Abstract

This research is focused on the evaluation of cutting edge wear of the delimbing knife by contactless methods. Delimbing knives were tested in an experimental device constructed in our laboratory, which operates on the principle of a forest harvester head. The greatest wear of the cutting edge was manifested in knife no. 1 with a blade angle of ∢ 7°. The research was focused on the wear of delimbing knives made of DIN 58SiCr8/WNr material when changing the angular geometry of the tool and using a constant delimbing speed of 2.0 m.s−1 while delimbing spruce wood of various wood diameters. The Alicona Infinite Focus device, which functions as a non-contact 3D optical device, was used to determine the amount of wear on the cutting edge of the knife. The size of cutting edge wear significantly affects chipless cutting wood, which can be observed in an increase in the cutting force during the delimbing process. The use of harvester technology in forestry is a highly topical issue today. From this point of view, it is necessary to focus on increasing the efficiency and reducing the energy consumption of the machine, which economically benefits its delimbing operation.

1. Introduction

The process of chipless wood processing (as an operation for delimbing trees used in all types of multi-operation machines) is characterized by many parameters that are related to each other very closely. Considerable attention is paid to the realization of theoretical and experimental research in chipless transverse wood cutting in the process of delimbing and debarking assortments of wood, as well as the analysis of dynamic and kinetic parameters of this type of wood cutting in multi-operational machines [1,2,3,4].

Chipless wood cutting is a technological process in which acting individual cutting tools are used on wood, thereby allowing one to obtain required shapes; alternatively, wood can be spread over smaller parts (called chips), thereby avoiding the production of wood waste. A considerable cutting force arises in the case of the chipless wood cutting process when using a V-blade or flat knives in a direction that is not the same as the direction of wood fibers. This is the reason why energy demands are increased in the wood cutting process. This method of wood cutting is also referred to as the force cutting of wood.

The innovation of forest machines for delimbing trees is connected to research in cutting resistance forces and optimal shapes for cutting tool geometry. The correct geometry considerably influences the delimbing quality. The cutting force acting in the direction of the speed vector is a result of all resistance forces acting on different parts of the knife, thereby creating its cutting profile (a rake face, flank face, and cutting edge) [5,6].

Harvesting and processing in the forest economy are significantly influenced by the development of machines and devices. Their progress increases the process effectivity and decreases economic operational costs. Decreasing energy and material demands in wood processing, high reliability of machines and automation implementation to this activity lead to research into the theoretical basics of utilization of technology in the forest economy. The automation and development of techniques and technologies have been ongoing. The time necessary for wood processing is shorter than that previously required, and the process is of higher quality. Productivity studies of the felling equipment have been performed in many countries, lasting more than 25 years. These studies showed that many factors influence the productivity of individual machines [7]. Felling activities all over the world vary significantly. The adaptation of technologies varies depending on complex, local and preventive conditions [8,9]. For this reason, the standard parameter of a harvester for the delimbing speed of the cutting tool, i.e., 2.0 m.s−1, was used. The technical parameters of the experimental equipment were designed based on the technical parameters of a harvester in the catalog sheets that was commercially available. Based on experimental measurements of the chosen factors (the cutting force, wood species, diameter of the trunk, and cutting tool) in the chipless delimbing process, the use of a designed experimental device is possible in order to define the delimbing knife wear with regard to the wood species processed during the experiment. The abrasive wear of cutting tools in the interaction of two bodies is a disadvantage of such wood processing in the forest economy. The demonstrative example is the component wear in the delimbing process. Studies conducted overseas [1,4,10,11] also used a flat separating knife in harvesting research using harvester technologies. The research teams of the presented publications emphasized the evaluation of the wear of the cutting edge of the delimbing knife, the influence of the cutting tool on the wood and the damage to the wood. Before beginning the individual research, it was necessary to design an experimental device. The main difference in the research solution is the final cutting force, which consumes the higher cutting force produced by a pneumatic cylinder with a separating knife. This is the reason that it can cause faster wear of the cutting edge or mechanical damage to the separating knife as a result of the high impacts to the reaction wood [5,12]. The aim of this paper was to evaluate the wear of the cutting edge of three different delimbing knives, using the wood spruce.

2. Materials and Methods

2.1. Materials

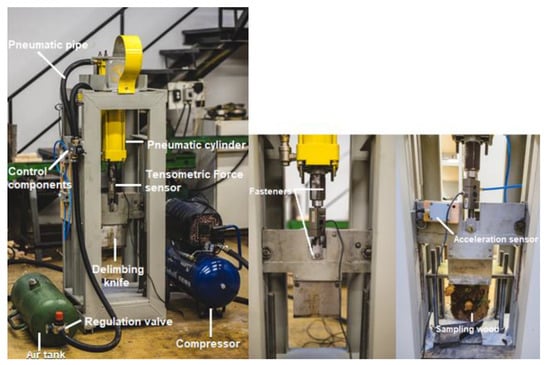

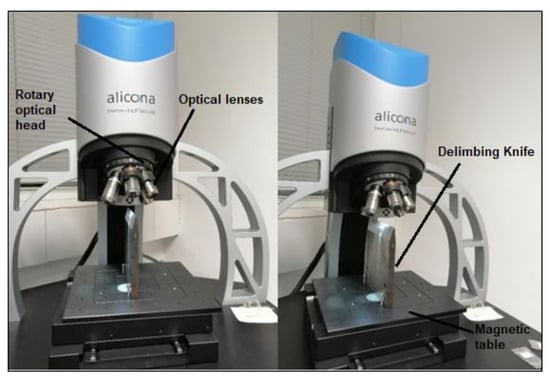

As part of the project activity, a device (Figure 1) was constructed, on which it is possible to carry out the experimental measurements of chipless wood splitting and debranching. Due to the unsafe conditions for humans while collecting data in the real delimbing process, we considered it beneficial for safety purposes and data robustness to construct laboratory equipment that could reproduce the conditions and phenomena very close to the technical reality that occur throughout the delimbing process, from the point of view of the cutting tool. The testing of delimbing knives is otherwise only possible on a harvester head; however it was safer to implement testing equipment prepared specifically for the research in order to observe the mechanical damage. The experimental device Figure 1. was designed from profiled steel and shaped elements via welded joints. The dimensions of the device are 1404 × 500 × 500 mm; the delimbing knife is 400 mm far from the wood sample. An air tank with a volume of 80 L was placed outside of the device. The reduction valve with a working pressure of 1.2 MPa for setting constant air flow in the system was a part of the air tank. The pneumatic cylinder with parameters according to standard ISO 6431 was joined to the device with screws. The tensometric force sensor HBM S9M was placed on the piston rod with designed fasteners. The starting movement of the cylinder was made possible by pneumatic mixing control type AC 9010 G1/2 UNIVER with manual control, equipped with a non-return valve and an air damper. The SAI/L acceleration sensor (SZ1/50) ensured the constant cutting speed of the branching knife. The sensor was connected to the 8-channel measuring control panel measurement unit Quantum MX 840 via a cable. The advantage of the measurement unit is compatibility with a device produced by the company HBM “Hottinger Brüel & Kjaer GmbH”. The cutting device consists of a flat delimbing knife placed on the piston and secured by a pin. After moving the piston rod, the knife was moved toward the wood sample and it created transverse delimbing wood cutting. The wood sample was protected against movements by a pressure roller controlled by an independent pneumatic control unit consisting of a pneumatic remote control, a choke valve, a starting valve and an exhaust valve in output from the pressure roller.

Figure 1.

Experimental device for the chipless delimbing wood cutting process and the application of sensors to the arrangement of the device and their fastening.

2.2. Experimental Delimbing Knife

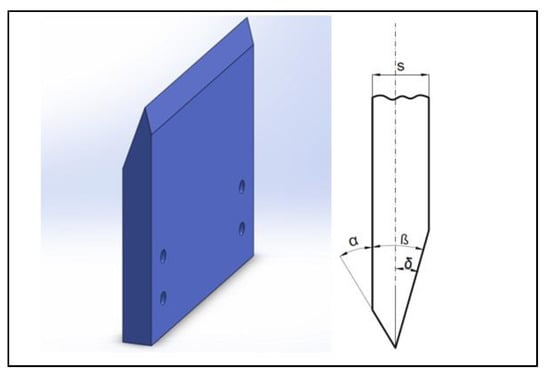

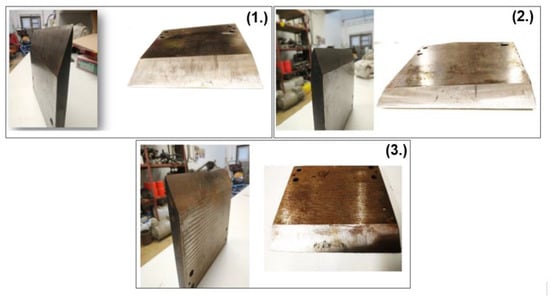

In the case of the chipless wood cutting process, the cutting tool was easier and more reliable in comparison with the experimental geometry of the saw chain. The operational costs were significantly lower. Analyses defining parameters for the delimbing process were made from research conducted [11,13,14] and the analysis performed at the Department of Environmental and Forest Technology of the Technical University in Zvolen [7,13]. Based on these studies and analyses, it was noted that the thickness of the delimbing knife had a significant influence on the cutting resistance in wood penetration. With an increase in the thickness of the cutting tool (S in Figure 2.), energy consumption increased and the quality of the cutting surface worsened. Delimbing is expensive in the felling process, and it usually decreases the final profit [15,16]. Based on this, flat delimbing knives were made (Figure 3). The knife with a straight cutting edge was used for an experimental measurement due to the easy evaluation of cutting forces responsible for the wear of the cutting knife. Three types of delimbing knives were used for laboratory measurements. The shape and angular geometry of the delimbing knife can be seen in Figure 2. The delimbing knives were made of the same material, EN 41 9452 DIN 58SiCr8/WNr, but had different tool geometry, as shown in Table 1.

Figure 2.

Experimental delimbing knife.

Figure 3.

Delimbing knives in re-sharpened condition.

Table 1.

Technical parameters of delimbing knives used in the experiment [17].

Initial measurements on an experimental delimbing device were performed with a set of cutting tools, first using delimbing knives with the angular geometry defined in Table 1. The wood of the Norway spruce (Picea Abies) was used as sampling material with a relative humidity of 27%.

Delimbing knife No. 1, shown in Figure 2, is made of the material EN 41 9452, representing a class-19 tool steel in an undamaged state before the start of the experiment. This type of material used in the experiment is a low-alloy Si-Cr steel suitable for cold work [18]. The reason behind the use of this material is its applicability to the production of medium-sized tools for machining and cutting non-metallic materials, especially wood, with the possibility of intermittent cutting with high demands on toughness. It is very malleable at the temperature range of 1050–850 °C with slow cooling. Good machinability of the material enables perfect sharpening of the cutting edge after wear. The cutting edges of the cutting knives were machine-sharpened before the experiment according to the defined parameters [2,7]. To confirm the exact type of the knife’s material, metallurgical analysis and material analysis were performed with the TASMAN Q4 test device in which the output tests of samples showed the percentage of carbon and silicon content in the material according to the defined technical standard of the knife material.

2.3. Wood Samples Used for Experimental Measurements

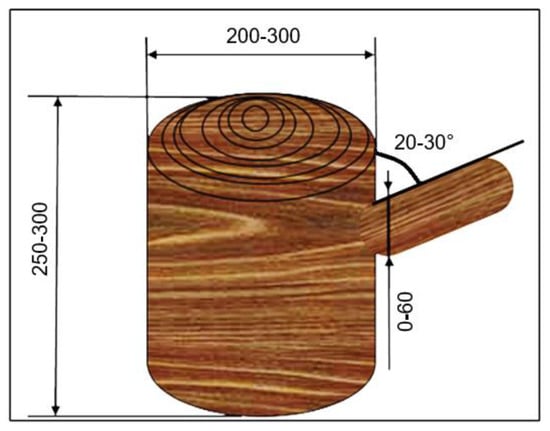

The experimental measurements for defining the wear of the cutting edge on the delimbing knife were performed with Norway spruce (Picea abies) (Figure 4). Material samples for the experimental measurements were in the shape of logs with a diameter of 20 cm to 30 cm and a length of 25 cm to 30 cm. The diameters of branches growing from the trunks were in the range of 0 to 60 mm and their lengths were in the range of 40 mm to 120 mm. The branch growing angle was 20–30° The size of the diameter of the basic wood trunk did not affect the cutting force. The moisture of the wood should represent the moisture of freshly sawn wood; i.e., the fiber saturation point was = 30%.

Figure 4.

Material sample of Norway spruce.

2.4. Method for Analysis of Cutting Edge Wear on the Delimbing Knife

The analysis of the cutting edge wear on the experimental delimbing knife was performed via a 3D optical device called Alicona Infinite Focus. All relevant surface properties of the micro-precision components were measured with just one multifunctional measuring sensor. We achieved traceable measurement results with high reliability and a precise vertical resolution of up to 10 nm.

Alicona Infinite Focus (Figure 5) is designed so that it has a certain freedom, which means that it does not have to pass through specified points but should pass near them. The method was designed for the estimation of values obtained via experimental measurements.

Figure 5.

Alicona Infinity Focus—3D optical method.

Individual values can be loaded by measurement error due to the measurement method; therefore, individual values are defined in the technical specification of the device Table 2.

Table 2.

Technical specification Alicona Infinite Focus.

If the errors were not taken into account, the resulting surface would copy the measurement error and would therefore be unrealistic—the only case is linear dependence, the result of which is a straight line. For the input point field, we found that such a linear function will pass through the points of the input point field as closely as possible to them.

2.5. Calculation of Experimental Input Parameters

The chipless wood cutting (especially delimbing) was examined on the designed experimental device for testing delimbing knives, and we observed the durability of knives and the wear of a tool cutting edge. The wear of the cutting edge and the energy consumption were evaluated after the delimbing of 270 pieces of wood samples, according to dimensional sets of wood. Only wood samples of Norway spruce were measured. The number of experimental measurements was defined by a calculation of the basic statistical file using a mathematical relation. After creating the basic statistical file, we created a basic table of descriptive statistics of mutual interactions. The decomposition table shows the average value of the max. of the cutting force in each interval of the diameters of the sample wood in the process of chipless wood cutting depending on the number of experimental measurements where Knife = 90 measurements with one type of delimbing knife. The standard deviation shows the mutual difference in the knives in a set of basic values. The compilation of the methodology was carried out on the basis of technical parameters of the machine and the properties of the tested wood Table 3 [19].

Table 3.

Decomposition table of descriptive statistics of mutual interactions of diameters of sampling trees and the variable max. cutting force Fc.

To define the size of the experimental sample measurement file for the analysis of cutting edge wear, there are empiric evaluation formulas for both the known and unknown variance [10,20,21].

2.6. Calculation of the Cutting Force of the Pneumatic Cylinder

The calculation precisely defines the resulting compressive force F at the end point of the pneumatic cylinder-piston rod, which ensures the functionality of the delimbing knife. Based on mathematical calculations, it was possible to set up an experimental device for testing branch knives. The constant compressive force ensures the same cutting speed of the delimbing knife when changing the wood and the diameter of the wood [21]. By observing the constant parameters of the experimental measurements, it was possible to evaluate the wear of the cutting edge of the delimbing knives.

where:

F force (N);

P working pressure of the pneumatic cylinder (MPa);

S surface acting on the knife (m2).

3. Results and Discussion

We performed initial measurements on an experimental delimbing device with a group of cutting tools (Table 1). We used Norway spruce with a relative humidity of 27% as a sampling material. The Results and Discussion Section provides a clear analysis of the interaction between the cutting tool and the wood due to the inhomogeneity of the wood material and the angular geometry of the cutting tool shown in Table 1. The thickness of the cutting tool has a significant influence on the evaluation of the cutting force and subsequent wear of the cutting edge of the knife-the greater the thickness, the greater the resistance leading to greater cutting force and greater damage to the cutting edge of the delimbing knife [22,23].

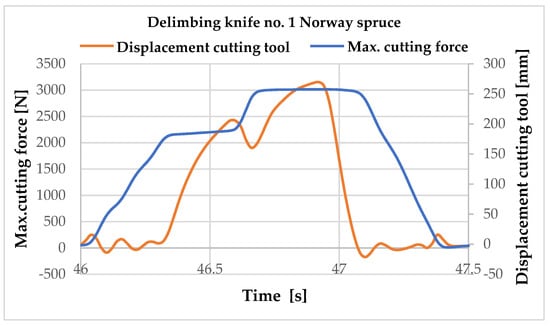

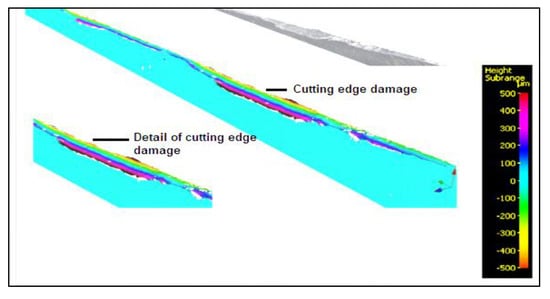

The experimental course of the delimbing process with a sample of spruce material and delimbing knife No. 1 (Table 1) is shown in Figure 6. The diameter of the sampling wood with a branch was in the range of 20–40 mm. The maximum cutting force required to separate the branch from the tree trunk was 3.1 kN for the given parameters. When the pneumatic cylinder was set in motion, we recorded a change in the path of the cutting tool, which changed with respect to the place where the branch grew out of the sampling wood. The maximum cutting force Fc was recorded at the point of separation of the branch from the tree trunk, where the wood is defined as the reaction wood. With the help of vector calculations and the point method of mutual distances (Figure 7), we evaluated the wear distance in the direction of the material with a value of 1.18 mm (Figure 8).

Figure 6.

The course of experimental measurement of delimbing—delimbing knife No.1.

Figure 7.

Cutting force and the path of the delimbing knife in the process of chipless wood cutting.

Figure 8.

Wear on the cutting edge of knife No. 1.

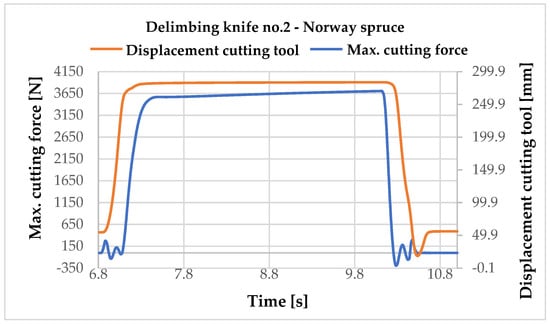

Figure 9 shows the course of the process of delimbing of the sample material, spruce, with a diameter in the range of 20–40 mm using delimbing knife No. 2. The maximum cutting force was recorded at the point of separation of the branch from the tree trunk due to the definition of the wood at this point as reaction wood. The specific properties of the reaction wood and the change in the angular geometry of the delimbing knife were reflected in the steep increase in the cutting force, where its maximum for this type of sampling wood is 3.75 kN. As can be seen in the graph, the influence of the cutting tool at the selected interval of wood diameters recorded a longer process of separation of the branch from the tree trunk.

Figure 9.

The course of experimental measurement of delimbing-delimbing knife No.2.

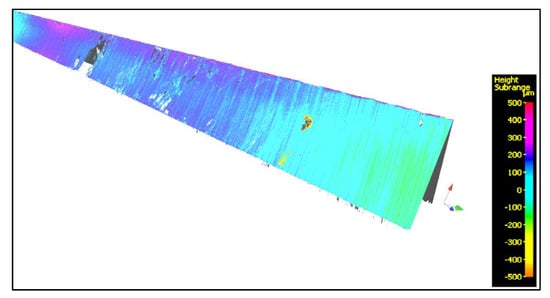

The wear of the cutting edge is evaluated in Figure 10, where the abrasion is only partial. This means that this type of a delimbing knife can be considered as suitable in terms of delimbing knife wear. The wear demonstrated by the color spectrum shows the embossing of the worn material on the cutting edge of the delimbing knife. Using vector recalculations and the point method of mutual distances, the wear distance toward the material was evaluated with a value of 0.3 mm on average.

Figure 10.

Cutting edge wear-knife No. 2-Norway spruce.

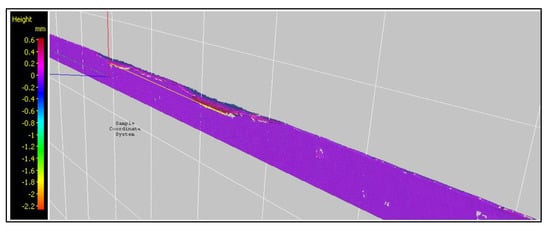

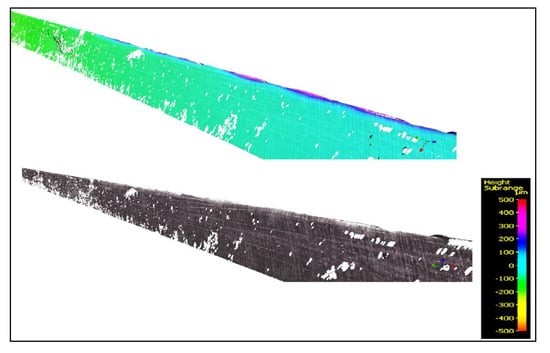

The wear of the cutting edge on delimbing knife No. 3 is indicated by the color spectrum. The software accurately evaluated the place where the greatest damage occurred during the delimbing process. Changing the wear distance of the cutting edge is defined as different because the type of deformation is not the same. Delimbing knife No. 3, in terms of energy consumption with a given angular geometry, consumed the greatest force in the delimbing process (as shown in Graph 3), which led to stronger shocks and faster wear of the cutting edge. The wear demonstrated by the color spectrum shows the embossing of the worn material on the cutting edge of the delimbing knife (Figure 10. Using vector recalculations and the point method of mutual distances, the wear distance toward the material with a value of 0.2 mm on average was evaluated. The scanning of the cutting edge was performed with the 3D optical device Alicona Infinite Focus.

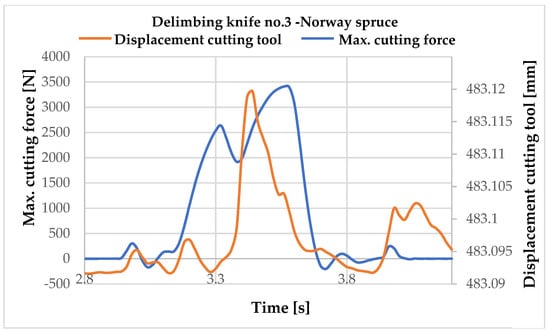

Figure 11 shows the course of the process of delimbing the sample material spruce with delimbing knife No. 3 and a wood diameter in the range of 20–40 mm. The maximum cutting force was recorded at the point of separation of the branch from the tree trunk. When the pneumatic cylinder was set in motion, we recorded a change in the path of the cutting tool, which changed with respect to the place where the branch grew out of the sampling wood. The maximum cutting force Fc was recorded at the point of separation of the branch from the tree trunk, where the wood is defined as the reaction wood. The course of the delimbing process for the first delimbing knife and the second delimbing knife recorded different energy intensities of the cutting tool due to the change in the sampling wood when using the same interval of branch diameters.

Figure 11.

The course of the experimental measurement of delimbing—delimbing knife No.3.

We can see the wear of the cutting edge on knife No. 3 in Figure 12. The color spectrum accurately removes the damage to the cutting edge.

Figure 12.

Cutting edge wear—knife No. 3—Norway spruce.

4. Conclusions

The cutting edge was evaluated using the Alicona Infinite Focus device. It is a highly accurate, fast and flexible optical 3D measuring system that can also evaluate the micro-structures of a material.

In light of the achieved results of the evaluation of the cutting edge wear using the material DIN 58SiCr8/WNr, it is recommended to use a cutting edge radius of the delimbing knife in the range of 0.012–0.0025 mm at the cutting edge ∢155° with a flank angle ∢α 4°. Although, in practice, it is not possible to use such a large cutting edge radius in terms of durability, this was necessary for testing in laboratory conditions to achieve higher cutting forces and evaluate wear. Higher cutting forces are necessary to ensure sufficient delimbing of diameters in the interval of 0–60 mm of branches. The delimbing process in practice is carried out by moving the debranched wood, and, in our case, the wood is fixed and the cutting tool moves.

The choice of a larger radius also caused more abrasive wear on the cutting edge, as proven in the results. Delimbing knife No. 1 with a cutting edge angle ∢20° and a back angle ∢α 7° had the greatest abrasive wear on the cutting edge, which can be observed in Figure 9. The size of the wear reached a depth of 1.18 mm. Delimbing knives No. 2 and No. 3 were much less damaged in terms of wear when using knives with an angular geometry of 15° and 20° and with a flank angle ∢α 4°. Wear was shown only in the form of slight craters on the radius of the cutting edge. Testing of debranching knives in the case of spruce was carried out on a special experimental device [19,24].Based on the processing of the results, we evaluated the maximum force of 6.59 kN in wood processing. The cutting force required to separate the branch in the experiment ranged from 2 to 7 kN, which, at a cutting tool speed of 2 m.s−1, was sufficient for delimbing a maximum branch diameter of 60 mm. Wear was observed after 90 measurements on one type of knife. We determined the number of measurements statistically with a basic file. The cutting edge wear was evaluated as the smallest value not affecting the delimbing process because the damage of the cutting edge was only partial. The evaluation of the wear on each delimbing knife was conducted after 90 measurements.

Author Contributions

Conceptualization, J.M. and J.K.(Jozef Krilek); methodology, J.M., J.K. and J.K. (Jozef Krilek); software, J.M.; validation, J.M., T.K., M.K. and J.K. (Ján Kováč); formal analysis, J.M.; investigation, J.M and J.K. (Ján Kováč); resources, M.K.; data curation, T.K. and J.M.; writing—original draft preparation, J.M. and J.K. ( Ján Kováč); writing—review and editing, J.K. and J.K. (Ján Kováč) and T.K.; visualization, J.M.; supervision, M.K. and J.K. (Jozef Krilek); project administration, J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under the Contract no. APVV-21-0180. This publication is the result of the project implementation: Progressive Research into Utility Properties of Materials and Products Based on Wood (LignoPro), ITMS 313011T720 supported by the Operational Programme Integrated Infrastructure (OPII) funded by the ERDF.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hatton, B. Experimental Determination of Delimbing Forces and Deformations in Hardwood Harvesting, Croatian Journal of Forest Engineering. ISSN 1845-5719. 2015. Available online: https://hrcak.srce.hr/index.php?id_clanak_jezik=200723&show=clanak* (accessed on 24 September 2015).

- Kirlek, J.; Ťavodová, M.; Kováč, J.; Tichý, B. Impact of irregular tooth pitch of circular saw blades on power for wood cross-cutting. Drv. Ind. 2020, 71, 3–11. [Google Scholar] [CrossRef]

- Kováč, J.; Krilek, J.; Jobbágy, J.; Dvořák, J. Technique and Mechanization in Forestry; Technical University in Zvolen: Zvolen, Slovakia, 2017; ISBN 978-80-228-3021-8. [Google Scholar]

- Melicherčík, J.; Krilek, J.; Harvánek, P. Simulation of stress and strain analysis on a delimbing knife with replaceable cutting edge. BioResources 2020, 15, 3799–3808. [Google Scholar] [CrossRef]

- Lindroos, O.; La Hera, P. Drivers of Advances in Mechanized Timber Harvesting—A Selective Review of Technological Innovation. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2017, 38, 243–258. [Google Scholar]

- Kalincová, D.; Ťavodová, M.; Ľuptáčiková, V. Application of the weld deposits on function surfaces of the forest machines components. Manuf. Technol. 2018, 18, 400–405. [Google Scholar] [CrossRef]

- Voronicyn, K.I.; Gugelev, S.M. 1989: Mašinnaja Obrezka Sučjev na Lesoseke; Lesnaja Promyšlennosť: Moscow, Russia, 1989; 272p. [Google Scholar]

- Ťavodová, M.; Krilek, J.; Perec, A.; Kalincová, D.; Kováč, J. Analysis of the wear of saw blade teeth and the proposal of methods of increasing their wear resistance. MM Sci. J. 2016, 9, 1287–1291. [Google Scholar] [CrossRef][Green Version]

- Spinelli, R.; Hartsough, B.R.; Magagnotti, N. Productivity Standards for Harvesters and Processors in Italy. For. Prod. J. 2010, 60, 226–235. [Google Scholar] [CrossRef]

- Hiesl, P.l.; Benjamin, J.G. Applicability of International Harvesting Equipment Productivity Studies in Maine, USA: A Literature Review. Forests 2013, 4, 898–921. [Google Scholar] [CrossRef]

- Schmidtova, J.; Vacek, V. Applied Statistics, 1st ed.; Technical University in Zvolen: Zvolen, Slovakia, 2013; 139p. [Google Scholar]

- Glöde, D.; Sikström, U. Two felling methods in final cutting of shelterwood, single-grip harvester productivity and damage to the regeneration. Silva Fenn. 2001, 35, 71–83. [Google Scholar] [CrossRef]

- Melicherčík, J.; Krilek, J. Design of methodology for measurement of chiplles of cutting wood. Acta Fac. Tech. Zvolen: Sci. J. Fac. Technol. 2021, 2, 39–45. [Google Scholar]

- Mikleš, M.; Holík, J.; Mikleš, J. Forestry Machinery. Technical University in Zvolen: Zvolen, Slovakia, 2014. [Google Scholar]

- Gellerstedt, S. Operation of the Single-Grip Harvester: Motor-Sensory and Cognitive Work. Int. J. For. Eng. 2013, 13, 35–47. [Google Scholar] [CrossRef]

- Watson, W.F.; Twaddle, A.A.; Hudscon, J.B. Review of Chain Flail Delimbing-Debarking, Forest Research Institute Rotorua, New Zealand, J. B. Hudson University of Aberdeen Aberdeen, Scotland. J. For. Eng. 2013, 4, 37–52. [Google Scholar] [CrossRef]

- Kalincová, D.; Ťavodová, M.; Hnilicová, M.; Veverková, D. Machinery for forest cultivation - increase of resistance to abrasive wear of the tool. MM Sci. J. 2016, 5, 1269–1272. [Google Scholar] [CrossRef]

- Kováč, J. The ergonomics of forest machines in the forest harvesting—VEGA 1/0403/11. In Kolokvium ku Grantovej úlohe č. 1/0403/11; Technická Univerzita vo Zvolene: Zvolen, Slovakia, 2013; Volume 1, pp. 39–43. ISBN 978-80-228-2594-8. [Google Scholar]

- Krilek, J.; Kováč., J.; Dvořák, J.; Mikleš, J. Výskum Rezných Mechanizmov v Lesníctve; Vedecká Monografia; Technická Univerzita vo Zvolene: Zvolen, Slovakia, 2015; ISBN 978-80-228-3056-0. [Google Scholar]

- Gerasimov, Y.; Seliverstov, A.; Syunev, V. Industrial Round-Wood Damage and Operational Efficiency Losses Associated with the Maintenance of a Single-Grip Harvester Head Model: A Case Study in Russia. Forests 2012, 3, 864–880. [Google Scholar] [CrossRef]

- Nuutinen, Y.; Väätäinen, K.; Asikainen, A.; Prinz, R.; Heinonen, J. Operational efficiency and damage to sawlogs by feed rollers of the harvester head. Silva Fenn. 2010, 44, 121–139. [Google Scholar] [CrossRef]

- Ťavodová, M.; Kalincová, D.; Hnilicová, M. The influence of heat treatment on tool properties mulcher. Manuf. Technol. J. Sci. Res. Prod. 2016, 16, 1169–1173. [Google Scholar] [CrossRef]

- Adebayo, A.B.; Han, H.S.; Johnson, L. Productivity and cost of cut-to-length and whole-tree harvesting in a mixed-conifer stand. For. Prod. J. 2007, 57, 59–69. [Google Scholar]

- Holzleitner, F.; Stampfer, K.; Visser, R. Utilization rates and cost factors in timber harvesting based on long-term machine data. Croat. J. For. Eng. 2011, 32, 501–508. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).