Abstract

This contribution explores the development of a digital twin for industrial valves, with a focus on mitigating the costly consequences of valve malfunctions in large-scale industrial environments. Industrial valves are critical components in fluid and gas control systems where unexpected failures can lead to significant downtime and financial loss. Digital twins as virtual replicas of physical systems offer a promising solution as they enable real-time monitoring and predictive maintenance. This paper looks at the creation of a digital twin for a specific valve type (74BS from SchuF Armaturen und Apparatebau GmbH) and considers key aspects such as model development, sensor integration and IT infrastructure. A test bench is constructed to collect the measured values to support the validation of the digital twin. The integration of sensors and the development of an IT system for data processing are also described in detail. Finally, the technically relevant frequencies are identified in an FFT.

1. Introduction

In the chemical or food industry, large-scale installations are used to realise chemical processes, mixtures or dosing. The installations are usually very costly capital goods that have to achieve precisely defined production quantities [1]. Unscheduled and unexpected downtimes or malfunctions in such systems often lead to losses in the millions and should be avoided by all means. These requirements also apply to the industrial valves installed in the systems, which are used to regulate media such as fluids or gases [2]. If such a valve fails, on the one hand this can have damaging consequences for the entire system, and on the other hand the system might need to be shut down in order to maintain or replace the valve [3]. This can lead to significant downtime.

For this reason, industrial valves are particularly suitable for the use of digital twins, which monitor the condition and damage of the valve and make the information usable [4]. If the users of the valve are aware of the damage, they can order replacements and schedule maintenance work before the failure occurs so that the system is idle for as short a time as possible. In this context, there is a project currently running at Hessen Agentur, which is considering the development of digital twins for industrial valves. The authors of this article are involved in the project and present some of the results. In particular, the following research questions are addressed:

- RQ1: How can a digital twin for an industrial valve be created systematically and methodically?

- RQ2: How can the behaviour of the valve be monitored in a digital twin?

2. State of the Art

This section includes the fundamentals of digital twins and their development. In addition, the basics of industrial valves are presented and the existing literature on the digital twins of valves is reviewed.

2.1. Fundamentals of Digital Twins

The concept of the digital twin was first introduced in 2002 in the context of a NASA report [5], and the term digital twin was subsequently applied in 2010 [6]. A digital twin is a digital representation of a physical product, which is then referred to as a physical twin. The behaviour of the physical twin is described in the models on which the digital twin is based.

The models of the digital twin are characterised by the model features of the general model theory. Models have to represent an original (the physical twin), focus on the relevant aspects and serve the purpose of a digital twin. [7] This can be achieved by creating simulation or calculation models, or via data-driven modelling such as machine learning [8,9]. However, any executable modelled description is suitable to serve as the basis for the digital twin. The modelled description, in particular its focus on the relevant aspects, leads to a neglect of the less important aspects of the physical twin. Therefore, a digital twin is not a 1:1 representation of the physical system, but has certain differences. The models must be designed in such a way that these differences are acceptable for the purpose of the digital twin.

The models are used to calculate and simulate this behaviour. This requires live data from the physical twin, which is recorded by sensors that are integrated into it. By calculating or simulating the behaviour of the physical twin during operation, it is possible to make predictions and draw conclusions about the system’s performance. For example, this can be used to determine specific stresses on individual components. This makes it possible to anticipate wear and tear and, based on this, to adjust the service intervals in terms of predictive maintenance. It is also possible to monitor the performance of the system and adjust it as required [10,11].

2.2. Methodical Development of a Digital Twin

The development of a digital twin requires a structured approach in order to achieve the desired goal. It is therefore advisable to choose a methodical approach in which there is a clear sequence of the various sub-steps. The development of a digital twin is based on digitally mapping a physical model in order to be able to observe tests, simulations or error symptoms. In order for the digital twin to react in the same way as its physical counterpart, it is necessary for the digital twin to be supplied with data. This data must be recorded and processed using sensors. For a better overview, the development of a digital twin can be divided into three areas: sensors, IT infrastructure and models. There are approaches in the literature to systematically consider these three areas in the context of digital twins. In the scope of this article, the approaches of the co-authors [9,12,13] are used in particular.

The methodical development of the models on which the digital twin is based begins with the identification of the requirements for the models. The focus here is on the desired metrics and functions. System boundaries are then defined to provide a separation from the environment. The next step is to model the behaviour of the digital twin. Initially, only the behaviour in various situations needs to be roughly considered. The model structure can be derived from the rough functions. Similarly, many detailed sub-models can be identified from the rough functional designs. These are then elaborated on and developed. Once all the functions required to simulate the behaviour of the physical twin have been developed, they can be transferred to a common, higher-level system. To ensure that the developed digital twin also fulfils the desired functions and delivers plausible predictions and results, the results are validated [9,14].

In order to select suitable sensors, it is first necessary to clarify the measurement task and determine the variables of interest. The digital twin should then be able to carry out simulations using this data. The measured variables can then be determined on this basis. The measurement location of the sensors is also relevant. Depending on the circumstances of the current project, there may be more or less suitable locations. Once a desired size and location for the recording is determined, one needs to choose a physical measuring principle that meets the desired requirements in terms of resolution, signal type and accuracy. With this information, the search for a sensor that meets these requirements begins. Here, particular attention must be paid to compatibility with the other components and the dimensions of the sensor. After suitable sensors are selected, they must be integrated at the intended location. It may be necessary to make changes to the existing components or to consider adaptations for future components. Once the sensors are installed, their function must be checked and the results validated [13].

The IT infrastructure forms the link between the sensors and models. When developing the IT infrastructure, the requirements must first be defined. This applies above all to data transfer rates, visualization options and compatibility. The desired functions of the architecture must then be determined. The next step is to define the architecture concept. This involves coordinating any cloud-based structures or local systems. Once this is performed, the selection of suitable components can be advanced. The selected software and hardware components must be checked for compatibility at the same time. The interfaces to the sensors and visualization are particularly important here. Once all the components are successfully selected, they must be implemented and connected to the sensors and other peripheral devices. The final development step is the verification and validation of the results presented in order to rule out incorrect data processing [12].

2.3. Industry Valves

Valves are mechanical components that are used to regulate the flow of a medium through a pipe. The valve can be set variably between fully open and fully closed. Modern valves can be found in various sizes and cover a wide range from miniature valves to large industrial valves [2]. Different types of flow can occur within a flowing medium, such as turbulent or laminar flows. The type of prevailing flow can fluctuate very dynamically and depends on factors such as the applied pressure or the volume flow [2]. Pressure pulsations can occur in the area of the valve due to fluctuating system parameters. This can cause the valve components to vibrate if there is an overlap with the natural vibration of the valve. The result is a measurable vibration of the valve components [4]. This can lead to abrasions and even plastic deformation of the valve. This makes it necessary to replace the affected components, as, after a certain amount of wear, the primary function can no longer be ensured [4].

2.4. Digital Twins of Industry Valves

In the following, the PRISMA approach [15,16] is used to select the literature that provides a comprehensive overview of the procedures for creating digital twins in conjunction with industrial valves. The literature also serves to uncover the possibilities for sensor integration. The aim of the PRISMA approach in this case is to find a selected number of research papers that deal with the topic of sensor integration and data acquisition on industrial valves and digital twins. To apply the Prisma approach, common databases for scientific papers such as ProQuest, TEMA or Web of Science are used. In order to keep the number of search results manageable, the search criteria are restricted as follows:

- -

- Only a title search and no full text search;

- -

- Use of synonyms for digital twin;

- -

- Use of abbreviations;

- -

- Combined search of valve and digital twin;

- -

- Implementation of the digital twin in the product life cycle;

- -

- English or German language.

The literature research provided 11 scientific papers that matched the search criteria. They provide a broad picture of the application of digital twins in context of industrial valves. The resulting scientific papers are briefly presented below:

- Berri et al. [17] developed a digital twin to validate the behaviour of a valve in the flight control of an aircraft. The flow within the valve is simulated, taking into account the properties of the hydraulic fluid and the component geometry. This makes it possible to assess the condition of the valve at an early stage.

- Bu et al. [18] reported on the development of digital twins for control valves. Here, particular reference is made to the complex geometry of industrial valves, which made it difficult to describe in terms of fluid dynamics. The use of a digital twin enabled real-time data acquisition from the system.

- Kapranova et al. [19] described the bubble energy during hydrodynamic cavitation in the valve. The data obtained provided the basis for modelling a cyber-physical system.

- Lauer-Bare et al. [20] discussed the creation of a digital twin for a hydraulic valve for the consideration of shear forces in viscous flow. The numerical simulations of fluid flow were realistic but very time consuming. The digital twin offered a validation of the simulations.

- Li et al. [21] considered the use of digital twins to analyse the state of bushings in a converter transformer. For this purpose, the geometric, material and electrical properties were analysed and fed to the digital twin as a data basis. The digital twin checked the characteristics inside and outside of the bushing.

- Manfren et al. [22] reported on carbon emissions in energy systems and on problem when the predicting energy consumption. They conclude that digital twins should therefore be used to actively monitor and analyse energy.

- Noskievic et al. [23] are developing continuous control of the oil flow via a valve with the help of digital twins. The digital twin is supplied with measurement data and valve parameters in real time and can therefore evaluate the condition.

- Pang et al. [24] stated that digital twins can be used to monitor product quality in manufacturing processes by carrying out data-based simulations. They also discussed the use of neural networks to determine the quality characteristics of industrial valves.

- Rituraj et al. [25] dealt with a model of a digital twin on balancing valves. Particular attention was paid to the accuracy of the predictions as well as the safe handling of the operator. The digital twin received parameters about the geometry of the component, the inertia and the friction properties and could thus validate the results.

- Sun et al. [26] discussed the fact that the production of industrial valves is significantly extended by the verification of precisely manufactured components. They reported on the integration of a digital twin to predict the performance of a servo valve based on measurement data. These were fed into the system via data correction methods.

- Tang et al. [27] dealt with leakages in precision control valves in aerospace applications. They assumed that the cause of leakages was errors in the surface topography of the valve. A digital twin was used to analyse the surface topography and improve the tightness. The material parameters and performance data were fed to the digital twin as a database.

It is evident that digital twins are already being used successfully in the analysis and simulation of industrial valves. A digital twin can be particularly useful for a flow analysis and the observation of failure phenomena. However, it is also clear that a digital twin must be designed so that it can be operated by any operator with the necessary basic knowledge. One important aspect when designing a digital twin is the data basis. If only material parameters and product data sheets are used as a data basis, the amount of information and benefit is low. Targeted and result-oriented sensor integration is essential in order to obtain meaningful results. Section 3 shows the development of a digital twin with sensor integration for predicting events on the valve. Particular attention is paid to the targeted and precise measurement of data acquisition. The various measured variables are recorded at different locations and prepared for further processing by the digital twin.

3. Development of the Digital Twin of the Valve

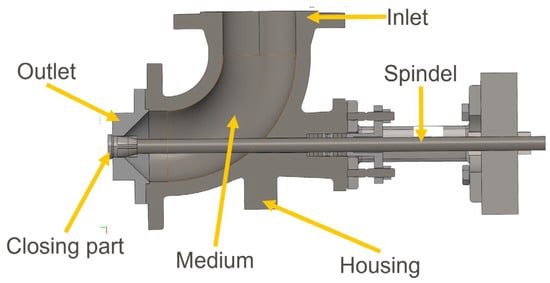

The valve for which a digital twin is to be created is a type 74BS valve from SchuF Armaturen und Apparatebau GmbH, which is also a project partner. The type 74BS valve used, which is shown in Figure 1, is an angle control valve with a disk head for flow control. The valve is particularly flow-optimized as it opens in the direction of the flow and therefore, the potential for bubble formation inside the valve is kept to a minimum [28]. The disk head can have different profiles depending on customer specifications, e.g., to achieve a fast flow directly after opening or a gradual increase in flow during opening. In its application, the 74BS is often used as the last fitting for a process circuit, which can compensate for load disturbances. Typical applications include level control and pressure relief in high pressure acid leaching (HPAL), hydrocracking and coal liquefaction. Depending on the requirements, additional design features can be provided for the lubrication and draining of the valve to reduce friction or detect leaks. However, the basic design of the type 74BS valves consists of an inlet, the actual valve with a closing part, the spindle and flange, and the outlet [28]. The inlet and outlet are the interface for the medium that will flow through the valve. They are optimally designed to enable installation on a wide variety of containers. The plate-shaped closing part is opened and closed by means of a spindle. A flange is also attached to the closing part for mounting. The damage to the valve manifests itself in the form of leaks. The valve vibrates due to flow phenomena. This can cause plastic deformations or material abrasions. In the long term, this can lead to leaks in the valve. To investigate this damage pattern for the 74BS, the three areas of models, sensor technology and IT infrastructure are considered in the context of a digital twin. A hardware prototype will also be built for this purpose.

Figure 1.

Model of valve 74BS.

To implement a digital twin of the industrial valve, sensors must be integrated and verified on the one hand, and on the other, preliminary tests must be carried out in order to collect a dataset for modelling. It would not be practical to carry out these steps on a valve under real operating conditions; firstly because of the interactions with the neighbouring systems and secondly because not all operating parameters can be tuned freely in this way. Instead, a test bench is built.

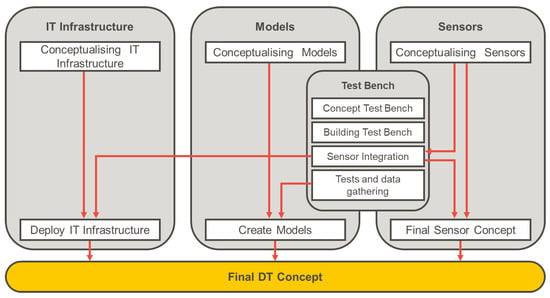

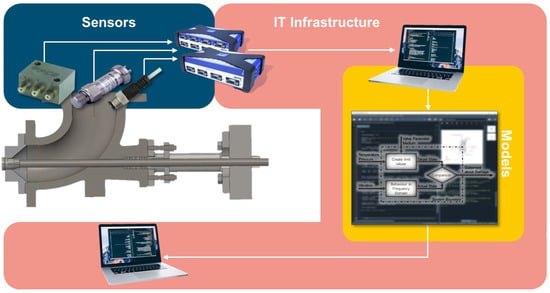

Figure 2 shows the process of developing a digital twin of the valve. The procedures described in Section 2.2 are used in the domains of the models, sensors and IT infrastructure.

Figure 2.

Overview of the procedure for developing a digital twin of the valve.

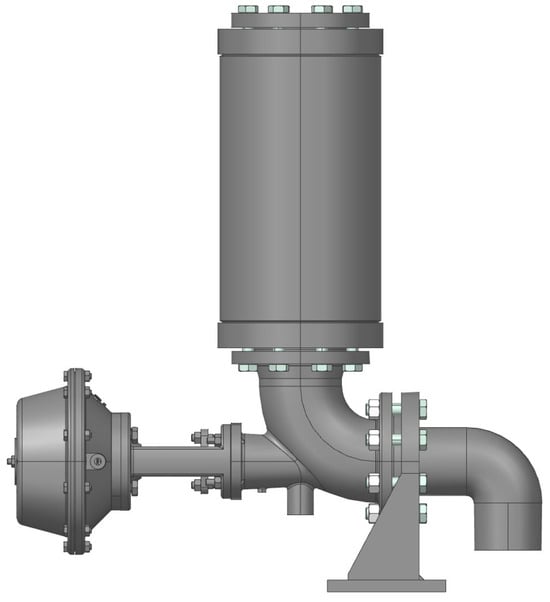

3.1. Test Bench of the Industry Valve

The test bench is divided into three areas: the inlet, the valve and the outlet. The inlet consists of an 80 L stainless steel tank. This cylindrical tank has a diameter of 264 mm and a height of 561 mm. A compressed air valve and a heating element are fitted at the top of the cylinder. The compressed air valve is used to connect an external compressed air reservoir. For the experiment, the tank can be pressurized to 5 bar. The connected heating element is used to heat the medium in the tank, usually water, to approx. 96 degrees Celsius. With an output of 10 kW, the water in the tank can be heated to the target temperature. The lower end of the water tank is connected to the valve via a flange.

The valve area consists of a pipe which is shaped at a 90 degree angle. The diameter of the pipe is 100 mm. At the upper end of the pipe, there is a flange to connect the pipe to the tank. The valve is installed at the lower end. This consists of a wedge-shaped closing part and a spindle. The spindle enables the valve to be opened and closed. Seals are distributed along the spindle to prevent leakage at the spindle. In addition, devices for holding sensors are provided in this area. In the event of a leak, these would detect it, and it would be possible to counteract it at an early stage.

The outlet is attached to a flange at the lower end of the valve. This consists of a pipe and a container for the medium flowing out. In Figure 3 and Figure 4, the inlet, outlet and valve are shown as a CAD model and in reality.

Figure 3.

CAD model of the test bench of the industry valve.

Figure 4.

Test bench of the industry valve.

3.2. Models for the Digital Twin

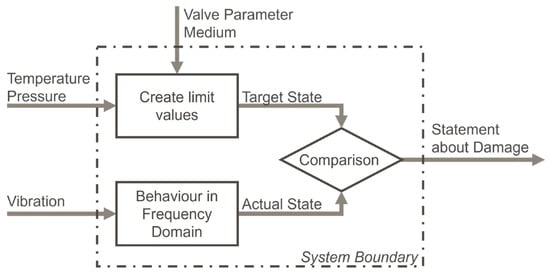

Models that depict the relevant behaviour of the physical twin are the basis of the digital twin. First, the requirements and the scope of the digital twin as well as the overall behaviour are defined. In the context of the present work, the main aim is to model damage mechanisms that lead to increasing vibrations of the closing part in the valve. Due to the tolerances, a valve already vibrates slightly when undamaged. These vibrations cause the closing part to repeatedly hit the valve wall, which leads to increasing notches as use progresses. These notches give the closure part more room to vibrate and the vibrations of the system increase. This eventually leads to the notches becoming so large that the valve starts to leak. In addition to the valve itself, the medium in the valve and its temperature and pressure must also be taken into account, as these have an influence on the vibration behaviour of the overall system.

In order to model the behaviour of the damage mechanisms, the behaviour of the valve is modelled in the frequency range. This model is intended to represent the oscillation that acts in the valve depending on the valve parameters, the temperature and pressure of the medium, and the progress of the damage. To create this model, vibration data from the valve are recorded (see Section 3.3) and transferred to the frequency domain using an FFT. Characteristics such as frequency shifts or amplitude changes are then analysed here and the threshold values for determining the valve status are defined. This model is then implemented in the form of Python scripts and transferred to an overall super model.

In the later application, the model is used to transfer the measured vibration of the sensors into the frequency range and to analyse the characteristic features there. These corresponds to the actual state of the valve. They are then compared with the threshold values, which represent the target state for an intact valve. Based on this comparison, a statement can then be made about the damage in the valve. Figure 5 shows the comparison of the target state of the valve and the actual state as a modelled description of the valve.

Figure 5.

Comparison of the target state of the valve and the actual state as a modelled description of the valve.

3.3. Sensors in the Industry Valve

The choice of sensors depends on various factors and conditions in the test environment. First of all, the measurement task and the variables to be measured must be recorded. To do this, it must be known which measured variables the digital twin requires in order to be able to carry out simulations. In addition, the measured variables that serve as a comparison or as auxiliary variables must be determined. For the industrial valve in this reference, the vibration at the valve, the temperature and the pressure are measured. The requirements that are concluded from this are important for the further selection process. At this point in the selection process, potential sensors can already be compared with each other in order to pre-filter the options. Based on this, the measuring location for the respective sensors is determined. When selecting the correct measuring location for the sensors, attention must be paid to, for example, the component dimensions or amplitude of the variable to be measured. For the industrial valve under consideration, there are a number of options for using the sensors, as shown in Figure 1. For the industrial valve, it is planned to measure the acceleration.

Based on the pre-filtering of the measured variable, measuring location and sensors, the measuring system can then be considered as a whole in order to determine suitable combinations. The utility value analyses are used as a filter to keep the number of possible combinations low. On this basis, the following selection of sensors can be determined as a result:

- One PCB-M356A71 triaxial vibration sensor is attached to the housing [29].

- One TS-200KLKD06 temperature sensor is attached to the housing [30], cf. Figure 6.

Figure 6. Installation position of the TS-200KLKD06 temperature sensor and the DMK331P pressure sensor at the test bench.

Figure 6. Installation position of the TS-200KLKD06 temperature sensor and the DMK331P pressure sensor at the test bench. - One DMK331P pressure sensor is attached to the housing [31], cf. Figure 6.

3.4. IT Infrastructure of the Digital Twin

The IT infrastructure forms the link between the sensors and the digital twin. The IT infrastructure is responsible for both data transmission and data storage. First of all, the requirements for the system must be determined. At the same time, the functions that the system has to fulfil must be defined. The damage mechanism in the valve runs over several weeks to months, in some cases even years. It is therefore sufficient if the live data are transmitted at intervals of several minutes in order to be analysed by the models. This reduces the significance of delays in data transmission. The signal quality should be maintained as far as possible, and the interference ratio should be kept to a minimum. The architecture options of the system must also be taken into account, as these can fulfil the requirements in different ways. Based on this, an architecture concept should be selected. It is advisable to choose local data storage for reasons of data security and for sensitive customer data. It should be possible to view the data from the last two weeks in detail. Local data collection and processing also offers the advantage that investment costs are kept low and there are no running costs.

A QuantumX is used to process the sensor data [32]. The data can be recorded and processed locally using the corresponding catmanEasy software [33]. A user interface with a corresponding monitor and a signal column are set up to visualize the results.

Once the hardware was successfully implemented, various test scenarios were carried out to ensure successful data transmission. The recorded data were validated for plausibility so that sensor errors could be ruled out.

4. Resulting Digital Twin of the Valve

The three sub-areas were developed iteratively and in mutual exchange. This enables an easy combination with and integration into the overall system of the digital twin. The sensors integrated in the valve record the vibration of the valve at various positions, as well as the pressure and temperature of the medium. The QuantumX is used together with the corresponding software to automatically carry out concrete measurements at regular intervals and save the data. The data are then automatically fed into the models, where the vibration is transferred to the frequency domain and the actual state of the valve is determined. A comparison with the target state then leads to recognition of the state of the valve. The status can be tracked by the user on a user interface. Figure 7 shows the data flow of the assembled digital twin.

Figure 7.

Main areas of the Digital Twin—Sensors, IT Infrastructure and Models.

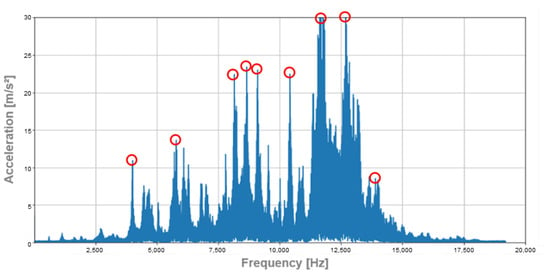

With the digital twin developed, it is possible to capture the oscillation of the physical twin. The oscillations are transferred to the frequency domain and analysed. Figure 8 shows an example of the FFT of a test on the test bench. For this test, the test bench was first prepared for the upcoming test. To do this, the system was filled with water, heated and pressurized to 5 bar. The valve was then opened. The peak values of the measurement can be recognized at 87.5 Hz, 137.5 Hz, 778 Hz, 826 Hz and 965.5 Hz. These are highlighted in Figure 8 by red circles. The first second after opening the valve was considered. The frequencies and amplitudes of these peaks can change as the damage progresses and can therefore be used to assess the damage. If a certain limit value is exceeded, an employee is informed, who can then initiate maintenance or a replacement of the valve before it fails.

Figure 8.

Result of the rest run of the Digital Twin—model description in the frequency domain.

5. Summary and Outlook

This article deals with the methodical development of digital twins for industrial valves. For this purpose, the authors’ preliminary work was used, which dealt with the possible development of digital twins for all types of products. Based on a literature review on the topic of digital twins for industrial valves, the authors’ approaches were then applied to a specific 74BS valve. Sensors were selected and integrated, data on the behaviour of the valve were collected in tests and transferred to a model, and an IT infrastructure was created to connect the sensors and models. These partial results were then integrated and transferred to a prototype test bench. The systematic approach of the preliminary work verified the results and answered research question one. Based on this, the limit values can be determined in the future using machine learning models. Valve parameters, measured temperature and pressure values as well as historical data can be used for this purpose.

The determined limit values serve as a measure from which the actual state must not deviate. A comparison of this actual state with the target state then leads to a statement about the damage to the valve; so that the digital twin can describe the progressive damage and initiate maintenance if a limit value is exceeded. This can be used to answer research question two.

The digital twin is currently set up as a proof of concept on the prototype test bench. Due to the exploratory nature of the project, a commercially available data acquisition system was used. This has a wide range of functions that were useful for the tests, but are no longer necessary for the application of the digital twin. As a result, the overall system of the digital twin is currently very expensive, which makes its use with low-cost standard valves less sensible. In the future, the necessary functionality can be transferred to an electronic measuring system designed and developed for this purpose in order to reduce the price.

Furthermore, the extent to which the results can be transferred to an industrial valve in real use and whether and to what extent adaptations to the developed digital twin concept are necessary, must be examined.

Author Contributions

Conceptualization, all; methodology, M.F., F.K. and R.B.; software, M.B.; validation, A.K. and F.K.; formal analysis, A.K., M.F., F.K. and R.B.; investigation, A.K.; resources, E.K.; data curation, A.K. and M.F.; writing—original draft preparation, A.K. and M.F.; writing—review and editing, all; visualization, A.K. and M.F.; supervision, E.K.; project administration, E.K.; funding acquisition, E.K. All authors have read and agreed to the published version of the manuscript.

Funding

This project (1398/22-103) was financed with funds from LOEWE—Landes-Offensive zur Entwicklung Wissenschaftlich-ökonomischer Exzellenz, Förderlinie 3; and the KMU-Verbundvorhaben (State Offensive for the Development of Scientific and Economic Excellence). This project was kindly carried out in cooperation with SchuF-Armaturen und Apparatenbau GmbH.

Data Availability Statement

The data in this work cannot be disclosed publicly.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Horlacher, H.-B.; Helbig, U. Rohrleitungen 1; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-642-39781-3. [Google Scholar]

- Stärker, M. Armaturen. In Rohrleitungen; Horlacher, H.-B., Helbig, U., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–50. ISBN 978-3-642-45027-3. [Google Scholar]

- Will, D.; Gebhardt, N. (Eds.) Hydraulik: Grundlagen, Komponenten, Schaltungen; 4., neu bearb. Aufl.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-79534-6. [Google Scholar]

- Ding, H.; Ji, J.C. Vibration control of fluid-conveying pipes: A state-of-the-art review. Appl. Math. Mech. 2023, 44, 1423–1456. [Google Scholar] [CrossRef]

- Grieves, M. Completing the Cycle: Using PLM Information in the Sales and Service Functions [slides]. SME Management Forum, SME Forum: South Orange, NJ, USA, 2002. [Google Scholar]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Draft Modeling, Simulation, Information Technology & Processing Roadmap; National Aeronautics and Space Administration: Washington, DC, USA, 2010. [Google Scholar]

- Stachowiak, H. Allgemeine Modelltheorie; Springer: Wien, Austria; New York, NY, USA, 1973; ISBN 3-211-811060. [Google Scholar]

- Adamenko, D.; Kunnen, S.; Pluhnau, R.; Loibl, A.; Nagarajah, A. Review and comparison of the methods of designing the Digital Twin. Procedia CIRP 2020, 91, 27–32. [Google Scholar] [CrossRef]

- Fett, M.; Wilking, F.; Goetz, S.; Kirchner, E.; Wartzack, S. A Literature Review on the Development and Creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems. Sensors 2023, 23, 9786. [Google Scholar] [CrossRef] [PubMed]

- Stark, R.; Anderl, R.; Thoben, K.-D.; Wartzack, S. WiGeP-Positionspapier: „Digitaler Zwilling“. Z. Wirtsch. Fabr. 2020, 115, 47–50. [Google Scholar] [CrossRef]

- Czwick, C.; Martin, G.; Anderl, R.; Kirchner, E. Cyber-Physische Zwillinge. Z. Wirtsch. Fabr. 2020, 115, 90–93. [Google Scholar] [CrossRef]

- Fett, M.; Kraft, M.; Wilking, F.; Goetz, S.; Wartzack, S.; Kirchner, E. Medium-Level Architectures for Digital Twins: Bridging Conceptual Reference Architectures to Practical Implementation in Cloud, Edge and Cloud–Edge Deployments. Electronics 2024, 13, 1373. [Google Scholar] [CrossRef]

- Fett, M.; Wilking, F.; Goetz, S.; Kirchner, E.; Wartzack, S. Sensor selection and integration for Cyber-Physical Systems in context of Digital Twins—A systematic review of requirements. In Proceedings of the 2023 18th Annual System of Systems Engineering Conference (SoSe), Lille, France, 14–16 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–7, ISBN 979-8-3503-2723-6. [Google Scholar]

- Schork, S.; Kirchner, E. Defining Requirements in Prototyping: The Holistic Prototype and Process Development. In Design in the Era of Digitalization, NordDesign 2018, Linköping, Sweden, 14–17 August 2018; The Design Society: Glasgow, UK, 2018; ISBN 9789176851852. [Google Scholar]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: Explanation and elaboration. BMJ 2009, 339, b2700. [Google Scholar] [CrossRef]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 explanation and elaboration: Updated guidance and exemplars for reporting systematic reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef] [PubMed]

- Berri, P.C.; Vedova, M.D.D.; Santaera, S. Digital twins for prognostics of electro-hydraulic actuators: Novel simplified fluid dynamic models for aerospace valves. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1226, 12106. [Google Scholar] [CrossRef]

- Bu, Q.; Aliyu, A.M.; Mishra, R. Local flow analysis and management for digital twins of control valves. In Proceedings of the 2021 International Conference on Maintenance and Intelligent Asset Management (ICMIAM), Ballarat, Australia, 12–15 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6, ISBN 978-1-6654-6671-4. [Google Scholar]

- Kapranova, A.B.; Lebedev, A.E.; Melzer, A.M.; Neklyudov, S.V.; Brykalov, A.S. The Applying of the Formalism of Cyber-Physical Systems in the Description of Hydrodynamic Cavitation in a Direct-Flow Valve. In Cyber-Physical Systems: Modelling and Intelligent Control; Kravets, A.G., Bolshakov, A.A., Shcherbakov, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 295–308. ISBN 978-3-030-66076-5. [Google Scholar]

- Lauer-Baré, Z.; Gaertig, E.; Krebs, J.; Arndt, C.; Sleziona, C.; Gensel, A. A Note on Leakage Jet Forces: Application in the Modelling of Digital Twins of Hydraulic Valves. Int. J. Fluid Power 2021, 22, 113–146. [Google Scholar] [CrossRef]

- Li, Z.; Liu, K.; Lin, M.; Xin, D.; Tang, H.; Wu, G. A zero-sample state evaluation model for valve-side bushing of UHV converter transformer oriented to digital twin under attribute analysis. IET Gener. Transm. Distrib. 2023, 17, 1123–1134. [Google Scholar] [CrossRef]

- Manfren, M.; James, P.A.B.; Aragon, V.; Tronchin, L. Lean and interpretable digital twins for building energy monitoring—A case study with smart thermostatic radiator valves and gas absorption heat pumps. Energy AI 2023, 14, 100304. [Google Scholar] [CrossRef]

- Noskievic, P.; Walica, D. Development and application of the digital twin of the hydraulic control valve. MM Sci. J. 2022, 2022, 5754–5758. [Google Scholar] [CrossRef]

- Pang, J.; Zhang, N.; Xiao, Q.; Qi, F.; Xue, X. A new intelligent and data-driven product quality control system of industrial valve manufacturing process in CPS. Comput. Commun. 2021, 175, 25–34. [Google Scholar] [CrossRef]

- Rituraj, R.; Scheidl, R. Towards digital twin development of counterbalance valves: Modelling and experimental investigation. Mech. Syst. Signal Process. 2023, 188, 110049. [Google Scholar] [CrossRef]

- Sun, X.; Liu, S.; Bao, J.; Li, J.; Liu, Z. A Performance Prediction Method for a High-Precision Servo Valve Supported by Digital Twin Assembly-Commissioning. Machines 2022, 10, 11. [Google Scholar] [CrossRef]

- Tang, W.; Xu, G.; Zhang, S.; Jin, S.; Wang, R. Digital Twin-Driven Mating Performance Analysis for Precision Spool Valve. Machines 2021, 9, 157. [Google Scholar] [CrossRef]

- Schuf GmbH. Typ 74BS X Flash Eckregelventil. Available online: https://schuf.de/de/typ-74bs-x-flash-eckregelventil/ (accessed on 2 August 2024).

- PCB Piezotronics. Triaxial Charge Output Accelerometer: Model 356A71. Available online: https://www.pcb.com/contentStore/docs/pcb_corporate/vibration/products/specsheets/356a71_d.pdf (accessed on 2 August 2024).

- ifm. TS-200KLKD06: Temperatur-Kabelsensor Mit Prozessanschluss. Available online: https://www.ifm.com/restservices/de/de/assets/c3VwcGxpZXJzL2lmbS9kb2N1bWVudHMvcHJvZHVjdC9UUzI0NTEtMDAvZGF0ZW5ibGFldHRlci9UUzI0NTEtMDBfREUtREUucGRm?v=84 (accessed on 2 August 2024).

- BD|Sensors—Pressure Measurement. DMK 331P: Industrial Pressure Transmitter. Available online: https://www.bdsensors.de/fileadmin/user_upload/Download/Datenblaetter_datasheets/DB_DMK331P_E.pdf (accessed on 2 August 2024).

- hbm. QuantumX: Universelles Messdatenerfassungssystem. Available online: https://www.hbm.com/de/2128/quantumx-kompaktes-universelles-messverstaerkersystem/?product_type_no=QuantumX (accessed on 2 August 2024).

- hbm. Datenerfassungssoftware Catman: Anschließen. Messen. Visualisieren. Auswerten. Available online: https://www.hbm.com/de/2290/catman-messtechnik-software/?product_type_no=Datenerfassungssoftware%20catman (accessed on 2 August 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).