Chatter Suppression during Milling of Ti-6Al-4V Based on Variable Pitch Tool and Process Damping Effect

Abstract

:1. Introduction

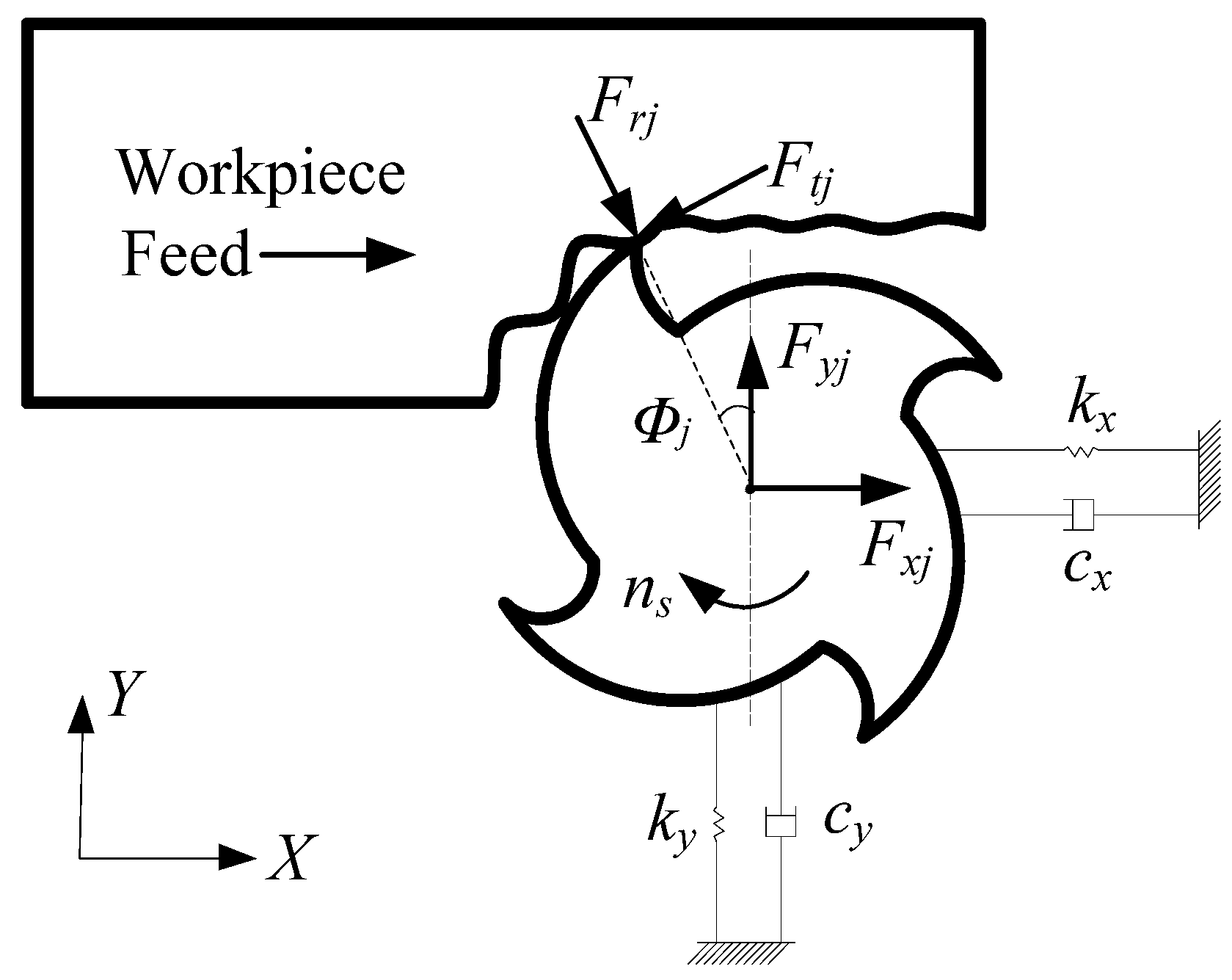

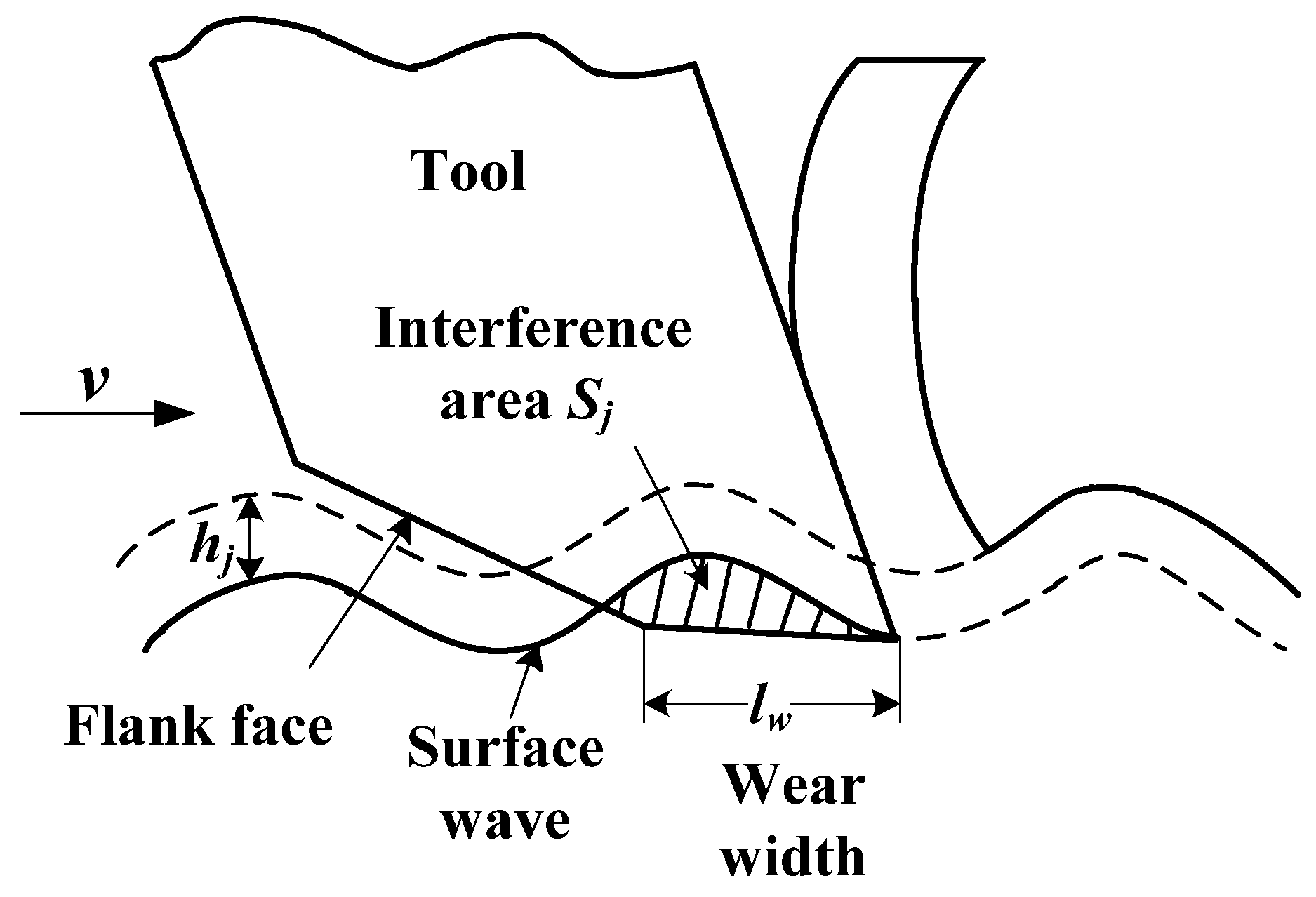

2. Milling Model of Variable Pitch Tool Considering Process Damping

3. Stability Analysis

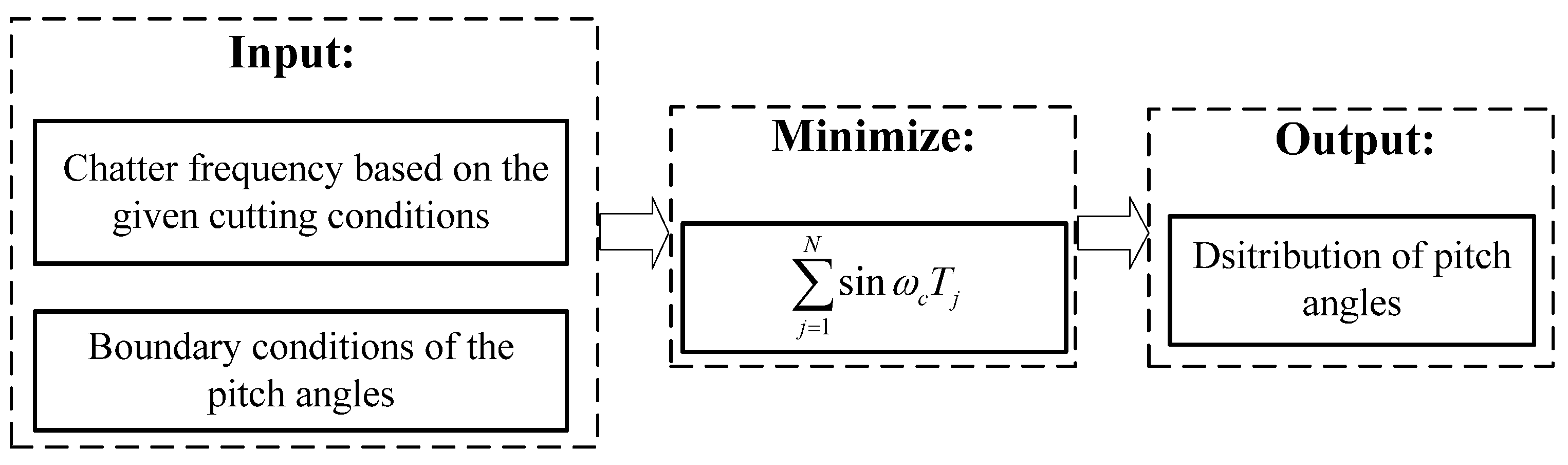

4. Optimization of Variable Pitch Angles

5. Case Study

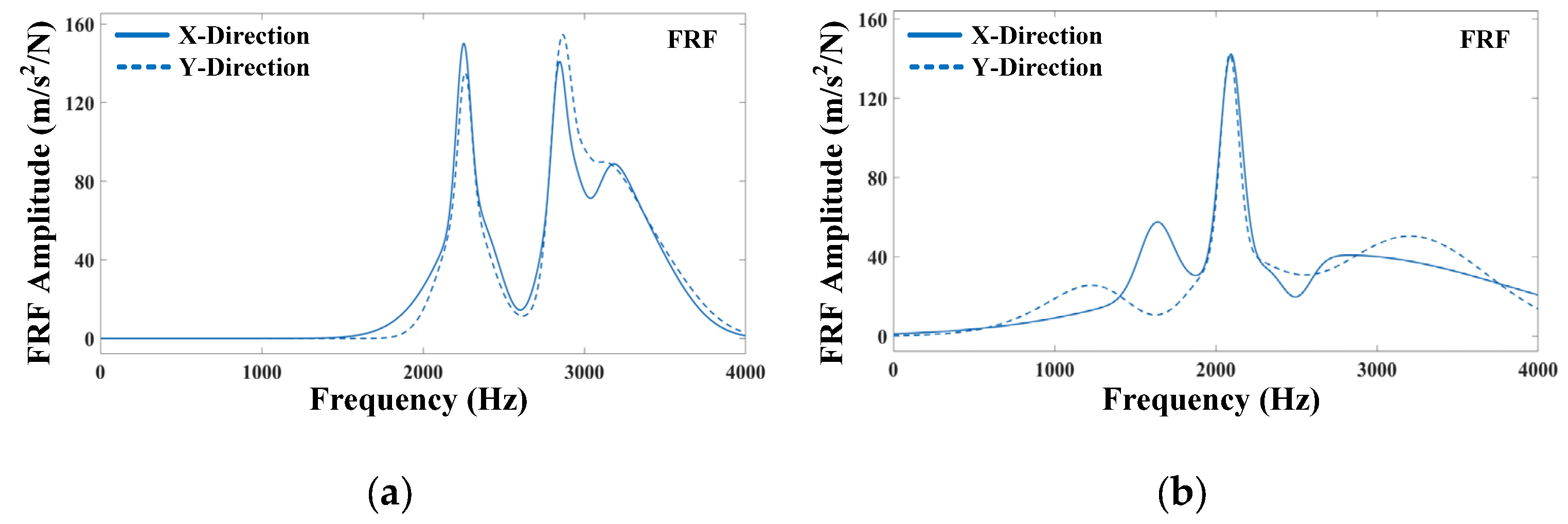

5.1. Industrial Case

5.2. Laboratory Case

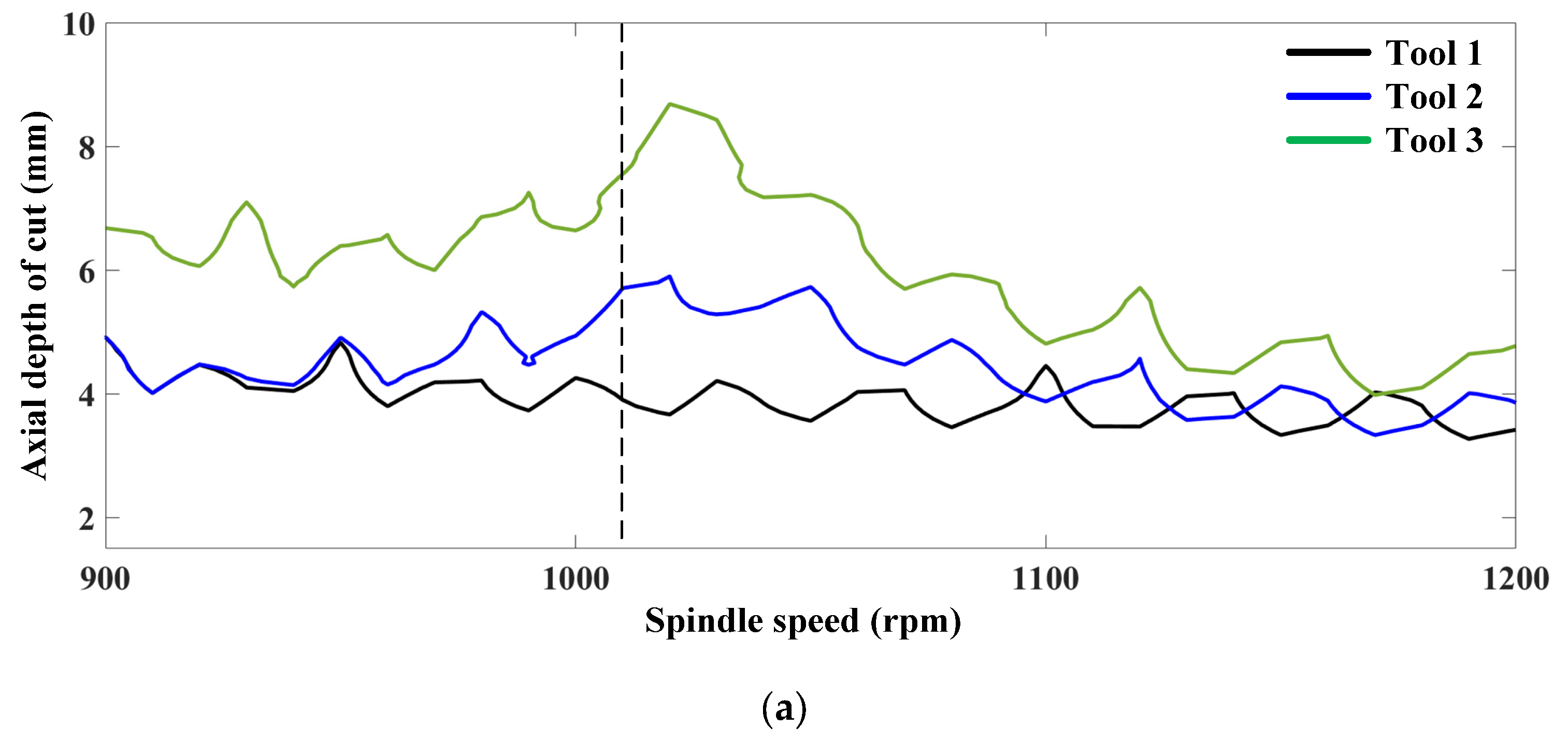

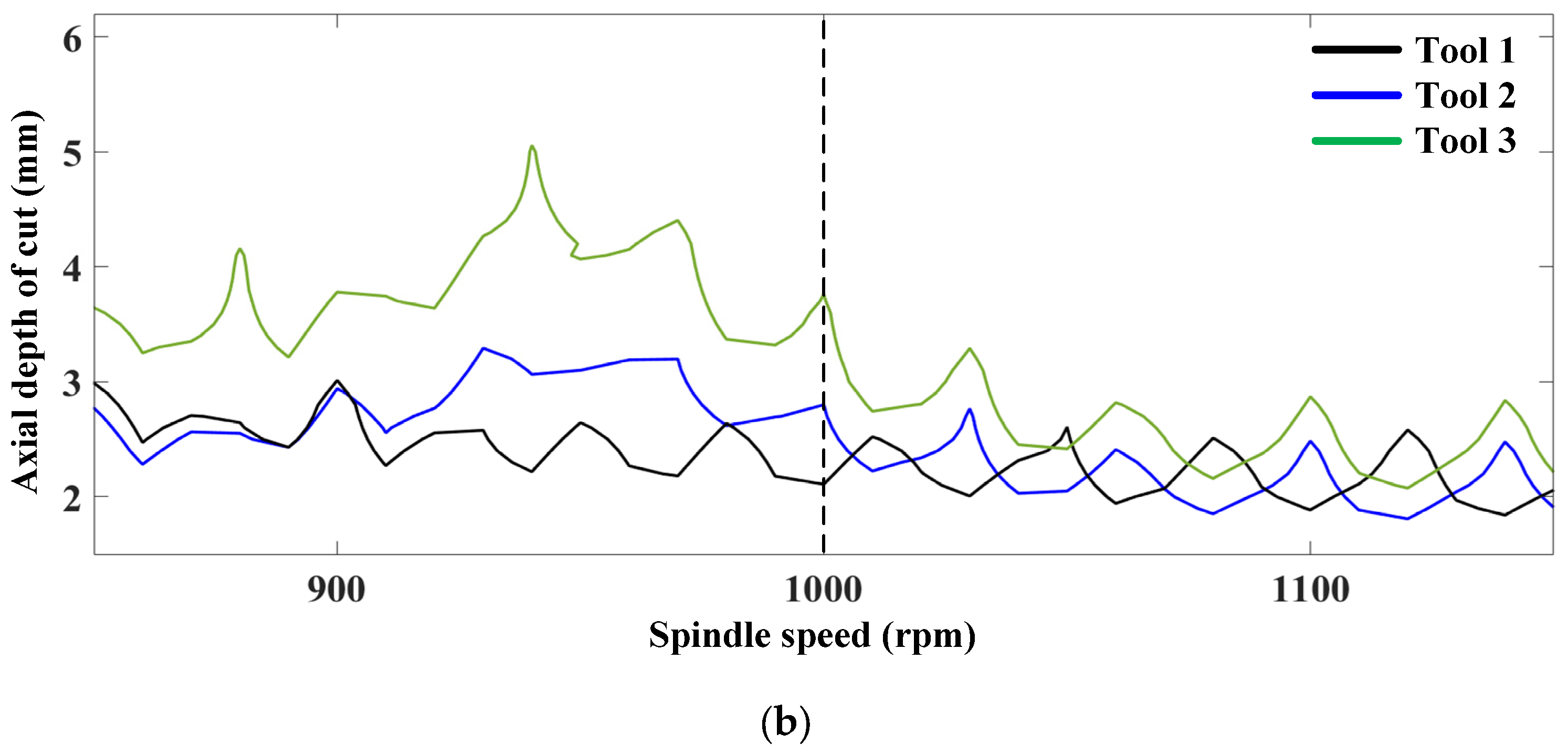

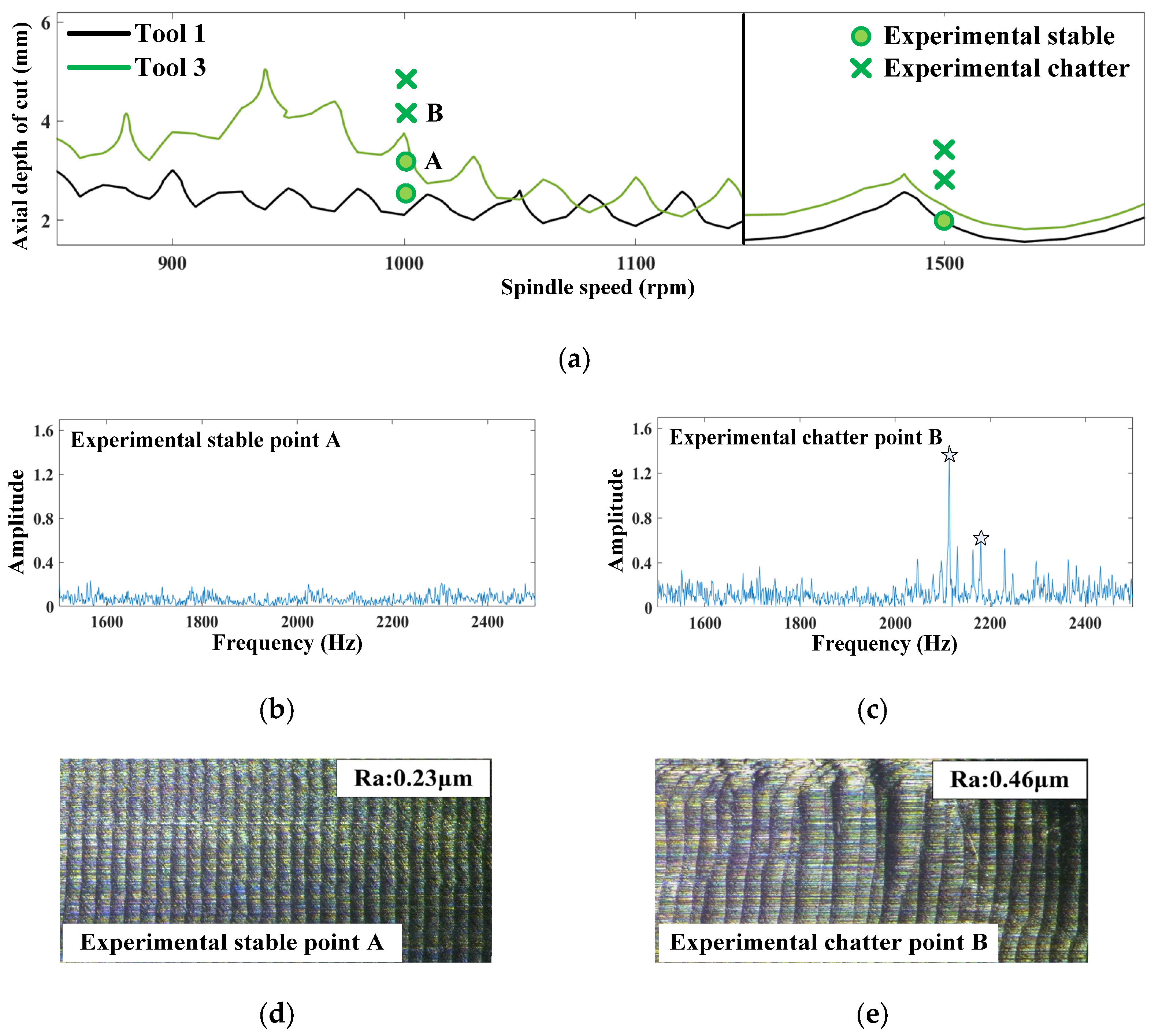

5.3. Stability Diagrams

6. Experimental Verification

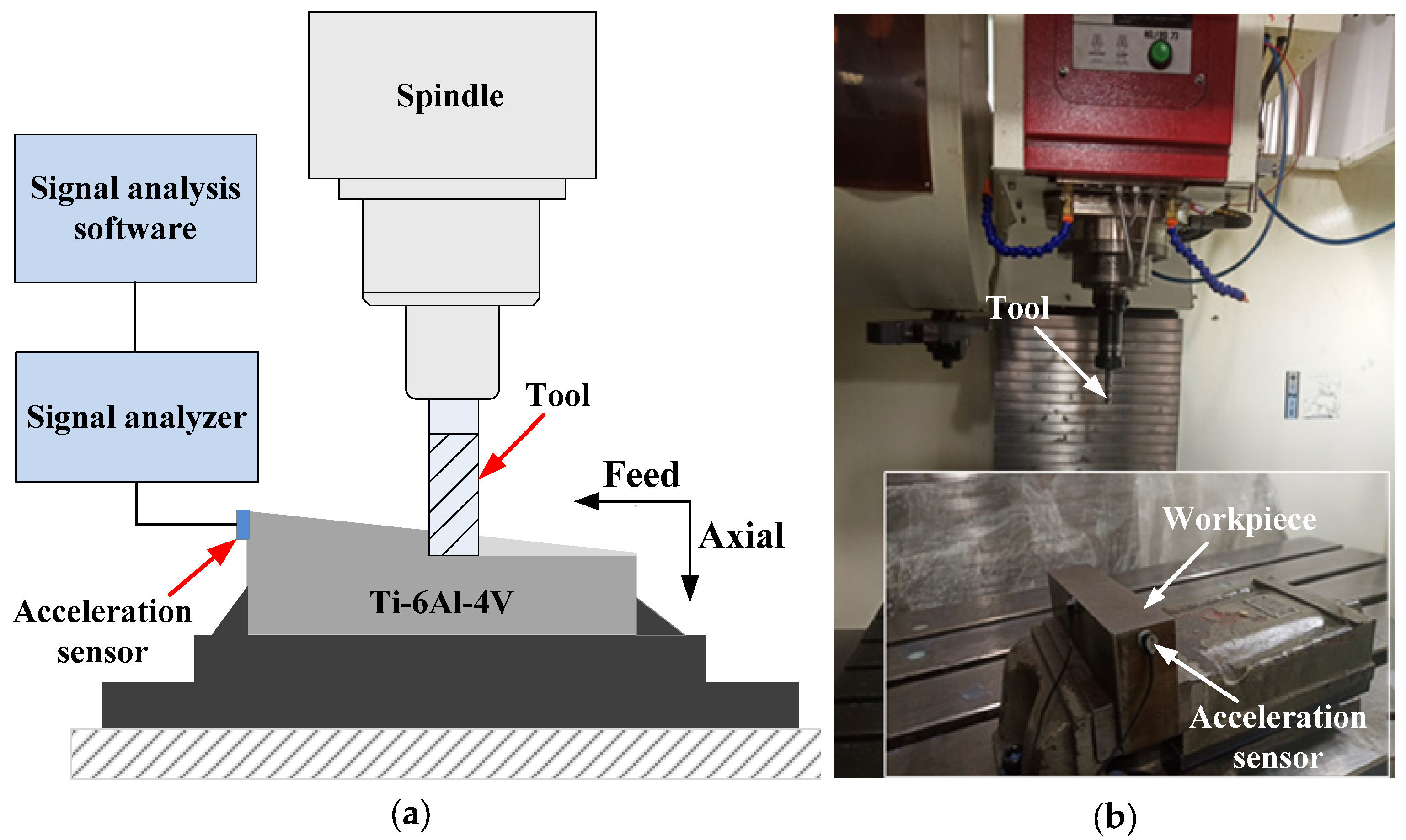

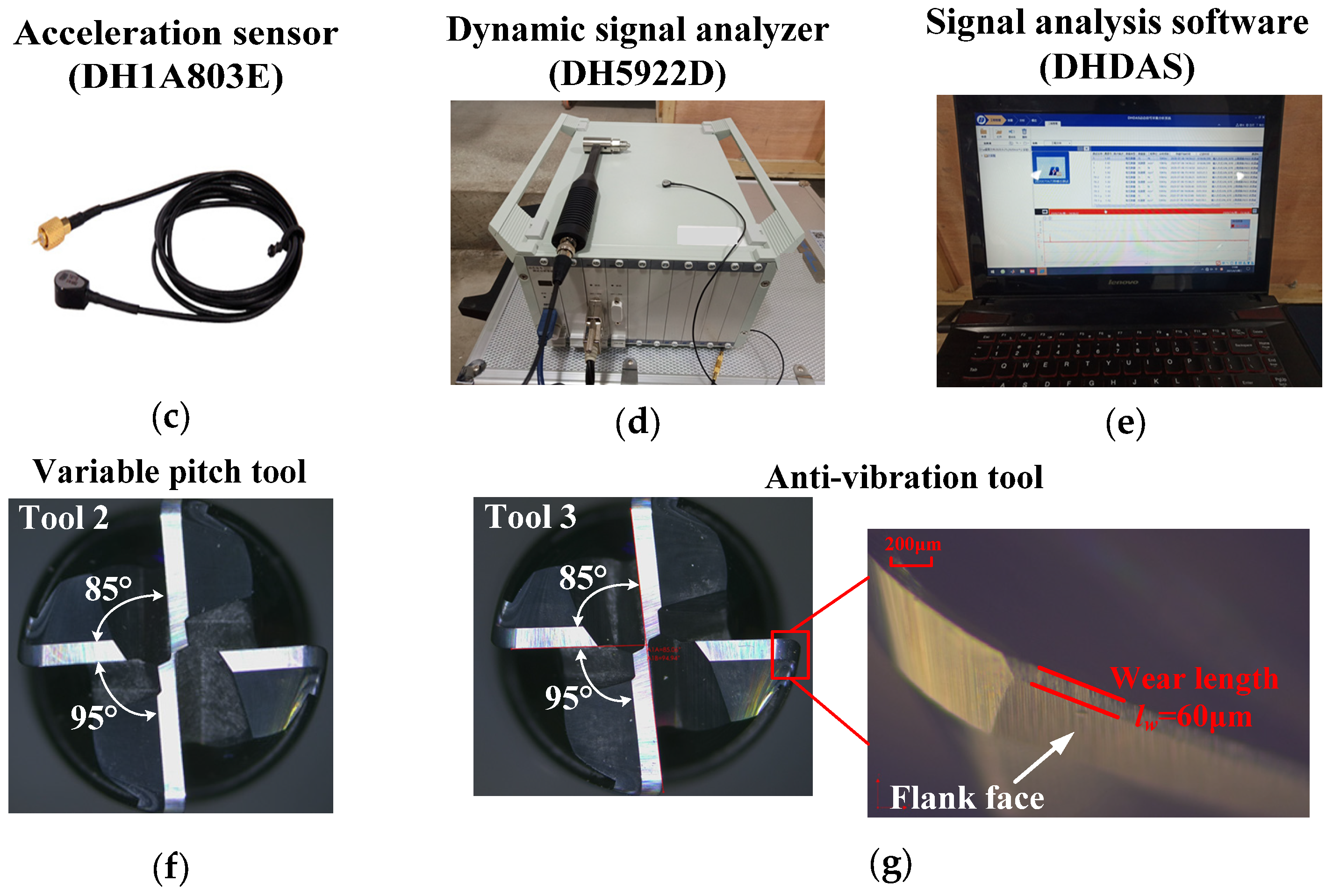

6.1. Experimental Equipment

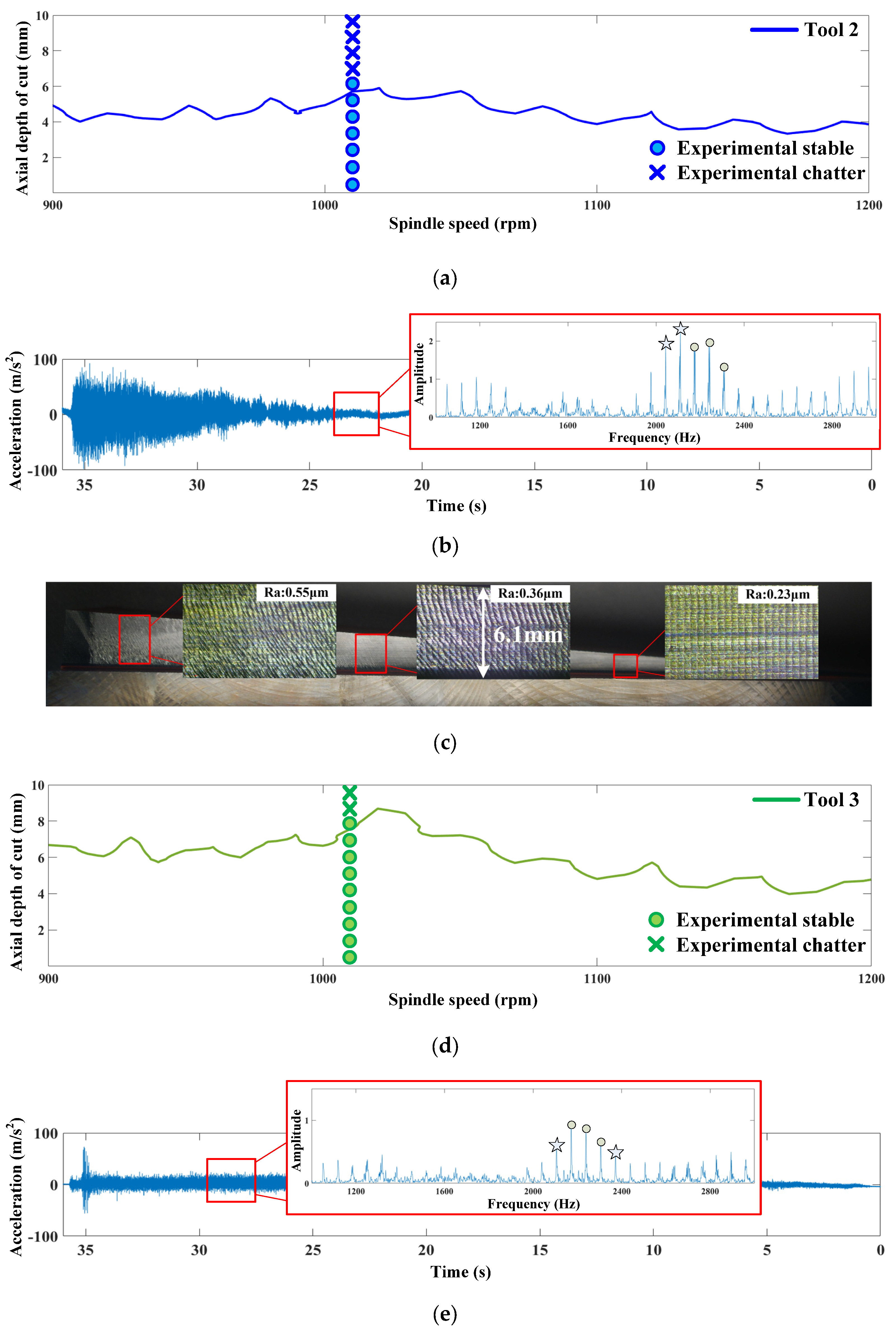

6.2. Industrial Validation

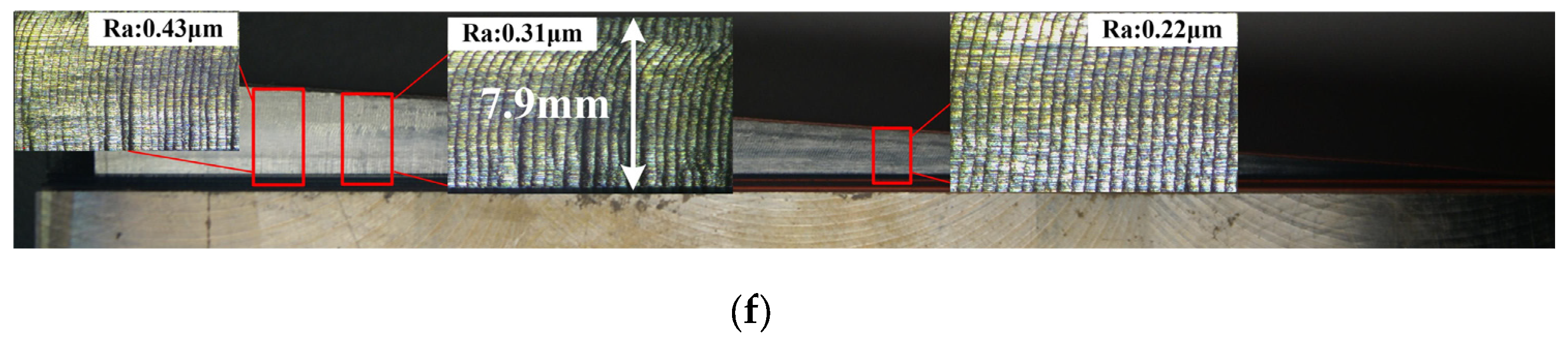

6.3. Laboratory Validation

7. Conclusions

- (1)

- The dynamic milling model of the proposed anti-vibration tool is built up and the milling stability of the anti-vibration tool is analyzed based on the SD method. The formula of ‘minimizing ’ is presented for optimal designing of the variable pitch angles based on the single frequency solution. Depending on the dynamic properties of the tool system, the ga method is used to obtain the global optimal solution. Numerical results show the best tooth spacing distribution scheme is 85°-95°-85°-95°.

- (2)

- Stability diagrams and milling experiments are carried out to prove the effectiveness of the optimized anti-vibration tool (with pitch angles of 85°-95°-85°-95° and wear edge of 60 μm on the flank face). Industrial experimental results have shown that compared with common regular pitch tool and onefold variable pitch tool, the ultimate process stability with 97.4% and 26.2% increase in axial depth of cut is found using the optimized anti-vibration tool in milling of Ti-6Al-4V.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Erdakov, I.; Glebov, L.; Pashkeev, K.; Bykov, V.; Bryk, A.; Lezin, V.; Radionova, L. Effect of the Ti6Al4V Alloy Track Trajectories on Mechanical Properties in Direct Metal Deposition. Machines 2020, 8, 79. [Google Scholar] [CrossRef]

- Mahardika, M.; Setyawan, M.A.; Sriani, T.; Miki, N.; Prihandana, G.S. Electropolishing Parametric Optimization of Surface Quality for the Fabrication of a Titanium Microchannel Using the Taguchi Method. Machines 2021, 9, 325. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, A.M.; Gupta, M.K.; Mia, M.; He, N.; Li, L.; Sivalingam, V.K. Influence of CO2-snow and subzero MQL on thermal aspects in the machining of Ti-6Al-4V. Appl. Therm. Eng. 2020, 177, 115480. [Google Scholar] [CrossRef]

- Li, X.; Zhao, W.; Li, L.; He, N.; Chi, S. Modeling and application of process damping in milling of thin-walled workpiece made of titanium alloy. Shock Vib. 2015, 2015, 431476. [Google Scholar] [CrossRef]

- Altintas, Y.; Weck, M. Chatter stability of metal cutting and grinding. CIRP Ann. Manuf. Technol. 2004, 53, 619–642. [Google Scholar] [CrossRef]

- Munoa, J.; Beudaert, X.; Dombovari, Z.; Altintas, Y.; Budak, E.; Brecher, C.; Stepan, G. Chatter suppression techniques in metal cutting. CIRP Ann. Manuf. Technol. 2016, 65, 785–808. [Google Scholar] [CrossRef]

- Yue, C.; Gao, H.; Liu, X.; Liang, S.Y.; Wang, L. A review of chatter vibration research in milling. Chin. J. Aeronaut. 2019, 32, 215–242. [Google Scholar] [CrossRef]

- Hahn, R.S. Metal-Cutting Chatter & Its Elimination. Trans. ASME 1952, 74, 1073–1080. [Google Scholar]

- Slavicek, J.; Slavic-Ek, J. The effect of irregular tooth pitch on stability of milling. Proc. 6th MTDR Conf. 1965, 1, 15–22. [Google Scholar]

- Altmtaş, Y.; Engin, S.; Budak, E. Analytical stability prediction and design of variable pitch cutters. J. Manuf. Sci. Eng. Trans. ASME 1999, 121, 173–178. [Google Scholar] [CrossRef]

- Altintaş, Y.; Budak, E. Analytical Prediction of Stability Lobes in Milling. CIRP Ann. Manuf. Technol. 1995, 44, 357–362. [Google Scholar] [CrossRef]

- Budak, E. An analytical design method for milling cutters with nonconstant pitch to increase stability, Part I: Theory. J. Manuf. Sci. Eng. Trans. ASME 2003, 125, 29–34. [Google Scholar] [CrossRef]

- Budak, E. An analytical design method for milling cutters with nonconstant pitch to increase stability, Part 2: Application. J. Manuf. Sci. Eng. Trans. ASME 2003, 125, 35–38. [Google Scholar] [CrossRef] [Green Version]

- Budak, E. Analytical models for high performance milling. Part II: Process dynamics and stability. Int. J. Mach. Tools Manuf. 2006, 46, 1489–1499. [Google Scholar] [CrossRef] [Green Version]

- Comak, A.; Budak, E. Modeling dynamics and stability of variable pitch and helix milling tools for development of a design method to maximize chatter stability. Precis. Eng. 2017, 47, 459–468. [Google Scholar] [CrossRef]

- Stepan, G.; Hajdu, D.; Iglesias, A.; Takacs, D.; Dombovari, Z. Ultimate capability of variable pitch milling cutters. CIRP Ann. 2018, 67, 373–376. [Google Scholar] [CrossRef]

- Tlusty, J.; Ismail, F. Special aspects of chatter in milling. J. Vib. Acoust. Trans. ASME 1983, 105, 24–32. [Google Scholar] [CrossRef]

- Saini, A.; Chauhan, P.; Pabla, B.S.; Dhami, S.S. Multi-process parameter optimization in face milling of Ti6Al4V alloy using response surface methodology. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1590–1602. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, A.M.; Hegab, H.; Gupta, M.K.; Mia, M.; He, N.; Zhao, G.; Song, Q.; Liu, Z. Milling of Ti-6Al-4V under hybrid Al2O3-MWCNT nanofluids considering energy consumption, surface quality, and tool wear: A sustainable machining. Int. J. Adv. Manuf. Technol. 2020, 107, 4141–4157. [Google Scholar] [CrossRef]

- Li, M.; Zhao, W.; Li, L.; He, N.; Jamil, M. Study the effect of anti-vibration edge length on process stability of milling thin-walled Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2021, 113, 2563–2574. [Google Scholar] [CrossRef]

- Das, M.K.; Tobias, S.A. The relation between the static and the dynamic cutting of metals. Int. J. Mach. Tool Des. Res. 1967, 7, 63–89. [Google Scholar] [CrossRef]

- Sisson, T.R.; Kegg, R.L. An explanation of low-speed chatter effects. J. Manuf. Sci. Eng. Trans. ASME 1969, 91, 951–958. [Google Scholar] [CrossRef]

- Wu, D.W. A new approach of formulating the transfer function for dynamic cutting processes. J. Manuf. Sci. Eng. Trans. ASME 1989, 111, 37–47. [Google Scholar] [CrossRef]

- Elbestawi, M.A.; Ismail, F.; Du, R.; Ullagaddi, B.C. Modelling machining dynamics including damping in the tool-workpiece interface. J. Manuf. Sci. Eng. Trans. ASME 1994, 116, 435–439. [Google Scholar] [CrossRef]

- Chiou, Y.S.; Chung, E.S.; Liang, S.Y. Analysis of tool wear effect on chatter stability in turning. Int. J. Mech. Sci. 1995, 37, 391–404. [Google Scholar] [CrossRef]

- Chiou, R.Y.; Liang, S.Y. Chatter stability of a slender cutting tool in turning with tool wear effect. Int. J. Mach. Tools Manuf. 1998, 38, 315–327. [Google Scholar] [CrossRef]

- Ahmadi, K.; Ismail, F. Experimental investigation of process damping nonlinearity in machining chatter. Int. J. Mach. Tools Manuf. 2010, 50, 1006–1014. [Google Scholar] [CrossRef]

- Feng, J.; Wan, M.; Dong, Z.Y.; Zhang, W.H. A unified process damping model considering the varying stiffness of the milling system. Int. J. Mach. Tools Manuf. 2019, 147, 103470. [Google Scholar] [CrossRef]

- Cao, C.; Zhang, X.M.; Huang, T.; Ding, H. An improved semi-analytical approach for modeling of process damping in orthogonal cutting considering cutting edge radius. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 641–653. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G. Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int. J. Numer. Methods Eng. 2004, 61, 117–141. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G. Semi-discretization method for delayed systems. Int. J. Numer. Methods Eng. 2002, 55, 503–518. [Google Scholar] [CrossRef]

- Ahmadi, K.; Ismail, F. Stability lobes in milling including process damping and utilizing Multi-Frequency and Semi-Discretization Methods. Int. J. Mach. Tools Manuf. 2012, 54–55, 46–54. [Google Scholar] [CrossRef]

- Jin, G.; Zhang, Q.; Hao, S.; Xie, Q. Stability Prediction of Milling Process with Variable Pitch Cutter. Math. Probl. Eng. 2013, 2013, 932013. [Google Scholar] [CrossRef] [Green Version]

- Wan, M.; Zhang, W.-H.; Dang, J.-W.; Yang, Y. A unified stability prediction method for milling process with multiple delays. Int. J. Mach. Tools Manuf. 2010, 50, 29–41. [Google Scholar] [CrossRef]

- Altintas, Y.; Stepan, G.; Merdol, D.; Dombovari, Z. Chatter stability of milling in frequency and discrete time domain. CIRP J. Manuf. Sci. Technol. 2008, 1, 35–44. [Google Scholar] [CrossRef]

- Huang, P.; Li, J.; Sun, J. Structure optimization of variable pitch helix end mills based on FEM simulation. Key Eng. Mater. 2010, 443, 291–296. [Google Scholar] [CrossRef]

- Altintas, Y.; Ber, A. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design. Appl. Mech. Rev. 2001, 54, B84. [Google Scholar] [CrossRef]

| Tool 1 | Tool 2 | Tool 3 | |

|---|---|---|---|

| Tool material | Carbide end mill | ||

| Diameter | 12 mm | ||

| Tool length | 125 mm (30 mm edge length) | ||

| Number of flutes | 4 | ||

| Helix angle | 35° | ||

| Pitch angles | 90°-90°-90°-90° | 85°-95°-85°-95° | 85°-95°-85°-95° |

| Flank wear length | 0 μm | 0 μm | 60 μm |

| Clearance angle | 9° | 9° | 4° and 9° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zhao, W.; Li, L.; He, N.; Jamil, M. Chatter Suppression during Milling of Ti-6Al-4V Based on Variable Pitch Tool and Process Damping Effect. Machines 2022, 10, 222. https://doi.org/10.3390/machines10040222

Li M, Zhao W, Li L, He N, Jamil M. Chatter Suppression during Milling of Ti-6Al-4V Based on Variable Pitch Tool and Process Damping Effect. Machines. 2022; 10(4):222. https://doi.org/10.3390/machines10040222

Chicago/Turabian StyleLi, Mengyu, Wei Zhao, Liang Li, Ning He, and Muhammad Jamil. 2022. "Chatter Suppression during Milling of Ti-6Al-4V Based on Variable Pitch Tool and Process Damping Effect" Machines 10, no. 4: 222. https://doi.org/10.3390/machines10040222

APA StyleLi, M., Zhao, W., Li, L., He, N., & Jamil, M. (2022). Chatter Suppression during Milling of Ti-6Al-4V Based on Variable Pitch Tool and Process Damping Effect. Machines, 10(4), 222. https://doi.org/10.3390/machines10040222