Evaluation of Different Contact Assumptions in the Analysis of Friction-Induced Vibrations Using Dynamic Substructuring †

Abstract

:1. Introduction

2. Numerical Methods for Contact Dynamic Analysis

2.1. Forward Increment Lagrange Multiplier Method

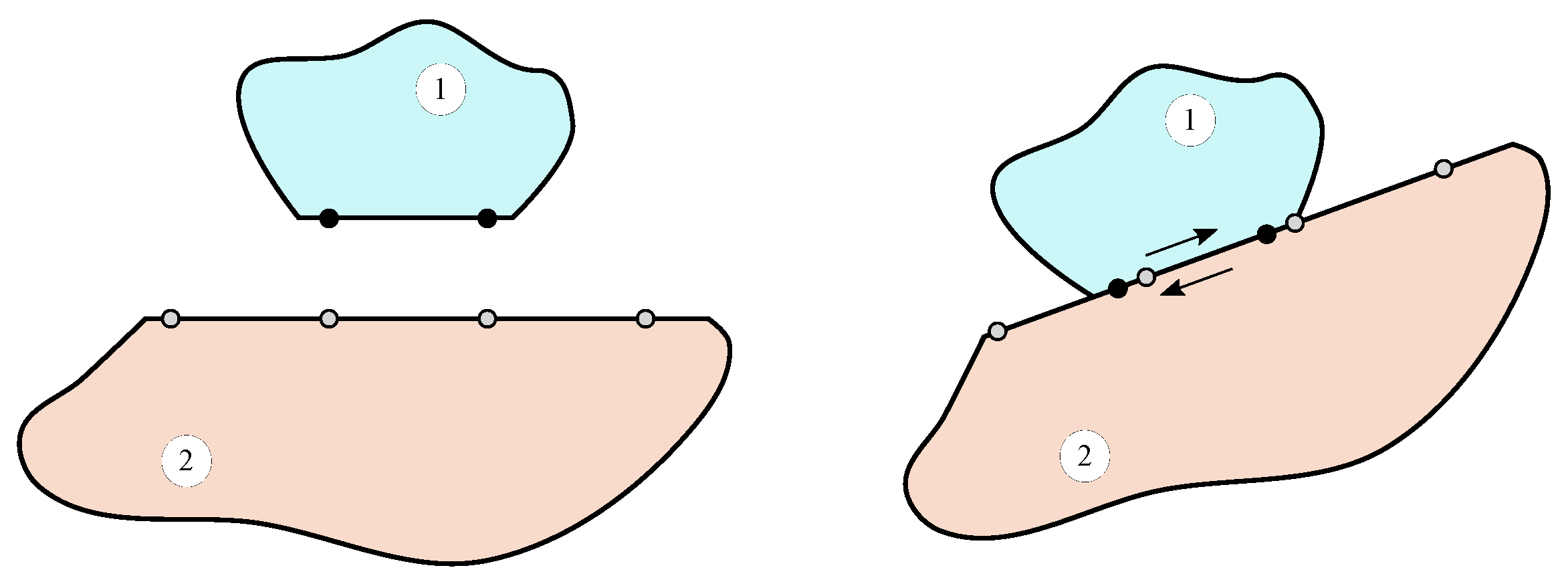

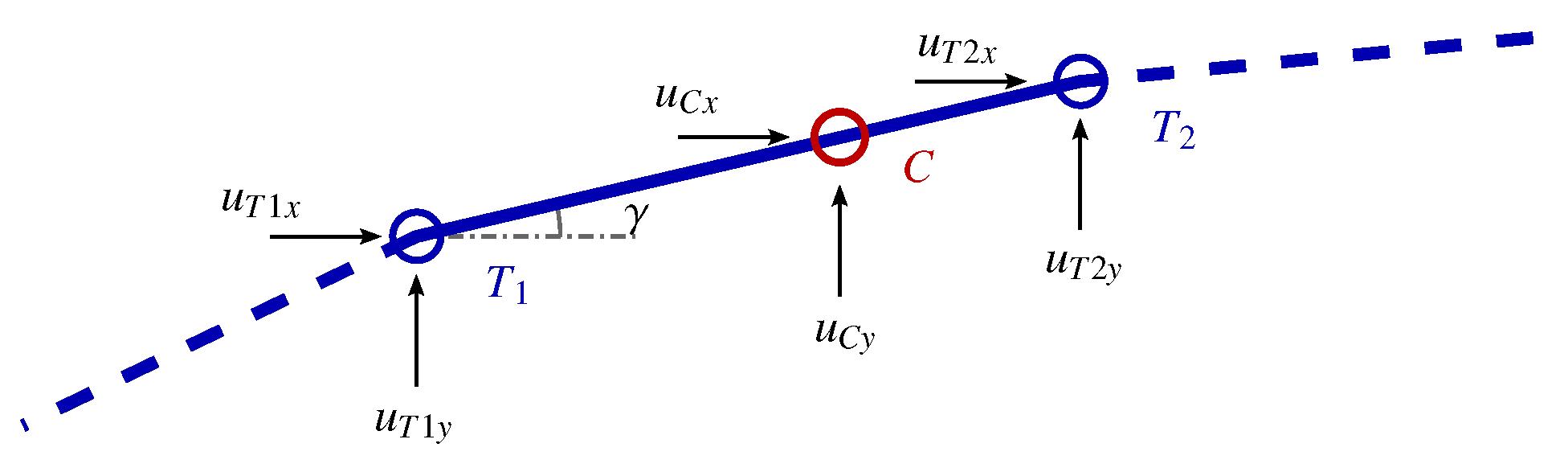

2.2. Substructuring with Time-Variant Coupling Conditions

- are the mass, damping and stiffness matrices of subsystem r;

- is the vector of displacements of subsystem r;

- is the vector of external forces on subsystem r;

- is the vector of connecting forces with other subsystems (internal constraint forces).

- (a)

- A basic contact assumption, introduced in [11], based on the a-priori defined rigid motion between the component subsystems described by the kinematic boundary conditions (Subs-a). It is assumed that the body to which the slave node belongs moves with respect to the other body with a velocity . Hence, by using a master element-slave node approach, the position of the slave node C at time t can be expressed as:where is the initial position of the slave node.

- (b)

- A realistic contact assumption, introduced in [25], considers the deformation of the contacting bodies (Subs-b) to account for friction-induced vibrations. To estimate the position of the contact point, the system position at time is evaluated using the predictor of displacements defined in (13), i.e.:where represents the undeformed position.

- (c)

- A simplification with respect to the realistic contact assumption is considered that disregards the direction change of the contact force due to the deformation (Subs-c).

3. Results

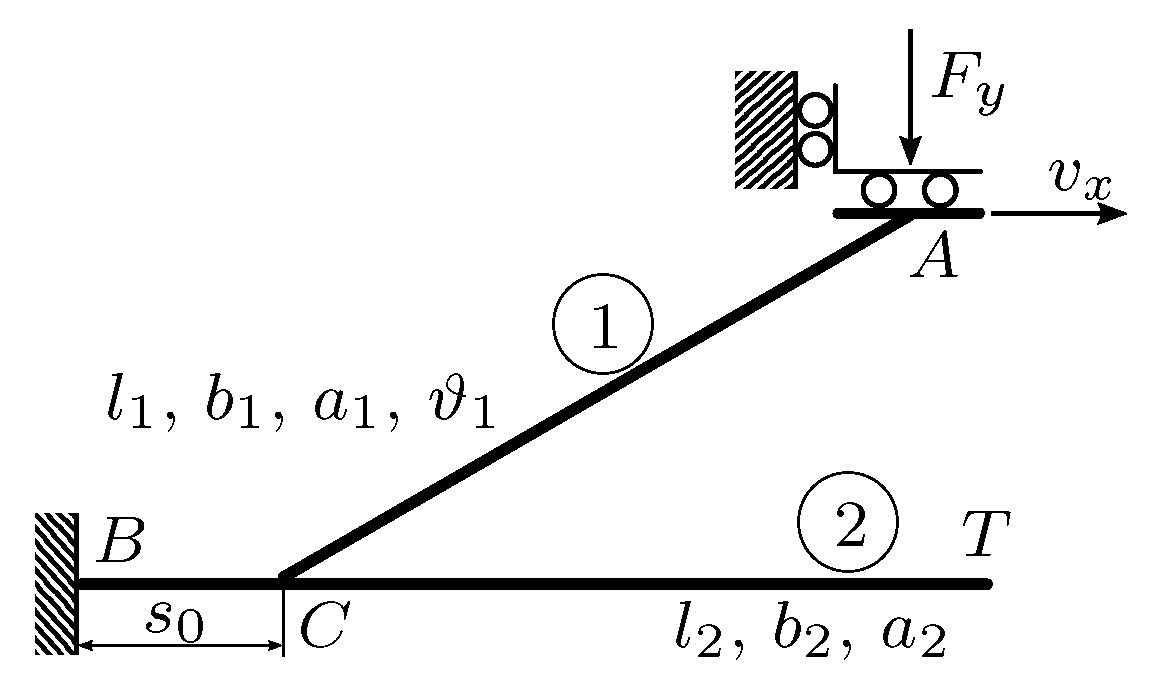

3.1. Numerical Model

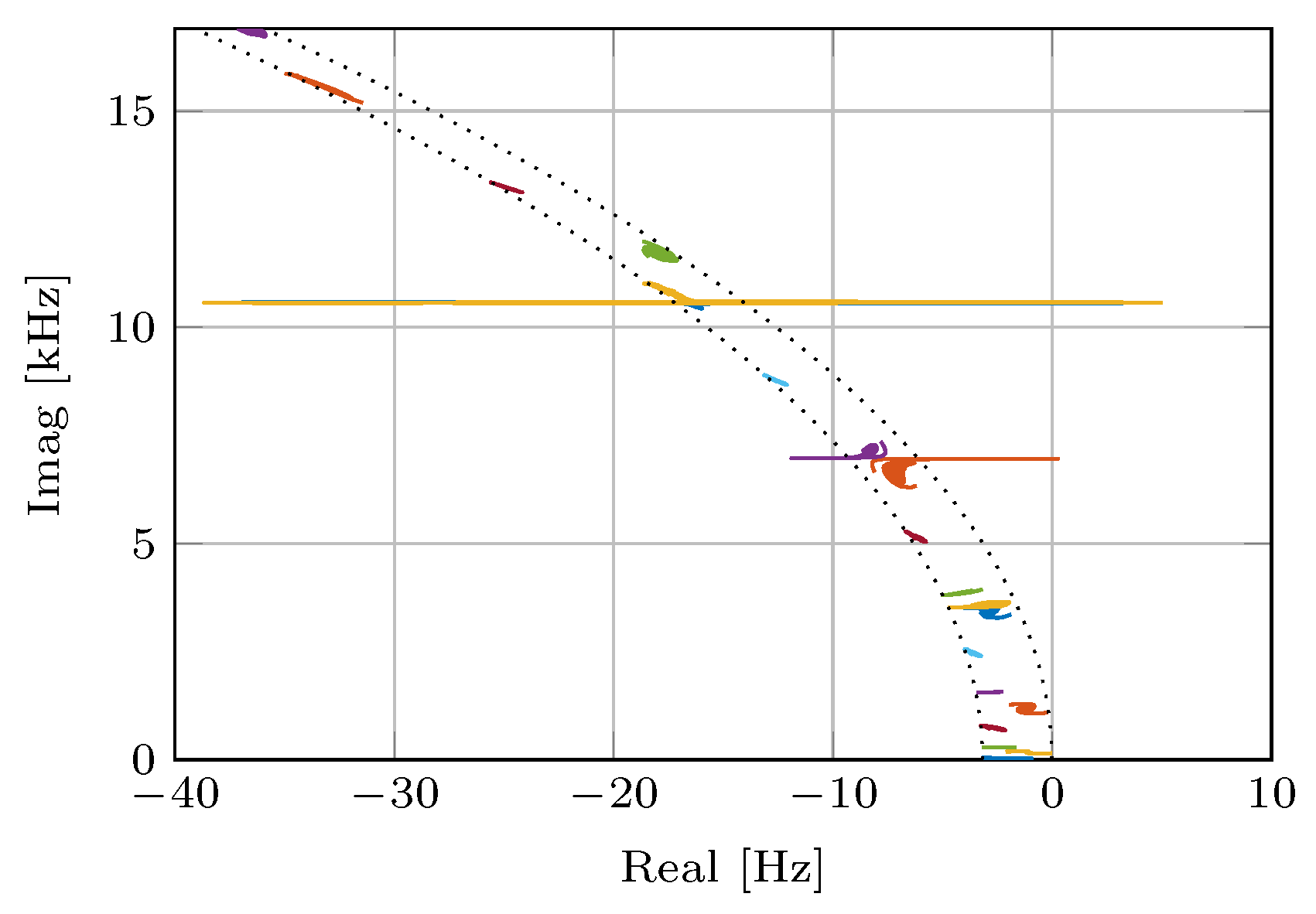

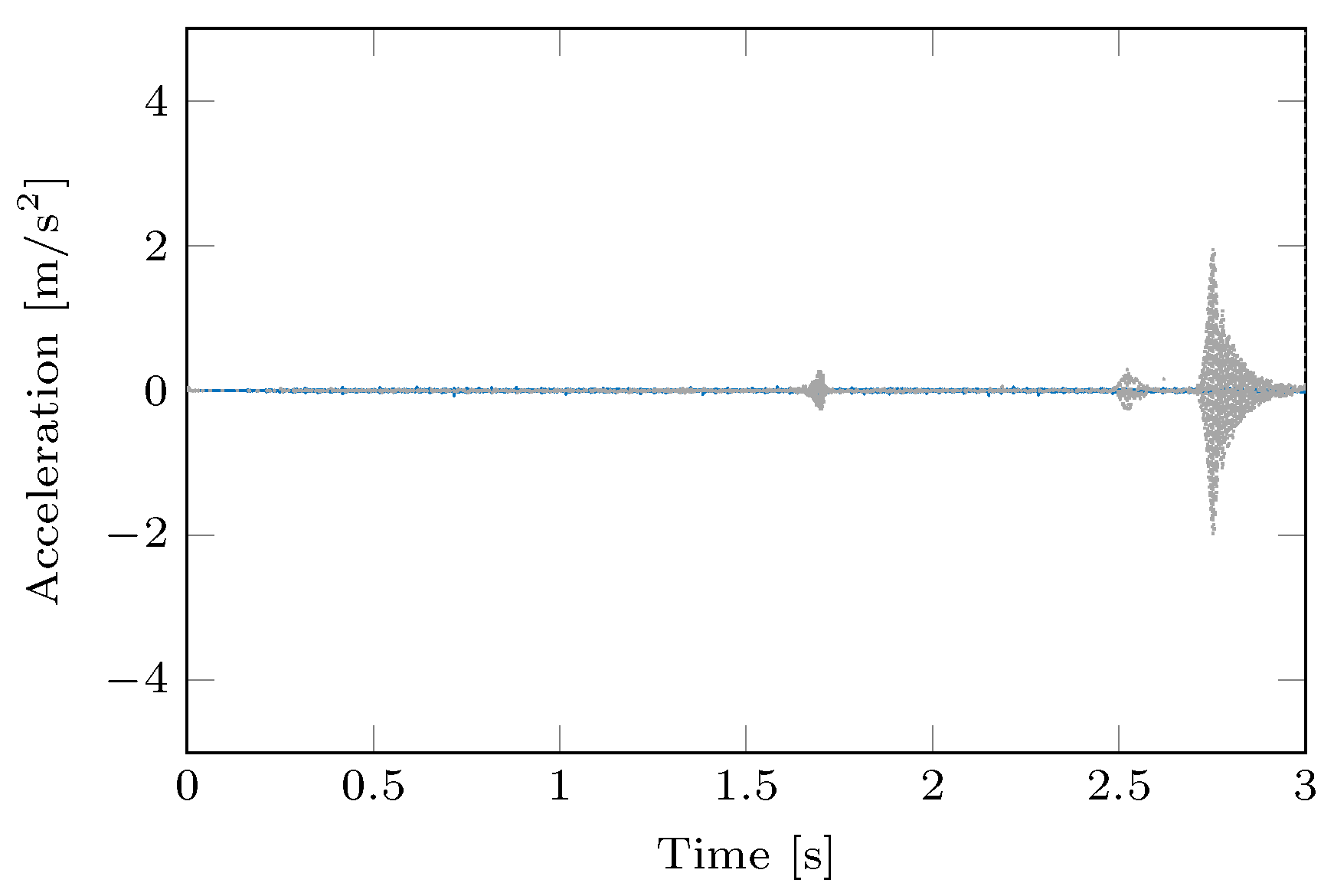

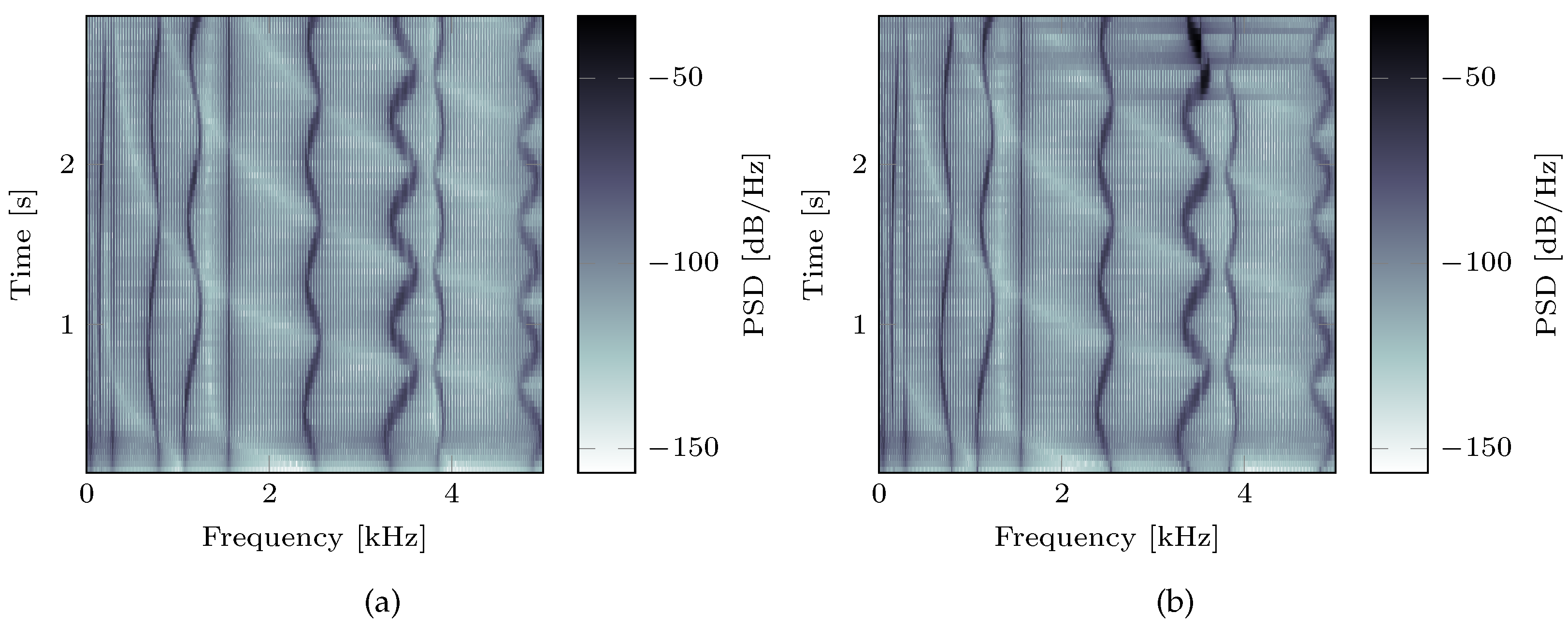

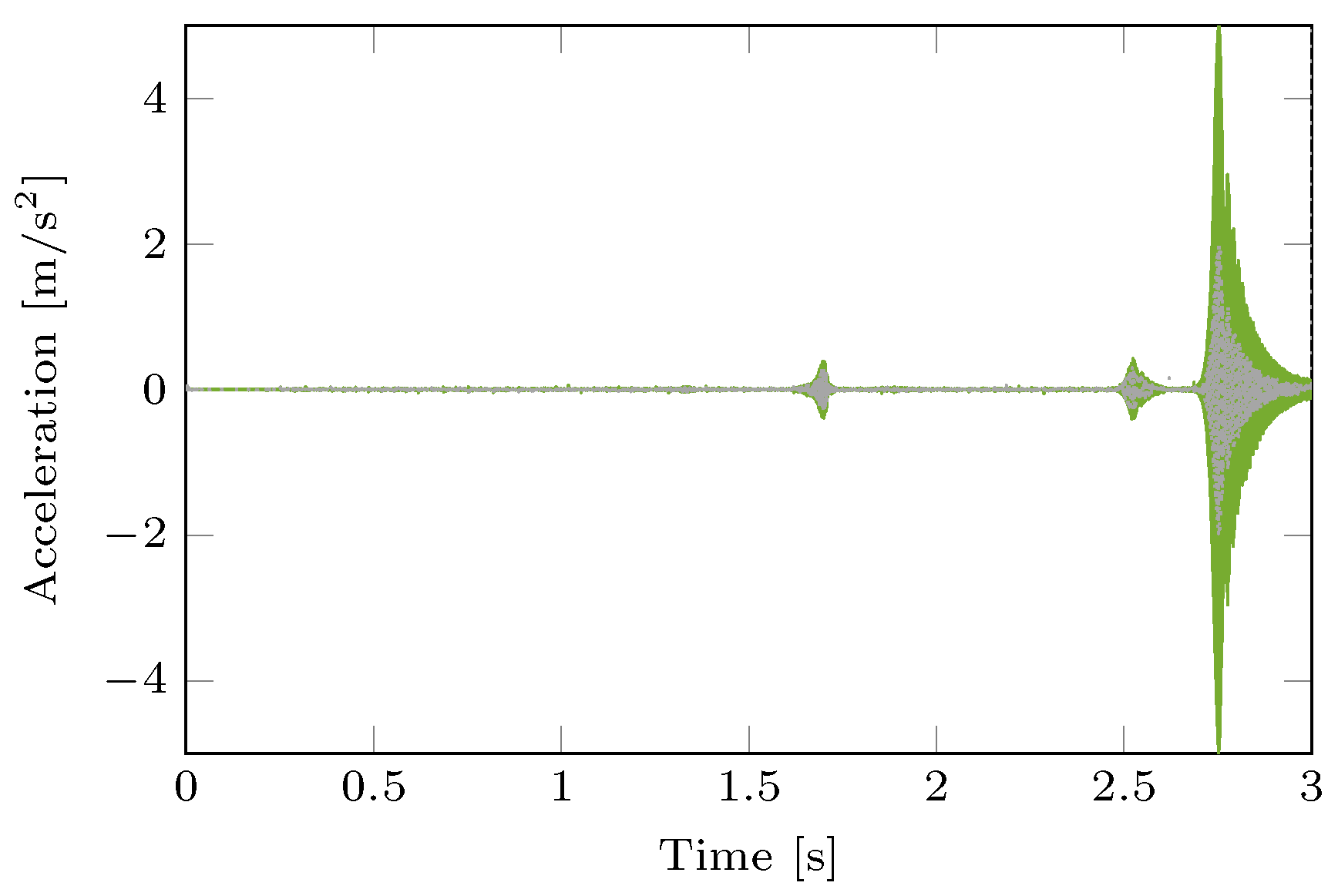

3.2. Subs-a and FiLm Comparison

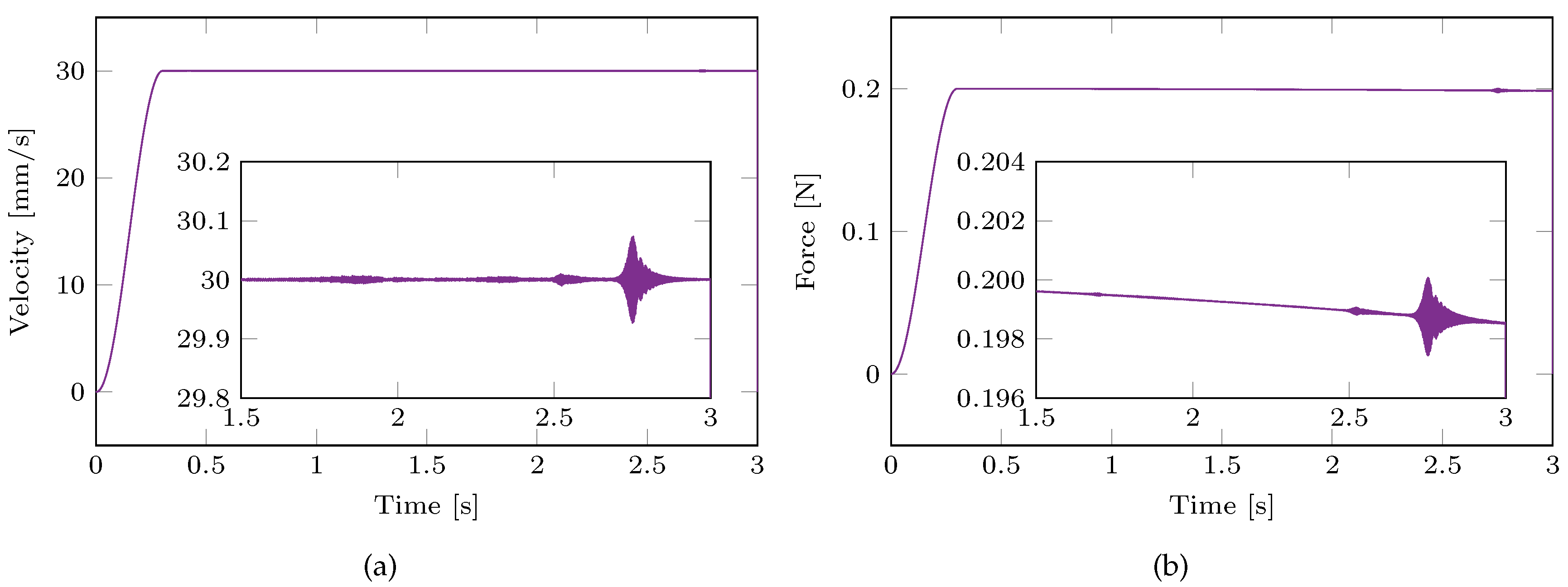

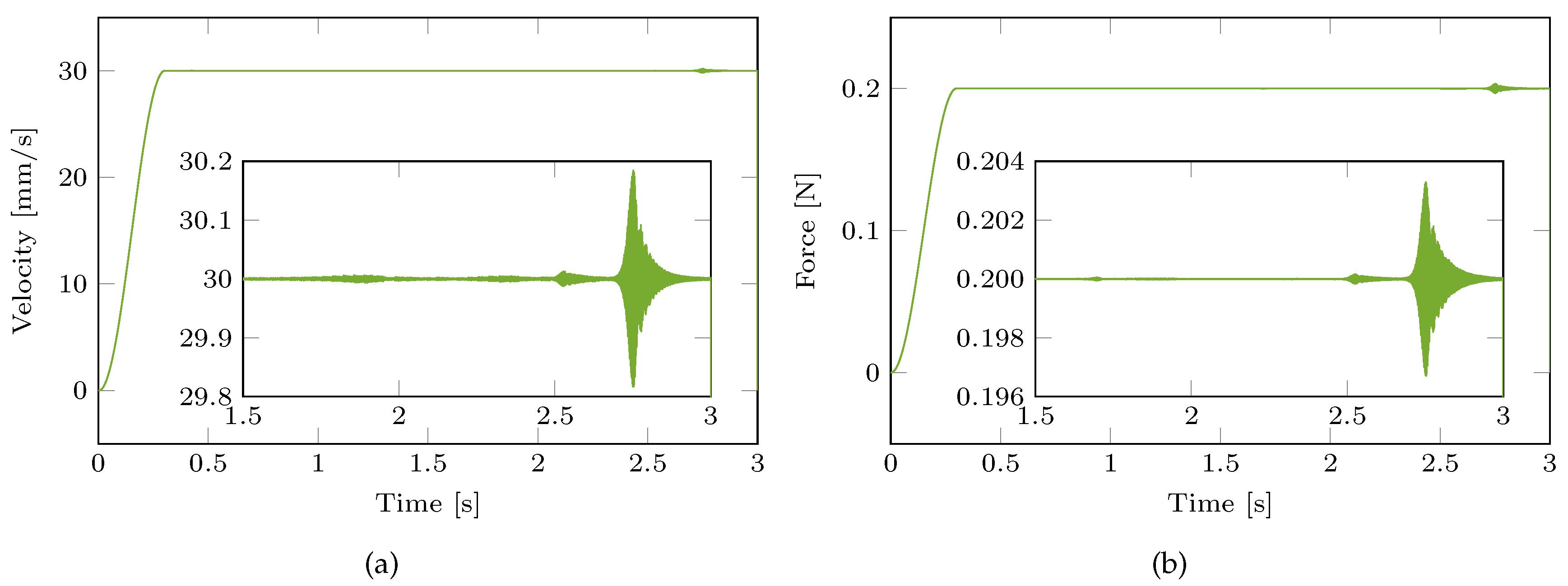

3.3. Subs-b and FiLm Comparison

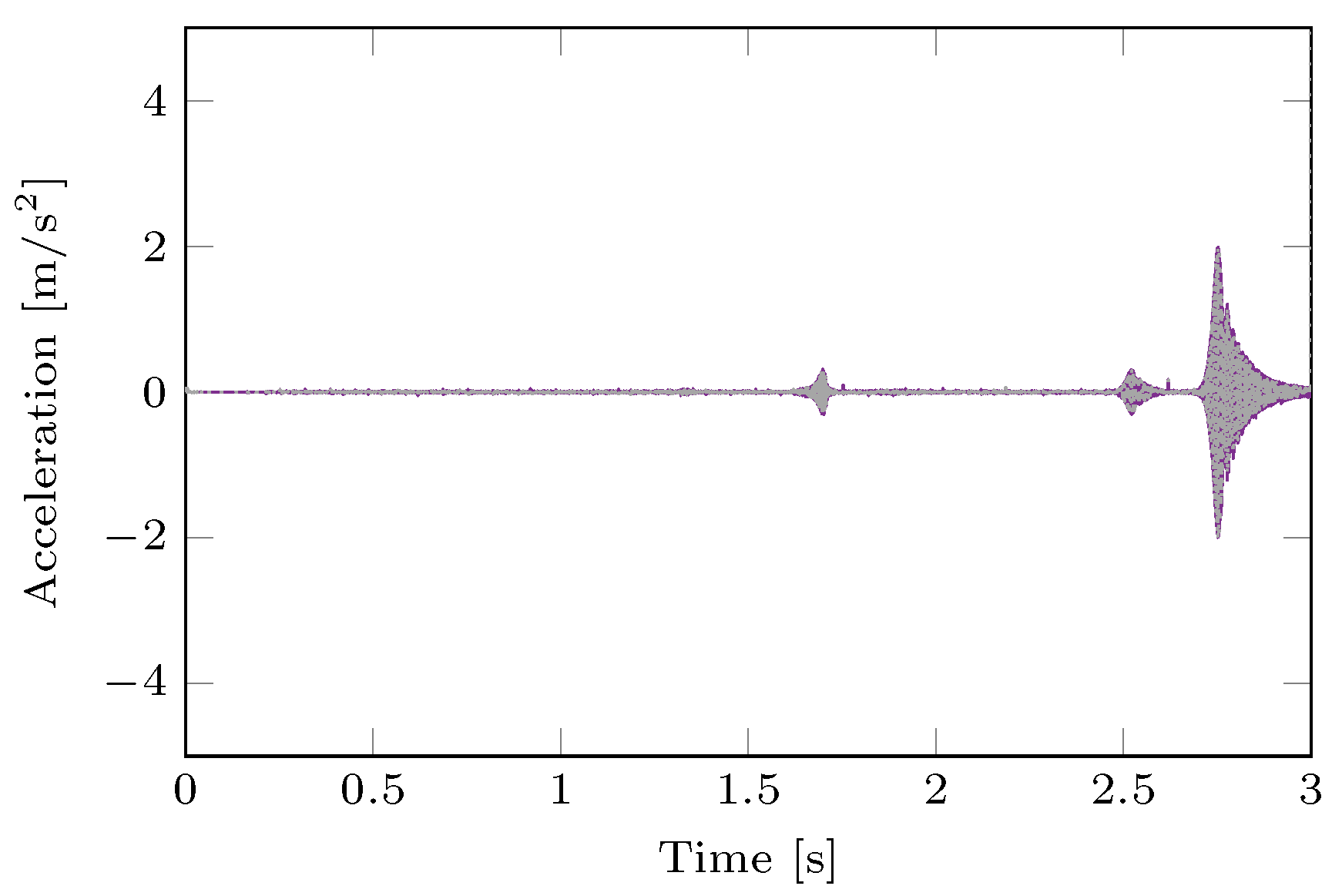

3.4. Subs-c and FiLm Comparison

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, R.A. Friction-Induced Vibration, Chatter, Squeal, and Chaos—Part I: Mechanics of Contact and Friction. Appl. Mech. Rev. 1994, 47, 209–226. [Google Scholar] [CrossRef]

- Ibrahim, R.A. Friction-Induced Vibration, Chatter, Squeal, and Chaos—Part II: Dynamics and Modeling. Appl. Mech. Rev. 1994, 47, 227–253. [Google Scholar] [CrossRef]

- Akay, A. Acoustics of friction. J. Acoust. Soc. Am. 2002, 111, 1525–1548. [Google Scholar] [CrossRef] [PubMed]

- de Klerk, D.; Rixen, D.J.; Voormeeren, S. General Framework for Dynamic Substructuring: History, Review, and Classification of Techniques. AIAA J. 2008, 46, 1169–1181. [Google Scholar] [CrossRef]

- Sjövall, P.; Abrahamsson, T. Substructure system identification from coupled system test data. Mech. Syst. Sig. Process. 2008, 22, 15–33. [Google Scholar] [CrossRef]

- D’Ambrogio, W.; Fregolent, A. Inverse dynamic substructuring using direct hybrid assembly in the frequency domain. Mech. Syst. Sig. Process. 2014, 45, 360–377. [Google Scholar] [CrossRef]

- Mayes, R.L.; Ross, M.R. Advancements in hybrid dynamic models combining experimental and finite element substructures. Mech. Syst. Sig. Process. 2012, 31, 56–66. [Google Scholar] [CrossRef]

- Rixen, D. A dual Craig-Bampton method for dynamic substructuring. J. Comput. Appl. Math. 2004, 168, 383–391. [Google Scholar] [CrossRef]

- Brunetti, J.; D’Ambrogio, W.; Fregolent, A. Contact problems in the framework of dynamic substructuring. In Proceedings of the ISMA 2018—International Conference on Noise and Vibration Engineering and USD 2018—International Conference on Uncertainty in Structural Dynamics, Leuven, Belgium, 17–19 September 2018; pp. 3987–3998. [Google Scholar]

- Carassale, L.; Silvestri, P.; Lengu, R.; Mazzaron, P. Modeling Rail-Vehicle Coupled Dynamics by a Time-Varying Substructuring Scheme. In Proceedings of the Dynamic Substructures; Linderholt, A., Allen, M.S., Mayes, R.L., Rixen, D., Eds.; Springer International Publishing: Cham, Switzerland, 2020; Volume 4, pp. 167–171. [Google Scholar]

- Brunetti, J.; D’Ambrogio, W.; Fregolent, A. Dynamic coupling of substructures with sliding friction interfaces. Mech. Syst. Sig. Process. 2020, 141. [Google Scholar] [CrossRef]

- Voormeeren, S.N.; Rixen, D.J. A Family of Substructure Decoupling Techniques Based on a Dual Assembly Approach. Mech. Syst. Sig. Process. 2012, 27, 379–396. [Google Scholar] [CrossRef]

- Renouf, M.; Massi, F.; Saulot, A.; Fillot, N. Numerical Tribology of Dry Contact. Tribol. Int. 2011, 44, 834–844. [Google Scholar] [CrossRef] [Green Version]

- Sinou, J.J. Transient non-linear dynamic analysis of automotive disc brake squeal - On the need to consider both stability and non-linear analysis. Mech. Res. Commun. 2010, 37, 96–105. [Google Scholar] [CrossRef] [Green Version]

- Brunetti, J.; Massi, F.; Baillet, L.; D’Ambrogio, W. Application of the modal absorption index (MAI) to reduce the CEA instability over-prediction on a complex frictional system. In Proceedings of the ISMA 2016—International Conference on Noise and Vibration Engineering and USD2016—International Conference on Uncertainty in Structural Dynamics, Leuven, Belgium, 19–21 September 2016; pp. 3073–3083. [Google Scholar]

- Papangelo, A.; Putignano, C.; Hoffmann, N. Self-excited vibrations due to viscoelastic interactions. Mech. Syst. Sig. Process. 2020, 144, 106894. [Google Scholar] [CrossRef]

- Adams, G.G. Steady Sliding of Two Elastic Half-Spaces With Friction Reduction due to Interface Stick-Slip. J. Appl. Mech. 1998, 65, 470–475. [Google Scholar] [CrossRef]

- Tonazzi, D.; Massi, F.; Baillet, L.; Brunetti, J.; Berthier, Y. Interaction between contact behaviour and vibrational response for dry contact system. Mech. Syst. Signal Process. 2018, 110, 110–121. [Google Scholar] [CrossRef]

- Sinou, J.J.; Thouverez, F.; Jézéquel, L. Analysis of friction and instability by the centre manifold theory for a non-linear sprag-slip model. J. Sound Vib. 2003, 265, 527–559. [Google Scholar] [CrossRef] [Green Version]

- Hoffmann, N.; Gaul, L. A sufficient criterion for the onset of sprag-slip oscillations. Arch. Appl. Mech. 2004, 73, 650–660. [Google Scholar] [CrossRef]

- Wang, A.; Mo, J.; Wang, X.; Zhu, M.; Zhou, Z. Effect of surface roughness on friction-induced noise: Exploring the generation of squeal at sliding friction interface. Wear 2018, 402-403, 80–90. [Google Scholar] [CrossRef]

- Lazzari, A.; Tonazzi, D.; Massi, F. Squeal propensity characterization of brake lining materials through friction noise measurements. Mech. Syst. Sig. Process. 2019, 128, 216–228. [Google Scholar] [CrossRef]

- Wang, D.; Mo, J.; Wang, X.; Ouyang, H.; Zhou, Z. Experimental and numerical investigations of the piezoelectric energy harvesting via friction-induced vibration. Energy Convers. Manag. 2018, 171, 1134–1149. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Shi, Z. Dynamic modelling of the defect extension and appearance in a cylindrical roller bearing. Mech. Syst. Sig. Process. 2022, 173, 109040. [Google Scholar] [CrossRef]

- Brunetti, J.; D’Ambrogio, W.; Fregolent, A. Friction-induced vibrations in the framework of dynamic substructuring. Nonlinear Dyn. 2021, 103, 3301–3314. [Google Scholar] [CrossRef]

- Di Bartolomeo, M.; Lacerra, G.; Baillet, L.; Chatelet, E.; Massi, F. Parametrical experimental and numerical analysis on friction-induced vibrations by a simple frictional system. Tribol. Int. 2017, 112, 47–57. [Google Scholar] [CrossRef]

- Carpenter, N.J.; Taylor, R.L.; Katona, M.G. Lagrange constraints for transient finite element surface contact. Int. J. Numer. Methods Eng. 1991, 32, 103–128. [Google Scholar] [CrossRef] [Green Version]

- Newmark, N.M. A method of computation for structural dynamics. J. Eng. Mech. Div. 1959, 85, 67–94. [Google Scholar] [CrossRef]

- Brunetti, J.; Massi, F.; D’Ambrogio, W.; Baillet, L. Steady state of modal coupling instabilities as a dynamic energy equilibrium. In Proceedings of the ISMA 2014—International Conference on Noise and Vibration Engineering and USD 2014—International Conference on Uncertainty in Structural Dynamics, Leuven, Belgium, 15–17 September 2014; pp. 1827–1842. [Google Scholar]

Subs-a and

Subs-a and  FiLm method.

FiLm method.

Subs-b and

Subs-b and  FiLm method.

FiLm method.

Subs-c and

Subs-c and  FiLm method.

FiLm method.

| Dimensions | Beam 1 | Beam 2 | Unit | |

|---|---|---|---|---|

| Length | l | 75 | 100 | mm |

| Thickness | b | 1.5 | 2 | mm |

| Width | a | 10 | 20 | mm |

| Angle | 30 | 0 | degree |

| Quantity | Beam 1 | Beam 2 | Unit | |

|---|---|---|---|---|

| Young mod | E | 71 | 2.38 | GPa |

| Poisson ratio | 0.33 | 0.40 | ||

| Density | 2770 | 1200 | kg/m | |

| prop. damping | 0.2 | 40 | s | |

| prop. damping | 4.0·10 | 4.0·10 | s | |

| Friction coefficient | 0.30 | |||

| Force | −0.20 | N | ||

| Velocity | 30 | mm/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunetti, J.; D’Ambrogio, W.; Fregolent, A. Evaluation of Different Contact Assumptions in the Analysis of Friction-Induced Vibrations Using Dynamic Substructuring. Machines 2022, 10, 384. https://doi.org/10.3390/machines10050384

Brunetti J, D’Ambrogio W, Fregolent A. Evaluation of Different Contact Assumptions in the Analysis of Friction-Induced Vibrations Using Dynamic Substructuring. Machines. 2022; 10(5):384. https://doi.org/10.3390/machines10050384

Chicago/Turabian StyleBrunetti, Jacopo, Walter D’Ambrogio, and Annalisa Fregolent. 2022. "Evaluation of Different Contact Assumptions in the Analysis of Friction-Induced Vibrations Using Dynamic Substructuring" Machines 10, no. 5: 384. https://doi.org/10.3390/machines10050384

APA StyleBrunetti, J., D’Ambrogio, W., & Fregolent, A. (2022). Evaluation of Different Contact Assumptions in the Analysis of Friction-Induced Vibrations Using Dynamic Substructuring. Machines, 10(5), 384. https://doi.org/10.3390/machines10050384