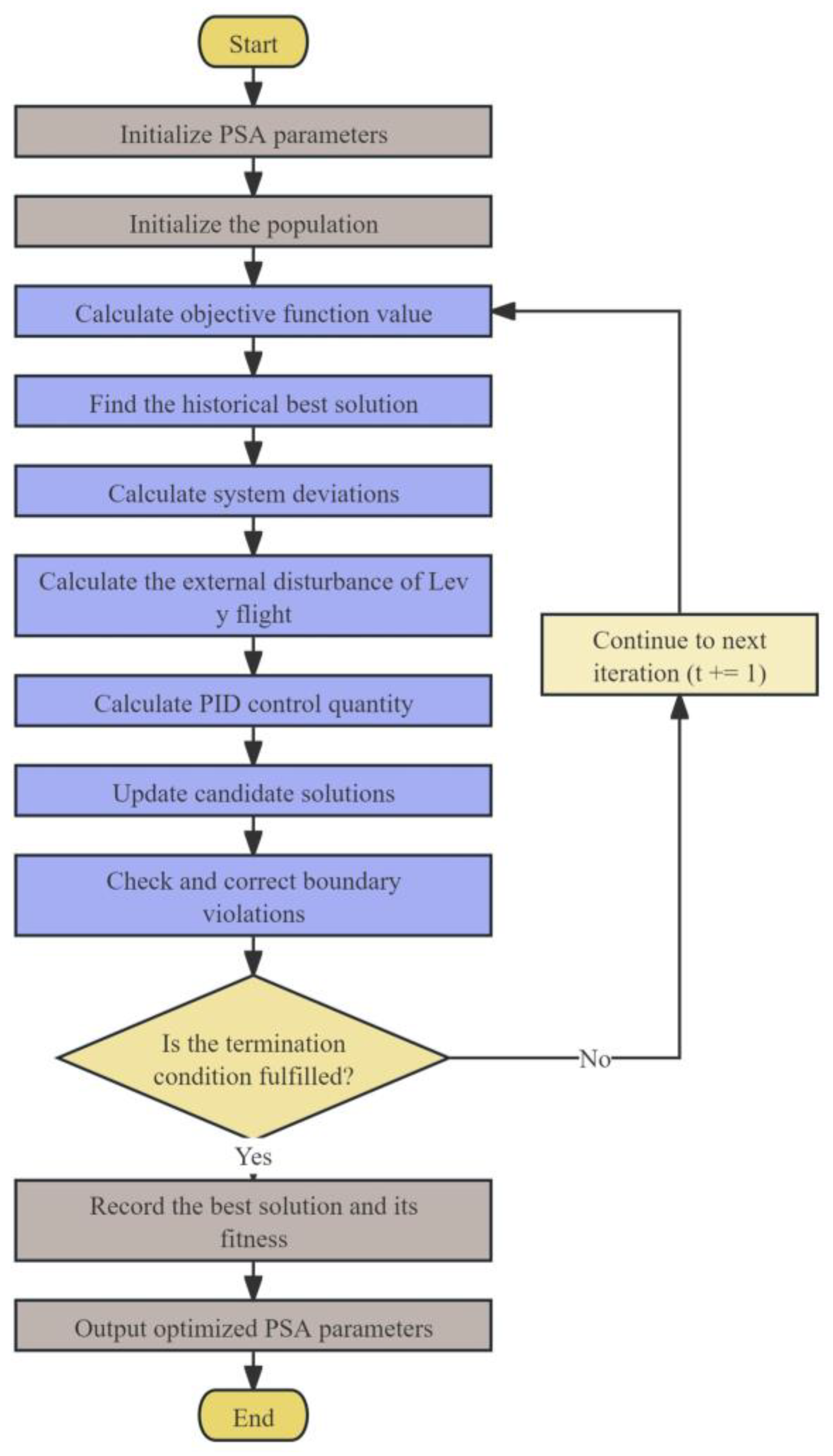

2.2. Hyperparameter Tuning Based on PSA

- PID-based Search Algorithm (PSA)

- 2.

- CNN-LSTM-Attention Method for Hyperparameter Optimization Based on PSA

- 1.

- The design of the deep learning model primarily combines Conv1D, LSTM, and self-attention.

- 2.

- PSA Hyperparameter Optimization Principle

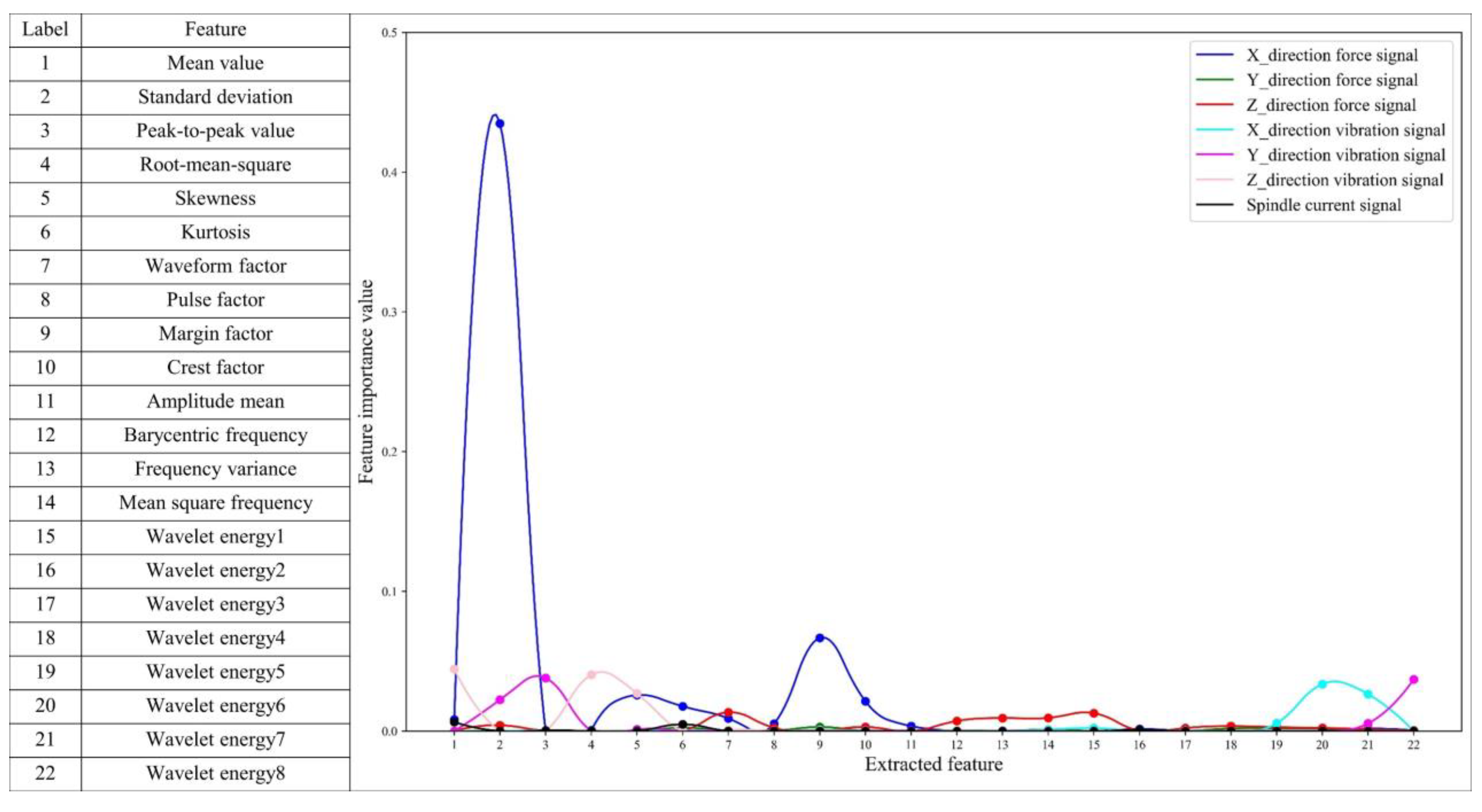

3. Multi-Channel Signal Fusion for Feature Extraction

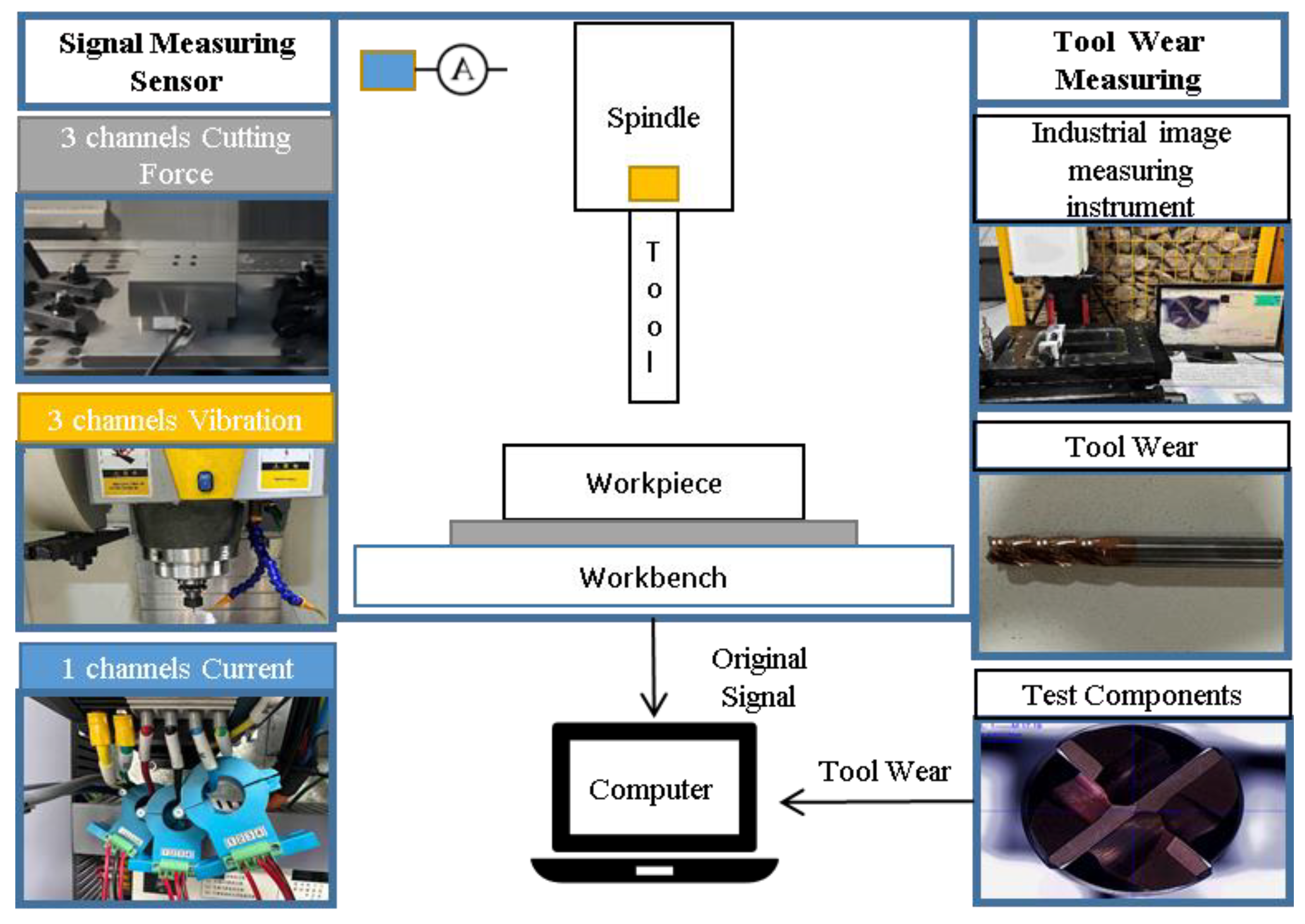

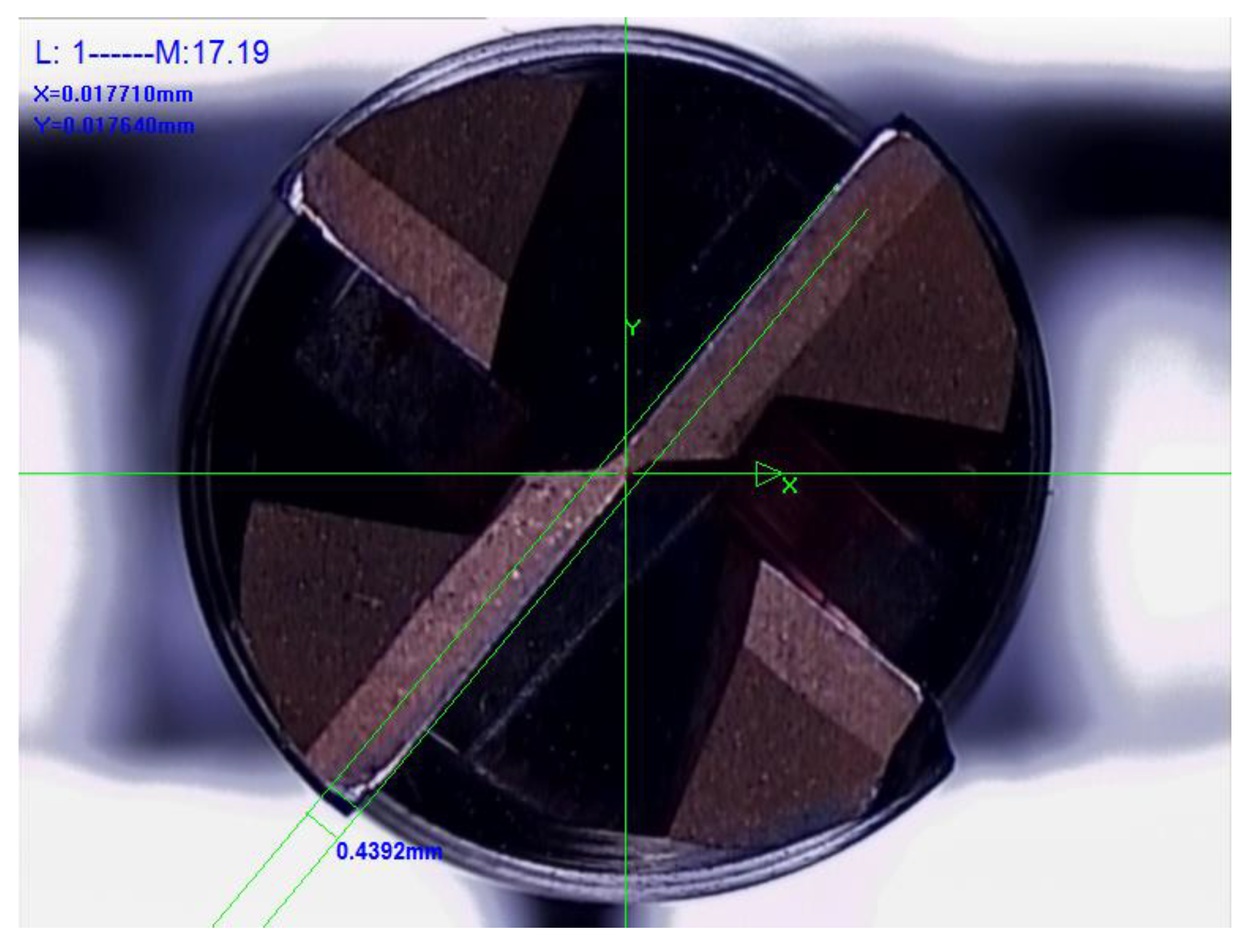

3.1. Source of Raw Data

- 1.

- Cutting Force Signal

- 2.

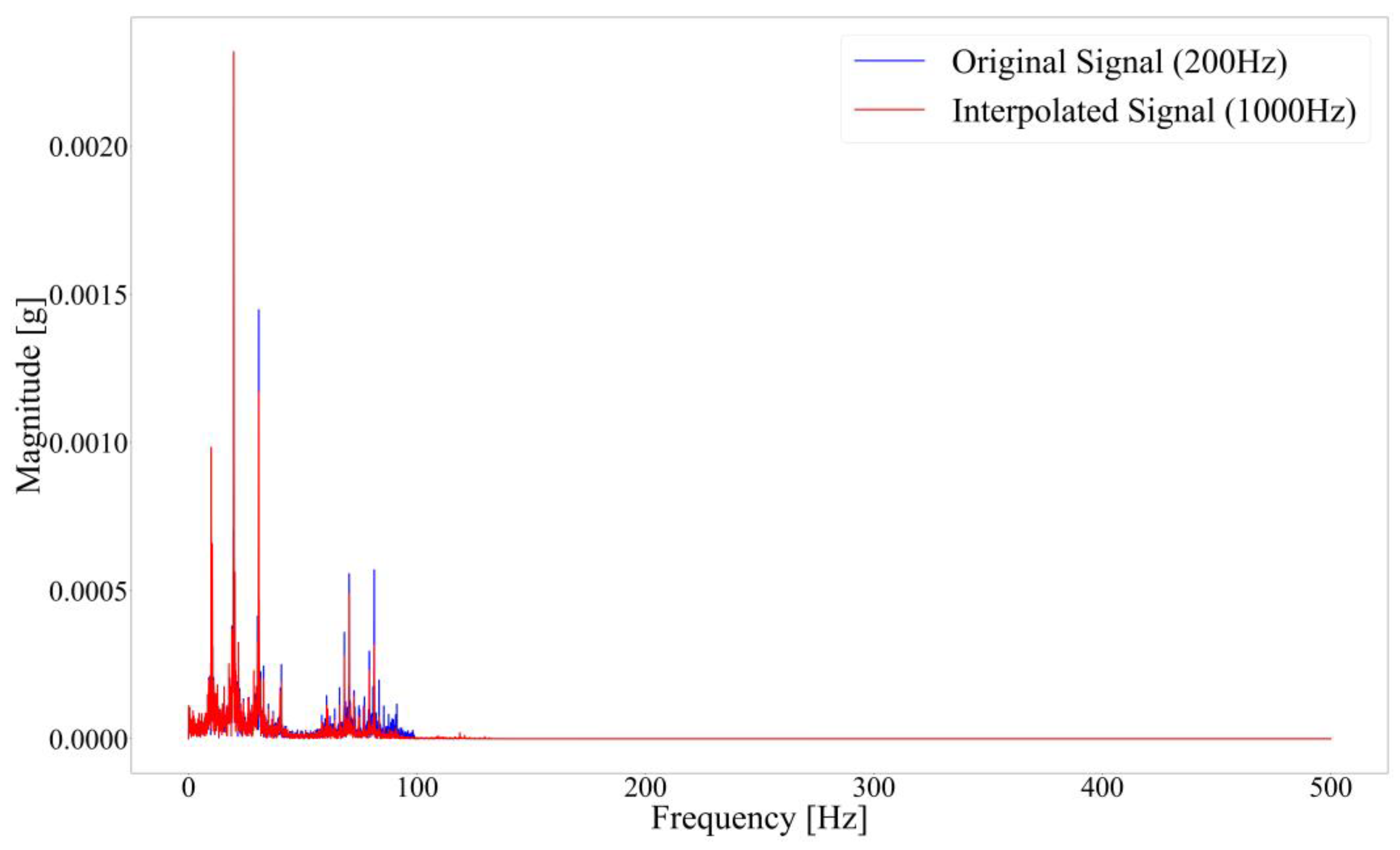

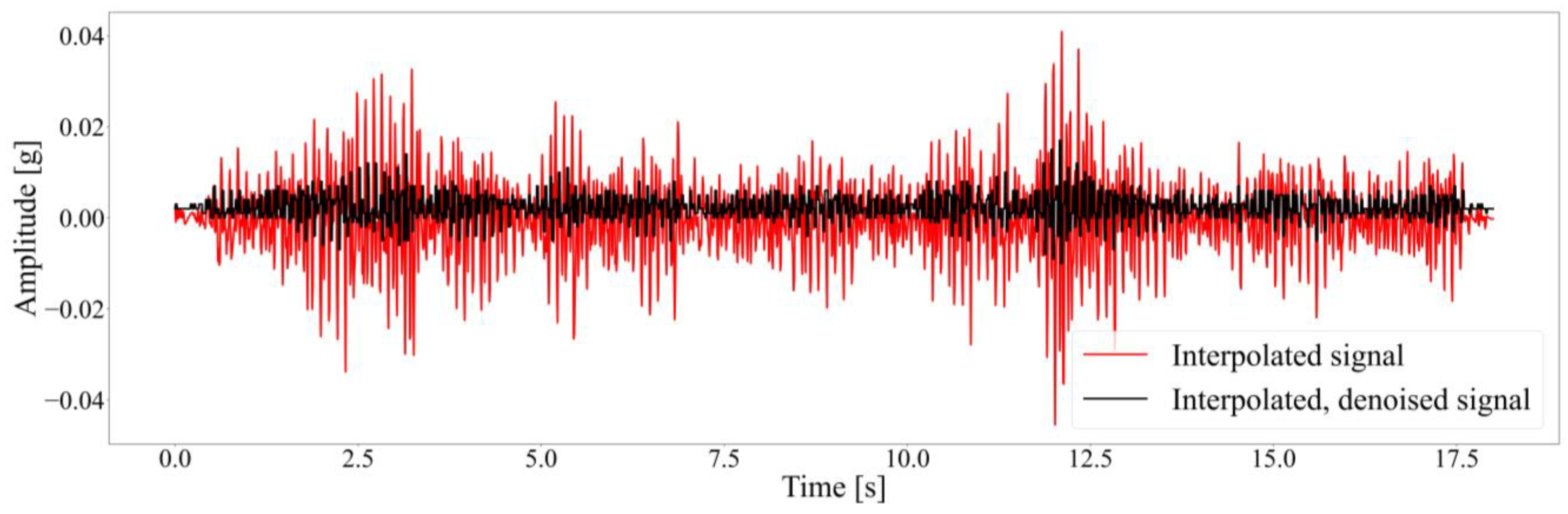

- Vibration Signal

- 3.

- Spindle Current Signal

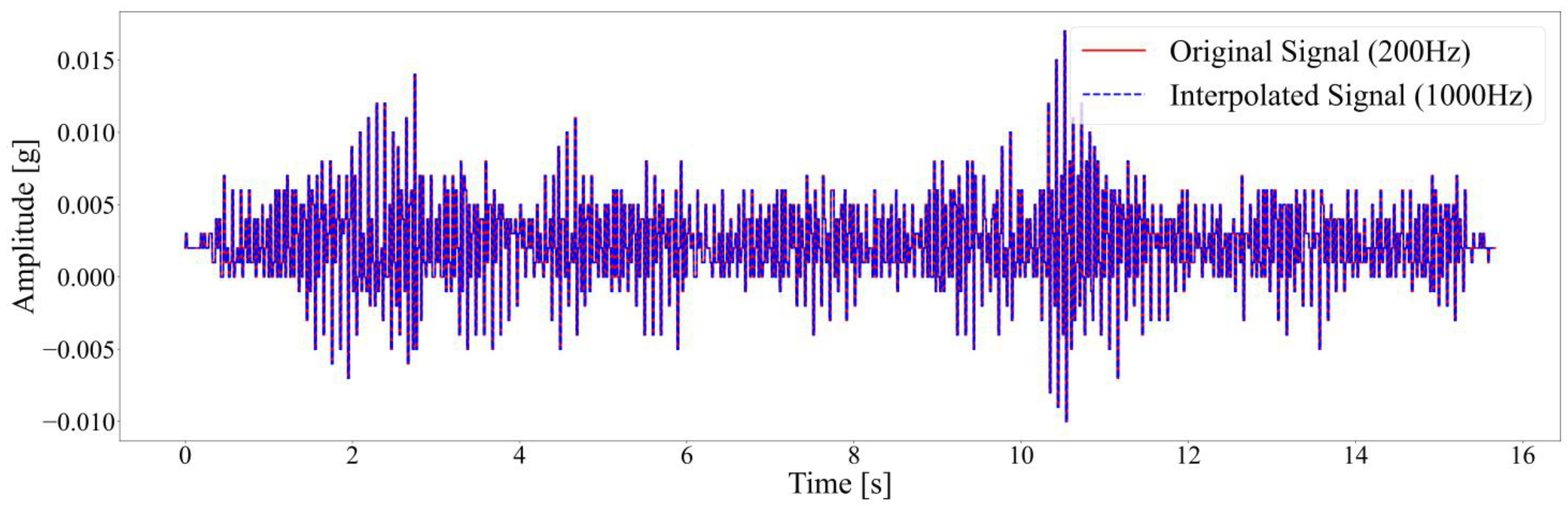

3.2. Data Preprocessing

3.3. Feature Engineering

4. Experimental Design and Method

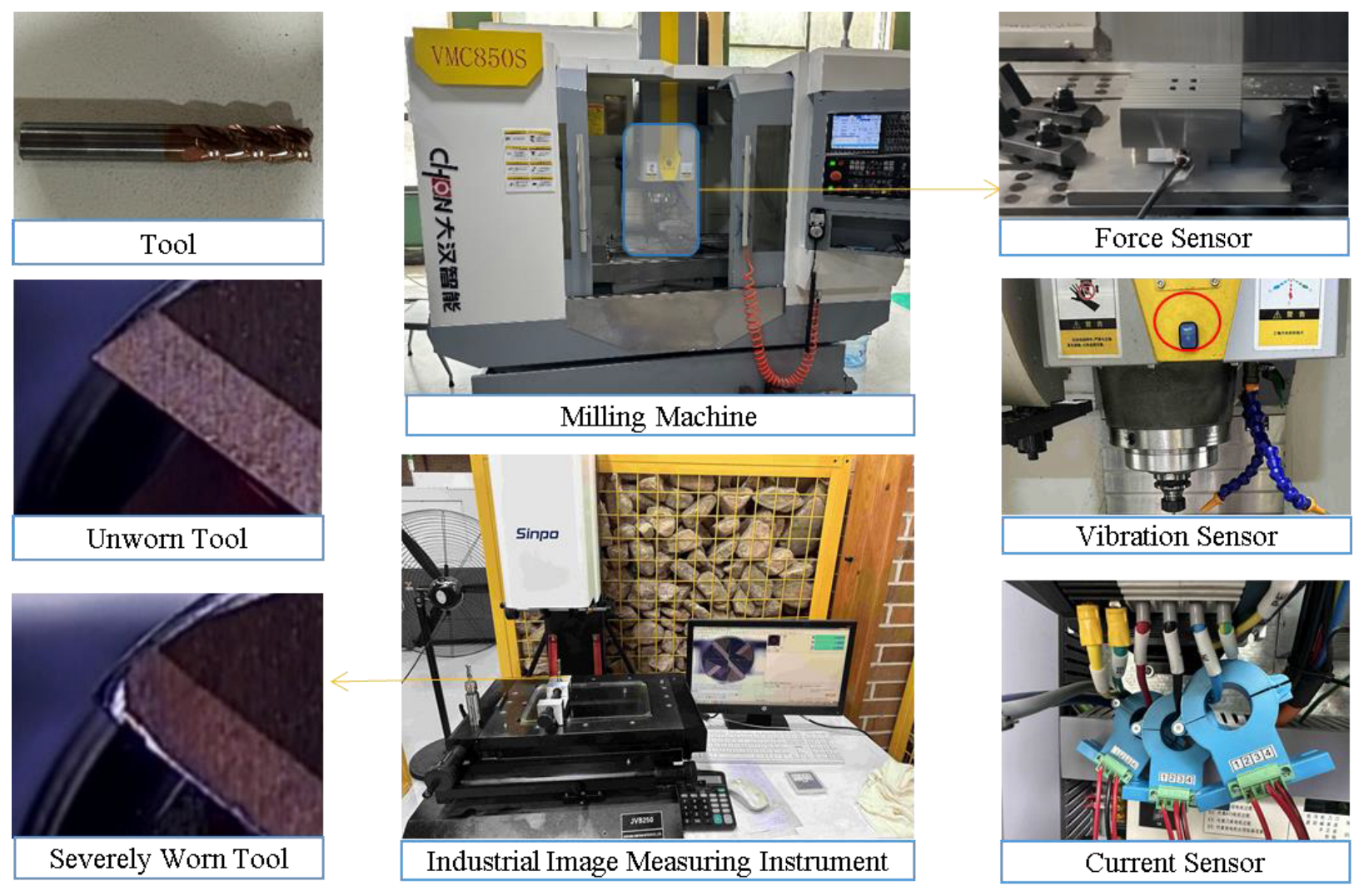

4.1. Experimental Setup

4.2. Experimental Method

5. Results and Discussion

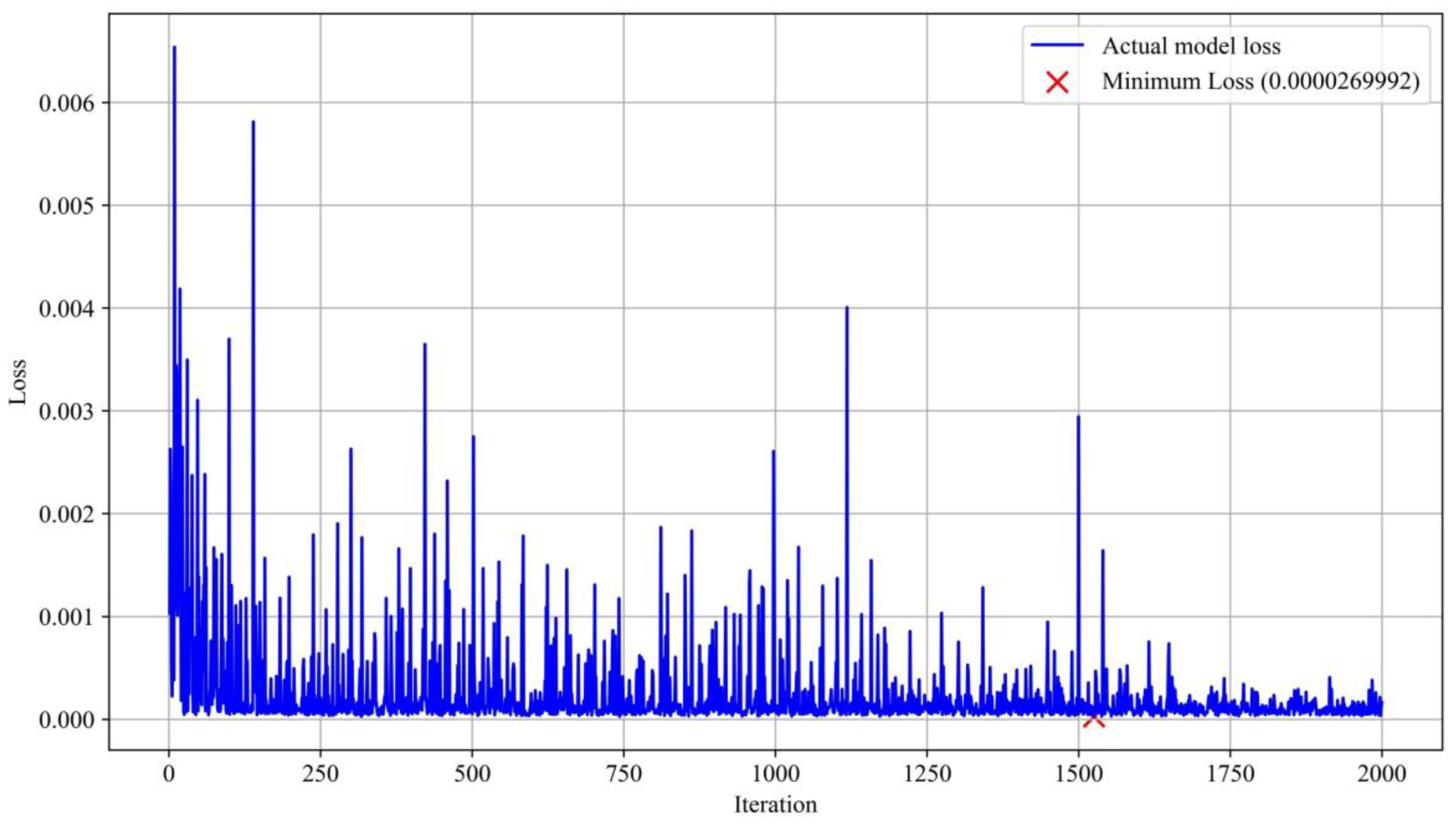

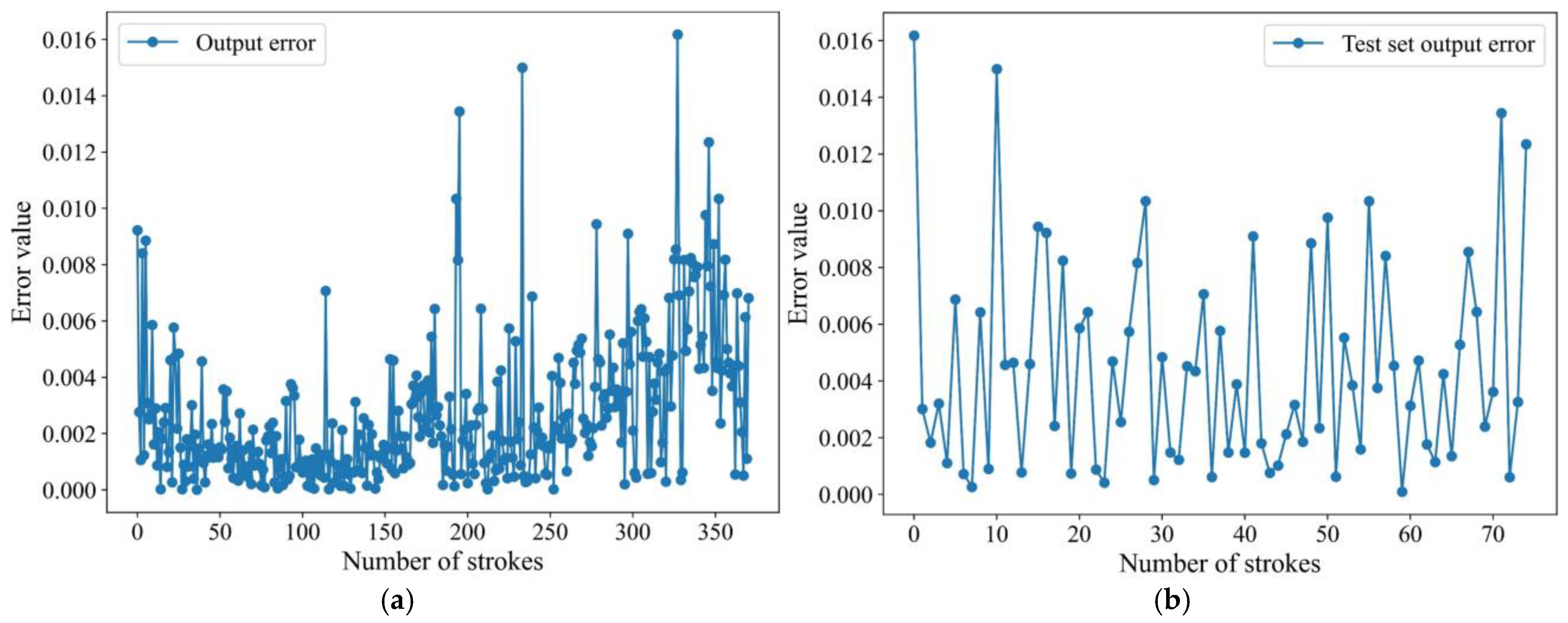

5.1. Construction of the Prediction Model

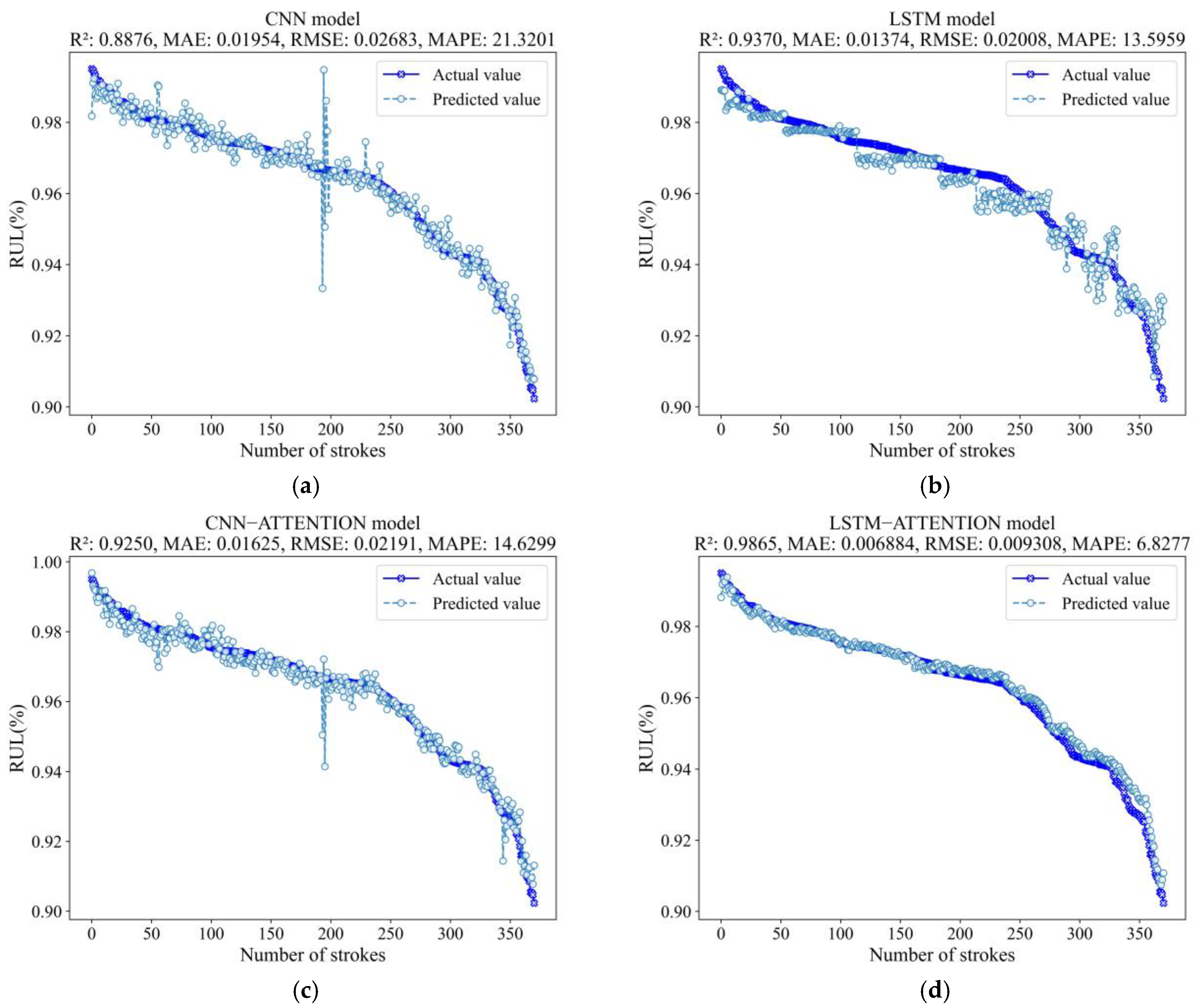

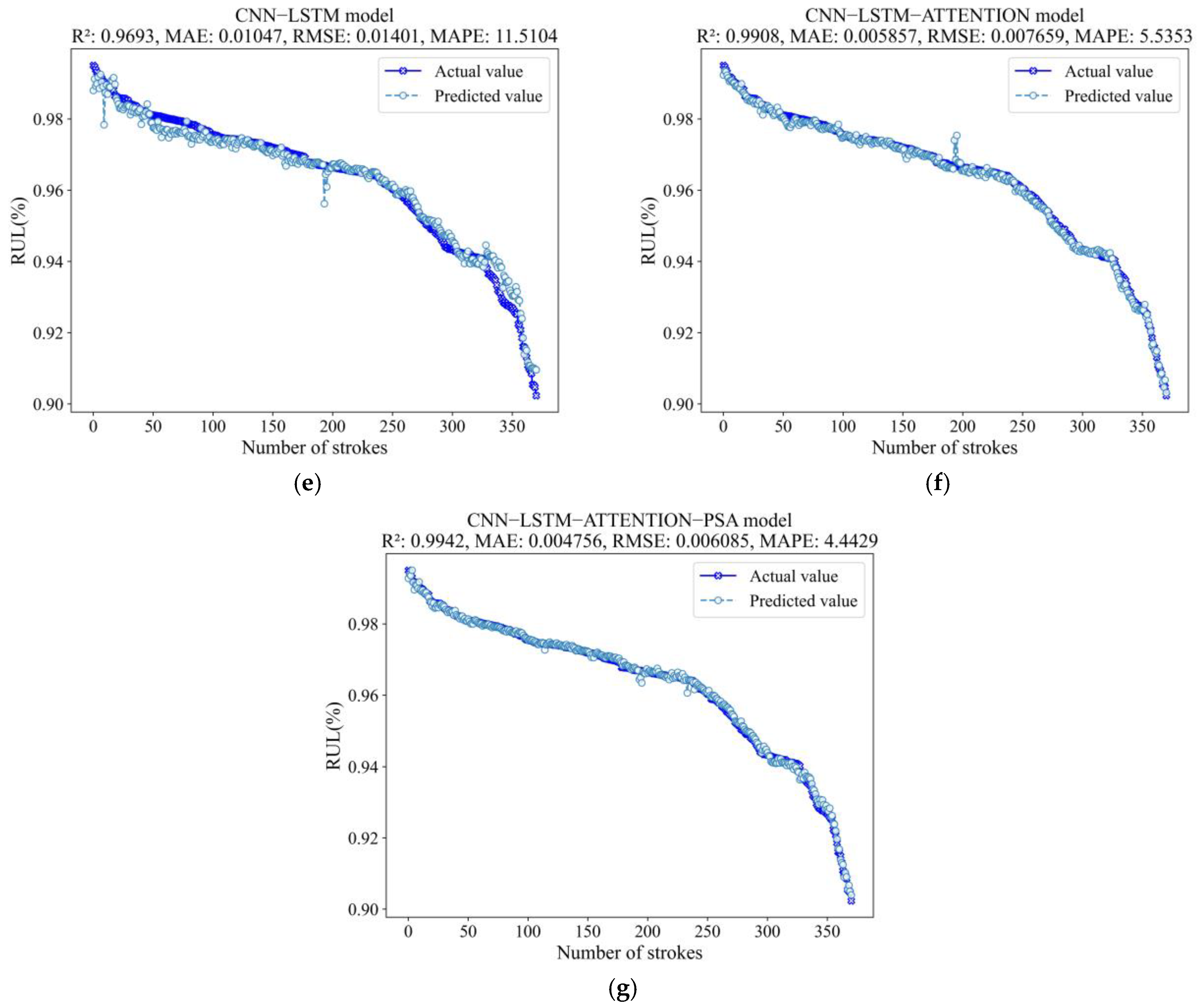

5.2. Prediction Performance Analysis

6. Conclusions

- (1)

- The fusion of multi-channel data features significantly impacts model prediction, enhancing the model’s generalization ability and prediction accuracy and avoiding the problem where single-sensor data might be insufficient to provide all the feature information needed by machine learning. The results obtained demonstrate that multi-channel signal integration, including force, vibration, and current signals, is essential for capturing the full range of tool wear characteristics;

- (2)

- Optimizing the model’s hyperparameters with the PID-based search algorithm (PSA) significantly improves the model’s predictive performance. The PSA optimization further enhances the robustness of the model by fine-tuning hyperparameters, thus yielding more reliable predictions compared to other baseline models. In the comparison of CNN-LSTM-Attention models with manually randomized hyperparameters to the hybrid CNN-LSTM-Attention-PSA model, while keeping the algorithmic structure constant, the hybrid model demonstrates superior performance;

- (3)

- Compared to CNN, CNN-LSTM, LSTM, CNN-Attention, LSTM-Attention, and CNN-LSTM-Attention models, the hybrid CNN-LSTM-Attention-PSA model outperforms others in predicting tool RUL. CNN algorithms lack in-depth processing of time-series data in RUL prediction. The LSTM algorithm lacks feature extraction and attention mechanism and has limited generalization ability. CNN-LSTM lacks attention mechanism and hyper-parameter optimization and has insufficient prediction accuracy and generalization.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Detailed Procedure of PSA Algorithm to Optimize Model Parameters

Appendix B. Detailed Process of Missing Value Processing and Denoising

References

- Kannadasan, K.; Edla, D.R.; Yadav, M.H.; Bablani, A. Intelligent-ANFIS Model for Predicting Measurement of Surface Roughness and Geometric Tolerances in Three-Axis CNC Milling. IEEE Trans. Instrum. Meas. 2020, 69, 7683–7694. [Google Scholar] [CrossRef]

- Zi, X.; Gao, S.; Xie, Y. An online monitoring method of milling cutter wear condition driven by digital twin. Sci. Rep. 2024, 14, 4956. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Guo, K.; Zhang, D.; Yang, B.; Sun, J.; Li, D.; Huang, T. A novel exponential model for tool remaining useful life prediction. J. Manuf. Syst. 2024, 73, 223–240. [Google Scholar] [CrossRef]

- Liu, Y.; Chang, Y.; Liu, S.; Chen, S. Data-driven prognostics of remaining useful life for milling machine cutting tools. In Proceedings of the 2019 IEEE International Conference on Prognostics and Health Management (ICPHM), San Francisco, CA, USA, 17–20 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–5. [Google Scholar]

- Peng, D.; Li, H.; Dai, Y.; Wang, Z.; Ou, J. Prediction of milling force based on spindle current signal by neural networks. Measurement 2022, 205, 112153. [Google Scholar] [CrossRef]

- Huang, Z.; Shao, J.; Zhu, J.; Zhang, W.; Li, X. Tool wear condition monitoring across machining processes based on feature transfer by deep adversarial domain confusion network. J. Intell. Manuf. 2024, 35, 1079–1105. [Google Scholar] [CrossRef]

- He, Z.; Shi, T.; Xuan, J. Milling tool wear prediction using multi-sensor feature fusion based on stacked sparse autoencoders. Measurement 2022, 190, 110719. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of signal behaviors for sensor fusion with tool condition monitoring system in turning. Measurement 2021, 173, 108582. [Google Scholar] [CrossRef]

- Wong, S.Y.; Chuah, J.H.; Yap, H.J. Technical data-driven tool condition monitoring challenges for CNC milling: A review. Int. J. Adv. Manuf. Technol. 2020, 107, 4837–4857. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, F.; Zhou, X.; Ding, K.; Shao, S.; Du, C.; Leng, J. Data-driven and knowledge-guided prediction model of milling tool life grade. Int. J. Comput. Integr. Manuf. 2023, 37, 669–684. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Hong, D.; Lu, Y.; Wang, Z.; Liao, Z. Intelligent tool wear monitoring based on multi-channel hybrid information and deep transfer learning. J. Manuf. Syst. 2023, 69, 31–47. [Google Scholar] [CrossRef]

- Guo, L.; Yu, Y.; Gao, H.; Feng, T.; Liu, Y. Online Remaining Useful Life Prediction of Milling Cutters Based on Multisource Data and Feature Learning. IEEE Trans. Ind. Inf. 2022, 18, 5199–5208. [Google Scholar] [CrossRef]

- Ambadekar, P.K.; Choudhari, C.M. CNN based tool monitoring system to predict life of cutting tool. SN Appl. Sci. 2020, 2, 860. [Google Scholar] [CrossRef]

- Marani, M.; Zeinali, M.; Songmene, V.; Mechefske, C.K. Tool wear prediction in high-speed turning of a steel alloy using long short-term memory modelling. Measurement 2021, 177, 109329. [Google Scholar] [CrossRef]

- Marei, M.; Li, W. Cutting tool prognostics enabled by hybrid CNN-LSTM with transfer learning. Int. J. Adv. Manuf. Technol. 2022, 118, 817–836. [Google Scholar] [CrossRef]

- Khayyam, H.; Jamali, A.; Bab-Hadiashar, A.; Esch, T.; Ramakrishna, S.; Jalili, M.; Naebe, M. A Novel Hybrid Machine Learning Algorithm for Limited and Big Data Modeling with Application in Industry 4.0. IEEE Access 2020, 8, 111381–111393. [Google Scholar] [CrossRef]

- Sayyad, S.; Kumar, S.; Bongale, A.; Kotecha, K.; Abraham, A. Remaining Useful-Life Prediction of the Milling Cutting Tool Using Time–Frequency-Based Features and Deep Learning Models. Sensors 2023, 23, 5659. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, X.; Li, W.; Wang, S. Prediction of the remaining useful life of cutting tool using the Hurst exponent and CNN-LSTM. Int. J. Adv. Manuf. Technol. 2021, 112, 2277–2299. [Google Scholar] [CrossRef]

- Xue, Z.; Li, L.; Chen, N.; Wu, W.; Zou, Y.; Yu, N. Tool Wear State Recognition Based on One-Dimensional Convolutional Channel Attention. Micromachines 2023, 14, 1983. [Google Scholar] [CrossRef]

- Chintakindi, S.; Alsamhan, A.; Abidi, M.H.; Kumar, M.P. Annealing of Monel 400 Alloy Using Principal Component Analysis, Hyper-parameter Optimization, Machine Learning Techniques, and Multi-objective Particle Swarm Optimization. Int. J. Comput. Int. Syst. 2022, 15, 18. [Google Scholar] [CrossRef]

- Mahmood, J.; Mustafa, G.; Ali, M. Accurate estimation of tool wear levels during milling, drilling and turning operations by designing novel hyperparameter tuned models based on LightGBM and stacking. Measurement 2022, 190, 110722. [Google Scholar] [CrossRef]

- Gao, Y. PID-based search algorithm: A novel metaheuristic algorithm based on PID algorithm. Expert Syst. Appl. 2023, 232, 120886. [Google Scholar] [CrossRef]

- Huang, Z.; Shao, J.; Guo, W.; Li, W.; Zhu, J.; He, Q.; Fang, D. Tool Wear Prediction Based on Multi-Information Fusion and Genetic Algorithm-Optimized Gaussian Process Regression in Milling. IEEE Trans. Instrum. Meas. 2023, 72, 1–16. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Guo, L.; Li, N.; Yan, T.; Lin, J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 2018, 104, 799–834. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, W.; Mei, J.; Si, G.; Xia, T.; Quan, J. A New Support Vector Regression Model for Equipment Health Diagnosis with Small Sample Data Missing and Its Application. Shock. Vib. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Lang, P.; Fu, X.; Martorella, M.; Dong, J.; Qin, R.; Meng, X.; Xie, M. A Comprehensive Survey of Machine Learning Applied to Radar Signal Processing. arXiv 2020, arXiv:2009.13702. [Google Scholar]

- Guan, L.; Yang, X.; Zhao, N.; Alomainy, A.; Imran, M.A.; Abbasi, Q.H. Domain-Independent Gesture Recognition Using Single-Channel Time-Modulated Array. IEEE Trans. Antenn. Propag. 2024, 72, 3386–3399. [Google Scholar] [CrossRef]

- Nasir, V.; Dibaji, S.; Alaswad, K.; Cool, J. Tool wear monitoring by ensemble learning and sensor fusion using power, sound, vibration, and AE signals. Manuf. Lett. 2021, 30, 32–38. [Google Scholar] [CrossRef]

- Peng, D.; Li, H. Intelligent monitoring of milling tool wear based on milling force coefficients by prediction of instantaneous milling forces. Mech. Syst. Signal Process. 2024, 208, 111033. [Google Scholar] [CrossRef]

- Alberts, M.; St. John, S.; Jared, B.; Karandikar, J.; Khojandi, A.; Schmitz, T.; Coble, J. Chatter detection in simulated machining data: A simple refined approach to vibration data. Int. J. Adv. Manuf. Technol. 2024, 132, 4541–4557. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar] [CrossRef]

- Li, T.; Si, X.; Pei, H.; Sun, L. Data-model interactive prognosis for multi-sensor monitored stochastic degrading devices. Mech. Syst. Signal Process. 2022, 167, 108526. [Google Scholar] [CrossRef]

- ISO 3685:1993; Tool-life testing with single-point turning tools. International Organization for Standardization: Geneva, Switzerland, 1993.

| Signal Type | Advantages | Disadvantages |

|---|---|---|

| Cutting Force | High correlation and accuracy | High cost, susceptible to interference |

| Vibration | High correlation, simple installation, low cost | Environmentally susceptible |

| Spindle Current | Simple installation, low cost | Noticeable delay effect |

| Acoustic Emission | Low interference signal | General correlation, high cost |

| Equipment Name | Product Model | Manufacturer | Main Parameters | Description |

|---|---|---|---|---|

| Three-Dimensional Force Sensor | KCDW | Bengbu Kechuang Sensor Co., Ltd., Bengbu, China | The range of measurement force: 10–2000 N, Sampling frequency: 1000 Hz, Sensitivity: 1.0–1.5 mv/v, Accuracy: 0.01 N | Precisely captures milling cutter forces |

| Vibration Sensor | WT9011DCL-BT50 | WitMotion Shenzhen Co., Ltd., Shenzhen, China | Sampling frequency: 200 Hz, Sensitivity: 0.0005 g/LSB, Accuracy: 0.0005 g | Sensitive to subtle vibrations |

| Open-ended Hall Current Sensor | JLK-36 | Measurement Specialties (China) Ltd., Shenzhen, China | Sampling frequency: 100 Hz, Sensitivity: 0.5% | Monitors spindle current for load changes |

| Current Acquisition Module | DAM3154 | Beijing Art Technology Development Co., Ltd., Beijing, China | Sampling frequency: 100 Hz, 4-channel single-ended analog input, Sensitivity: 1‰ | Convert current signal to digital signal |

| Model | Learning Rate | Batch Size | Units | Dropout rate | R2 | MAE | RMSE | MAPE |

|---|---|---|---|---|---|---|---|---|

| CNN-LSTM- Attention | 0.01 | 8 | 10 | 0.1 | 0.8997 | 1.8414 × 10−2 | 2.5346 × 10−2 | 17.3628 |

| 0.005 | 32 | 10 | 0.2 | 0.9908 | 5.8573 × 10−3 | 7.6585 × 10−3 | 5.5353 | |

| 0.005 | 8 | 10 | 0.3 | 0.9661 | 1.0738 × 10−2 | 1.4743 × 10−2 | 15.3060 | |

| 0.001 | 32 | 60 | 0.3 | 0.9764 | 8.7046 × 10−3 | 1.2283 × 10−2 | 10.2052 | |

| CNN-LSTM- Attention-PSA | 0.0068 | 13 | 127 | 0.3620 | 0.9942 | 4.7557 × 10−3 | 6.0846 × 10−3 | 4.4429 |

| Model | R2 | MAE | RMSE | MAPE |

|---|---|---|---|---|

| CNN | 0.8876 | 1.9540 × 10−2 | 2.6827 × 10−2 | 21.3201 |

| LSTM | 0.9370 | 1.3742 × 10−2 | 2.0080 × 10−2 | 13.5959 |

| CNN-Attention | 0.9250 | 1.6247 × 10−2 | 2.1913 × 10−2 | 14.6299 |

| LSTM-Attention | 0.9865 | 6.8843 × 10−3 | 9.3078 × 10−3 | 6.8277 |

| CNN-LSTM | 0.9693 | 1.0473 × 10−2 | 1.4013 × 10−2 | 11.5104 |

| CNN-LSTM-Attention | 0.9908 | 5.8573 × 10−3 | 7.6585 × 10−3 | 5.5353 |

| CNN-LSTM-Attention-PSA | 0.9942 | 4.7557 × 10−3 | 6.0846 × 10−3 | 4.4429 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, M.; Zhang, J.; Bu, L.; Nie, S.; Bai, Y.; Zhao, Y.; Mei, N. Methodology and Experimental Verification for Predicting the Remaining Useful Life of Milling Cutters Based on Hybrid CNN-LSTM-Attention-PSA. Machines 2024, 12, 752. https://doi.org/10.3390/machines12110752

Zhu M, Zhang J, Bu L, Nie S, Bai Y, Zhao Y, Mei N. Methodology and Experimental Verification for Predicting the Remaining Useful Life of Milling Cutters Based on Hybrid CNN-LSTM-Attention-PSA. Machines. 2024; 12(11):752. https://doi.org/10.3390/machines12110752

Chicago/Turabian StyleZhu, Mengge, Ji Zhang, Lingfan Bu, Sen Nie, Yu Bai, Yueqi Zhao, and Ning Mei. 2024. "Methodology and Experimental Verification for Predicting the Remaining Useful Life of Milling Cutters Based on Hybrid CNN-LSTM-Attention-PSA" Machines 12, no. 11: 752. https://doi.org/10.3390/machines12110752

APA StyleZhu, M., Zhang, J., Bu, L., Nie, S., Bai, Y., Zhao, Y., & Mei, N. (2024). Methodology and Experimental Verification for Predicting the Remaining Useful Life of Milling Cutters Based on Hybrid CNN-LSTM-Attention-PSA. Machines, 12(11), 752. https://doi.org/10.3390/machines12110752