1. Introduction

Electric vehicles (EVs) have grown in popularity in the past few years because of their benefits, such as zero emissions, high efficiency, and low greenhouse gas emissions [

1]. Internal combustion engines are replaced by an electric motor for the propulsion of EVs. The electric motor, considered as the heart of EVs, determines their performance. Major factors that hamper the penetration of EVs into the market are short mileage and high cost in conjunction with the performance of the electric motor [

2]. Several types of electric motors are widely used for EVs, including DC-brushed motors, DC brushless motors, permanent magnet synchronous motors (PMSMs), induction motors (IMs), and switch-reluctant motors (SRMs) [

3]. PMSMs and IMs have become preferable choices by manufacturers because of their favorable torque and power characteristics [

2,

4]. Although the efficiency of the PMSMs is good enough to reach the required mileage, the overall cost of EVs is expensive because of the high cost of permanent magnets to obtain the desired characteristics, which leads to the reduction in the number of EV users [

5]. IMs and SRMs can be alternative solutions for the PMSMs because of less dependence on permanent magnets. Therefore, they are the cheapest option for EVs. However, SRMs have some disadvantages, such as low torque density, high torque ripples, and high noise [

6]. Alternatively, the low-cost advantage and other exceptional features of IM, such as adequate efficiency, favorable field weakening characteristics, robustness, and control flexibility, make it a preferable option for EV applications [

7,

8]. The application of IM for EVs needs to be appropriately designed to give high performance in terms of starting torque, efficiency, breakdown torque, and power factor [

9]. However, this study does not consider the starting torque because it can be controlled by adopting existing control schemes, such as vector control and direct torque control [

10].

The performance of IM is strongly related to the geometry parameters of stator and rotor slots and other components. The effect of adjusting the core axial length toward efficiency improvement of IM is carried out in [

11]. In [

12], optimal rotor slot design to improve the torque characteristics of IM is investigated. A small-scale IM model for EVs is studied using finite element analysis (FEA) to improve efficiency by minimizing losses and temperature rise [

13]. In [

14], an optimal axial flux IM is designed for EVs by optimizing several design parameters, including air-gap length, the number of turns per slot, rotor slot width to slot pitch ratio, and stator slot width to slot pitch ratio. The axial flux IM is also optimized using FEA in [

15] by considering different driving cycles. Temperature rise analysis on IM is carried out using FEA for EV application in [

16,

17]. Research work has been performed to test the effect of coil pitch on the performance of IM for propulsion-related applications [

18]. A study on modeling and simulation of IM for starting conditions is analyzed in [

19]. The benefits of solid bar conductors over conventional stranded winding for the IM in traction drive are investigated in [

20]. A low starting current to increase the torque, a wider stator, and rotor slots to reduce iron and skin effects and a higher number of stator slots than the number of rotor slots to reduce the effect of harmonics are suggested in [

21] to make IM suitable for EVs. The effects of leakage and mutual inductance on the constant power region and constant torque region in the torque speed characteristics of EV are studied using FEA in [

22]. The review indicates that the previous works separately addressed three main performance indicators: efficiency, breakdown torque, and power factor. Furthermore, only a few design parameters of stator and rotor slots are considered because of the limitations of the FEA method. Therefore, a comprehensive number of design parameters should be considered, and all the main performance indicators need to be addressed simultaneously, which requires a good optimization technique to solve the optimal stator and rotor slots design problem.

Among the different types of optimization techniques, meta-heuristic optimization techniques provide a promising solution because of their ability to escape from local optimum traps [

23]. Previous works have applied several meta-heuristic optimizations to improve the performance of IMs for EVs. Optimal modeling of stator and rotor slots is carried out using binary-coded GA in [

9]. A IM model is optimized with PSO and GA by considering efficiency and power factor as a multi-objective function, derived using weight sum method in [

24]. In [

25], a multistage optimization technique is formulated by amalgamating evolutionary search and pattern search algorithms to solve the IM optimization problem. An optimal design of advanced IM is proposed for EVs using GA and FEA method in [

26]. In [

27], the efficiency and cost of IM are considered in the objective function, and the optimization problem is solved using GA. In [

28], a Hooke Jeeves optimization technique is suggested to solve the optimal IM modeling after comparing it with GA. A new cost pattern value method is introduced in [

29] for local search algorithms to obtain an optimal FEA-based IM design by maximizing the breakdown torque. However, the meta-heuristic techniques used in the previous works suffer from premature convergence, the imbalance between exploration and exploitation ability and computational burdens. A recent meta-heuristic technique, introduced in [

30] as jellyfish search optimization (JSO), is a good alternative to replace the existing optimization techniques. Although JSO performs well in solving complex optimization problems, the optimization technique is subjected to low exploration ability [

31] that affects its convergence rate.

Opposition-based learning (OBL) is normally adopted in meta-heuristic optimizations, such as GA [

32], differential evaluation algorithm [

33], ant colony optimization [

34], gravitational search algorithm [

35], firefly algorithm [

36], and PSO [

37], to enhance and accelerate their performance. Furthermore, OBL is also applied with JSO but limited to the initialization stage only [

38]. No work has used OBL to update the population in each iteration for JSO. Therefore, a new hybrid meta-heuristic optimization technique called opposition-based jellyfish search optimization (OBJSO) is proposed in this study by adopting the OBL operator after the location updating procedure of JSO in each iteration to solve the optimal stator and rotor slots design of IM. An analytical model of IM is used and based on design constraints in [

9] for preliminary study as the scope of work to evaluate performance of the proposed optimization technique and for comparison purposes. A more detailed explanation will be given in the following sections.

Section 2 presents an analytical modeling of IM for EV application.

Section 3 presents the optimization formulation to optimize the stator and rotor slots of the IM. Then,

Section 4 showcases the performance of OBJSO by comparing it with the existing meta-heuristic optimization techniques. Finally,

Section 5 draws the conclusion.

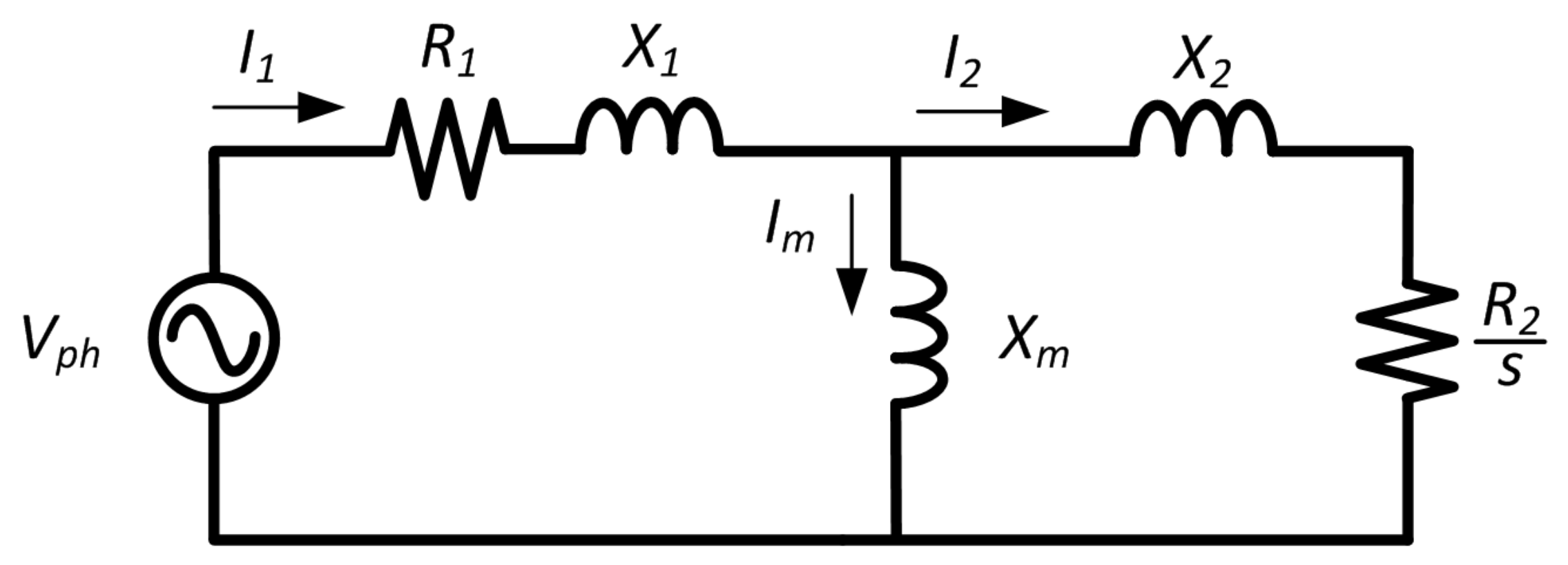

3. Optimization Problem Formulation

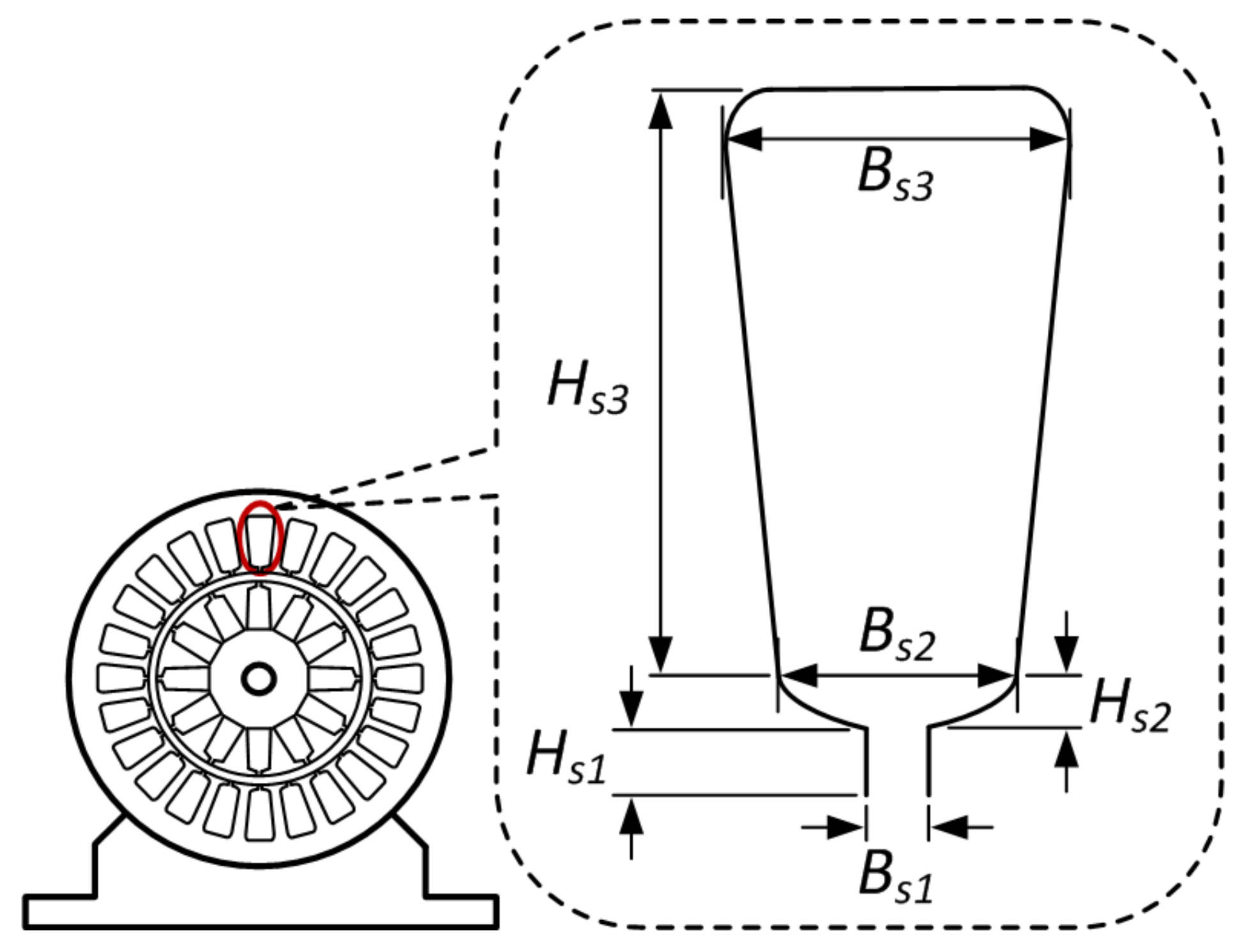

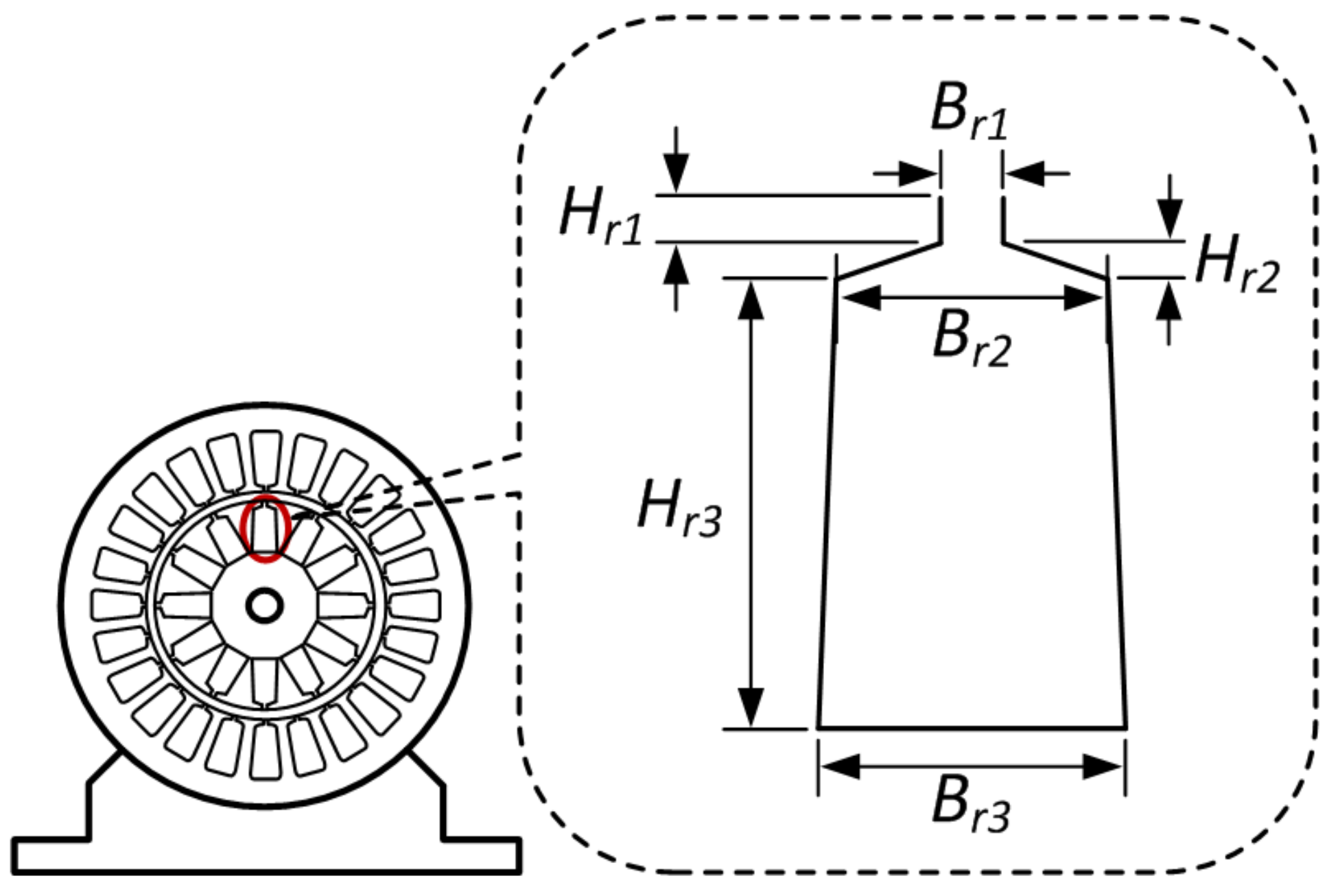

The IM is modeled by considering the stator and rotor slots design parameters as presented in

Section 2. The stator and rotor slots design of IM can be optimized to give the best performance while ensuring IM to operate within the acceptable limits for EVs. As discussed earlier, six parametric geometries of stator and rotor slots (

,

,

,

,

, and

) are selected as control variables to give the best performance, which can be performed by maximizing the performance indicators (efficiency, breakdown torque, and power factor) while keeping the control variables (the selected design parameters) within the permissible limits, as given in

Table 3 and

Table 4. A multi-objective function can be derived from the three performance indicators using the weighted sum method as follows:

where

represents the per unit breakdown torque and

,

, and

are weights assigned to each objective function. In this case, an equal weight is used for

,

, and

. In the objective function, a per unit value of the breakdown torque is used, instead of the actual value, to give a balanced treatment between the three performance indicators during the optimization process.

The next following subsections will discuss the proposed OBJSO to solve the optimal stator and rotor slots design problem using the formulated multi-objective function, as expressed in (

16). Given that the proposed optimization technique combines JSO and OBL, their original formulations are presented to understand better and highlight the modifications to develop OBJSO.

3.1. Jellyfish Search Optimization

JSO algorithm is a recently introduced swarm intelligent-based meta-heuristic optimization that mimics jellyfish behavior in the ocean [

30]. The algorithm works based on the following three main principles:

3.1.1. Jellyfishes Follow the Ocean Current

The jellyfishes follow the ocean current because of a large amount of nutrients [

47]. The direction of the ocean current can be determined by calculating the average distance between all jellyfishes and the best jellyfish, as expressed in the following expression [

30]:

where

is the current best location of jellyfish,

is a factor that governs the attraction, and

represents the mean location of all jellyfish. In a normal spatial distribution, jellyfishes are scattered from the mean location given by a distribution coefficient,

. Therefore,

can be determined by multiplying

and a uniform random variable

in a range between 0 and 1. The direction of the ocean current can be re-written as follows [

30]:

Then, a new bit

k of the

i-th jellyfish location can be updated as follows [

30]:

where

is another random variable in range [0,1].

3.1.2. Jellyfishes Swim Inside the Swarm

Jellyfishes exhibit two types of motion when they swim inside the swarm: passive motion (type A) and active motion (type B). The jellyfishes in the swarm exhibit type A motion at the beginning of the swarm formation and exhibit type B motion over time. In the type A motion, the new bit

k of

i-th jellyfish location is now updated using the following expression [

30]:

where

r is a random variable in range [0,1] and

is a motion coefficient.

and

are the

k-th bit of upper and lower bounds, respectively.

On the other hand, the new bit

k of the

i-th jellyfish location in type B motion is updated using the following expression [

30]:

where

is the direction of motion of jellyfish that exhibits type B motion. In this motion, another

j-th jellyfish is required for comparison purposes to evaluate the current

i-th jellyfish’s performance. The

j-th jellyfish is selected at random. Then,

can be determined using the following condition [

30]:

A time control function is used to control the selection between passive and active motions. It is also used to select between swim inside the swarm and follow the ocean current.

3.1.3. Time Control Mechanism

A time control mechanism is used in JSO to regulate different movements. In the first stage, it is used to decide either the jellyfish will follow the ocean current or swim inside the swarm. The time control function,

varies randomly in an initial range of [0,1], but it reduces monotonously along the iteration as expressed by the following [

30]:

where

t is the current iteration and

T is total number of iterations. The value of

is compared to a constant,

. The jellyfishes are decided to follow the ocean current if

is greater or equal to

or swim inside the swarm otherwise. In the second stage, when jellyfishes are decided to swim inside the swarm, a function is derived from

as

to select either type A or B motion. The value of

is compared with

r (a random variable in range [0,1]). Type A motion is selected if

r is higher than

; or otherwise, type B motion is selected.

After all, the new location of jellyfish needs to be checked for any boundary violations. If the boundary is violated, the jellyfish is brought back into the search space using the following condition [

30]:

3.2. Opposition-Based Learning

The OBL technique was introduced by Tizhoosh in 2005 [

32]. It is employed in optimizations to allow simultaneous search in the opposite direction along with the current search direction. If the current solutions are far from the globally optimal solution (i.e., on the opposite side), their opposite direction could lead to the solution. Thus, it improves the exploration capability and helps to escape from the local optimum. The application of OBL to generate an opposition location in search space is explained in the next paragraph.

Let

be a real number within a set interval, where

. The opposite of

M (

) can be determined as follows:

In the same way, the opposition of a high-dimensional variable can be obtained. Let

be a location in a

d dimensional space, where

and

. The opposition of the location in the search space can be obtained as follows [

36]:

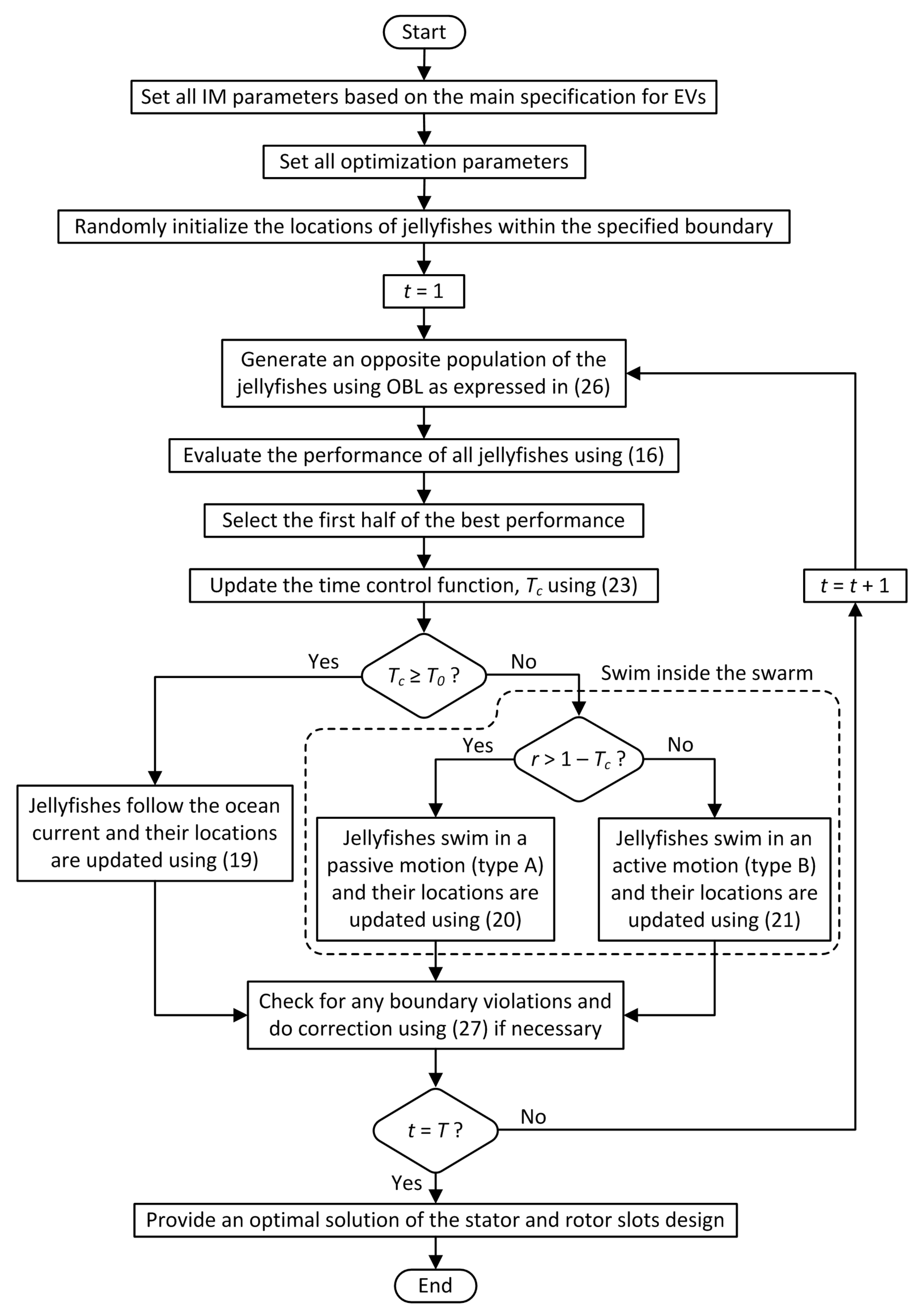

3.3. Opposition-Based Jellyfish Search Optimization

In this study, OBJSO is proposed to enhance the performance of JSO by adopting OBL. An opposition population,

is generated from the obtained population using JSO,

, by applying (

26) after a new location is updated in each iteration or initialization in the first iteration. Then, the performance of

and

is evaluated, and only the first half of the best performance is selected to maintain the population size,

for the optimization process. In this way, OBL explores any better solutions in opposite locations of the suggested solutions by JSO to improve exploration capability. This process continues until the stopping criteria is met. In this work, the optimization process is stopped when the number of iterations reaches the maximum for overall performance evaluation purposes.

Apart from adopting OBL, the boundary correction mechanism in (

24) is modified because of a convergence issue. In the original mechanism, the violated jellyfish position is relocated to the opposite site of search space according to the distance from the violated boundary. This mechanism is almost similar to OBL, but it uses an outside position instead. The mechanism is unsuitable for OBJSO because of the redundancy of the operation, ultimately jeopardizing the decision of JSO. Therefore, the violated jellyfish position in OBJSO is relocated to the nearest boundary as follows:

In the suggested boundary correction, the jellyfish position is limited to the search space boundary in the same direction of the position updating procedure by JSO. The same boundary correction is used in other optimization techniques, including JSO, to highlight the effectiveness of the OBL application. In the OBL application, the original population is kept and evaluated together with the opposition population to maintain the advantages of JSO while getting the benefits of OBL. The proposed OBJSO is then applied to solve the optimal design of stator and rotor slots for EV application.

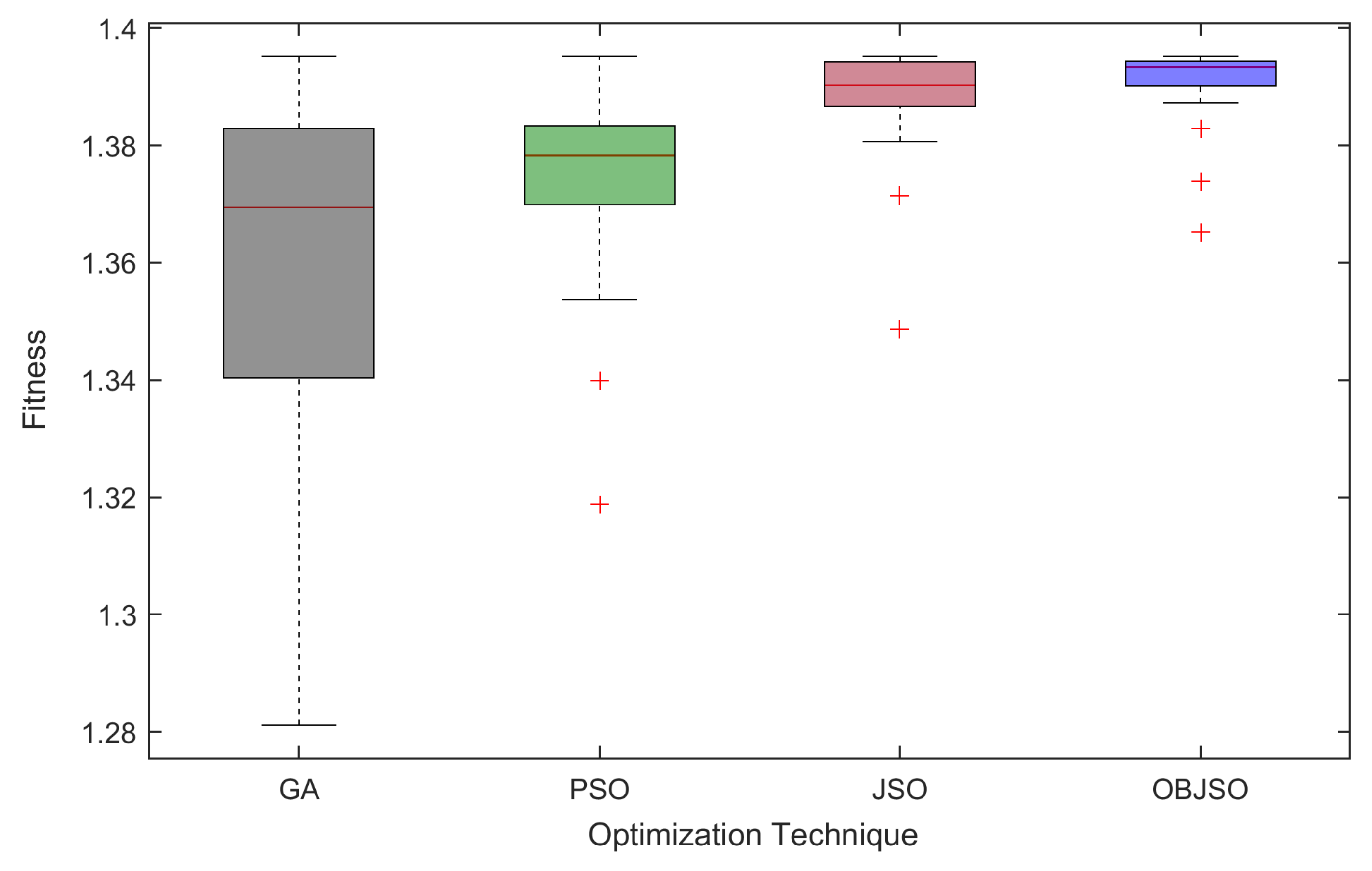

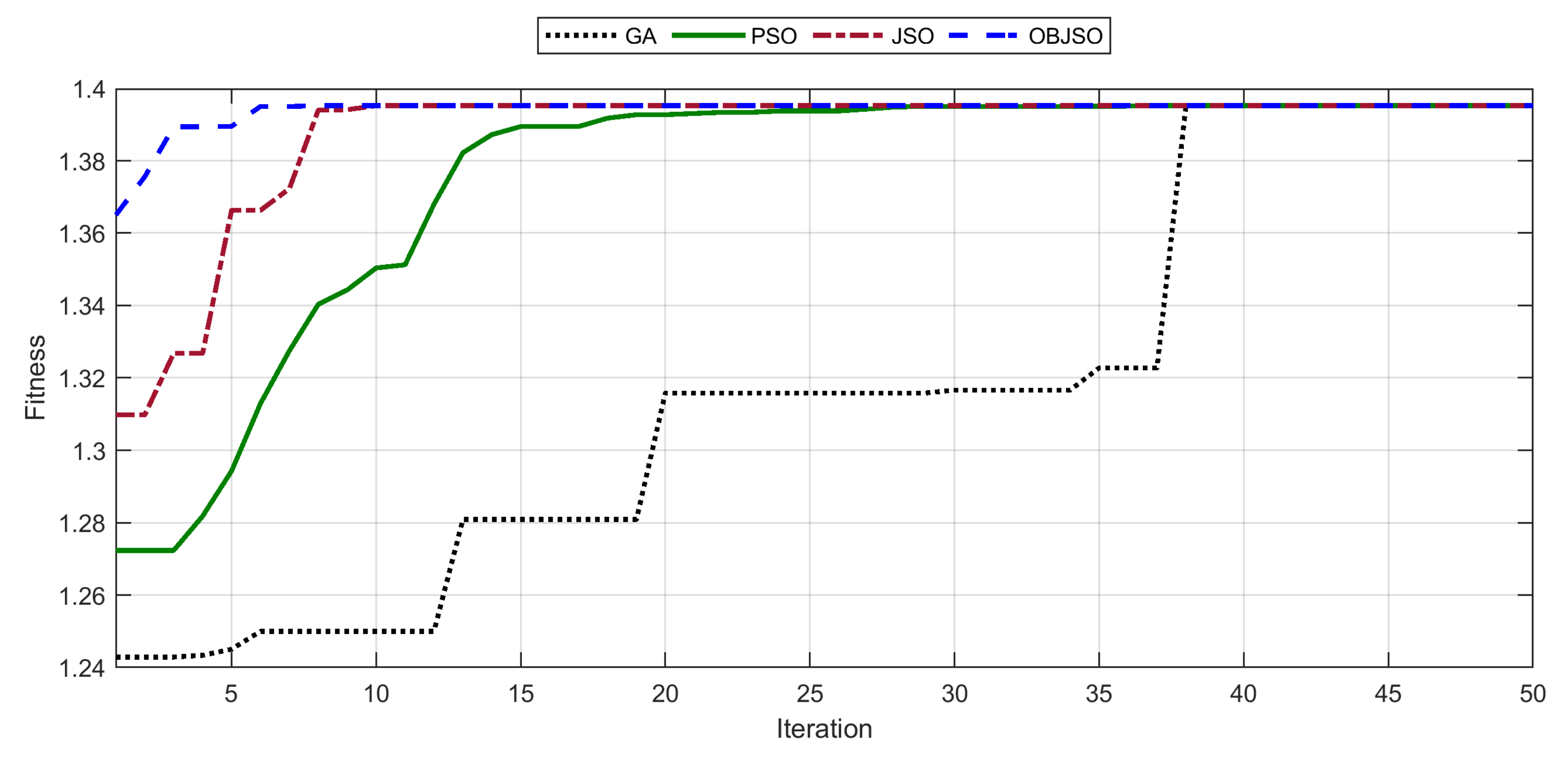

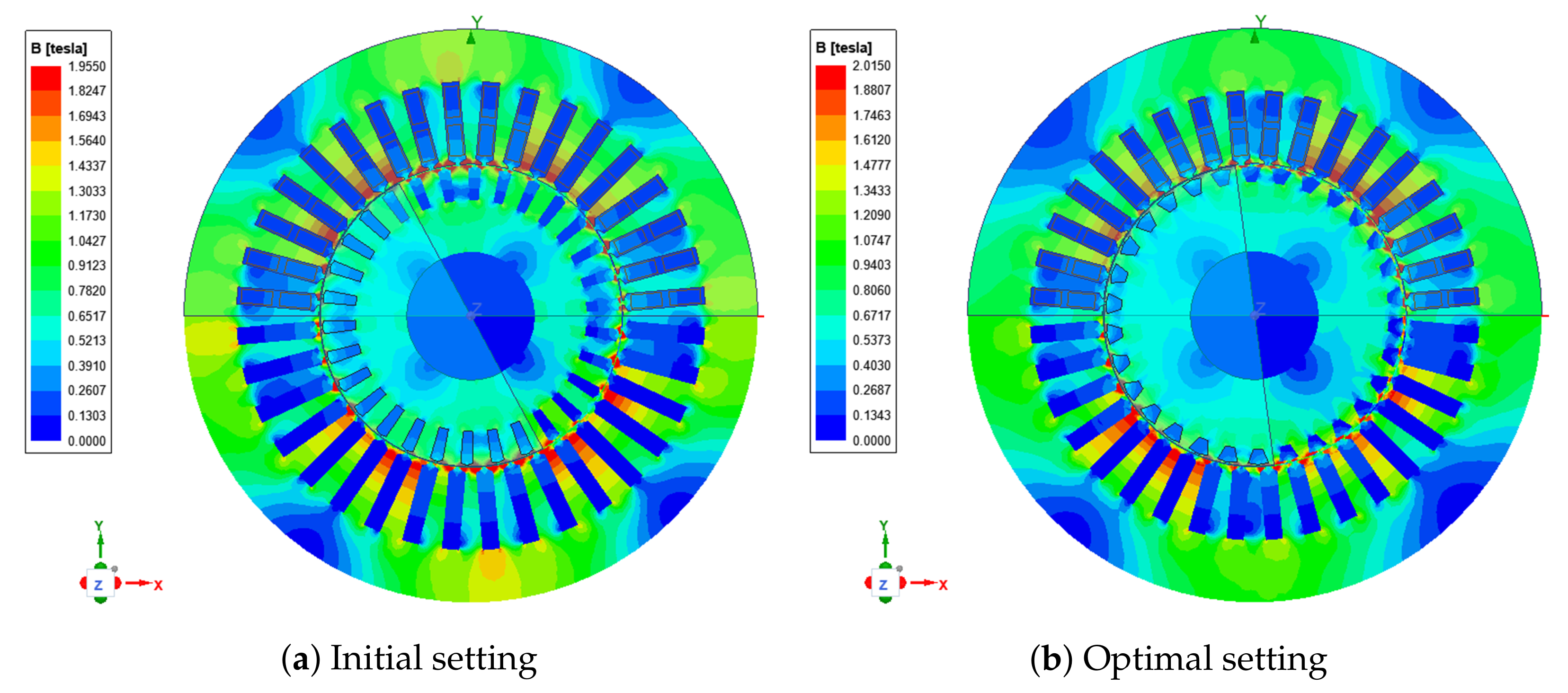

Figure 4 shows an overall flowchart of the OBJSO application derived from the formulation discussed earlier. In the next section, the performance of OBJSO is tested and compared with the conventional meta-heuristic optimizations, such as GA, PSO, and JSO, in solving the optimal design of stator and rotor slots problem.