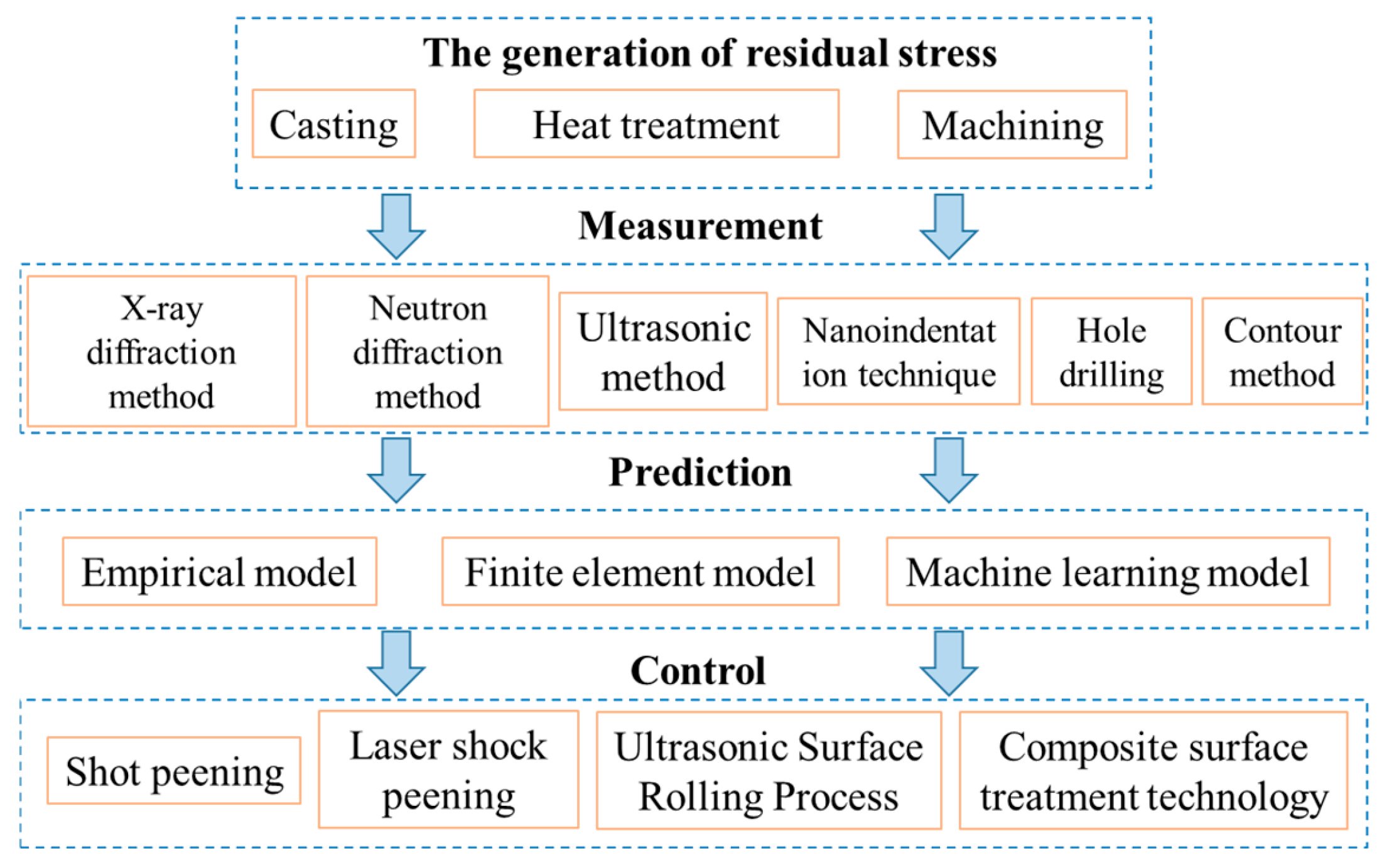

The Generation, Measurement, Prediction, and Prevention of Residual Stress in Nickel-Based Superalloys: A Review

Abstract

1. Introduction

2. The Source of Residual Stresses

2.1. Investment Casting

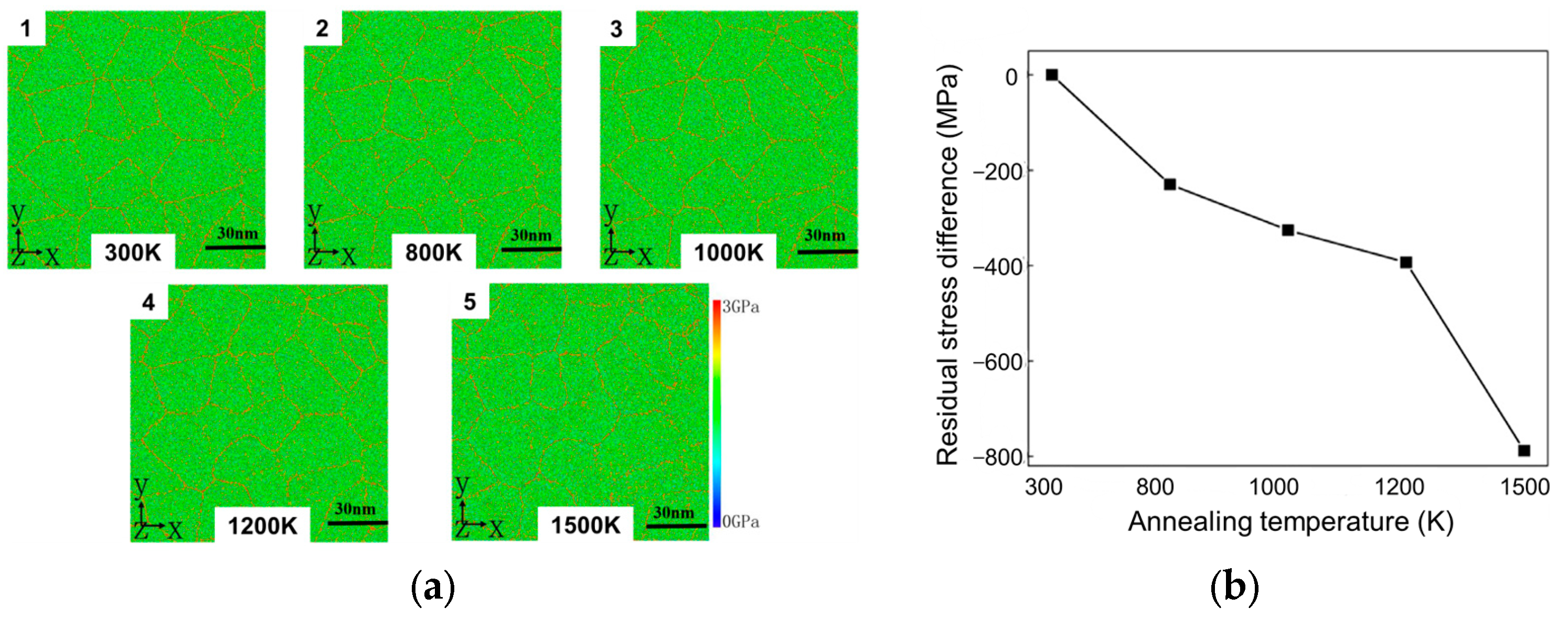

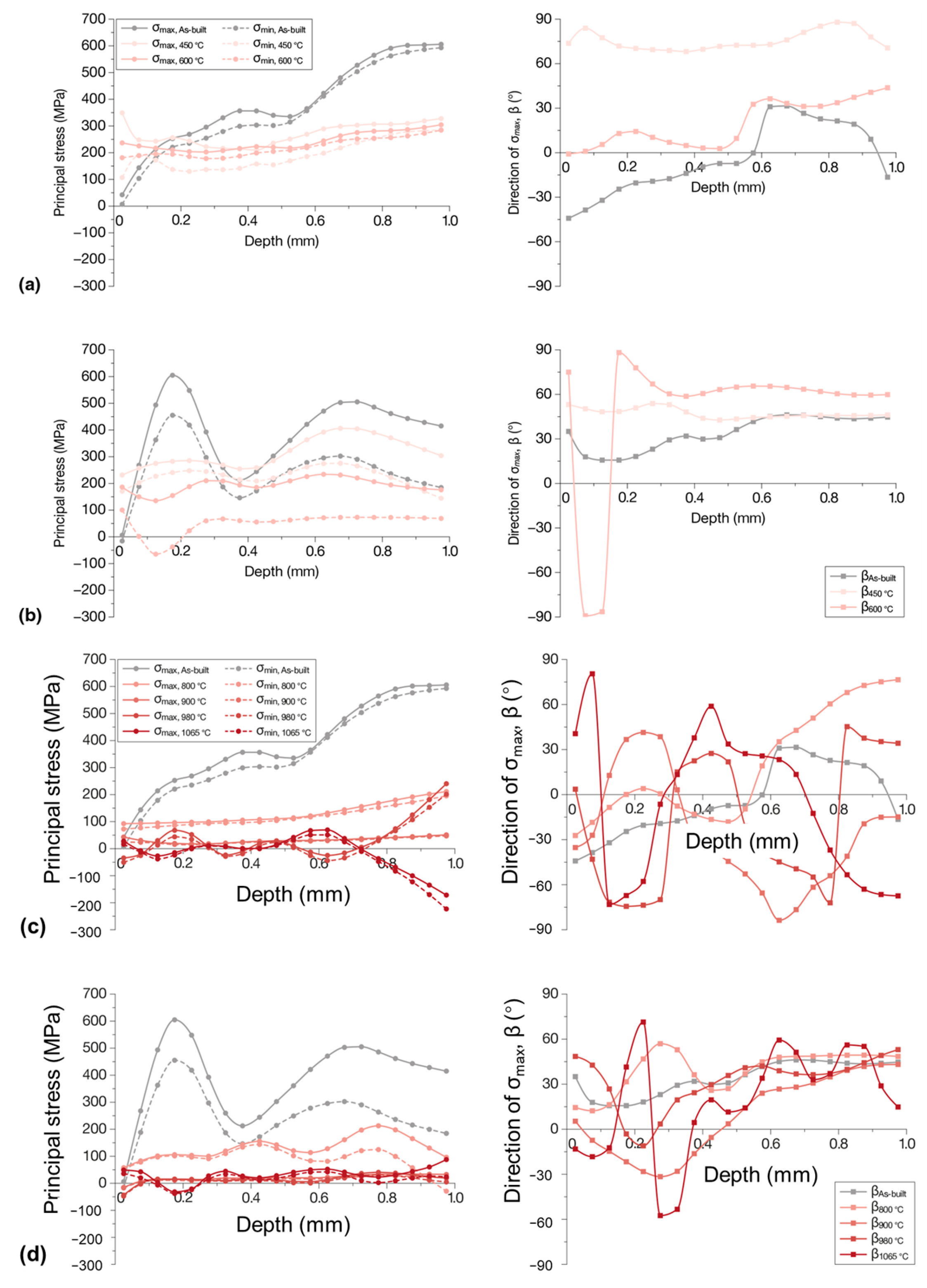

2.2. Heat Treatment

2.3. Machining

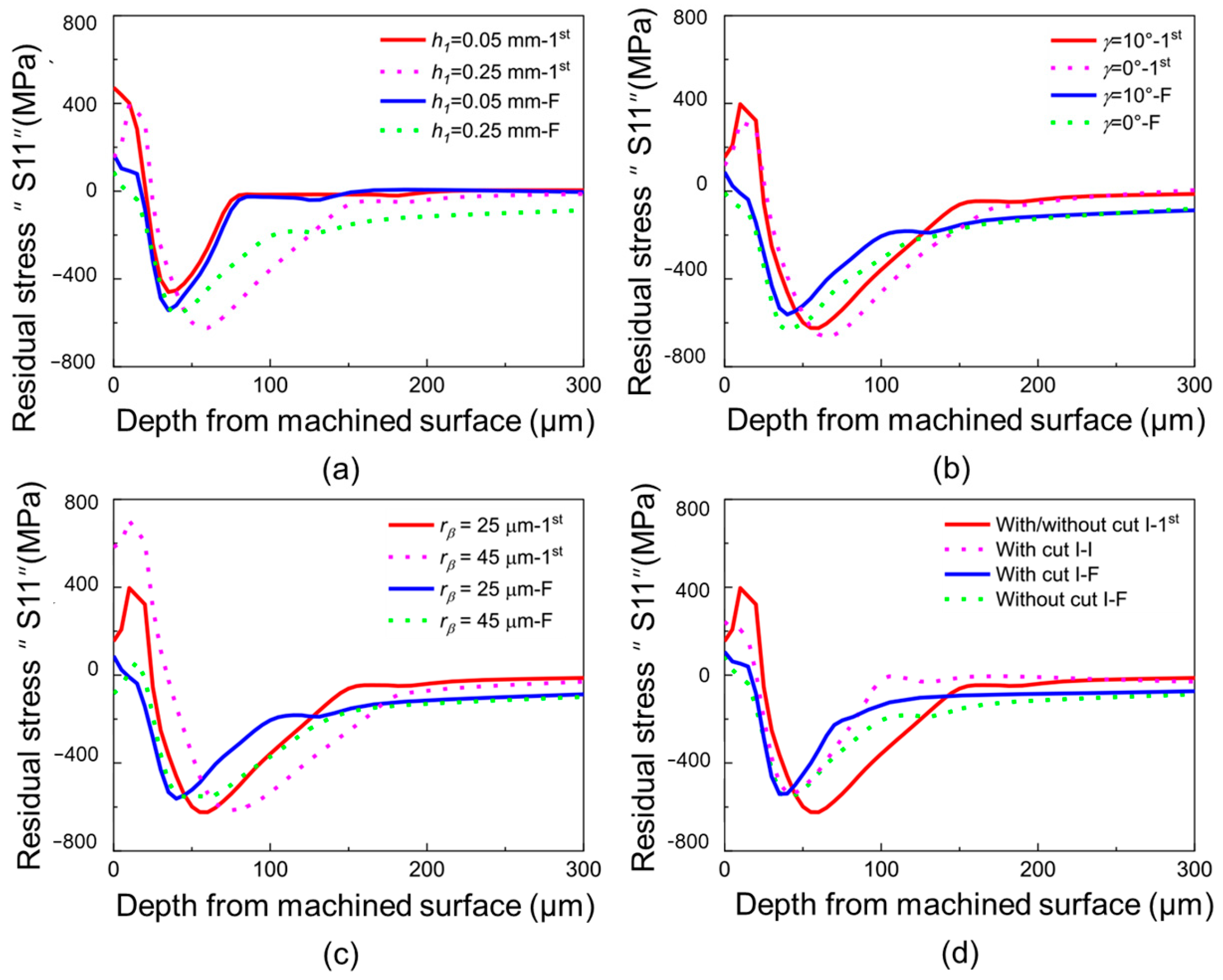

2.3.1. Milling

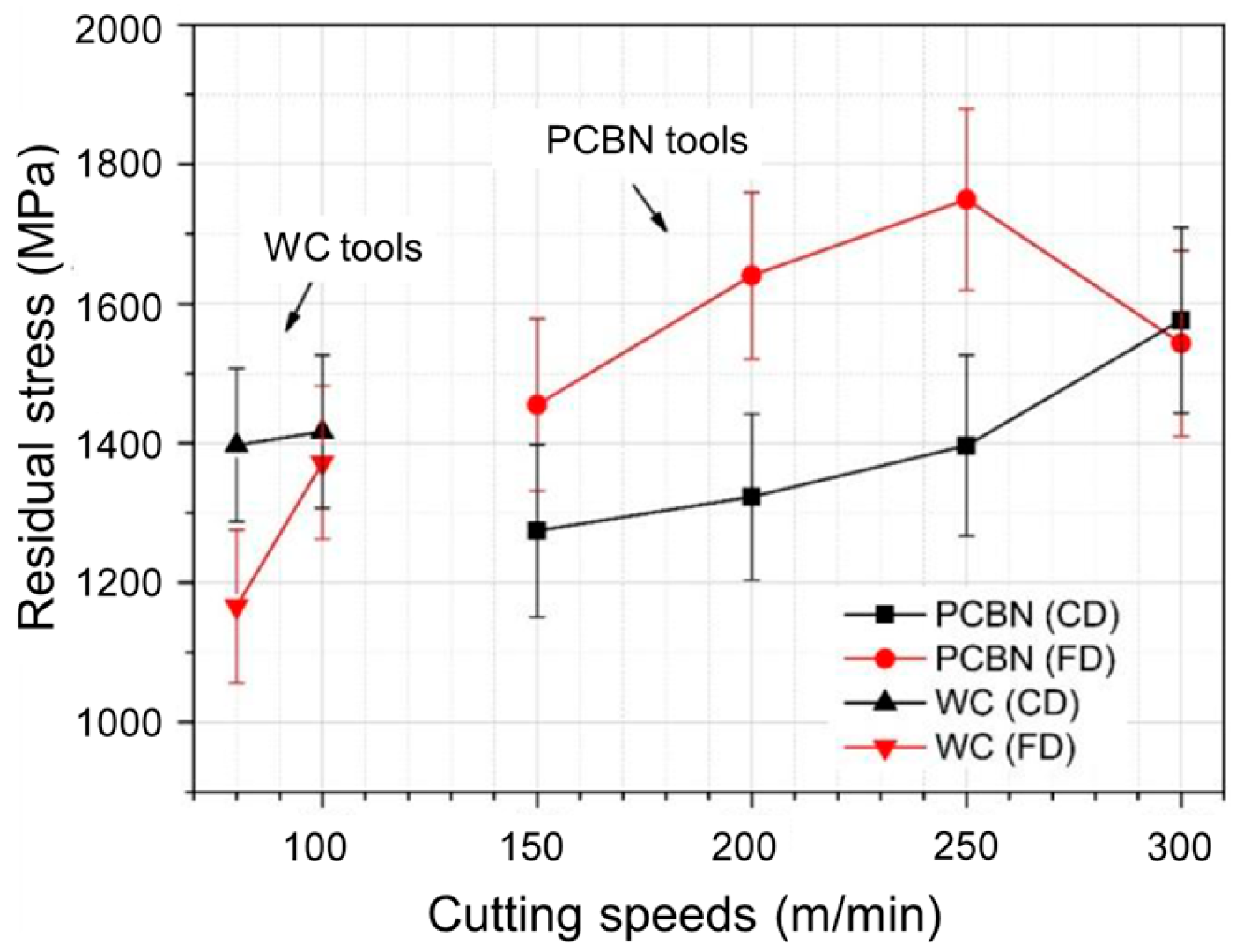

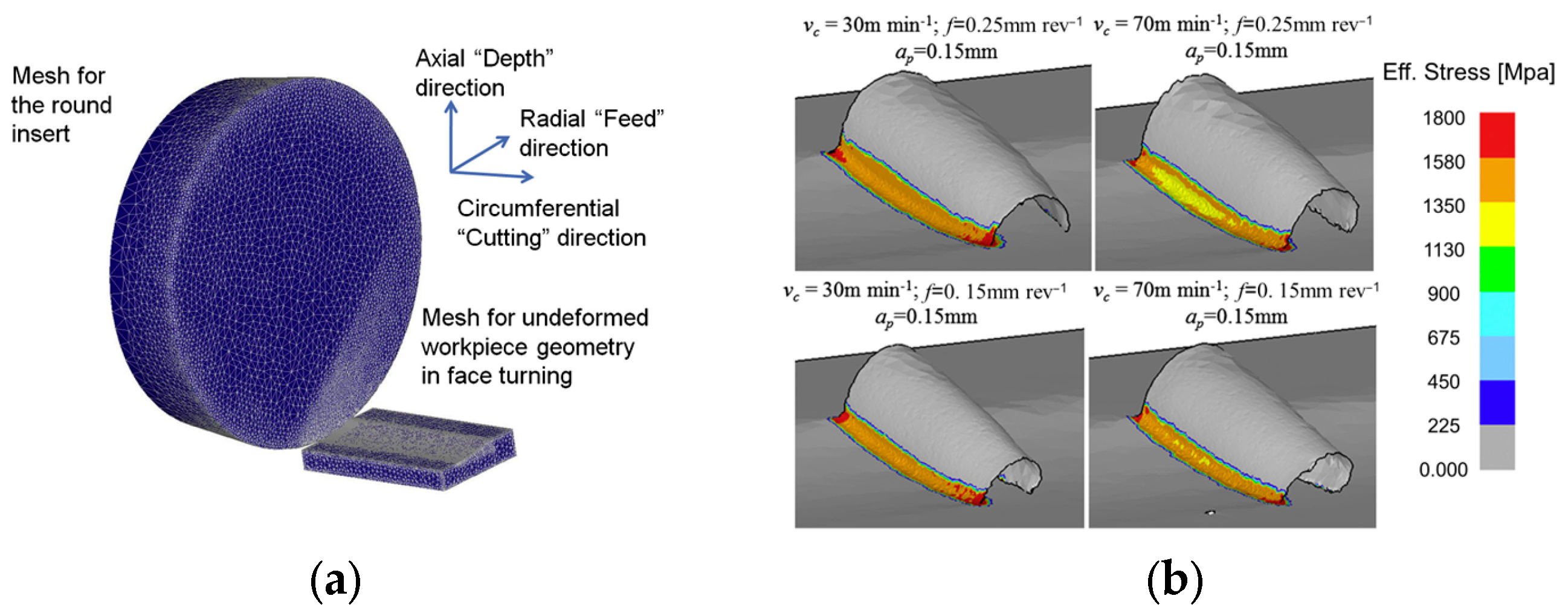

2.3.2. Turning

2.3.3. Grinding

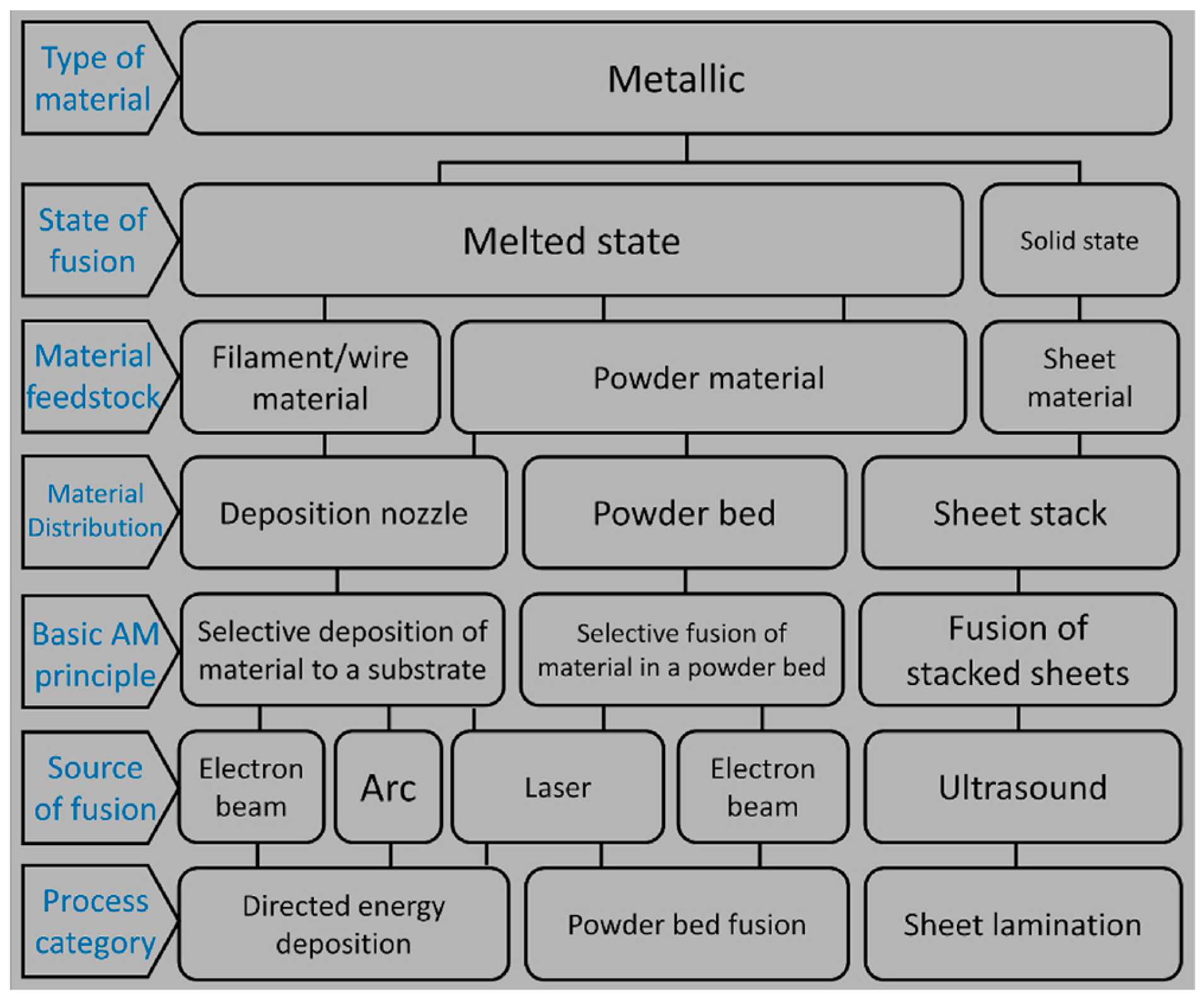

2.4. Additive Manufacturing

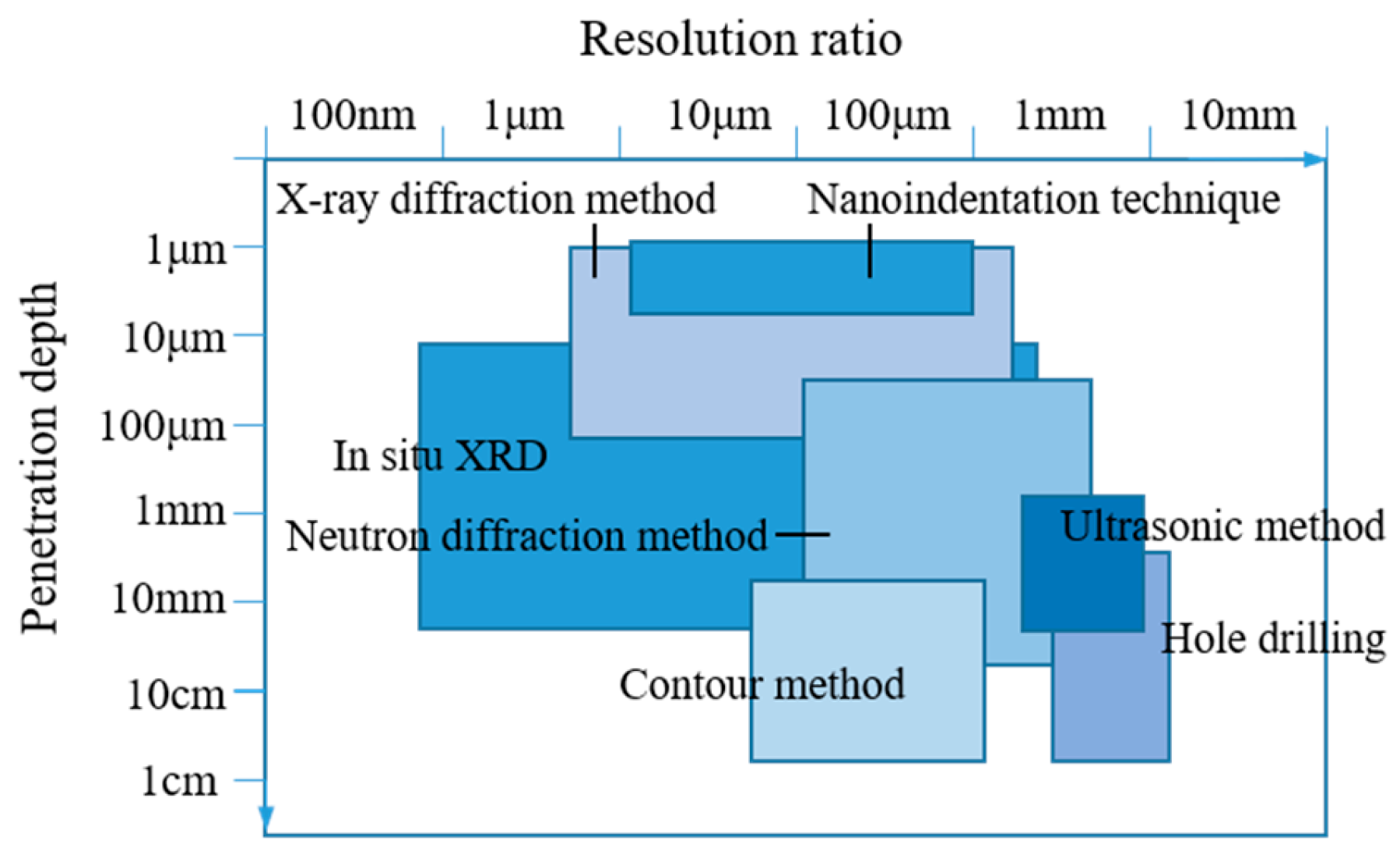

3. The Measurement of Residual Stresses

3.1. X-ray Diffraction Method

3.2. Neutron Diffraction Method

3.3. Ultrasonic Method

3.4. Nanoindentation Technique

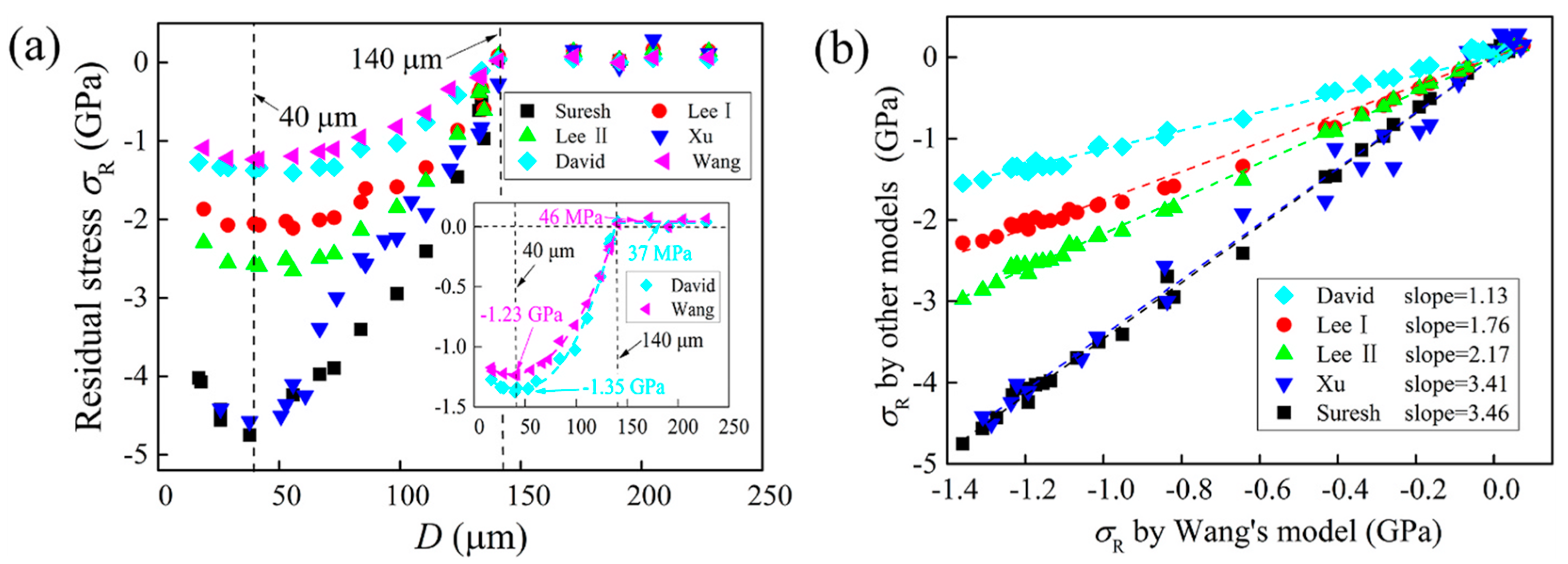

3.5. Destructive Method

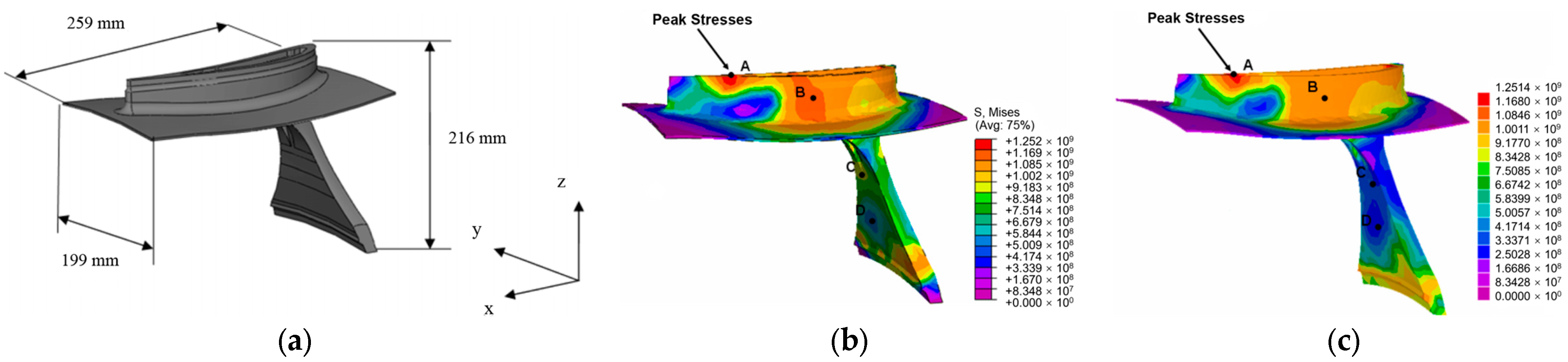

4. The Prediction of Residual Stress

4.1. Empirical Model

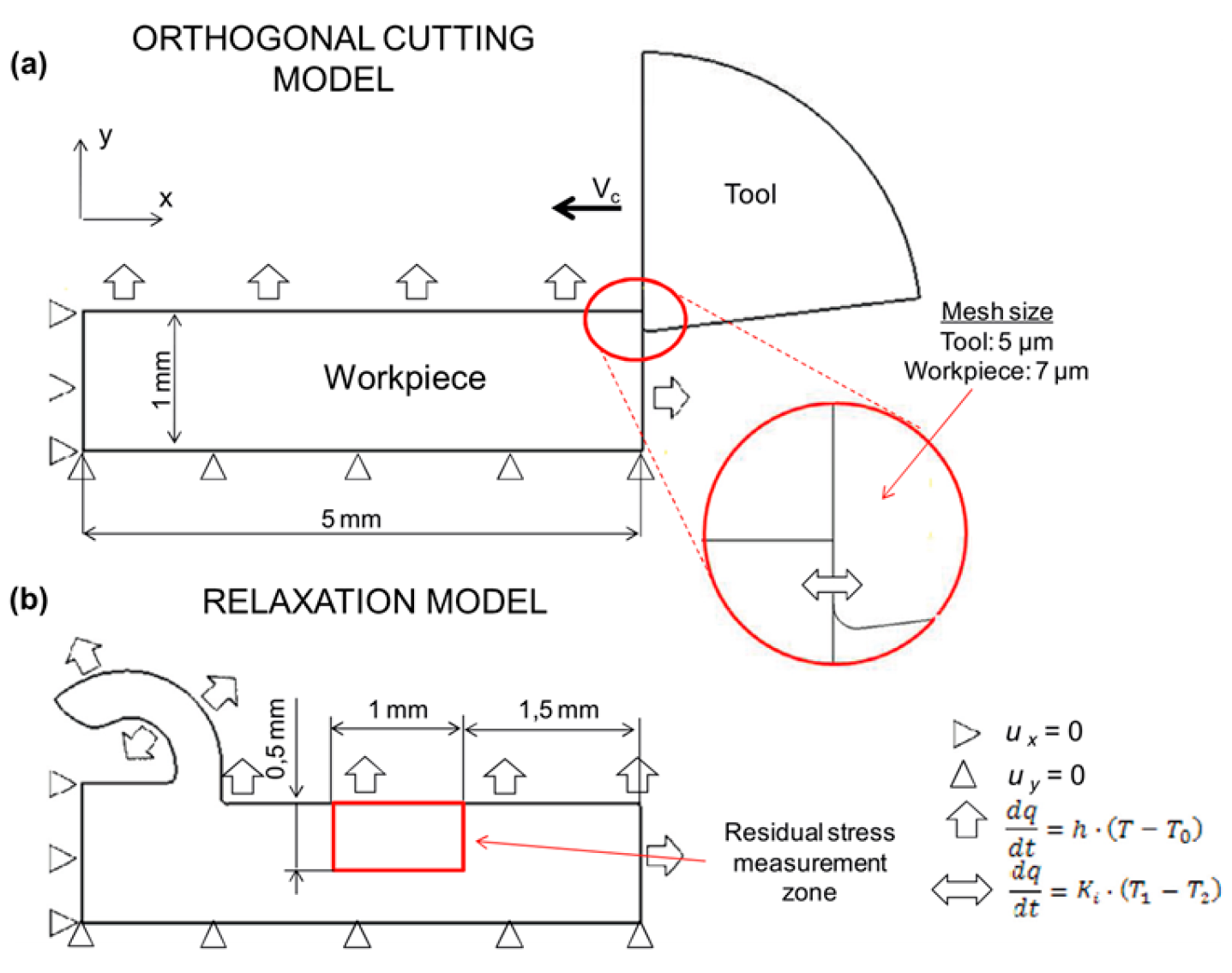

4.2. Finite Element Method

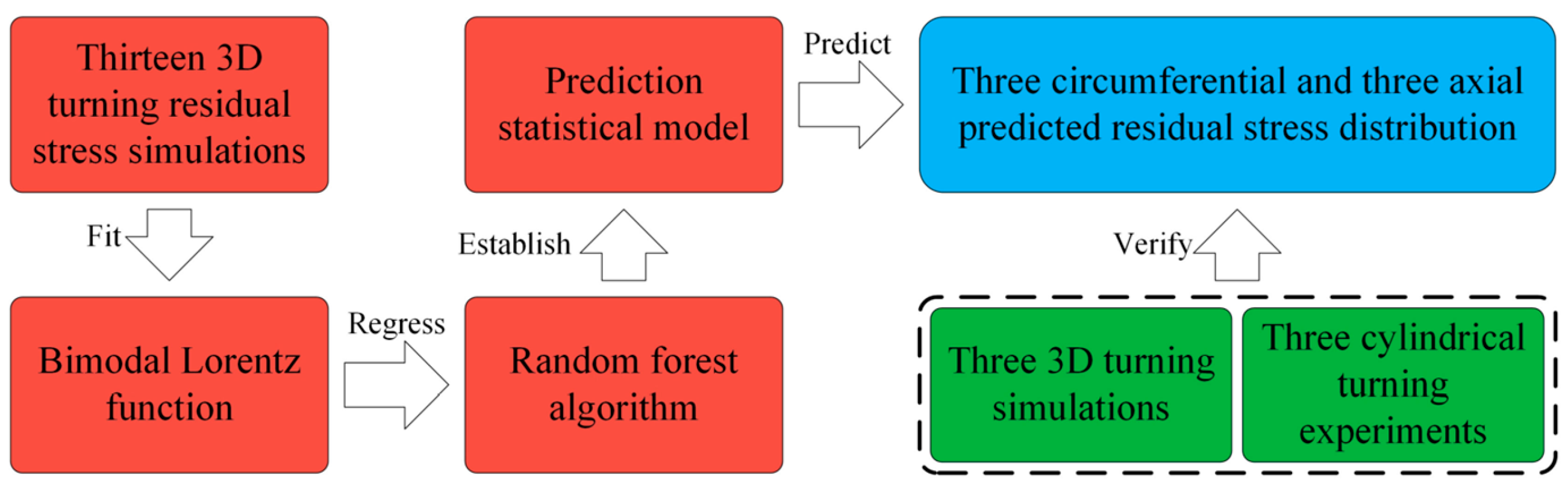

4.3. Machine Learning Model

5. Methods of Mitigating Residual Stress

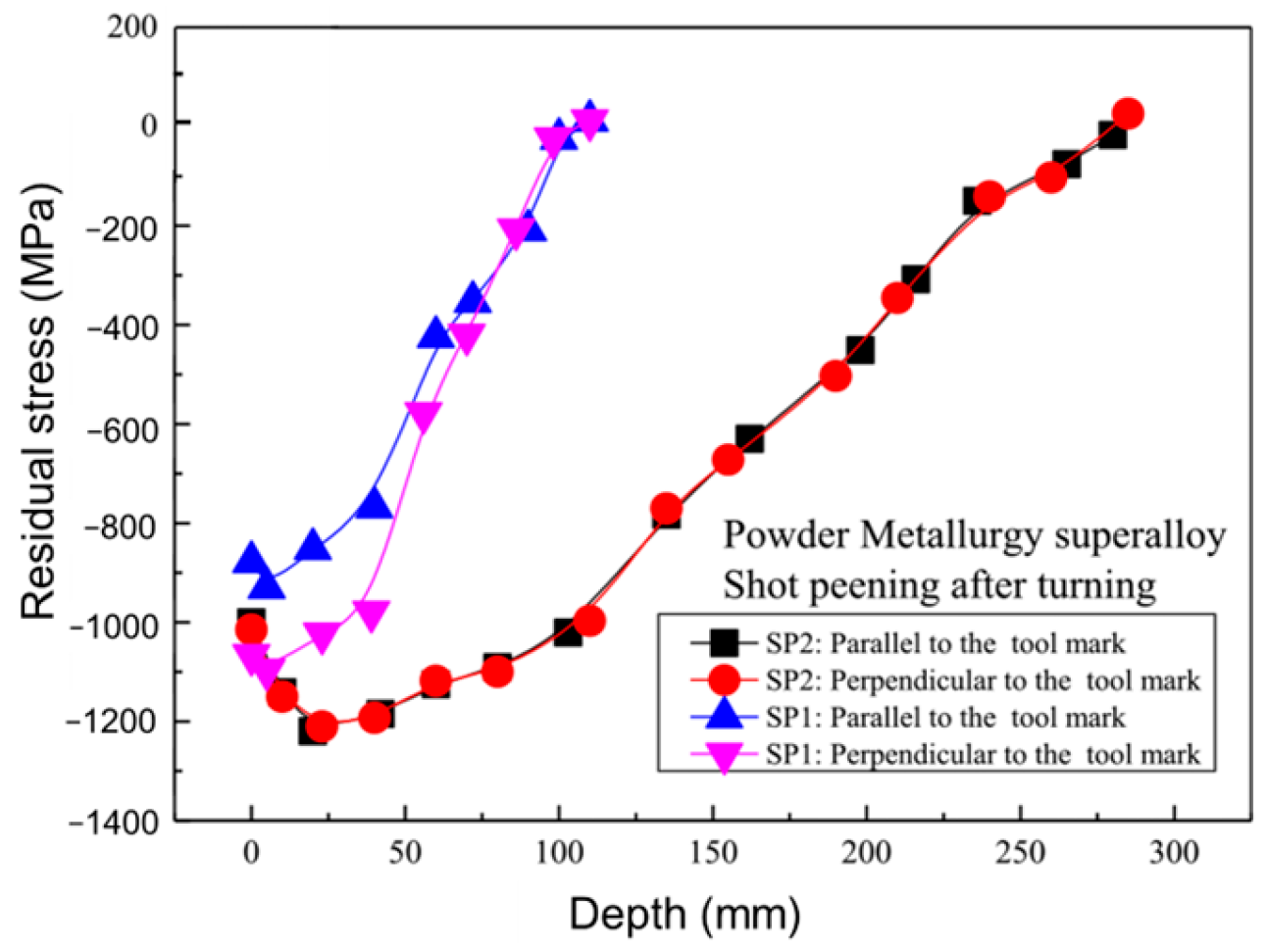

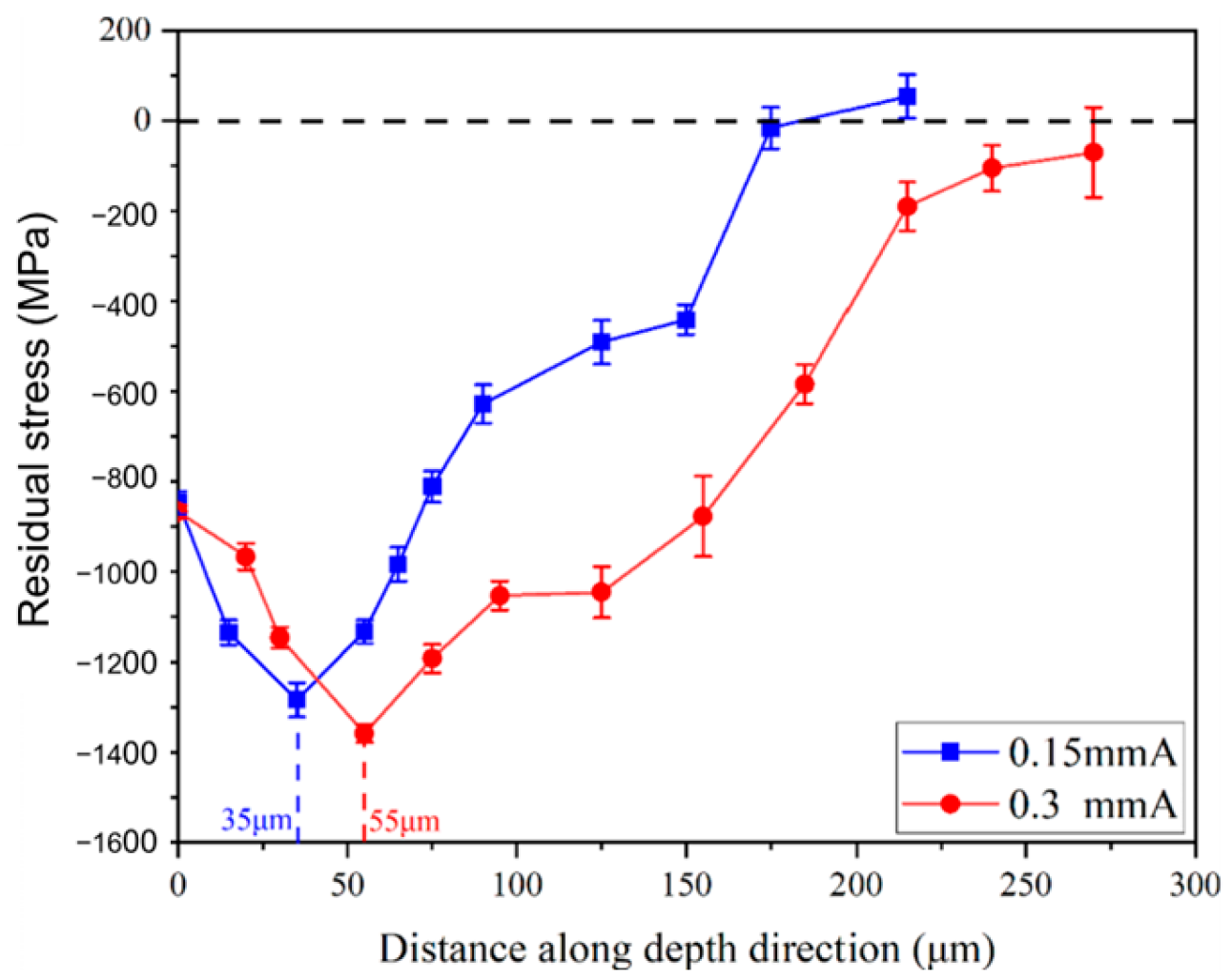

5.1. Shot Peening

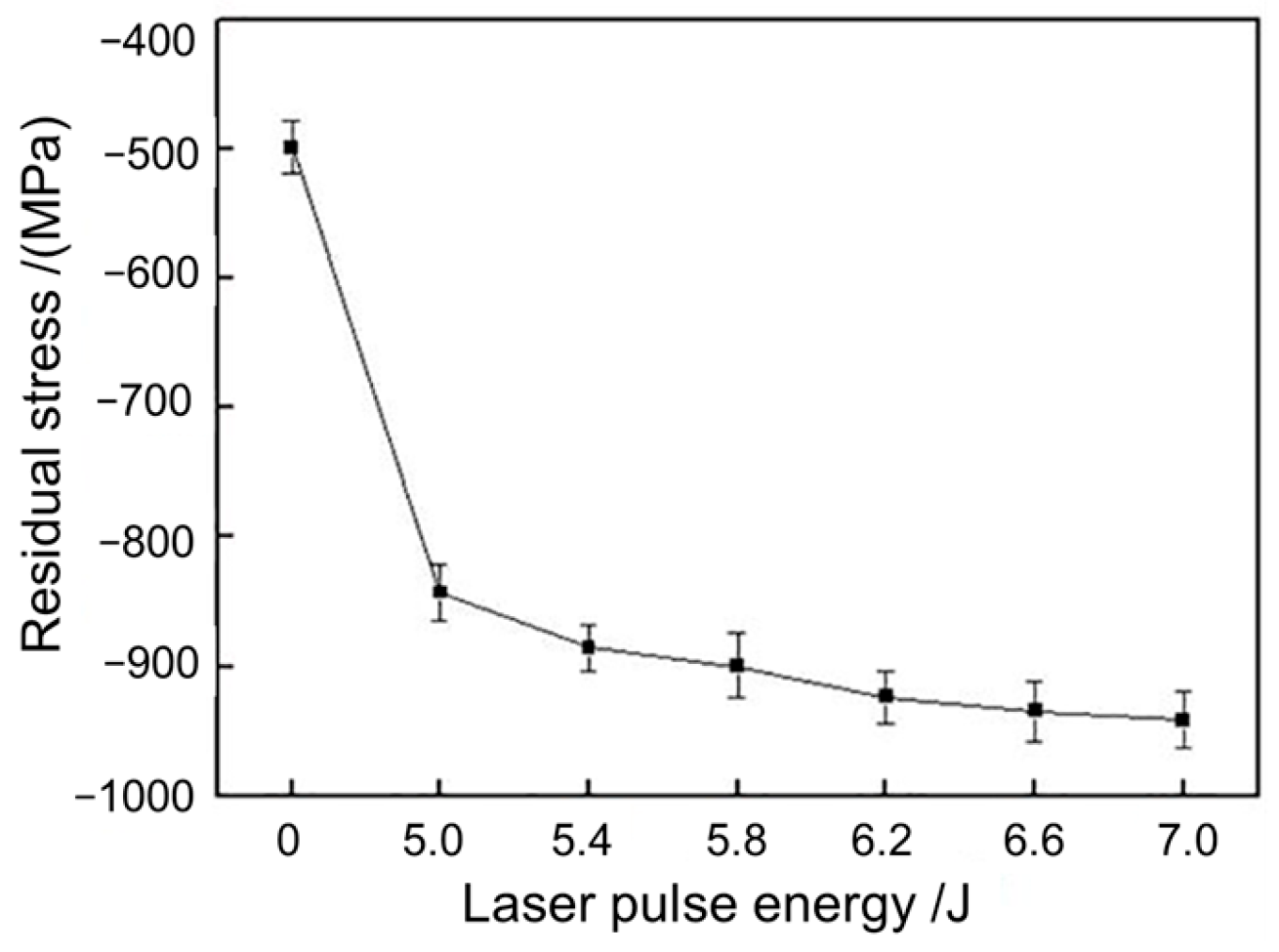

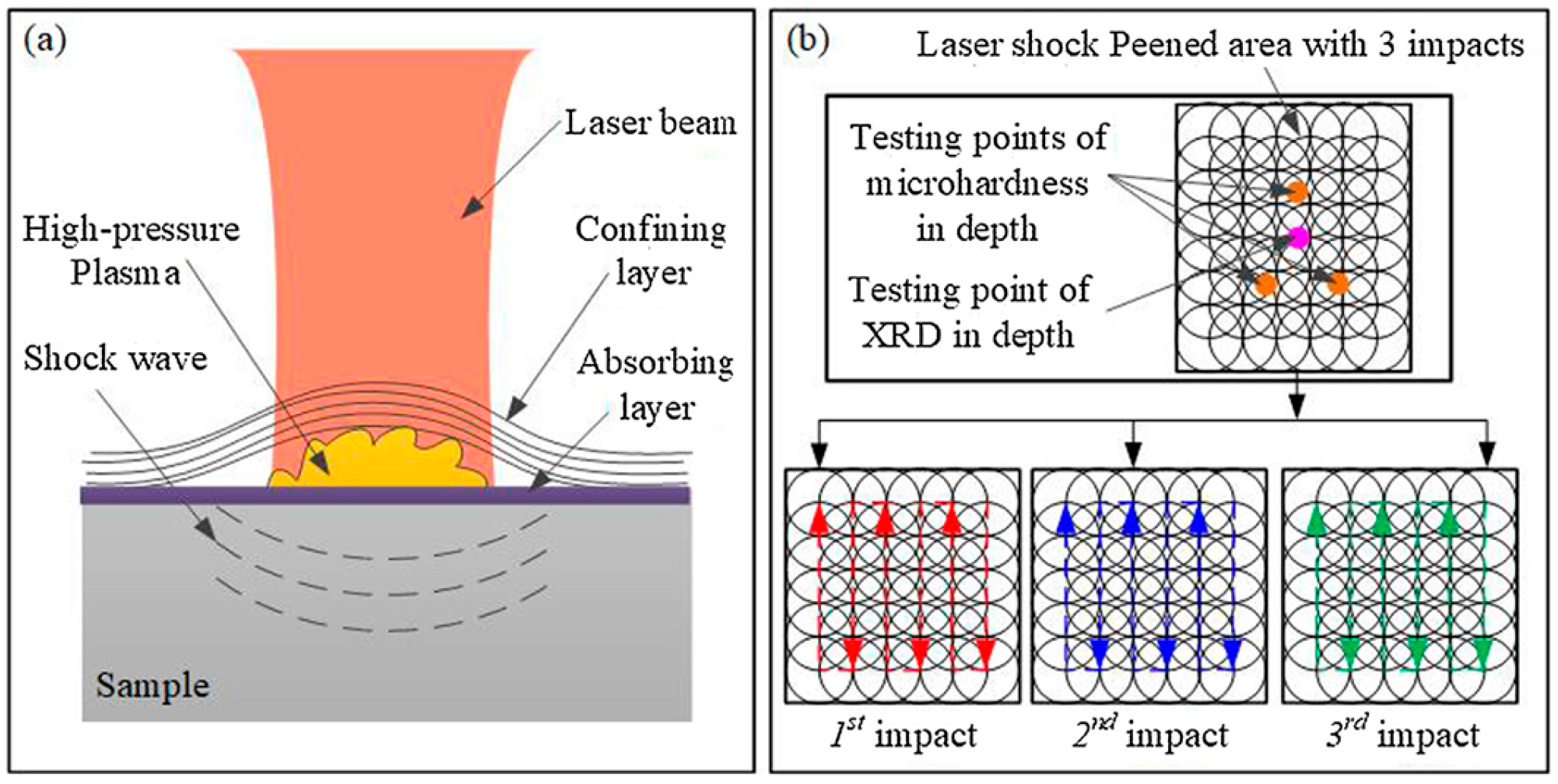

5.2. Laser Shock Peening

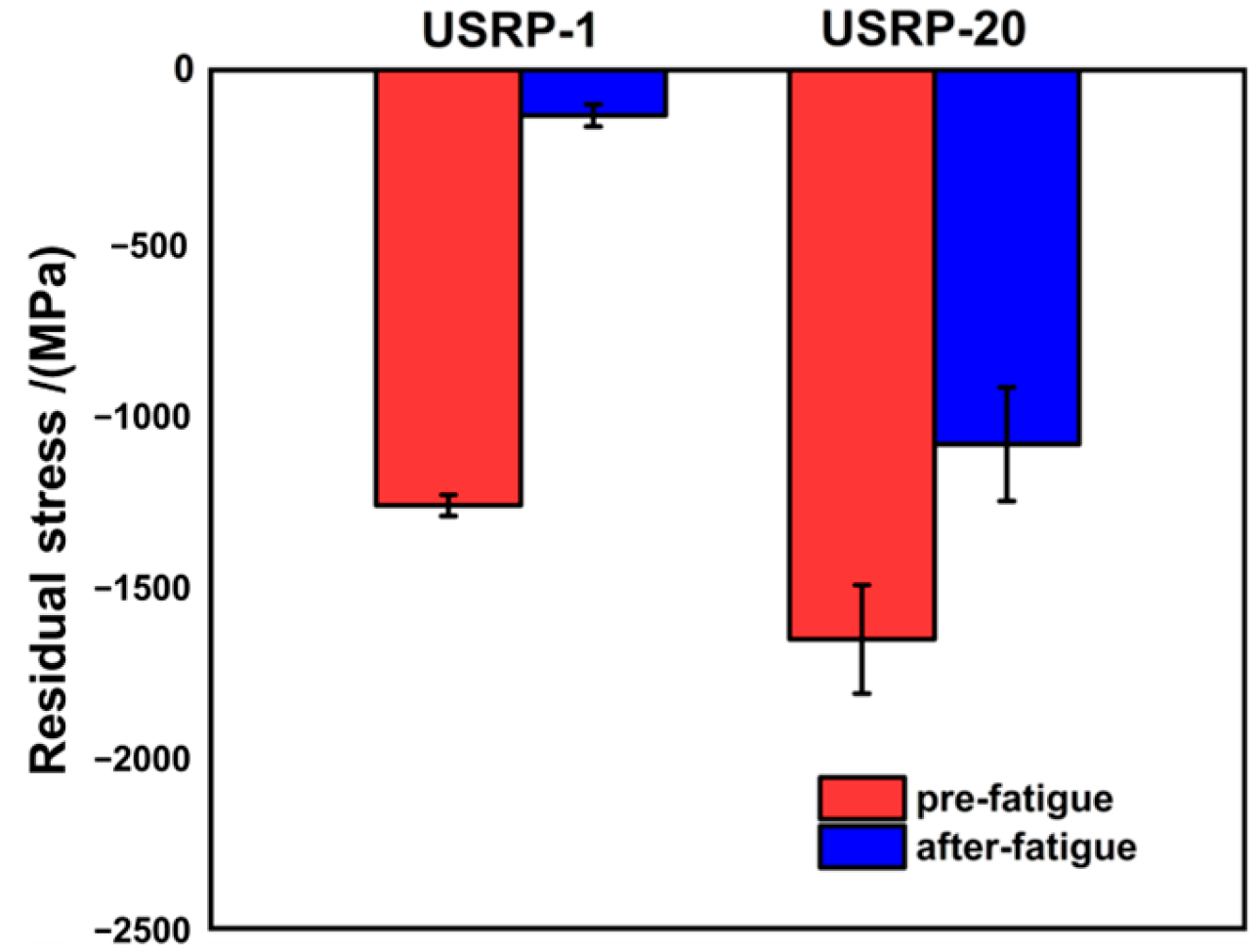

5.3. Ultrasonic Surface Rolling Process

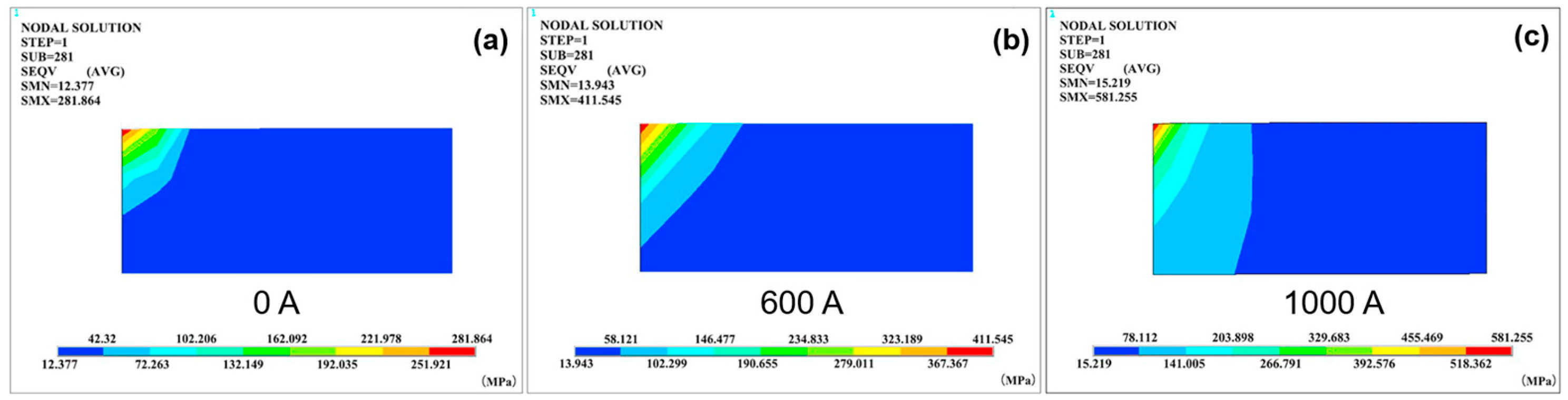

5.4. Composite Surface Treatment Technology

6. Conclusions and Future Research Trends

- (1)

- Although a variety of mature detection techniques are available, such as neutron diffraction and X-ray diffraction, the accuracy and portability of these techniques should be focused on improving in the future. In addition, the development of new non-invasive, high-resolution detection technologies, such as detection systems based on advanced sensors and artificial intelligence algorithms, will be an important research direction.

- (2)

- More accurate and practical residual stress prediction models need to be developed using computer simulation and machine learning techniques, which can accurately simulate the effects of different processing conditions, material states, and environmental factors on residual stress.

- (3)

- The microscopic generation mechanisms of residual stress in nickel-based superalloys need to be further explored, including the microstructural and stress distribution of the nickel-based superalloys in an extreme environment, which helps develop more effective stress control and mitigation strategies. Hence, the adaptability of the new residual stress control techniques to optimize the stress state of nickel-based superalloys can be improved.

- (4)

- The connection between residual stress research and practical industrial applications needs to be strengthened, especially in key industries such as aerospace, nuclear energy, and automotive manufacturing. The research on the application of new detection, prediction, and control technologies to practical manufacturing and maintenance processes to improve the performance and reliability of materials is the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, S.; Li, L.; Hu, C.; Li, Q.; Yuan, T. Tribological behavior of a shot-peened nickel-based single crystal superalloy at high temperature. Tribol. Lett. 2022, 70, 100. [Google Scholar] [CrossRef]

- Lu, X.; Lu, Y.; Wang, F.; Zhao, C.; Gao, L.; Si, L. Research on surface residual stress of micro-milling nickel-based superalloy Inconel 718. Int. J. Nanomanuf. 2016, 12, 82–92. [Google Scholar] [CrossRef]

- Pan, L.; Wu, Z.; Fang, L.; Song, Y. Investigation of surface damage and roughness for nickel-based superalloy GH4169 under hard turning processing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 679–691. [Google Scholar]

- Yong, L.; Wanni, G.; Wenbin, Z.; Dongsheng, L. Review on residual stress and its effects on manufacturing of aluminium alloy structural panels with typical multi-processes. Chin. J. Aeronaut. 2023, 36, 96–124. [Google Scholar]

- Jiang, G.; Haiyang, F.; Bo, P.; Renke, K. Recent progress of residual stress measurement methods: A review. Chin. J. Aeronaut. 2021, 34, 54–78. [Google Scholar]

- Clausen, B.; Lorentzen, T.; Leffers, T. Self-consistent modelling of the plastic deformation of fcc polycrystals and its implications for diffraction measurements of internal stresses. Acta Mater. 1998, 46, 3087–3098. [Google Scholar]

- Wagner, J.; Hofmann, M.; Wimpory, R.; Krempaszky, C.; Stockinger, M. Microstructure and temperature dependence of intergranular strains on diffractometric macroscopic residual stress analysis. Mater. Sci. Eng. A 2014, 618, 271–279. [Google Scholar]

- Jafarian, F.; Amirabadi, H.; Sadri, J.; Banooie, H.R. Simultaneous optimizing residual stress and surface roughness in turning of Inconel718 superalloy. Mater. Manuf. Process. 2014, 29, 337–343. [Google Scholar]

- Jiang, X.; Wei, Y.; Zhou, J.; Zhan, K.; Ding, Z.; Liang, S.Y. Residual stress generation and evaluation in milling: A review. Int. J. Adv. Manuf. Technol. 2023, 126, 3783–3812. [Google Scholar]

- Yin, M.-g.; Cai, Z.-b.; Zhang, Z.-x.; Yue, W. Effect of ultrasonic surface rolling process on impact-sliding wear behavior of the 690 alloy. Tribol. Int. 2020, 147, 105600. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Cui, Z.; Ahmad, T.; Wang, C.; Hong, N.; Liang, T.; Yang, B. Effects of ultrasonic surface rolling processing and plasma nitriding on the fretting wear behavior of Inconel 690TT. Surf. Coat. Technol. 2020, 402, 126312. [Google Scholar] [CrossRef]

- Fortunato, A.; Orazi, L.; Cuccolini, G.; Ascari, A. Laser shock peening and warm laser shock peening: Process modeling and pulse shape influence. In Proceedings of the High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications II, San Francisco, CA, USA, 5–7 February 2013; pp. 136–143. [Google Scholar]

- Zhou, W.; Ren, X.; Yang, Y.; Tong, Z.; Chen, L. Tensile behavior of nickel with gradient microstructure produced by laser shock peening. Mater. Sci. Eng. A 2020, 771, 138603. [Google Scholar] [CrossRef]

- Gibson, G.; Perkins, K.; Gray, S.; Leggett, A. Influence of shot peening on high-temperature corrosion and corrosion-fatigue of nickel based superalloy 720Li. Mater. High Temp. 2016, 33, 225–233. [Google Scholar] [CrossRef]

- Messé, O.; Stekovic, S.; Hardy, M.; Rae, C. Characterization of plastic deformation induced by shot-peening in a Ni-base superalloy. JOM 2014, 66, 2502–2515. [Google Scholar] [CrossRef]

- Yuan, T.; Dou, M.; Liu, L.; Li, L.; Sun, S.; Hu, C. Improving high temperature fretting fatigue performance of nickel-based single crystal superalloy by shot peening. Int. J. Fatigue 2023, 171, 107563. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, L.; Li, M.; Cai, Z.; Luo, S.; He, W.; Fang, X. Research on fretting regime transition of DD6 single-crystal superalloy via femtosecond laser-induced asperity and hardened layer. Appl. Surf. Sci. 2023, 610, 155392. [Google Scholar] [CrossRef]

- Yao, C.; Luo, J.; Tan, L.; Cui, M.; Sun, Y.; Gao, X.; Zhang, Y. Experimental investigation on surface integrity and fatigue of nickel-based single-crystal superalloy DD6 during grinding-shot peening composite manufacturing. Int. J. Adv. Manuf. Technol. 2023, 125, 3449–3463. [Google Scholar] [CrossRef]

- Ortiz, A.; Tian, J.; Villegas, J.; Shaw, L.; Liaw, P. Interrogation of the microstructure and residual stress of a nickel-base alloy subjected to surface severe plastic deformation. Acta Mater. 2008, 56, 413–426. [Google Scholar] [CrossRef]

- Staron, P.; Cihak, U.; Clemens, H.; Stockinger, M.; Schreyer, A. Characterization of Residual Stresses in 718 Turbine Discs by Neutron Diffraction and Finite Element Modelling. Adv. Mater. Res. 2011, 278, 102–107. [Google Scholar] [CrossRef]

- Rist, M.; James, J.; Tin, S.; Roder, B.; Daymond, M. Residual stresses in a quenched superalloy turbine disc: Measurements and modeling. Metall. Mater. Trans. A 2006, 37, 459–467. [Google Scholar] [CrossRef]

- Qin, H.; Bi, Z.; Li, D.; Zhang, R.; Lee, T.L.; Feng, G.; Dong, H.; Du, J.; Zhang, J. Study of precipitation-assisted stress relaxation and creep behavior during the ageing of a nickel-iron superalloy. Mater. Sci. Eng. A 2019, 742, 493–500. [Google Scholar] [CrossRef]

- Vangi, D.; Virga, A. A practical application of ultrasonic thermal stress monitoring in continuous welded rails. Exp. Mech. 2007, 47, 617–623. [Google Scholar] [CrossRef]

- Palanichamy, P.; Vasudevan, M.; Jayakumar, T. Measurement of residual stresses in austenitic stainless steel weld joints using ultrasonic technique. Sci. Technol. Weld. Join. 2009, 14, 166–171. [Google Scholar] [CrossRef]

- Javadi, Y.; Najafabadi, M.A.; Akhlaghi, M. Residual stress evaluation in dissimilar welded joints using finite element simulation and the L CR ultrasonic wave. Russ. J. Nondestruct. Test. 2012, 48, 541–552. [Google Scholar] [CrossRef]

- Javadi, Y.; Pirzaman, H.S.; Raeisi, M.H.; Najafabadi, M.A. Ultrasonic inspection of a welded stainless steel pipe to evaluate residual stresses through thickness. Mater. Des. 2013, 49, 591–601. [Google Scholar] [CrossRef]

- Long, X.; Shen, Z.; Li, J.; Dong, R.; Liu, M.; Su, Y.; Chen, C. Size effect of nickel-based single crystal superalloy revealed by nanoindentation with low strain rates. J. Mater. Res. Technol. 2024, 29, 2437–2447. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Gutierrez, C.; Gan, B.; Molina-Aldareguia, J.M. High-throughput nanoindentation mapping of cast IN718 nickel-based superalloys: Influence of the Nb concentration. J. Mater. Res. 2021, 36, 2213–2222. [Google Scholar] [CrossRef]

- Song, Y.; Pan, Z.; Li, Y.; Jin, W.; Gao, Z.; Wu, Z.; Ma, Y. Nanoindentation characterization on the temperature-dependent fracture mechanism of Chinese 316H austenitic stainless steel under creep-fatigue interaction. Mater. Charact. 2022, 186, 111806. [Google Scholar] [CrossRef]

- Dong, P.; Peng, H.; Cheng, X.; Xing, Y.; Tang, W.; Zhou, X. Semi-empirical prediction of residual stress profiles in machining IN718 alloy using bimodal Gaussian curve. Materials 2019, 12, 3864. [Google Scholar] [CrossRef]

- Feng, Y.; Hung, T.-P.; Lu, Y.-T.; Lin, Y.-F.; Hsu, F.-C.; Lin, C.-F.; Lu, Y.-C.; Liang, S.Y. Residual stress prediction in laser-assisted milling considering recrystallization effects. Int. J. Adv. Manuf. Technol. 2019, 102, 393–402. [Google Scholar] [CrossRef]

- Jafarian, F. 3D modeling of recrystallized layer depth and residual stress in dry machining of nickel-based alloy. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 198. [Google Scholar] [CrossRef]

- Kortabarri, A.; Madariag, A.; Fernandez, E.; Esnaol, J.; Arrazola, P.J. A comparative study of residual stress profiles on Inconel 718 induced by dry face turning. Procedia Eng. 2011, 19, 228–234. [Google Scholar] [CrossRef]

- Careri, F.; Imbrogno, S.; Umbrello, D.; Outeiro, J.C.; Batista, A.C. A residual stress prediction of machining IN718 produced by direct energy deposition. Procedia CIRP 2021, 102, 13–18. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Chen, H.; Wu, Y.; Chen, J.; Xiong, J.; Ren, L.; Qian, J. Multi-scale residual stress prediction for selective laser melting of high strength steel considering solid-state phase transformation. Opt. Laser Technol. 2022, 146, 107578. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, T.; Hao, Z.; Liu, X.; Gao, S.; Li, R. Surface residual stress in high speed cutting of superalloy Inconel718 based on multiscale simulation. J. Manuf. Process. 2018, 31, 480–493. [Google Scholar] [CrossRef]

- Karataş, C.; Sozen, A.; Dulek, E. Modelling of residual stresses in the shot peened material C-1020 by artificial neural network. Expert Syst. Appl. 2009, 36, 3514–3521. [Google Scholar] [CrossRef]

- Sembiring, J.; Amanov, A.; Pyun, Y. Artificial neural network-based prediction model of residual stress and hardness of nickel-based alloys for UNSM parameters optimization. Mater. Today Commun. 2020, 25, 101391. [Google Scholar] [CrossRef]

- Silva, D.P.; Bastos, I.N.; Fonseca, M.C. Influence of surface quality on residual stress of API 5L X80 steel submitted to static load and its prediction by artificial neural networks. Int. J. Adv. Manuf. Technol. 2020, 108, 3753–3764. [Google Scholar] [CrossRef]

- Cheng, M.; Jiao, L.; Yan, P.; Feng, L.; Qiu, T.; Wang, X.; Zhang, B. Prediction of surface residual stress in end milling with Gaussian process regression. Measurement 2021, 178, 109333. [Google Scholar] [CrossRef]

- Afazov, S.; Becker, A.; Hyde, T. FE modelling of investment casting of a high pressure turbine blade under directional cooling. Mater. Manuf. Eng. J 2011, 12, 6–12. [Google Scholar]

- Afazov, S.; Becker, A.; Hyde, T. FE prediction of residual stresses of investment casting in a Bottom Core Vane under equiaxed cooling. J. Manuf. Process. 2011, 13, 30–40. [Google Scholar] [CrossRef]

- Hao, Z.; Tian, T.; Peng, S.; Ge, C.; Li, X.; Jia, C.; Guo, C.; Zhu, Q. Effect of heat treatment on microstructure and properties of FGH4096M superalloy processed by selective laser melting. Met. Mater. Int. 2020, 26, 1270–1285. [Google Scholar] [CrossRef]

- Lei, Y.; Li, X.; Sun, R.; Tang, Y.; Niu, W. Effect of sintering temperature and heat treatment on microstructure and properties of nickel-based superalloy. J. Alloys Compd. 2020, 818, 152882. [Google Scholar] [CrossRef]

- Wang, A.; Lv, J.; Chen, C.; Xu, W.; Zhang, L.; Mao, Y.; Zhao, Y. Effects of heat treatment on microstructure and high-temperature tensile properties of nickel-based single-crystal superalloys. Mater. Res. Express 2019, 6, 126527. [Google Scholar] [CrossRef]

- Shrestha, D.; Azarmi, F.; Tangpong, X. Effect of heat treatment on residual stress of cold sprayed nickel-based superalloys. J. Therm. Spray Technol. 2022, 31, 197–205. [Google Scholar] [CrossRef]

- Kim, S.Y.; Luzin, V.; Sesso, M.L.; Thornton, J.; Gulizia, S. The effect of low temperature range heat treatment on the residual stress of cold gas dynamic sprayed Inconel 718 coatings via neutron diffraction. J. Therm. Spray Technol. 2020, 29, 1477–1497. [Google Scholar] [CrossRef]

- Xie, B.; Li, L.; Fang, Q.; Li, J.; Liu, B.; Huang, Z.; Tan, L. Evolution of residual stress and its impact on Ni-based superalloy. Int. J. Mech. Sci. 2021, 202, 106494. [Google Scholar] [CrossRef]

- Marchese, G.; Atzeni, E.; Salmi, A.; Biamino, S. Microstructure and residual stress evolution of laser powder bed fused Inconel 718 under heat treatments. J. Mater. Eng. Perform. 2021, 30, 565–574. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, Y.; Liang, C.; Sun, Y.; Zhao, J. Study on milling material removal mechanism and surface integrity of nickel-based single crystal superalloy DD5. Int. J. Adv. Manuf. Technol. 2023, 125, 2323–2338. [Google Scholar] [CrossRef]

- Gong, Y.; Li, Q.; Li, J.; Liu, Y.; Sun, Y. Tool wear performance and surface integrity studies for milling DD5 Ni-based single crystal superalloy. Sci. China Technol. Sci. 2018, 61, 522–534. [Google Scholar] [CrossRef]

- Cai, X.; Qin, S.; Li, J.; An, Q.; Chen, M. Experimental investigation on surface integrity of end milling nickel-based alloy—Inconel 718. Mach. Sci. Technol. 2014, 18, 31–46. [Google Scholar] [CrossRef]

- Li, Q.; Gong, Y.-d.; Sun, Y.; Liu, Y.; Liang, C.-x. Milling performance optimization of DD5 Ni-based single-crystal superalloy. Int. J. Adv. Manuf. Technol. 2018, 94, 2875–2894. [Google Scholar] [CrossRef]

- Kwong, J.; Axinte, D.; Withers, P. The sensitivity of Ni-based superalloy to hole making operations: Influence of process parameters on subsurface damage and residual stress. J. Mater. Process. Technol. 2009, 209, 3968–3977. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, D.; Wu, B.; Luo, M. Residual stresses analysis in ball end milling of nickel-based superalloy Inconel 718. Mater. Res. 2017, 20, 1681–1689. [Google Scholar] [CrossRef]

- Aspinwall, D.; Dewes, R.; Ng, E.-G.; Sage, C.; Soo, S. The influence of cutter orientation and workpiece angle on machinability when high-speed milling Inconel 718 under finishing conditions. Int. J. Mach. Tools Manuf. 2007, 47, 1839–1846. [Google Scholar] [CrossRef]

- Zhuang, K.; Zhang, X.; Ding, H. Evaluation of Cutting Forces and Surface Integrity in Flank Milling of Heat-Resistant-Super-Alloys with Coated Cemented Carbide Tools. In Proceedings of the Intelligent Robotics and Applications: 8th International Conference, ICIRA 2015, Portsmouth, UK, 24–27 August 2015; Proceedings, Part II 8. pp. 651–663. [Google Scholar]

- Liu, Y.; Xu, D.; Agmell, M.; Ahadi, A.; Stahl, J.-E.; Zhou, J. Investigation on residual stress evolution in nickel-based alloy affected by multiple cutting operations. J. Manuf. Process. 2021, 68, 818–833. [Google Scholar] [CrossRef]

- Zeng, H.; Yan, R.; Peng, F.; Zhou, L.; Deng, B. An investigation of residual stresses in micro-end-milling considering sequential cuts effect. Int. J. Adv. Manuf. Technol. 2017, 91, 3619–3634. [Google Scholar] [CrossRef]

- Sun, J.; Wang, T.; Su, A.; Chen, W. Surface integrity and its influence on fatigue life when turning nickel alloy GH4169. Procedia CIRP 2018, 71, 478–483. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, D.; Yao, C. Effect of turning and surface polishing treatments on surface integrity and fatigue performance of nickel-based alloy GH4169. Metals 2018, 8, 549. [Google Scholar] [CrossRef]

- Schlauer, C.; Peng, R.L.; Odén, M. Residual stresses in a nickel-based superalloy introduced by turning. In Proceedings of the Materials Science Forum, Linkoping, Sweden, 2–5 September 2002; pp. 173–178. [Google Scholar]

- Schlauer, C.; Odén, M. Residual stress evolution and near-surface microstructure after turning of the nickel-based superalloy Inconel 718. Int. J. Mater. Res. 2022, 96, 385–392. [Google Scholar]

- Sharman, A.; Hughes, J.; Ridgway, K. An analysis of the residual stresses generated in Inconel 718™ when turning. J. Mater. Process. Technol. 2006, 173, 359–367. [Google Scholar] [CrossRef]

- Sharman, A.; Hughes, J.; Ridgway, K. The effect of tool nose radius on surface integrity and residual stresses when turning Inconel 718™. J. Mater. Process. Technol. 2015, 216, 123–132. [Google Scholar] [CrossRef]

- Madariaga, A.; Esnaola, J.; Fernandez, E.; Arrazola, P.; Garay, A.; Morel, F. Analysis of residual stress and work-hardened profiles on Inconel 718 when face turning with large-nose radius tools. Int. J. Adv. Manuf. Technol. 2014, 71, 1587–1598. [Google Scholar] [CrossRef]

- Zou, B.; Chen, M.; Li, S. Study on finish-turning of NiCr20TiAl nickel-based alloy using Al2O3/TiN-coated carbide tools. Int. J. Adv. Manuf. Technol. 2011, 53, 81–92. [Google Scholar] [CrossRef]

- Loureiro, D.; Diniz, A.E.; Farina, A.B.; Delijaicov, S. The influence of turning parameters on surface integrity of nickel alloy 625. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1837–1847. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Mach. Tools Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Maurya, R.K.; Niranjan, M. Experimental investigations of effect of tempering on residual stresses developed during the turning operation. Mater. Today Proc. 2021, 47, 3852–3858. [Google Scholar]

- Hosseini, E.; Rehman, S.; Alimoradi, A. Surface integrity of fatigue strength of nickel based super alloy in turning by wire electrical discharge process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 135–145. [Google Scholar] [CrossRef]

- Ulutan, D.; Ozel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Pawade, R.; Joshi, S.S.; Brahmankar, P. Effect of machining parameters and cutting edge geometry on surface integrity of high-speed turned Inconel 718. Int. J. Mach. Tools Manuf. 2008, 48, 15–28. [Google Scholar]

- Chen, Z.; Zhou, J.; Peng, R.L.; M’Saoubi, R.; Gustafsson, D.; Palmert, F.; Moverare, J. Plastic deformation and residual stress in high speed turning of AD730™ nickel-based superalloy with PCBN and WC tools. Procedia CIRP 2018, 71, 440–445. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, Z. Experimental investigation of principal residual stress and fatigue performance for turned nickel-based superalloy Inconel 718. Materials 2018, 11, 879. [Google Scholar] [CrossRef] [PubMed]

- Axinte, D.; Andrews, P.; Li, W.; Gindy, N.; Withers, P.; Childs, T. Turning of advanced Ni based alloys obtained via powder metallurgy route. CIRP Ann. 2006, 55, 117–120. [Google Scholar] [CrossRef]

- Peng, R.; Liu, K.; Tang, X.; Liao, M.; Hu, Y. Effect of prestress on cutting of nickel-based superalloy GH4169. Int. J. Adv. Manuf. Technol. 2019, 100, 813–825. [Google Scholar] [CrossRef]

- Gupta, S.N.; Chak, S.K. Grinding temperature and its consequences on induced residual stresses during grinding of nickel-based superalloys: A review. Eng. Res. Express 2023, 4, 042002. [Google Scholar] [CrossRef]

- Ming, C.; Yadong, G.; Yao, S.; Shuoshuo, Q.; Yin, L.; Yuying, Y. Experimental study on grinding surface properties of nickel-based single crystal superalloy DD5. Int. J. Adv. Manuf. Technol. 2019, 101, 71–85. [Google Scholar] [CrossRef]

- Hamdi, H.; Zahouani, H.; Bergheau, J.-M. Residual stresses computation in a grinding process. J. Mater. Process. Technol. 2004, 147, 277–285. [Google Scholar] [CrossRef]

- Curtis, D.; Krain, H.; Winder, A.; Novovic, D. Impact of grinding wheel specification on surface integrity and residual stress when grinding Inconel 718. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1668–1681. [Google Scholar] [CrossRef]

- Ding, W.; Zhang, L.; Li, Z.; Zhu, Y.; Su, H.; Xu, J. Review on grinding-induced residual stresses in metallic materials. Int. J. Adv. Manuf. Technol. 2017, 88, 2939–2968. [Google Scholar] [CrossRef]

- Wang, J.; Xu, J.; Wang, X.; Zhang, X.; Song, X.; Chen, X. A comprehensive study on surface integrity of nickel-based superalloy Inconel 718 under robotic belt grinding. Mater. Manuf. Process. 2019, 34, 61–69. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, G.; Liu, L.; Qin, Y. Investigation into grindability of a superalloy and effects of grinding parameters on its surface integrity. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 238–250. [Google Scholar] [CrossRef]

- Gong, Y.; Zhou, Y.; Wen, X.; Cheng, J.; Sun, Y.; Ma, L. Experimental study on micro-grinding force and subsurface microstructure of nickel-based single crystal superalloy in micro grinding. J. Mech. Sci. Technol. 2017, 31, 3397–3410. [Google Scholar] [CrossRef]

- Zhou, Y.; Ma, L.; Gong, Y.; Zhang, L.; Yin, G.; Sun, Y. Study on the mechanism of chip forming and the microhardness of micro-grinding nickel-based single-crystal superalloy. Int. J. Adv. Manuf. Technol. 2019, 103, 281–295. [Google Scholar] [CrossRef]

- Oliveira, J.; Santos, T.; Miranda, R. Revisiting fundamental welding concepts to improve additive manufacturing: From theory to practice. Prog. Mater. Sci. 2020, 107, 100590. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Li, S.; Hu, X.; Lu, H.; Li, X.; Xu, Z.; Chen, Y.; Li, Q.; Lu, J. Additive manufacturing of Ni-based superalloys: Residual stress, mechanisms of crack formation and strategies for crack inhibition. Nano Mater. Sci. 2023, 5, 53–77. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Singh, U.P.; Swaminathan, S.; Phanikumar, G. Thermo-mechanical approach to study the residual stress evolution in part-scale component during laser additive manufacturing of alloy 718. Mater. Des. 2022, 222, 111048. [Google Scholar] [CrossRef]

- Withers, P.J.; Bhadeshia, H. Residual stress. Part 1–measurement techniques. Mater. Sci. Technol. 2001, 17, 355–365. [Google Scholar] [CrossRef]

- Shi, J.; Geng, C.; Xing, P.; Wang, Y.; Wang, G. Test and Analysis on Residual Stress of Aeroengine Components Based on Neutron Diffraction. Aeroengine 2020, 46, 59–65. [Google Scholar]

- Rossini, N.; Dassisti, M.; Benyounis, K.; Olabi, A.-G. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Anderoglu, O. Residual Stress Measurement Using X-ray Diffraction. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2005. [Google Scholar]

- Hauk, V. Structural and Residual Stress Analysis by Nondestructive Methods: Evaluation-Application-Assessment; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Morancais, A.; Fevre, M.; François, M.; Kanoute, P.; Kruch, S.; Longuet, A. Impact of shot-peening on a single crystal nickel-based superalloy. Adv. Mater. Res. 2014, 996, 70–75. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Kortabarria, A.; Madariaga, A.; Esnaola, J.; Fernandez, E.; Cappellini, C.; Ulutan, D.; Özel, T. On the machining induced residual stresses in IN718 nickel-based alloy: Experiments and predictions with finite element simulation. Simul. Model. Pract. Theory 2014, 41, 87–103. [Google Scholar] [CrossRef]

- Madariaga, A.; Arrazola, P.J.; Esnaola, J.A.; Ruiz-Hervias, J.; Muñoz, P. Evolution of residual stresses induced by machining in a nickel based alloy under static loading at room temperature. Procedia CIRP 2014, 13, 175–180. [Google Scholar] [CrossRef][Green Version]

- Masoudi, S.; Amini, S.; Saeidi, E.; Eslami-Chalander, H. Effect of machining-induced residual stress on the distortion of thin-walled parts. Int. J. Adv. Manuf. Technol. 2015, 76, 597–608. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. The effects of shot peening, laser shock peening and ultrasonic nanocrystal surface modification on the fatigue strength of Inconel 718. Mater. Sci. Eng. A 2021, 810, 141029. [Google Scholar] [CrossRef]

- Schajer, G. Practical Residual Stress Measurement Methods; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Meyer, H.; Epp, J. In Situ x-ray diffraction analysis of stresses during deep rolling of steel. Quantum Beam Sci. 2018, 2, 20. [Google Scholar] [CrossRef]

- Meyer, H.; Epp, J. Spatial Internal Material Load and Residual Stress Distribution Evolution in Synchrotron In Situ Investigations of Deep Rolling. Quantum Beam Sci. 2020, 4, 3. [Google Scholar] [CrossRef]

- Wang, H.; Tong, R.; Liu, G.; Sha, A.; Song, L.; Zhang, T. In-Situ Synchrotron HEXRD Study on the Micro-Stress Evolution Behavior of a Superalloy during Room-Temperature Compression. Materials 2023, 16, 3761. [Google Scholar] [CrossRef]

- Tanaka, K.; Akiniwa, Y. Diffraction Measurements of Residual Macrostress and Microstress Using X-rays, Synchrotron and Neutrons. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2004, 47, 252–263. [Google Scholar] [CrossRef]

- Allen, A.; Hutchings, M.; Windsor, C.; Andreani, C. Neutron diffraction methods for the study of residual stress fields. Adv. Phys. 1985, 34, 445–473. [Google Scholar] [CrossRef]

- Smith, T.; Carter, R.; An, K.; Chen, Y.; Locci, I.; Pawlik, R.; Gabb, T.; Telesman, I.; Evans, L. Residual Stress Measurements of Ni-base Superalloys through Neutron Diffraction; Glenn Research Center: Cleveland, OH, USA, 2020. Available online: https://ntrs.nasa.gov/citations/20205008113 (accessed on 29 October 2020).

- Chen, Y.; Cernatescu, I.; Venkatesh, V.; Stoica, A.D.; An, K. On the residual stress relaxation in Inconel 718 superalloys at high temperature by real-time neutron diffraction. Mater. Des. 2023, 232, 112135. [Google Scholar] [CrossRef]

- Liu, X.; Luzin, V.; Qin, H.; Bi, Z.; Li, M.; Liu, Y.; Sun, K.; Chen, D. Mapping of three-dimensional residual stresses by neutron diffraction in nickel-based superalloy discs prepared under different quenching conditions. Mater. Today Commun. 2022, 32, 103876. [Google Scholar] [CrossRef]

- Pereira, P.; Santos, A. Influence of anisotropy generated by rolling on the stress measurement by ultrasound in 7050 T7451 aluminum. Exp. Mech. 2013, 53, 415–425. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Lee, T.-G.; Yeom, Y.-T.; Kwon, S.-D.; Kim, H.-H.; Lee, K.-Y.; Kim, H.-J.; Song, S.-J. Nondestructive Evaluation of Residual Stress in Shot Peened Inconel Using Ultrasonic Minimum Reflection Measurement. Materials 2023, 16, 5075. [Google Scholar] [CrossRef]

- Zongxing, P.; Junkai, S.; Yukui, G. Residual Stress Measurement of GH4169 Superalloy Based on Laser Ultrasonic Method. Chin. Q. Mech. 2021, 42, 98. [Google Scholar]

- Liu, M.; Zheng, Q.; Wang, X.; Xu, C. Characterization of Distribution of Microstructure and Micro-mechanical Properties of Nickel-Based Single Crystal Superalloy Within the Shot-Peened Layer. Met. Mater. Int. 2023, 29, 2257–2286. [Google Scholar] [CrossRef]

- Liu, M.; Zheng, Q.; Wang, X.; Xu, C. Characterization of distribution of residual stress in shot-peened layer of nickel-based single crystal superalloy DD6 by nanoindentation technique. Mech. Mater. 2022, 164, 104143. [Google Scholar] [CrossRef]

- Xiao, L.; Ye, D.; Chen, C. A further study on representative models for calculating the residual stress based on the instrumented indentation technique. Comput. Mater. Sci. 2014, 82, 476–482. [Google Scholar] [CrossRef]

- Suresh, S.; Giannakopoulos, A. A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 1998, 46, 5755–5767. [Google Scholar] [CrossRef]

- Carlsson, S.; Larsson, P.-L. On the determination of residual stress and strain fields by sharp indentation testing: Part I: Theoretical and numerical analysis. Acta Mater. 2001, 49, 2179–2191. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Kwon, D. Measurement of residual-stress effect by nanoindentation on elastically strained (100) W. Scr. Mater. 2003, 49, 459–465. [Google Scholar] [CrossRef]

- Wang, Q.; Ozaki, K.; Ishikawa, H.; Nakano, S.; Ogiso, H. Indentation method to measure the residual stress induced by ion implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2006, 242, 88–92. [Google Scholar] [CrossRef]

- Prime, M.B. Residual stress measurement by successive extension of a slot: The crack compliance method. Appl. Mech. Rev. 1999, 52, 75–96. [Google Scholar] [CrossRef]

- Withers, P.; Webster, P. Neutron and synchrotron x-ray strain scanning. Strain 2001, 37, 19–33. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, L.; Meng, W.; Zu, X.; Zhang, Z. A novel analytical modeling for prediction of residual stress induced by thermal-mechanical load during orthogonal machining. Int. J. Adv. Manuf. Technol. 2020, 109, 475–489. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, Z.; Wang, B.; Jiang, J. Residual stress regenerated on low plasticity burnished Inconel 718 surface after initial turning process. J. Manuf. Sci. Eng. 2019, 141, 121004. [Google Scholar] [CrossRef]

- Peng, H.; Dong, P.; Cheng, X.; Zhang, C.; Tang, W.; Xing, Y.; Zhou, X. Semi-empirical prediction of residual stress distributions introduced by turning Inconel 718 alloy based on Lorentz function. Materials 2020, 13, 4341. [Google Scholar] [CrossRef]

- Ulutan, D.; Arisoy, Y.; Özel, T.; Mears, L. Empirical modeling of residual stress profile in machining nickel-based superalloys using the sinusoidal decay function. Procedia CIRP 2014, 13, 365–370. [Google Scholar] [CrossRef]

- Nagesha, B.; Kumar, S.A.; Vinodh, K.; Pathania, A.; Barad, S. A thermo–Mechanical modelling approach on the residual stress prediction of SLM processed HPNGV aeroengine part. Mater. Today Proc. 2021, 44, 4990–4996. [Google Scholar] [CrossRef]

- Wang, F.; Men, X.; Liu, Y.; Fu, X. Experiment and simulation study on influence of ultrasonic rolling parameters on residual stress of Ti-6Al-4V alloy. Simul. Model. Pract. Theory 2020, 104, 102121. [Google Scholar] [CrossRef]

- Seddik, R.; Ben Sghaier, R.; Fathallah, R. A numerical–analytical approach to predict the effects of shot peening on the fatigue performance of the nickel-based super alloy Waspaloy. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 128–140. [Google Scholar] [CrossRef]

- Goulmy, J.-P.; Boyer, V.; Retraint, D.; Kanoute, P.; Toualbi, L.; Rouhaud, E. Modeling of the shot peening of a nickel alloy with the consideration of both residual stresses and work hardening. Int. J. Solids Struct. 2023, 264, 112120. [Google Scholar] [CrossRef]

- Kortabarria, A.; Armentia, I.; Arrazola, P. Sensitivity analysis of material input data influence on machining induced residual stress prediction in Inconel 718. Simul. Model. Pract. Theory 2016, 63, 47–57. [Google Scholar] [CrossRef]

- Wu, J.; Liu, X.; Qiao, H.; Zhao, Y.; Hu, X.; Yang, Y.; Zhao, J. Using an artificial neural network to predict the residual stress induced by laser shock processing. Appl. Opt. 2021, 60, 3114–3121. [Google Scholar] [CrossRef]

- Wu, J.; Li, Y.; Zhao, J.; Qiao, H.; Lu, Y.; Sun, B.; Hu, X.; Yang, Y. Prediction of residual stress induced by laser shock processing based on artificial neural networks for FGH4095 superalloy. Mater. Lett. 2021, 286, 129269. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, C.; Wang, Z.; Zhan, K. Influence of shot peening on surface-layer characteristics of a monocrystalline nick-el-based superalloy. Powder Diffr. 2010, 25, 355–358. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, C. Effect of shot peening on surface characteristics of Ni-based single-crystal superalloy. Mater. Trans. 2013, 54, 1894–1897. [Google Scholar] [CrossRef]

- Kumar, D.; Idapalapati, S.; Wei, W. Microstructural response and strain hardening in deep cold rolled nickel-based superalloy for aerospace application. Procedia CIRP 2018, 71, 374–379. [Google Scholar] [CrossRef]

- Hu, T.; Li, S.; Qiao, H.; Lu, Y.; Sun, B.; Wu, J. Effect of warm laser shock peening on microstructure and properties of GH4169 superalloy. IOP Conf. Ser. Mater. Sci. Eng. 2018, 423, 012054. [Google Scholar] [CrossRef]

- Yang, J.; Liu, D.; Zhang, X.; Liu, M.; Zhao, W.; Liu, C. The effect of ultrasonic surface rolling process on the fretting fatigue property of GH4169 superalloy. Int. J. Fatigue 2020, 133, 105373. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, K.; Dong, X.; Duan, W.; Mei, X. Effect of warm laser shock peening on the low-cycle fatigue behavior of DD6 nickel-based single-crystal superalloy. J. Mater. Eng. Perform. 2021, 30, 2930–2939. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, K.; Geng, Y.; Dong, X.; Duan, W.; Sun, X.; Mei, X. An investigation of the effect of warm laser shock peening on the surface modifications of [001]-oriented DD6 superalloy. Int. J. Adv. Manuf. Technol. 2021, 113, 1973–1988. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, Y.; Zhao, J.; Yang, Y.; Qiao, H.; Hu, X.; Wu, J.; Sun, B. Impact on mechanical properties and microstructural response of nickel-based superalloy GH4169 subjected to warm laser shock peening. Materials 2020, 13, 5172. [Google Scholar] [CrossRef] [PubMed]

- Sheng, J.; Zhang, H.; Hu, X.; Huang, S. Influence of laser peening on the high-temperature fatigue life and fracture of Inconel 718 nickel-based alloy. Theor. Appl. Fract. Mech. 2020, 109, 102757. [Google Scholar] [CrossRef]

- Hu, X.; Yang, Y.; Zhao, J.; Lu, Y.; Wu, J.; Qiao, H. Surface integrity evolution of a Ni-based single crystal superalloy by laser shock peening. Appl. Surf. Sci. Adv. 2021, 6, 100183. [Google Scholar] [CrossRef]

- Tang, Z.; Dong, X.; Geng, Y.; Wang, K.; Duan, W.; Gao, M.; Mei, X. The effect of warm laser shock peening on the thermal stability of compressive residual stress and the hot corrosion resistance of Ni-based single-crystal superalloy. Opt. Laser Technol. 2022, 146, 107556. [Google Scholar] [CrossRef]

- Zhou, Z.; Yao, C.-F.; Zhao, Y.; Wang, Y.; Tan, L. Effect of ultrasonic impact treatment on the surface integrity of nickel alloy 718. Adv. Manuf. 2021, 9, 160–171. [Google Scholar] [CrossRef]

- Yao, C.; Zhou, Z.; Zhao, Y.; Tan, L.; Cui, M.; Wang, Y. Experimental study on surface integrity changes during turning-ultrasonic impact of nickel alloy 718. Int. J. Adv. Manuf. Technol. 2021, 112, 1359–1371. [Google Scholar] [CrossRef]

- Chen, M.; Xing, S.; Li, J.; He, J.; Lu, Y.; Jiang, C.; Ji, V. Surface residual stress and microstructure evolutions of Hastelloy X alloy after severe shot peening. Vacuum 2021, 187, 110136. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Yang, K.; Song, X. Characteristics of microstructure evolution of surface treated IN718 superalloy by warm laser shock peening during long-term aging at high temperatures. Mater. Charact. 2022, 193, 112261. [Google Scholar] [CrossRef]

- Yang, J.; Liu, D.; Fan, K.; Liu, Y.; Ren, Z.; Liu, D.; Xu, X.; Jia, T.; Zhang, H.; Ye, C. Designing a gradient structure in a Ni-based superalloy to improve fretting fatigue resistance at elevated temperatures through an ultrasonic surface rolling process. Int. J. Fatigue 2023, 168, 107397. [Google Scholar] [CrossRef]

- Wang, X.; Xu, C.; Wang, X.; Hu, D.; Ma, S.; Tang, Z. Turning/Shot peening of Nickel-based powder metallurgy superalloy: Effect on surface integrity and high-temperature low-cycle fatigue properties. Int. J. Fatigue 2023, 166, 107291. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.; Shan, J.; Wu, A.; Sato, Y.S.; Tokita, S.; Kadoi, K.; Inoue, H.; Gu, H.; Tang, X. The role of shot peening on liquation cracking in laser cladding of K447A nickel superalloy powders over its non-weldable cast structure. Mater. Sci. Eng. A 2021, 823, 141678. [Google Scholar] [CrossRef]

- Foss, B.; Gray, S.; Hardy, M.; Stekovic, S.; McPhail, D.; Shollock, B.A. Analysis of shot-peening and residual stress relaxation in the nickel-based superalloy RR1000. Acta Mater. 2013, 61, 2548–2559. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, H.; Liu, Y. Effect of shot peening on the fatigue properties of nickel-based superalloy GH4169 at high temperature. Results Phys. 2018, 11, 452–460. [Google Scholar] [CrossRef]

- Li, Y.; Cockings, H.; Mignanelli, P.; Whittaker, M.; Cockings, B.; Buckingham, R.; Bache, M. High temperature corrosion-fatigue behavior of a shot peened nickel based superalloy. Corros. Sci. 2022, 207, 110577. [Google Scholar] [CrossRef]

- Lesyk, D.; Dzhemelinskyi, V.; Martinez, S.; Mordyuk, B.; Lamikiz, A. Surface shot peening post-processing of inconel 718 alloy parts printed by laser powder bed fusion additive manufacturing. J. Mater. Eng. Perform. 2021, 30, 6982–6995. [Google Scholar] [CrossRef]

- Qin, Z.; Li, B.; Chen, R.; Zhang, H.; Xue, H.; Yao, C.; Tan, L. Effect of shot peening on high cycle and very high cycle fatigue properties of Ni-based superalloys. Int. J. Fatigue 2023, 168, 107429. [Google Scholar] [CrossRef]

- Sihai, L.; Weifeng, H.; Liucheng, Z.; Xiangfan, N.; Yinghong, L. Aluminizing mechanism on a nickel-based alloy with surface nanostructure produced by laser shock peening and its effect on fatigue strength. Surf. Coat. Technol. 2018, 342, 29–36. [Google Scholar] [CrossRef]

- Karthik, D.; Swaroop, S. Laser shock peening enhanced corrosion properties in a nickel based Inconel 600 superalloy. J. Alloys Compd. 2017, 694, 1309–1319. [Google Scholar] [CrossRef]

- Geng, Y.; Dong, X.; Wang, K.; Mei, X.; Tang, Z.; Duan, W. Evolutions of microstructure, phase, microhardness, and residual stress of multiple laser shock peened Ni-based single crystal superalloy after short-term thermal exposure. Opt. Laser Technol. 2020, 123, 105917. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Cheng, G.J. A review: Warm laser shock peening and related laser processing technique. Opt. Laser Technol. 2016, 78, 15–24. [Google Scholar] [CrossRef]

- Chin, K.; Idapalapati, S.; Ardi, D. Thermal stress relaxation in shot peened and laser peened nickel-based superalloy. J. Mater. Sci. Technol. 2020, 59, 100–106. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, J.; Qiao, H.; Wun, J.; Hu, X. The research progress on strengthen property and mechanism of warm laser shock peening. In Proceedings of the 24th National Laser Conference & Fifteenth National Conference on Laser Technology and Optoelectronics, Shanghai, China, 17–20 October 2020; pp. 104–114. [Google Scholar]

- Ye, C.; Liao, Y.; Cheng, G.J. Warm laser shock peening driven nanostructures and their effects on fatigue performance in aluminum alloy 6160. Adv. Eng. Mater. 2010, 12, 291–297. [Google Scholar] [CrossRef]

- Lu, Y.; Zhao, J.; Qiao, H.; Hu, T.; Sun, B.; Wu, J. A study on the surface morphology evolution of the GH4619 using warm laser shock peening. Aip Adv. 2019, 9, 085030. [Google Scholar] [CrossRef]

- Tani, G.; Orazi, L.; Fortunato, A.; Ascari, A.; Campana, G. Warm laser shock peening: New developments and process optimization. CIRP Ann. 2011, 60, 219–222. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Kim, B.-J.; Suslov, S.; Stach, E.A.; Cheng, G.J. Nucleation of highly dense nanoscale precipitates based on warm laser shock peening. J. Appl. Phys. 2010, 108, 063518. [Google Scholar] [CrossRef]

- Nagarajan, B.; Kumar, D.; Fan, Z.; Castagne, S. Effect of deep cold rolling on mechanical properties and microstructure of nickel-based superalloys. Mater. Sci. Eng. A 2018, 728, 196–207. [Google Scholar] [CrossRef]

- Oevermann, T.; Wegener, T.; Liehr, A.; Hübner, L.; Niendorf, T. Evolution of residual stress, microstructure and cyclic performance of the equiatomic high-entropy alloy CoCrFeMnNi after deep rolling. Int. J. Fatigue 2021, 153, 106513. [Google Scholar] [CrossRef]

- Kuschel, S.; Kinner-Becker, T.; Zmich, R.; Sölter, J.; Meyer, D. Modelling and Simulation of Mechanical Loads and Residual Stresses in Deep Rolling at Elevated Temperature. J. Manuf. Mater. Process. 2021, 5, 76. [Google Scholar] [CrossRef]

- Kinner-Becker, T.; Hettig, M.; Sölter, J.; Meyer, D. Analysis of internal material loads and Process Signature Components in deep rolling. CIRP J. Manuf. Sci. Technol. 2021, 35, 400–409. [Google Scholar] [CrossRef]

- Jiang, W.; Xu, P.; Li, Y.; Wang, H.; Cai, Z.; Li, J.; Liang, Y.; Liang, Y. Effect of a gradient structure on the mechanical performance of Inconel 718 Ni-based superalloy at elevated temperatures. J. Mater. Res. Technol. 2023, 23, 2031–2042. [Google Scholar] [CrossRef]

- Hao, J.; Niu, Q.; Ji, H.; Liu, H. Effect of ultrasonic rolling on the organization and properties of a high-speed laser cladding IN 718 superalloy coating. Crystals 2023, 13, 1214. [Google Scholar] [CrossRef]

- John, M.; Ralls, A.M.; Dooley, S.C.; Thazhathidathil, A.K.V.; Perka, A.K.; Kuruveri, U.B.; Menezes, P.L. Ultrasonic surface rolling process: Properties, characterization, and applications. Appl. Sci. 2021, 11, 10986. [Google Scholar] [CrossRef]

- Wu, D.; Lv, H.; Wang, H.; Yu, J. Surface micro-morphology and residual stress formation mechanisms of near-net-shaped blade produced by low-plasticity ultrasonic rolling strengthening process. Mater. Des. 2022, 215, 110513. [Google Scholar] [CrossRef]

- Yu, W.; Wu, J.; Li, Y.; An, Q.; Ming, W.; Chen, D.; Wang, H.; Chen, M. Investigations on surface modification of nickel-based superalloy subjected to ultrasonic surface rolling process. Int. J. Adv. Manuf. Technol. 2023, 129, 1473–1488. [Google Scholar] [CrossRef]

- Luan, X.; Zhao, W.; Liang, Z.; Xiao, S.; Liang, G.; Chen, Y.; Zou, S.; Wang, X. Experimental study on surface integrity of ultra-high-strength steel by ultrasonic hot rolling surface strengthening. Surf. Coat. Technol. 2020, 392, 125745. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, D.; Wan, M. A review of strengthening mechanisms and applications of the multifield-coupled manufacturing process. J. Mater. Process. Technol. 2023, 320, 118128. [Google Scholar] [CrossRef]

- Ji, R.; Zheng, Q.; Liu, Y.; To, S.; Yip, W.S.; Yang, Z.; Jin, H.; Wang, H.; Cai, B.; Cheng, W. An investigation of mechanical-thermal coupling treatment on material properties, surface roughness, and cutting force of Inconel 718. Int. J. Adv. Manuf. Technol. 2019, 105, 1917–1931. [Google Scholar] [CrossRef]

- Sun, Z.; Ye, Y.; Xu, J.; Hu, T.; Ren, S.; Li, B. Effect of electropulsing on surface mechanical behavior and microstructural evolution of inconel 718 during ultrasonic surface rolling process. J. Mater. Eng. Perform. 2019, 28, 6789–6799. [Google Scholar] [CrossRef]

- Yan, J.; Zhao, R.; Wan, M.; Meng, B. Coupled effect of pulsed current and ultrasonic vibration on deformation behavior of Inconel 718 sheet: Phenomena and modeling. J. Mater. Res. Technol. 2023, 25, 5538–5560. [Google Scholar] [CrossRef]

- Ji, R.; Liu, Y.; To, S.; Jin, H.; Yip, W.S.; Yang, Z.; Zheng, C.; Cai, B. Efficient fabrication of gradient nanostructure layer on surface of commercial pure copper by coupling electric pulse and ultrasonics treatment. J. Alloys Compd. 2018, 764, 51–61. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, B.; Du, M.; Wan, M. Electroplastic effect and microstructural mechanism in electrically assisted deformation of nickel-based superalloys. Mater. Sci. Eng. A 2022, 840, 142975. [Google Scholar] [CrossRef]

- Ji, R.; Yang, Z.; Jin, H.; Liu, Y.; Wang, H.; Zheng, Q.; Cheng, W.; Cai, B.; Li, X. Surface nanocrystallization and enhanced surface mechanical properties of nickel-based superalloy by coupled electric pulse and ultrasonic treatment. Surf. Coat. Technol. 2019, 375, 292–302. [Google Scholar] [CrossRef]

- Tang, Z.; Dong, X.; Wang, K.; Geng, Y.; Gao, M.; Mei, X. An investigation on the effect of change in experimental sequence of warm laser shock peening and laser shock peening on the performance of DD6 nickel-based single-crystal superalloy. Surf. Coat. Technol. 2023, 464, 129450. [Google Scholar] [CrossRef]

- Ye, Y.; Kure-Chu, S.-Z.; Sun, Z.; Li, X.; Wang, H.; Tang, G. Nanocrystallization and enhanced surface mechanical properties of commercial pure titanium by electropulsing-assisted ultrasonic surface rolling. Mater. Des. 2018, 149, 214–227. [Google Scholar] [CrossRef]

- Ye, Y.; Kuang, J.; Kure-Chu, S.-Z.; Song, G.; Sun, Z.; Tang, G. Improvement of microstructure and surface behaviors of welded S50C steel components under electropulsing assisted ultrasonic surface modification. J. Mater. Res. 2016, 31, 2125–2135. [Google Scholar] [CrossRef]

- Duan, C.; Qu, S.; Hu, X.; Jia, S.; Li, X. Microstructures and fatigue behaviors of 25CrNi2MoV steel under electropulsing-assisted ultrasonic surface rolling. Int. J. Fatigue 2022, 158, 106733. [Google Scholar] [CrossRef]

- Qu, S.; Ren, Z.; Hu, X.; Lai, F.; Sun, F.; Li, X.; Yang, C. The effect of electric pulse aided ultrasonic rolling processing on the microstructure evolution, surface properties, and fatigue properties of a titanium alloy Ti5Al4Mo6V2Nb1Fe. Surf. Coat. Technol. 2021, 421, 127408. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Gao, C.; Wong, K.; Ye, S.; Xiao, Z. Modified wear behavior of selective laser melted Ti6Al4V alloy by direct current assisted ultrasonic surface rolling process. Surf. Coat. Technol. 2020, 381, 125122. [Google Scholar] [CrossRef]

| Method | Advantages | Disadvantages |

|---|---|---|

| Empirical models | (1) Clear formulas and easy calculations. (2) Low demand for computing resources. (3) For prediction under known operating conditions. | (1) Limited scope of application. (2) Lack of physical basis and reliance on empirical data. (3) Limited accuracy in nonlinear or complex situations. |

| Finite element models | (1) Capable of simulating complex stress distributions and residual stress fields. (2) Works under a wide range of loads and boundary conditions. (3) Predicts spatial distribution of stress. | (1) High computational cost. (2) Complex model setup, with demanding pre-processing and validation. (3) Strong reliance on material models. |

| Machine learning models | (1) Strong generalization ability. (2) Excellent predictive ability for nonlinear problems. (3) Automatically learns parameters without pre-defined models. | (1) Requires large datasets for training. (2) “Black box” nature: difficult to interpret the physical meaning of the model parameters. (3) Sensitive to data quality, may lead to overfitting. |

| Method | Advantages | Disadvantages |

|---|---|---|

| Shot Peening | (1) Low cost (2) Easily applied to large-scale industrial applications | Residual compressive stresses are introduced at a limited depth and usually act only in the surface layer, making it difficult to adapt to deep strengthening needs |

| Laser Shock Peening | (1) Ability to introduce compressive residual stresses deep in the material (2) Low impact on surface roughness | (1) Higher costs and complex equipment requirements (2) Slower processing speed, not suitable for mass production |

| Deep Rolling | (1) Relatively mature and stable process (2) Reduced surface roughness | (1) Lower adaptability to complex shaped parts (2) The improvement in surface microstructure was lower compared to USRP |

| Ultrasonic Surface Rolling Process | (1) Stronger residual compressive stresses can be induced while refining the surface grains and improving the surface microstructure (2) Improved surface finish | (1) Limited applicability to complex shaped parts (2) Specialized equipment is required, and the operation process is more complicated |

| Composite Surface Treatment Technology | (1) The comprehensive enhancement effects can be realized (2) Meet the needs of different working conditions | (1) Complex and costly treatment process (2) Difficult to standardize production |

| Year | Workpiece | Method | Scheme | Measurement Method | Effect of Residual Stress | Reference |

|---|---|---|---|---|---|---|

| 2010 | DD3 | SP | Shot media: ceramic | XRD | Overlapping rate ↑, residual stress ↑ | [133] |

| Shot media diameter: 0.2 mm | ||||||

| Overlapping rate: 80%, 200%, 400% Almen intensity: 0.6 mmA Shot peening distance: 100 mm | ||||||

| 2013 | DD3 | SP | Shot media: Al2O3 Shot media diameter: 0.3 mm Jet pressure: 0.3 MPa Almen intensity: 0.13 mmA Treatment time: 10\30\60\120 s | XRD | Peening time ↑, residual compressive stress ↑ | [134] |

| 2018 | Udimet 720Li | Deep Cold Rolled | Hydrostatic tool: 6 mm Hydraulic pressures: 10\30\50 MPa Speed: 1 m/min Stepover: 0.06 mm | XRD | Hydraulic pressures ↑, residual compressive stress ↑ | [135] |

| 2018 | GH4169 | LSP WLSP | Pulse energy: 5 J Wavelength: 1064 nm Overlapping rate: 50% Spot diameter: 2 mm Pulse width: 14 ns | XRD | WLSP > LSP; WLSP: temperature ↑, residual stress first ↑, then ↑ | [136] |

| 2019 | GH4169 | USRP | Static load: 900 N Spindle speed: 100 r/min Ultrasonic frequency: 20 kHz Amplitude: 12 μm Feed rate: 0.08 mm/r Treatment times: 1 and 3 | XRD | Treatment times ↑, residual stress ↑ | [137] |

| 2020 | DD6 | WLSP | Pulse energy: 7 J Wavelength: 1064 nm Overlapping rate: 50% Spot diameter: 3 mm Pulse width: 20 ns Pulse frequency: 1 Hz | Number of shocks ↑, residual stress ↑ | [138] | |

| 2020 | DD6 | WLSP | Spot diameter: 3 mm Overlapping rate: 30% Pulse energy: 7 J Pulse width: 20 ns Pulse frequency: 1 Hz | ANSYS/LS-DYNA | Temperature ↑, residual stress ↑ | [139] |

| 2020 | GH4169 | LSP WLSP | Pulse energy: 5 J Wavelength: 1064 nm Overlapping rate: 50% Spot diameter: 2 mm Pulse width: 14 ns Pulse frequency: 2 Hz | XRD | Exposure time ↑, residual compressive stress: WLSP > LSP | [140] |

| 2020 | IN718 | LP | Pulse energy: 4.6 J, 5.0 J, 5.6 J Wavelength: 1064 nm Overlapping rate:50% Spot diameter: 2.2 mm Pulse width:15 ns Pulse frequency: 1 Hz Laser power densities: 6.05\6.58\7.37 GW/cm2 | XRD | Laser power densities ↑, residual compressive stress ↑ | [141] |

| 2021 | SRR99 | LSP | Wavelength: 1064 nm Spot diameter: 2.6 mm Pulse energy: 5–7 J Overlapping rate: 50% Pulse width: 14 ns Pulse frequency: single point | XRD | Pulse energy ↑, residual compressive stress ↑ | [142] |

| 2021 | DD6 | WLSP | Pulse energy: 7 J Wavelength: 1064 nm Overlapping rate: 50% Spot diameter: 3 mm Pulse width: 20 ns Pulse frequency: 1 Hz | XRD | Temperature ↑, residual compressive stress ↑; WLSP > LSP | [143] |

| 2021 | IN718 | Ultrasonic impact treatment | Ultrasonic frequency: 34 kHz Amplitude: 6 μm Pre-extrusion depth: 0.01–0.025 mm Feed rate: 0.05–0.2 mm/r Linear velocity: 2.83–5.65 m/min | XRD | Rank the impact for RS: feed rate > pre-extrusion depth > linear velocity | [144] |

| 2021 | IN718 | Ultrasonic impact treatment | Ultrasonic frequency: 34 kHz Amplitude: 6 μm Feed rate: 0.08 mm/r Spindle speed: 60 r/min Pre-extrusion depth:0.01 mm | XRD | Turning surface roughness ↑, residual stress ↑ | [145] |

| 2021 | Hastelloy X alloy | SSP, SP | Shot media: S230 steel Shot media diameter: 0.3 mm Overlapping rate: 100%, 1500% Almen intensity: 0.2, 0.5 mmA Air pressure: 0.1, 0.3 MPa | XRD | Residual compressive stress: SSP > SP | [146] |

| 2022 | IN718 | LSP WLSP | Spot diameter: 2.5 mm Pulse energy: 7 J Pulse width: 15 ns Overlapping rate: 60% | XRD | WLSP > LSP | [147] |

| 2022 | GH4169 | USRP | Static load: 300 N Spindle speed: 60 rev/min Ultrasonic frequency: 25 kHz Amplitude: 10 μm Feed rate: 0.08 mm/r Workpiece speed: 200 r/min Treatment times: 1 and 20 | XRD | Treatment times ↑, residual stress ↑, residual stress becomes more stable in high-temperature environments | [148] |

| 2022 | FGH96 PM | SP | Shot media: Ceramic beads AZB300 and cast iron shot ASH110 Shot media diameter: 0.3 mm Almen intensity: 0.08–0.13 mmA and 0.25–0.33 mmA | XRD | Residual compressive stress: Ceramic bead peening < Ceramic bead peening | [149] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wen, G.; Li, L.; Lei, Z.; Qi, X.; Huang, B.; Su, Y.; Zhang, Z.; Nie, X.; Zhang, Z. The Generation, Measurement, Prediction, and Prevention of Residual Stress in Nickel-Based Superalloys: A Review. Machines 2024, 12, 715. https://doi.org/10.3390/machines12100715

Zhang Y, Wen G, Li L, Lei Z, Qi X, Huang B, Su Y, Zhang Z, Nie X, Zhang Z. The Generation, Measurement, Prediction, and Prevention of Residual Stress in Nickel-Based Superalloys: A Review. Machines. 2024; 12(10):715. https://doi.org/10.3390/machines12100715

Chicago/Turabian StyleZhang, Yuanlin, Guangrui Wen, Liangbo Li, Zihao Lei, Xiaogang Qi, Boyang Huang, Yu Su, Zhifen Zhang, Xiangfan Nie, and Zhanling Zhang. 2024. "The Generation, Measurement, Prediction, and Prevention of Residual Stress in Nickel-Based Superalloys: A Review" Machines 12, no. 10: 715. https://doi.org/10.3390/machines12100715

APA StyleZhang, Y., Wen, G., Li, L., Lei, Z., Qi, X., Huang, B., Su, Y., Zhang, Z., Nie, X., & Zhang, Z. (2024). The Generation, Measurement, Prediction, and Prevention of Residual Stress in Nickel-Based Superalloys: A Review. Machines, 12(10), 715. https://doi.org/10.3390/machines12100715