Investigating the Role of Stator Slot Indents in Minimizing Flooded Motor Fluid Damping Loss

Abstract

:1. Introduction

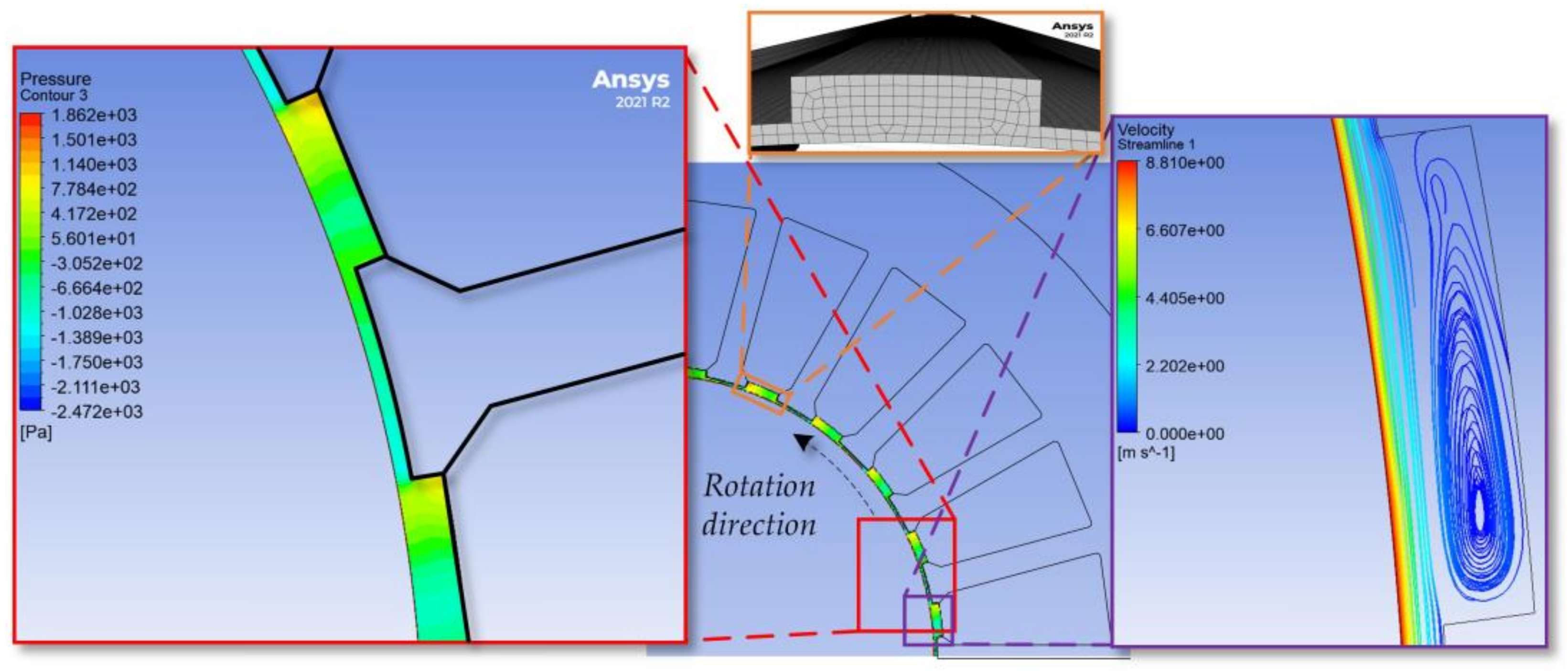

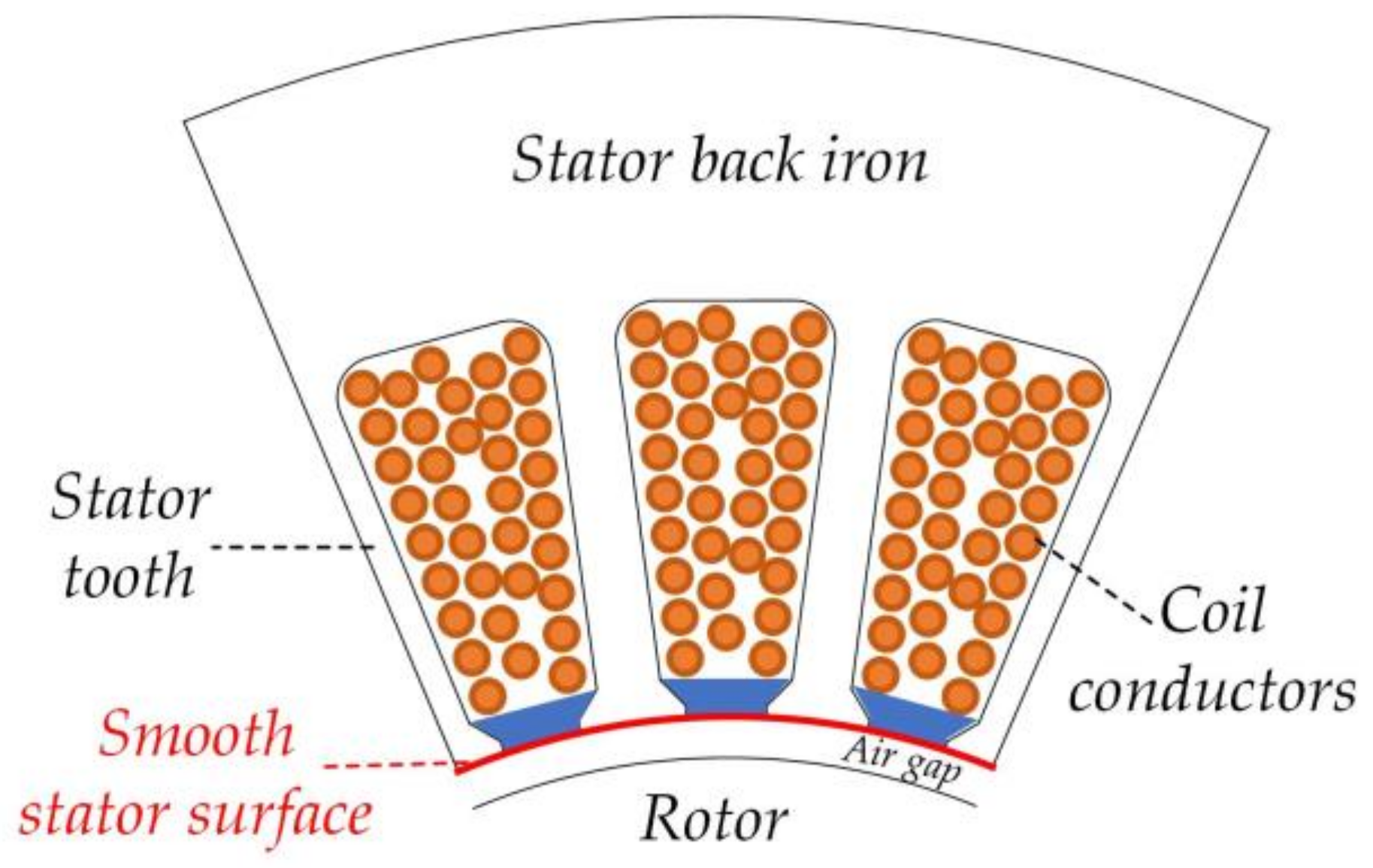

2. Fluid Damping Loss

3. Damping Loss Analysis with Different Slot Opening Structures

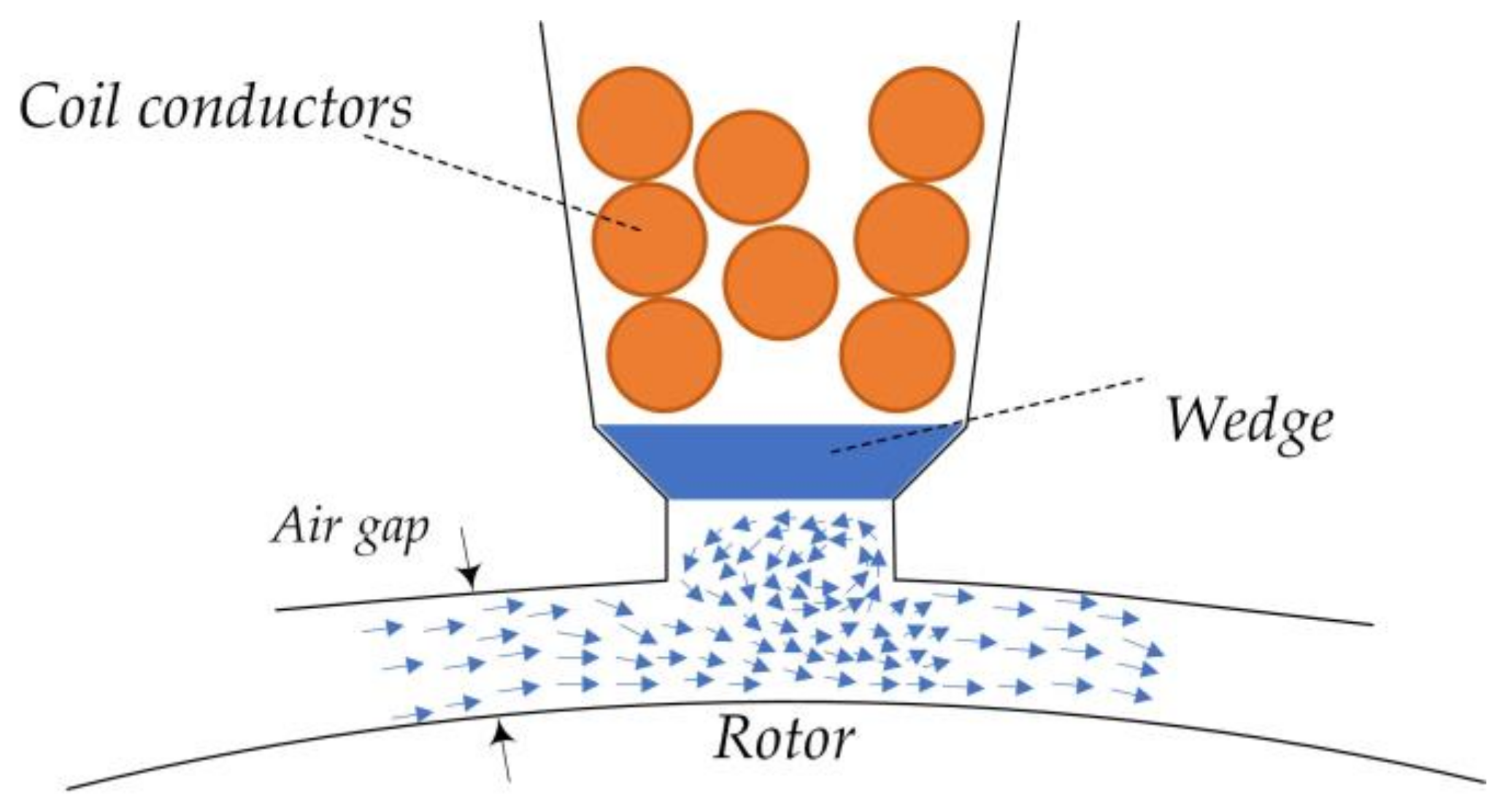

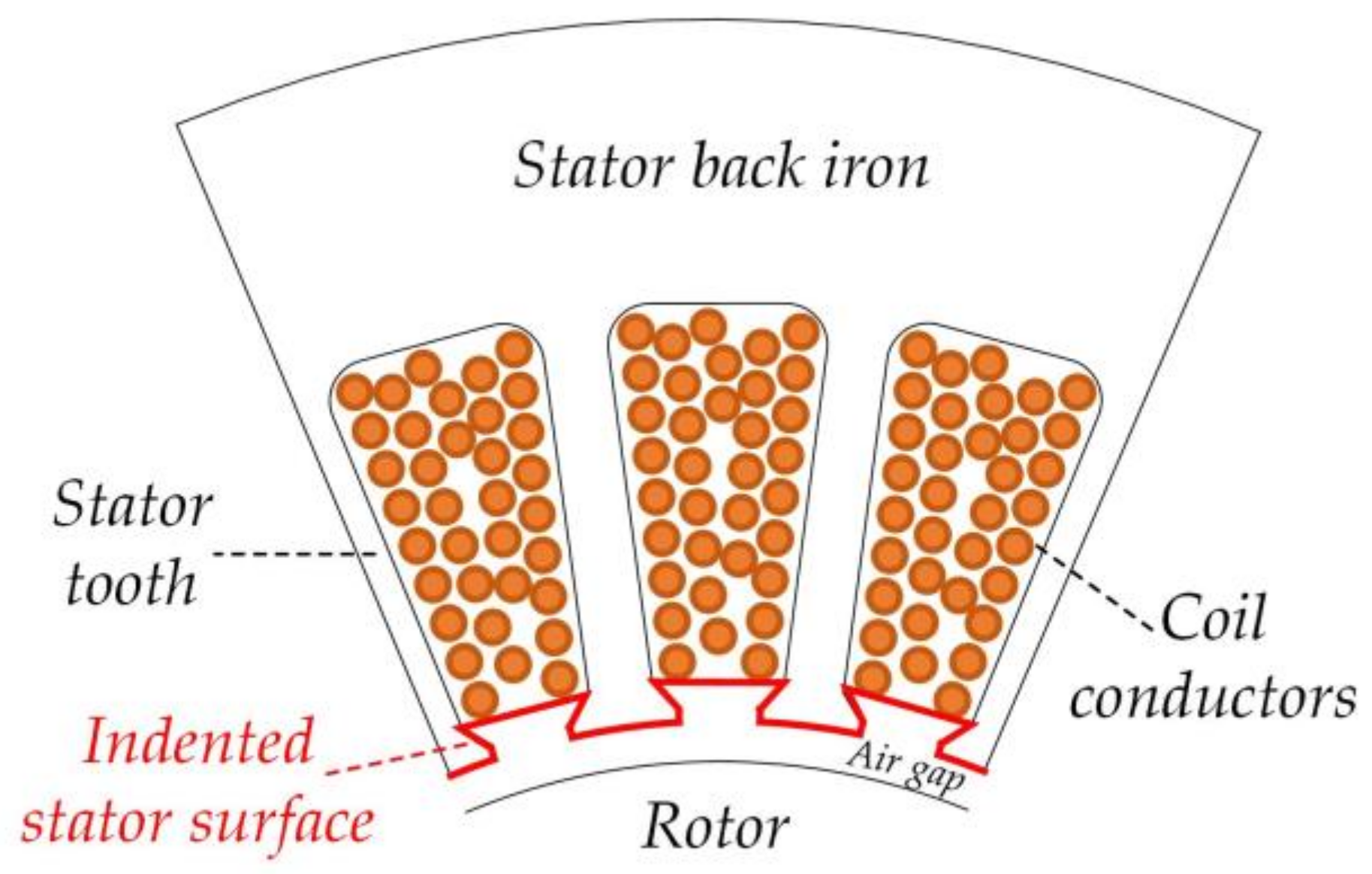

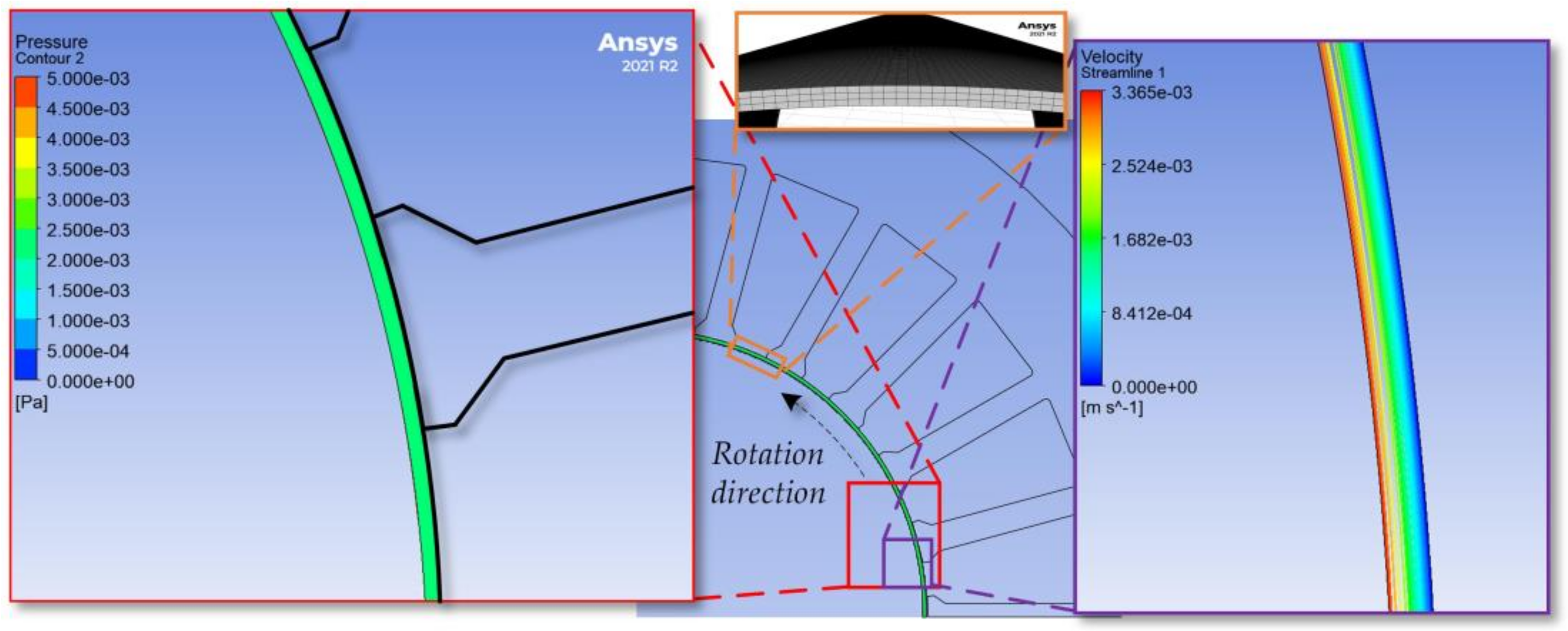

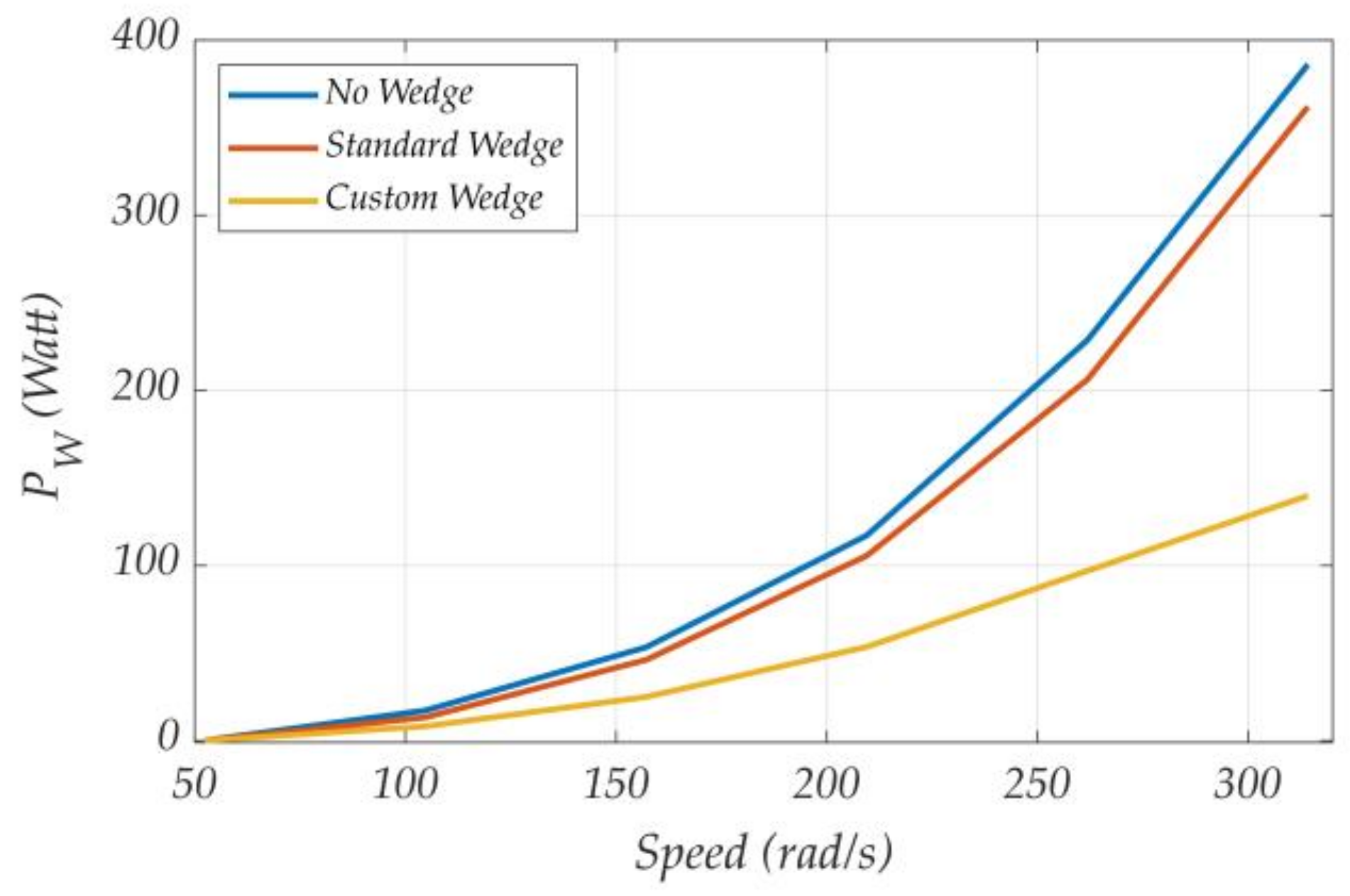

3.1. Analysis without a Wedge Inserted in Stator Slots

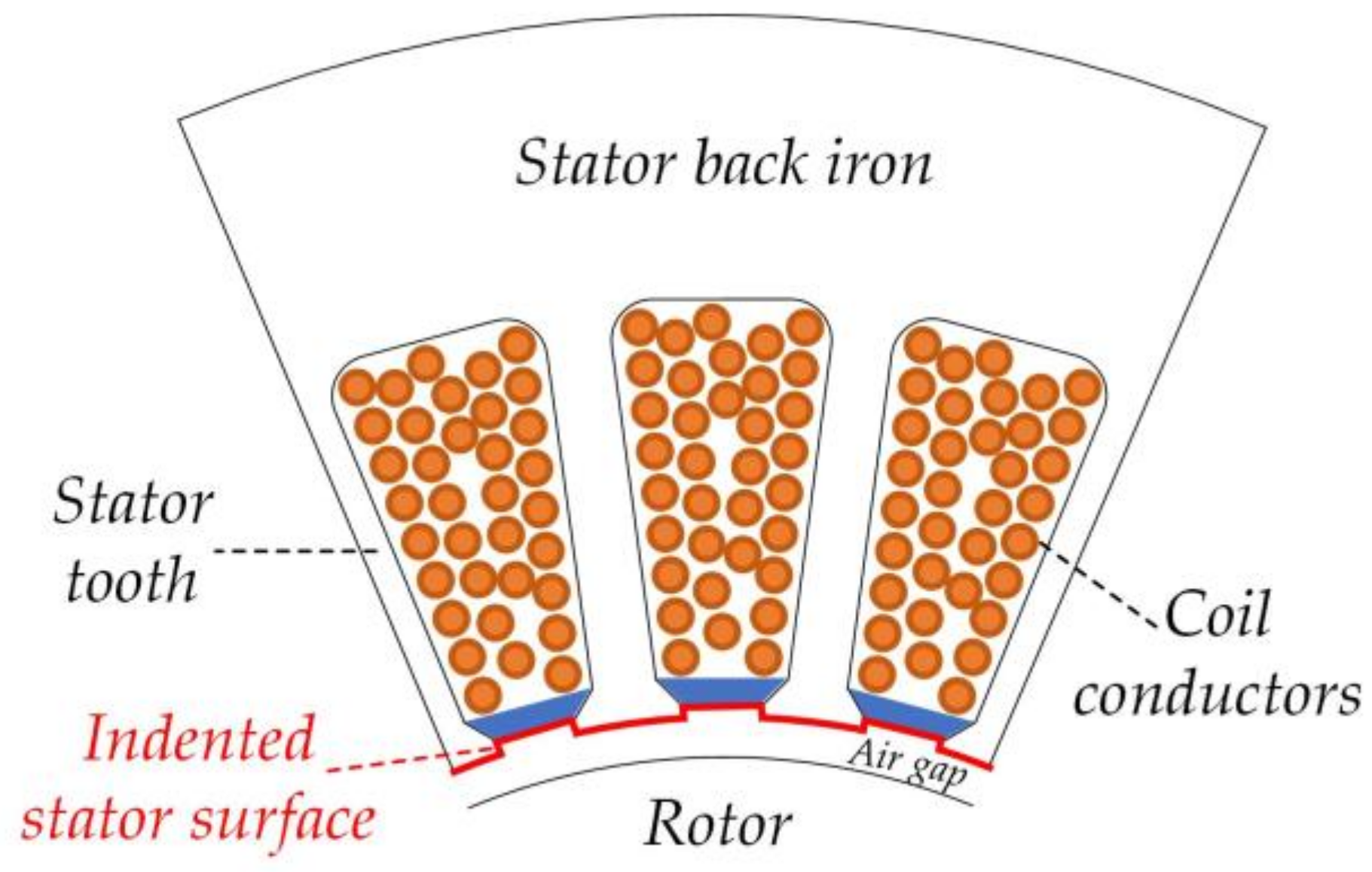

3.2. Analysis with Standard Wedge Inserted in Stator Slots

3.3. Analysis with Custom Wedge Inserted in Stator Slots

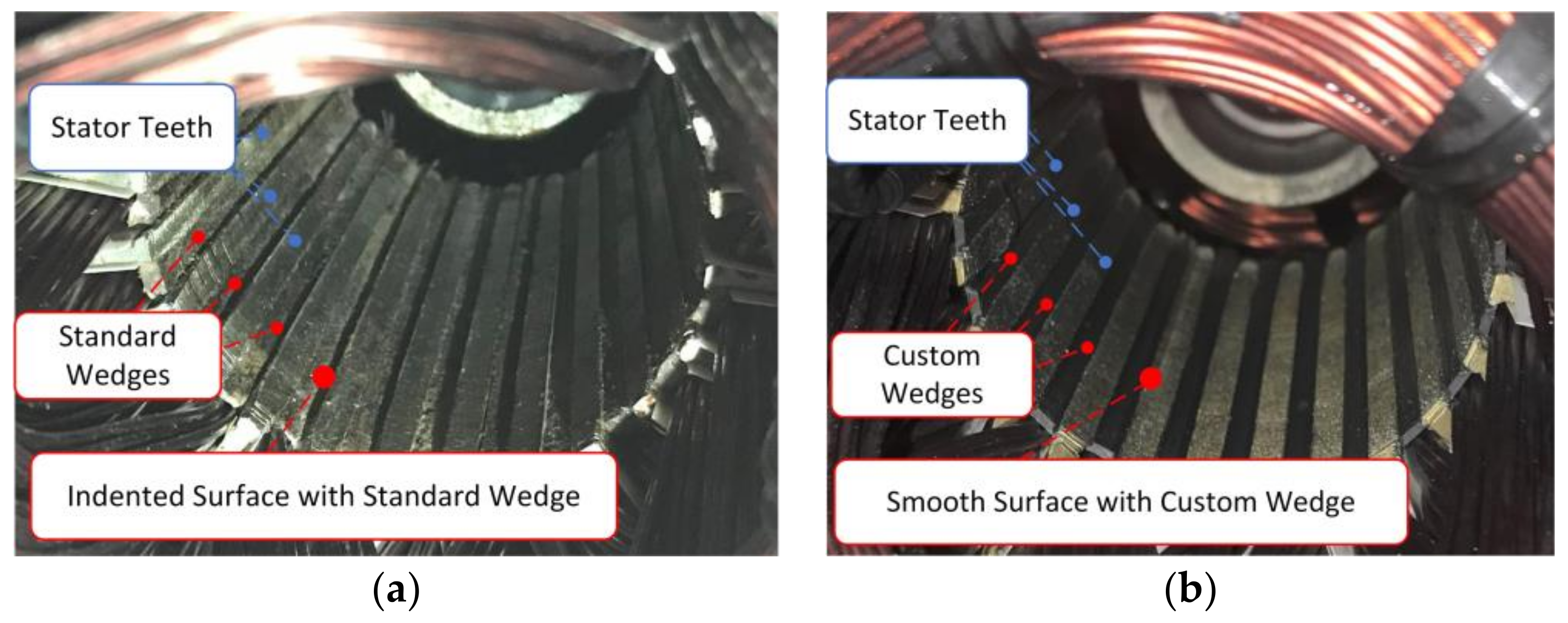

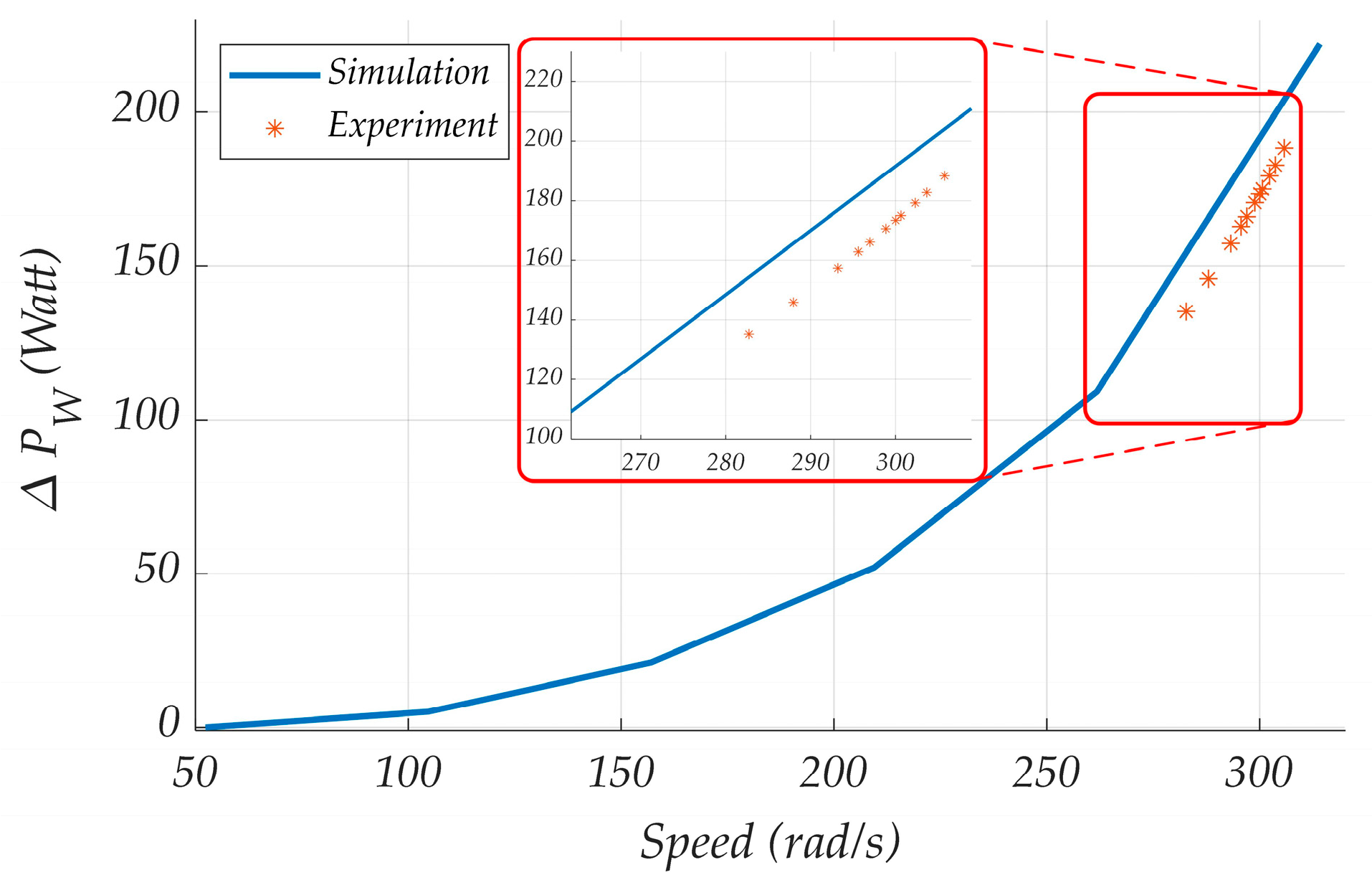

4. Experimental Verification

4.1. Test Setup

4.2. Experimental Results and Discussion

5. Conclusions

- Fluid damping loss represents a substantial fraction of the total losses in submerged motors and should not be disregarded in the design phase.

- Smooth surfaces facilitate fluid flow, resulting in reduced pressure variations and a significant reduction in damping loss. Consequently, sealing all stator slot openings with custom-designed wedges emerges as a highly effective approach to achieving this goal.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stoffel, B. The Role of Pumps for Energy Consumption and Energy Saving. In Assessing the Energy Efficiency of Pumps and Pump Units; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–24. [Google Scholar] [CrossRef]

- Ahmed, S.; Toliyat, H.A. Coupled Field Analysis Needs in the Design of Submersible Electric Motors. In Proceedings of the 2007 IEEE Electric Ship Technologies Symposium, Arlington, VA, USA, 21–23 May 2007. [Google Scholar]

- Borkowski, D.; Węgiel, M.; Ocłoń, P.; Węgiel, T. CFD Model and Experimental Verification of Water Turbine Integrated with Electrical Generator. Energy 2019, 185, 875–883. [Google Scholar] [CrossRef]

- Sashidhar, S.; Fernandes, B.G. A Novel Ferrite SMDS Spoke-Type BLDC Motor for PV Bore-Well Submersible Water Pumps. IEEE Trans. Ind. Electron. 2017, 64, 104–114. [Google Scholar] [CrossRef]

- Villani, M.; Santececca, M.; Parasiliti, F. High-Efficiency Line-Start Synchronous Reluctance Motor for Fan and Pump Applications. In Proceedings of the 2018 23rd International Conference on Electrical Machines, ICEM 2018, Alexandroupoli, Greece, 3–6 September 2018; pp. 2178–2184. [Google Scholar] [CrossRef]

- Li, J.; Song, J.; Cho, Y. High Performance Line Start Permanent Magnet Synchronous Motor for Pumping System. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 1308–1313. [Google Scholar] [CrossRef]

- Baka, S.; Sashidhar, S.; Fernandes, B.G. Design of an Energy Efficient Line-Start Two-Pole Ferrite Assisted Synchronous Reluctance Motor for Water Pumps. IEEE Trans. Energy Convers. 2021, 36, 961–970. [Google Scholar] [CrossRef]

- Sorgdrager, A.J.; Wang, R. Design and Optimisation of a Line-Start Synchronous Reluctance Motor. In Proceedings of the Southern African Universities Power Engineering Conference, Johannesburg, South Africa, 26–28 January 2016. [Google Scholar] [CrossRef]

- Al-Timimy, A.; Giangrande, P.; Degano, M.; Xu, Z.; Galea, M.; Gerada, C.; Lo Calzo, G.; Zhang, H.; Xia, L. Design and Losses Analysis of a High Power Density Machine for Flooded Pump Applications. IEEE Trans. Ind. Appl. 2018, 54, 3260–3270. [Google Scholar] [CrossRef]

- Liu, J.; Yan, L.; He, X.; Zhou, Y.; Yu, Z. Analysis of Oil Viscous Drag Loss of Deep-Sea Motor Based on CFD Method. In Proceedings of the ICIEA 2022—17th IEEE Conference on Industrial Electronics and Applications, Chengdu, China, 16–19 December 2022; pp. 1289–1293. [Google Scholar] [CrossRef]

- Guo, H.; Lv, Z.; Wu, Z.; Wei, B. Multi-Physics Design of a Novel Turbine Permanent Magnet Generator Used for Downhole High-Pressure High-Temperature Environment. IET Electr. Power Appl. 2013, 7, 214–222. [Google Scholar] [CrossRef]

- Andereckt, I.D.; Lius, S.S.; Swinney, H.L. Flow Regimes in a Circular Couette System with Independently Rotating Cylinders. J. Fluid Mech. 1986, 164, 155–183. [Google Scholar] [CrossRef]

- Xianghui, L.; Dianrong, G. Flow Field Analysis and Computation of the Fixed Damping Orifice of the Servo Valve. In Proceedings of the 2011 International Conference on Fluid Power and Mechatronics, Beijing, China, 17–20 August 2011; pp. 10–15. [Google Scholar] [CrossRef]

- Zou, J.; Qi, W.; Xu, Y.; Xu, F.; Li, Y.; Li, J. Design of Deep Sea Oil-Filled Brushless DC Motors Considering the High Pressure Effect. IEEE Trans. Magn. 2012, 48, 4220–4223. [Google Scholar] [CrossRef]

- Wonham, J. Effect of Pressure on the Viscosity of Water. Nature 1967, 215, 1053–1054. [Google Scholar] [CrossRef]

- Tekgun, D.; Alan, I. A New Oval Shaft, High Performance, 2 Pole Line Start Synchronous Reluctance Machine for Submersible Pump Applications. Int. J. Appl. Electromagn. Mech. 2022, 70, 73–93. [Google Scholar] [CrossRef]

- Tekgun, D.; Muhsin Cosdu, M.; Tekgun, B.; Alan, I. Effect of the Stator Slot Indents on Fluid Damping Loss in Submersible Pump Applications; Effect of the Stator Slot Indents on Fluid Damping Loss in Submersible Pump Applications. In Proceedings of the 2022 4th Global Power, Energy and Communication Conference (GPECOM), Nevsehir, Turkey, 14–17 June 2022. [Google Scholar] [CrossRef]

- Sarlioglu, B. Understanding Electric Motors and Loss Mechanisms. Available online: https://irc.wisc.edu/export.php?ID=421 (accessed on 31 October 2023).

- Sadr, S.; Abdelli, A.; Ben-NachouaneIntuitive, A.; Friedrich, G.; Vivier, S. Comprehension and Estimation of Windage Losses in Rotor Slotted Air Gaps of Electrical Machines Using CFD-LES Methods. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 6078–6083. [Google Scholar] [CrossRef]

- Vrancik, J.E. Prediction of Windage Loss in Alternators; NASA: Cleveland, OH, USA, 1967.

- Ng, Y.T. Characterising Low-Speed, Transitional Cavity Flow. Aeronaut. J. 2012, 116, 1185–1199. [Google Scholar] [CrossRef]

- Ukeiley, L.; Murray, N. Velocity and Surface Pressure Measurements in an Open Cavity. Exp. Fluids 2005, 38, 656–671. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Rated Power (HP/kW) | 5.5/4 |

| Rated Voltage (V) | 380 |

| Rated Current (A) | 9.8 |

| Number of Phases | 3 |

| Number of Poles | 2 |

| Rated Motor Speed (rad/s) | 298.45 |

| Number of Stator Slots | 24 |

| Rotor Radius (mm) | 34.15 |

| Stator Radius (mm) | 78 |

| Air Gap Length (mm) | 0.6 |

| Axial Motor Length (mm) | 154 |

| Speed (rad/s) | Cd | Pw (W) |

|---|---|---|

| 52.4 | 0.0177 | 1.7 |

| 104.7 | 0.0197 | 14.8 |

| 157.1 | 0.0203 | 51.3 |

| 209.4 | 0.0195 | 116.9 |

| 261.8 | 0.0196 | 229.5 |

| 314.2 | 0.0190 | 384.4 |

| Speed (rad/s) | Cd | Pw (W) |

|---|---|---|

| 52.4 | 0.0169 | 1.6 |

| 104.7 | 0.0183 | 13.7 |

| 157.1 | 0.0198 | 50.1 |

| 209.4 | 0.0195 | 116.9 |

| 261.8 | 0.0187 | 218.9 |

| 314.2 | 0.0186 | 376.3 |

| Speed (rad/s) | Cd | Pw (W) |

|---|---|---|

| 52.4 | 0.0135 | 1.3 |

| 104.7 | 0.0118 | 8.8 |

| 157.1 | 0.0101 | 25.5 |

| 209.4 | 0.0092 | 55.1 |

| 261.8 | 0.0086 | 100.7 |

| 314.2 | 0.0070 | 141.6 |

| Speed (rad/s) | Total Loss with Standard Wedge (W) | Total Loss with Custom Wedge (W) | Total Loss Difference (W) |

|---|---|---|---|

| 282.7 | 3512 | 3377 | 135 |

| 288.0 | 2893 | 2747 | 146 |

| 293.2 | 2257 | 2100 | 157 |

| 295.8 | 1970 | 1807 | 163 |

| 297.4 | 1812 | 1646 | 166 |

| 298.5 | 1601 | 1430 | 171 |

| 299.5 | 1478 | 1305 | 173 |

| 300.5 | 1414 | 1239 | 175 |

| 302.6 | 1250 | 1071 | 179 |

| 303.7 | 1127 | 944 | 183 |

| 305.8 | 962 | 774 | 188 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tekgun, D.; Tekgun, B. Investigating the Role of Stator Slot Indents in Minimizing Flooded Motor Fluid Damping Loss. Machines 2023, 11, 1088. https://doi.org/10.3390/machines11121088

Tekgun D, Tekgun B. Investigating the Role of Stator Slot Indents in Minimizing Flooded Motor Fluid Damping Loss. Machines. 2023; 11(12):1088. https://doi.org/10.3390/machines11121088

Chicago/Turabian StyleTekgun, Didem, and Burak Tekgun. 2023. "Investigating the Role of Stator Slot Indents in Minimizing Flooded Motor Fluid Damping Loss" Machines 11, no. 12: 1088. https://doi.org/10.3390/machines11121088

APA StyleTekgun, D., & Tekgun, B. (2023). Investigating the Role of Stator Slot Indents in Minimizing Flooded Motor Fluid Damping Loss. Machines, 11(12), 1088. https://doi.org/10.3390/machines11121088