Design and Experiment of Apple Foam Net Sleeve Packaging Machine with Posture Adjustment Function

Abstract

:1. Introduction

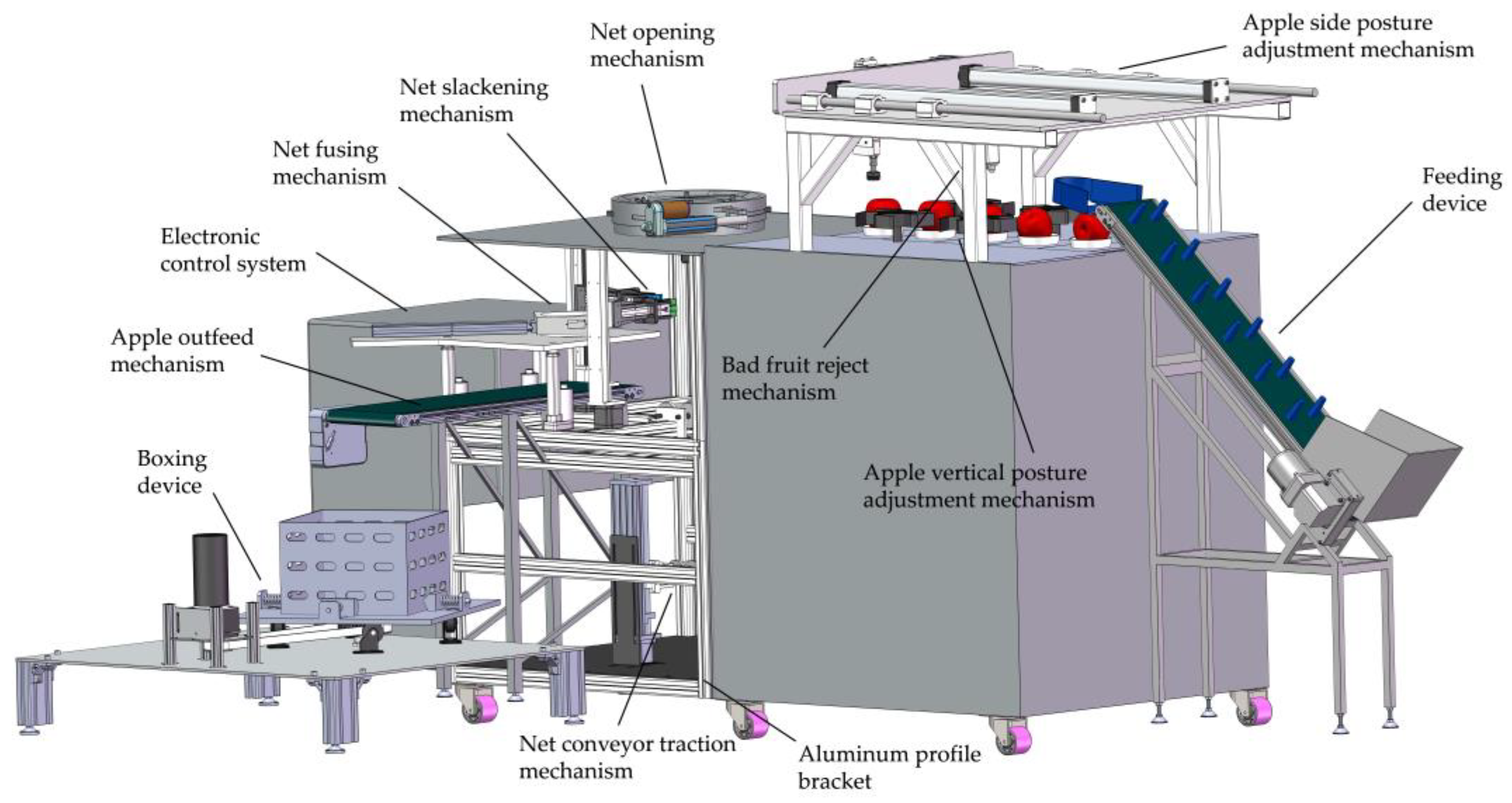

2. Foam Net Sleeve Packaging Machine for Apple Composition and Working Principle

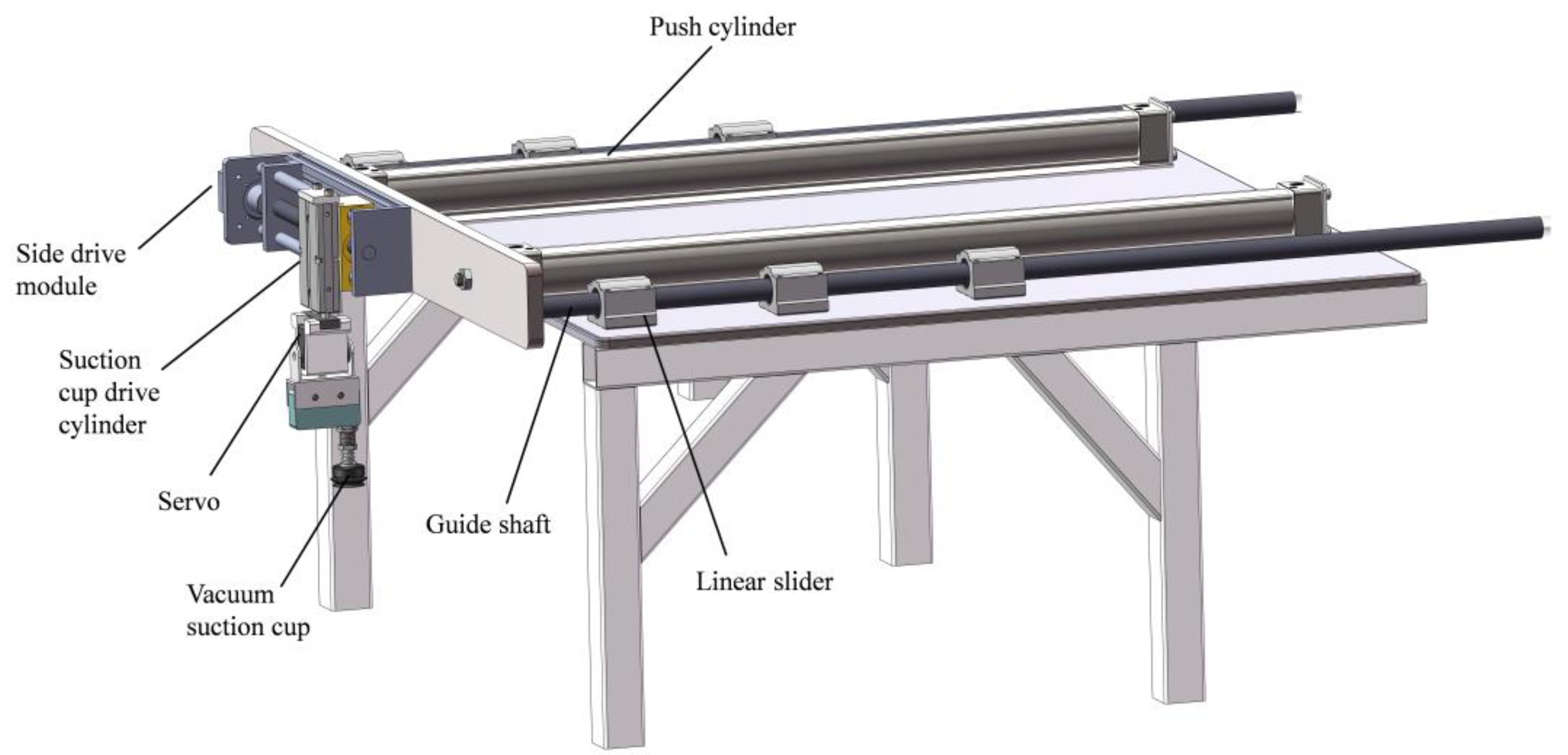

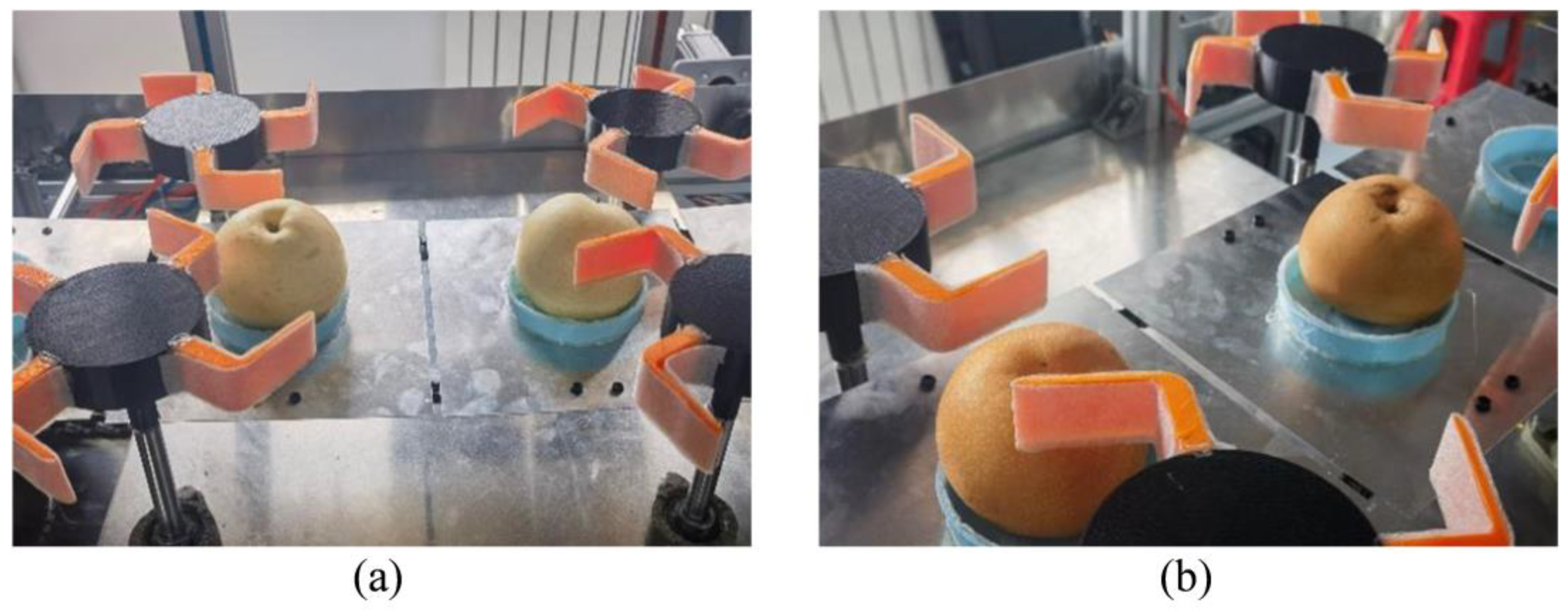

2.1. Foam Net Sleeve Packaging Machine for Apple Composition

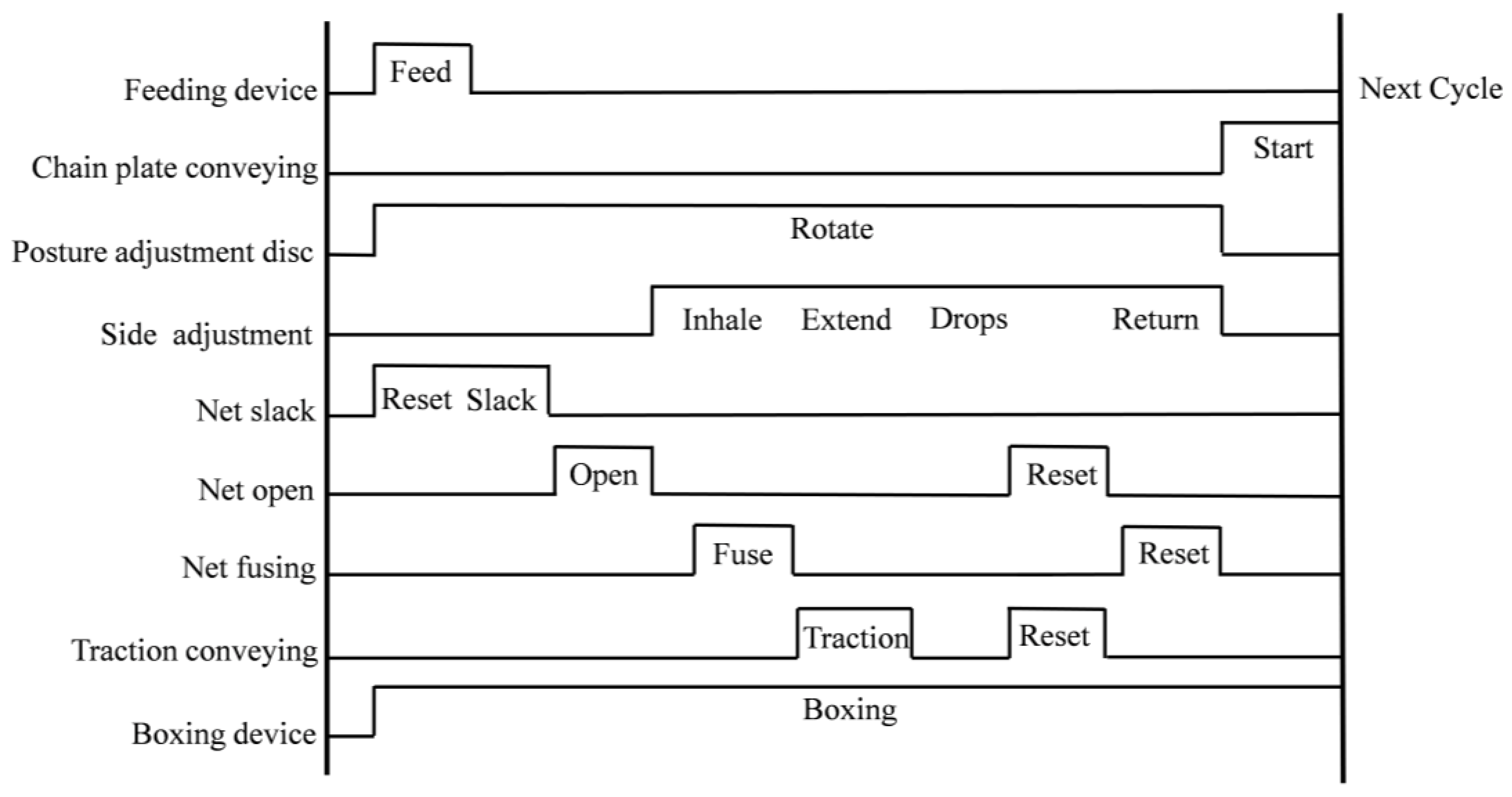

2.2. Foam Net Sleeve Packaging Machine for Apple Working Principle

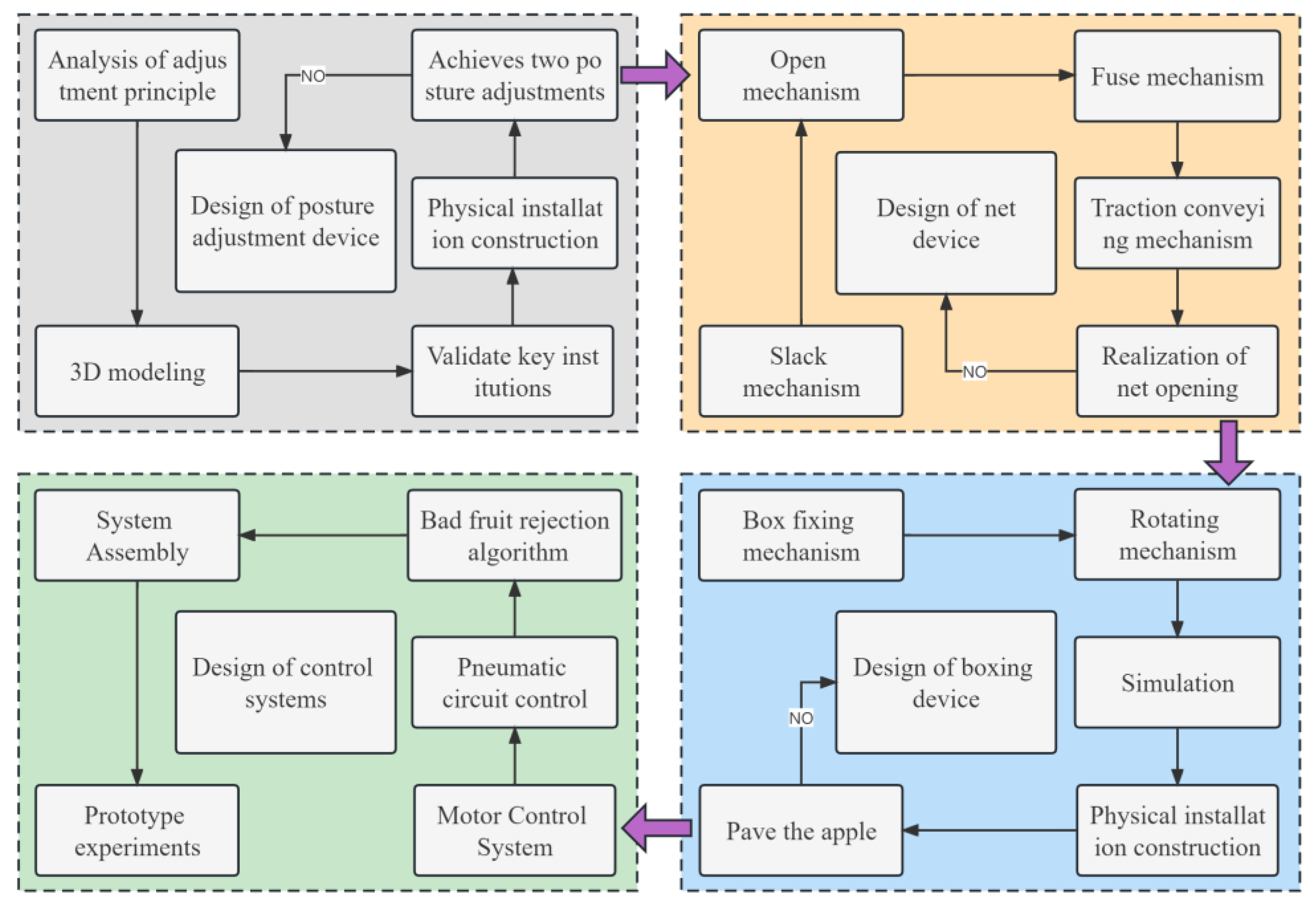

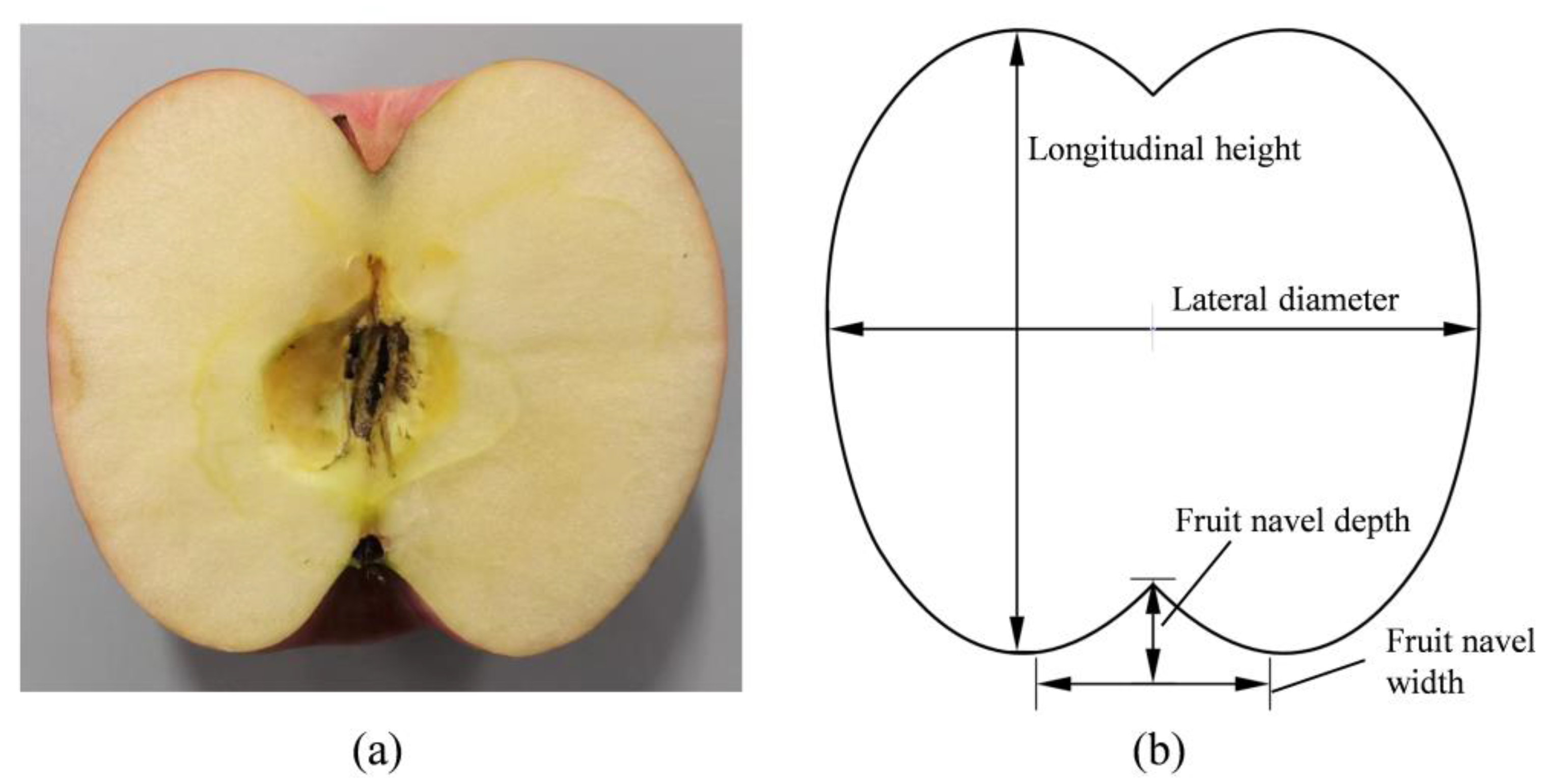

3. Analysis of Apple Shape Characteristics and Net Sleeve Mechanical Properties

3.1. Apple Shape Feature Analysis

3.2. Analysis of the Mechanical Properties of the Net Sleeve

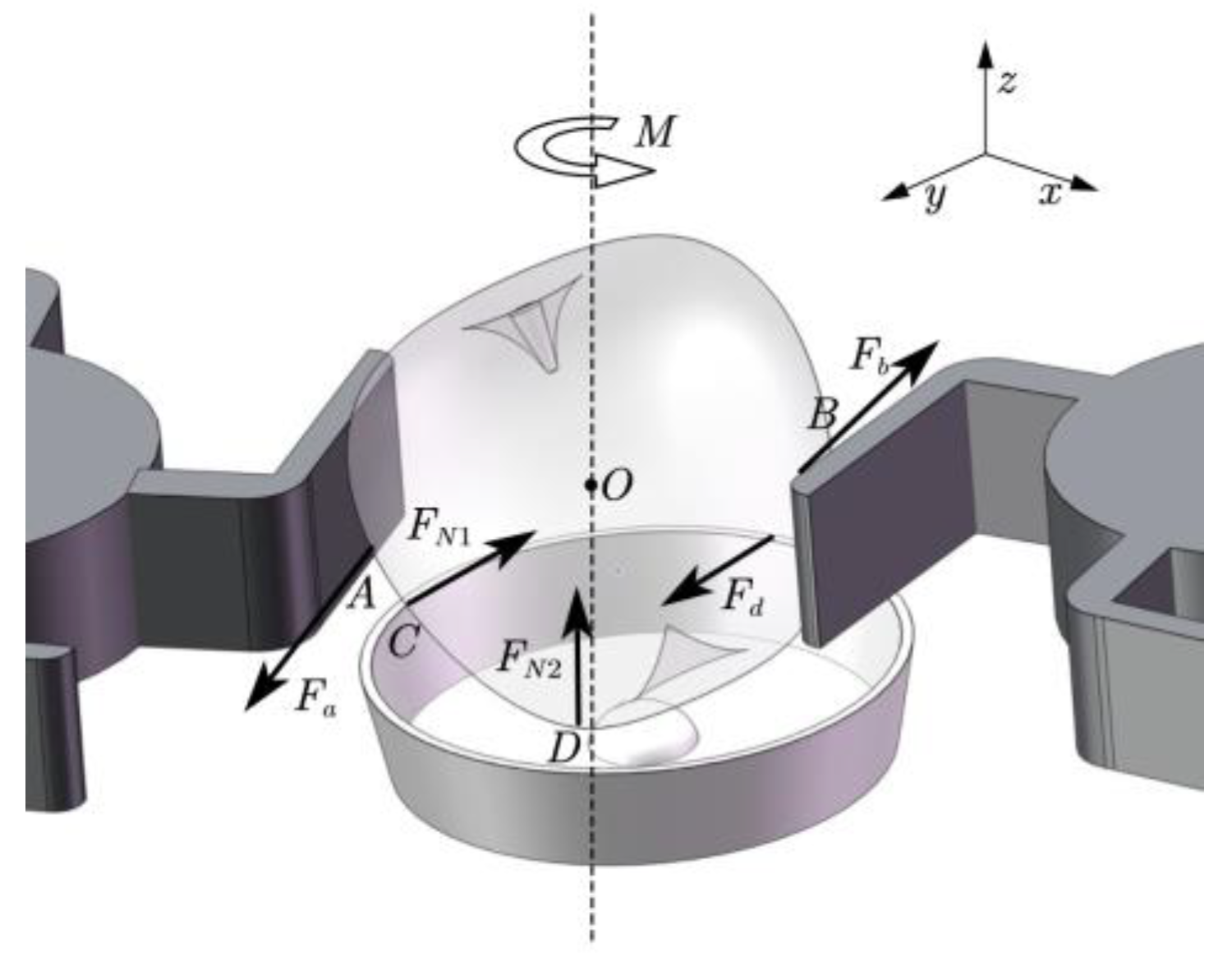

4. Apple Posture Adjustment Device Adjustment Principal Analysis and Design

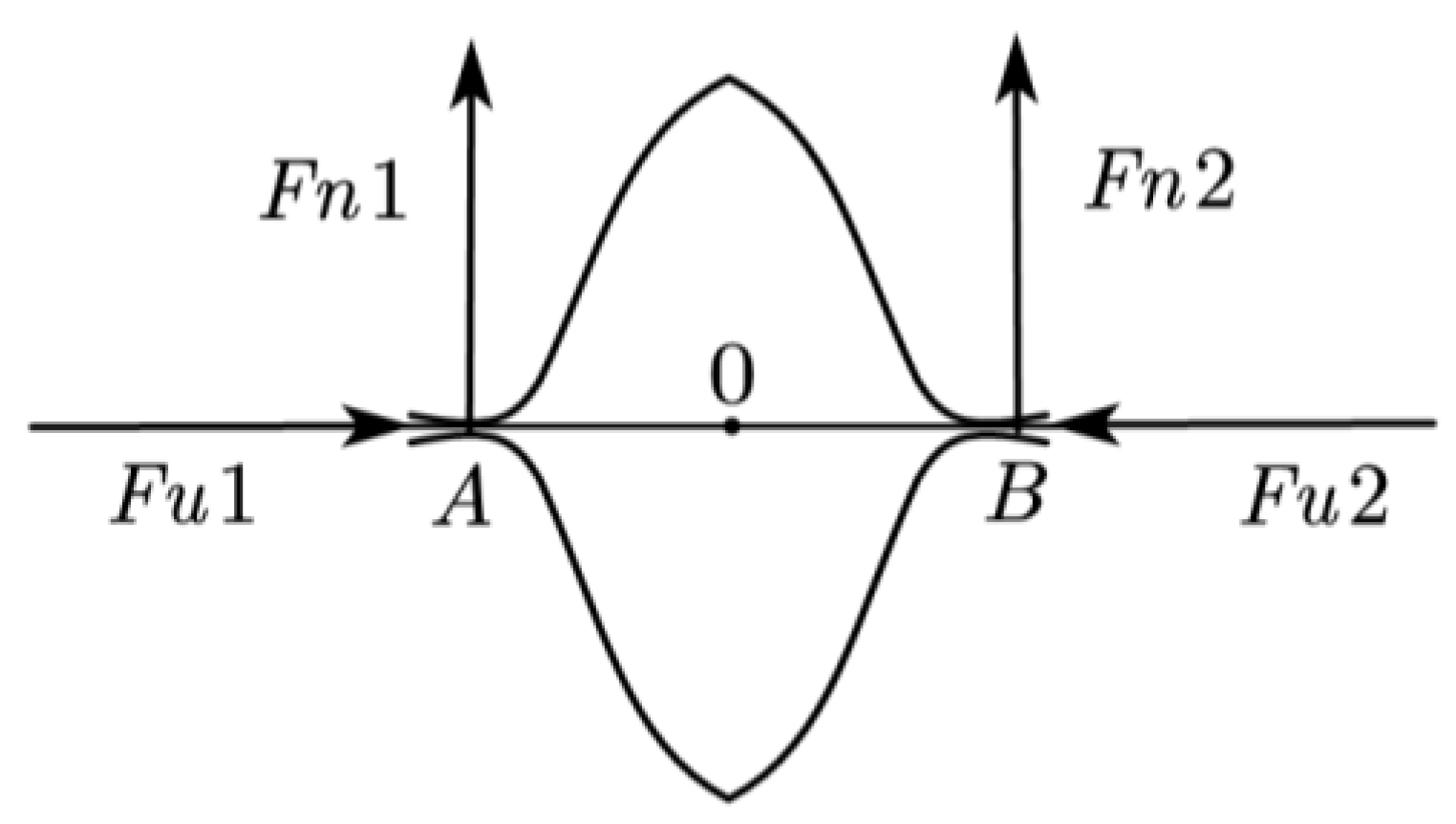

4.1. Analysis of the Adjustment Principle of the Vertical Posture Adjustment Mechanism

4.2. Design of Vertical Posture Adjustment Mechanism

4.3. Design of Side Posture Adjustment Mechanism

4.4. Finite Element Analysis of Guide Shaft of Side Posture Adjustment Mechanism

5. Design of Net Device

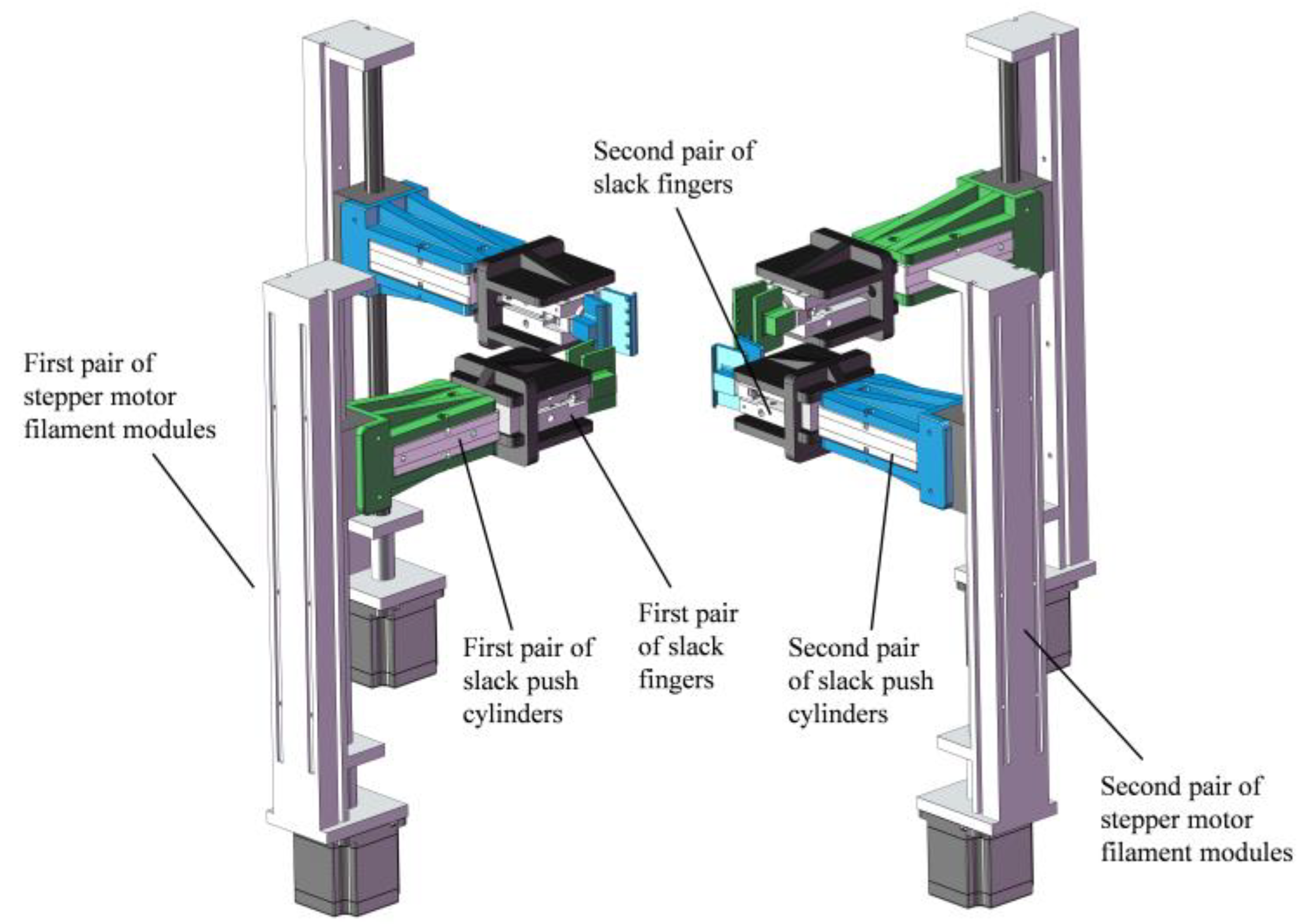

5.1. Design of Net Slack Mechanism

- (1)

- The first pair of net slackening push cylinders drive the first pair of net slackening fingers to move, when the front of the net slackening finger is 5 mm from the edge of the net, the net slackening finger is closed to clamp the net.

- (2)

- As shown in Figure 12a, the second pair of net slackening push cylinders push the second pair of net slackening fingers into motion, when the second pair of sleeve slack fingers moves to the end, the paired net slack fingers clamp the net by squeezing.

- (3)

- As shown in Figure 12b, the two pairs of mesh sleeve slackening push cylinders return simultaneously to slacken the mesh sleeve.

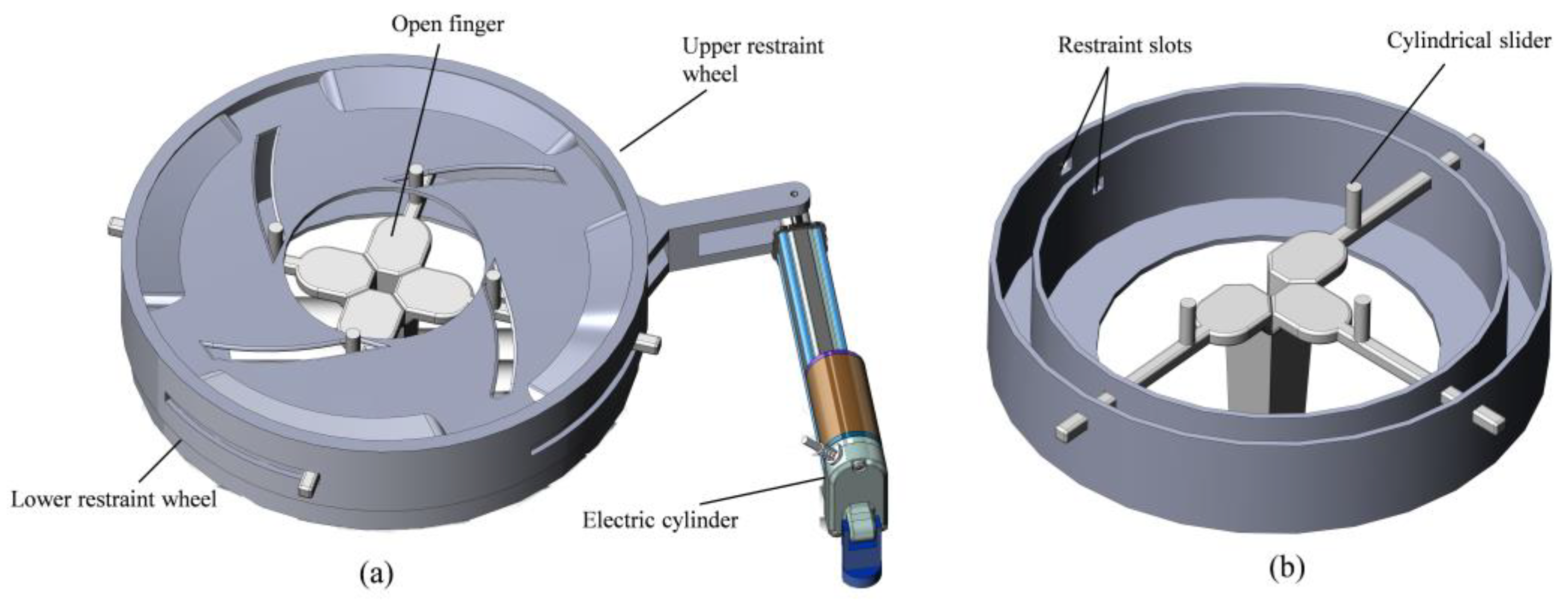

5.2. Design of Net Opening Mechanism

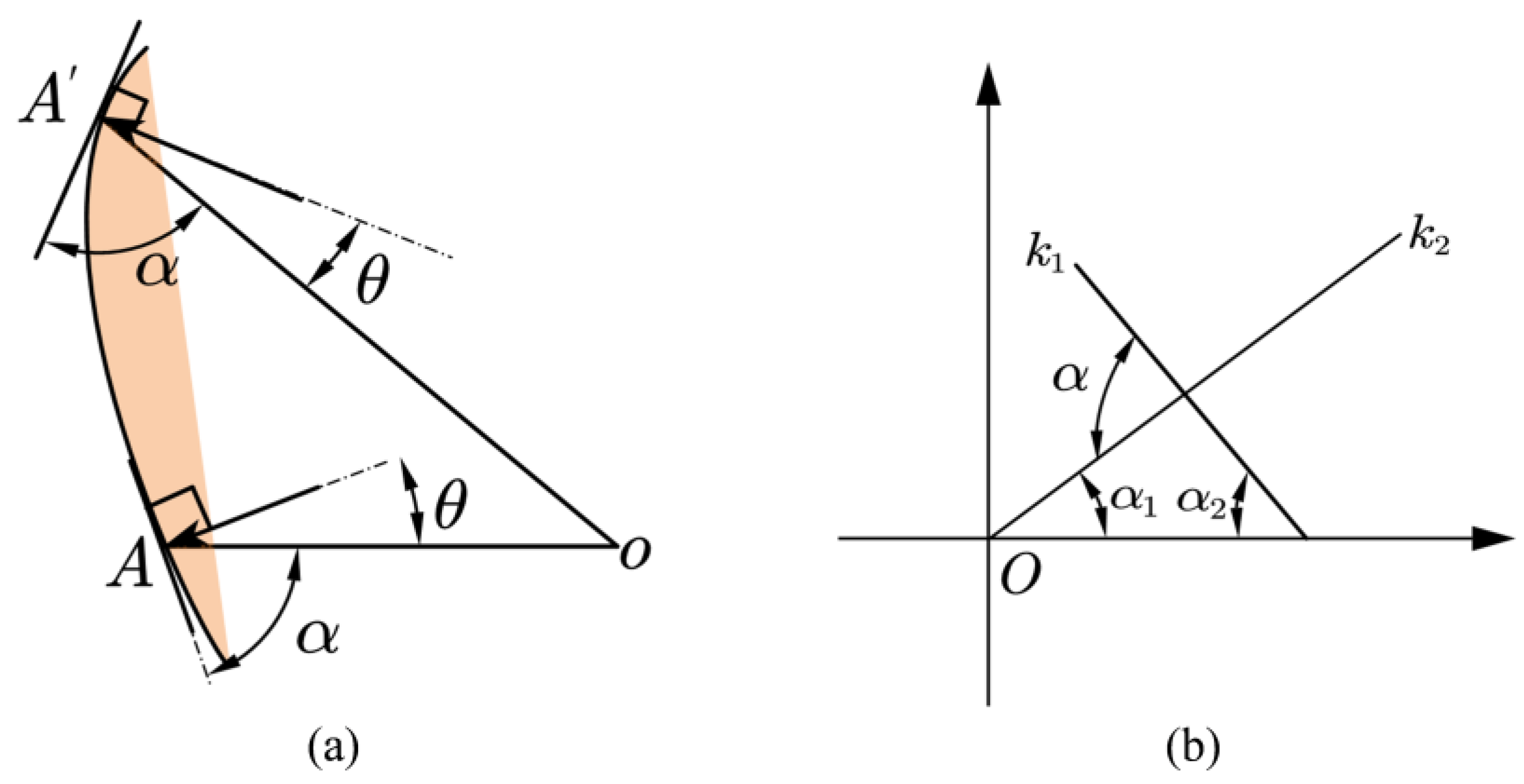

5.2.1. Design of Equiangular Spiral Type Chute Curve

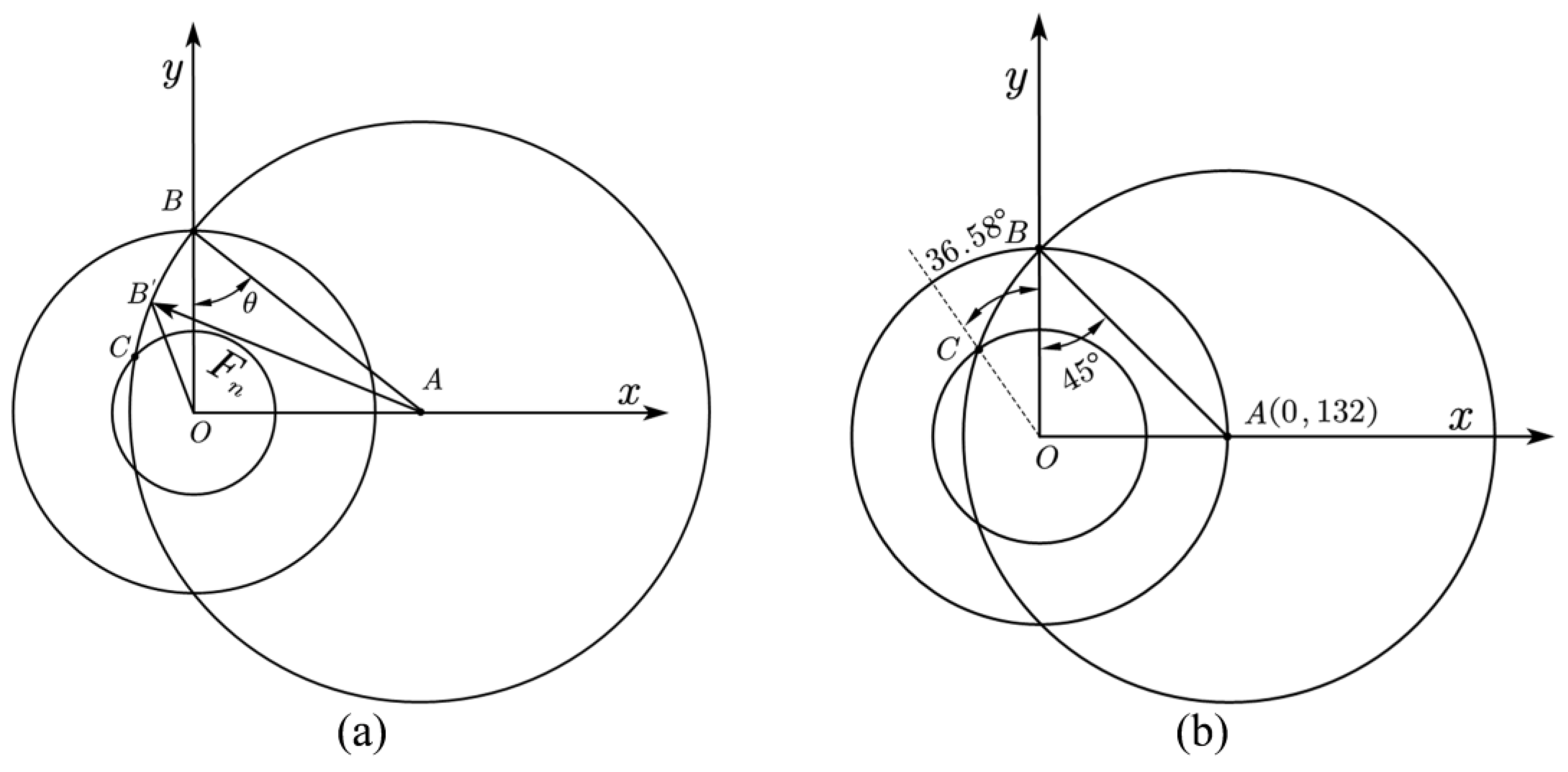

5.2.2. Design of Circumferential Type Chute Curve

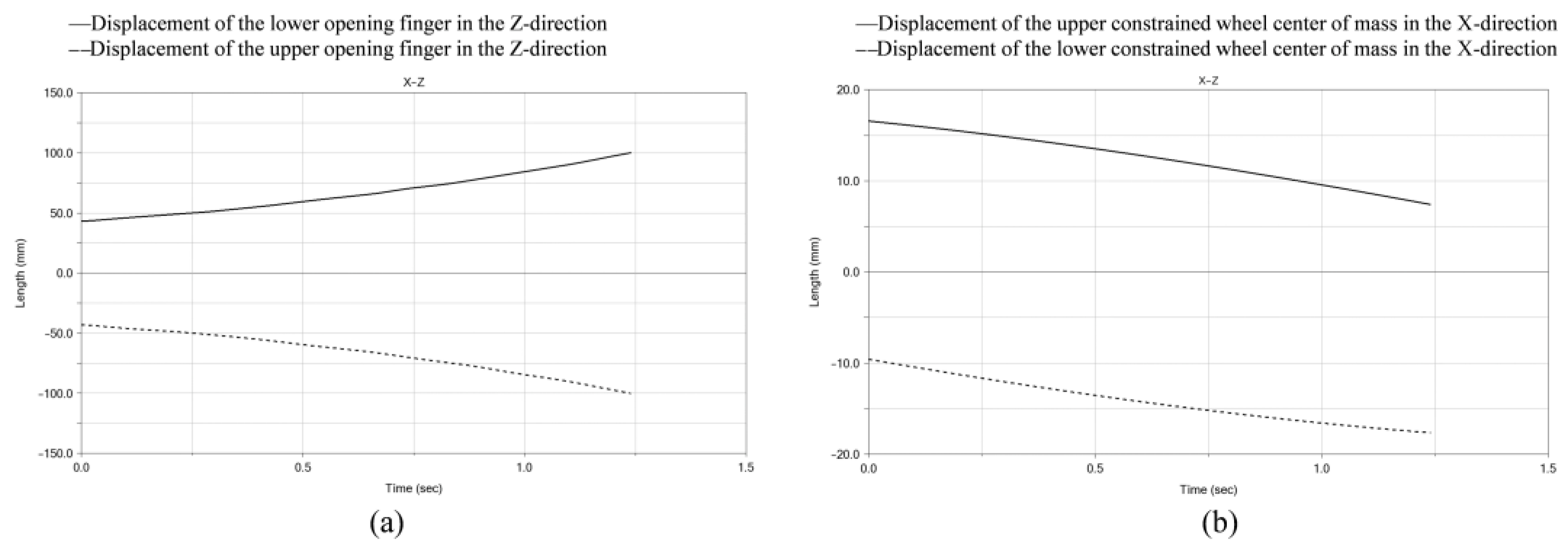

5.2.3. ADAMS Simulation Analysis of the Circumferential Opening Mechanism

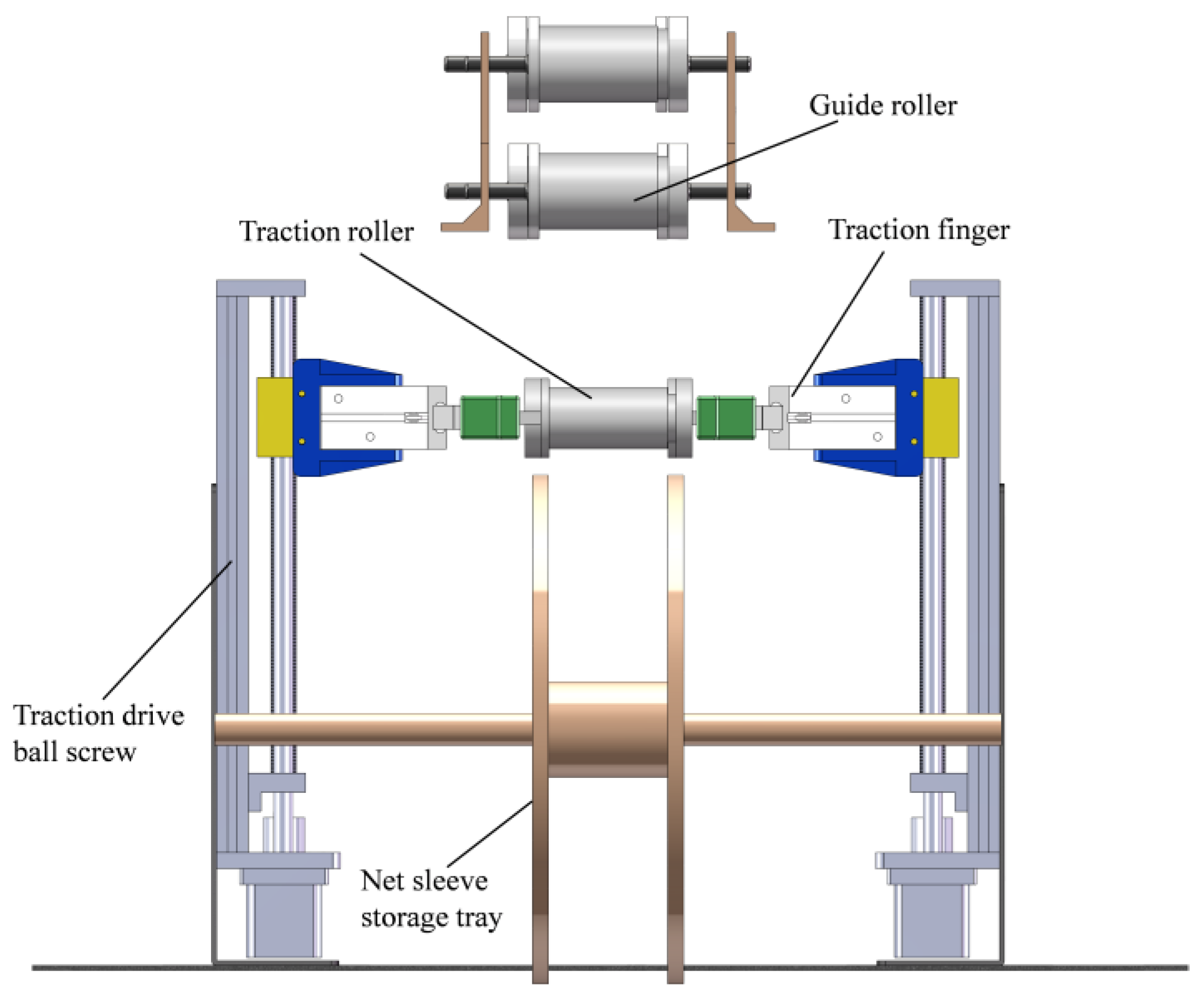

5.3. Design of Net Traction Conveying Mechanism

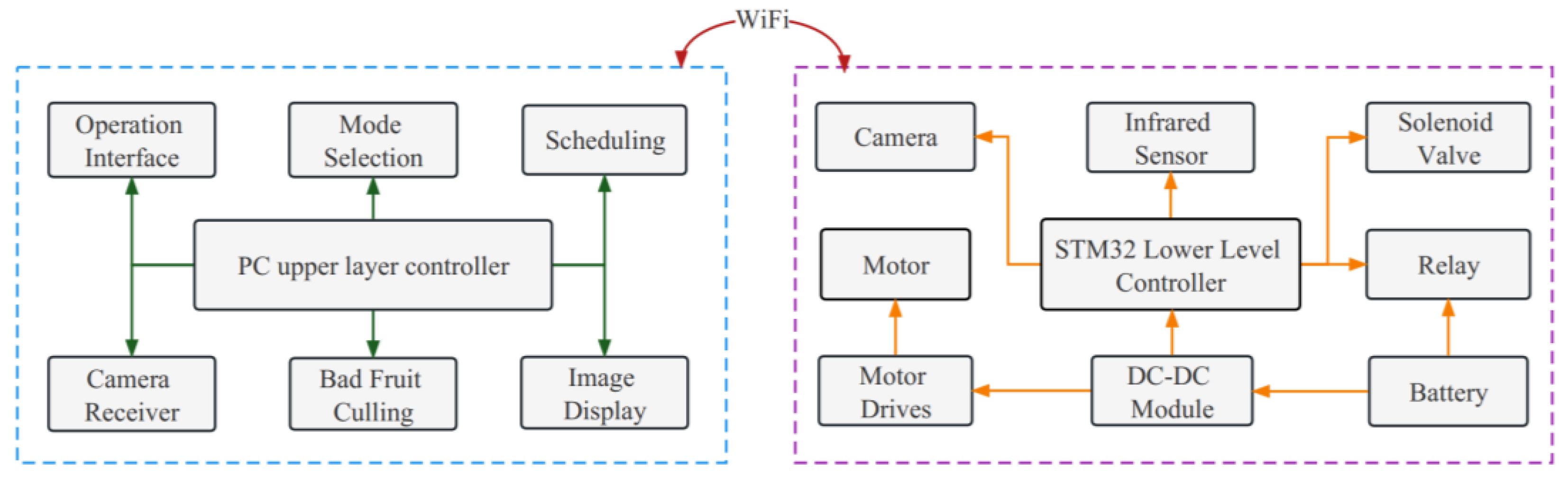

6. Design of Control System

6.1. The Overall Design Idea of the Control System

6.2. Design of Motor Drive System

7. Packaging Machine Prototype Experiment

8. Discussion

- (1)

- Experimental basis: Experiments on the analysis of apple shape characteristic parameters and the effect of foam mesh sleeve opening size on its shrinkage characteristics were conducted to provide an experimental basis for the selection of packaging machine design parameters.

- (2)

- Principal analysis: Analysis of the principle of vertical release attitude adjustment based on D’Alembert’s principle and analysis of the principle of the chute curve of the opening mechanism based on the self-locking principle.

- (3)

- Design simulation: SolidWorks-based 3D virtual prototype construction, mechanical analysis of the apple foam sleeve wrapping machine, and ADAMS View-based dynamics analysis of the sleeve opening mechanism chute curve.

- (4)

- Prototype experiments: From Table 4 in Section 7, it can be seen that the packing rate is 98.10%, the single-fruit packing speed is 10 s/pcs, and the working efficiency is 355–365 pcs/h. The operation of the packaging machine is not only limited to apples but also to pears, peaches, oranges, and other spherical fruits.

8.1. The Advantages of This Study

8.2. Application Prospects and Economic Benefits

9. Conclusions

- (1)

- Traditional manual packaging methods have the following problems: manual packaging labor is costly, inefficient, and cannot be operated continuously with limited daily working hours. The existing apple net packaging machine has the following problems: High processing and manufacturing costs (up to 100,000 yuan per unit); Large size is not adapted to the national conditions of Chinese apple retail farming; The single form of packaging cannot meet the market demand for packaging diversification; The form of net support mostly adopts the form of a sleeve with a manipulator which is easy to pull off the net sleeve causing a low utilization rate of the net sleeve. The apple foam mesh sleeve packaging machine designed in this paper has the following advantages: The machine is small in size, can operate continuously, and has a low processing cost (40,000 yuan per unit); Two different types of packaging can be realized for apples: vertical packaging and side packaging, so the machine packaging form diversification to meet the market demand; using the combination of the net slackening mechanism and the net opening mechanism to improve the utilization rate of the net sleeve. Therefore, the packaging machine designed in this paper can be a good solution to the above problems.

- (2)

- In this paper, experiments were conducted on the effect of the opening size of the net sleeve on its shrinkage characteristics. The experimental results showed that the best wrapping effect on apples was achieved when the net opening size was 130 mm. The design and analysis of the adjustment principle of the vertical posture adjustment mechanism, the selection of the vacuum generator of the side posture adjustment mechanism, the squeezing and clamping principle of the net slackening mechanism, and the chute curve of the net opening mechanism of the apple foam net packaging robot were carried out. The analysis results showed that the upper constraint wheel slideway curve can be equiangular helix type or circumferential type, this paper adopts circumferential type for physical design. The calculation results showed that the finger can be moved in the slide groove when the control ∠AOB was less than 78.14°. According to the actual working condition, ∠AOB = 45° was selected and the rotation angle of the upper constraint wheel was calculated to be 36.58°.

- (3)

- SolidWorks software for static analysis of the guiding axis of the apple side release posture adjustment mechanism. According to the simulation results, we can see that , , . The maximum strain of the guiding shaft was 2.384 within the allowable strain range, and the maximum deformation stress was within the yield stress range, which can withstand the gravity of the front part and complete the guiding work smoothly to meet the requirements of use. ADAMS View software was used to analyze the dynamics of the circumferential bracing mechanism to verify the rationality of the slide curve design. According to the simulation results, it can be seen that the travel distance of the opening finger in the Z direction is 57.0452 mm, which is within the error tolerance of the theoretical design parameter of 57 mm, the rotation angle = 36.61° is within the error tolerance of 36.58° of the theoretical design.

- (4)

- Based on the 3D model and the results of theoretical analysis, a physical prototype of the apple foam net packaging machine was built, and apple packaging experiments were conducted. Prototype experimental results showed that the machine can realize the continuous operation of feeding, posture adjustment, and nesting and boxing of red Fuji apples. The success rate of machine posture adjustment was 99%, the success rate of the net sleeve was 99%, the packing rate was 98.10%, the fused net sleeve was mainly within 138–143 mm, the packing speed of single fruit was 10 s/pcs, the working efficiency was 355–365 pcs/h and the working object was not only limited to apple, but also to pear, peach, orange, and other spherical fruits.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huo, X.; Liu, T.; Liu, J.; Wei, Y.; Yao, X.; Ma, X.; Lu, P. China Apple Industry Development Report in 2020. China Fruit Veg. 2022, 42, 1–6. [Google Scholar] [CrossRef]

- Vasylieva, N.; James, H. Production and trade patterns in the world apple market. Innov. Mark. 2021, 17, 16–25. [Google Scholar] [CrossRef]

- Bondonno, C.P.; Bondonno, N.P.; Shinde, S.; Shafaei, A.; Boyce, M.C.; Swinny, E.; Jacob, S.R.; Lacey, K.; Woodman, R.J.; Croft, K.D.; et al. Phenolic composition of 91 Australian apple varieties: Towards understanding their health attributes. Food Funct. 2020, 11, 7115–7125. [Google Scholar] [CrossRef]

- Skinner, R.C.; Gigliotti, J.C.; Ku, K.M.; Tou, J.C. A comprehensive analysis of the composition, health benefits, and safety of apple pomace. Nutr. Rev. 2018, 76, 893–909. [Google Scholar] [CrossRef]

- Kim, S.J.; Anh, N.H.; Jung, C.W.; Long, N.P.; Park, S.; Cho, Y.H.; Yoon, Y.C.; Lee, E.G.; Kim, M.; Son, E.Y.; et al. Metabolic and Cardiovascular Benefits of Apple and Apple-Derived Products: A Systematic Review and Meta-Analysis of Randomized Controlled Trials. Front. Nutr. 2022, 9, 766155. [Google Scholar] [CrossRef]

- Liddle, D.M.; Lin, X.; Cox, L.C.; Ward, E.M.; Ansari, R.; Wright, A.J.; Robinson, L.E. Daily apple consumption reduces plasma and peripheral blood mononuclear cell-secreted inflammatory biomarkers in adults with overweight and obesity: A 6-week randomized, controlled, parallel-arm trial. Am. J. Clin. Nutr. 2021, 114, 752–763. [Google Scholar] [CrossRef]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple Pomace as a Functional and Healthy Ingredient in Food Products: A Review. Processes 2020, 8, 319. [Google Scholar] [CrossRef] [Green Version]

- Basumatary, I.B.; Mukherjee, A.; Katiyar, V.; Kumar, S. Biopolymer-based nanocomposite films and coatings: Recent advances in shelf-life improvement of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2022, 62, 1912–1935. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Harvest and Postharvest Factors Affecting Bruise Damage of Fresh Fruits. Hortic. Plant J. 2020, 6, 1–13. [Google Scholar] [CrossRef]

- Zhou, T.T.; Sun, X.L.; Sun, Z.Z.; Peng, H.H.; Sun, T.; Hu, D. Current Status and Future Perspective of Spectroscopy and Imaging Technique Applications in Bruise Detection of Fruits and Vegetables: A Review. Spectrosc. Spectr. Anal. 2022, 42, 2657–2665. [Google Scholar] [CrossRef]

- Fried, M.; Zuern, L.; Stahnecker, E. Manufacture of Crosslinked Foamable Moldings from Olefin Polymers. U.S. Patent 4,166,890, 4 September 1979. [Google Scholar]

- Kuhnigk, J.; Standau, T.; Dörr, D.; Brütting, C.; Altstädt, V.; Ruckdäschel, H. Progress in the development of bead foams—A review. J. Cell. Plast. 2022, 58, 707–735. [Google Scholar] [CrossRef]

- Jiang, J.; Feng, W.; Zhao, D.; Zhai, W. Poly(ether imide)/Epoxy Foam Composites with a Microcellular Structure and Ultralow Density: Bead Foam Fabrication, Compression Molding, Mechanical Properties, Thermal Stability, and Flame-Retardant Properties. ACS Omega 2020, 5, 25784–25797. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.; Chen, J.; Chen, F.; Zhu, C.; Wu, D.; Wang, J.; Chen, K. Effects of cushioning materials and temperature on quality damage of ripe peaches according to the vibration test. Food Packag. Shelf Life 2020, 25, 100518. [Google Scholar] [CrossRef]

- Raps, D.; Hossieny, N.; Park, C.B.; Altstädt, V. Past and present developments in polymer bead foams and bead foaming technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Meng, X.; Liu, F.; Guo, C.; Ge, H.; Wu, H.; Wang, L.; Cai, F.; Xie, G. A Kind of Automatic Apple Sleeve Net Case Packing Machine. CN108327967B, 25 September 2018. [Google Scholar]

- Occhiuzzi, C.; D’Uva, N.; Nappi, S.; Amendola, S.; Giallucca, C.; Chiabrando, V.; Garavaglia, L.; Giacalone, G.; Marrocco, G. Radio-Frequency-Identification-Based Intelligent Packaging: Electromagnetic Classification of Tropical Fruit Ripening. IEEE Antennas Propag. Mag. 2020, 62, 64–75. [Google Scholar] [CrossRef]

- Rodriguez-Parada, L.; Mayuet, P.F.; Gamez, A.J. Custom Design of Packaging through Advanced Technologies: A Case Study Applied to Apples. Materials 2019, 12, 467. [Google Scholar] [CrossRef] [Green Version]

- Suprem, A.; Mahalik, N.; Kim, K. A review on application of technology systems, standards and interfaces for agriculture and food sector. Comput. Stand. Interfaces 2013, 35, 355–364. [Google Scholar] [CrossRef]

- Giefer, L.A.; Arango Castellanos, J.D.; Babr, M.M.; Freitag, M. Deep Learning-Based Pose Estimation of Apples for Inspection in Logistic Centers Using Single-Perspective Imaging. Processes 2019, 7, 424. [Google Scholar] [CrossRef] [Green Version]

- Bhargava, A.; Bansal, A. Machine learning based quality evaluation of mono-colored apples. Multimed. Tools Appl. 2020, 79, 22989–23006. [Google Scholar] [CrossRef]

- Elkaoud, N.S.M.; Mahmoud, R.K. Design and implementation of sequential fruit size sorting machine. Rev. Bras. Eng. Agric. E Ambient. 2022, 26, 722–728. [Google Scholar] [CrossRef]

- Zhang, Z.; Igathinathane, C.; Li, J.; Cen, H.; Lu, Y.; Flores, P. Technology progress in mechanical harvest of fresh market apples. Comput. Electron. Agric. 2020, 175, 105606. [Google Scholar] [CrossRef]

- Vallone, M.; Alleri, M.; Bono, F.; Catania, P. A New Wireless Device for Real-Time Mechanical Impact Evaluation in a Citrus Packing Line. Trans. ASABE 2020, 63, 1–9. [Google Scholar] [CrossRef]

- XU, Q.; Chen, H.; Pan, H.; Li, S. Design and test of foam net packing machine for spherical fruit. Trans. Chin. Soc. Agric. Eng. 2019, 35, 56–61. [Google Scholar]

- Hu, J.; Dai, Y.; WU, H.; Yang, Y. Design of automation equipment for apple protect foam net packaging. Manuf. Autom. 2021, 43, 102–106. [Google Scholar]

- Xia, H.; Zhen, W.; Chen, D.; Zeng, W. An Ordinary Multilayer Fruit Paper Bag Supplying Device for Fruit Bagging. HortScience 2019, 54, 1644–1649. [Google Scholar] [CrossRef]

- Liu, R.; Song, F.; Liu, X. The Design of the Automatic Fruit Packing Machine. Mech. Electr. Eng. Technol. 2017, 46, 79–81+127. [Google Scholar]

- Fan, P.; Yan, B.; Wang, M.; Lei, X.; Liu, Z.; Yang, F. Three-finger grasp planning and experimental analysis of picking patterns for robotic apple harvesting. Comput. Electron. Agric. 2021, 188, 106353. [Google Scholar] [CrossRef]

- Ji, W.; Tang, C.; Xu, B.; He, G. Contact force modeling and variable damping impedance control of apple harvesting robot. Comput. Electron. Agric. 2022, 198, 107026. [Google Scholar] [CrossRef]

- Wu, C.; Wang, Y.; Sun, Q.; Zhao, Y.; Zhang, L. Design and Test of Auxiliary Harvesting Device of Apple. Recent Pat. Eng. 2021, 15, 107–116. [Google Scholar] [CrossRef]

- Li, H.; Gao, P.; Cheng, W.; Yin, H.; Wu, H.; Wei, X. Tribological Properties of Wedge-Shaped Crown Texture on Surface of 3D Printed Photosensitive Resin. Eng. Plast. Appl. 2022, 50, 112–118+123. [Google Scholar]

| Technical Parameters | Value |

|---|---|

| Overall size(L · W · H)/(mm · mm · mm) | 3900 × 1550 × 1620 |

| Overall machine mass/(kg) | 132.4 |

| Net slackening mechanism stepper motor torque/(N·M) | 2.3 |

| Side posture adjustment mechanism stepper motor torque/(N·M) | 1.2 |

| Net traction conveyor mechanism stepper motor torque/(N·M) | 2.3 |

| Feeding device conveyor belt line speed/(m/s) | 0–0.17 |

| Discharge mechanism conveyor belt line speed/(m/s) | 0.17 |

| Side posture adjustment mechanism rudder power/(kg·cm) | 20.5 |

| Apple posture adjustment disc rotation line speed | 0.31 |

| Electric cylinder line speed/(m/s) | 0.1 |

| Work efficiency/(pcs/h) | 355–365 |

| Serial Number | Opening Size/(mm) | Required Tension(N) |

|---|---|---|

| 1 | 80 | 1.82 |

| 2 | 85 | 2.03 |

| 3 | 90 | 2.24 |

| 4 | 95 | 2.38 |

| 5 | 100 | 2.42 |

| 6 | 105 | 2.53 |

| 7 | 110 | 2.74 |

| 8 | 115 | 2.93 |

| 9 | 120 | 3.15 |

| 10 | 125 | 3.28 |

| 11 | 130 | 3.42 |

| 12 | 135 | 3.55 |

| 13 | 140 | 3.67 |

| 14 | 145 | 3.78 |

| 15 | 150 | 3.96 |

| Properties | Value | Unit |

|---|---|---|

| Modulus of elasticity | 2.1 × 1011 | N/m2 |

| Poisson’s ratio | 0.28 | |

| Shear modulus | 7.9 × 1010 | N/m2 |

| Mass density | 7700 | kg/m3 |

| Tension strength | 723,825,600 | N/m2 |

| Yield strength | 620,422,000 | N/m2 |

| Coefficient of thermal expansion | 1.3 × 10−5 | /K |

| Thermal conductivity | 50 | W/(m·k) |

| Specific heat | 460 | J/(kg·k) |

| Total Sample /pcs | Length of Packing Net/mm | Quantity/ pcs | Posture Adjustment Rate/% | Net Rate/% | Packing Rate/% | Packaging Speed /(s/pcs) | Work Efficiency /(pcs/h) |

|---|---|---|---|---|---|---|---|

| 135–137 mm | 8 | ||||||

| 100 | 138–140 mm | 41 | 99% | 99% | 98.10% | 10 | 355–365 |

| 141–143 mm | 39 | ||||||

| 144–146 mm | 12 |

| Total Sample /pcs | Length of Packing Net/mm | Quantity/ pcs | Packaging Speed /(s/pcs) | Net Breakage Rate/% | Work Efficiency /(pcs/h) |

|---|---|---|---|---|---|

| 135–137 mm | 6 | ||||

| 100 | 138–140 mm | 41 | 4 | 0% | 895–905 |

| 141–143 mm | 41 | ||||

| 144–146 mm | 12 |

| Total Sample /pcs | Posture Adjustment Speed /(s/pcs) | Work Efficiency /(pcs/h) |

|---|---|---|

| 100 | 9.5 | 374–384 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Sun, Q.; Wang, Q.; Liang, Z.; Zhao, Y.; Yu, X.; Xu, H. Design and Experiment of Apple Foam Net Sleeve Packaging Machine with Posture Adjustment Function. Machines 2023, 11, 436. https://doi.org/10.3390/machines11040436

He S, Sun Q, Wang Q, Liang Z, Zhao Y, Yu X, Xu H. Design and Experiment of Apple Foam Net Sleeve Packaging Machine with Posture Adjustment Function. Machines. 2023; 11(4):436. https://doi.org/10.3390/machines11040436

Chicago/Turabian StyleHe, Shisheng, Qun Sun, Quanjin Wang, Zhiqin Liang, Ying Zhao, Xiuhao Yu, and Haigang Xu. 2023. "Design and Experiment of Apple Foam Net Sleeve Packaging Machine with Posture Adjustment Function" Machines 11, no. 4: 436. https://doi.org/10.3390/machines11040436

APA StyleHe, S., Sun, Q., Wang, Q., Liang, Z., Zhao, Y., Yu, X., & Xu, H. (2023). Design and Experiment of Apple Foam Net Sleeve Packaging Machine with Posture Adjustment Function. Machines, 11(4), 436. https://doi.org/10.3390/machines11040436