1. Introduction

Compared with the traditional crank press, multi-link presses, such as elbow bar presses, have the characteristics of good quick return, high forming accuracy, and strong bearing capacity [

1]. The motion accuracy of the slider is one of the important indexes to evaluate the performance of the press. Under the background of near net shape [

2], the requirements for the product quality of the press are increasing, and there is an urgent need to improve its accuracy performance. The design of ultraprecision machines and the research of related key technologies become particularly important to achieve rapid and economic production [

3]. The improvement and guarantee of the motion accuracy of the slider is the key technology studied in the design and manufacture of the multi-link press [

4]. Therefore, it is necessary to analyze the key factors affecting the accuracy of the press and reasonably allocate the accuracy parameters of each part from the perspective of saving the manufacturing cost of the press to meet the processing requirements of near net shape forming.

Establishing the mapping relationship between the geometric error source and the output error of the mechanism is the basis of accuracy synthesis, which has been studied by many scholars. In error modeling, common methods include homogeneous transformation matrixes [

5,

6], Denavit–Hartenberg (D–H) transformation matrixes [

7], screw theory [

8,

9,

10,

11], and exponential product [

12]. Wu et al. [

13] established the geometric error model of the rotating axis based on the theory of multi-body dynamics and studied a prediction method of the comprehensive error field in the machining space of five-axis machine tools based on the S-shaped specimen family. Chen et al. [

14] proposed a unified method for the accurate analysis of general planar three-legged parallel robots based on constrained planar motion generalized kinematic mapping. Tian et al. [

15] extended the generalized Jacobian method to the error modeling of machine tools, which can divide the source error into two subsets related to the compensated and non-compensated pose accuracy. Zhao et al. [

16] proposed an angle error analysis method for a planar synthetic aperture radar antenna multi-closed-loop deployment mechanism considering link deviation and joint clearance, which provides an effective tool for designers to evaluate its accuracy performance in the design stage. From the current research situation, most of the error modeling research was mainly aimed at error prediction and error compensation.

Accuracy synthesis is a structural optimization problem, is the inverse problem of accuracy analysis, and has more practical significance in engineering. A. K. Srivastava et al. [

6] proposed a compact volumetric error model, which directly considers the inaccurate links and joint shapes and joint transformations using small angle approximation and then finds the total volume error in the workspace as a function of all possible errors. A. Chaker et al. [

17] took five different non-over-constrained spherical parallel mechanisms (SPM) as the research object and analyzed the influence of the manufacturing error of the connecting rod on the position and orientation of its output end platform. The results show that different non-over-constrained versions of SPM have different pose accuracy. Tian et al. [

15,

18] applied the generalized Jacobian method to the error modeling of machine tools. They proposed a general and systematic method to divide the source error into two subsets related to the compensated and uncompensated pose accuracy so as to model the geometric error of machine tools. Chen et al. [

19] took the dimensional tolerance unit and tolerance grade coefficient as the weighting coefficient; using the linear weighting method, the multi-objective optimization was transformed into a single objective optimization, and the mathematical model of the optimal dimensional tolerance and the fitting tolerance of the kinematic pair of the planar linkage mechanism was established. Jin et al. [

20] proposed a tolerance design method in the early design stage of auto parts based on the Shapley value method (SVM) of joint game theory. P. K. Singh [

21] and Krishna [

22] used an optimization method to realize the simultaneous distribution and allocation of machine tool manufacturing tolerance and assembly tolerance based on the minimum manufacturing cost. Chen et al. [

23] proposed a static accuracy design method based on global optimization and error sensitivity analysis, which transforms the static error allocation problem of machine tools into a multi-objective optimization problem with nonlinear constraints. Zhang et al. [

24] proposed a precision design method for multi-axis CNC machine tools based on reliability theory. Cha et al. [

25] proposed a robust optimization design method using the hybrid response surface method (H-RSM), which directly finds the best advantage to meet the target Z value or failure probability.

The previous literature shows that there is relatively little research on the mechanical press in the field of comprehensive precision research, and most of the research objects are lathes, milling machines, or machining centers. Among the many factors that affect the output accuracy of the press, the geometric dimension error of the transmission mechanism has a greater impact, as it leads to the lower dead center accuracy of the slider beyond the design range, affecting the forming quality of the workpiece and the service life of the die. Bai et al. [

26,

27] used the matrix analysis method to analyze a four-driven parallel press and concluded that the most significant factor affecting the accuracy of the press is the structural parameter error of the output branch chain. Lu Xinjian [

28] derived the error transfer function equation of the rod length and fixed contact coordinates by using the differential method and compared the error transfer coefficient at the bottom dead center. Qian Huanan [

29] established a comprehensive error model of the transmission link frame of the press by using the matrix method and the theory of multi-body systems.

Due to the complexity of multi-link mechanisms, the research on the motion error of multi-link mechanism is not mature enough at present, and there is still a big gap regarding the practical application. To solve the above problems, this paper uses the loop increment method to model the error of the transmission mechanism. On this basis, the error transmission model of the transmission mechanism of the multi-link mechanical press is established according to the principle of error-independent action so that the influence of the connecting rod and positioning error on the output accuracy of the press slider can be easily clarified. The key error influencing factors are determined through sensitivity analysis, and the accuracy of the transmission mechanism of the press is comprehensively optimized, considering the influence of the machining accuracy on the manufacturing cost.

2. Problem Description

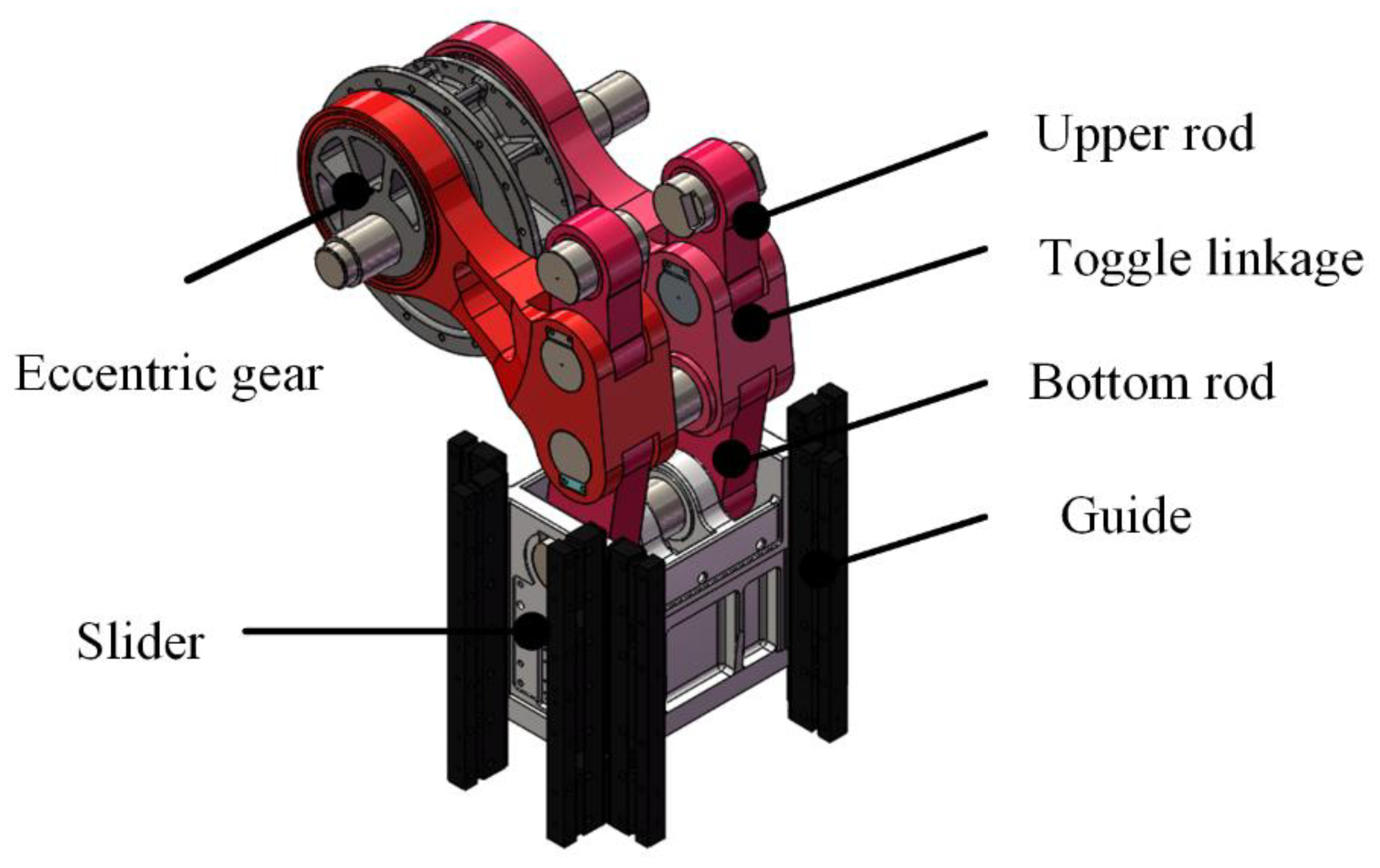

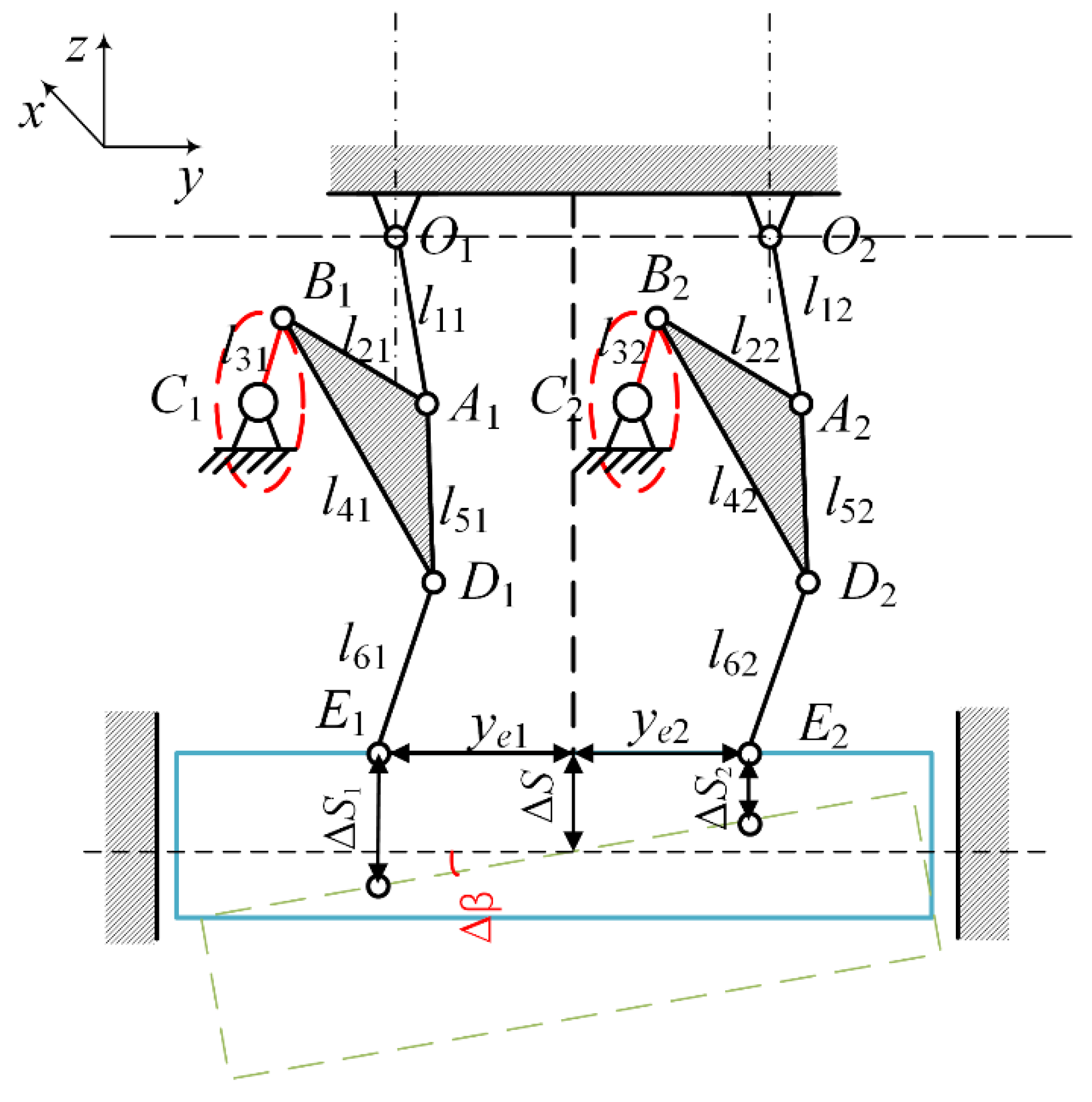

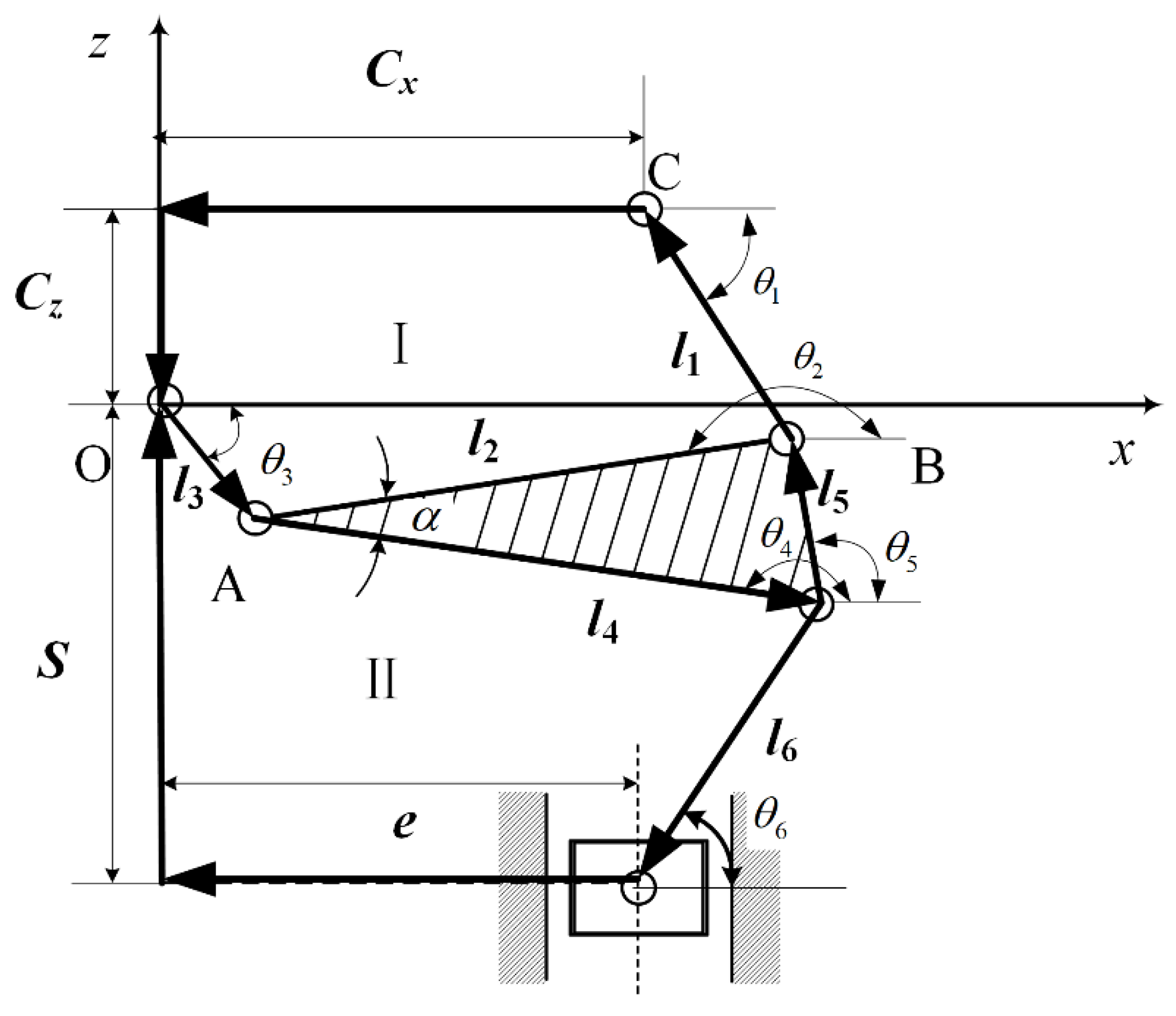

A toggle transmission mechanism, as shown in

Figure 1, is a typical mechanism of a multi-link mechanical press, which is commonly used in the cold and warm forging process. Multi-link cold and warm forging mechanical presses are the key equipment to realize the near net shape of cold and warm forging. The elbow bar transmission mechanism expands the stroke of the press and reduces the speed within the nominal stroke. The transmission mechanism is composed of two sets of toggle linkages, which are symmetrically distributed on both sides. The toggle linkage mechanism is composed of an eccentric gear, a toggle linkage, an upper rod, a bottom rod and a slider. During operation, the motor drives the eccentric gear to rotate at a constant speed at a certain angular speed through gear transmission. Through the multi-link transmission mechanism, it is finally transformed into the reciprocating motion output of the slider with quick return characteristics.

The accuracy of the rod system determines the quality of forging and also affects the service life of the die. Since the toggle mechanical press is driven by an AC motor and flywheel instead of a servo motor, it is difficult to guarantee the position precision by popular closed-loop control. In an ideal case, the transmission mechanism composed of two sets of symmetrical rod systems needs to be consistent so that the slider can remain horizontal and perpendicular to the guide rail. However, due to the inevitable error defect of the rod length, the running curve of the rod system will inevitably deviate from the ideal situation, and the slider will also tilt. In other words, the accuracy of the bar system has a great impact on the dynamic performance of the press. Therefore, in order to analyze the accuracy of the transmission mechanism of the multi-link press, two problems need to be clarified: (1) how to calculate the output error of the linkage caused by the design and manufacturing deviation of the linkage and (2) when considering the manufacturing cost, how to determine the length tolerance of each member and the machining and positioning tolerance of the shaft hole.

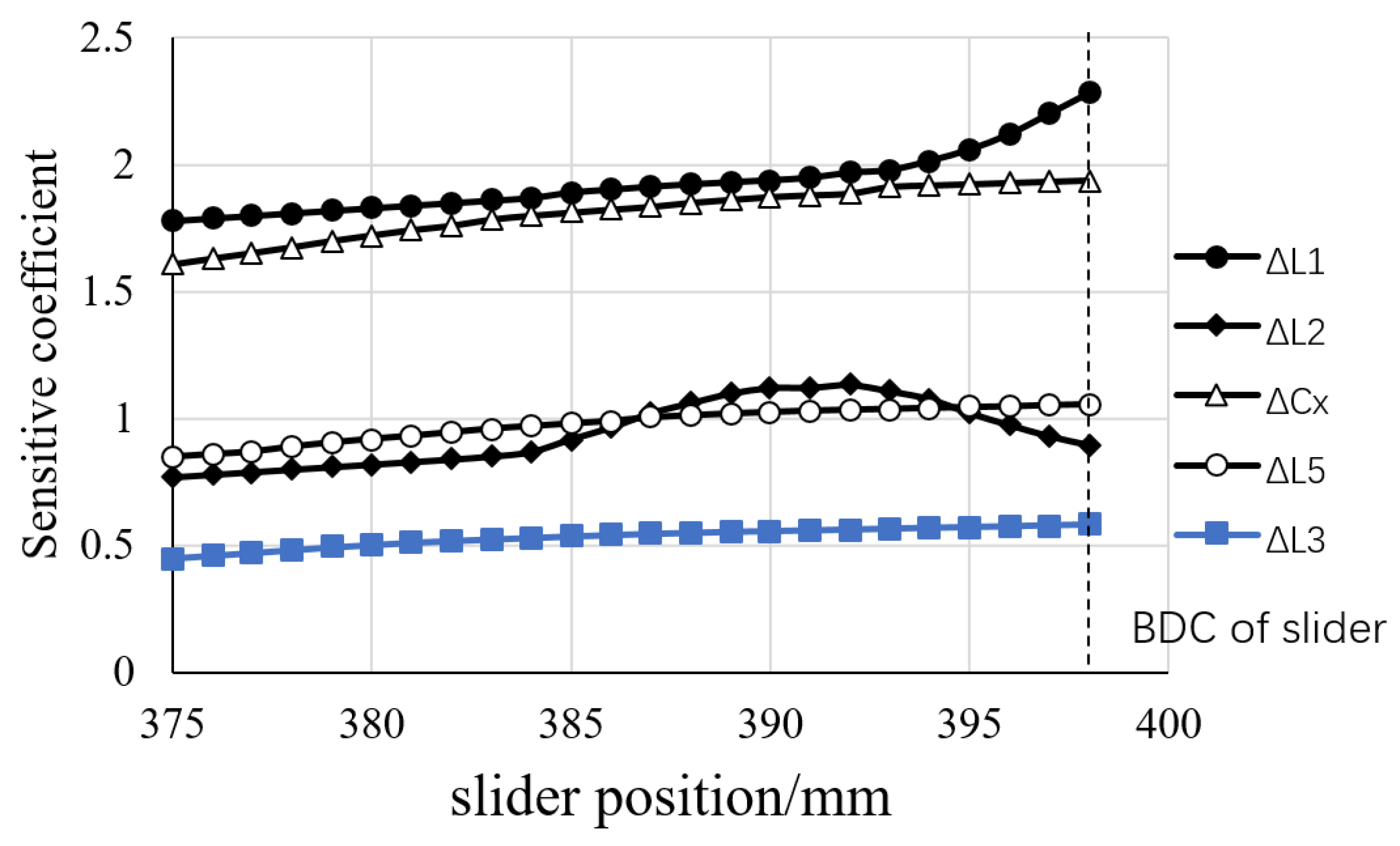

4. Key Error Identification Based on Sensitivity Analysis

Based on the above error model, the sensitivity analysis of the mechanism’s output error of each error source can be carried out, which will contribute to the accuracy design after the size optimization of the transmission mechanism. We can better understand the importance of each error, and these errors should be paid more attention to in the design.

The error sensitivity is used to reflect the influence of small changes in each error factor on the total output error. The error sensitivity is the absolute value of the sliding block motion output error on the partial derivative of each error factor. If the sensitivity of the

i-th error Δ

i is

ξi, then there is

In order to compare the influence degree of different error sources and highlight the main influencing factors, the error sources with significant influence can be determined. A statistical significance index can be used to measure the influence of a single structural parameter error under a finger positioning shape. In order to better identify and analyze the key error sources and normalize the sensitivity coefficients of the parameters of each error source, we can define

The structural parameters of the press (unit: mm) are:

l1 = 575,

l2 = 1697.5,

l3 = 205,

l4 = 1891,

l5 = 585,

l6 = 835,

Cx = 1500,

Cz = 570,

e = −23. MATLAB is used for simulation and analysis, and the sensitivity of the forming area near the BDC of each error source to the position error of the slider is obtained. Sensitivity analysis can be used to guide the precision design of the press so as to provide a basis for controlling the error to a small extent in the design stage of the multi-link transmission mechanism. The sensitivity of the influence of the key parameter error on the slider output position error is shown in

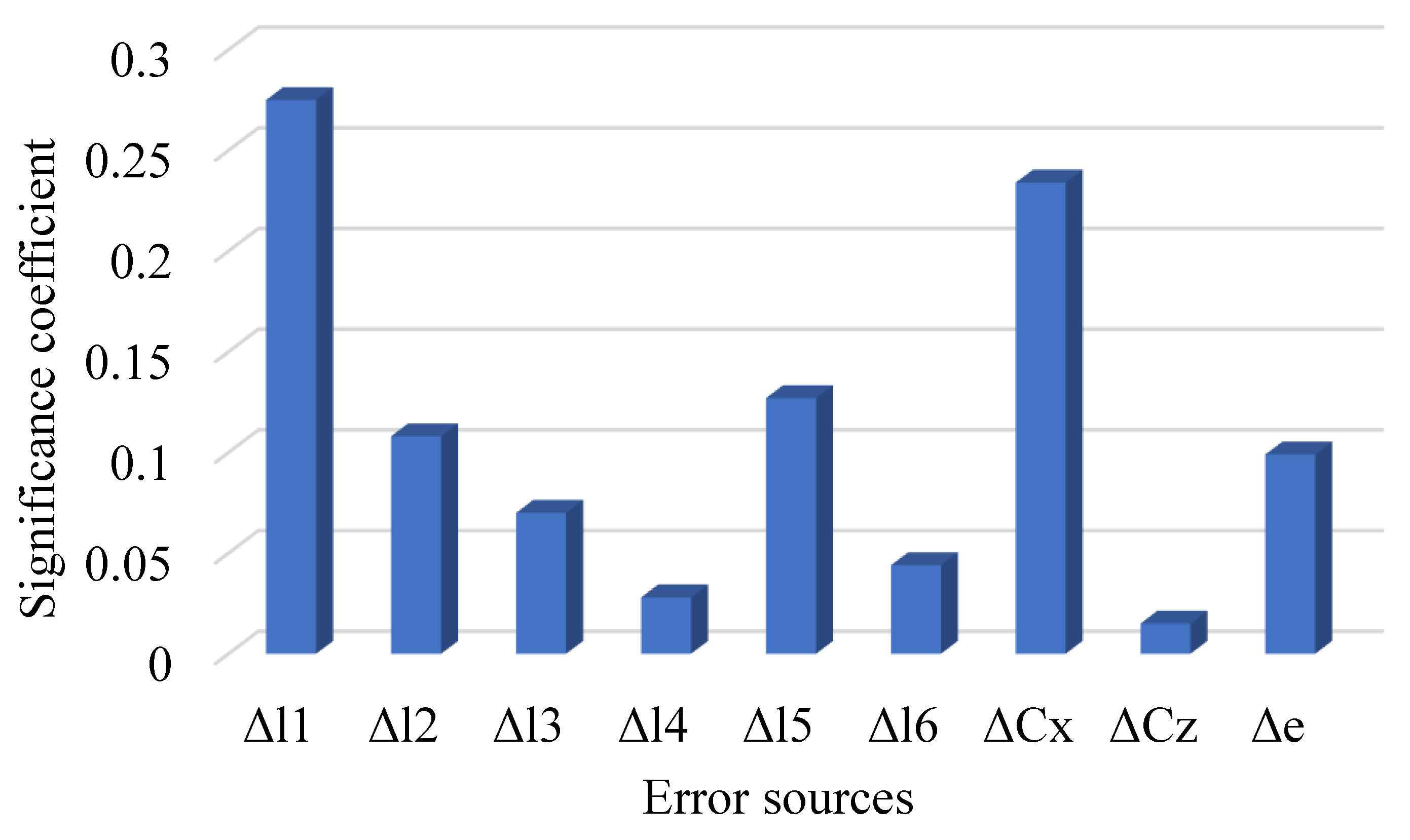

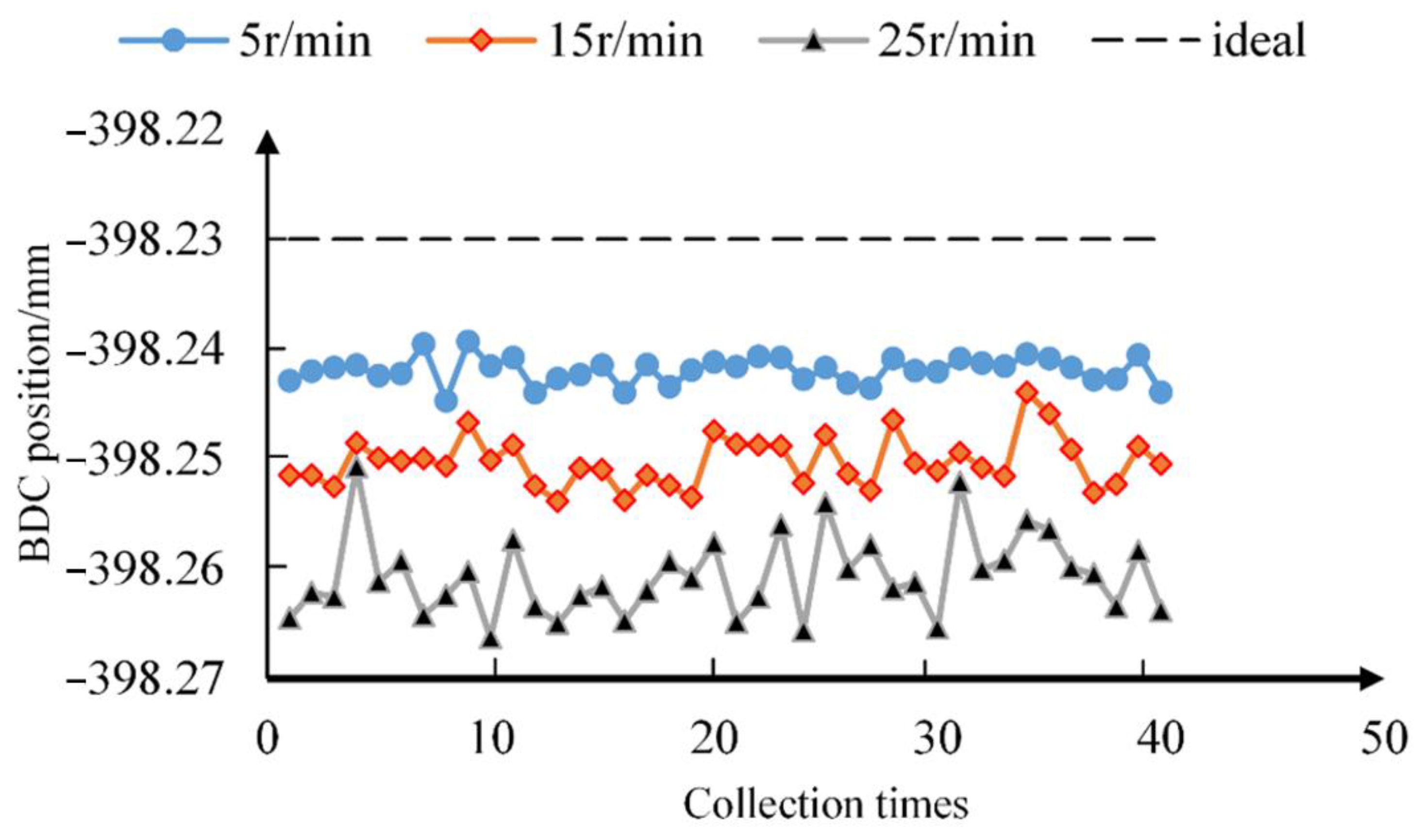

Figure 5. The sensitivity and significance of each geometric error source are shown in

Table 3Figure 6 shows the significance comparison diagram of each error element corresponding to the slider position error. Through this mapping function, the mapping relationship between the 9 original errors of the transmission mechanism and the slider displacement error is established. It can be seen from the figure that each error source has different effects on the position error of the press slider. Through sensitivity analysis, it can be seen that the position error of the BDC of the slider showed a significant correlation with Δ

l1 and Δ

Cx, accounting for 51% of the impact of all error sources. Δ

Cz and Δ

l4 have little impact on the position error.

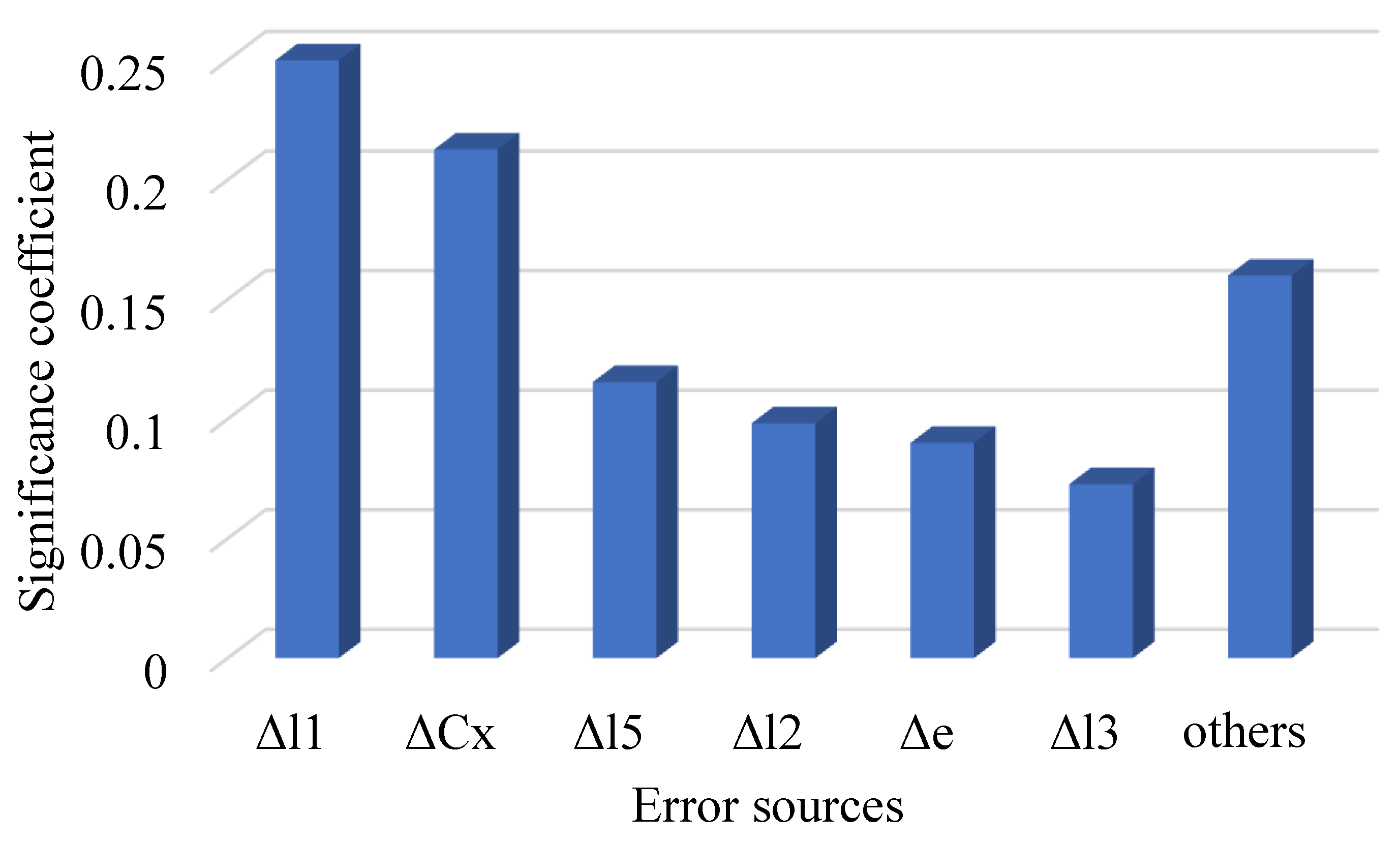

Similarly, the key error source parameters that have an important impact on the inclined angle error of the slider can be identified. The key error source of the slider tilt angle error at the bottom dead center position is the original error of 10 items. As shown in

Figure 7, Δ

l1, Δ

Cx and Δ

l5 have a great effect on the error, with the influence on the error accounting for 85% of the influence degree of all error sources.