Effect of Optimization Software on Part Shape Accuracy and Production Times during Rough Milling of Aluminum Alloy

Abstract

1. Introduction

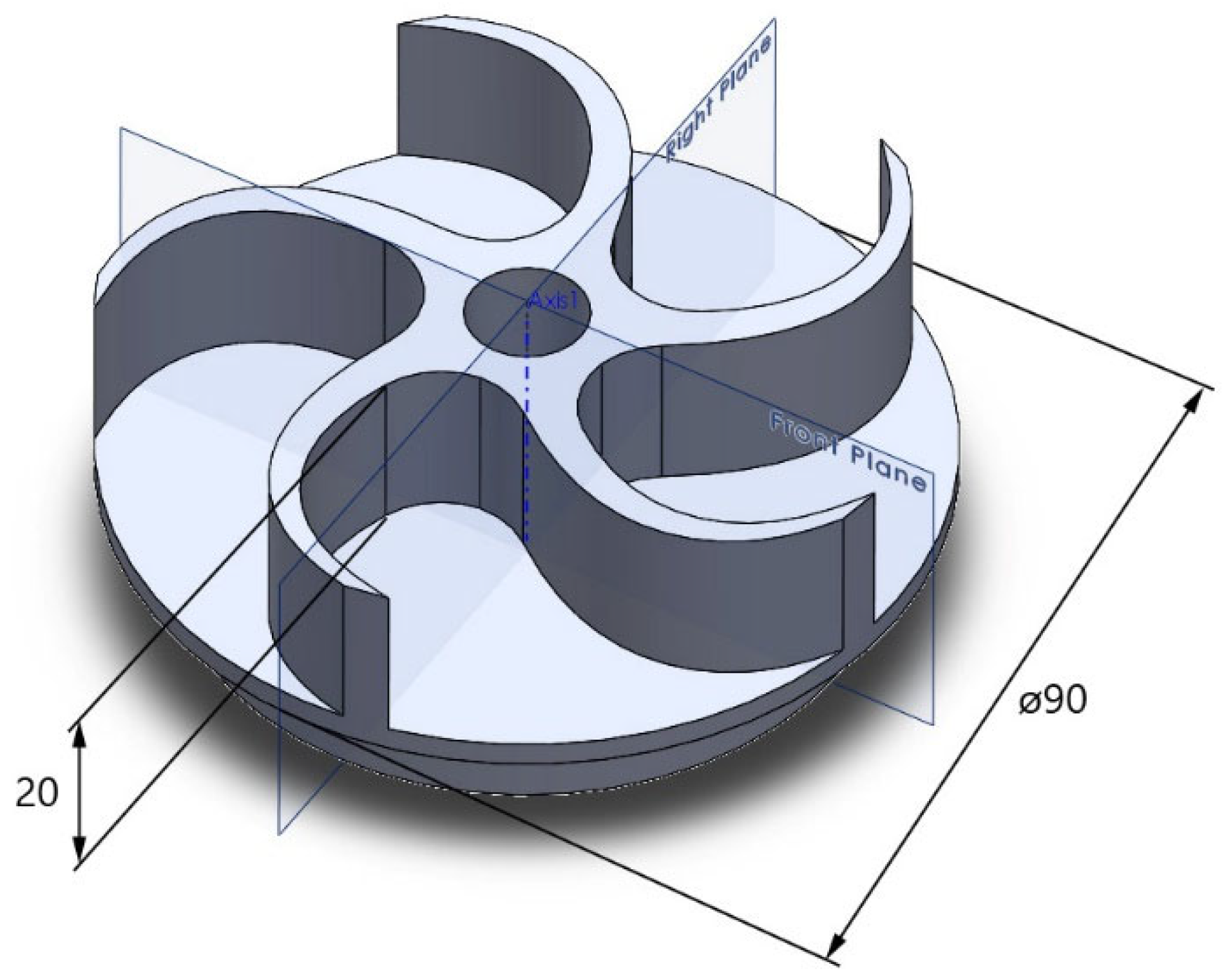

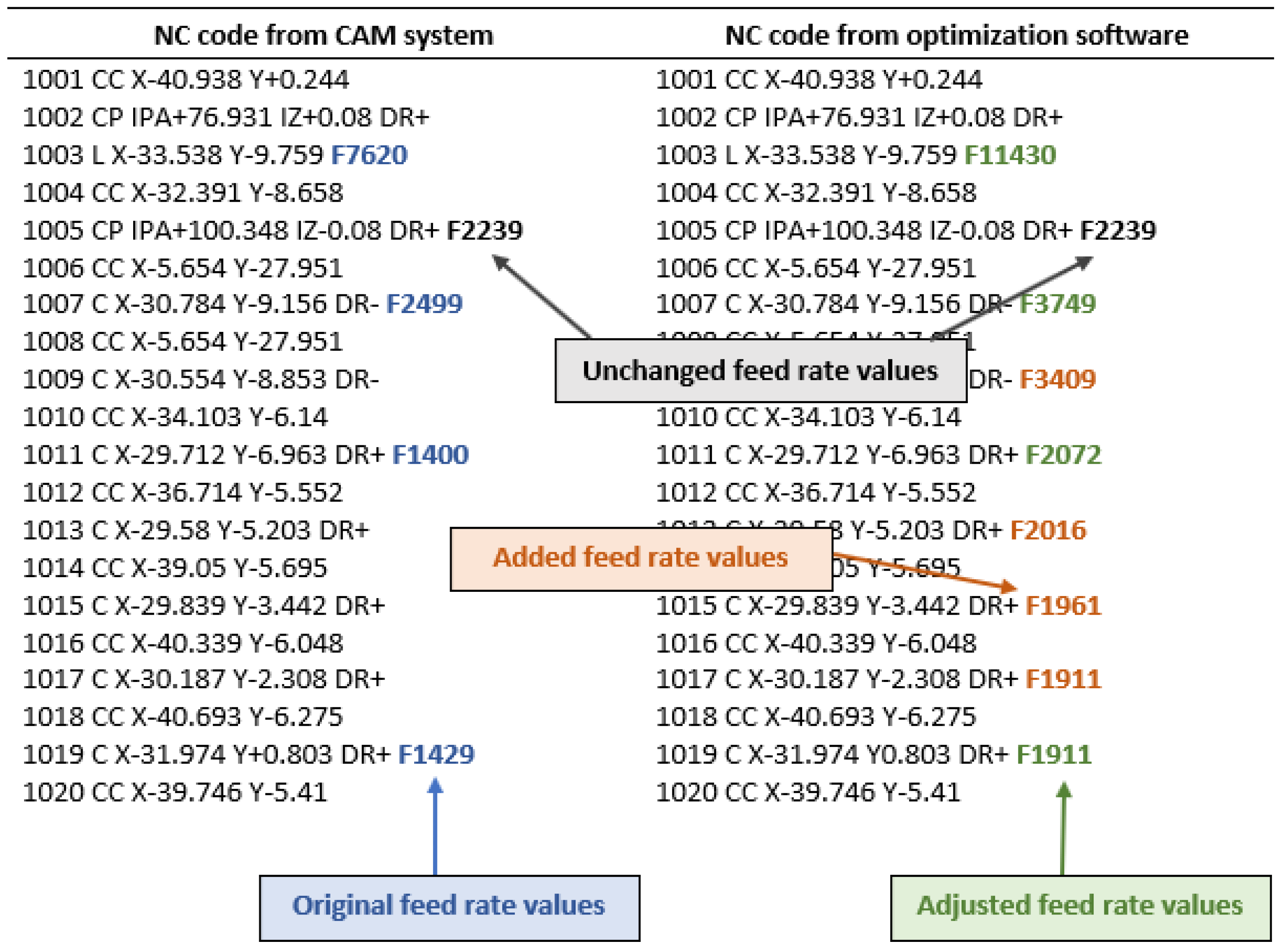

2. Design and Implementation of Experiments

2.1. Methodology

- Production of a sample with five open pockets, each pocket being made with a different tool-load intensity. A CAM system was used for programming.

- Production of identical samples using NC programs modified by optimization software.

- Comparison of accuracy of pockets made on individual samples and between all samples using a coordinate measuring machine (CMM).

- Comparison of rough milling times for standard and optimized NC programs.

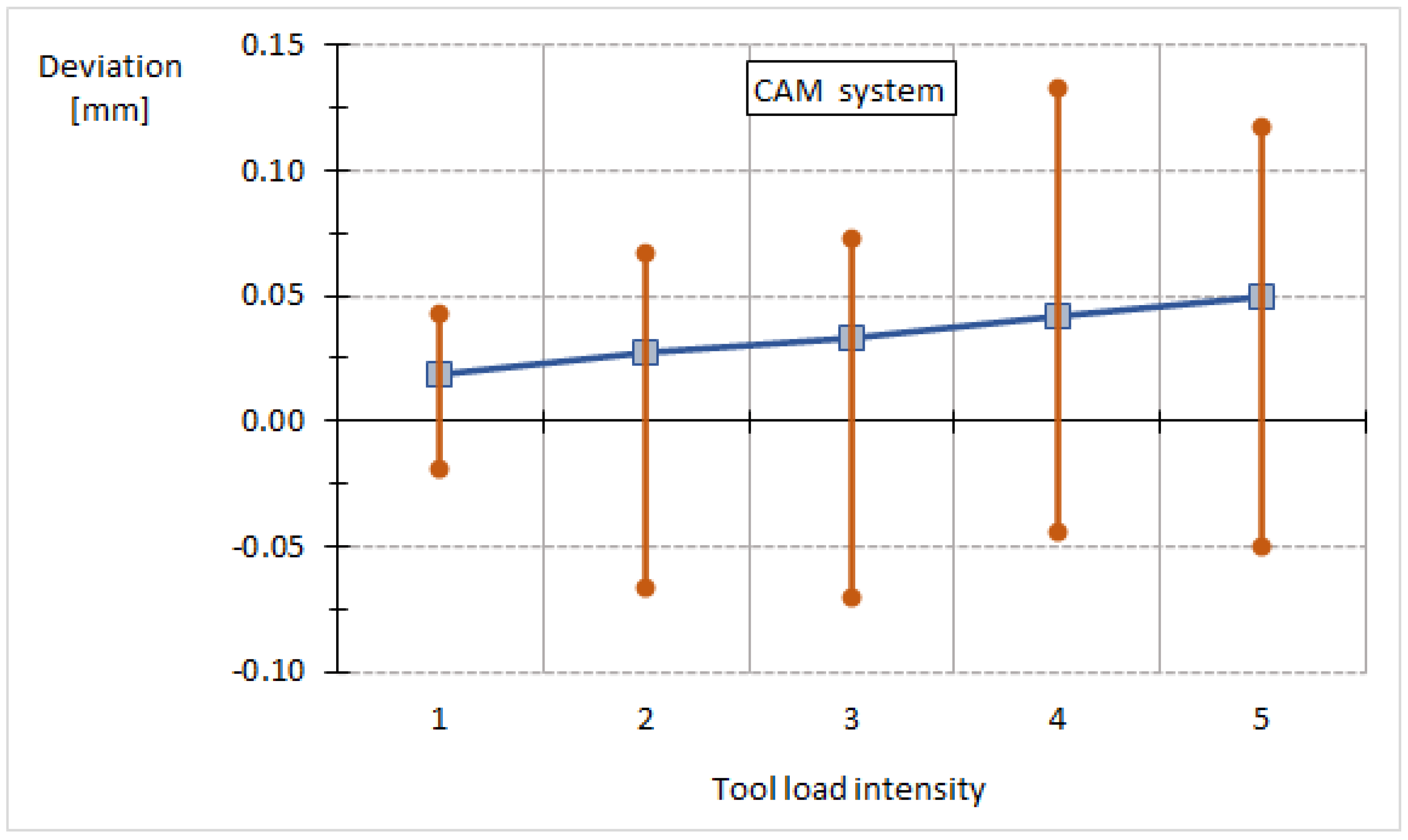

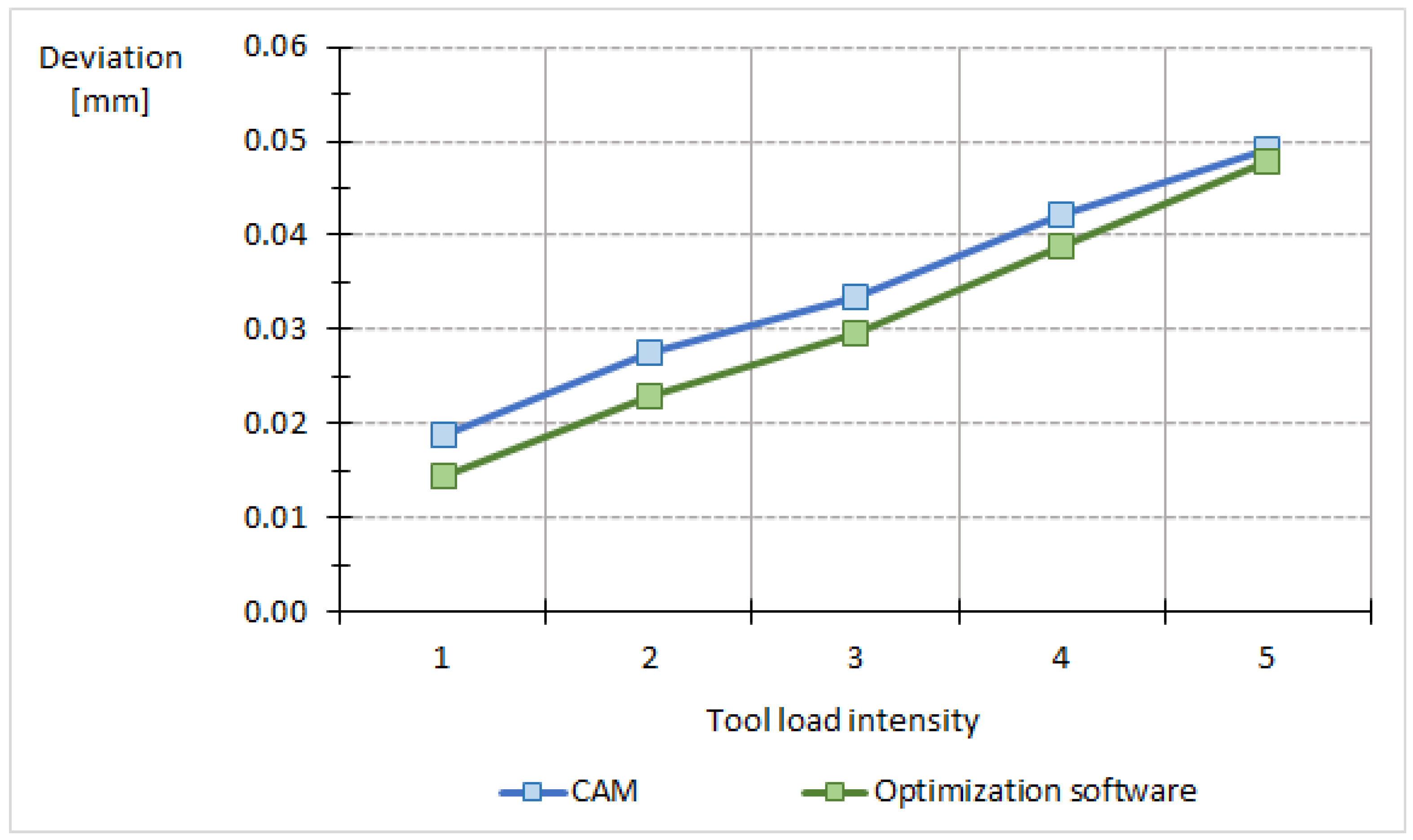

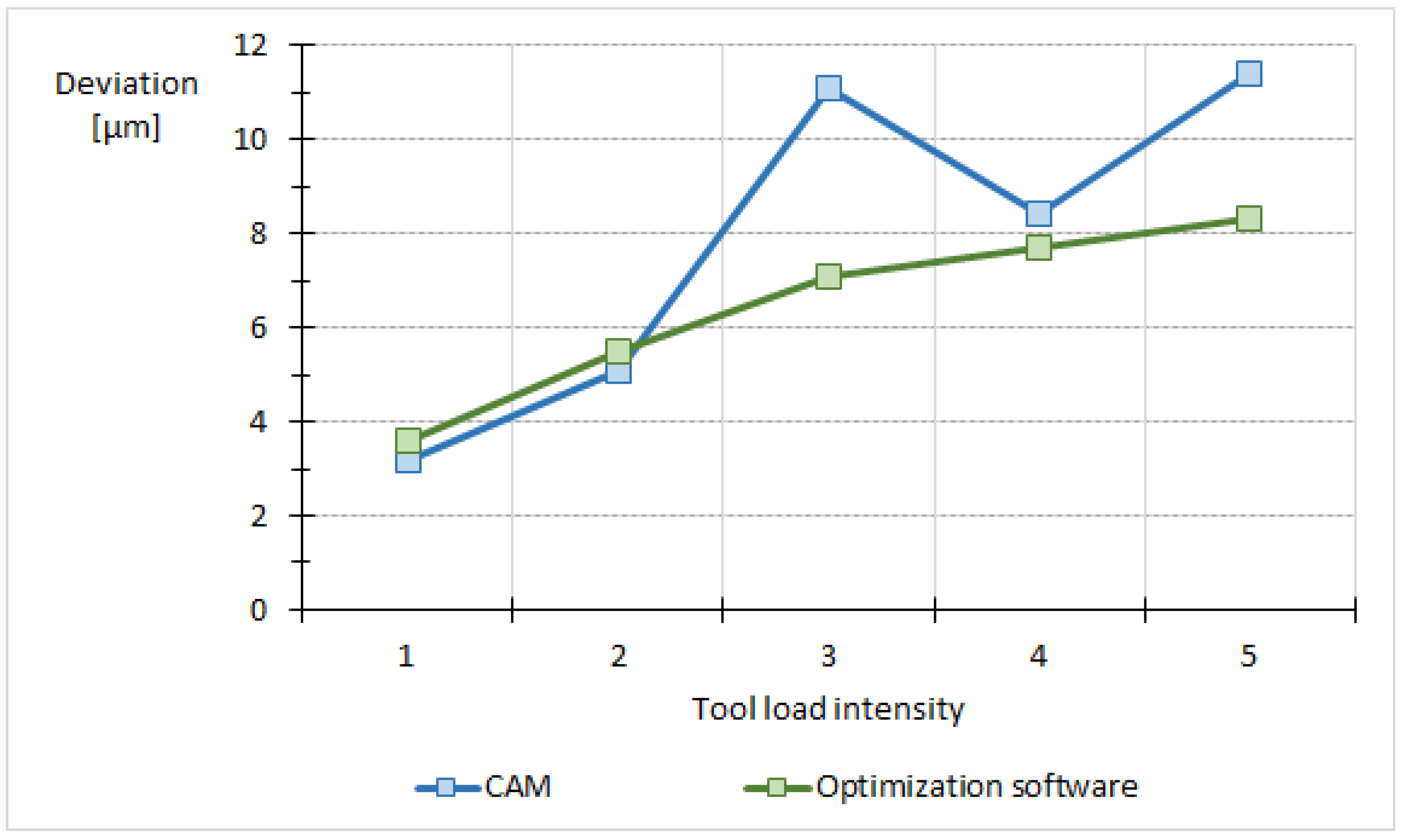

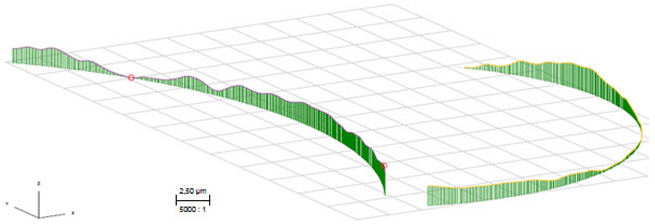

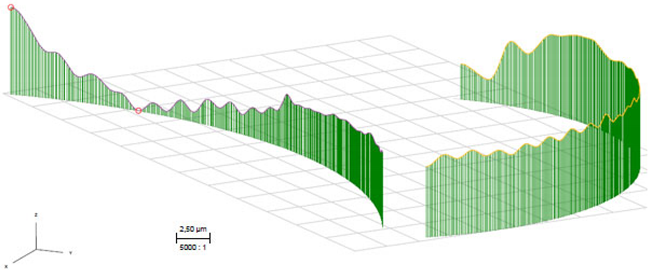

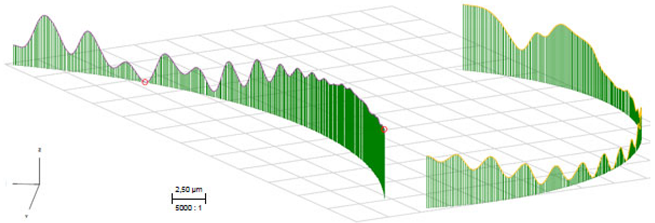

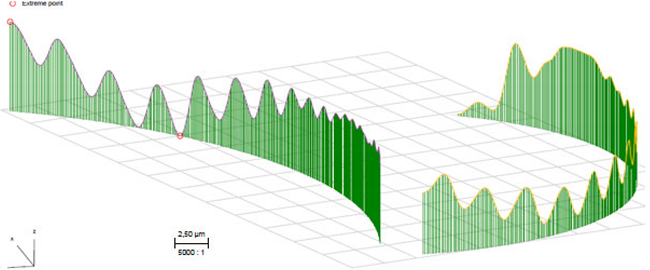

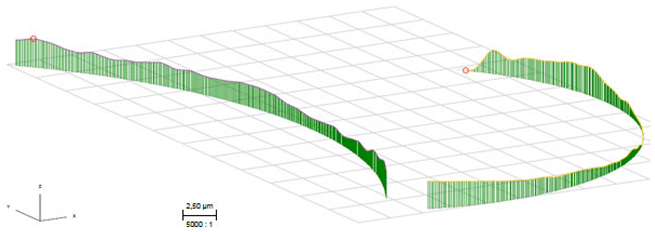

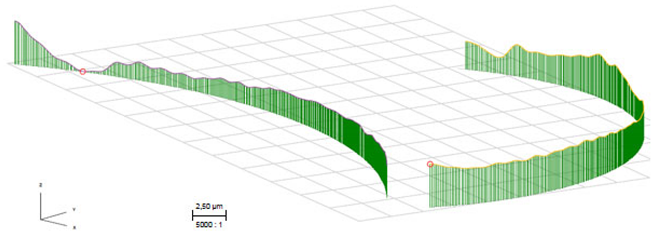

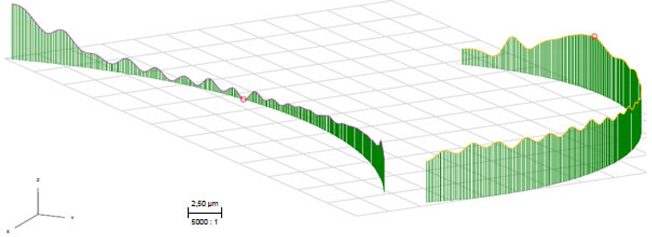

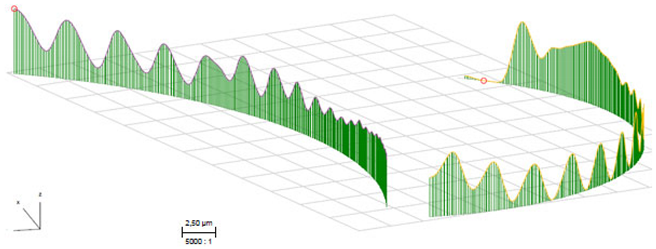

2.2. Deviations on the Side Surfaces

2.3. Deviations on the Horizontal Surfaces

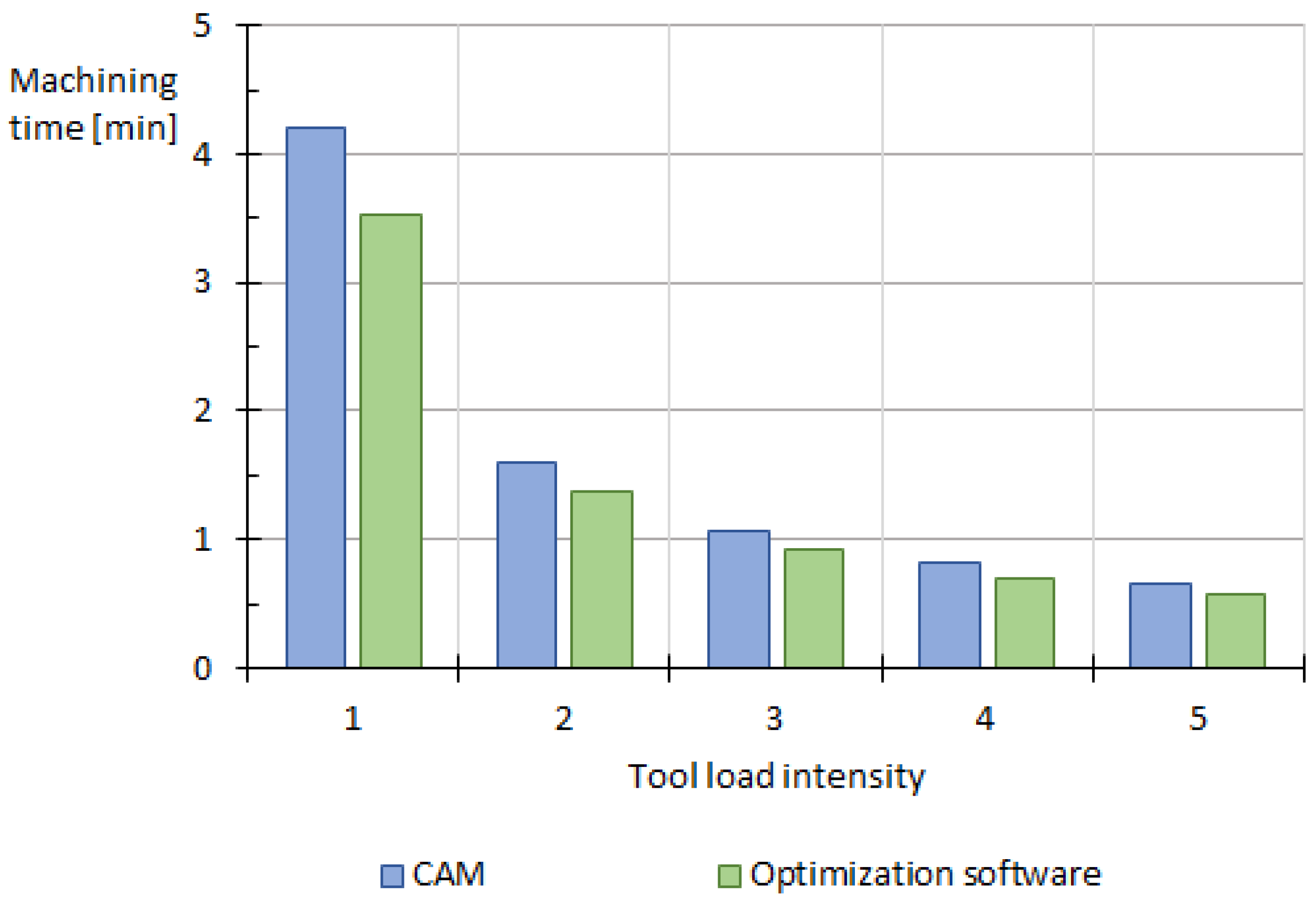

2.4. Comparison of Machining Times

3. Conclusions

- Despite the intensification of the cutting conditions by the optimization software, there was no increase in the deviations of the produced sidewall surfaces. In contrast, at each tool-load intensity, lower deviations, ranging from 3 to 23%, were achieved using the optimization software. Thus, optimization software can be used without enlarging the side-finishing allowances.

- On horizontal surfaces, the optimization software caused an increase in deviations at the two lowest tool-load intensities (by 12.5 and 7.8%). For the other three load intensities, a decrease in the deviations was observed from 8.3 to 36%. Using the optimization software, the deviations increased evenly with increasing tool load. Owing to the use of absolute deviations in the optimization software, it was not necessary to increase the finishing allowances.

- There was a reduction in the machining times in all cases, regardless of the cutting tool presetting load. At the lowest set load intensity, a time saving of 15.9% was achieved. With increasing load intensity, the time saving decreased; however, even the lowest achieved time saving of 12.8% is a great benefit for practical use.

- when compared with other CAM systems,

- when deployed on machine tools with a different control system,

- during five-axis milling of shaped surfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Singh, P.K.; Saini, P.; Kumar, D. Multi response optimization of CNC end milling of AISI H11 alloy steel for rough and finish machining using TGRA. Mater. Today Proc. 2020, 26, 2564–2573. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, T.; Ma, A.; Zhao, W. High efficiency orientated milling parameter optimization with tool wear monitoring in roughing operation. Mech. Syst. Signal Process. 2022, 165, 108394. [Google Scholar] [CrossRef]

- Urbikain Pelayo, G.; Olvera-Trejo, D.; Luo, M.; Tang, K.; López de Lacalle, L.N.; Elías-Zuniga, A. A model-based sustainable productivity concept for the best decision-making in rough milling operations. Measurement 2021, 186, 110120. [Google Scholar] [CrossRef]

- Feng, C.; Guo, H.; Zhang, J.; Huang, Y.; Huang, S. A systematic method of optimization of machining parameters considering energy consumption, machining time, and surface roughness with experimental analysis. Int. J. Adv. Manuf. Technol. 2022, 119, 7383–7401. [Google Scholar] [CrossRef]

- Li, W.; Li, B.; He, S.; Mao, X.; Qiu, C.; Qiu, Y.; Tan, X. A novel milling parameter optimization method based on improved deep reinforcement learning considering machining cost. J. Manuf. Process. 2022, 84, 1362–1375. [Google Scholar] [CrossRef]

- Zoghipour, N.; Yaratan, A.F.; Kaynak, Y. Multi objective optimization of rough pocket milling strategies during machining of lead-free brass alloys using Desirability function and Genetic algorithms-based analysis. Procedia CIRP 2021, 99, 145–150. [Google Scholar] [CrossRef]

- Ridwan, F.; Xu, X.; Ho, F.C.L. Adaptive execution of an NC program with feed rate optimization. Int. J. Adv. Manuf. Technol. 2012, 63, 1117–1130. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, P.; Hu, P.; Yin, Y.; Zhou, H.; Chen, J.; Yang, J. Multi-objective feed rate optimization of three-axis rough milling based on artificial neural network. Int. J. Adv. Manuf. Technol. 2021, 114, 1323–1339. [Google Scholar] [CrossRef]

- Plaza, M.; Zebala, W. A decision model for investment analysis in CNC centers and CAM technology. Comput. Ind. Eng. 2019, 131, 565–577. [Google Scholar] [CrossRef]

- Beňo, J.; Ižol, P.; Tomáš, M.; Varga, J. A fragmentation based approach to the free form surface milling. Acta Mech. Slov. 2015, 19, 26–32. [Google Scholar] [CrossRef]

- CGTech. Feed Rate Optimization. Available online: https://cgtech.com/feed-rate-optimization (accessed on 14 June 2022).

- Ižol, P.; Vrabeľ, M.; Maňková, I. Comparison of milling strategies when machining freeform surfaces. In MSF; Materials Science Forum—Novel Trends in Production Devices and Systems; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2016; Volume 862, pp. 18–25. [Google Scholar] [CrossRef]

- Heidenhain. Dynamic Efficiency—Effizient und Prozesssicher Bearbeiten. Available online: https://www.heidenhain.de/fileadmin/pdf/de/01_Produkte/Technische_Dokumentation/TI_Dynamic_Efficiency_ID1081192_de.pdf (accessed on 17 March 2022).

- Park, H.-S.; Qi, B.; Dang, D.-V.; Park, D.Y. Development of smart machining system for optimizing feedrates to minimize machining time. J. Comp. Des. Eng. 2018, 5, 299–304. [Google Scholar] [CrossRef]

- Liu, X.; Ding, Y.-P.; Yue, C.; Zhang, R.; Tong, X. Off-line feedrate optimization with multiple constraints for corner milling of a cavity. Int. J. Adv. Manuf. Technol. 2016, 82, 1899–1907. [Google Scholar] [CrossRef]

- Lee, C.-H.; Yang, F.; Zhou, H.; Hu, P.; Min, K. Cross-directional feed rate optimization using tool-path surface. Int. J. Adv. Manuf. Technol. 2020, 108, 2645–2660. [Google Scholar] [CrossRef]

- Gassara, B.; Baili, M.; Dessein, G.; Hbaieb, M.; Saï, W.B. Feed rate modeling in circular–circular interpolation discontinuity for high-speed milling. Int. J. Adv. Manuf. Technol. 2013, 65, 1619–1634. [Google Scholar] [CrossRef][Green Version]

- Rattunde, L.; Laptev, I.; Klenske, E.D.; Möhring, H.-C. Safe optimization for feedrate scheduling of power-constrained milling processes by using Gaussian processes. Procedia CIRP 2021, 99, 127–132. [Google Scholar] [CrossRef]

- Eureka. Eureka Chronos. Available online: https://www.roboris.it/wp-content/uploads/2021/04/Chronos-Eng-042021.pdf (accessed on 15 March 2022).

- Ceratizit Group. CircularLine—End Milling Cutter with Corner Radius. Available online: https://cuttingtools.ceratizit.com/gb/en/products/5359512002.html (accessed on 20 May 2022).

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others |

|---|---|---|---|---|---|---|---|---|

| 0.4 | 0.4 | 0.1 | 0.5 | 3.6 | 0.3 | 0.2 | 0.15 | 0.15 |

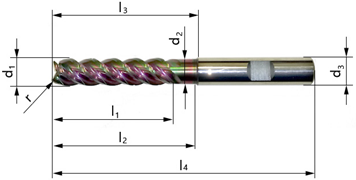

| ød1 [mm] | ød2 [mm] | ød3 [mm] | r [mm] | l1 [mm] | l2 [mm] | l3 [mm] | l4 [mm] | z [–] | λs [°] | γs [°] |

|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 11.6 | 12 | 0.2 | 49 | 60 | 64 | 109 | 4 | 45 | 8 |

| Sketch of the tool |  | |||||||||

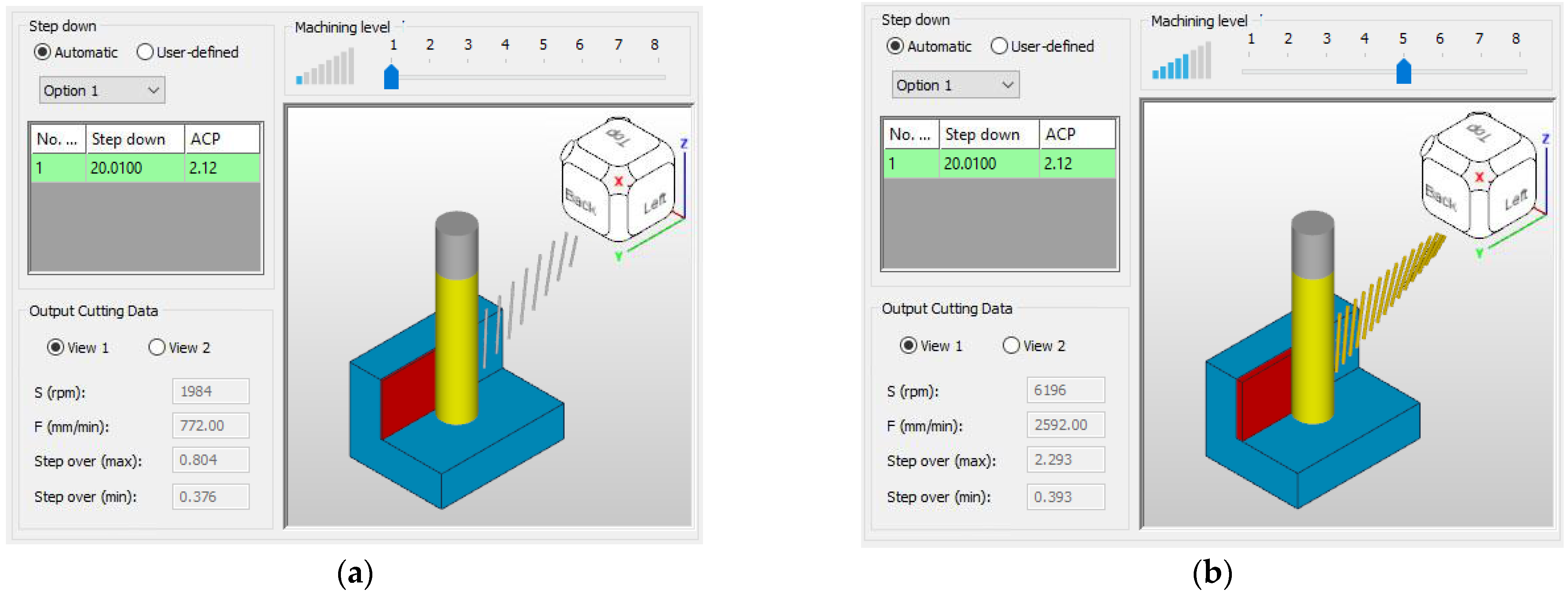

| Tool-Load Intensity | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Spindle speed [min−1] | 1984 | 4457 | 5600 | 6075 | 6196 |

| Feed rate [mm·min−1] | 772 | 1754 | 2239 | 2479 | 2592 |

| Step over min–max [mm] | 0.38–0.80 | 0.40–1.11 | 0.40–1.47 | 0.40–1.86 | 0.39–2.29 |

| Tool-Load Intensity | CAM | Optimization Software | ||||

|---|---|---|---|---|---|---|

| Maximum Negative Deviation [mm] | Maximum Positive Deviation [mm] | Mean Deviation [mm] | Maximum Negative Deviation [mm] | Maximum Positive Deviation [mm] | Mean Deviation [mm] | |

| 1 | −0.020 | 0.043 | 0.019 | −0.017 | 0.056 | 0.014 |

| 2 | −0.066 | 0.067 | 0.028 | −0.027 | 0.063 | 0.023 |

| 3 | −0.070 | 0.073 | 0.033 | −0.034 | 0.074 | 0.030 |

| 4 | −0.044 | 0.133 | 0.042 | −0.041 | 0.106 | 0.039 |

| 5 | −0.050 | 0.117 | 0.049 | −0.050 | 0.128 | 0.048 |

| Tool-Load Intensity | Course of Deviations |

|---|---|

| 1 |  |

| 2 |  |

| 3 |  |

| 4 |  |

| 5 |  |

| Tool-Load Intensity | Course of Deviations |

|---|---|

| 1 |  |

| 2 |  |

| 3 |  |

| 4 |  |

| 5 |  |

| Deviations [µm] | |||||

|---|---|---|---|---|---|

| Tool-Load Intensity | 1 | 2 | 3 | 4 | 5 |

| CAM | 3.2 | 5.1 | 11.1 | 8.4 | 11.4 |

| Optimization software | 3.6 | 5.5 | 7.1 | 7.7 | 8.3 |

| Tool-Load Intensity | CAM Simulated Time [Min] | Optimization Software | |

|---|---|---|---|

| Simulated Time [Min] | Estimated Time Saved [%] | ||

| 1 | 4:00 | 3:17 | 17.92 |

| 2 | 1:23 | 1:09 | 16.87 |

| 3 | 0:53 | 0:44 | 16.98 |

| 4 | 0:38 | 0:33 | 13.16 |

| 5 | 0:31 | 0:26 | 16.13 |

| Tool-Load Intensity | CAM Real Time [Min] | Optimization Software | |

|---|---|---|---|

| Real Time [Min] | Real Time Saved [%] | ||

| 1 | 4:12 | 3:32 | 15.9 |

| 2 | 1:36 | 1:22 | 14.6 |

| 3 | 1:04 | 0:55 | 14.1 |

| 4 | 0:49 | 0:42 | 14.3 |

| 5 | 0:39 | 0:34 | 12.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ižol, P.; Brindza, J.; Vrabeľ, M.; Demko, M.; Basilio, S. Effect of Optimization Software on Part Shape Accuracy and Production Times during Rough Milling of Aluminum Alloy. Machines 2022, 10, 1212. https://doi.org/10.3390/machines10121212

Ižol P, Brindza J, Vrabeľ M, Demko M, Basilio S. Effect of Optimization Software on Part Shape Accuracy and Production Times during Rough Milling of Aluminum Alloy. Machines. 2022; 10(12):1212. https://doi.org/10.3390/machines10121212

Chicago/Turabian StyleIžol, Peter, Jozef Brindza, Marek Vrabeľ, Michal Demko, and Shander Basilio. 2022. "Effect of Optimization Software on Part Shape Accuracy and Production Times during Rough Milling of Aluminum Alloy" Machines 10, no. 12: 1212. https://doi.org/10.3390/machines10121212

APA StyleIžol, P., Brindza, J., Vrabeľ, M., Demko, M., & Basilio, S. (2022). Effect of Optimization Software on Part Shape Accuracy and Production Times during Rough Milling of Aluminum Alloy. Machines, 10(12), 1212. https://doi.org/10.3390/machines10121212