Experimental Assessment of Hole Quality and Tool Condition in the Machining of an Aerospace Alloy

Abstract

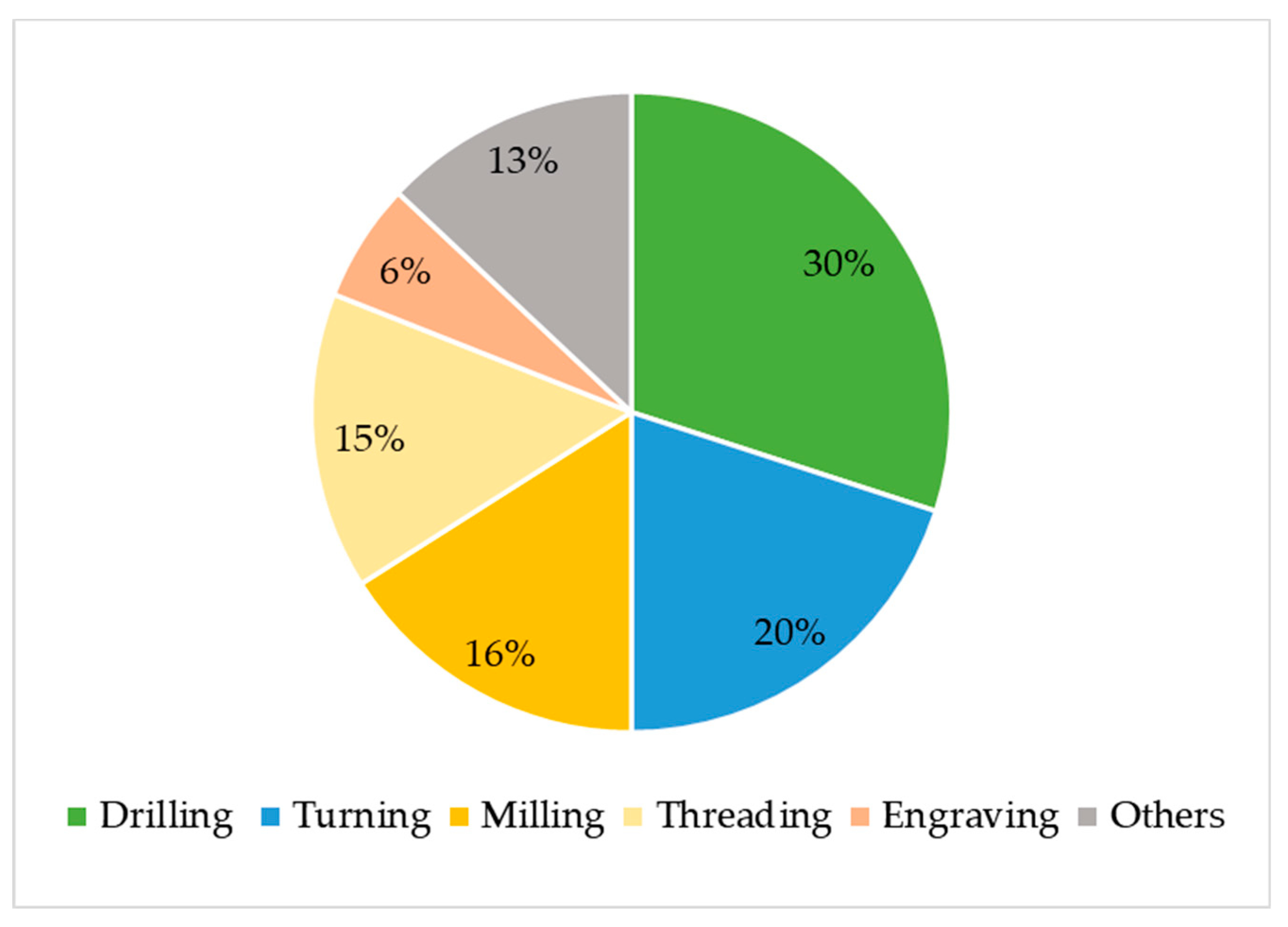

1. Introduction

2. Materials and Methods

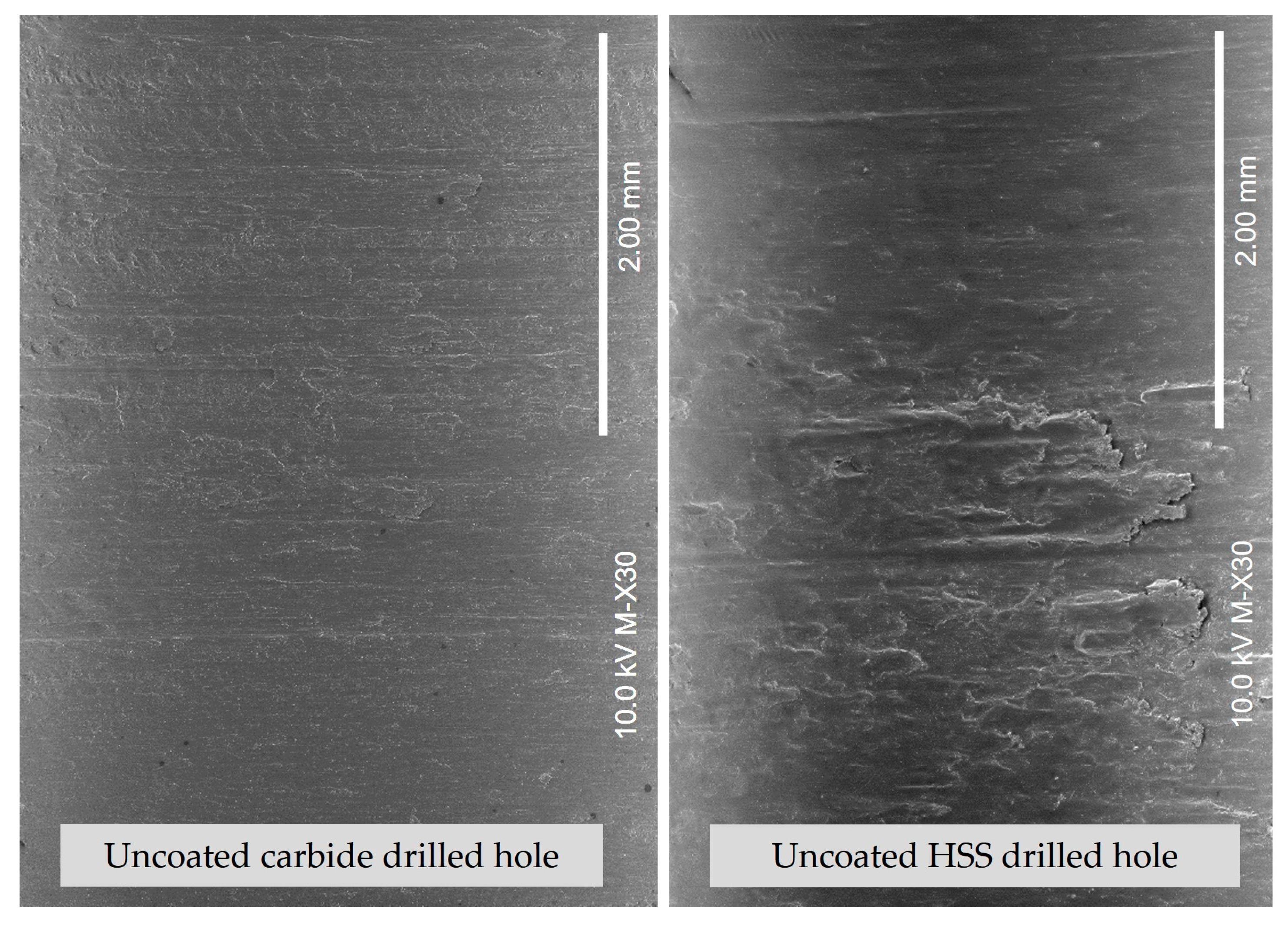

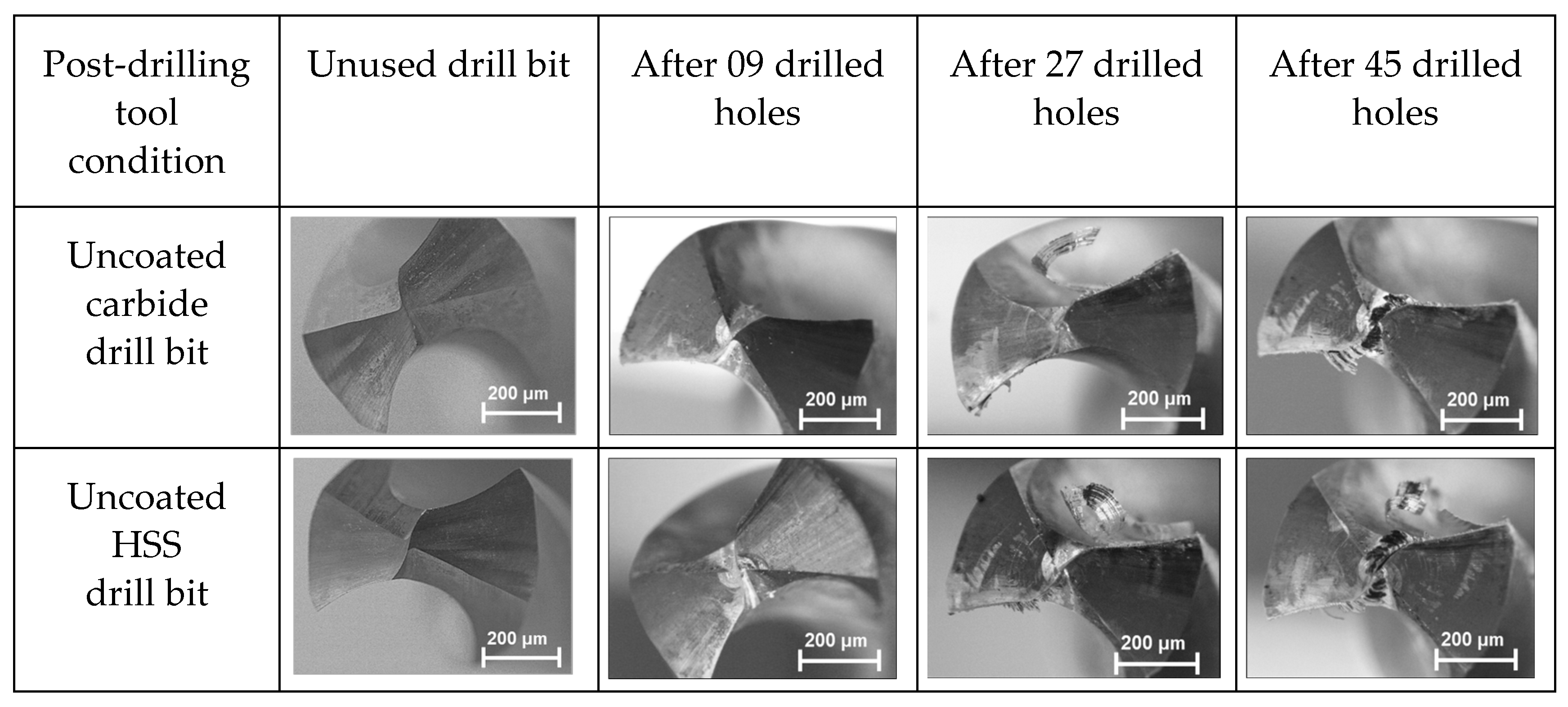

3. Experimental Results and Analysis of Variance

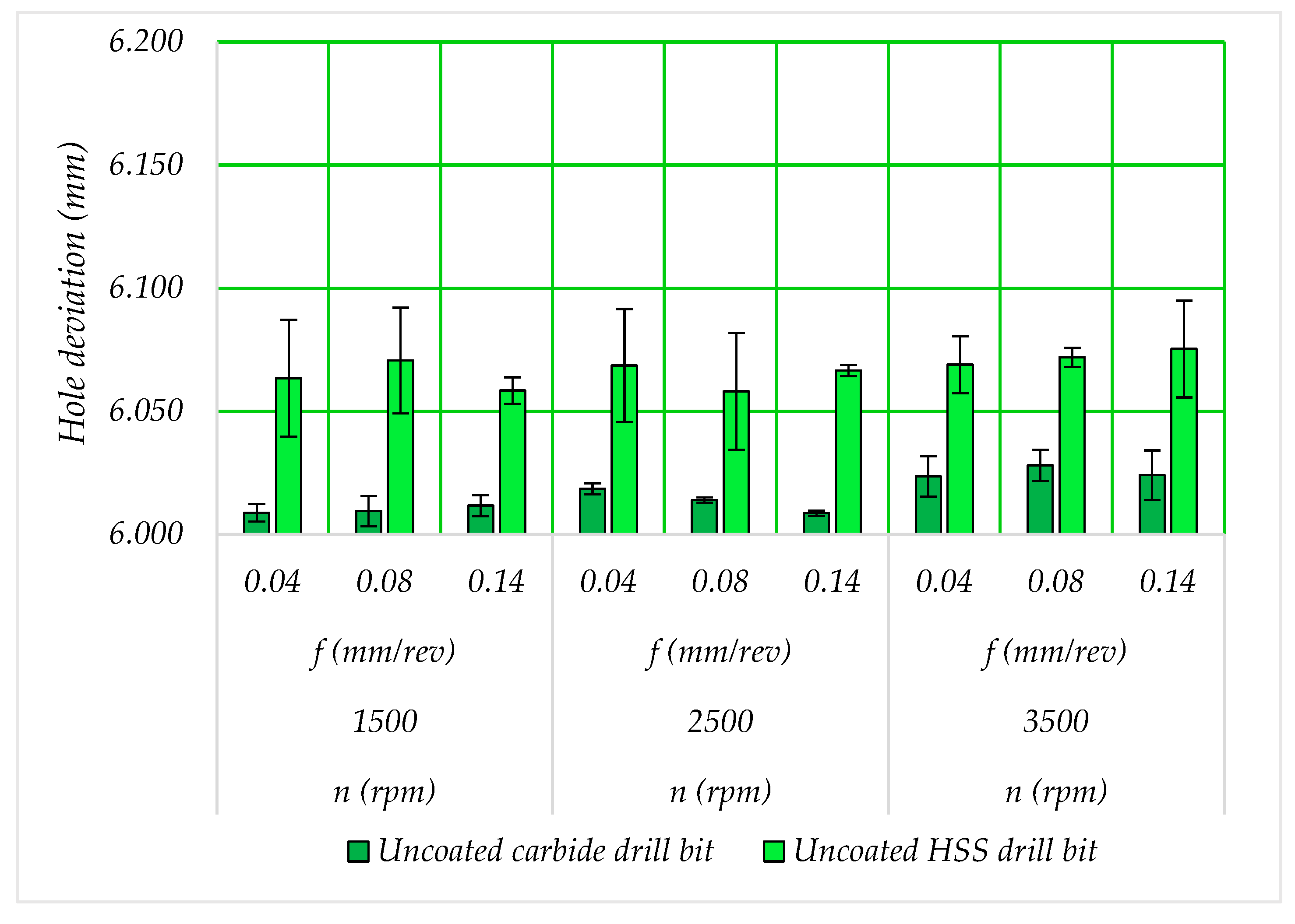

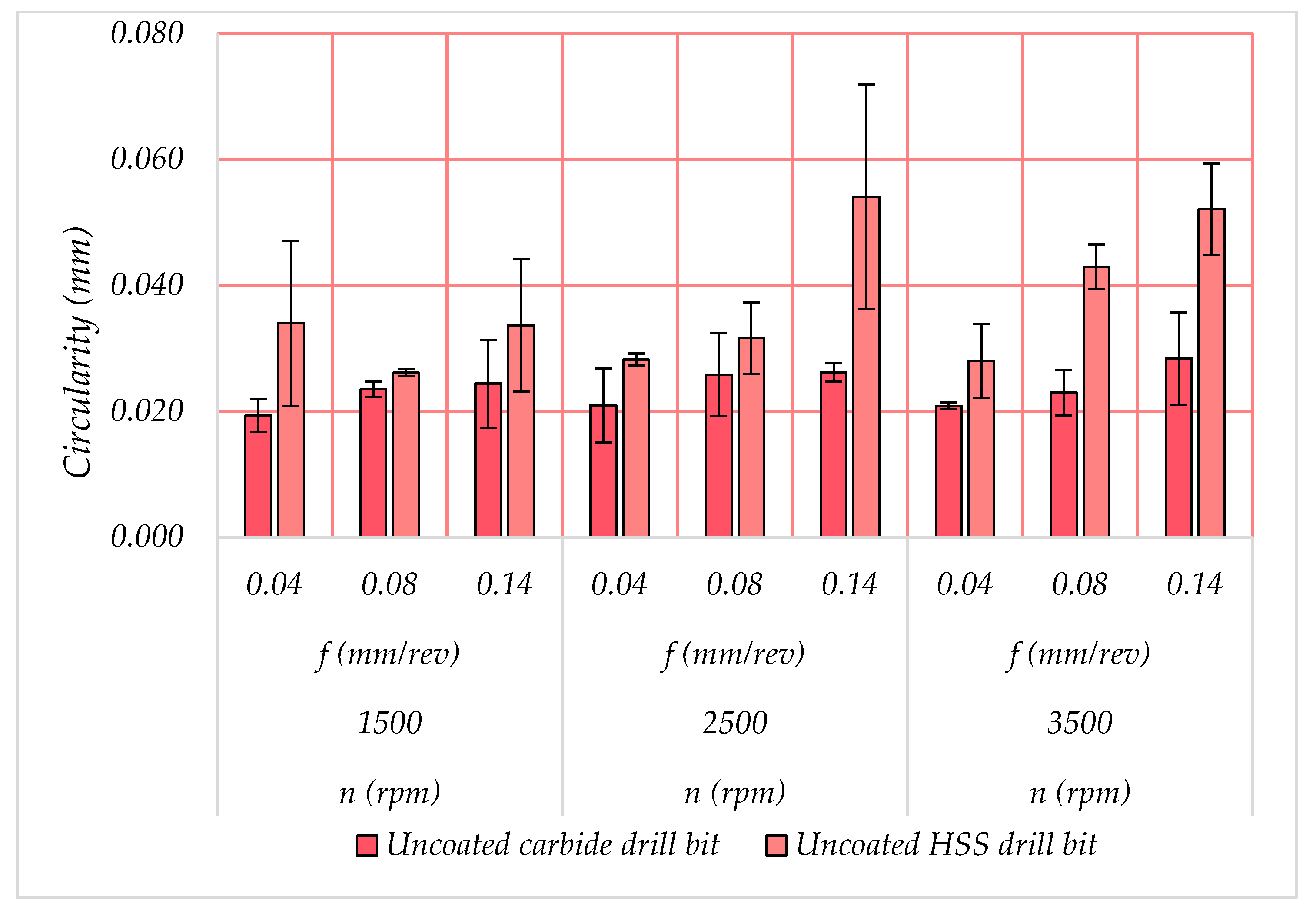

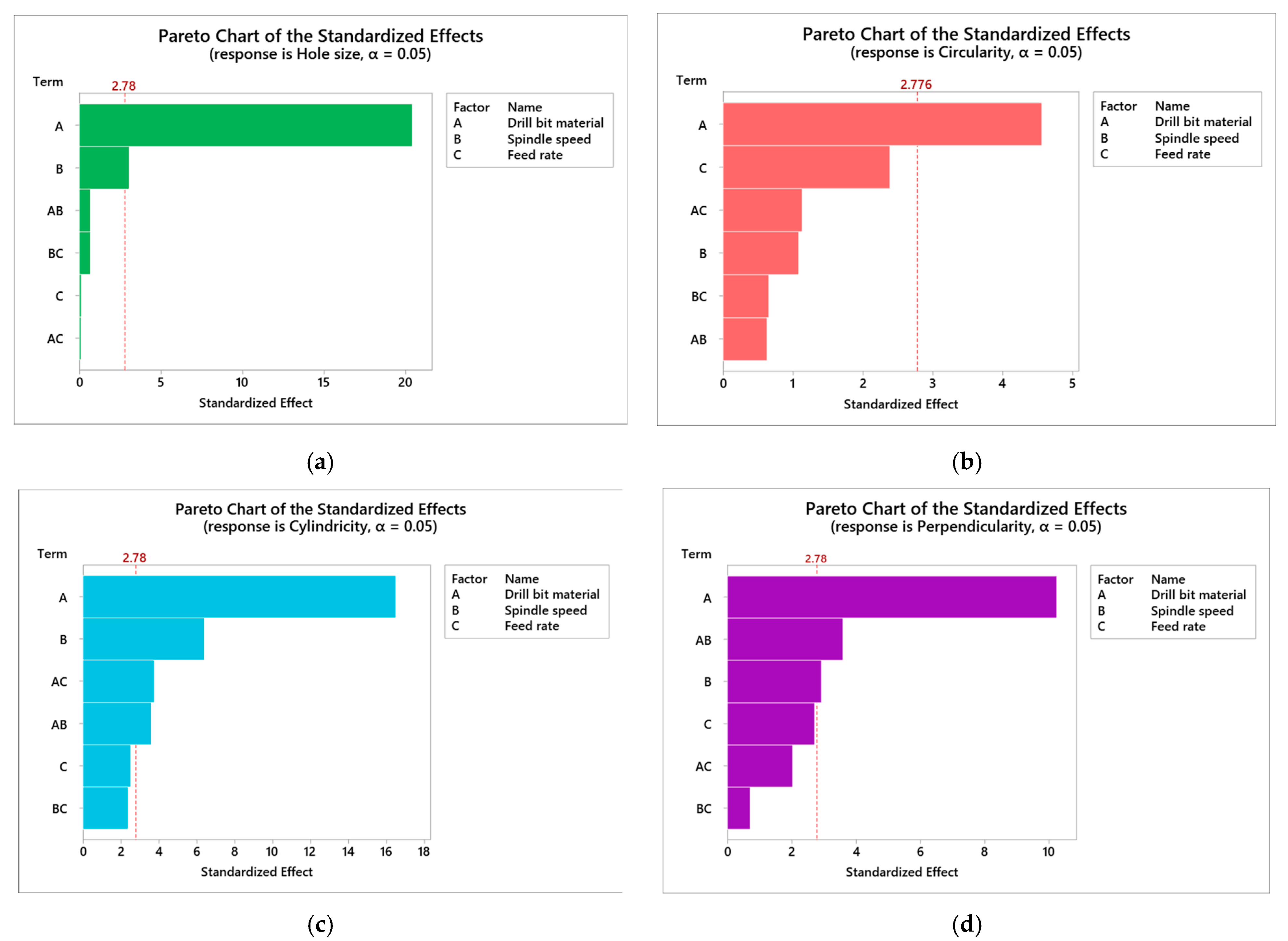

3.1. Hole Deviation and Circularity

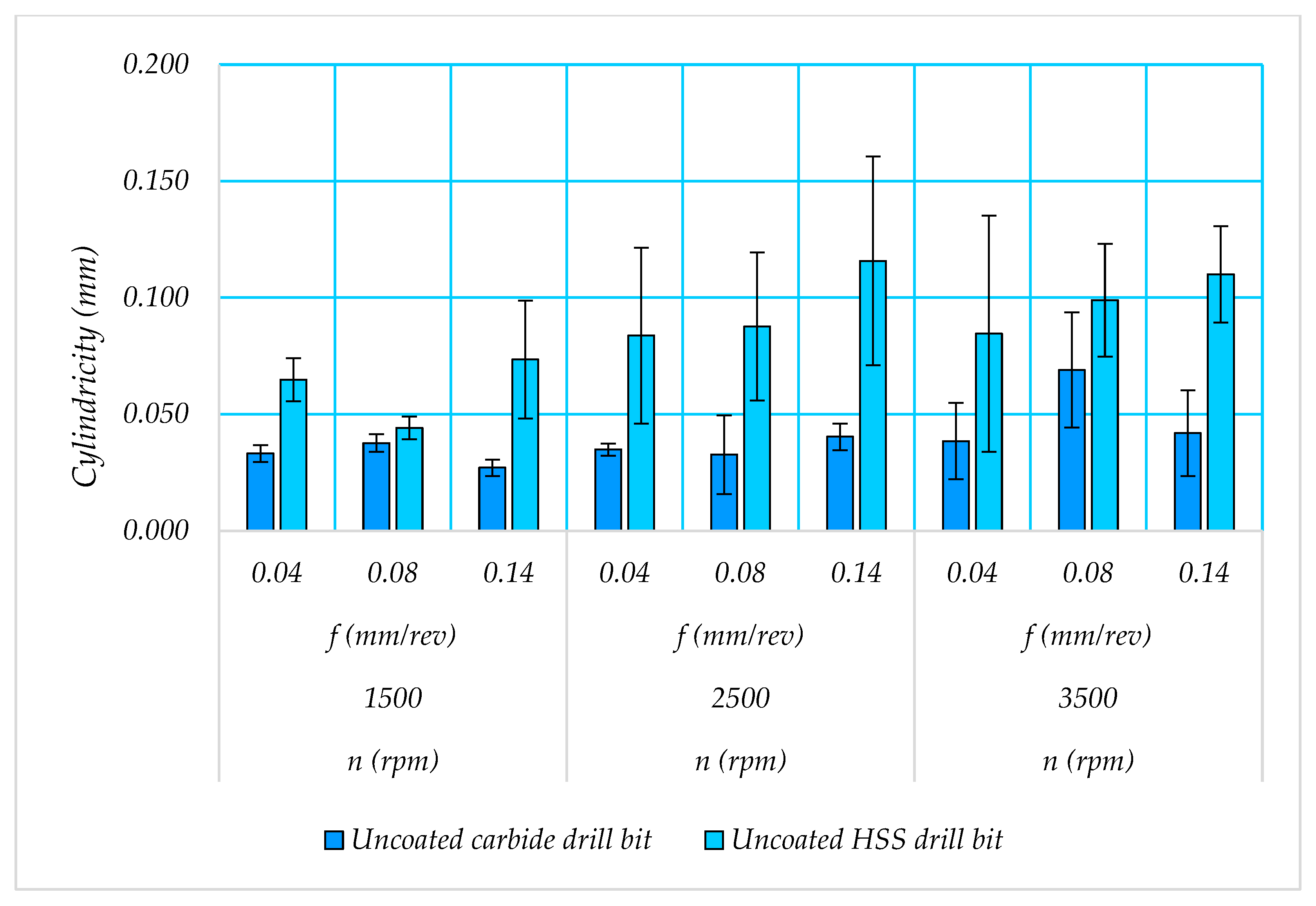

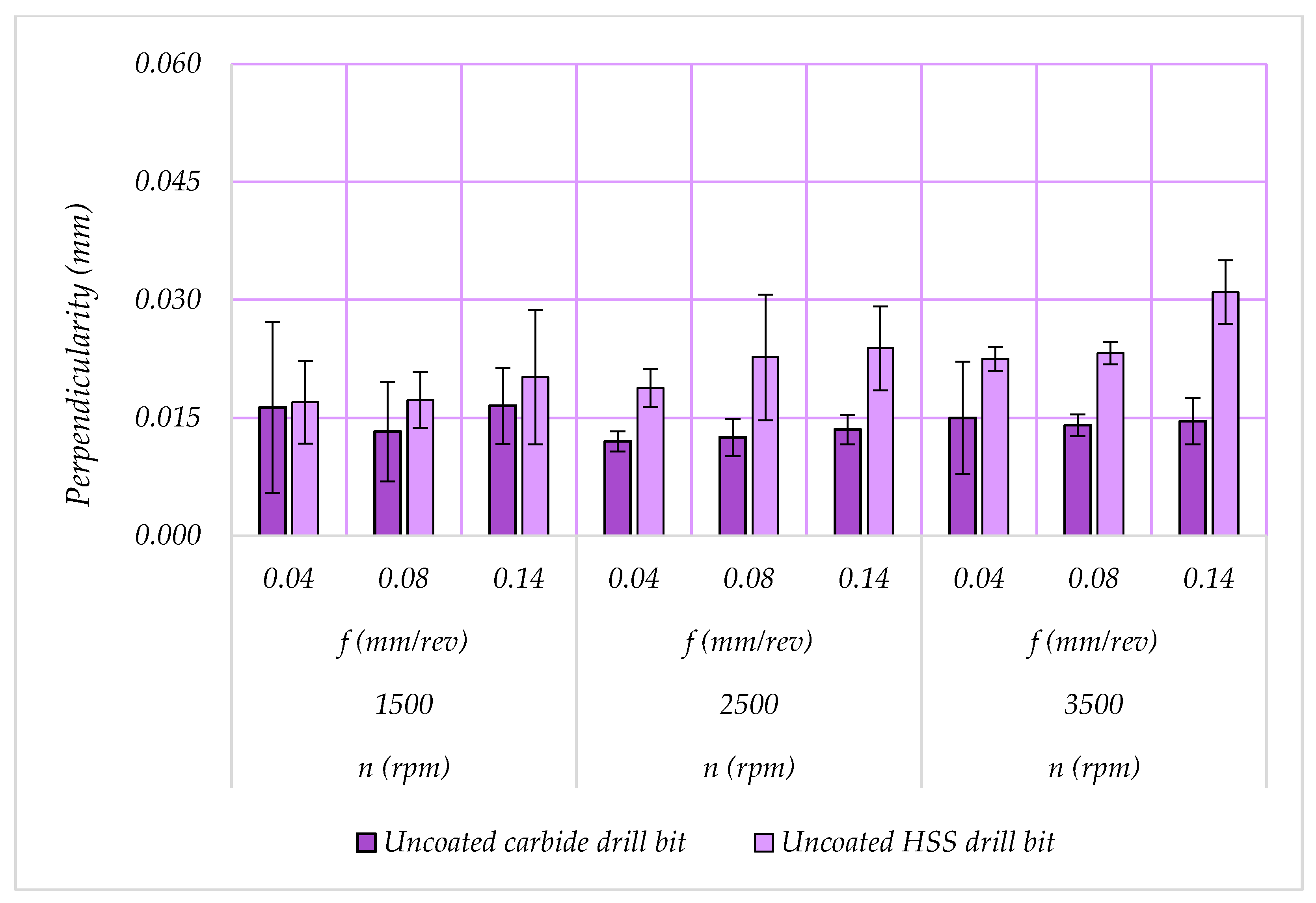

3.2. Cylindricity and Perpendicularity

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

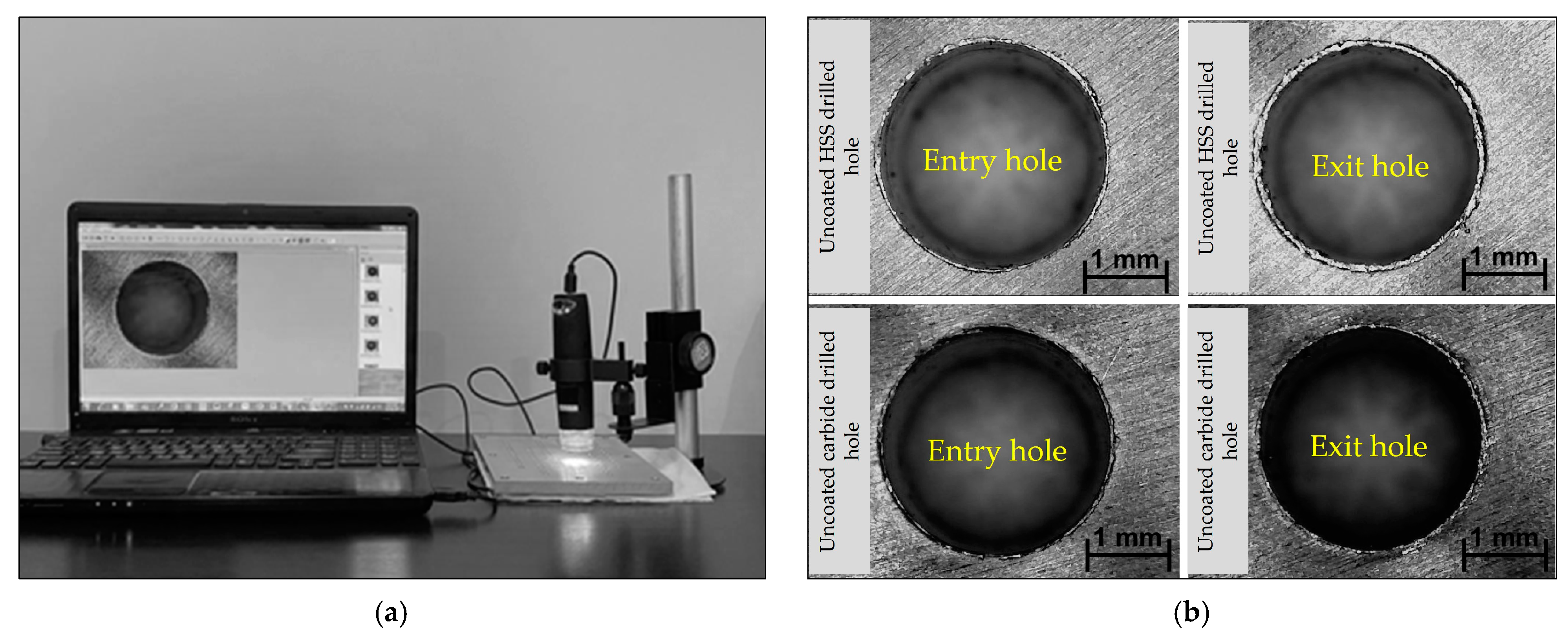

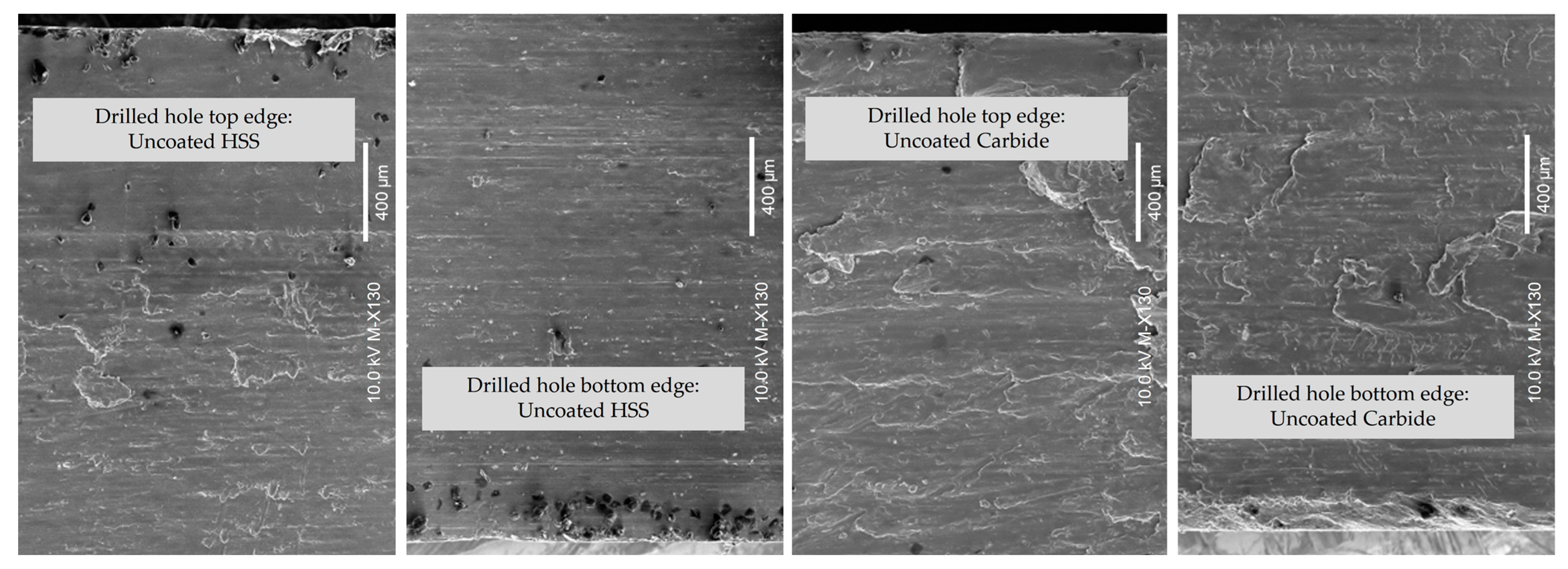

Appendix A. Entry and Exit Hole Burrs at Varying Drilling Parameters

References

- Rivero, A.; Aramendi, G.; Herranz, S.; de Lacalle, L.L. An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int. J. Adv. Manuf. Technol. 2006, 28, 1–11. [Google Scholar] [CrossRef]

- Xu, J.; Kolesnyk, V.; Li, C.; Lysenko, B.; Peterka, J.; Gupta, M.K. A critical review addressing conventional twist drilling mechanisms and quality of CFRP/Ti stacks. J. Mater. Res. Technol. 2023, 24, 6614–6651. [Google Scholar] [CrossRef]

- Yuan, P.; Lai, T.; Li, Y.; Han, W.; Lin, M.; Zhu, Q.; Liu, Y.; Shi, Z. The attitude adjustment algorithm in drilling end-effector for aviation. Adv. Mech. Eng. 2016, 8, 1687814016629348. [Google Scholar] [CrossRef]

- Adin, M.Ş. Performances of cryo-treated and untreated cutting tools in machining of AA7075 aerospace aluminium alloy. Eur. Mech. Sci. 2023, 7, 70–81. [Google Scholar] [CrossRef]

- Selvakumar, S.J.; Muralidharan, S.M. Performance analysis of drills with structured surfaces when drilling CFRP/AA7075 stack under MQL condition. J. Manuf. Process. 2023, 89, 194–219. [Google Scholar] [CrossRef]

- Habib, N.; Sharif, A.; Hussain, A.; Aamir, M.; Giasin, K.; Pimenov, D.Y.; Ali, U. Analysis of Hole Quality and Chips Formation in the Dry Drilling Process of Al7075-T6. Metals 2021, 11, 891. [Google Scholar] [CrossRef]

- Habib, N.; Sharif, A.; Hussain, A.; Aamir, M.; Giasin, K.; Pimenov, D.Y. Assessment of Hole Quality, Thermal Analysis, and Chip Formation during Dry Drilling Process of Gray Cast Iron ASTM A48. Eng 2022, 3, 301–310. [Google Scholar] [CrossRef]

- Dahnel, A.N.; Fauzi, M.H.; Raof, N.A.; Mokhtar, S.; Khairussaleh, N.K.M. Tool wear and burr formation during drilling of aluminum alloy 7075 in dry and with cutting fluid. Mater. Today Proc. 2022, 59, 808–813. [Google Scholar] [CrossRef]

- Gupta, M.K.; Niesłony, P.; Korkmaz, M.E.; Kuntoğlu, M.; Królczyk, G.; Günay, M.; Sarikaya, M. Comparison of Tool Wear, Surface Morphology, Specific Cutting Energy and Cutting Temperature in Machining of Titanium Alloys under Hybrid and Green Cooling Strategies. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 1–14. [Google Scholar] [CrossRef]

- Ghasemian Fard, M.; Baseri, H.; Zolfaghari, A. Experimental investigation of the effective parameters and performance of different types of structural tools in drilling CFRP/AL alloy stacks. J. Compos. Mater. 2022, 56, 4461–4471. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B. Cutting tool wear minimization in drilling operations of titanium alloy Ti-6Al-4V. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 1250–1263. [Google Scholar] [CrossRef]

- Dahnel, A.N.B.; Raof, N.A.; MK, N.K.; Mokhtar, S. The effect of cutting parameters on tool wear in drilling aluminium 7075. Test Eng. Manag. 2020, 83, 1274–1280. [Google Scholar]

- Islam, M.N.; Boswell, B. Effect of cooling methods on hole quality in drilling of aluminium 6061-6T. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012022. [Google Scholar] [CrossRef]

- Khunt, C.P.; Makhesana, M.A.; Patel, K.M.; Mawandiya, B.K. Performance assessment of vegetable oil-based minimum quantity lubrication (MQL) in drilling. Mater. Today Proc. 2021, 44, 341–345. [Google Scholar] [CrossRef]

- Luo, H.; Fu, J.; Wu, T.; Chen, N.; Li, H. Numerical Simulation and Experimental Study on the Drilling Process of 7075-t6 Aerospace Aluminum Alloy. Materials 2021, 14, 553. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S.; Chattopadhyaya, S. Sustainability in drilling of aluminum alloy. Clean. Mater. 2022, 3, 100048. [Google Scholar] [CrossRef]

- Banerjee, B.; Dhar, A.K.; Bhattacharjee, S.; Mahato, N.K. Process Parameters Optimization in Drilling Using Taguchi Method. In Proceedings of the Recent Trends in Product Design and Intelligent Manufacturing Systems, Singapore, 30–31 December 2021; pp. 701–708. [Google Scholar]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Ud Din, I.; Hanif, M.I.; Kuklu, U.; Pimenov, D.Y.; Ikhlaq, M. Effect of Cutting Parameters and Tool Geometry on the Performance Analysis of One-Shot Drilling Process of AA2024-T3. Metals 2021, 11, 854. [Google Scholar] [CrossRef]

- Kang, J.; Yao, E. Study On Burrs And Hole Quality Of Drilling AA2024 Plates Based On FEM And Experimental Investigation. J. Appl. Sci. Eng. 2022, 26, 911–921. [Google Scholar] [CrossRef]

- Giasin, K.; Hodzic, A.; Phadnis, V.; Ayvar-Soberanis, S. Assessment of cutting forces and hole quality in drilling Al2024 aluminium alloy: Experimental and finite element study. Int. J. Adv. Manuf. Technol. 2016, 87, 2041–2061. [Google Scholar] [CrossRef]

- Ashrafi, S.A.; Davoudinejad, A.; Barzani, M.M.; Salehi, P. Investigation into effect of tool wear on drilling force and surface finish while dry drilling aluminum 2024. Adv. Mater. Res. 2012, 548, 387–392. [Google Scholar] [CrossRef]

- Kurt, M.; Bagci, E.; Kaynak, Y. Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes. Int. J. Adv. Manuf. Technol. 2009, 40, 458–469. [Google Scholar] [CrossRef]

- Benchmarkabrasives. HSS VS Cobalt VS Carbide Drill Bits: What to Choose. Available online: https://benchmarkabrasives.com/blogs/news/hss-vs-cobalt-vs-carbide-drill-bits-what-to-choose (accessed on 30 June 2023).

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Feasibility of tool configuration and the effect of tool material, and tool geometry in multi-hole simultaneous drilling of Al2024. Int. J. Adv. Manuf. Technol. 2020, 111, 861–879. [Google Scholar] [CrossRef]

- Oberg, E. Machinery’s Handbook 29th Edition-Full Book; Industrial Press: New York, NY, USA, 2012. [Google Scholar]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. A review: Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Mohammadi, F.; Mirhashemi, M.; Rashidzadeh, R. A Coordinate Measuring Machine with Error Compensation in Feature Measurement: Model Development and Experimental Verification. Int. J. Adv. Manuf. Technol. 2022. [Google Scholar] [CrossRef]

- Mydin, N.M.M.; Dahnel, A.N.; Raof, N.A.; Khairussaleh, N.M.; Mokhtar, S. Comparison of Tool Wear Mechanisms During Drilling of Aluminium Alloy 7075 in Dry and Chilled Air Conditions. J. Sci. Technol. 2022, 14, 67–74. [Google Scholar] [CrossRef]

- Musavi, S.H.; Sepehrikia, M.; Davoodi, B.; Niknam, S.A. Performance analysis of developed micro-textured cutting tool in machining aluminum alloy 7075-T6: Assessment of tool wear and surface roughness. Int. J. Adv. Manuf. Technol. 2022, 119, 3343–3362. [Google Scholar] [CrossRef]

- Ramulu, M.; Branson, T.; Kim, D. A study on the drilling of composite and titanium stacks. Compos. Struct. 2001, 54, 67–77. [Google Scholar] [CrossRef]

| Material | Spindle Speed/ Cutting Speed | Feed Rate | Drill Bits | Areas Studied | Ref. |

|---|---|---|---|---|---|

| Al2024 | 1000, 2000, and 3000 (rpm) | 0.04, 0.08, and 0.14 (mm/rev) | Uncoated carbide, 6 mm and 10 mm | Thrust force, surface roughness, burrs, hole surface damage analysis, chips formation, and tool condition | [18] |

| AA2024 | 60, 120, and 180 (m/min) | 0.05, 0.15, and 0.25 (mm/rev) | HSS twist drill with cobalt, 6 mm | Surface roughness, thrust force, hole diameter, and exit burr height | [19] |

| Al2024 | 1000, 3000, 6000, and 9000 (rpm) | 100, 300, 600, 900 (mm/min) | TiAlN-coated carbide twist drill | Chip formation, surface roughness, hole size, burrs, and circularity error | [20] |

| Al2024 | 28 and 94 (m/min) | 0.04 (mm/rev) | HSS and HSS-Co | Thrust force, torque, and surface finish | [21] |

| Al 2024 | 30, 45, and 60 (m/min) | 0.15, 0.20, and 0.25 (mm/rev) | Uncoated HSS, TiN and TiAlN-coated | Surface finish and hole diameter | [22] |

| Material Details | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Material | Al2024-T3 | ||||||||

| Dimension | 150 × 200 mm2 | ||||||||

| Thickness | 10 mm | ||||||||

| Chemical composition | Mg | Cr | Si | Z | Cu | Mn | Fe | Ti | Al |

| 1.5 | 0.1 | 0.5 | 0.25 | 4.5 | 0.6 | 0.5 | 0.15 | Balance | |

| Ultimate tensile strength | 445 MPa | ||||||||

| Drilling parameters | |||||||||

| Feed rate (mm/rev) | 0.04, 0.08, 0.14 | ||||||||

| Spindle speed (rpm) | 1500, 2500, 3500 | ||||||||

| Drilling condition | Dry | ||||||||

| Drill bit details | |||||||||

| Type | Twist drill | ||||||||

| Material | HSS, carbide | ||||||||

| Coating | None | ||||||||

| Drill diameter | 6 mm | ||||||||

| Shank diameter | 6 mm | ||||||||

| Helix angle | 30° | ||||||||

| Number of flutes | 2 mm | ||||||||

| Machines used | |||||||||

| Machine tool | CNC | ||||||||

| Hole size, circularity, cylindricity, and perpendicularity | Coordinate measuring machine (Taichung, Taiwan) | ||||||||

| Burrs | USB digital microscope | ||||||||

| Hole surface defects | Scanning electron microscopy (Hitachi SU5000 Chiyoda, Japan) | ||||||||

| Tool condition | Optical microscope (LEICA M80) | ||||||||

| Hole Size | |||||||

|---|---|---|---|---|---|---|---|

| Source | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value | Contribution |

| Model | 13 | 0.012127 | 0.012127 | 0.000933 | 33.73 | 0.002 | 99.10% |

| Linear | 5 | 0.01198 | 0.01198 | 0.002396 | 86.63 | 0 | 97.89% |

| Drill bit material | 1 | 0.011516 | 0.011516 | 0.011516 | 416.38 | 0 | 94.10% |

| Spindle speed | 2 | 0.000459 | 0.000459 | 0.000229 | 8.29 | 0.038 | 3.75% |

| Feed rate | 2 | 0.000006 | 0.000006 | 0.000003 | 0.11 | 0.9 | 0.05% |

| Two-way interactions | 8 | 0.000147 | 0.000147 | 0.000018 | 0.66 | 0.712 | 1.20% |

| Drill bit material × spindle speed | 2 | 0.000041 | 0.000041 | 0.000021 | 0.74 | 0.532 | 0.34% |

| Drill bit material × feed rate | 2 | 0.000005 | 0.000005 | 0.000002 | 0.08 | 0.922 | 0.04% |

| Spindle speed × feed rate | 4 | 0.000101 | 0.000101 | 0.000025 | 0.92 | 0.533 | 0.83% |

| Error | 4 | 0.000111 | 0.000111 | 0.000028 | - | - | 0.90% |

| Total | 17 | 0.012238 | - | - | - | - | 100.00% |

| Circularity | |||||||

| Model | 13 | 0.001579 | 0.001579 | 0.000121 | 3.24 | 0.133 | 91.33% |

| Linear | 5 | 0.001282 | 0.001282 | 0.000256 | 6.84 | 0.043 | 74.19% |

| Drill bit material | 1 | 0.000779 | 0.000779 | 0.000779 | 20.79 | 0.01 | 45.07% |

| Spindle speed | 2 | 0.000107 | 0.000107 | 0.000054 | 1.43 | 0.34 | 6.21% |

| Feed rate | 2 | 0.000396 | 0.000396 | 0.000198 | 5.28 | 0.075 | 22.91% |

| Two-way interactions | 8 | 0.000296 | 0.000296 | 0.000037 | 0.99 | 0.544 | 17.14% |

| Drill bit material × spindle speed | 2 | 0.00005 | 0.00005 | 0.000025 | 0.67 | 0.563 | 2.89% |

| Drill bit material × feed rate | 2 | 0.000115 | 0.000115 | 0.000057 | 1.53 | 0.321 | 6.63% |

| Spindle speed × feed rate | 4 | 0.000132 | 0.000132 | 0.000033 | 0.88 | 0.548 | 7.63% |

| Error | 4 | 0.00015 | 0.00015 | 0.000037 | - | - | 8.67% |

| Total | 17 | 0.001728 | - | - | - | - | 100.00% |

| Cylindricity | |||||||

|---|---|---|---|---|---|---|---|

| Source | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value | Contribution |

| Model | 13 | 0.014233 | 0.014233 | 0.001095 | 32.18 | 0.002 | 99.05% |

| Linear | 5 | 0.011966 | 0.011966 | 0.002393 | 70.34 | 0.001 | 83.28% |

| Drill bit material | 1 | 0.009246 | 0.009246 | 0.009246 | 271.76 | 0 | 64.35% |

| Spindle speed | 2 | 0.002323 | 0.002323 | 0.001162 | 34.14 | 0.003 | 16.17% |

| Feed rate | 2 | 0.000396 | 0.000396 | 0.000198 | 5.82 | 0.065 | 2.76% |

| Two-Way Interactions | 8 | 0.002267 | 0.002267 | 0.000283 | 8.33 | 0.029 | 15.78% |

| Drill bit material × spindle speed | 2 | 0.000765 | 0.000765 | 0.000382 | 11.24 | 0.023 | 5.32% |

| Drill bit material × feed rate | 2 | 0.000831 | 0.000831 | 0.000415 | 12.21 | 0.02 | 5.78% |

| Spindle speed × feed rate | 4 | 0.000671 | 0.000671 | 0.000168 | 4.93 | 0.076 | 4.67% |

| Error | 4 | 0.000136 | 0.000136 | 0.000034 | - | - | 0.95% |

| Total | 17 | 0.014369 | - | - | - | - | 100.00% |

| Perpendicularity | |||||||

| Model | 13 | 0.00042 | 0.00042 | 0.000032 | 12.89 | 0.012 | 97.67% |

| Linear | 5 | 0.000334 | 0.000334 | 0.000067 | 26.69 | 0.004 | 77.74% |

| Drill bit material | 1 | 0.000262 | 0.000262 | 0.000262 | 104.83 | 0.001 | 61.08% |

| Spindle speed | 2 | 0.000038 | 0.000038 | 0.000019 | 7.65 | 0.043 | 8.92% |

| Feed rate | 2 | 0.000033 | 0.000033 | 0.000017 | 6.65 | 0.053 | 7.75% |

| Two-Way interactions | 8 | 0.000086 | 0.000086 | 0.000011 | 4.27 | 0.088 | 19.93% |

| Drill bit material × spindle speed | 2 | 0.000056 | 0.000056 | 0.000028 | 11.21 | 0.023 | 13.06% |

| Drill bit material × feed rate | 2 | 0.00002 | 0.00002 | 0.00001 | 3.97 | 0.112 | 4.63% |

| Spindle speed × feed rate | 4 | 0.00001 | 0.00001 | 0.000002 | 0.96 | 0.516 | 2.23% |

| Error | 4 | 0.00001 | 0.00001 | 0.000003 | - | - | 2.33% |

| Total | 17 | 0.00043 | - | - | - | - | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aamir, M.; Sharif, A.; Zahir, M.Z.; Giasin, K.; Tolouei-Rad, M. Experimental Assessment of Hole Quality and Tool Condition in the Machining of an Aerospace Alloy. Machines 2023, 11, 726. https://doi.org/10.3390/machines11070726

Aamir M, Sharif A, Zahir MZ, Giasin K, Tolouei-Rad M. Experimental Assessment of Hole Quality and Tool Condition in the Machining of an Aerospace Alloy. Machines. 2023; 11(7):726. https://doi.org/10.3390/machines11070726

Chicago/Turabian StyleAamir, Muhammad, Aamer Sharif, Muhammad Zeeshan Zahir, Khaled Giasin, and Majid Tolouei-Rad. 2023. "Experimental Assessment of Hole Quality and Tool Condition in the Machining of an Aerospace Alloy" Machines 11, no. 7: 726. https://doi.org/10.3390/machines11070726

APA StyleAamir, M., Sharif, A., Zahir, M. Z., Giasin, K., & Tolouei-Rad, M. (2023). Experimental Assessment of Hole Quality and Tool Condition in the Machining of an Aerospace Alloy. Machines, 11(7), 726. https://doi.org/10.3390/machines11070726