1. Introduction

Materials with excellent quality and properties are always desired in any engineering application. Besides metals and alloys, polymer matrix composites are now used in many worldwide industries, which include aerospace, automotive, medical, and sporting industries [

1,

2,

3]. Among various polymer matrix composites, carbon-fibre-reinforced polymer (CFRP) is one of the most well-known composite materials used worldwide [

4,

5]. Due to the nature and properties of CFRP composites, conventional methods of machining have proven to be costly and inaccurate and to cause surface damages [

6] that could impact the performance of the final component when it is used in high-performance applications [

7,

8]. In aircraft and other structural applications where CFRP composites are used, the parts are often mechanically joined together through the use of bolts and rivets [

9,

10]. This requires making a large number of holes with accurate dimensions so that they pass quality control at the assembly stage [

2]. Therefore, having accuracy and quality is very important for the joint strength and fatigue life of the components [

6].

Conventional methods of machining have been proven to be very inefficient and to cause negative effects on the CFRP composite workpieces [

9,

11]. These negative effects involve cracking, fibre pull out, fibre breakage, thermal degradation, and delamination, which, in turn, affect the mechanical properties [

1]. Thus, non-conventional methods of machining, such as abrasive waterjet machining (AWJM), are found to be excellent alternatives for CFRP composites. This machining process uses small grains of an abrasive, such as garnet. During AWJM, the momentum of the waterjet is partially transferred into the abrasive particles, and a portion of this momentum change causes the disintegration of particles inside the mixing chamber (the inner part of the cutting head). This kinetic energy of the particles causes controlled erosion of the surface of the material and cuts through it [

12]. It causes no thermal effects, does not require the material to be conductive, and involves relatively low cutting force, which makes it more appealing than similar processes, such as laser cutting, plasma cutting, and/or electro-discharge machining (EDM) [

13]. Therefore, AWJM has the potential to cut slits and holes into CFRP composites accurately with minimal damage to provide a quality product that can be used in advanced scenarios.

Although AWJM seems to be the best option for cutting/machining CFRP composites, it does also have some drawbacks. The input parameters for the AWJM have been found to influence the final surface characteristics, the accuracy of the cut, and the damages. As there are a number of input parameters involved with abrasive waterjet machining and a large range of values that they can be programmed to be, this proves to be a complicated problem to analyse in depth. Therefore, experiments to investigate the particular effects of each input parameter and their interaction effects on the other input parameters are a very important area of study.

According to Dhanawade et al. [

7,

8], the traverse speed is the most significant factor, followed by the water pressure, to affect the surface roughness of the machined CFRP composite, whereas the standoff distance and abrasive feed rate have insignificant effects. The surface delamination was observed to be more frequent at the bottom of the test piece. The kerf taper ratio was found to decrease with an increase in the water pressure, while having a decrease in the traverse speed and the standoff distance increases both the kerf width and the taper [

14]. It was also reported that increasing the abrasive feed rate resulted in a decrease in the kerf taper. This concludes that a higher value of water pressure, a low value of traverse speed and standoff distance, and a high abrasive feed rate resulted in minimum surface roughness. Thongkaew et al. [

15] and Lee et al. [

16] reported that hole drilling generates greater damages to the CFRP composite due to the initial shockwave impact of the waterjet on the workpiece surface. They concluded that a higher water pressure and a lower traverse speed were key to ensuring minimal kerf taper. It was observed that even though every parameter does affect the outcome of the machining process, the water pressure, traverse rate, and abrasive feed rate seem to be the most important ones. A study into AWJM of graphite/glass/epoxy composite [

17] also showed that an increasing water pressure increases the kerf width, although increasing the traverse speed decreased the same kerf width. The interaction effects of the process parameters on the kerf width were insignificant; therefore, all could be independently altered to obtain the required kerf width. A study by El-Hofy et al. [

18] is an example of a full factorial experimental design, with the results being analysed using analysis of variance (ANOVA). This study looked at the impacts of the input parameters, such as the water pressure, traverse speed, and standoff distance, on the top and bottom kerf width, kerf taper, machinability, and surface characteristics of a ‘straight line cut’ into a sheet of multidirectional CFRP laminate [

19,

20]. It was concluded that the kerf width at the top and bottom increased with the water pressure and standoff distance and decreased with the traverse speed. For a better surface finish, high water pressure, low traverse speed, and low standoff distance were recommended; meanwhile, in order to decrease the kerf taper, it was found that high water pressure, low standoff distance, and high traverse speed were the most effective. As delamination is the most common and prevalent surface damage that occurs from AWJM, a preliminary study conducted by Mayuet et al. [

21] looked exclusively into the delamination damages caused directly by altering the input parameters. It highlighted the importance of the abrasive size, abrasive flow rate, and interaction time in terms of the material removal mechanism and its contribution towards defects formation. Although there are a number of reports available in the literature [

1,

15,

18,

21,

22] on AWJM of CFRP composites, almost all of these studies deal with ‘straight line cutting’ rather than drilling holes and their characteristics. However, it is imperatively needed to exploit the potentials of ‘hole fabrication’ in CFRP composites by AWJM.

Therefore, the motivation of the current work is to analyse the effects of the input parameters of AWJM on the quality of the cut and how this affects the surface finish of CFRP polymers. The objective was achieved by experimental investigation and by evaluating the effects of the independent input variables of traverse speed, water pressure, and abrasive flow rate within the waterjet on the output parameters, such as circularity, cylindricity, kerf taper ratio, and surface roughness, of a circular 12 mm hole drilled into a 6 mm thick sheet of a CFRP composite.

3. Results

After the experiments, the dimensions of the holes/cut-offs were measured as detailed in the experimental section. The outcomes of the experiments are tabulated in

Table 4 in terms of the circularity, cylindricity, surface roughness, and kerf data. The presented data are the average values of several measurements, as mentioned before.

3.1. Main Effects of the Variables

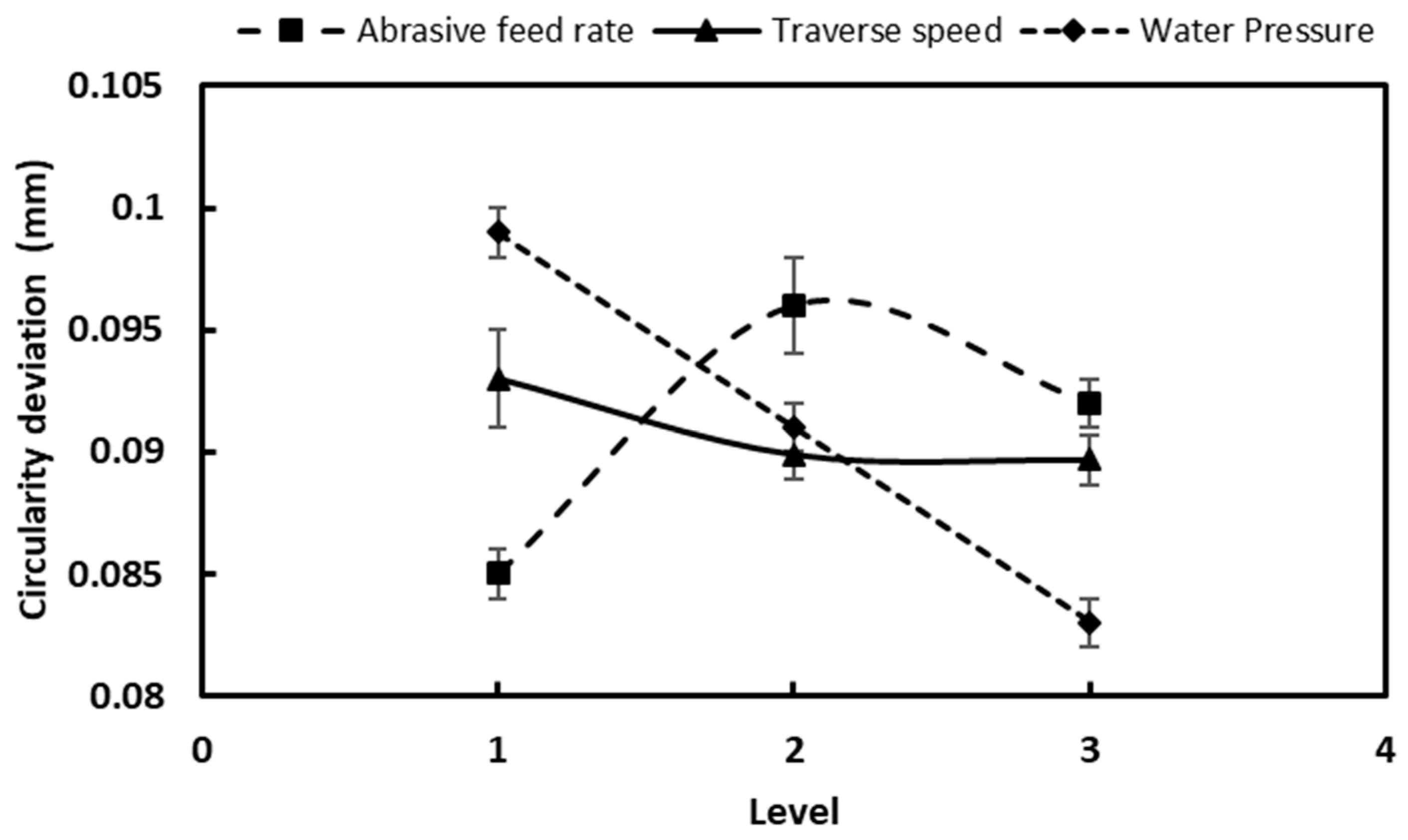

The main effect of each variable at each of its subsequent levels was analysed. This was performed by calculating the average results for each independent variable, i.e., the water pressure, abrasive mass flow rate, and traverse speed, at each of its levels (one, two, and three) and then graphing these averages against the dependent variable in question. This allowed for a visual method for analysing the main effect of each independent variable on the dependent variable. It is important to note that this method does not take into consideration the interaction effects of the independent variables on each other. The effect of the input parameters on the circularity deviation is shown in

Figure 1.

There was a clear linear relationship such that increasing the water pressure reduced the circularity deviation by approximately 9% at each level. This was due to the greater cutting power of the jet, which causes an increase in kinetic energy to overcome the ‘momentum loss’ caused by the cutting process. The abrasive flow rate seemed to have a parabolic trend, as the lowest level gave the best results, with level two (increase of about 12.66%) giving the worst and level three (increase of about 7.96% from level one) giving results in between. As the circularity reduced from level two to level three, this suggests that there are some secondary effects between the other independent variables that cause this difference and that need to be analysed further. As the traverse speed increased, the deviation was slightly decreased before becoming plateaued between level two and three; all were within 5%. This suggests that the traverse speed had the least main effect on the average circularity deviation compared with the other independent variables, and that the interactions of the other independent variables were either very similar or opposites, which then averaged out. Thus, it can be concluded that the water pressure had the greatest main effect on the circularity, followed by the abrasive flow rate, while the traverse speed did not affect this greatly.

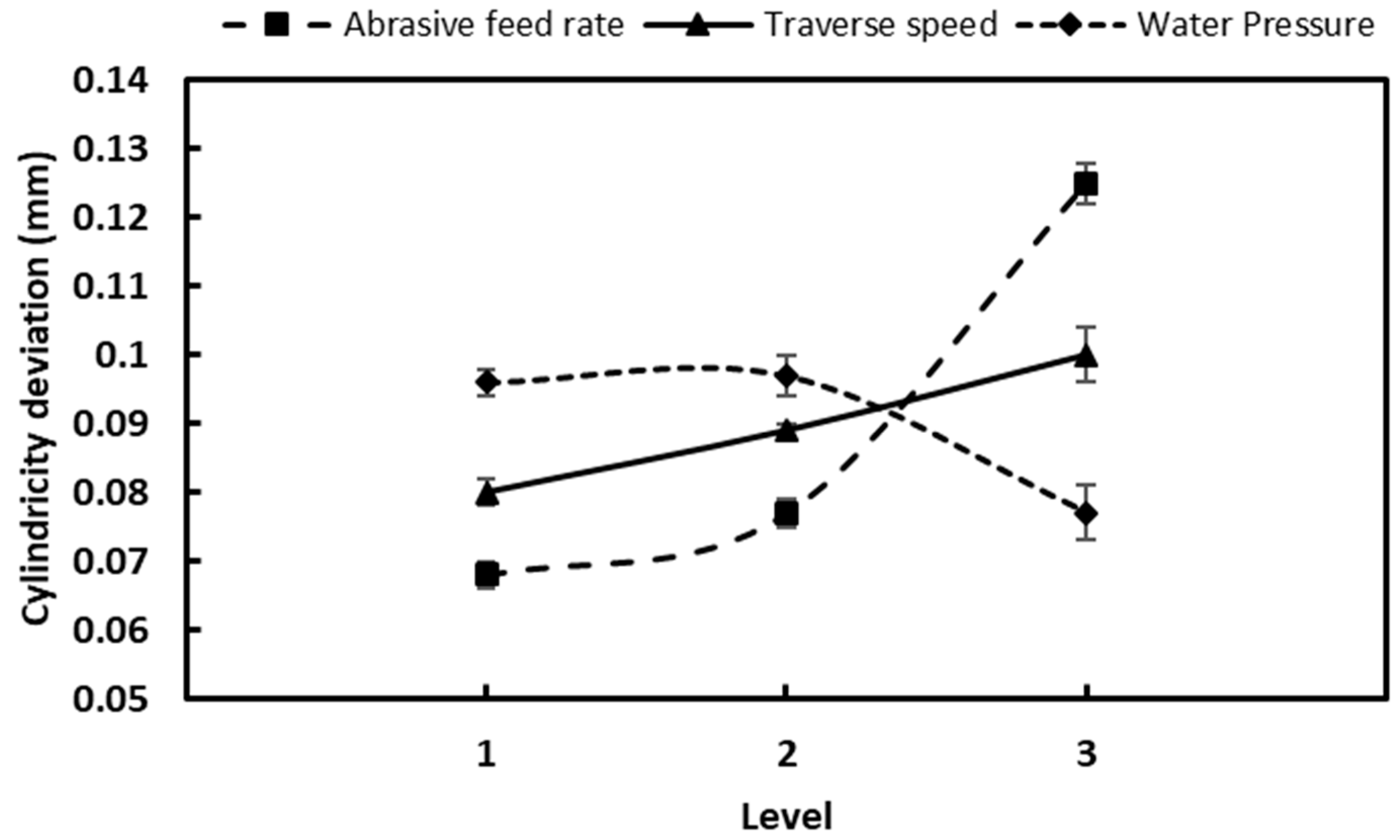

The effect of the input parameters on the cylindricity deviation is shown in

Figure 2. The only independent variable whose main effect decreased the cylindricity of the cuts was the increase in the water pressure at each level. It can be seen from

Figure 2 that levels one and two are quite similar, while the final level shows a great decrease in the cylindricity deviation (20.91%). This result was expected because as the water pressure increases, so does the cutting energy of the waterjet, which allows more of the material to be cut before all of the kinetic energy is absorbed.

Increasing the traverse speed had a negative linear relationship with the cylindricity of the cut, with an approximate increase in the cylindricity deviation of about 11.2% and 11.94% between level one and level two and between level two and level three, respectively. This was expected due to the fact that reducing the cutting time by speeding up the traverse speed does not allow the jet to complete a full equal cut through the CFRP composite sheet from top to bottom, leaving more material on the bottom half than on the top half. Lastly, as the abrasive flow rate was increased from level one to level two, there was a small increase in the cylindricity deviation (13.49%), but between level two and level three, an increase of about 63.62% was found to occur. This may have been due to the increasing number of abrasive particles in the jet stream, which would allow for greater erosion and result in an exaggeration of the effects of the other independent variables. This means that the interactions between the other independent variables would be in greater effect here and need to be investigated. The abrasive flow rate was shown to have the greatest main effect on the cylindricity of the cut, while the water pressure and the traverse speed had similar effects.

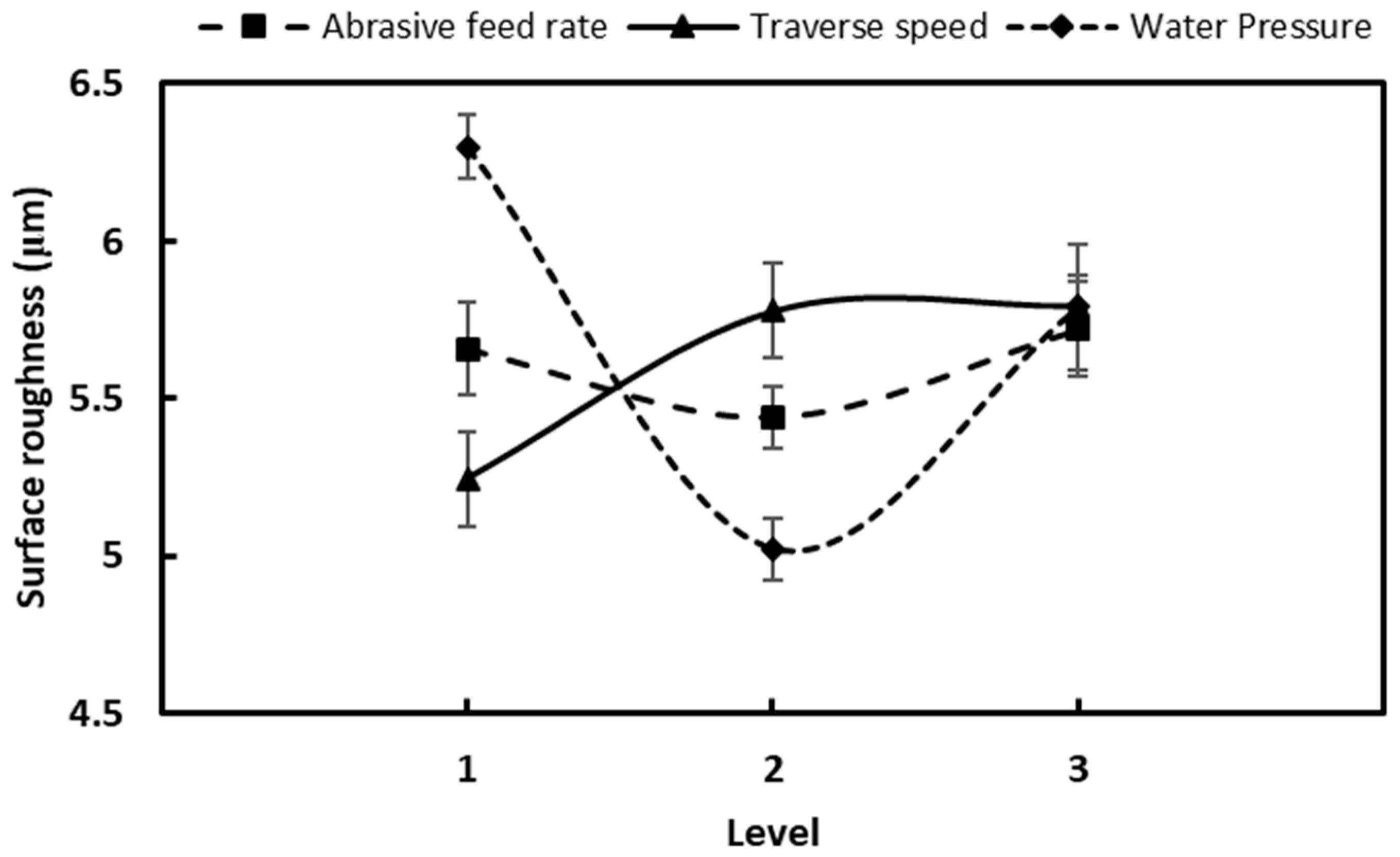

The effect of the input parameters on the surface roughness is shown in

Figure 3. The abrasive flow rate had the lowest effect of about 5.2% at each level. Increasing the traverse speed caused an increase in the surface roughness, with a 10.15% increase between levels one and two, followed by a plateau of the results between levels two and three. This would be due once again to the jet not being able to have enough time to conduct a clean cut through the material thickness. Finally, the water pressure showed a large parabolic effect, with levels one and three having an increased surface roughness of about 19.62% and 15.34% when compared with level two. This could be due to the fact that at lower levels of water pressure, the cutting forces produce fewer cleaner cuts, while at the high levels, they can produce not only cleaner cuts but also cause larger surface damages due to the greater cutting forces.

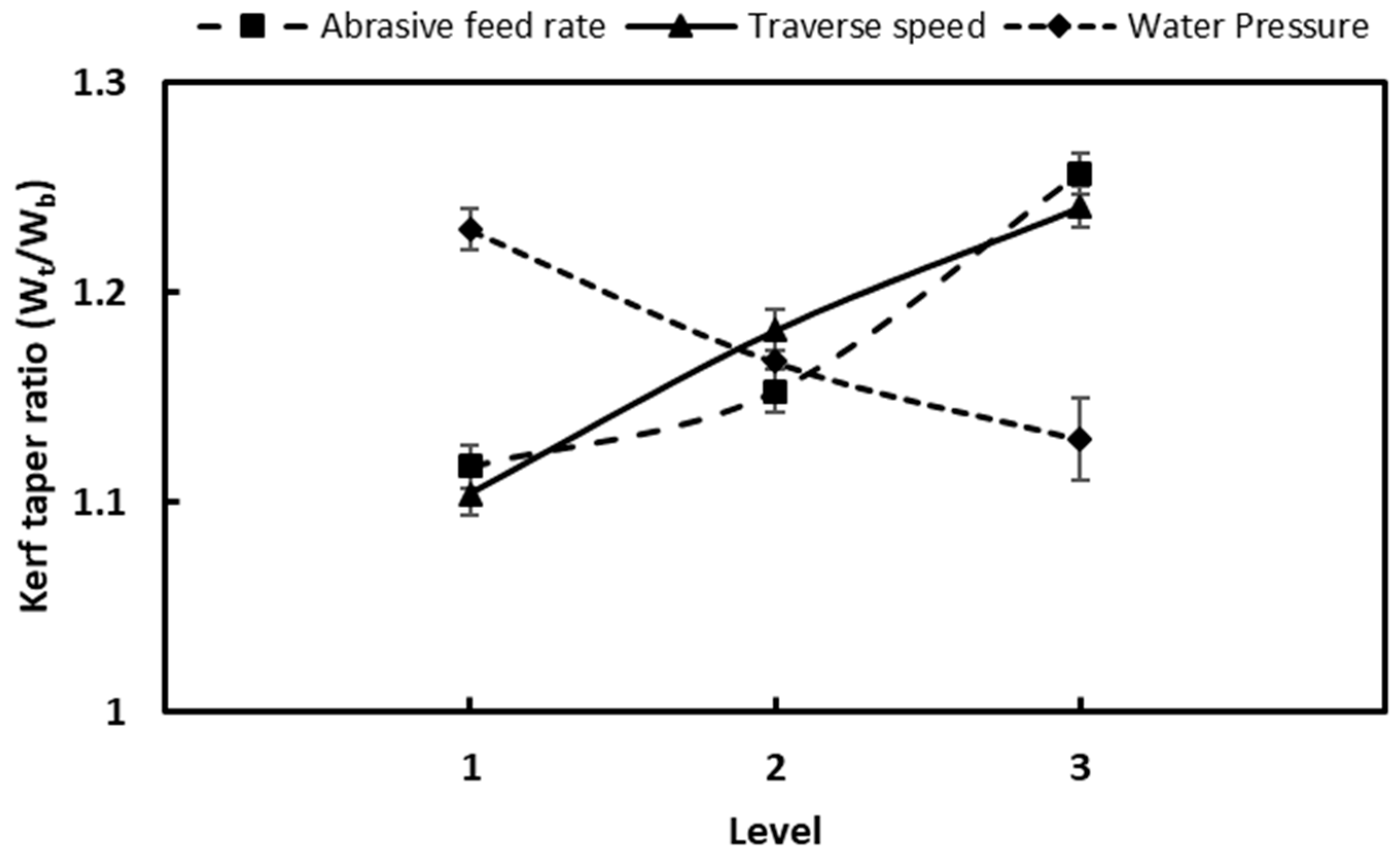

The effect of the input parameters on the kerf taper ratio is shown in

Figure 4. The main effects produced by each independent variable for the kerf taper ratio were most pronounced (

Figure 4) compared to the other graphs. Each variable showed a clear relationship at each level. Firstly, increasing the water pressure created a linear relationship of reducing the kerf taper ratio from level one to level three of about 5.16% followed by 3.15%, respectively. This would be due to the greater cutting forces provided to the jet stream from increasing the water pressure, which, in turn, would allow more of the CFRP composite to be cut before the stream loses the energy to continue cutting. Secondly, increasing the traverse speed created a linear relationship of increasing the kerf taper ratio by 7.09% and then by 4.97% between levels one and three. This increase makes sense to occur, as increasing the traverse speed reduces the amount of time the jet has to cut through the material. This decrease in cut time does not allow the waterjet to complete the “perfect cut” and thus increases the kerf taper ratio. Finally, the abrasive flow rate also had a linear relationship, as it increased the kerf taper ratio by about 3.20% and 9.09% between levels one, two, and three, respectively. This increase in kerf taper ratio could be a result of the increased cutting particles and the interaction between other independent variables. This will be discussed in greater detail in the following sections.

3.2. Surface Damage

During the AWJM process, some damages of the surface [

1,

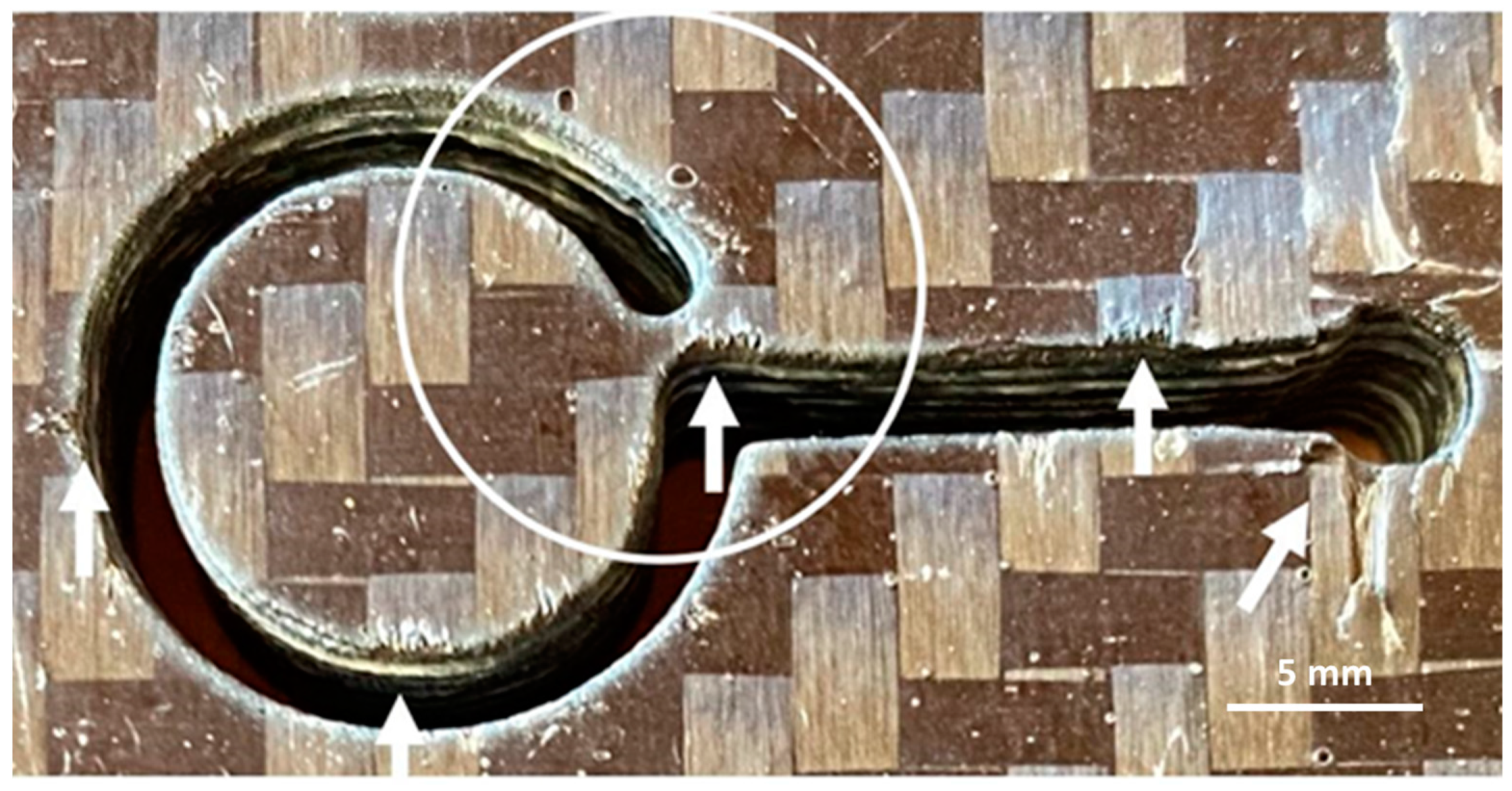

14] took place not only along the pre-defined path but also in the vicinity.

Figure 5 displays such an example of delamination, fibre breakage, and fibre pull out along the pre-defined path, as well as cavitation, as marked by arrows. The cavitation damage was observed all over the test plate but increased in size and number around the cut areas. This could be due to the short amount of time the jet was left on in the final stationary position before it was turned off.

To figure out the overall best-performing test conditions, the output values, such as the circularity, cylindricity, surface roughness, and kerf taper ratio, were summed together. Based on the presented graphs (

Figure 1,

Figure 2,

Figure 3,

Figure 4 and

Figure 5), it can be concluded that the optimum input parameters for the presently investigated AWJM process were 200 g/min of abrasive feed rate, 345 MPa of water pressure, and 75 mm/s of traverse speed. It is important to note that surface roughness measurements were measured in micrometres; therefore, when all the results were summed together under same SI units of millimetres, the surface roughness had no effect on the ranking of the total results due to being a factor of 10

3. Thus, excluding the effect of the surface roughness, the optimum input parameters for the presently investigated AWJM process were 200 g/min of abrasive feed rate, 345 MPa of water pressure, and 60 mm/s of traverse speed. The worst combination, excluding surface roughness, was 600 g/min of abrasive feed rate, 275 MPa of water pressure, and 180 mm/s of traverse speed; including surface roughness, it was 200 g/min of abrasive feed rate, 413 MPa of water pressure, and 180 mm/s of traverse speed. These results indicate that high traverse speed decreases the surface finish, as expected, and the water pressure and abrasive feed have an inversely negative relationship. The difference between the best and worst values of the circularity deviation was 0.087 mm at 64.9%; for the cylindricity deviation, it was 0.161 mm at 84.74%; for the surface roughness, it was 4.6433 μm at 59.58%; and, lastly, the difference in the kerf taper ratio was 0.4651 mm at 31.47%. Therefore, the cylindricity ratio was the most affected variable in this experiment.

4. Discussion

This section will be analysing the results found and presented in the previous section (

Section 3). It will discuss the main and interaction effects of the independent input variables, what caused these effects based on the primary mechanisms, as well as if they were expected or not based on the information available in the literature. It will also analyse the dependent variables and their characteristics, as well as surface damages caused by the waterjet.

4.1. Effect of Water Pressure on AWJM Process

The effects of the water pressure on the independent variables were as follows. As the waterjet increased in pressure, it reduced the circularity of the cut hole as well as the cylindricity deviation and the kerf taper ratio due to all of these dependent variables measuring a similar geometric shape. Increasing the water pressure from 275 to 345 MPa was shown to improve the surface roughness by decreasing the roughness value of the inside surface of the hole. Although increasing this pressure to 413 MPa showed an increase in the roughness value, it was still less than the 275 MPa value, indicating that there may be an optimum value for pressure or that the other independent variables have interaction effects which then affect the roughness. This observation was in line with previous reports [

28].

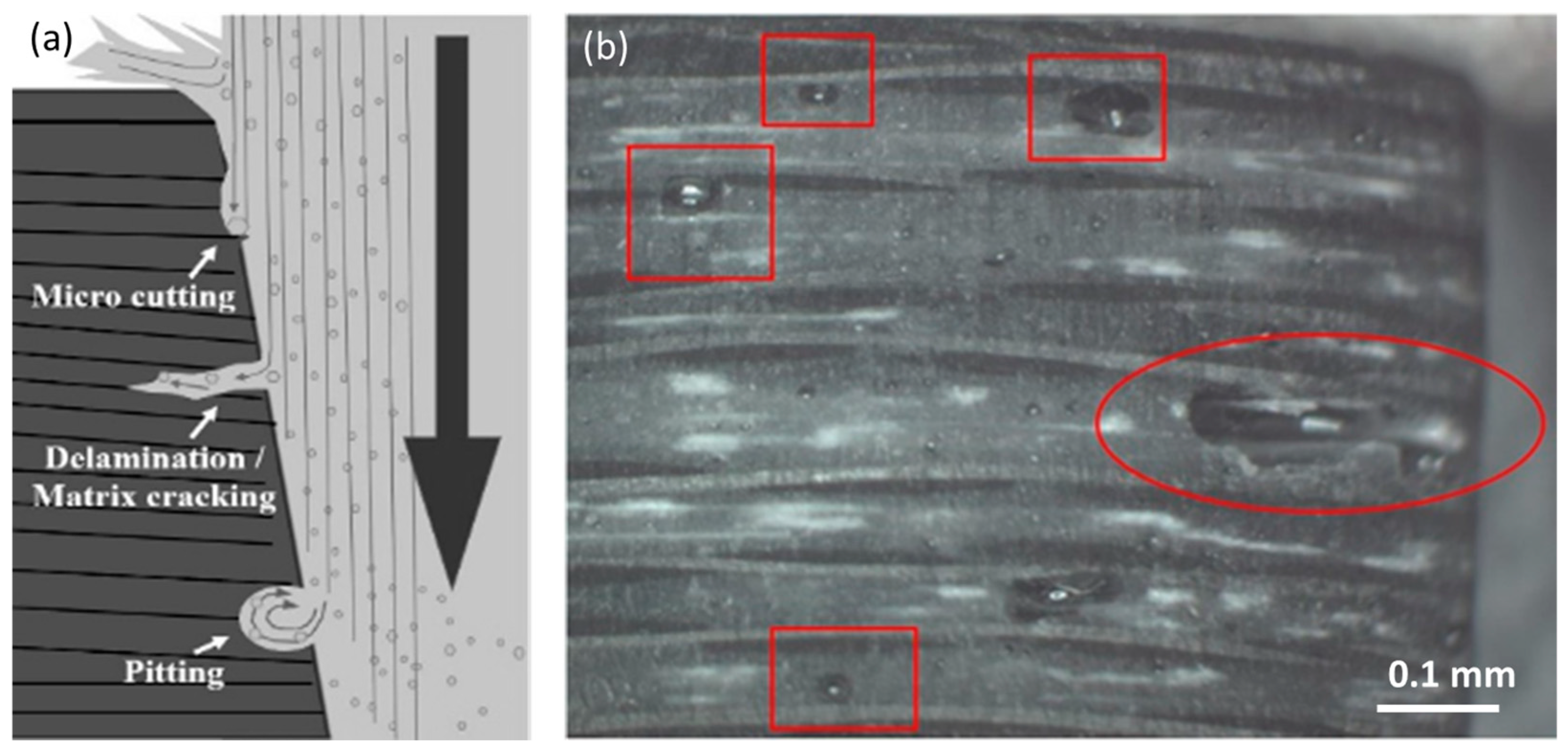

The material removal efficiency depends on the sharpness of the particles, the particle mass, the speed of travel, and the angle of impacts. Therefore, decreasing the pressure reduces the speed of the particle, and, therefore, this could be the cause. The high level of water pressure was also shown to cause increased roughness, even though it would increase the cutting efficiency of the abrasive particles, thereby causing a cleaner cut, which was evident in the workpieces. This can be explained by having an over-pressure scenario where the increased pressure increases the size of the damages from the waterjet that occur and/or causes the damages due to the materials’ defects being exaggerated. Delamination and matrix cracking were likely to occur when the water pressure was greatly increased, and the fibres were left un-encased and damaged as the waterjet and the abrasive particles broke apart and eroded away the matrix (resin) material. This can also leave the abrasive particles embedded into the CFRP composite, thus causing discontinuities, which reduces the ultimate tensile strength and the endurance limit [

6]. This phenomenon is graphically represented in

Figure 6a. Pitting was another type of damage that was seen to occur when a smooth cavity was produced, as the waterjet is swirled around a spherical indentation of the workpiece, as shown in

Figure 6b. The pitting increases the roughness as it causes large differences in the average surface level; during the assembling of components, this can also reduce the total available surface area for the mating of the CFRP surfaces. As the holes that were cut were theoretically meant to be used in mechanical fixing with CFRP composite/other materials, this reduction in surface area would lead to a decrease in the material’s mechanical properties and performance. If it was to be mated to a rivet or bolt for high-force applications, the stress of the forces to the rivet/bolt would have less area to be spread across, thus causing stress raisers.

In summary, the water pressure of the jet had a great importance for the cutting mechanism. If the jet pressure was too low, the kinetic energy within the jet would also be low and cause a decrease in the cutting force of the abrasive particles. This reduced cutting force can lower the cutting efficiency while also stopping the particle from being able to perform its correct cutting mechanism, and, therefore, produce a poor cut quality [

15]. However, increasing the pressure can exaggerate the damages occurring from the abnormalities and irregularities within the manufactured CFRP composite when the jet energy is increased during the machining process.

4.2. Effect of Traverse Speed on AWJM Process

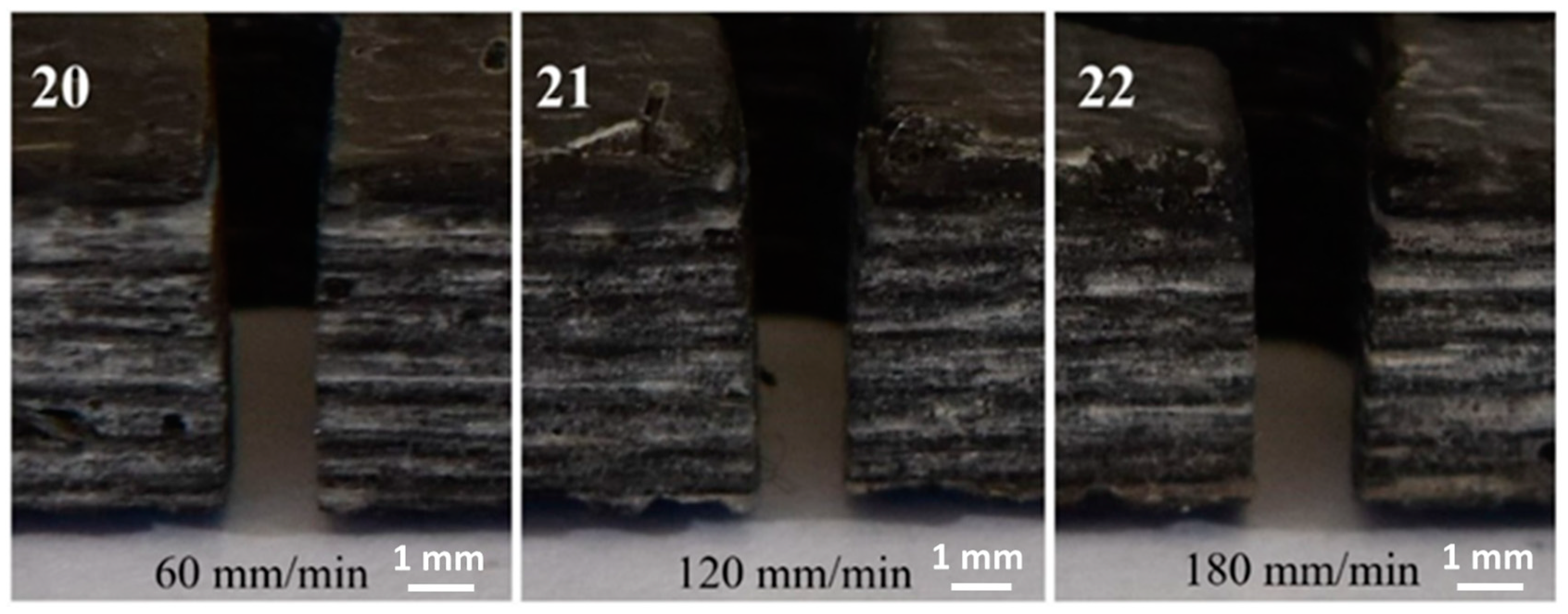

As the traverse speed was increased from level one to level three, it was clear that the surface finish and quality of the cut decreased. Increasing the traverse speed caused the cylindricity deviation of the cut to increase, as well as the kerf taper ratio and the roughness. However, the circularity deviation decreased slightly on average as the traverse speed increased. The increase in the kerf taper ratio and the cylindricity deviation was expected, as both of them were related to each other. They were both measured from the formation of the top and bottom kerf width. Increasing the traverse speed had a major impact on the material removal rate, as schematically shown in

Figure 7. Taking one minute to cut L

1 at 60 mm/min would only take 20 s at 180 mm/min. Thus, a 300% increase in the material removal rate altered the effective cutting ability of the abrasive grains inside the waterjet, which led to an overall decrease in the total material removed (per mm) as the jet was not able to fully develop and continue its cutting ability near the bottom of the CFRP composite sheet.

This was verified by investigating the cut profiles from side views, as shown in

Figure 8. There was a clear increase of the top kerf width, as can be seen, as the traverse speed increased. The cut also lost its sharp definition of the edges at the top, which resulted in a larger curve and increased the initial damage region when compared with the 60 mm/min cut.

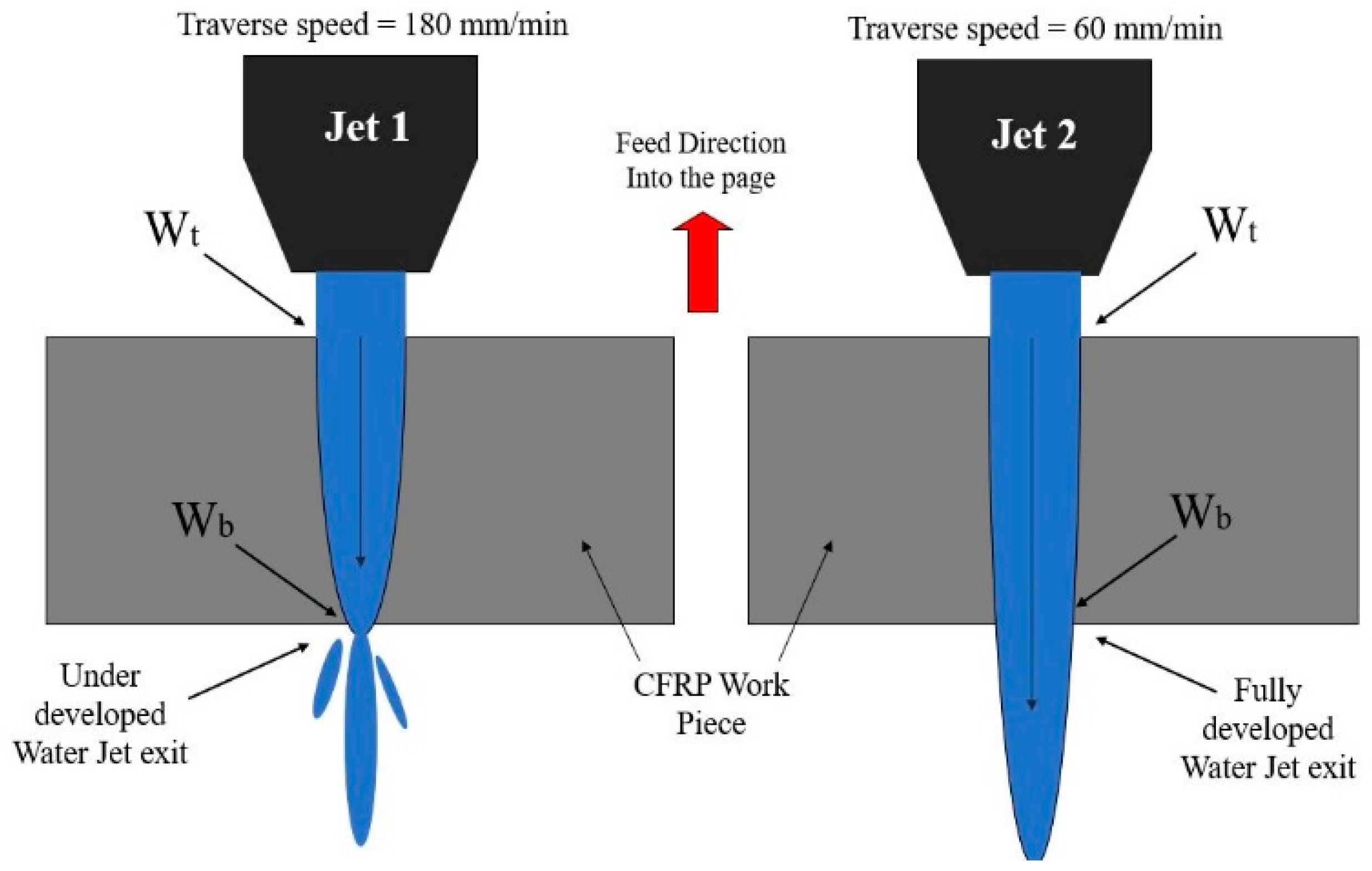

Increasing the traverse speed did not allow the waterjet to fully develop at the exit of the workpiece, resulting in large differences in the top and bottom kerf widths (

Figure 8). Reducing the traverse speed allows the jet to produce a fully developed waterjet at the exit; thus, this allows the difference between the top and bottom kerf lengths to be minimised. Just purely reducing the traverse speed alone will not always produce a fully developed jet exit, nor will it reduce the difference in the top and bottom kerf widths. The water pressure must also be at a sufficient level such that its kinetic energy is not lost before exiting the workpiece, as shown schematically in

Figure 9. It is important to note that

Figure 9 is a simplified schematic to have a general understanding of this. In reality, it is much more complex due to the interaction of the material and the waterjet together with the action of the abrasives, which is hard to incorporate in a single schematic. The effective part of the waterjet in contact with material changes, but several factors are involved, and the kerf taper is the result of a combination of them. The abrasive waterjet does not shorten with the acceleration of the traverse speed, as the time of its action on the material mainly changes. Therefore, the slower peripheral parts cannot perform the same work on the material as during slower movement.

Large traverse speeds produce a greater angle on the cutting front of the jet, which increases the surface roughness in the cutting region and causes an increase in the kerf angle as well the initial damage region (IDR). This increased damage in the IDR encouraged the formation of cavitation on the surface of the CFRP, as shown in

Figure 6. Lowering the traverse speed will reduce the inclination angle of the cutting front, as illustrated in

Figure 10. This reduces the kerf taper ratio and improves the quality of the cut while also removing more of the material. However, this can make the process time-consuming and not cost-effective in an industrial application.

4.3. Effect of AWJM Process on Circularity

The results obtained for circularity show a difference of 3.69% between levels one and two and a difference of less than 0.25% between levels one and three. This small difference was expected, as the traverse speed would have no effect on the circularity of the cut. The schematic of the circularity and the circularity deviation are illustrated in

Figure 11. This figure also illustrates an exaggerated view if the circularity was measured at the top, middle, and bottom of the cut. If it was completed at multiple depths in the hole, there may have been different circularity deviation values, which would have increased the accuracy of the final result over the range of the depth of the cut. Therefore, it can be said that the traverse speed should not have any influence on this measurement, because the main effect of increasing the traverse speed was an increase in the kerf taper angle, which was not picked up in the circularity measurement.

Therefore, it can be concluded that the traverse speed was responsible for the time that the waterjet was allowed to perform its cutting/eroding mechanism. Increasing this speed decreased the time the waterjet was able to cut through the material, thus leaving undeveloped cuts in the material, which increased the difference in the kerf widths from the top and bottom. In conclusion, the traverse speed should therefore be minimised for the best results.

Increasing the abrasive feed rate greatly increased the circularity deviation as well as the kerf taper angle, especially when the water pressure remained low and/or the traverse speed was high. The effect of the abrasive feed rate on the circularity deviation was not clear, as the high and low levels were both in the top five best results. Thus, it can be said that the effect of the abrasive feed rate on the circularity deviation was dependent on the water pressure and the traverse speed input levels. The results of the roughness changing due to the abrasive feed rate were very difficult to interpret, as stated earlier. Thus, no clear trend was identified.

The number of abrasive particles in the waterjet increases the cutting power of the jet. Due to this fact, it greatly affects the top kerf width, and this can be explained because the first 50% of the material thickness would have received the majority of the kinetic energy supplied by the waterjet; thus, most of the cutting ability would have occurred [

29]. Beyond that thickness, the number of abrasive particles would have reduced kinetic energy, as their collisions within the jet would have interfered with their kinetic energy and greatly reduced their cutting ability. This effect can be slightly mitigated if the water pressure was to be increased, giving more energy to the abrasive particles to cut efficiently past the 50% mark. Increasing the abrasive feed rate has been said to reduce the roughness, as there is a more even flow of abrasive particles to erode and cut away the workpiece [

29]. However, previous studies [

3] have reported that the particle size must also decrease to help produce a better surface roughness.

4.4. Effect of AWJM Process on Surface Finish

The surface damages that occurred from the AWJM were better than expected, and this could be due to the fact that the input parameters were in a smaller range than in previous studies [

30], thus not allowing larger damages to occur. After careful examination of the area around each test, there seemed to be multiple types of surface damages with varying degrees of severity. Delamination, fibre breakage, and fibre pull out were observed at the top kerf surfaces where the initial cutting of the waterjet began, whereas other damages, such as cavitation and matrix cracking, occurred on the internal areas of the cut holes, as reported in

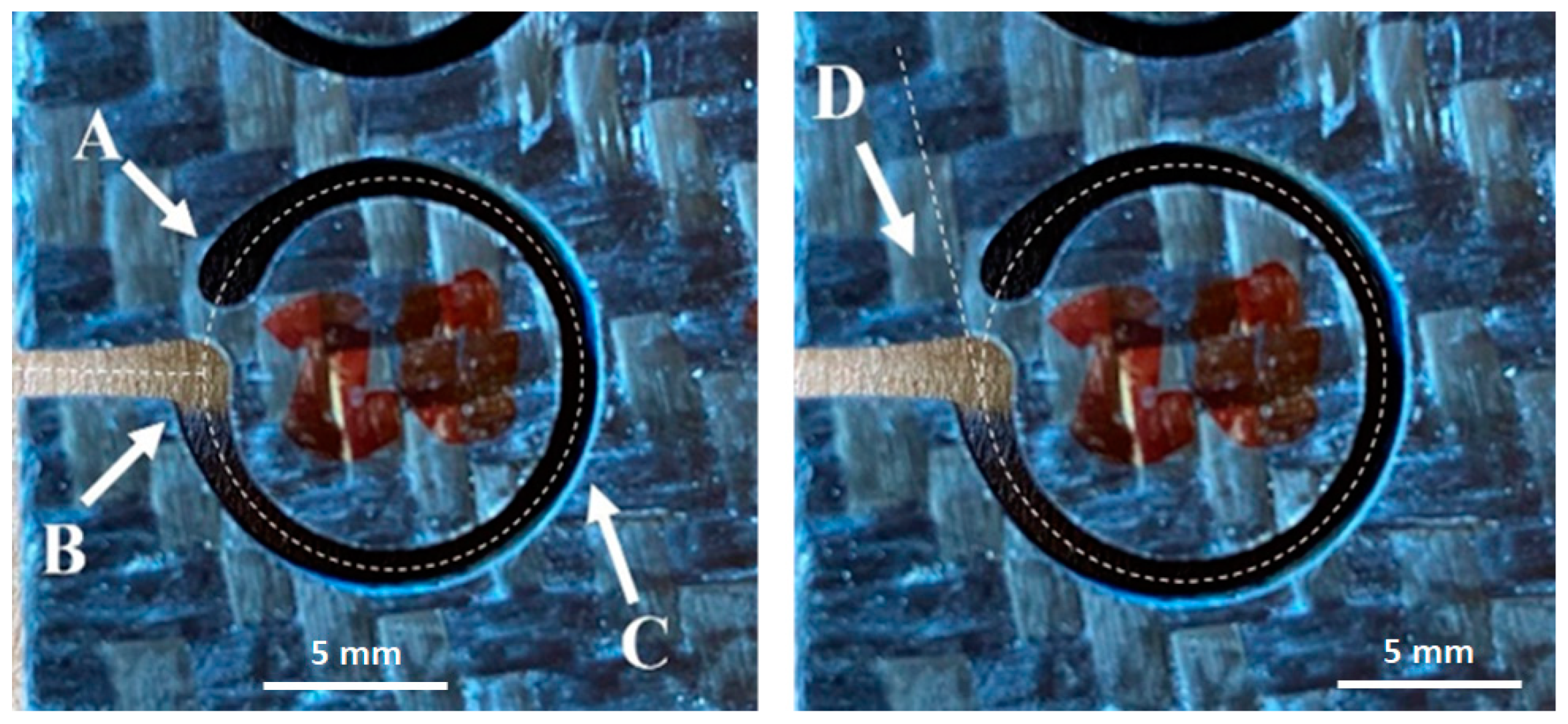

Section 3. The pathing of the jet combined with the machines’ programming also influenced the overall shape of the cut. The machines’ code was programmed to automatically slow the jets’ trajectory as they reached a sharp corner. This reduced the traverse speed to a lower value than the test parameter and allowed the jet to cut more material, which caused a widened cut, as shown in

Figure 12 (point

B). As the jet increased back to operating speed, the kerf width returned back to its average width for the rest of the cut, as shown by point

C in

Figure 12. Point

A (in

Figure 12) shows a similar widening of the cut, as this was where the jet slowed down to a halt and then powered down in this stationary position. This occurred because the jet had an increased cutting time and, thus, was able to remove more material until the jet was shut off. Furthermore, if the jet path was to continue, the irregular shape at point

A would not occur, so this point was avoided in all the measurements. However, the irregular shape at point

B would still occur, and, therefore, to stop this from occurring, an alteration to the jet cut path could be made so that it followed a tangent line to the hole, as shown by point

D, which would allow the speed to remain constant for the entire cut.

The delamination damage [

12,

31,

32] was observed to occur in all of the test cuts to an extent. The delamination factor was not investigated or measured in this study; thus, a concise remark about the effect of the input parameters on delamination cannot be stated with evidence to back it up. However, the low and high levels of water pressure caused more noticeable damage (visual inspection), as did increasing the traverse speed, while increasing the abrasive feed rate was shown to decrease the delamination damage at the top kerf surfaces.

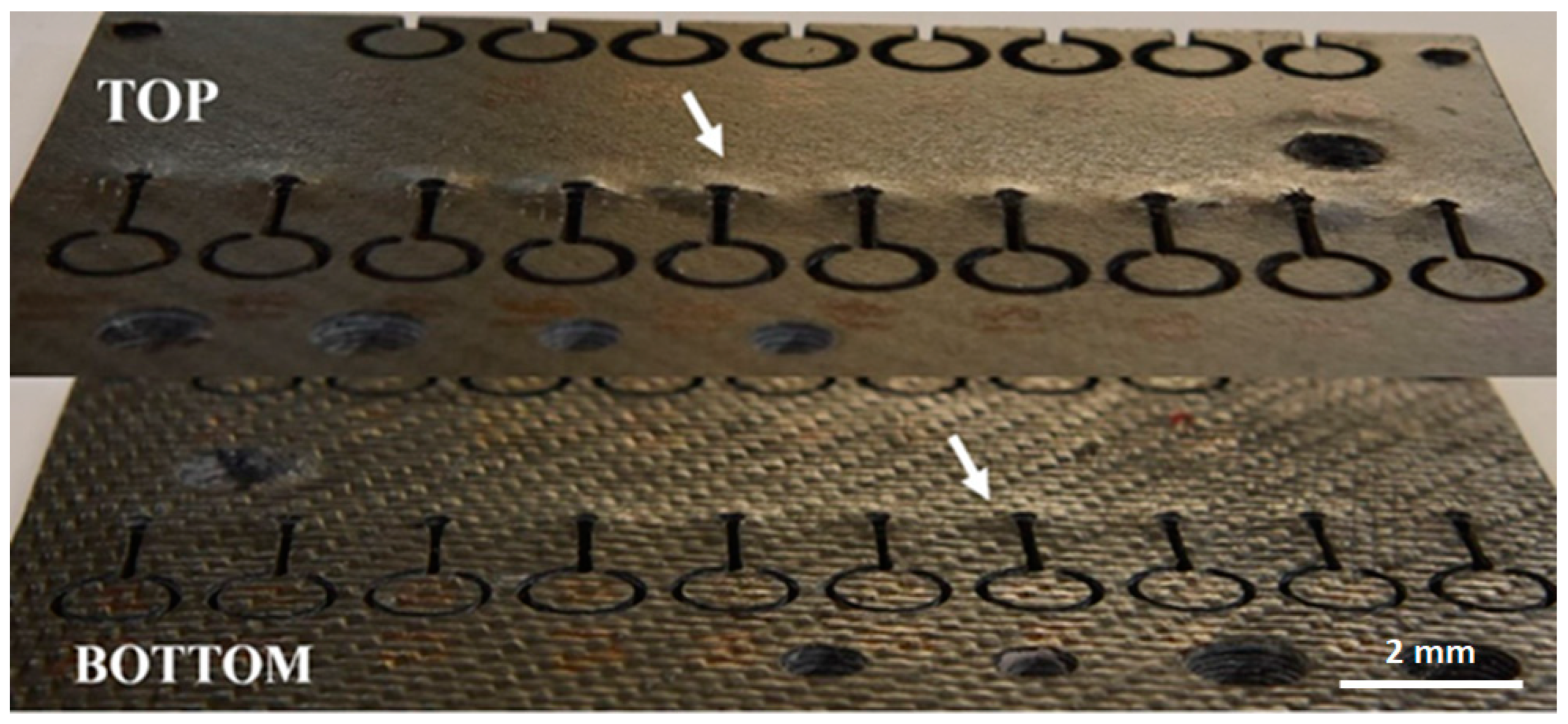

A drilling action from the AWJM was used to start the cuts for the centrally located tests instead of cutting the CFRP composite sheet into smaller pieces, which would have caused increased difficulty in securing them for further cutting. The surface finish that occurred from this drilling action caused increased surface damages when compared to using a fully developed jet and then moving it into the cutting position. This could be due to the fact that as the jet was increasing in pressure, the energy provided to the jet of water was not able to completely penetrate through the entire surface. Therefore, due to the water being restricted and having nowhere to exit from at the bottom of the test sheet, it would have been pushed into the layers of the CFRP composite along with the abrasive particles, thus breaking through the bonding of the matrix and fibre layers and causing delamination before the residual water was then pushed back out the top, which resulted in the raised humps and cracking, as pointed out in

Figure 13.

As shown in the actual workpiece in

Figure 14, the top surface endured the largest damage compared to the bottom surface. The top surface showed large areas of delamination, fibre pull out, and breakage, together with a raised surface and cracking, whereas the bottom surface only had a raised surface. This minimal damage (raised or deformed surface) could be due to the pressure build-up of the waterjet before it cut through the piece, and, as the pressure ramped up to maximum capacity, it may have provided enough cutting force to remove the initially damaged areas, thus degrading the surface finish quality.

Other surface damage occurred in the form of cavitation and pitting (

Figure 6), as reported earlier. The surface cavitation could be assumed to have occurred from small deviations in the jet’s trajectory occurring from the waterjets’ behaviour during operation. As the pressure of the jet was so immense, even a slight off spray would be able to slice through most materials, thus causing the cavitation. Another hypothesis was that it could also be caused by the dispersion of the water as it initially hit the top surface of the CFRP composite sheet and traveled perpendicularly in all directions to the original jet direction. The extremely high pressure, energy, and the turbulent behaviour of the water would cause currents to impact the top of the CFRP composite sheet, thus removing and eroding the matrix material and leaving a cavity. This mechanism is schematically presented in

Figure 15. This could be reduced by having the waterjet submerged below the water tank level, thus reducing the splashing effect from the waterjet, and, in turn, reducing the cavitation damage, as suggested by Ibrahim et al. [

33] and others [

29]. This violent erosion behaviour from the waterjet would also be responsible for the pitting within the internally cut surface. Low- and high-water pressure levels combined with high traverse speed seem to decrease the surface quality by increasing the damages, while increasing the abrasive feed rate reduces the delamination and fibre pull out, which could be attributed to the increased cutting ability of the waterjet. This cavitation damage is somewhat similar to what also occurs in the metallic/ceramic system in the presence of abrasives [

34,

35].

Based on the above experimental results and analysis, it could be summarized that the best overall results to reduce the circularity and cylindricity deviation and the kerf taper ratio were seen at a low level of the abrasive feed rate (200 g/min), a low level of the traverse speed (60 mm/min), and at all three levels of the water pressure (275, 345, and 413 MPa). Furthermore, this indicates that lowering the traverse speed improves the quality of the cut, which was expected. However, this was not a productive approach, as this increased the overall machining time. The results do show that if the traverse speed needs to be increased, the water pressure must also be increased to improve the quality of the cut, indicating a linear positive relationship between these two independent variables. If the traverse speed was to increase, the abrasive feed rate would need to be decreased to maintain the best outcome, therefore showing an inverse relationship. If the abrasive feed rate was to increase, the water pressure would also have to increase, thus providing a linear positive relationship. However, the best performance occurred when the abrasive feed rate was kept constant and the water pressure increased. The values of the water pressure proved to be very interesting, as these values had interactions with both the abrasive feed rate and the traverse speed. Increasing the water pressure while keeping the traverse speed and the abrasive feed rate at the same level irrespective of their level results offered an overall better surface finish. If the abrasive feed rate needs to be increased, the water pressure must also be increased, and the traverse speed should be reduced to provide the best results. Lastly, the traverse speed should not be increased, but if the traverse speed needs to be increased, the water pressure should also be increased while decreasing or keeping the abrasive feed rate constant.

5. Conclusions

In the present research, a three-factorial experiment was designed to investigate the effects of the water pressure, traverse speed, and abrasive flow rate on the circularity, cylindricity, kerf taper ratio, and surface roughness of a 12 mm hole cut into a 6 mm thick CFRP composite sheet. The results were then examined and analysed using statistical, mathematical, and visual representations to find out the main effects and the interaction effects of the independent input variables on the output parameters, as well as their effects on the damage mechanisms.

The results of this study found that the traverse speed had a main effect on the cylindricity of the hole, the kerf taper ratio, and the surface roughness, for which reducing this input parameter greatly improved the results. Secondly, it was found that the abrasive feed rate had a main effect on the cylindricity of the hole and the kerf taper ratio, for which reducing this input parameter also produced the best result. Lastly, it was found that the water pressure of the jet had main effects on the circularity and cylindricity of the hole, the kerf taper ratio, and the surface roughness, for which it should be increased to provide the best results; however, increasing this pressure can result in the exaggeration of the surface damages.

The interaction effects between these three independent variables were as follows. With the increase in traverse speed, the pressure also had to be increased under the constant abrasive feed rate. Secondly, if the pressure increased, there was no need to increase the other input parameters. Lastly, if the abrasive feed rate was to be increased, the traverse speed had to be reduced, and the water pressure had to be increased. It must be noted that these relationships resulted in the best average results over all the dependent variables. The minimum circularity achieved was 0.05 mm, the minimum cylindricity achieved was 0.029 mm, the minimum surface roughness was found to be 3.15 μm, and, lastly, the minimum kerf taper ratio was achieved as 1.0131. The optimum input parameters for the best average performance of all the output variables was found at an abrasive feed rate of 200 g/min, a water pressure of 345 MPa, and a traverse speed of 75 mm/min.