Numerical Study on Aerodynamic and Noise Responses of Rotor with Ramp Increase in Collective Pitch Based on Time-Accurate Free-Wake Method

Abstract

:1. Introduction

2. Calculation Methods

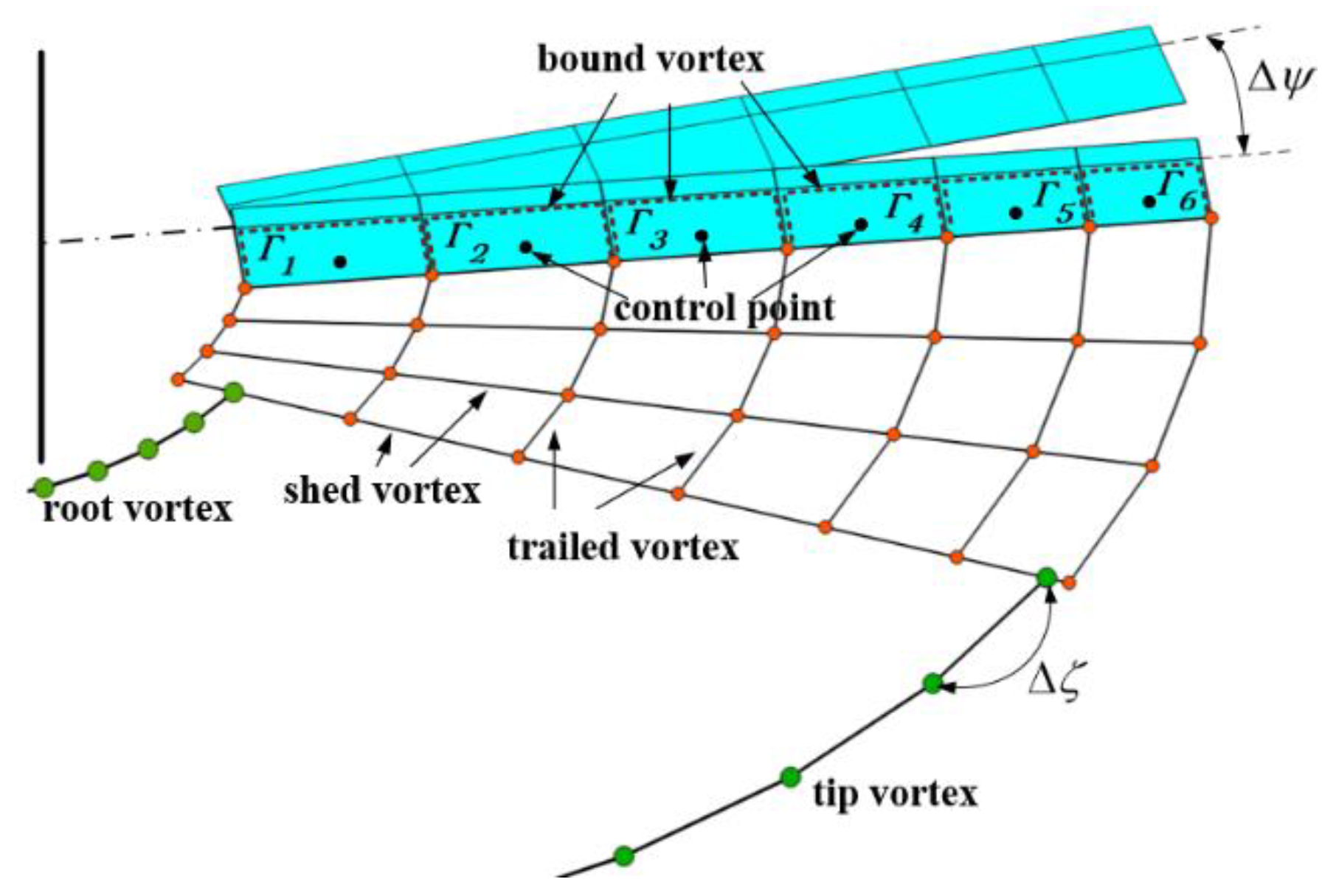

2.1. Time-Accurate Free-Wake Model

2.2. Noise Prediction Method

3. Validation for Proposed Methods

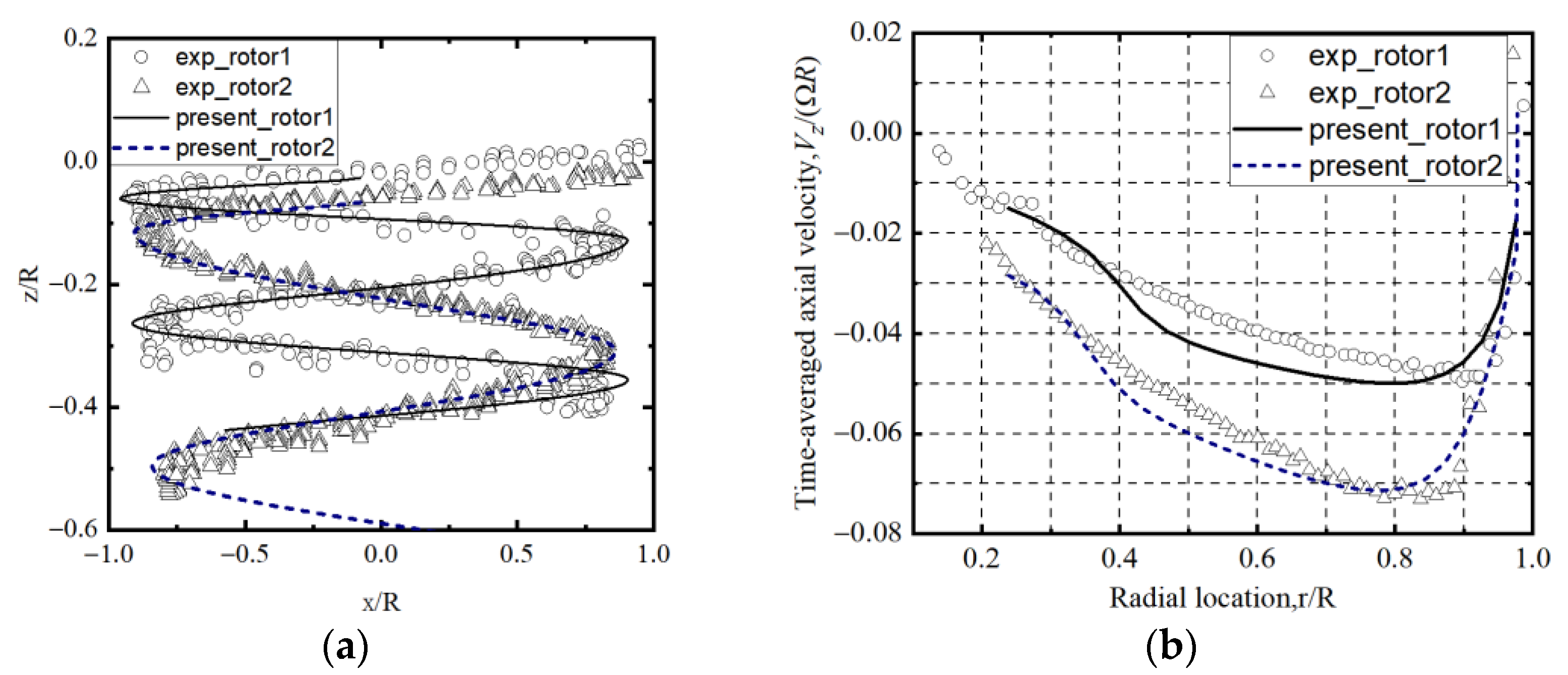

3.1. Hover Tests by the University of Maryland

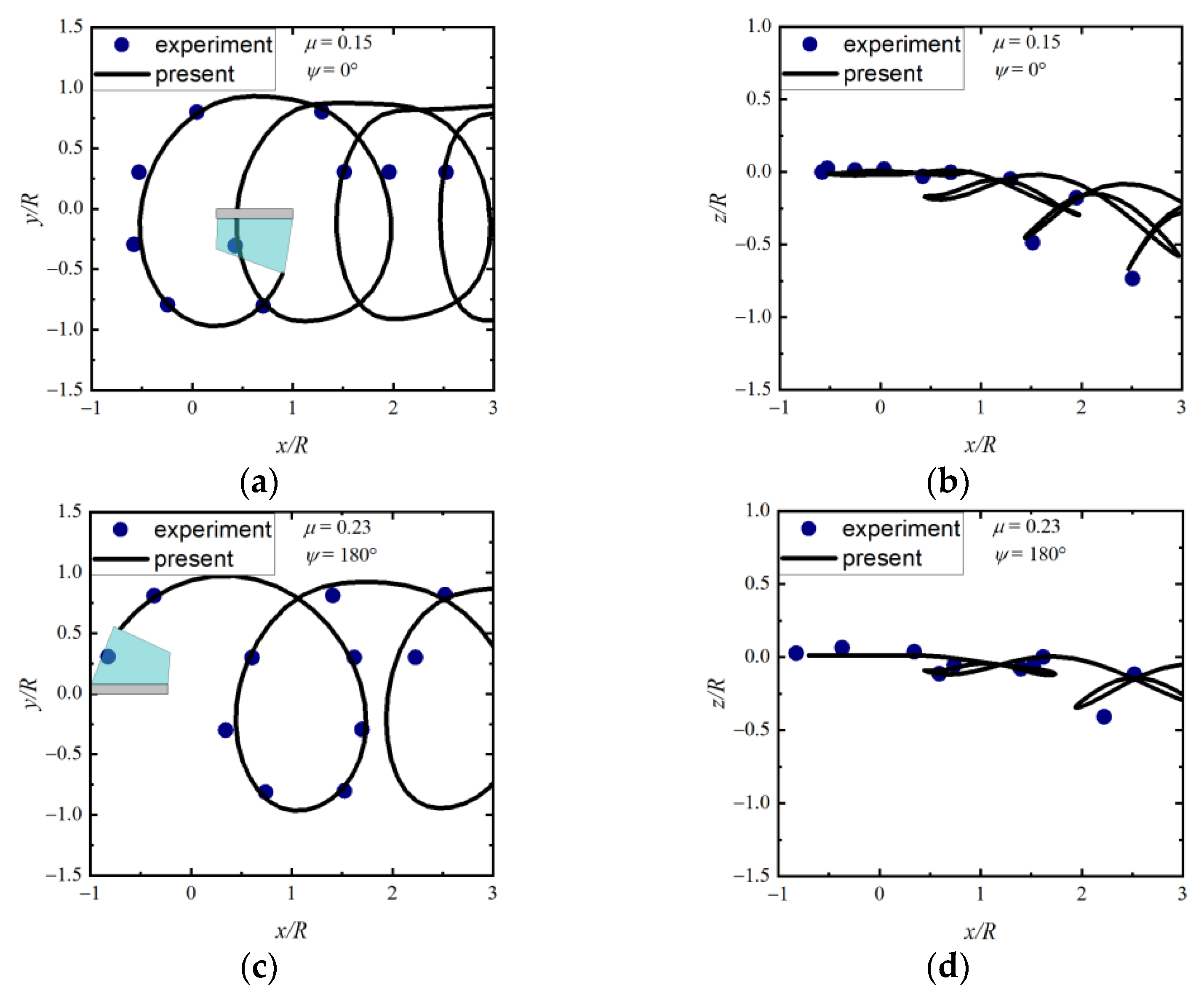

3.2. The Langley 2MRTS Rotor Test

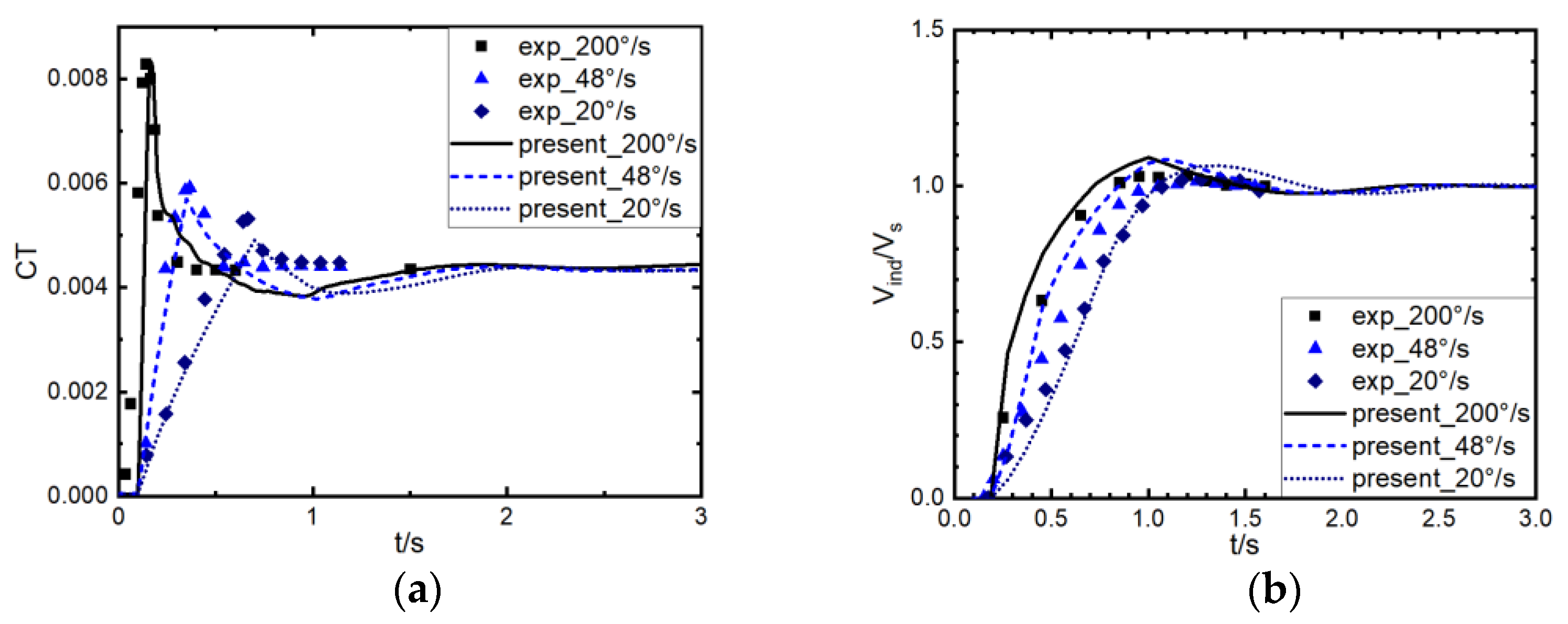

3.3. NACA Rotor with a Ramp Increase in Collective Pitch

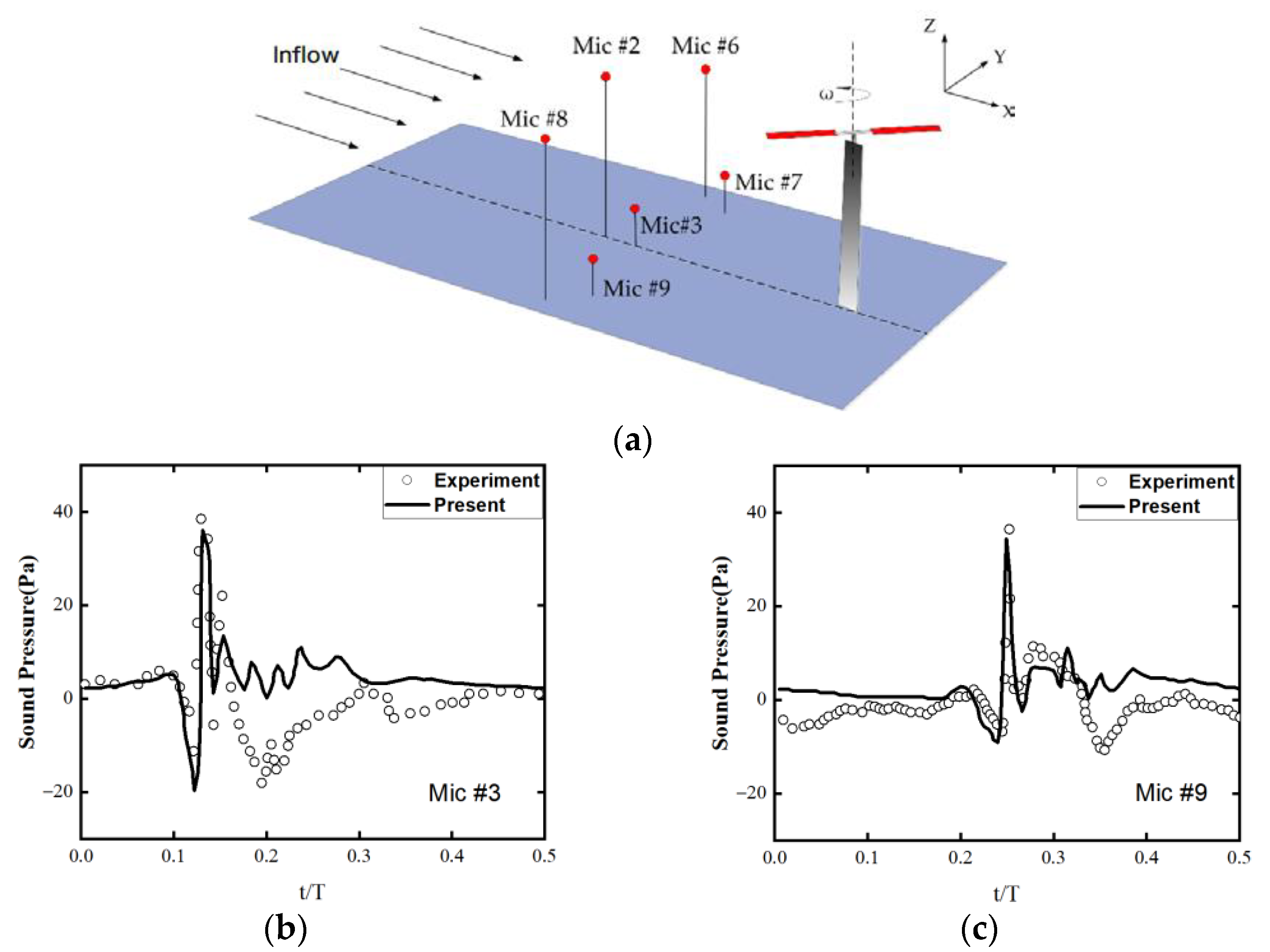

3.4. Aeroacoustic Experiment with AH-1/OLS

4. Aerodynamic and Noise Responses of the Rotor with a Ramp Increase in Collective Pitch

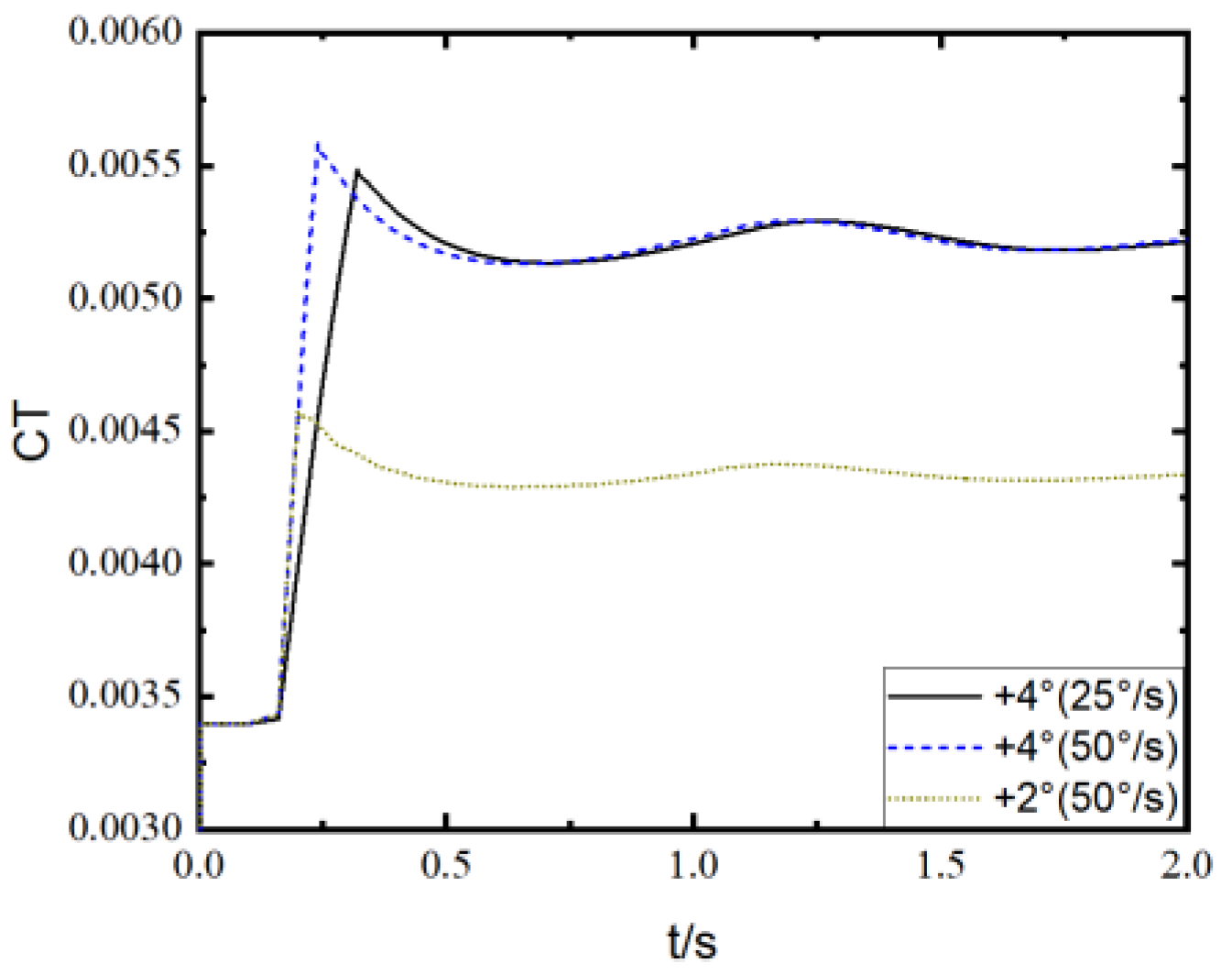

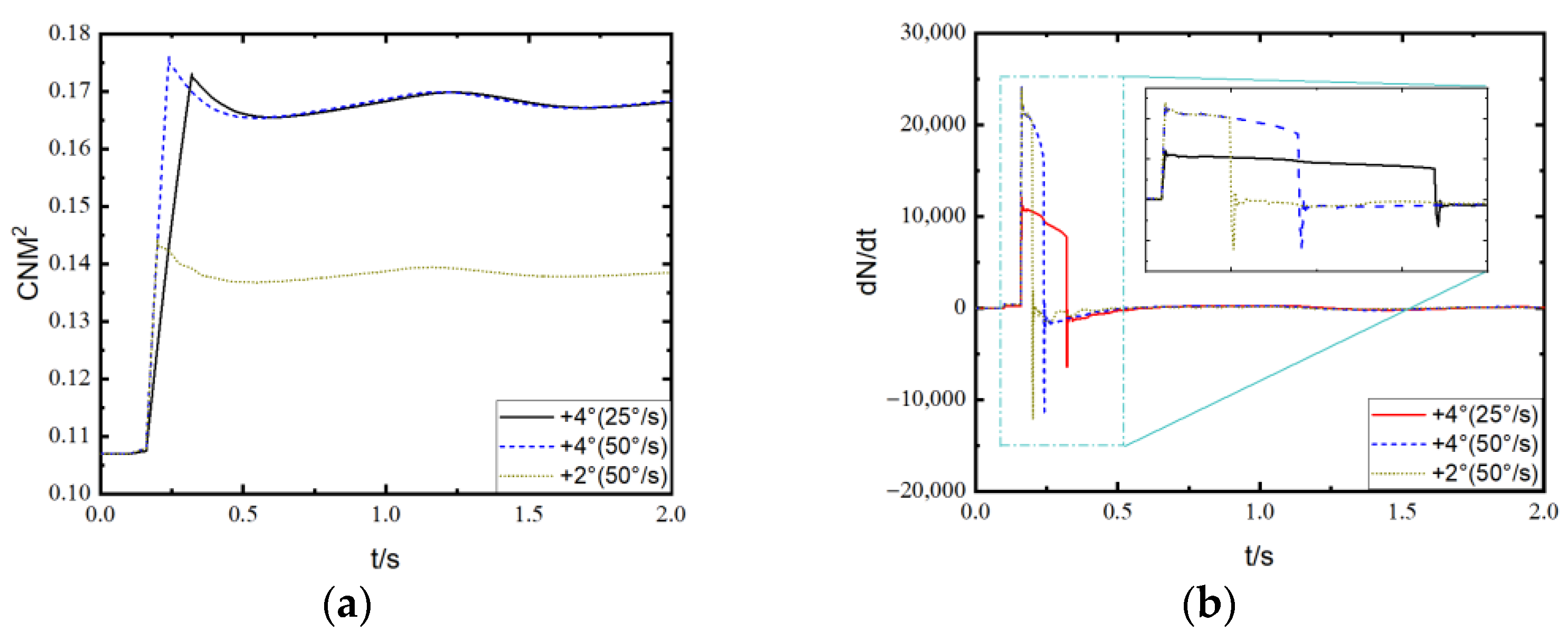

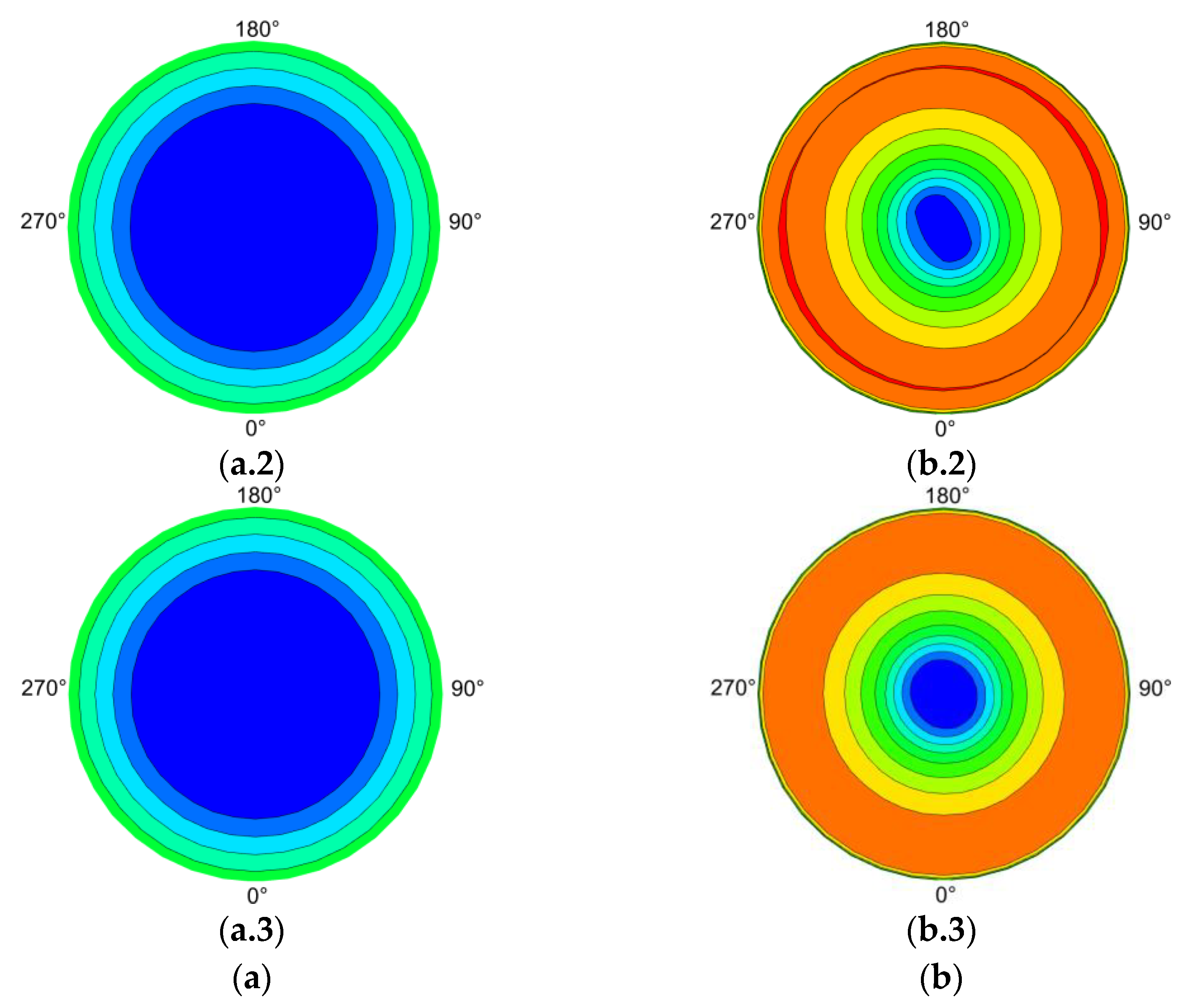

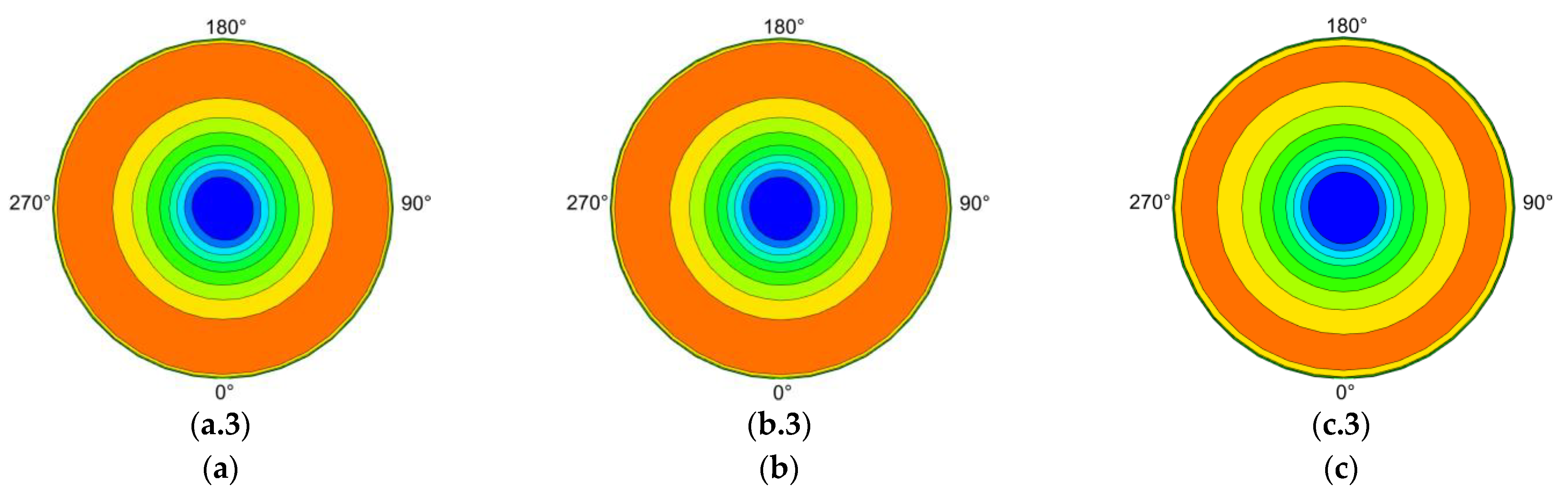

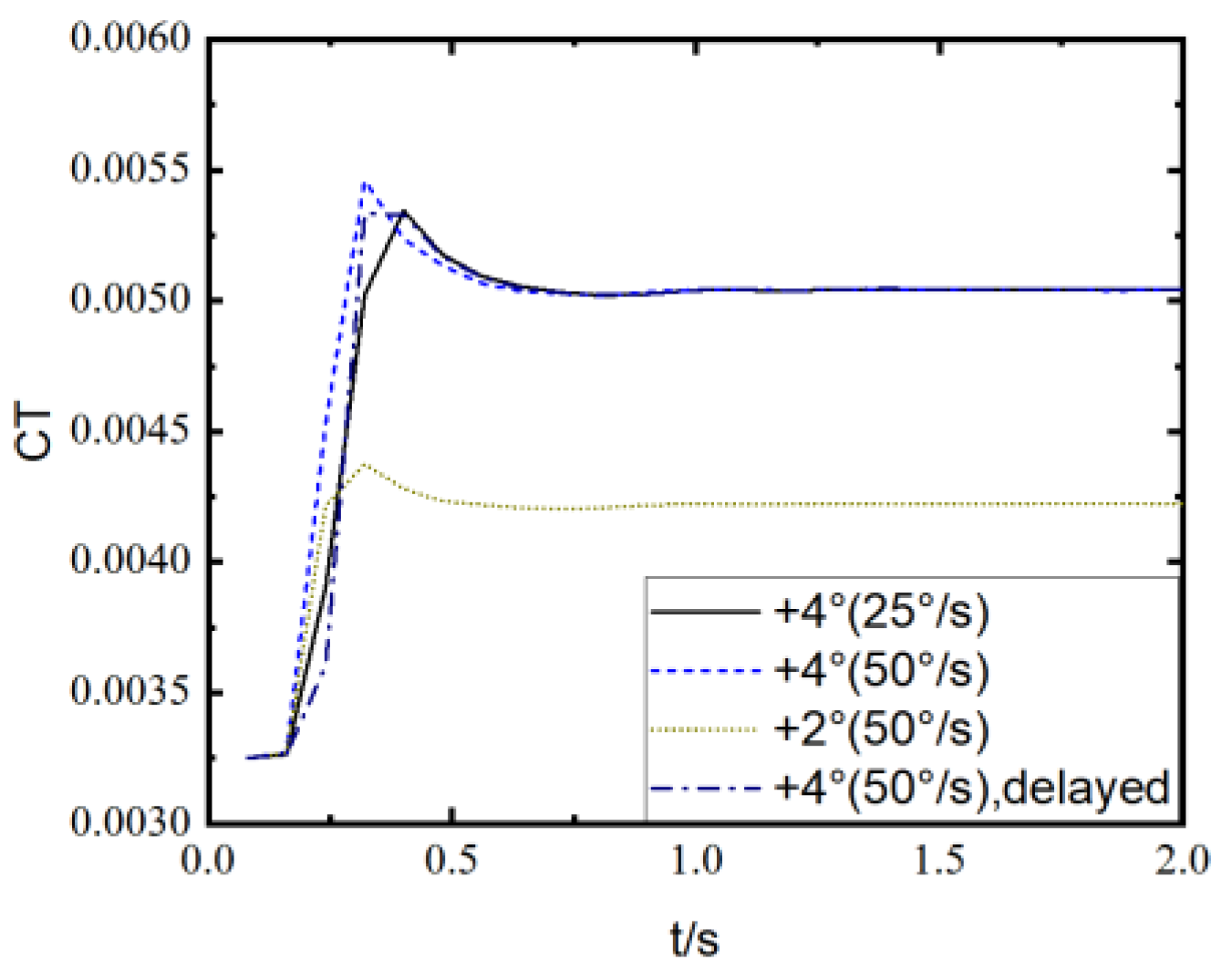

4.1. Ramp Increase in Collective Pitch in Hover

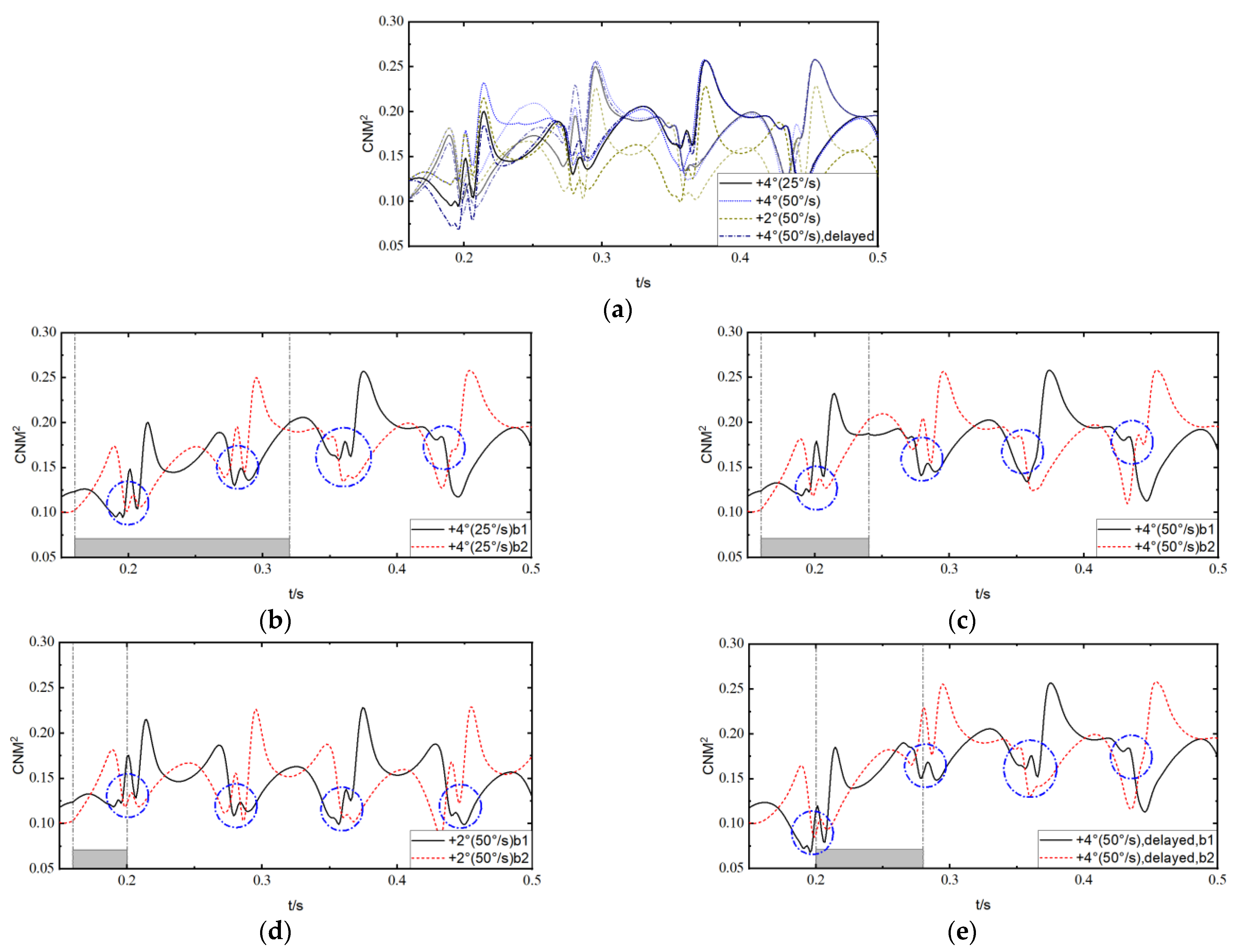

4.2. Ramp Increase in Collective Pitch in Forward Flight

5. Conclusions

- (1)

- The numerical cases verify that the modified TAFW scheme proposed has good numerical stability and simulation accuracy for the wake shape and induced velocity distribution of the rotor in steady hover and forward flight, and good consistency with the test for the aerodynamic load simulation of ramp increase in collective pitch. The rotor aerodynamic noise analysis method established also has good effectiveness in predicting rotor aerodynamic noise.

- (2)

- The ramp increase in collective pitch in hover leads to a rapid increase, overshoot, oscillation, and convergence variation in the aerodynamic force of the rotor. The time derivative of aerodynamic load suddenly increases at the initiation of the ramp increase in collective pitch, and the amplitude is large but gradually decreases during the ramp change until it suddenly decreases at the termination. The amplitude of the load derivative after the ramp change is much smaller than that during the ramp change.

- (3)

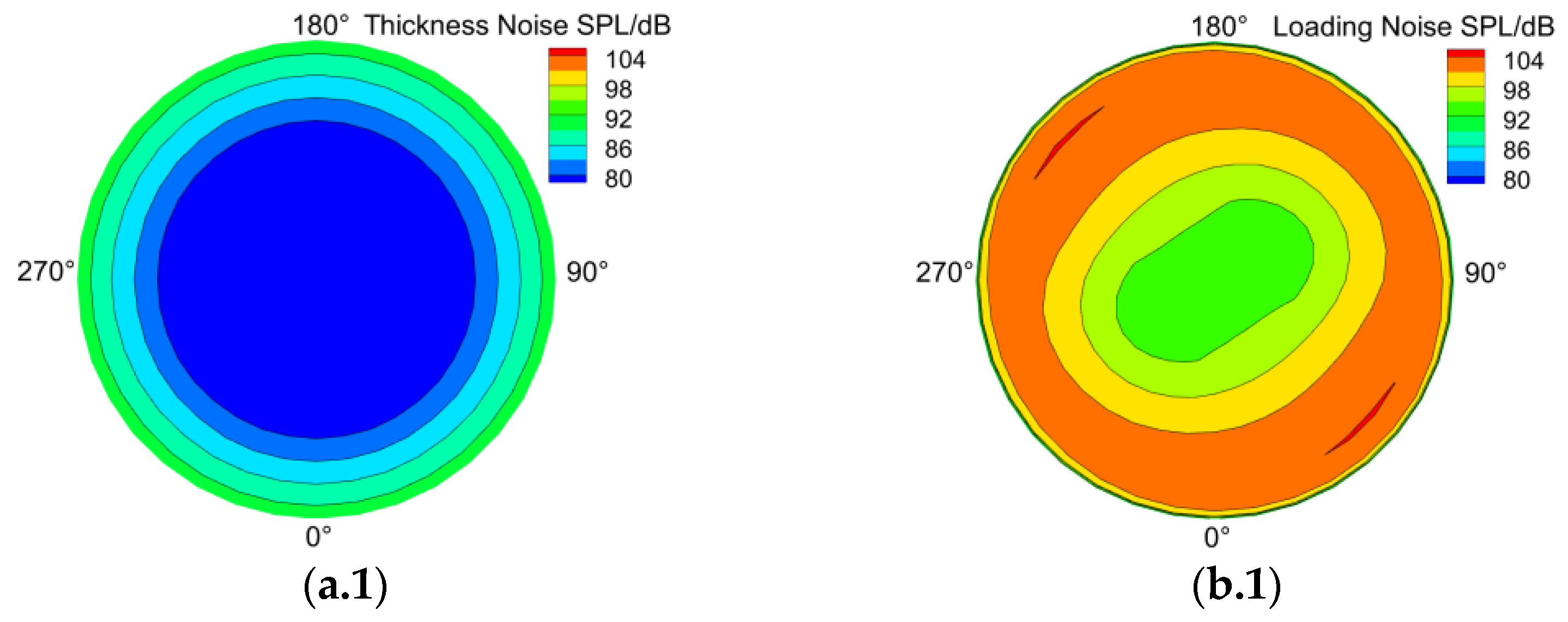

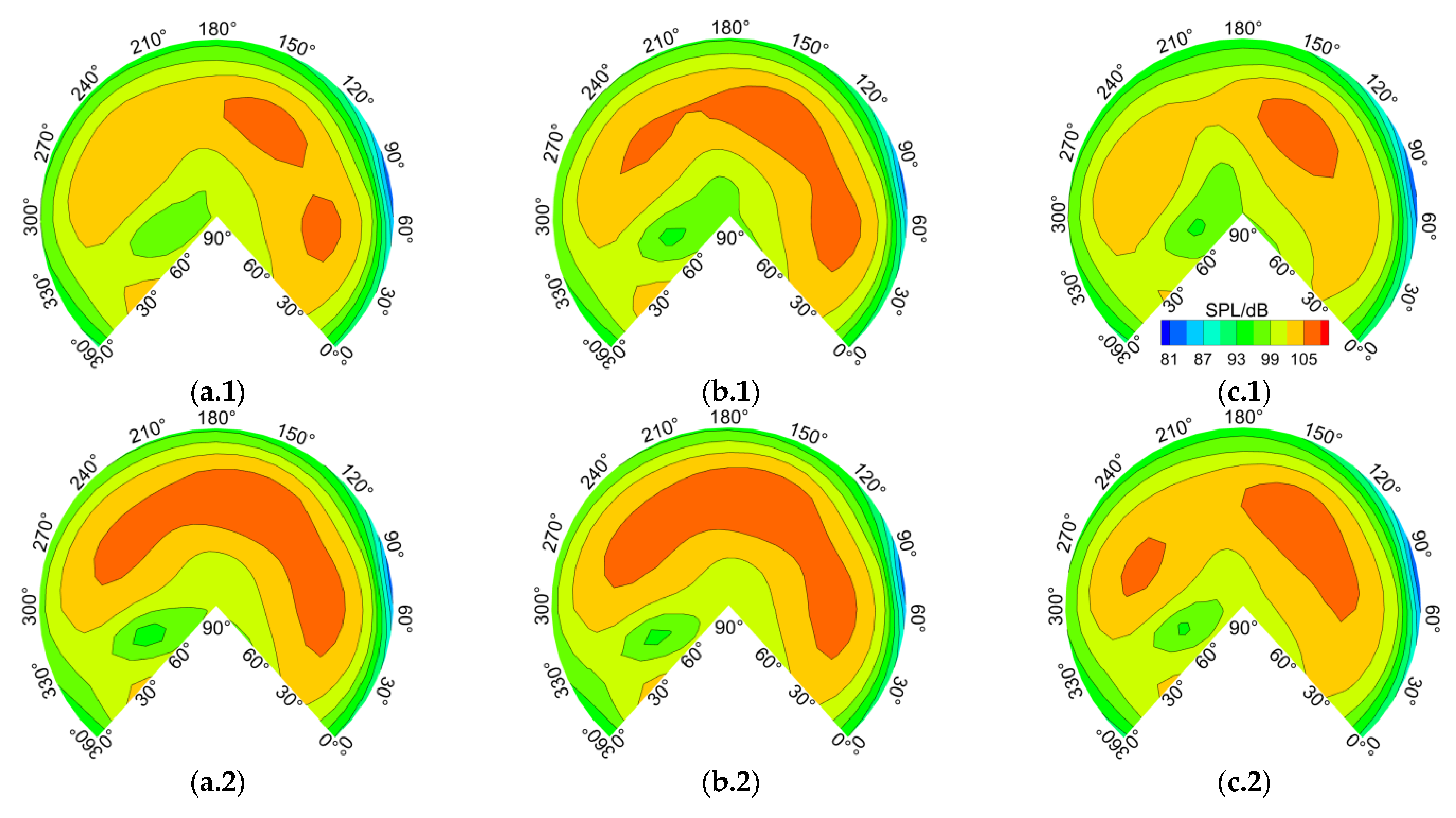

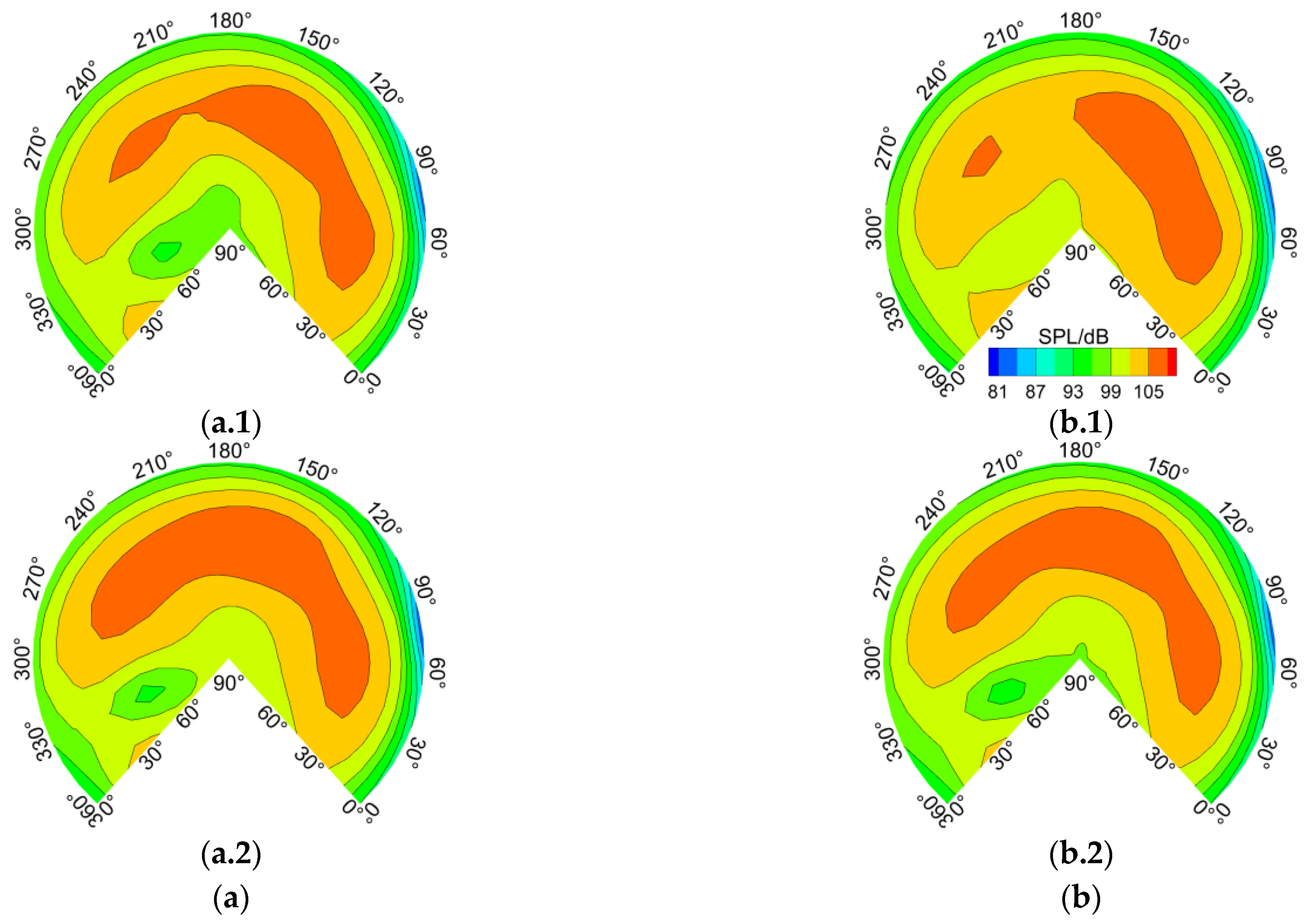

- The ramp increase in collective pitch has a relatively smaller impact on thickness noise but significantly affects loading noise, resulting in a clear directionality in hover loading noise. However, this phenomenon mainly exists during the ramp change. After the ramp change stops, the loading noise quickly converges to a new steady state.

- (4)

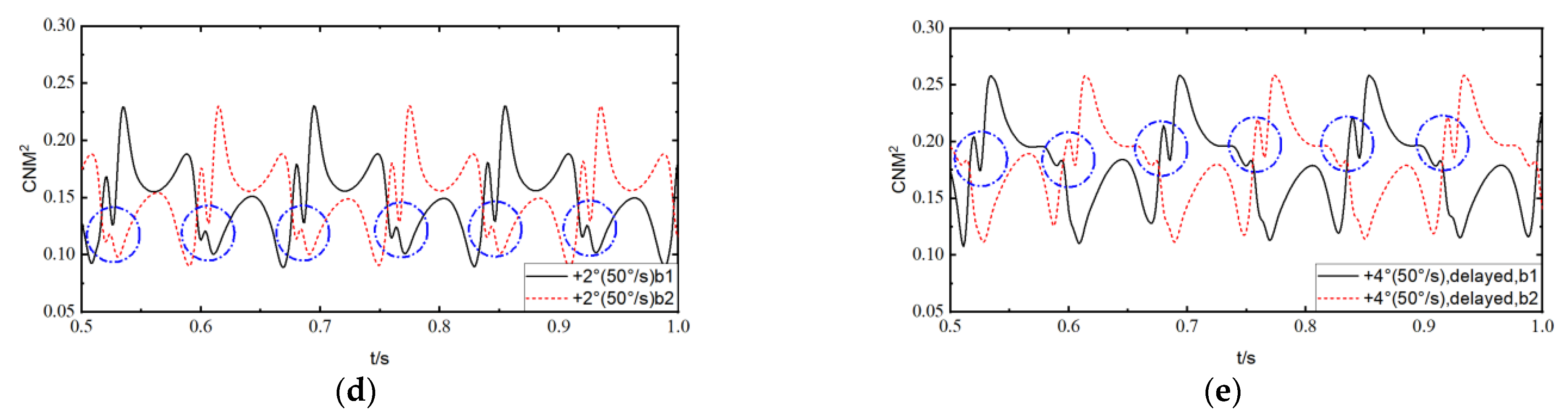

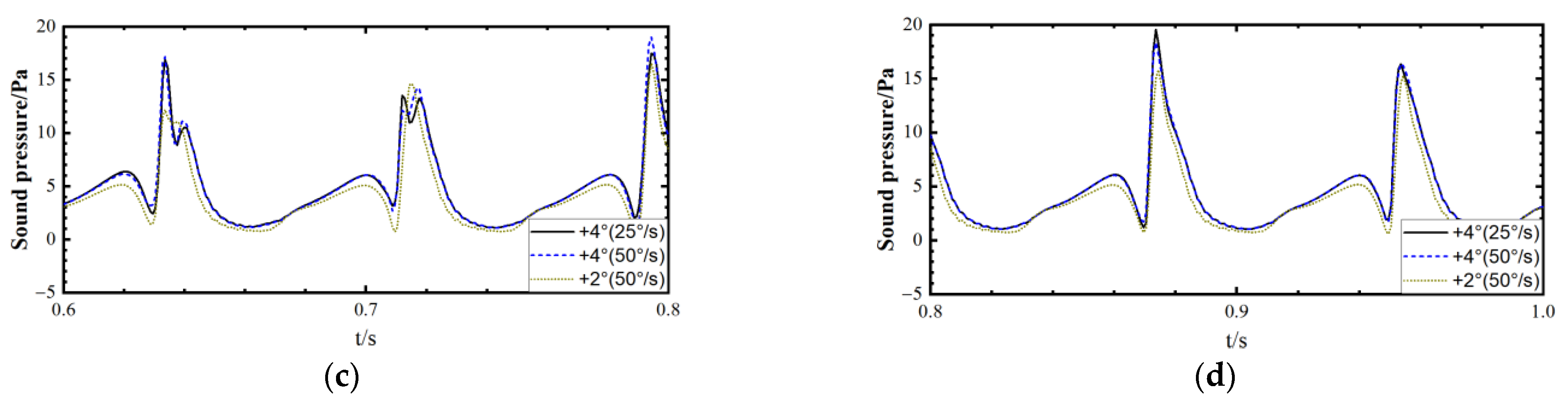

- When the collective pitch experiences a ramp increase in forward flight, there are mainly three timescales of variation in rotor load and loading noise: short-term, medium-term, and long-term, among which the short-term and medium-term variations show significant aperiodicity. In cases with BVI, the BVI noise shows a non-periodic variation in the mid-term timescale.

- (5)

- The influences of pitch rate and the start and stop azimuth angles are mainly reflected in short-term variations, where a higher pitch rate leads to higher loading noise, while the start and end azimuth angles can significantly affect the directionality of loading noise by influencing the azimuth angle of sudden changes in load derivatives and the subsequent evolution of the flow field. A reasonable selection of various ramp change start and end azimuth angles in maneuvering flight has the prospect of becoming an active control method for maneuvering flight noise.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| sound speed | |

| Mach number | |

| outer normal | |

| pressure | |

| r | distance to the center of the rotor |

| position vector | |

| R | rotor radius |

| velocity | |

| vorticity magnitude | |

| the age angle of the wake vortex | |

| advance ratio | |

| density | |

| the azimuth angle of the blade | |

| the rotation speed of the rotor | |

| sound source time | |

| observation time | |

| 3 upwind BDF | third-order upwind backward differentiation formulas |

| BVI | blade vortex interaction |

| CB2D | Center difference and backward difference second-order scheme with numerical dissipation |

| CFD | computational fluid dynamics |

| F1A | Farassat 1A |

| FW H | Fowcs Williams–Hawkings |

| PC2B | Predictor-Corrector second-order backward difference |

| TAFW | time-accurate free-wake |

References

- Chen, H.-N.; Brentner, K.; Shirey, J. An Investigation of Transient Rotor Noise in Maneuvering Flight. In Proceedings of the 11th AIAA/CEAS Aeroacoustics Conference, Monterey, CA, USA, 23–25 May 2005; pp. 1306–1319. [Google Scholar]

- Chen, H.-N.; Brentner, K.S.; Ananthan, S.; Leishman, J.G. A Computational Study of Helicopter Rotor Wakes and Noise Generated During Transient Maneuvers. J. Am. Helicopter Soc. 2008, 53, 37–55. [Google Scholar] [CrossRef]

- Sickenberger, R.D. Modeling Helicopter Near-Horizon Harmonic Noise Due to Transient Maneuvers. Ph.D. Thesis, The University of Maryland, College Park, MD, USA, 2013. [Google Scholar]

- Marze, H.-J.; Gervais, M.; Martin, P.; Dupont, P. Acoustic Flight Test of the EC130 B4 in the Scope of the Friendcopter Project. In Proceedings of the 33rd European Rotorcraft Forum, Kazan, Russia, 11–13 September 2007; pp. 2199–2244. [Google Scholar]

- Schmitz, F.H.; Greenwood, E.; Sickenberger, R.D.; Gopalan, G.; Sim, B.W.-C.; Moralez, E., III; Decker, W.A. Measurement and Characterization of Helicopter Noise in Steady-State and Maneuvering Flight. In Proceedings of the American Helicopter Society International 63rd Annual Forum—Riding the Wave of New Vertical Flight Technology, Virginia Beach, VA, USA, 1–3 May 2007; pp. 28–44. [Google Scholar]

- Watts, M.E.; Snider, R.; Greenwood, E.; Baden, J. Maneuver Acoustic Flight Test of the Bell 430 Helicopter. In Proceedings of the American Helicopter Society 68th Annual Forum, Fort Worth, TX, USA, 1–3 May 2012; pp. 24–40. [Google Scholar]

- Duc, A.L.; Spiegel, P.; Guntzer, F.; Lummer, M.; Buchholz, H.; Götz, J. Simulation of Complete Helicopter Noise in Maneuver Flight Using Aeroacoustic Flight Test Database. In Proceedings of the American Helicopter Society 64th Annual Forum, Montréal, QC, Canada, 26 April–1 May 2008; pp. 2288–2306. [Google Scholar]

- Greenwood, E.; Schmitz, F.H.; Sickenberger, R.D. A Semi-Empirical Noise Modeling Method for Helicopter Maneuvering Flight Operations. In Proceedings of the American Helicopter Society 68th Annual Forum, Fort Worth, TX, USA, 1–3 May 2012; pp. 55–72. [Google Scholar]

- Gennaretti, M.; Serafini, J.; Bernardini, G.; Castorrini, A.; Matteis, G.D.; Avanzini, G. Numerical Characterization of Helicopter Noise Hemispheres. Aerosp. Sci. Technol. 2016, 52, 18–28. [Google Scholar] [CrossRef]

- Greenwood, E.; Rau, R. A Maneuvering Flight Noise Model for Helicopter Mission Planning. J. Am. Helicopter Soc. 2020, 65, 1–10. [Google Scholar] [CrossRef]

- Brentner, K.; Jones, H. Noise Prediction for Maneuvering Rotorcraft. In Proceedings of the 6th Aeroacoustics Conference and Exhibit, Lahaina, HI, USA, 12–14 June 2000. [Google Scholar]

- Brès, G.A.; Brentner, K.S.; Perez, G.; Jones, H.E. Maneuvering Rotorcraft Noise Prediction. J. Sound Vib. 2004, 275, 719–738. [Google Scholar] [CrossRef]

- Brentner, K.S.; Lopes, L.V.; Chen, H.-N.; Horn, J.F. Near Real-Time Simulation of Rotorcraft Acoustics and Flight Dynamics. J. Aircr. 2005, 42, 347–355. [Google Scholar] [CrossRef]

- Rajmohan, N. Application of Hybrid Methodology to Rotors in Steady and Maneuvering Flight. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2010. [Google Scholar]

- Chen, H.-N. Rotor Noise in Maneuvering Flight. Ph.D. Thesis, The Pennsylvania State University, University Park, PA, USA, 2006. [Google Scholar]

- Ananthan, S. Analysis of Rotor Wake Aerodynamics during Maneuvering Flight Using a Free-Vortex Wake Methodology. Ph.D. Thesis, The University of Maryland, College Park, MD, USA, 2006. [Google Scholar]

- Wang, L. Research on Blade-Vortex Interaction Simulation and Helicopter Maneuvering Flight Noise. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. [Google Scholar]

- Steijl, R.; Barakos, G.; Badcock, K. A Framework for Cfd Analysis of Helicopter Rotors in Hover and Forward Flight. Int. J. Numer. Methods Fluids 2006, 51, 819–847. [Google Scholar] [CrossRef]

- Hu, Z. Active Noise Reduction of Rotors Based on Trailing-Edge Flap Control. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2021. [Google Scholar]

- Woodgate, M.A.; Shi, Y.; Fitzgibbon, T.A.; Barakos, G.N.; Li, P. Simulation of Step Input in Collective Pitch for Hovering Rotor. Aerosp. Sci. Technol. 2021, 110, 106425. [Google Scholar] [CrossRef]

- Zhang, K.; Zhao, Q.; Zhang, X.; Xu, G. Analysis of Rotor Aerodynamic Response During Ramp Collective Pitch Increase by Cfd Method. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2020, 235, 994–1007. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, K.; Zhao, Q.; Wang, W. Numerical Analysis of Rotor Aeroacoustic Characteristics During Collective Pitch Aperiodic Variation in Hover. Aerosp. Sci. Technol. 2022, 124, 107411. [Google Scholar] [CrossRef]

- Weissinger, J. The Lift Distribution of Swept-Back Wings; NASA: Hampton, VA, USA, 1947. [Google Scholar]

- Crighton, D.G. The Kutta Condition in Unsteady Flow. Annu. Rev. Fluid Mech. 1985, 17, 411–445. [Google Scholar] [CrossRef]

- Bagai, A. Contributions to the Mathematical Modeling of Rotor Flow-Fields Using a Pseudo-Implicit Free-Wake Analysis. Ph.D. Thesis, The University of Maryland, College Park, MD, USA, 1995. [Google Scholar]

- Betz, A. Verhalten Von Wirbelsystemen. Z. Angew. Math. Mech. 1932, 12, 164–174. [Google Scholar] [CrossRef]

- Rossow, V.J. Extended-Betz Methods for Roll-up of Vortex Sheets. J. Aircr. 1997, 34, 592–599. [Google Scholar] [CrossRef]

- Leishman, J.G.; Beddoes, T.S. A Semi-Empirical Model for Dynamic Stall. J. Am. Helicopter Soc. 1989, 34, 3–17. [Google Scholar]

- Miranda, L.R.; Elliot, R.D.; Baker, W.M. A Generalized Vortex Lattice Method for Subsonic and Supersonic Flow Applications; NASA: Hampton, VA, USA, 1977. [Google Scholar]

- Leishman, G.J. Principles of Helicopter Aerodynamics; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Bhagwat, M.J. Mathematical Modeling of the Transient Dynamics of Helicopter Rotor Wakes Using a Time-Accurate Free-Vortex Method. Ph.D. Thesis, The University of Maryland, College Park, MD, USA, 2001. [Google Scholar]

- Li, P. Rotor Unsteady Free-Vortex Wake Model and Investigation on High-Fidelity Modeling of Helicopter Flight Dynamics. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2010. [Google Scholar]

- Lv, W. Research on the Stability, Numerical Method of Rotor Wake Systems and the Aerodynamic Characteristics of Abc Helicopters. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2013. [Google Scholar]

- Beljadid, A.; Mohammadian, A.; Qiblawey, H.M. An Unstructured Finite Volume Method for Large-Scale Shallow Flows Using the Fourth-Order Adams Scheme. Comput. Fluids 2013, 88, 579–589. [Google Scholar] [CrossRef]

- Farassat, F. Derivation of Formulations 1 and 1a of Farassat; NASA: Hampton, VA, USA, 2007. [Google Scholar]

- Casalino, D. An Advanced Time Approach for Acoustic Analogy Predictions. J. Sound Vib. 2003, 261, 583–612. [Google Scholar] [CrossRef]

- Bhagwat, M.J.; Leishman, J.G. On the Relationship between Blade Circulation and Tip Vortex Characteristics. In Proceedings of the 54th Annual Forum of the American Helicopter Society, Washington, DC, USA, 20–22 May 1998; pp. 557–575. [Google Scholar]

- Bhagwat, M.J.; Leishman, J.G. Measurements of Bound and Wake Circulation on a Helicopter Rotor. J. Aircr. 2000, 37, 227–234. [Google Scholar] [CrossRef]

- Naca Airfoil. Available online: https://en.wikipedia.org/wiki/NACA_airfoil (accessed on 15 February 2006).

- Elliott, J.W.; Althoff, S.L.; Sailey, R.H. Inflow Measurements Made with a Laser Velocimeter on a Helicopter Model in Forward Flight. Volume 1 Rectangular Planform Blades at an Advance Ration of 0.15; NASA: Hampton, VA, USA, 1988. [Google Scholar]

- Ghee, T.A.; Elliott, J.W. The Wake of a Small-Scale Rotor in Forward Flight Using Flow Visualization. J. Am. Helicopter Soc. 1995, 40, 52–65. [Google Scholar] [CrossRef]

- Carpenter, P.J.; Fridovich, B. Effect of a Rapid Blade-Pitch Increase on the Thrust and Induced-Velocity Response of a Full-Scale Helicopter Rotor; NASA: Hampton, VA, USA, 1953. [Google Scholar]

- Yu, Y.H.; Tung, C.; Gallman, J.; Schultz, K.J.; van der Wall, B.; Spiegel, P.; Michea, B. Aerodynamics and Acoustics of Rotor Blade-Vortex Interactions. J. Aircr. 1995, 32, 970–977. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Xia, R.; Shi, Y.; Xu, G. Numerical Study on Aerodynamic and Noise Responses of Rotor with Ramp Increase in Collective Pitch Based on Time-Accurate Free-Wake Method. Machines 2023, 11, 1007. https://doi.org/10.3390/machines11111007

Hu Z, Xia R, Shi Y, Xu G. Numerical Study on Aerodynamic and Noise Responses of Rotor with Ramp Increase in Collective Pitch Based on Time-Accurate Free-Wake Method. Machines. 2023; 11(11):1007. https://doi.org/10.3390/machines11111007

Chicago/Turabian StyleHu, Zhiyuan, Runze Xia, Yongjie Shi, and Guohua Xu. 2023. "Numerical Study on Aerodynamic and Noise Responses of Rotor with Ramp Increase in Collective Pitch Based on Time-Accurate Free-Wake Method" Machines 11, no. 11: 1007. https://doi.org/10.3390/machines11111007

APA StyleHu, Z., Xia, R., Shi, Y., & Xu, G. (2023). Numerical Study on Aerodynamic and Noise Responses of Rotor with Ramp Increase in Collective Pitch Based on Time-Accurate Free-Wake Method. Machines, 11(11), 1007. https://doi.org/10.3390/machines11111007