Energy Efficiency Optimization for Machining of Wood Plastic Composite

Abstract

:1. Introduction

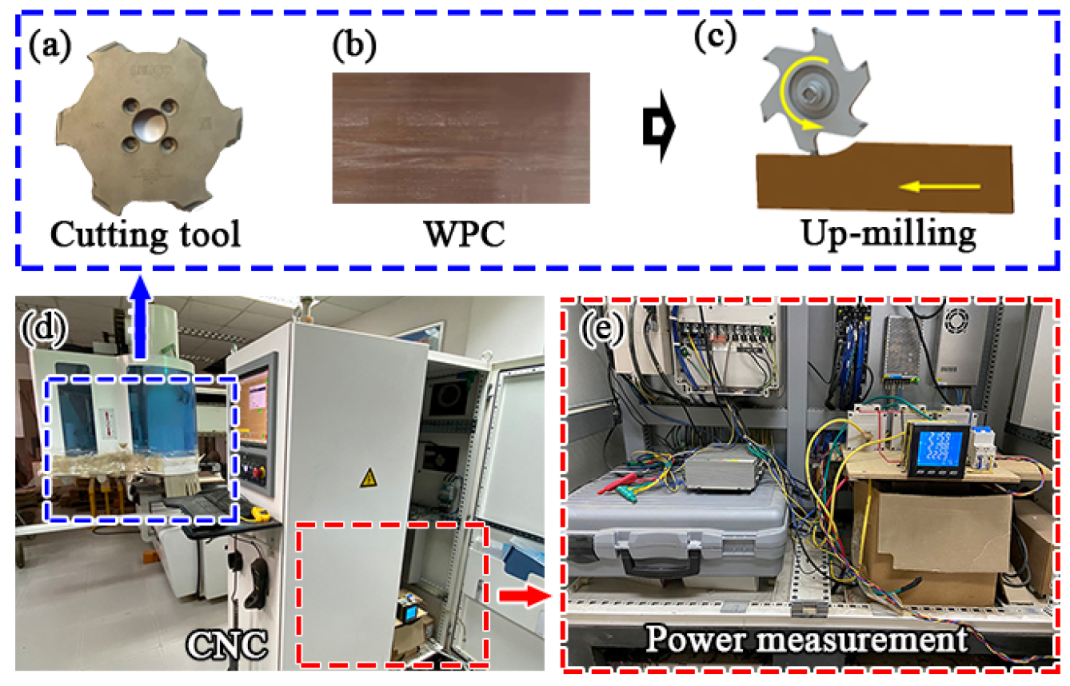

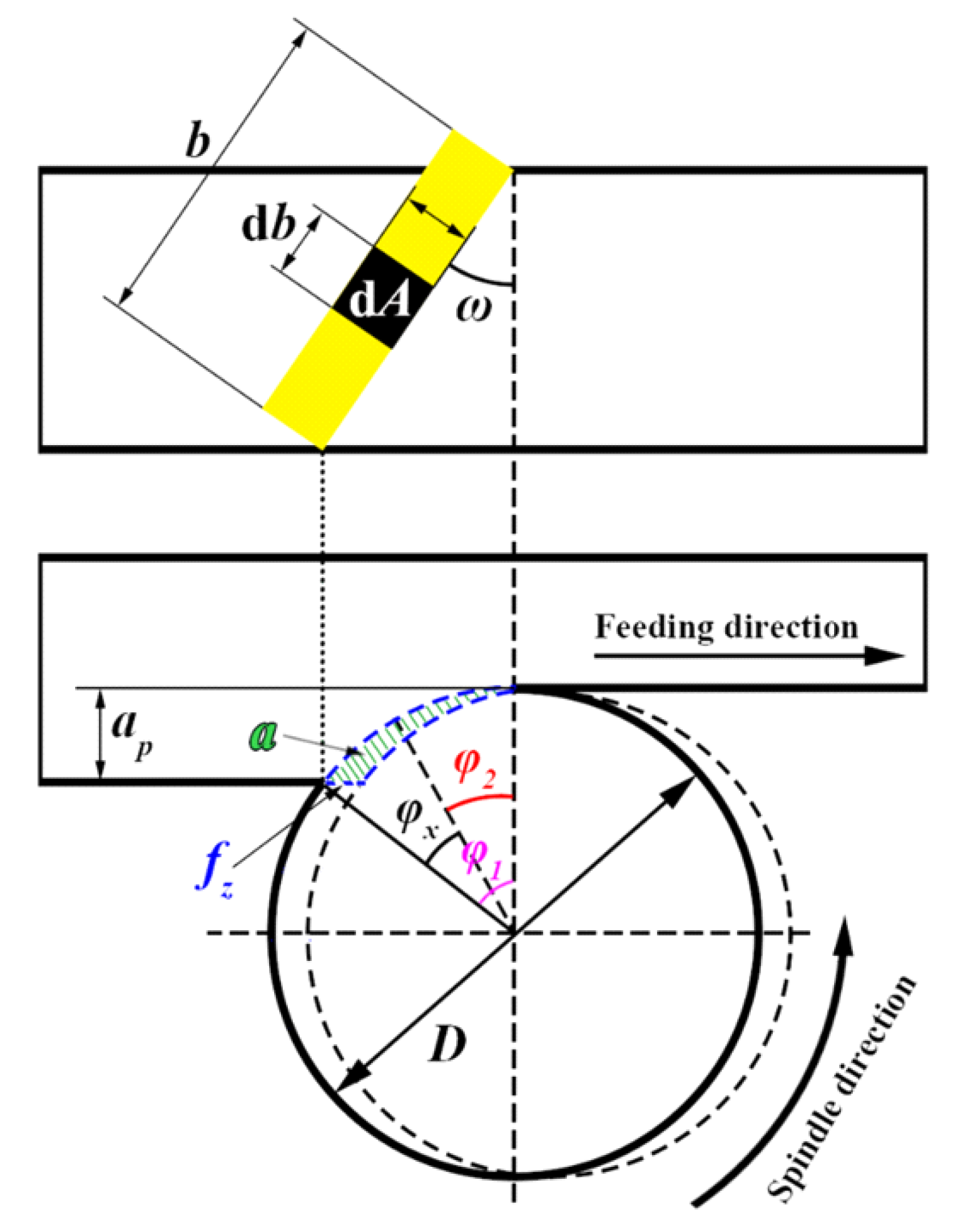

2. Materials and Methods

2.1. Cutters and Workpieces

2.2. Experimental Setup

2.3. Experimental Methods

3. Results and Discussion

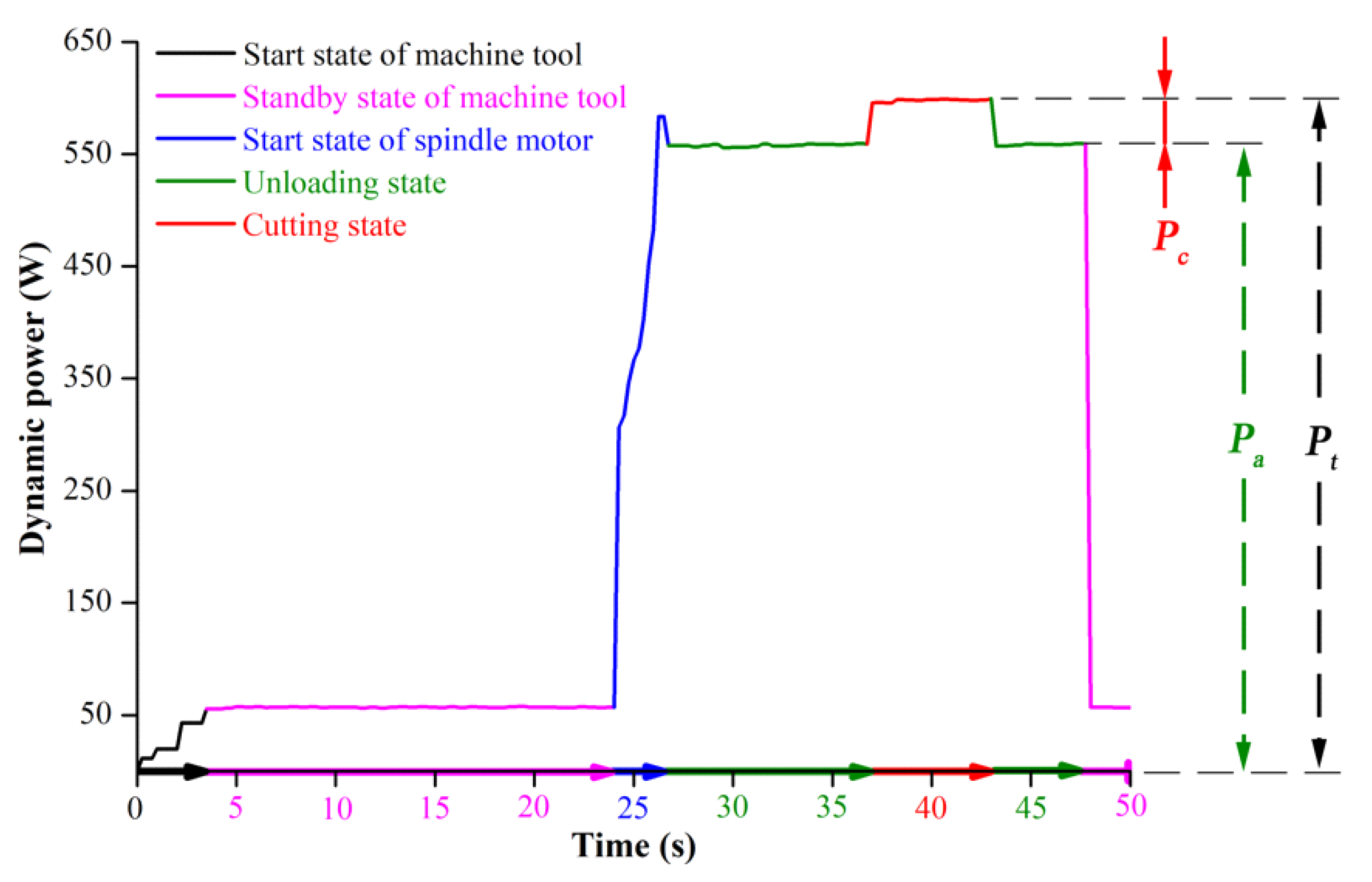

3.1. Dynamic Characteristics of Cutting Power

3.2. Developed Mathematical Model of Power Efficiency

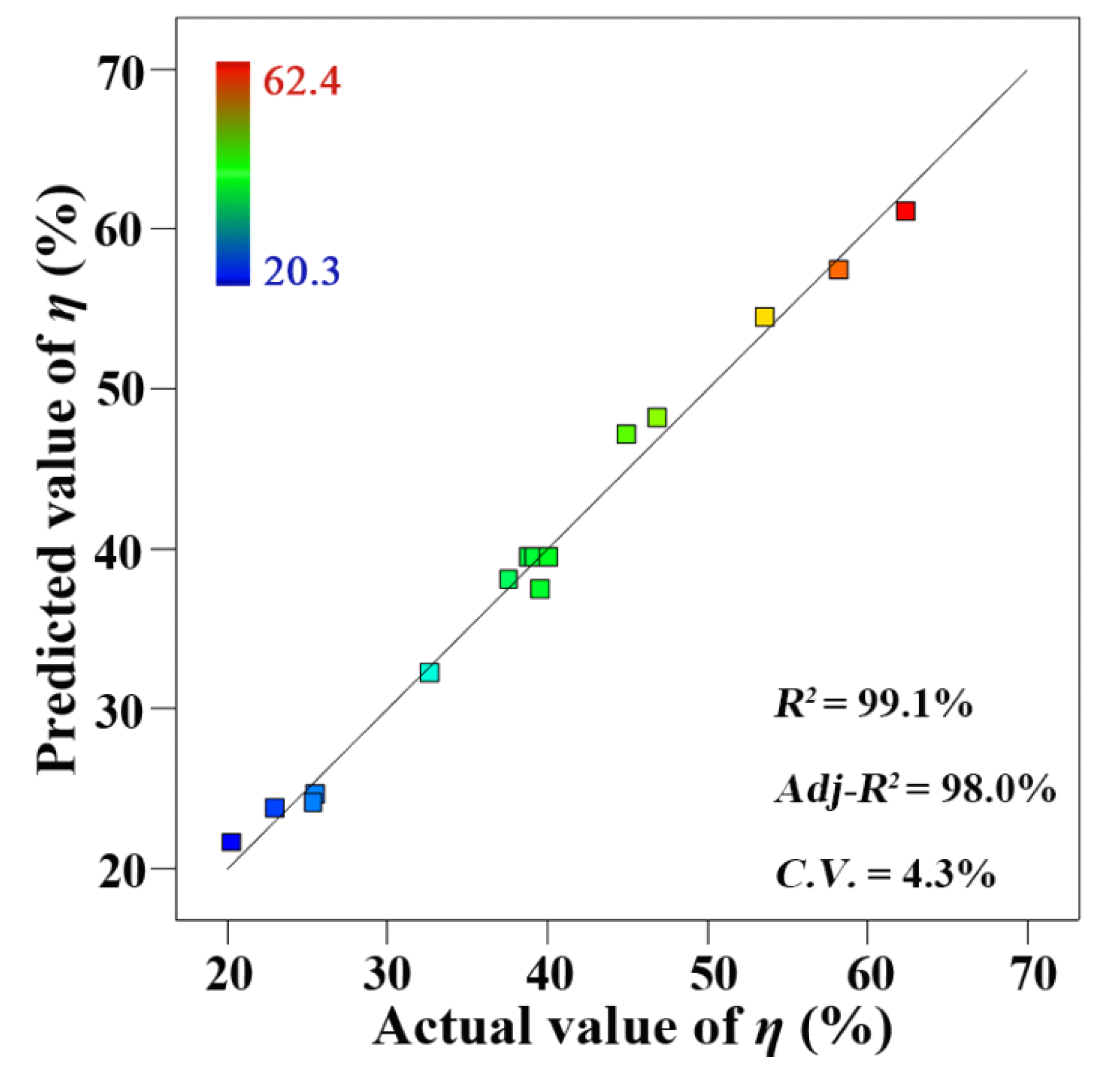

3.3. Analysis of Variance for Power Efficiency

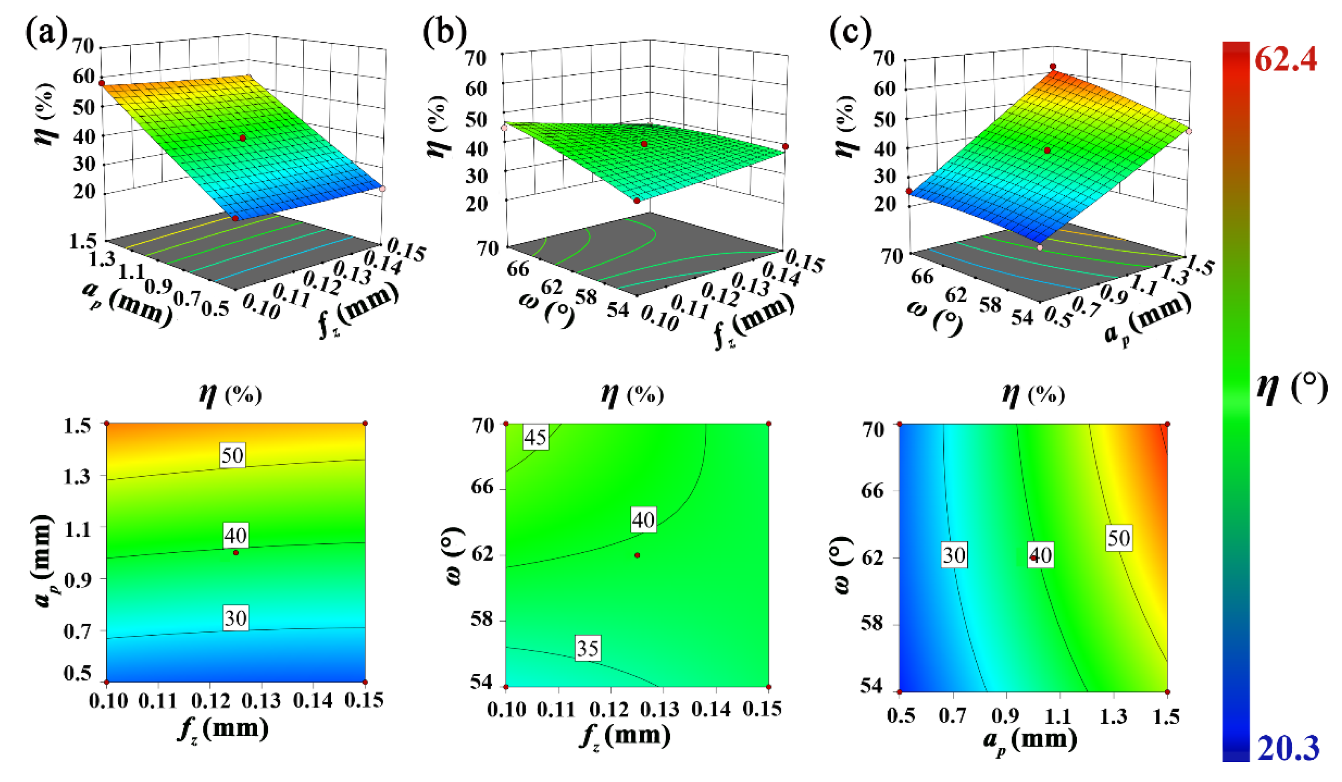

3.4. Effects of Milling Variables on Power Efficiency

3.5. Optimization and Verification for High-Performance Machining

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.G.; Wang, X. Research on enabling technologies and development path. J. For. Eng. 2021, 6, 177–183. [Google Scholar]

- Sun, Y.; Yu, L.; Ji, G.; Liu, J.Q.; Guo, W. The efficiency analysis on cutting power of EPB shield cutter. Mater. Sci. Forum 2011, 697–698, 706–711. [Google Scholar]

- Bo, H.K.; Choi, B.K. Machining efficiency comparison direction-parallel tool path with contour-parallel tool path. Comput.-Aided Des. 2002, 34, 89–95. [Google Scholar]

- Hu, W.G.; Guan, H.Y. Experimental and numerical investigation on compression creep behavior of wood. For. Prod. J. 2018, 68, 138–146. [Google Scholar]

- Faizrakhmanov, R.A.; Murzakaev, R.T.; Pristupov, V.S.; Polyakov, A.N. Optimization of the energy consumption of a CNC machine cutting tool with hard-to-formalize restrictions. Russ. Electr. Eng. 2017, 88, 701–705. [Google Scholar] [CrossRef]

- Lacalle, L.N.L.D.; Fernandez-Larrinoa, J.; Rodriguez-Ezquerro, A.; Fernandez-Valdivielso, A.; Lo’pez-Blanco, R.; Azkona-Villaverde, I. On the cutting of wood for joinery applications. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2015, 229, 940–952. [Google Scholar] [CrossRef]

- Malkoçoğlu, A.; Özdemir, T. The machining properties of some hardwoods and softwoods naturally grown in Eastern Black Sea Region of Turkey. J. Mater. Process. Technol. 2006, 173, 315–320. [Google Scholar] [CrossRef]

- Dong, W.; Xiong, X.; Ma, Y.; Yue, X. Woodworking tool wear condition monitoring during milling based on power signals and a particle swarm optimization-back propagation neural network. Appl. Sci. 2021, 11, 9026. [Google Scholar] [CrossRef]

- Cao, P.; Zhu, Z.; Guo, X.; Wang, X.; Fu, C.; Zhang, C. Cutting force and cutting quality during tapered milling of glass magnesium board. Appl. Sci. 2019, 9, 2533. [Google Scholar] [CrossRef] [Green Version]

- Camposeco-Negrete, C. Optimization of cutting parameters for minimizing energy consumption in turning of AISI 6061 T6 using Taguchi methodology and ANOVA. J. Clean. Prod. 2013, 53, 195–203. [Google Scholar] [CrossRef]

- Zhu, Z.; Buck, D.; Guo, X.; Cao, P.; Wang, J. Cutting performance in the helical milling of stone-plastic composite with diamond tools. CIRP J. Manuf. Sci. Technol. 2020, 31, 119–129. [Google Scholar] [CrossRef]

- Zhu, Z.; Buck, D.; Guo, X.; Cao, P. High-quality and high-efficiency machining of stone-plastic composite with diamond helical cutters. J. Manuf. Process. 2020, 58, 914–922. [Google Scholar] [CrossRef]

- Chaharmahali, M.; Tajvidi, M.; Najafi, S.K. Mechanical properties of wood plastic composite panels made from waste fiberboard and particleboard. Polym. Compos. 2008, 29, 606–610. [Google Scholar] [CrossRef]

- Tabarsa, T.; Khanjanzadeh, H.; Pirayesh, H. Manufacturing of wood-plastic composite from completely recycled materials. Key Eng. Mater. 2011, 471–472, 62–66. [Google Scholar]

- Jayaraman, K.; Bhattacharyya, D. Mechanical performance of woodfibre–waste plastic composite materials. Resour. Conserv. Recycl. 2004, 41, 307–319. [Google Scholar] [CrossRef]

- Cai, C.; Haapala, A.; Rahman, M.H.; Tiitta, M.; Tiitta, V.; Tomppo, L.; Lappalainen, R.; Heräjärvi, H. Effect of two-year natural weathering on chemical and physical properties of thermally modified Picea abies, Pinus sylvestris and Fraxinus excelsior wood. Can. J. For. Res. 2020, 50, 1160–1171. [Google Scholar] [CrossRef]

- Soury, B.; Esfahani, A.H.; Zolfaghari, Z.R. Design, optimization and manufacturing of wood-plastic composite pallet. Mater. Des. 2009, 30, 4183–4191. [Google Scholar] [CrossRef]

- Association CFI. Floor sales in China in 2020. China Wood-Based Panels 2021, 28, 47. [Google Scholar]

- Guo, X.; Wang, J.; Buck, D.; Zhu, Z.; Guo, Y. Machinability of wood fiber/polyethylene composite during orthogonal cutting. Wood Sci. Technol. 2021, 55, 521–534. [Google Scholar] [CrossRef]

- Pei, Z.; Zhu, N.; Gong, Y. A study on cutting temperature for wood–plastic composite. J. Thermoplast. Compos. Mater. 2016, 29, 1627–1640. [Google Scholar] [CrossRef]

- Zhao, Z.; Sun, S.; Wu, D.; Zhang, M.; Huang, C.; Umemura, K.; Yong, Q. Synthesis and characterization of sucrose and ammonium dihydrogen phosphate (SADP) adhesive for plywood. Polymers 2019, 11, 1909. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, X.; Ekevad, M.; Marklund, B.; Li, R.; Cao, P.; Grönlund, A. Cutting forces and chip morphology during wood plastic composites orthogonal cutting. Bioresources 2014, 9, 2090–2106. [Google Scholar] [CrossRef] [Green Version]

- Li, R.R.; He, C.J.; Wang, X.D. Evaluation and modeling of processability of laser removal technique for bamboo outer layer. JOM 2021, 73, 2423–2430. [Google Scholar] [CrossRef]

- Li, R.R.; Chen, J.; Wang, X.A. Prediction of the color variation of moso bamboo during CO2 laser thermal modification. Bioresources 2020, 15, 5049–5057. [Google Scholar] [CrossRef]

- Lu, F.; Jian, Z.; Xiaomei, L.; Yuanyuan, Z.; Jialing, S. Tensile shear strength and microscopic characterization of veneer bonding interface with polyethylene film as wood adhesive. Sci. Adv. Mater. 2019, 11, 1223–1231. [Google Scholar]

- Li, R.; Fang, L.; Xu, W.; Xiong, X.; Wang, X.A. Effect of laser irradiation on the surface wettability of poplar wood. Sci. Adv. Mater. 2019, 11, 655–660. [Google Scholar] [CrossRef]

- Li, R.R.; Yao, Q. Research on equipment configurations of the flexible production line for intelligently manufacturing customized panel furnitures. Chin. J. Wood Sci. Technol. 2021, 35, 23–29. [Google Scholar]

- Oda, Y.; Mori, M.; Ogawa, K.; Nishida, S.; Fujishima, M.; Kawamura, T. Study of optimal cutting condition for energy efficiency improvement in ball end milling with tool-workpiece inclination. CIRP Ann. 2012, 61, 119–122. [Google Scholar] [CrossRef]

- Barcík, Š.; Pivolusková, E.; Kminiak, R. Effect of technological parameters and wood properties on cutting power in plane milling of juvenile poplar wood. Drv. Ind. 2008, 59, 107–112. [Google Scholar]

- Fernández-Abia, A.I.; Barreiro, J.; de Lacalle, L.N.L.; Martínez-Pellitero, S. Behavior of austenitic stainless steels at high speed turning using specific force coefficients. Int. J. Adv. Manuf. Technol. 2012, 62, 505–515. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Miao, Y.F.; Yang, Z.Q.; Wang, H.; Sang, R.J.; Fu, Y.C.; Huang, C.X.; Wu, Z.H.; Zhang, M.; Sun, S.J.; et al. Effects of sulfuric acid on the curing behavior and bonding performance of tannin-sucrose adhesive. Polymers 2018, 10, 651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mandic, M.; Todorovic, N.; Popadic, R.; Danon, G. Influence of wood properties and technological parameters of processing on cutting power in milling of thermally modified beechwood. Bull. Fac. For. 2011, 104, 109–124. [Google Scholar] [CrossRef]

| No. | Tool Angles | Material Properties | ||||

|---|---|---|---|---|---|---|

| Spiral Angle | Rake Angle | Wedge Angle | Coefficient of Thermal Expansion | Thermal Conductivity | Hardness | |

| 1 | 54° | 10° | 72° | 1.18 × 10−6 | 560 W·m−1·K−1 | 8000 HV |

| 2 | 62° | 10° | 72° | |||

| 3 | 70° | 10° | 72° | |||

| Workpiece | Density | Bending Strength | Tensile Strength | Modulus of Elasticity |

|---|---|---|---|---|

| WPC | 1.45 g/cm3 | 4.69 MPa | 26.21 MPa | 4270 MPa |

| Factor Level | fz | ap | ω |

|---|---|---|---|

| 1 | 0.10 mm | 0.5 mm | 54° |

| 2 | 0.125 mm | 1.0 mm | 62° |

| 3 | 0.15 mm | 1.5 mm | 70° |

| No. | fz (mm) | ap (mm) | ω (°) | η (%) |

|---|---|---|---|---|

| 1 | 0.10 | 1.0 | 54 | 32.7 |

| 2 | 0.10 | 0.5 | 62 | 25.5 |

| 3 | 0.10 | 1.0 | 70 | 45 |

| 4 | 0.10 | 1.5 | 62 | 58.2 |

| 5 | 0.125 | 1.5 | 70 | 62.4 |

| 6 | 0.125 | 0.5 | 54 | 20.3 |

| 7 | 0.125 | 1.5 | 54 | 46.9 |

| 8 | 0.125 | 0.5 | 70 | 25.4 |

| 9 | 0.125 | 1.0 | 62 | 39.2 |

| 10 | 0.125 | 1.0 | 62 | 40.1 |

| 11 | 0.125 | 1.0 | 62 | 38.9 |

| 12 | 0.125 | 1.0 | 62 | 39.2 |

| 13 | 0.125 | 1.0 | 62 | 39.8 |

| 14 | 0.15 | 1.5 | 62 | 53.6 |

| 15 | 0.15 | 1.0 | 54 | 39.6 |

| 16 | 0.15 | 1.0 | 70 | 37.6 |

| 17 | 0.15 | 0.5 | 62 | 23.0 |

| Source | Sum of Squares | % Cont. | DF | Mean Square | F-Value | p-Value | Remark |

|---|---|---|---|---|---|---|---|

| η | 2223.79 | / | 9 | 7.22 | 87.84 | <0.0001 | Significant |

| fz | 7.22 | 0.32 | 1 | 2012.95 | 2.57 | 0.1532 | Insignificant |

| ap | 2012.95 | 89.72 | 1 | 119.35 | 715.64 | <0.0001 | Significant |

| ω | 119.35 | 5.32 | 1 | 1.10 | 42.43 | 0.0003 | Significant |

| fz × ap | 1.10 | 0.05 | 1 | 51.12 | 0.39 | 0.5511 | Insignificant |

| fz × ω | 51.12 | 2.28 | 1 | 27.04 | 18.18 | 0.0037 | Significant |

| ap × ω | 27.04 | 1.21 | 1 | 0.39 | 9.61 | 0.0173 | Significant |

| fz2 | 0.39 | 0.02 | 1 | 0.46 | 0.14 | 0.7200 | Insignificant |

| ap2 | 0.46 | 0.02 | 1 | 4.38 | 0.16 | 0.6984 | Insignificant |

| ω2 | 4.38 | 0.20 | 1 | 7.22 | 1.56 | 0.2521 | Insignificant |

| Residual | 19.69 | 0.88 | 7 | 2.81 | - | - | - |

| Total | 2243.48 | 100 | 16 | - | - | - | - |

| No. | fz (mm) | ap (mm) | ω (°) | MRR (mm2/s) | Ra (μm) | Actual-η | Predicted-η | Error |

|---|---|---|---|---|---|---|---|---|

| I | 0.1 | 1.5 | 70 | 3862.3 | 1.9 | 63.0% | 66.4% | −5.1% |

| II | 0.15 | 1.5 | 62 | 4110.5 | 2.1 | 58.2% | 54.5% | 6.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Buck, D.; Guo, X.; Xiong, X.; Xu, W.; Cao, P. Energy Efficiency Optimization for Machining of Wood Plastic Composite. Machines 2022, 10, 104. https://doi.org/10.3390/machines10020104

Zhu Z, Buck D, Guo X, Xiong X, Xu W, Cao P. Energy Efficiency Optimization for Machining of Wood Plastic Composite. Machines. 2022; 10(2):104. https://doi.org/10.3390/machines10020104

Chicago/Turabian StyleZhu, Zhaolong, Dietrich Buck, Xiaolei Guo, Xianqing Xiong, Wei Xu, and Pingxiang Cao. 2022. "Energy Efficiency Optimization for Machining of Wood Plastic Composite" Machines 10, no. 2: 104. https://doi.org/10.3390/machines10020104

APA StyleZhu, Z., Buck, D., Guo, X., Xiong, X., Xu, W., & Cao, P. (2022). Energy Efficiency Optimization for Machining of Wood Plastic Composite. Machines, 10(2), 104. https://doi.org/10.3390/machines10020104