Identification Modelling and Fault-Tolerant Predictive Control for Industrial Input Nonlinear Actuator System

Abstract

:1. Introduction

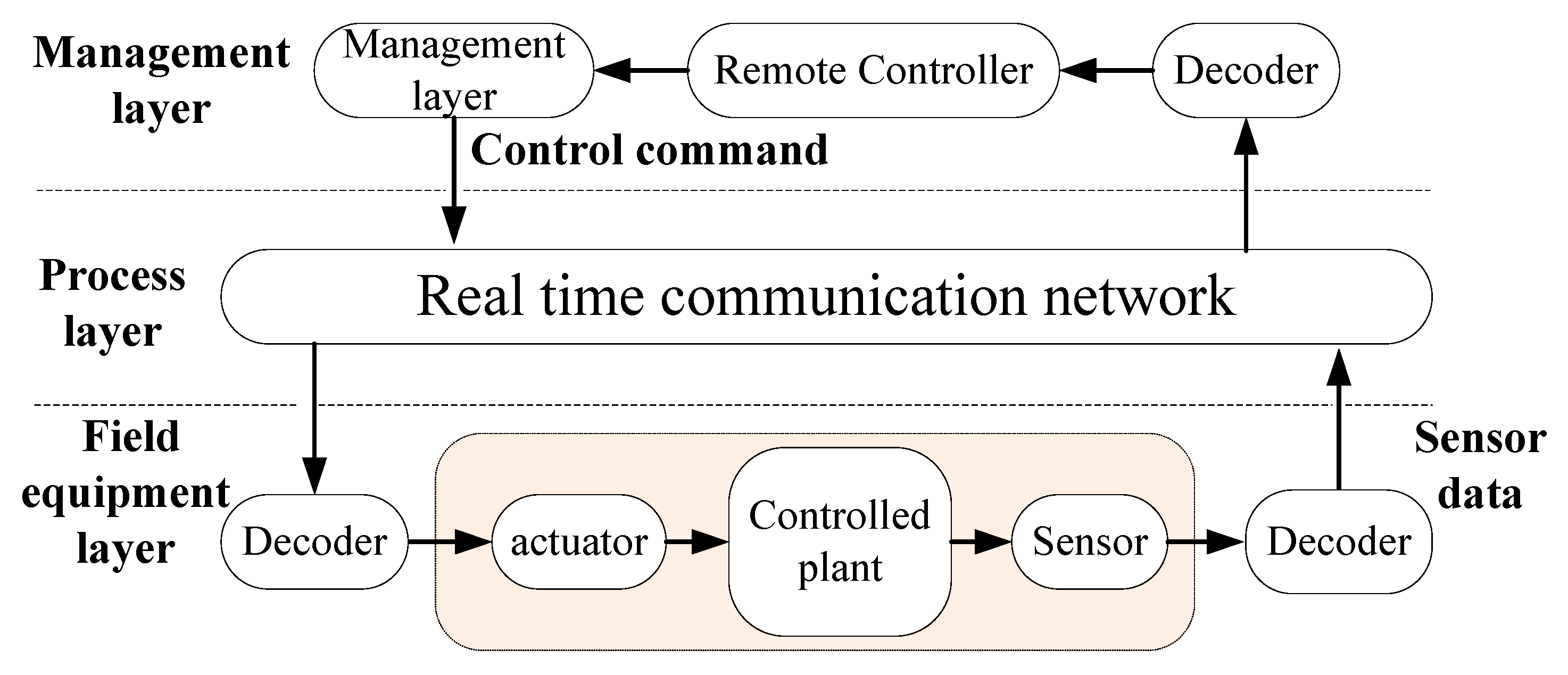

2. Industrial Control System

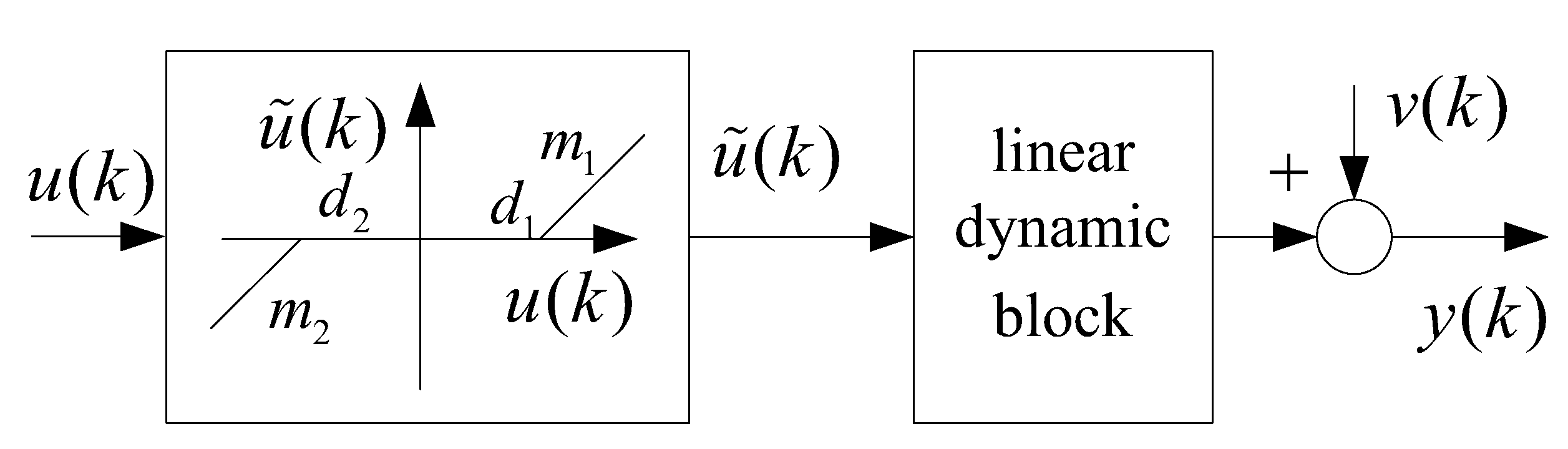

3. Modeling Problem Description

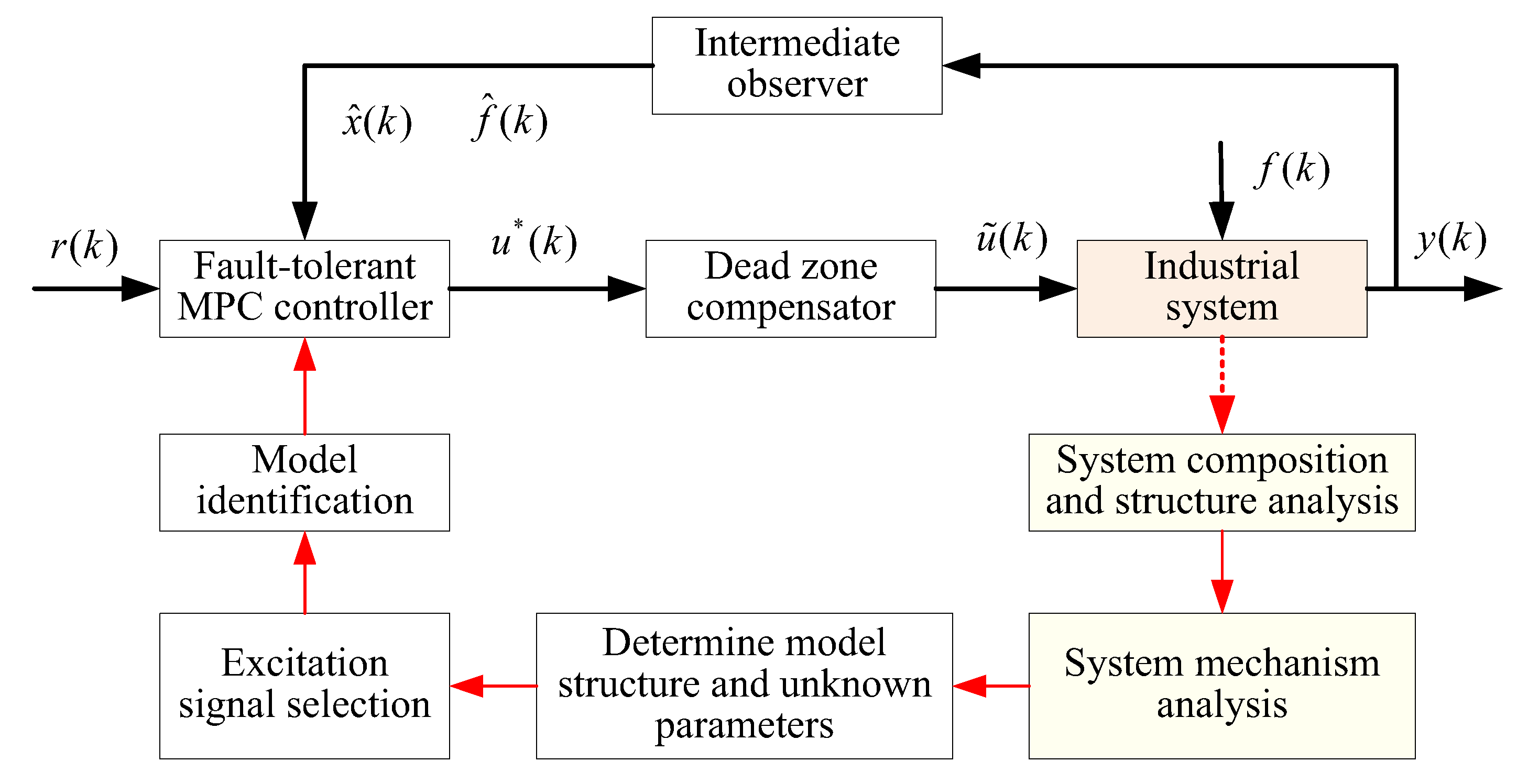

4. Parametric Identification Algorithm

4.1. Identification Algorithm

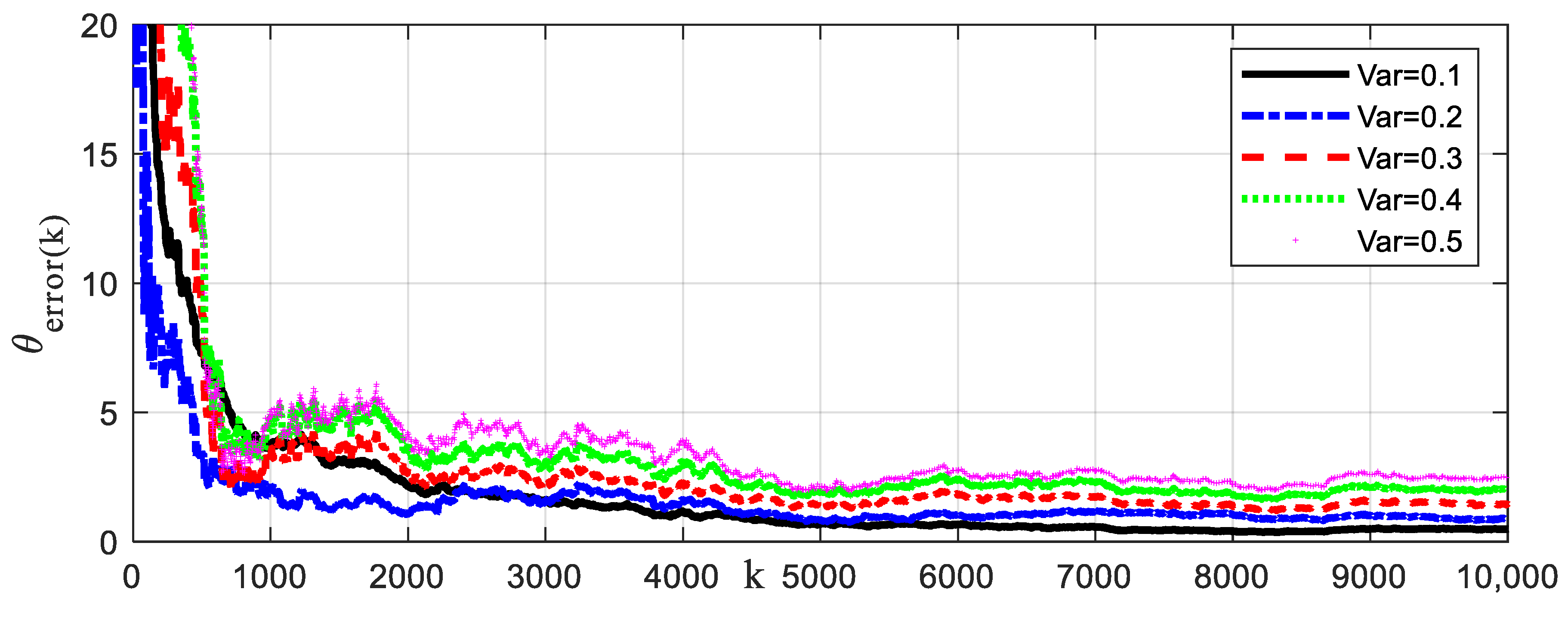

4.2. Convergence Characteristic of Identification Algorithm

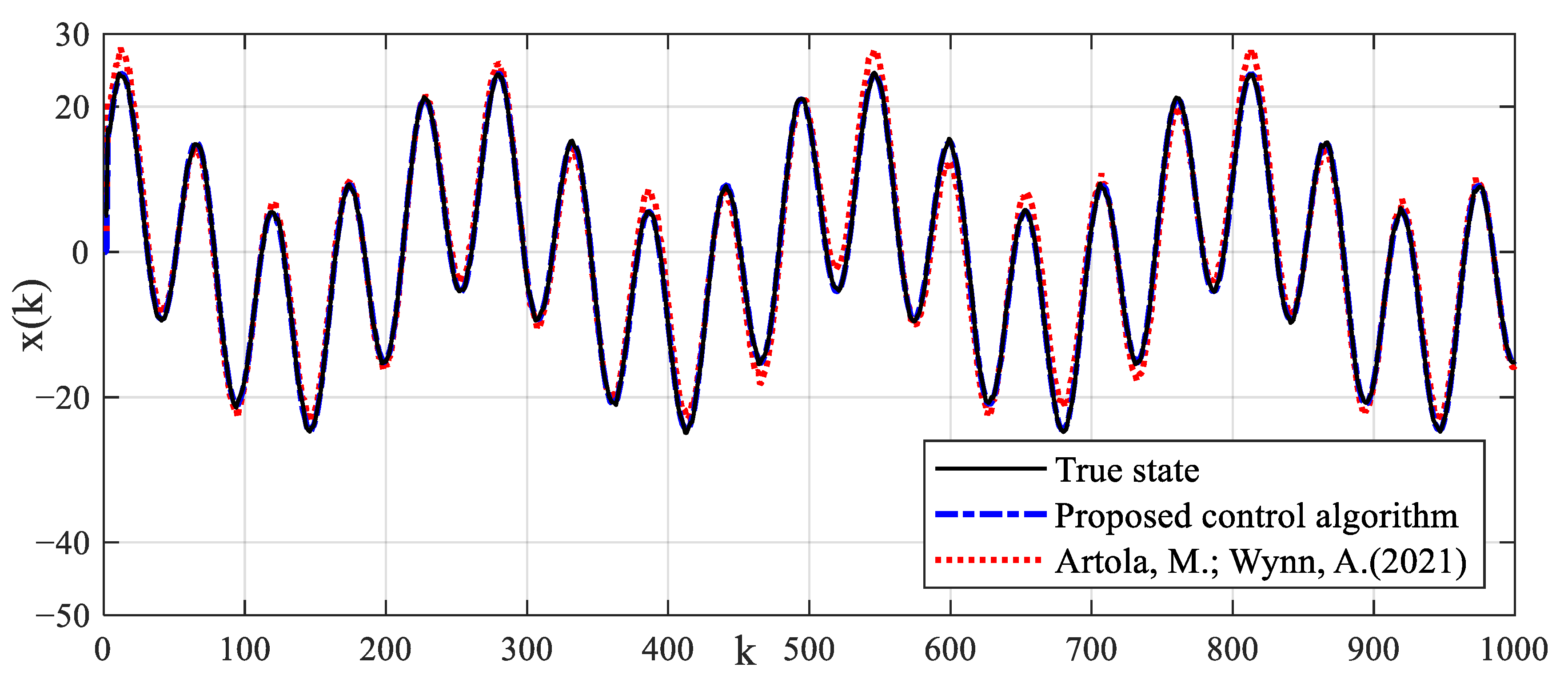

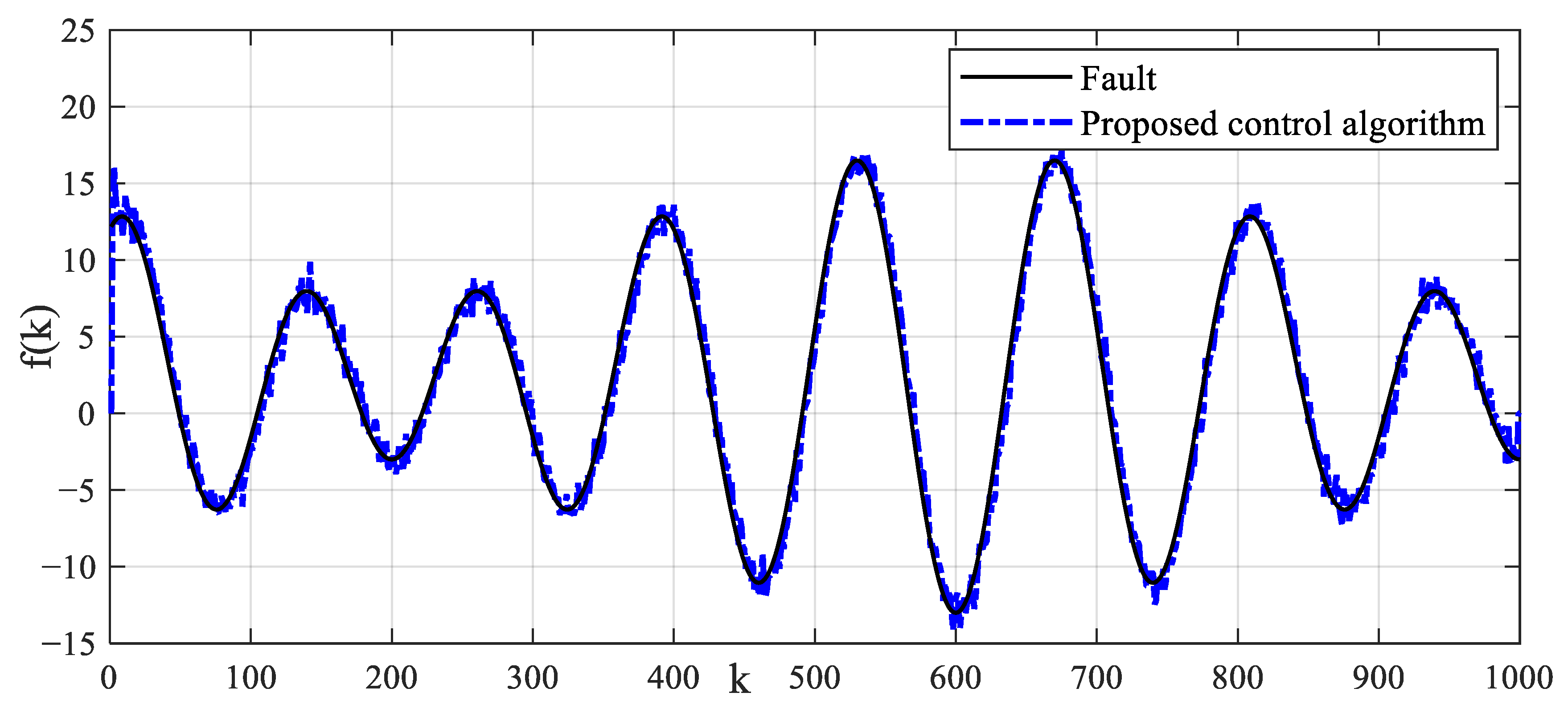

5. Fault-Tolerant MPC Control

5.1. Fault-Tolerant Control Based on Intermediate Observer

5.2. Fault-Tolerant Model Predictive Control Based on Identification Model

6. Validation Examples

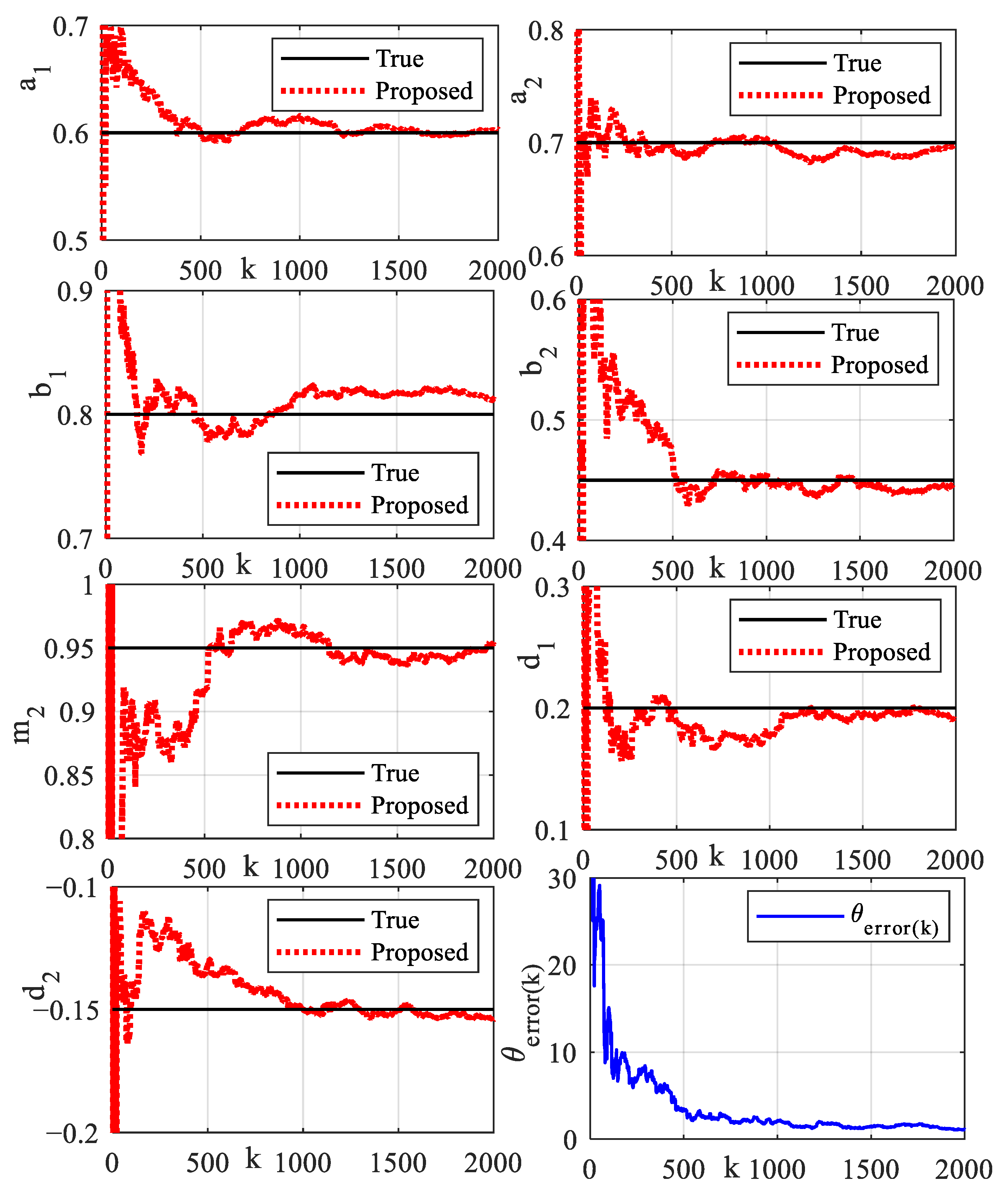

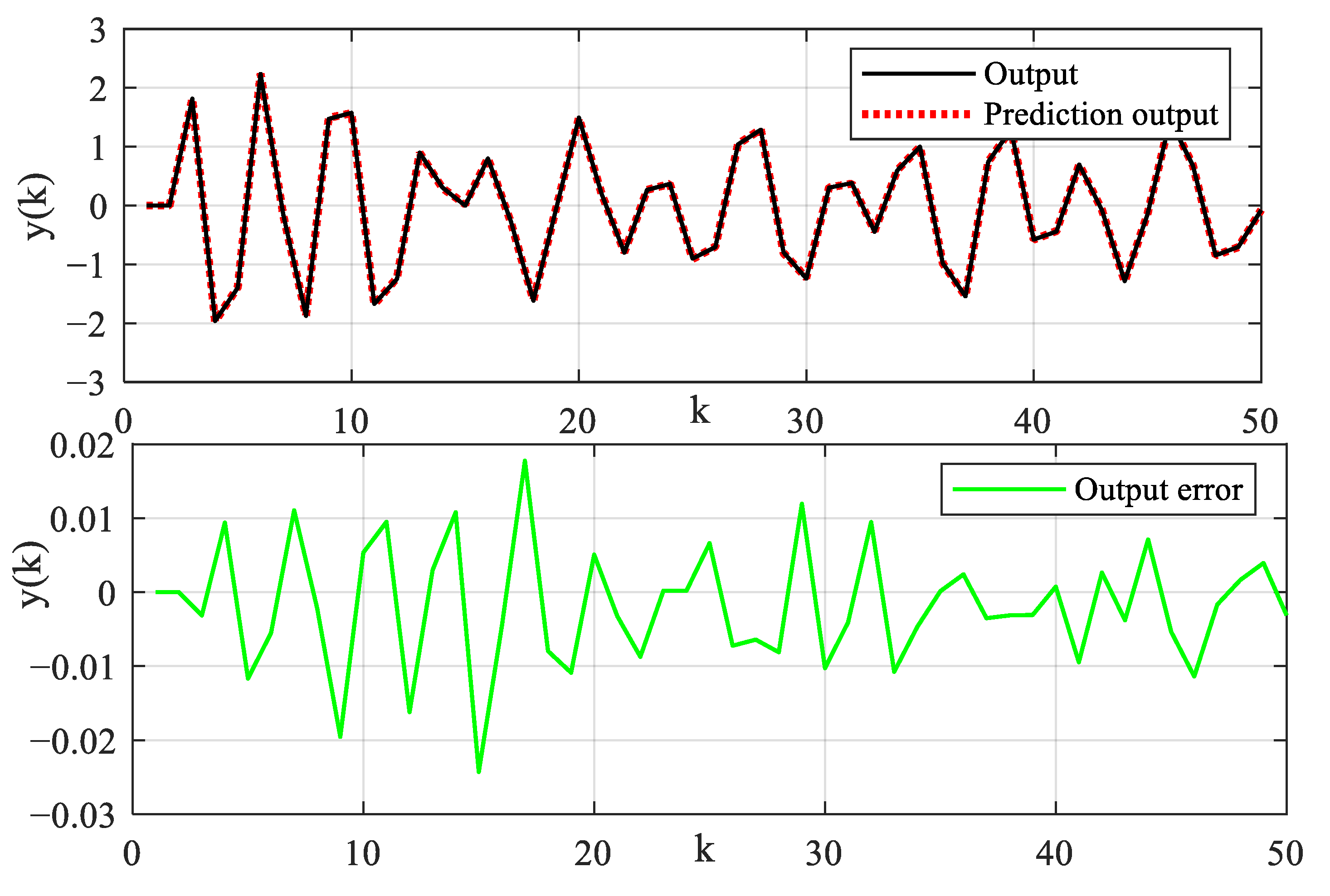

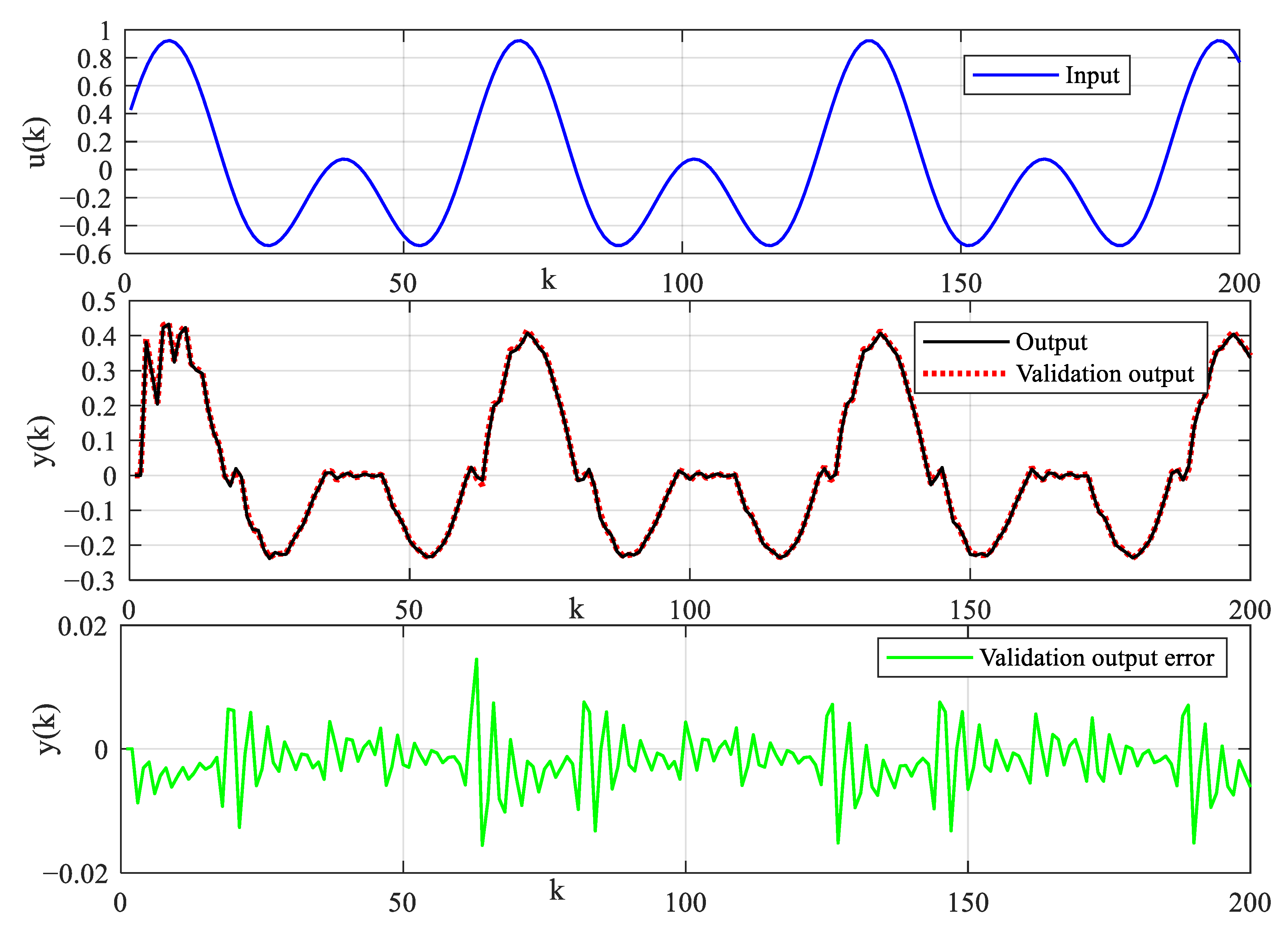

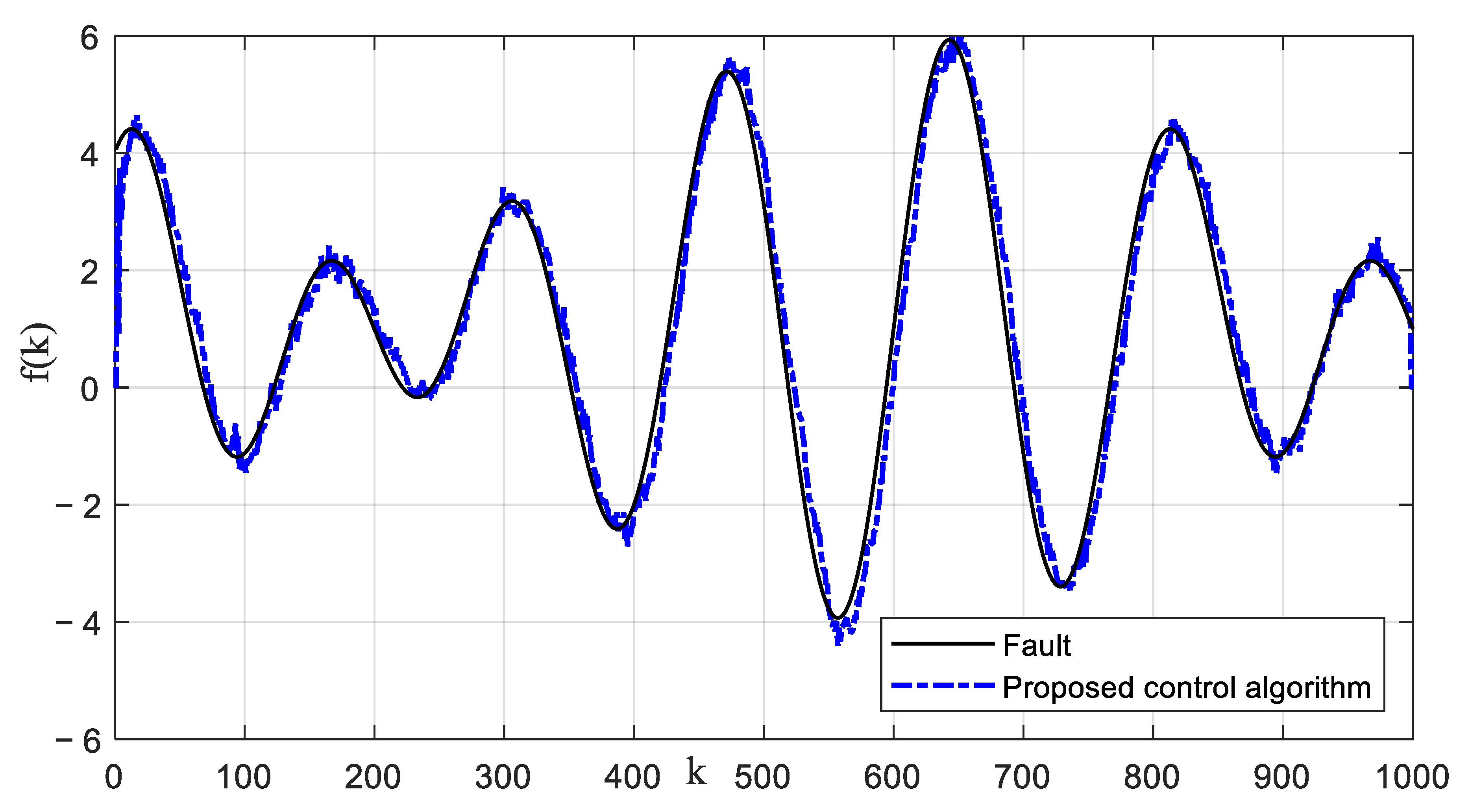

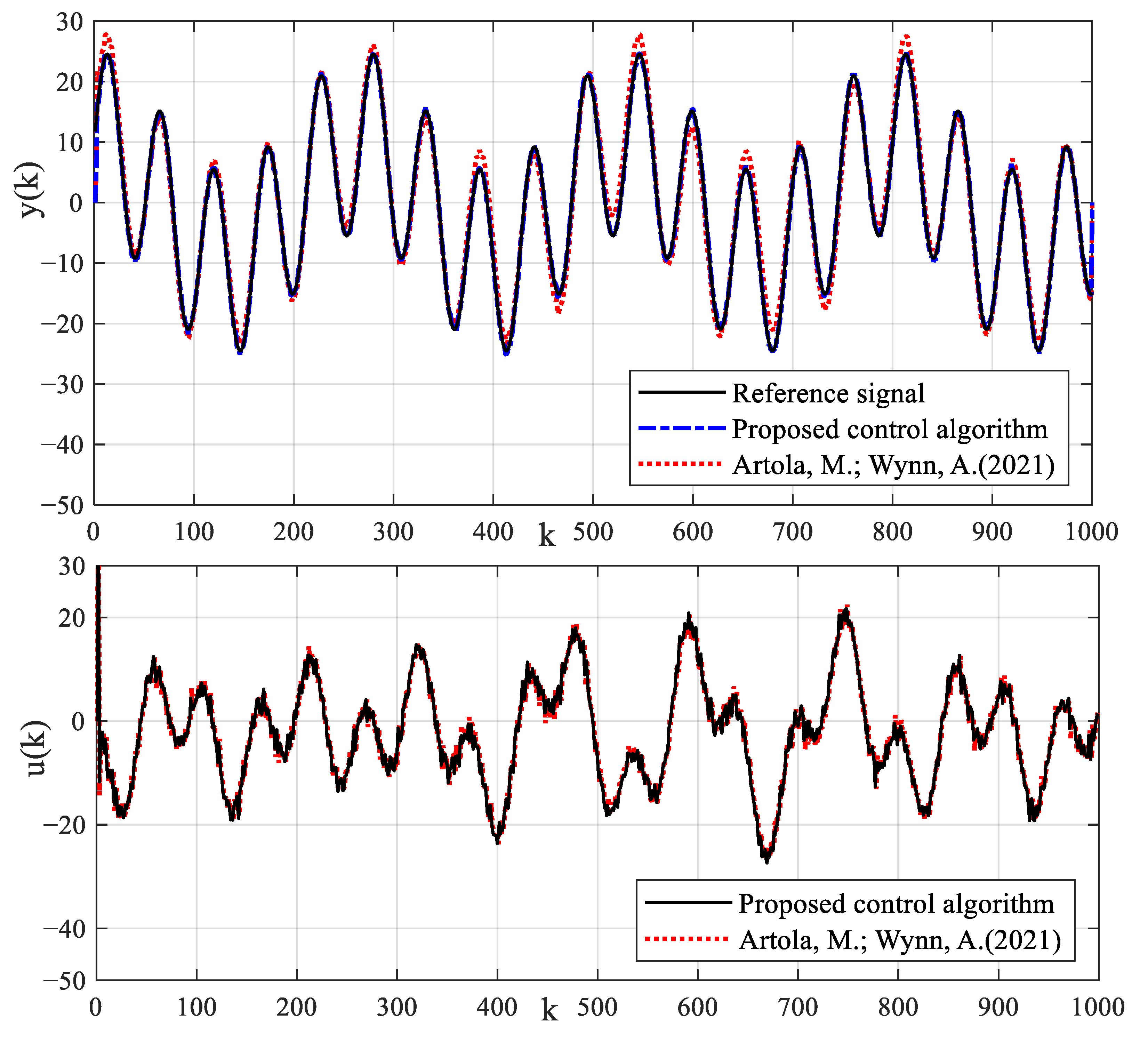

6.1. Numerical Example

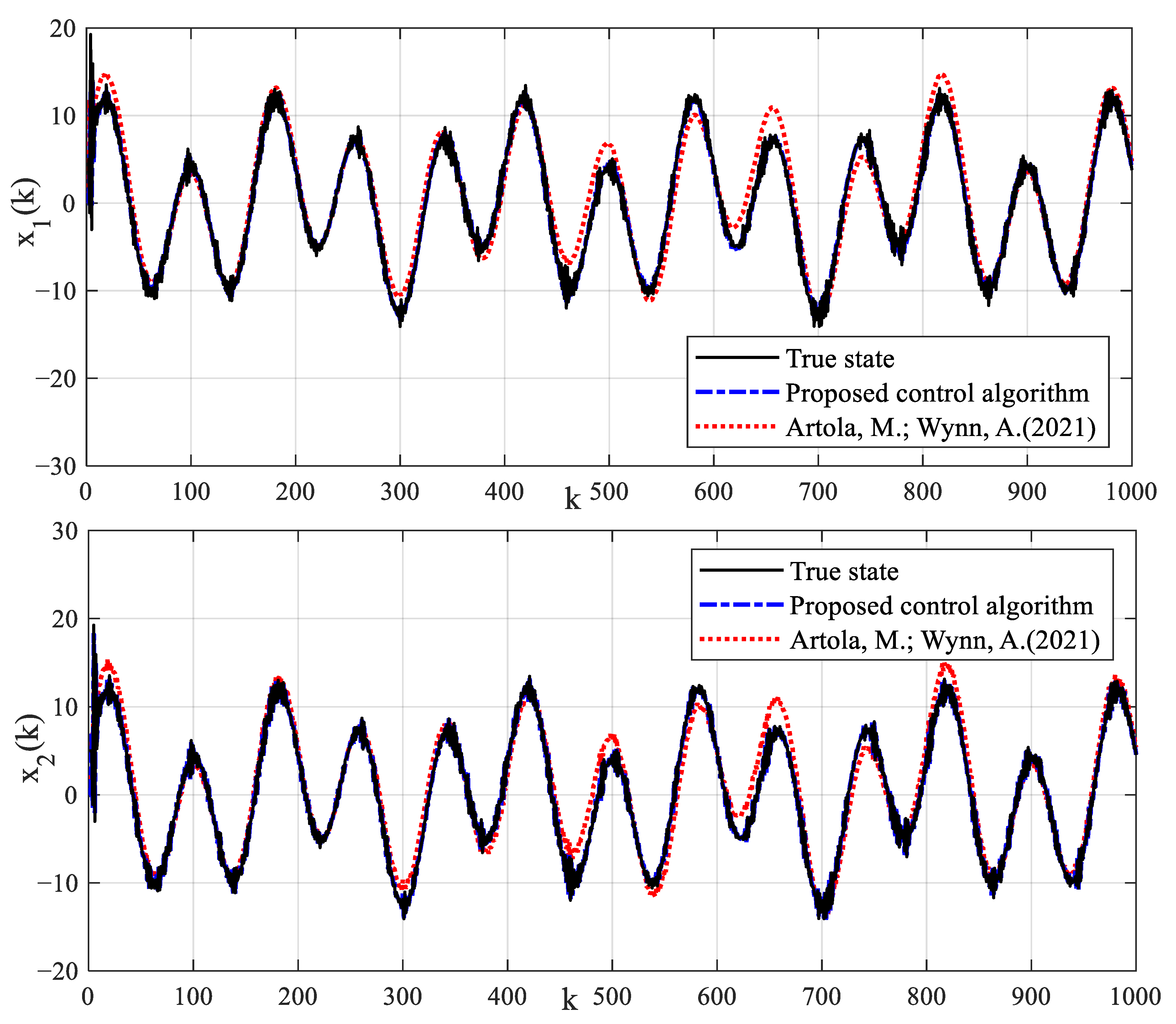

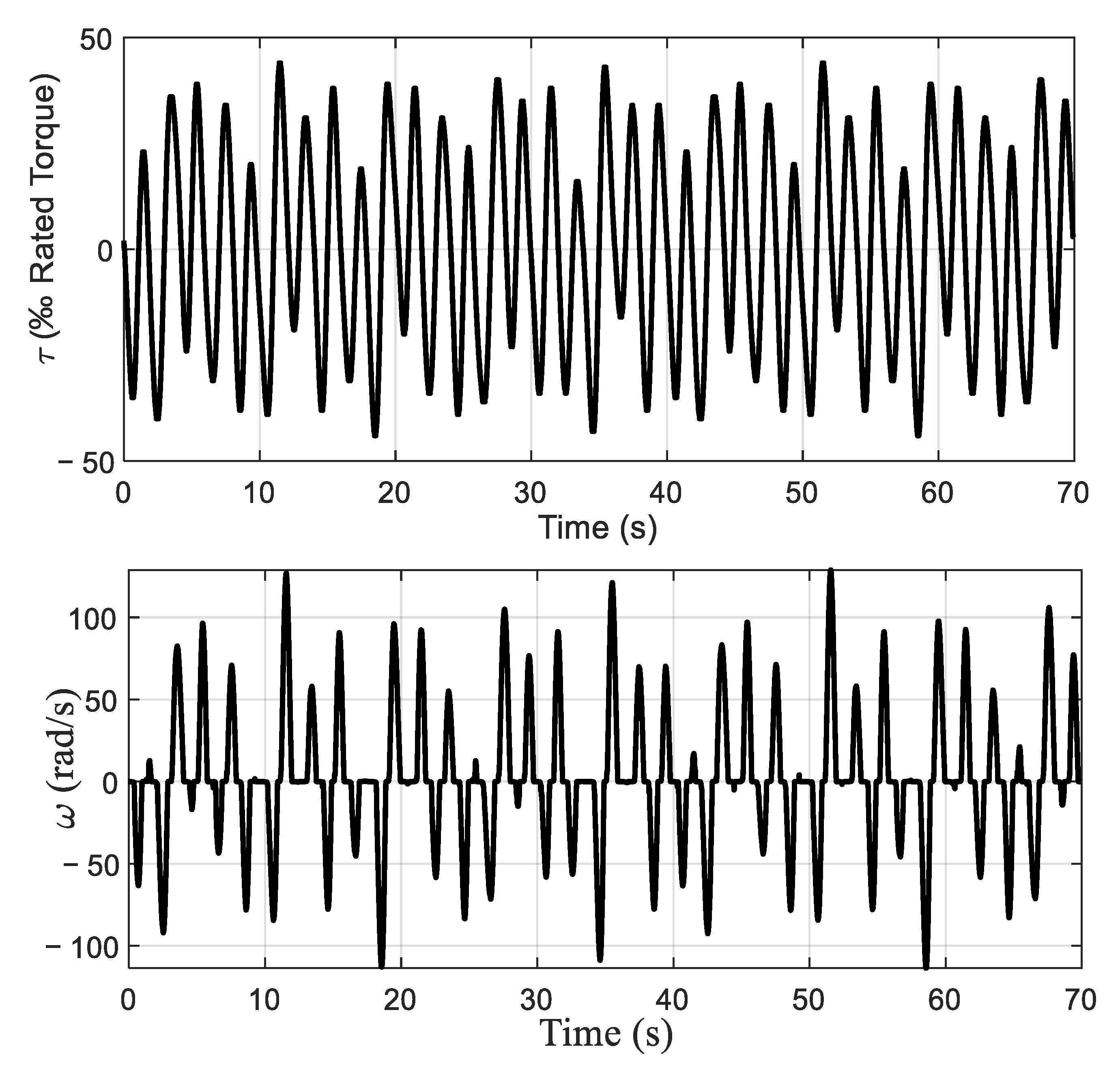

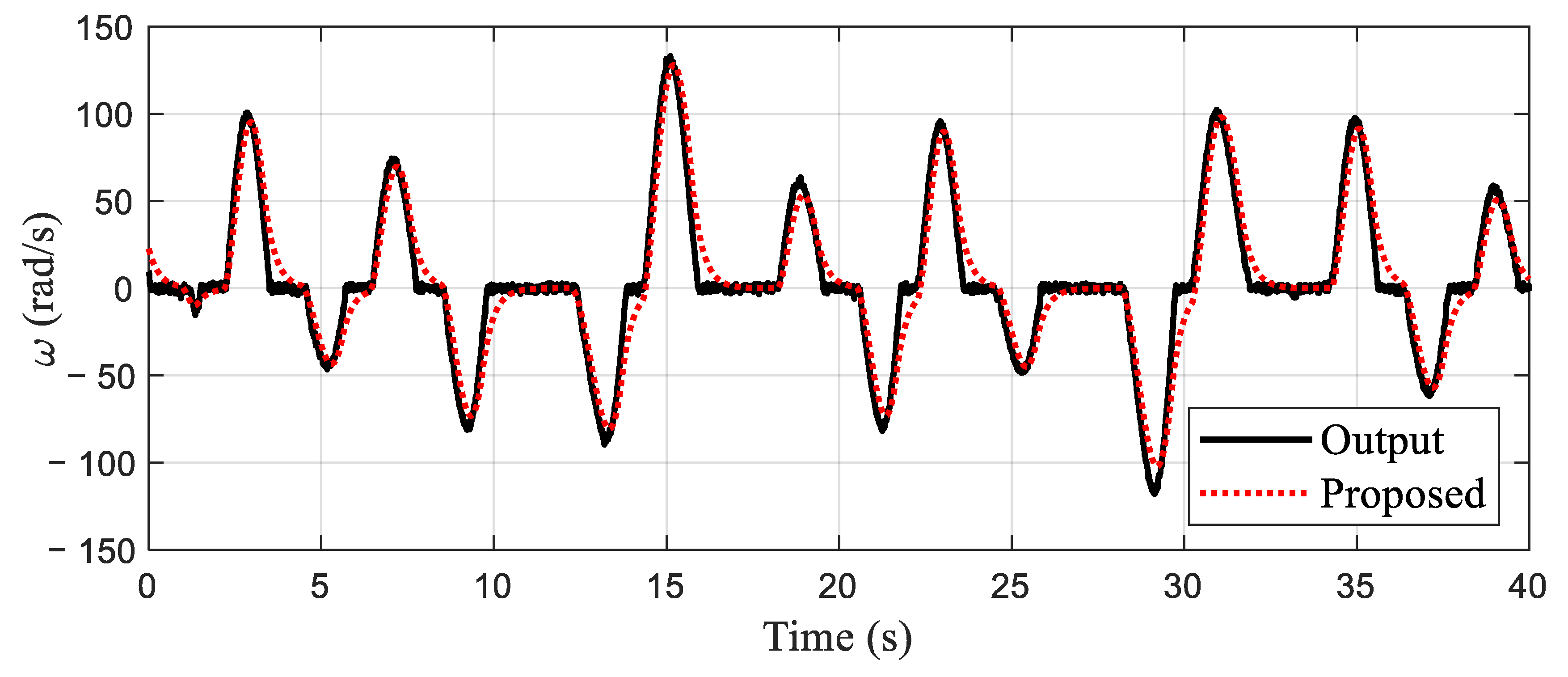

6.2. Experimental Test

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, X.; Wang, F.; Pan, J. 3-D online modeling and assessment of operating performance for nonstationary industrial processes with nonlinearity. J. Process Control 2021, 101, 1–10. [Google Scholar] [CrossRef]

- Costa, T.V.; Sencio, R.R.; Oliveira-Lopes, L.C.; Silva, F.V. Fault-tolerant control by means of moving horizon virtual actuators: Concepts and experimental investigation. Control Eng. Pract. 2021, 107, 104683. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, X.; Li, P.; Li, Y.; Su, Z.; Liu, H.; Lu, Z.; Yao, M. Modeling, Identification, and Compensation Control of Friction for a Novel Dual-Drive Hydrostatic Lead Screw Micro-Feed System. Machines 2022, 10, 914. [Google Scholar] [CrossRef]

- Mi, W.; Zheng, W.X. Adaptive Rational Orthogonal Basis Functions for Identification of Continuous-Time Systems. IEEE Trans. Autom. Control 2020, 66, 1809–1816. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, H.; Liu, C. MILM hybrid identification method of fractional order neural-fuzzy Hammerstein model. Nonlinear Dyn. 2022, 108, 2337–2351. [Google Scholar] [CrossRef]

- Teng, A.; Wu, Q.; Yang, T.; Sun, L.; Sun, N. X-Shaped Structure-Based Modeling and Control for a Stable Platform with a Series Elastic Actuator. Machines 2022, 10, 430. [Google Scholar] [CrossRef]

- Abreu, P.E.; Tavares, L.A.; Teixeira, B.O.; Aguirre, L.A. Identification and nonlinearity compensation of hysteresis using NARX models. Nonlinear Dyn. 2020, 102, 285–301. [Google Scholar] [CrossRef]

- Dai, J.; Chen, N.; Yuan, X.; Gui, W.; Luo, L. Temperature prediction for roller kiln based on hybrid first-principle model and data-driven MW-DLWKPCR model. ISA Trans. 2020, 98, 403–417. [Google Scholar] [CrossRef]

- Pappalardo, C.M.; Guida, D. System identification algorithm for computing the modal parameters of linear mechanical systems. Machines 2018, 6, 12. [Google Scholar] [CrossRef]

- Yu, M.; Guo, G.; Liu, J.; Shang, L. Closed-loop time-varying continuous-time recursive subspace-based prediction via principle angles rotation. ISA Trans. 2022, 122, 135–145. [Google Scholar] [CrossRef]

- Mi, W.; Rao, H.; Qian, T.; Zhong, S. Identification of discrete Hammerstein systems by using adaptive finite rational orthogonal basis functions. Appl. Math. Comput. 2019, 361, 354–364. [Google Scholar] [CrossRef]

- Palkin, G.; Suvorov, I. Simulation Modeling of First Rise Section of Water Supply System with Installed Complex of Automatic Pump Performance Control. Machines 2021, 9, 63. [Google Scholar] [CrossRef]

- Dong, S.; Yu, L.; Zhang, W.A.; Chen, B. Robust extended recursive least squares identification algorithm for Hammerstein systems with dynamic disturbances. Digit. Signal Process. 2020, 101, 102716. [Google Scholar] [CrossRef]

- Chen, F.; Young, P.C. A simple robust method of fractional time-delay estimation for linear dynamic systems. Automatica 2022, 137, 110117. [Google Scholar] [CrossRef]

- Du, N.; Zhang, L.; Long, X.; Yang, X.; Yu, F. Recursive identification for choke finger system in wind tunnel. ISA Trans. 2020, 107, 173–180. [Google Scholar] [CrossRef] [PubMed]

- Giri, F.; Rochdi, Y.; Chaoui, F.Z. Hammerstein systems identification in presence of hard nonlinearities of preload and dead-zone type. IEEE Trans. Autom. Control 2009, 54, 2174–2178. [Google Scholar] [CrossRef]

- Hadid, B.; Duviella, E.; Lecoeuche, S. Data-driven modeling for river flood forecasting based on a piecewise linear ARX system identification. J. Process Control 2020, 86, 44–56. [Google Scholar] [CrossRef]

- Yu, F.; Mao, Z.; Jia, M. Recursive identification for Hammerstein–Wiener systems with dead-zone input nonlinearity. J. Process Control 2013, 23, 1108–1115. [Google Scholar] [CrossRef]

- Na, J.; He, H.; Huang, Y.; Dong, R. Adaptive estimation of asymmetric dead-zone parameters for sandwich systems. IEEE Trans. Control Syst. Technol. 2021, 30, 1336–1344. [Google Scholar] [CrossRef]

- Ding, S.X. Advanced Methods for Fault Diagnosis and Fault-Tolerant Control; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Deng, C.; Yang, G.H. Distributed adaptive fault-tolerant control approach to cooperative output regulation for linear multi-agent systems. Automatica 2019, 103, 62–68. [Google Scholar] [CrossRef]

- Ning, X.; Zhang, Y.; Wang, Z.; Yu, D.; Guo, H.; Mei, H. BLS-based adaptive fault tolerant control for a class of space unmanned systems with time-varying state constraints and input nonlinearities. Eur. J. Control 2021, 61, 1–12. [Google Scholar] [CrossRef]

- Yang, X.; Gao, J.; Li, L.; Luo, H.; Ding, S.X.; Peng, K. Data-driven design of fault-tolerant control systems based on recursive stable image representation. Automatica 2020, 122, 109246. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, Z.; He, W.; Hong, K.S.; Li, H.X. Boundary adaptive fault-tolerant control for a flexible Timoshenko arm with backlash-like hysteresis. Automatica 2021, 130, 109690. [Google Scholar] [CrossRef]

- Li, Z.; Yang, G.H. Integrated design of event-triggered closed-loop subspace predictive control scheme. IEEE/ASME Trans. Mechatron. 2017, 23, 80–88. [Google Scholar] [CrossRef]

- Guo, G.; Wang, Y. An integrated MPC and deep reinforcement learning approach to trams-priority active signal control. Control Eng. Pract. 2021, 110, 104758. [Google Scholar] [CrossRef]

- Xie, S.; Xie, Y.; Gui, W.; Yang, C. Weighted-coupling CSTR modeling and model predictive control with parameter adaptive correction for the goethite process. J. Process Control 2018, 68, 254–267. [Google Scholar] [CrossRef]

- He, D.; Wang, L.; Sun, J. On stability of multiobjective NMPC with objective prioritization. Automatica 2015, 57, 189–198. [Google Scholar] [CrossRef]

- Galuppini, G.; Magni, L.; Raimondo, D.M. Model predictive control of systems with deadzone and saturation. Control Eng. Pract. 2018, 78, 56–64. [Google Scholar] [CrossRef]

- Zhang, B.; Mao, Z. Adaptive control of stochastic Hammerstein systems with dead-zone input non-linearity. Trans. Inst. Meas. Control 2015, 37, 746–759. [Google Scholar] [CrossRef]

- Bernardi, E.; Adam, E.J. Fault-tolerant predictive control based on linear parameter varying scheme for industrial processes. J. Taiwan Inst. Chem. Eng. 2021, 129, 1–14. [Google Scholar] [CrossRef]

- Ren, Y.; Zhu, P.; Zhao, Z.; Yang, J.; Zou, T. Adaptive fault-tolerant boundary control for a flexible string with unknown dead zone and actuator fault. IEEE Trans. Cybern. 2021, 52, 7084–7093. [Google Scholar] [CrossRef]

- Keller, R.; Ding, S.X.; Müller, M.; Stolten, D. Fault-tolerant model predictive control of a direct methanol-fuel cell system with actuator faults. Control Eng. Pract. 2017, 66, 99–115. [Google Scholar] [CrossRef]

- Qu, S.; He, T.; Zhu, G.G. Engine EGR valve modeling and switched LPV control considering nonlinear dry friction. IEEE/ASME Trans. Mechatron. 2020, 25, 1668–1678. [Google Scholar] [CrossRef]

- Pang, Z.H.; Xia, C.G.; Zhai, W.F.; Liu, G.P.; Han, Q. Networked active fault-tolerant predictive control for systems with random communication constraints and actuator/sensor faults. IEEE Trans. Circuits Syst. II Express Briefs 2021, 69, 2166–2170. [Google Scholar] [CrossRef]

- Heshmati-alamdari, S.; Eqtami, A.; Karras, G.C.; Dimarogonas, D.V.; Kyriakopoulos, K.J. A self-triggered position based visual servoing model predictive control scheme for underwater robotic vehicles. Machines 2020, 8, 33. [Google Scholar] [CrossRef]

- Artola, M.; Wynn, A.; Palacios, R. Modal-Based Nonlinear Model Predictive Control for 3-D Very Flexible Structures. IEEE Trans. Autom. Control 2021, 67, 2145–2160. [Google Scholar] [CrossRef]

| Parameter Name | Configuration |

|---|---|

| CPU | Core i5-4210M 2.6 GHz |

| RAM | 8 GM |

| Operating system | Windows10 64 bit |

| Embedded interface board chip | STM32F407ZGT6 168M Hz |

| Ethernet communication rate | 100 Mb/s |

| CAN communication rate | 1 Mb/s |

| Sampling period | 1 ms–5 ms |

| AC server | DeltaASDA-A2 |

| Permanent magnet synchronous motor | DeltaECMA-C10604RS |

| Electronic gear ratio | 1/128(10,000 pulses/cycles) |

| Sensor position accuracy | 5 × 10−4 mm |

| Range of liabilities for hysteresis | −10 N–10 N |

| 0.6 | 0.7 | 0.8 | 0.45 | 0.16 | 0.09 | 0.76 | 0.4275 | −0.076 | −0.04275 | ||

| 0.603 | 0.6979 | 0.8122 | 0.4454 | 0.1691 | 0.077 | 0.7644 | 0.4293 | −0.073 | −0.0513 | 1.473 |

| 100 | 0.695 | 0.734 | 0.862 | 0.639 | 0.248 | −0.082 | 0.860 | 15.079 |

| 1000 | 0.616 | 0.703 | 0.816 | 0.454 | 0.178 | −0.100 | 0.961 | 2.053 |

| 1500 | 0.602 | 0.691 | 0.817 | 0.445 | 0.192 | −0.101 | 0.941 | 1.454 |

| 2000 | 0.603 | 0.698 | 0.812 | 0.445 | 0.191 | −0.108 | 0.952 | 1.120 |

| True | 0.6 | 0.7 | 0.8 | 0.45 | 0.2 | −0.1 | 0.95 |

| Prediction Error | Validation Error | |

|---|---|---|

| Mean | −0.0021 | −0.0018 |

| Variance |

| Noise Variance | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 |

|---|---|---|---|---|---|

| NSR≈ | 9.5% | 19.1% | 28.6% | 38.2% | 47.8 |

| 0.49 | 0.92 | 1.45 | 2.03 | 2.51 |

| 1000 | −0.9917 | −0.3142 | 37.4050 | −23.0047 | −0.1903 |

| 2000 | −0.9857 | 0.1611 | 25.3040 | −20.2972 | 0.4977 |

| 3000 | −0.9779 | 0.1632 | 21.7613 | −19.6379 | 0.6746 |

| 4000 | −0.9716 | 0.1910 | 20.7626 | −20.3252 | 0.7600 |

| 5000 | −0.9678 | 0.2141 | 21.1731 | −20.2032 | 0.7478 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Zhang, Y. Identification Modelling and Fault-Tolerant Predictive Control for Industrial Input Nonlinear Actuator System. Machines 2023, 11, 240. https://doi.org/10.3390/machines11020240

Dong S, Zhang Y. Identification Modelling and Fault-Tolerant Predictive Control for Industrial Input Nonlinear Actuator System. Machines. 2023; 11(2):240. https://doi.org/10.3390/machines11020240

Chicago/Turabian StyleDong, Shijian, and Yuzhu Zhang. 2023. "Identification Modelling and Fault-Tolerant Predictive Control for Industrial Input Nonlinear Actuator System" Machines 11, no. 2: 240. https://doi.org/10.3390/machines11020240

APA StyleDong, S., & Zhang, Y. (2023). Identification Modelling and Fault-Tolerant Predictive Control for Industrial Input Nonlinear Actuator System. Machines, 11(2), 240. https://doi.org/10.3390/machines11020240