Numerical Simulation and Test of the Disturbance Air Suction Garlic Seed Metering Device

Abstract

1. Introduction

2. Materials and Methods

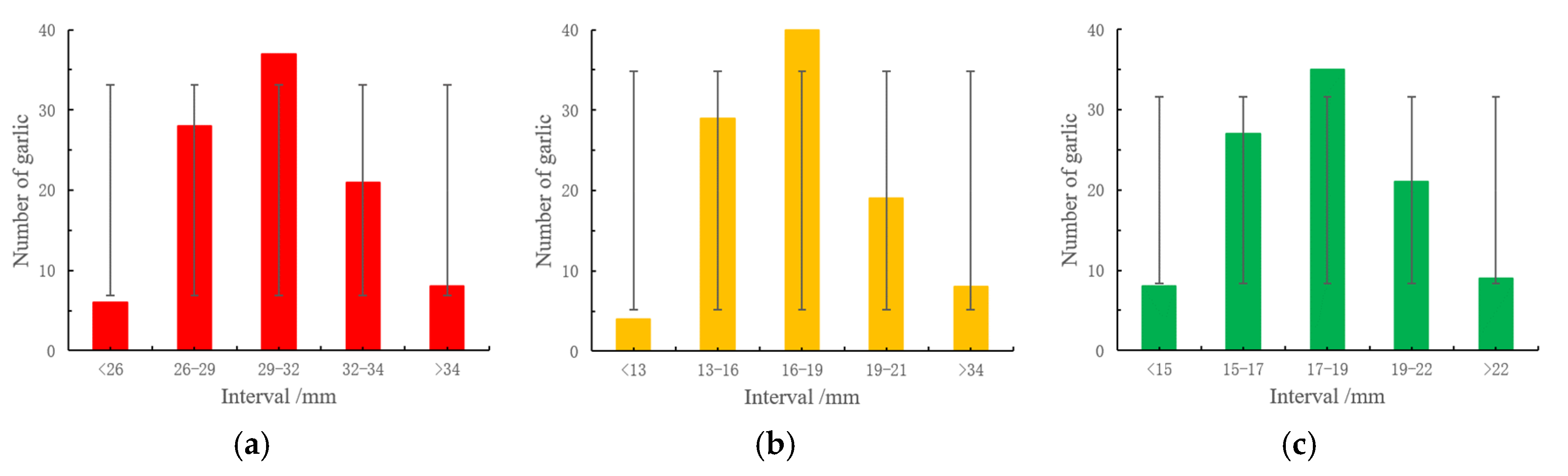

2.1. Agronomic Requirements and Form Factor Measurement

- —Equivalent diameter of garlic seeds, mm;

- —Average length of garlic seeds, mm;

- —Average width of garlic seeds, mm;

- —Average thickness of garlic seeds, mm.

2.2. Theory and Calculation of Model

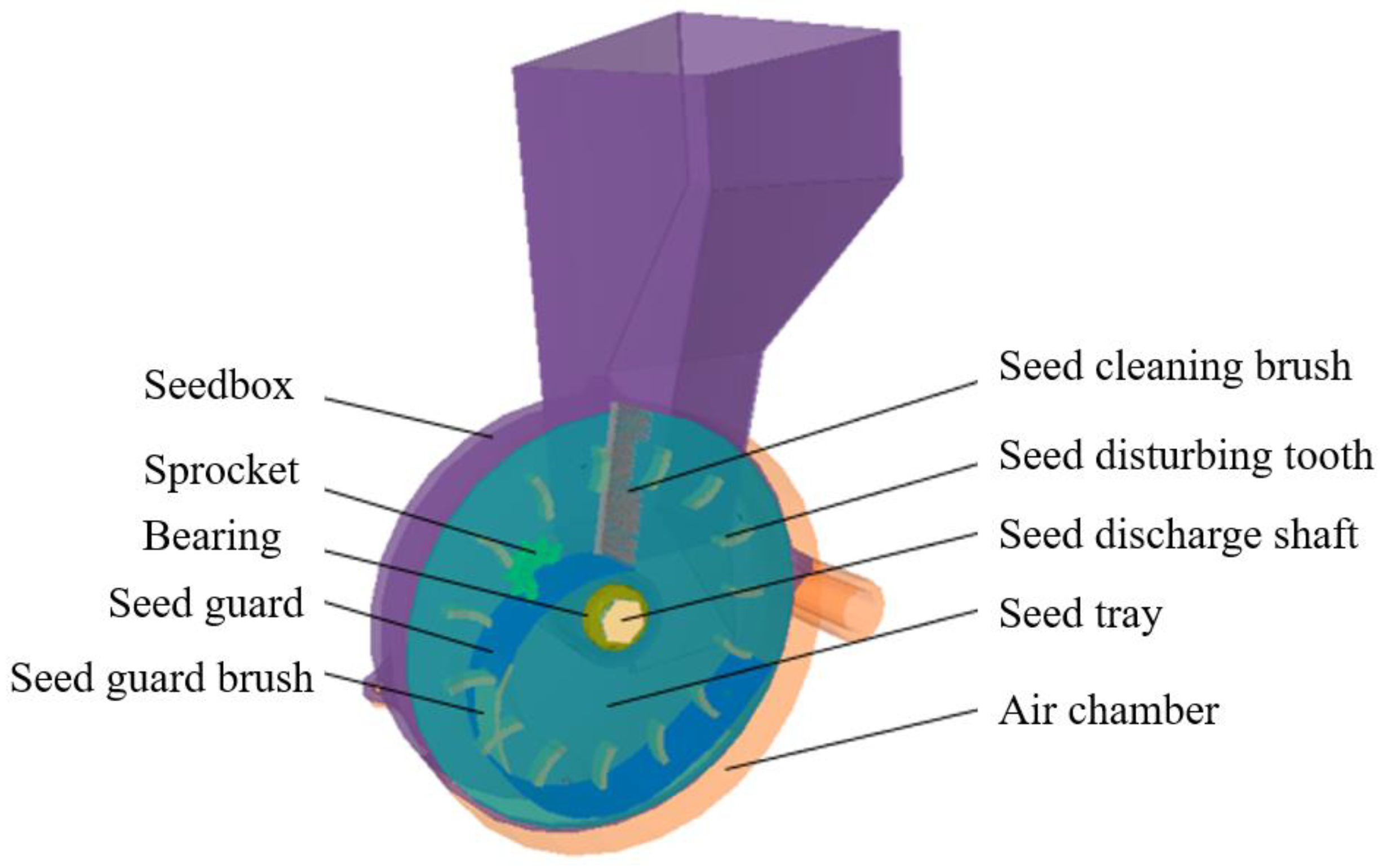

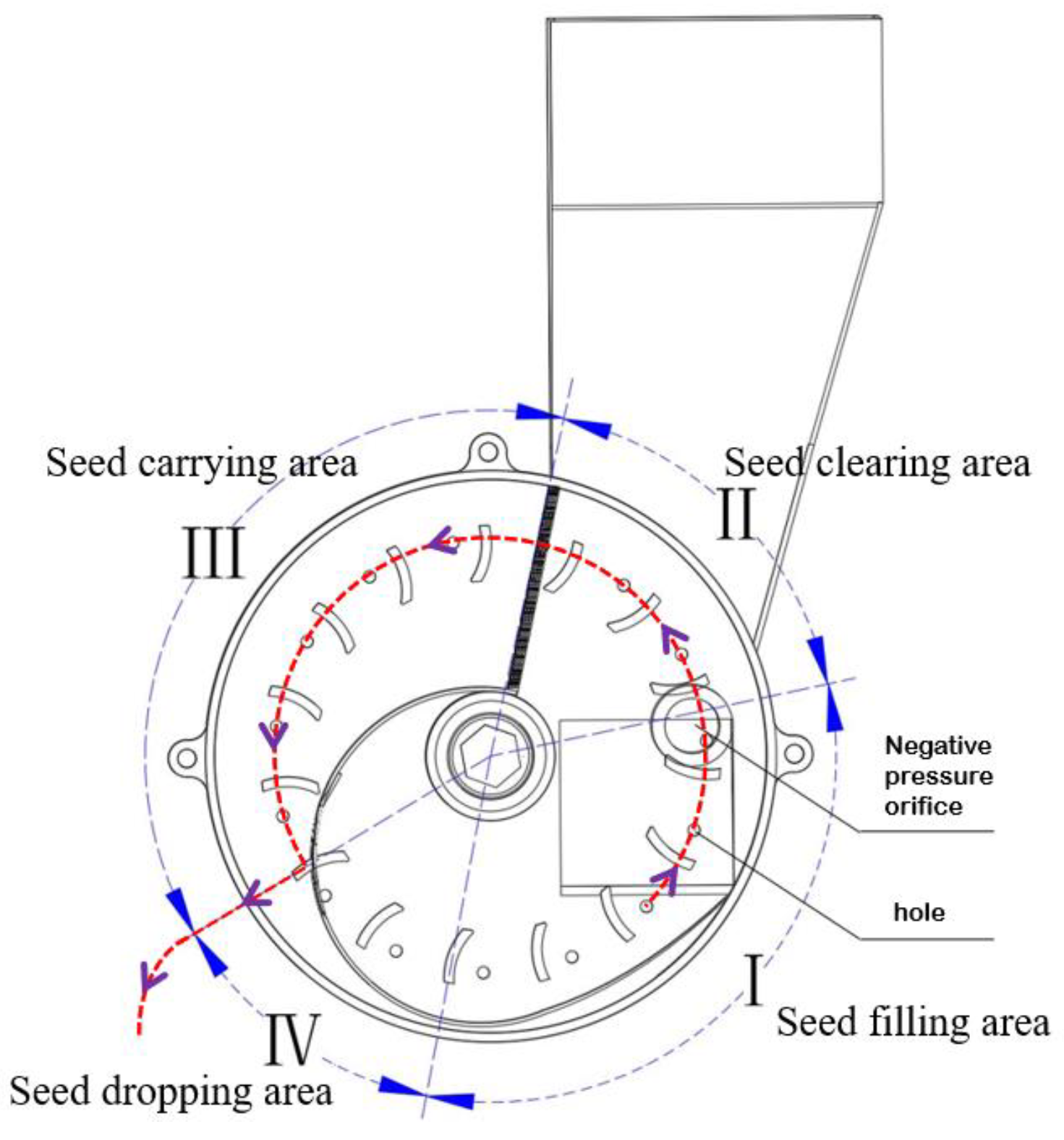

2.2.1. Seed Discharger Structure Composition and Working Principle

2.2.2. Design of Seed Tray

- —Seed filling time, s;

- —Length of seed-filling area, m;

- —Line speed of seed tray, m/s;

- —Seed-filling angle, rad;

- —Diameter of the seed tray, m;

- —Rotational speed of seed tray, rpm;

- —The radial distance between the center of the hole and the edge of the seed tray, m.

- —Unit forward speed, km/h;

- —Seeding spacing, m, garlic agronomy requires plant spacing of 0.08~0.12 m;

- —Rotational speed of seed tray, rpm;

- —The number of teeth and holes.

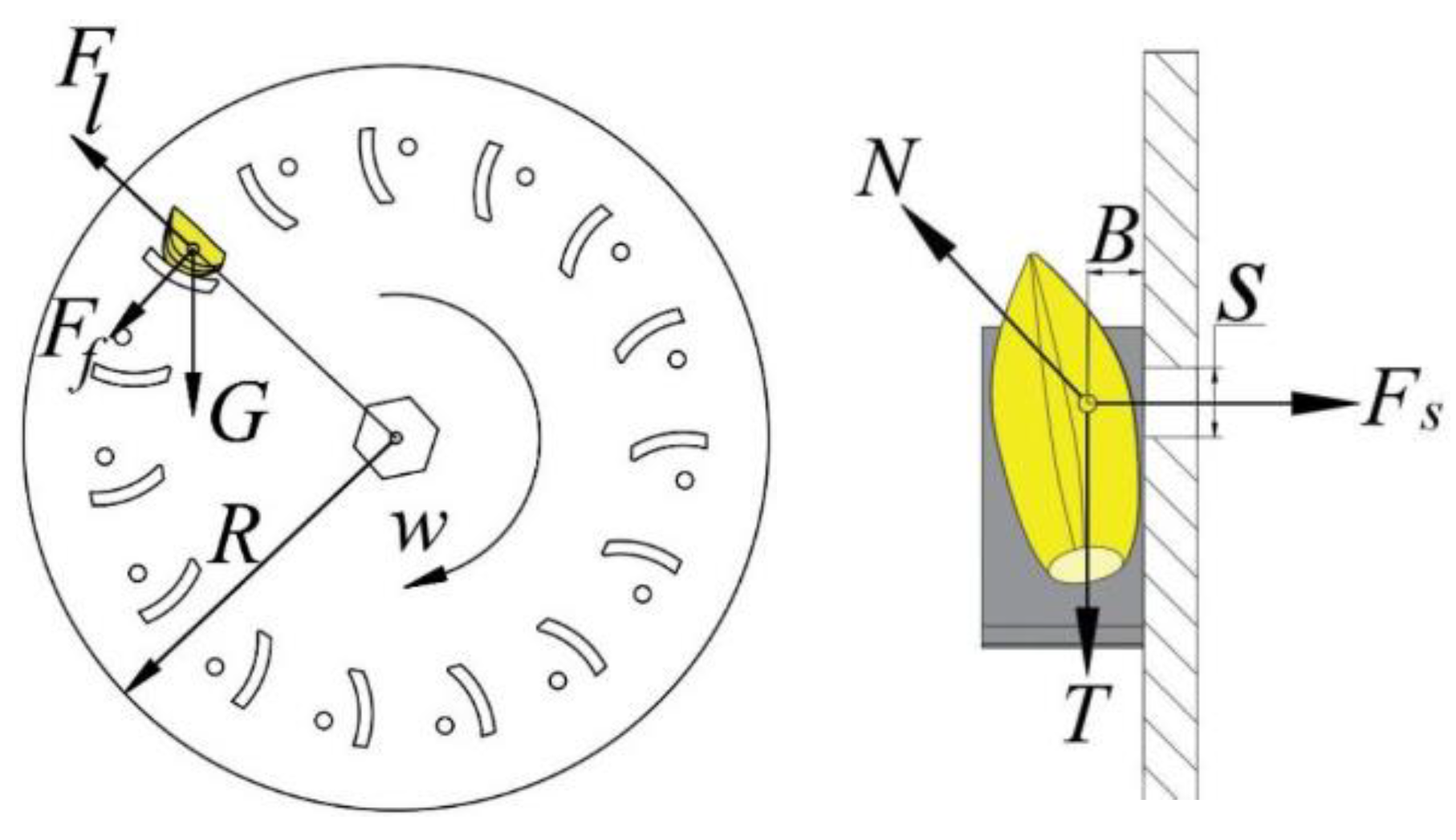

- —Gravity of garlic seed, N;

- —Centrifugal force on garlic seed, N;

- —Internal frictional resistance between garlic seeds, N;

- —Force of hole on garlic seed adsorption, N;

- —The right amount of combined external force on the side, N;

- —The vectorial combined external power of , , and , N;

- —Adsorption pressure through a hole, Pa;

- —Quality of garlic seed, kg;

- —Gravity acceleration, m/s2;

- —Angular velocity of the seed tray, rad/s;

- —Diameter of the hole, m;

- —Cross-sectional area of the hole, m2;

- —The distance between the center of gravity of the garlic seed and the seed tray, m;

- —Radius of the circle in which the center of the hole is located, m.

- —Combined coefficient of frictional resistance of garlic species.

- —Diameter of a hole, mm;

- —Coefficient, generally taken as 0.64~0.66 [25];

- —Average width of garlic seeds, mm.

2.2.3. Seed-Disturbing Tooth Design

- —Average length of garlic seeds, mm;

- —Length of a seed-disturbing tooth, mm;

- —Distance between at the smallest of two seed-disturbing teeth, mm;

- —Average width of garlic seeds, mm;

- —Width of a seed-disturbing tooth, mm;

- —Outer circle radius of seed-disturbing tooth, mm;

- —Inner circle outer diameter of a seed-disturbing tooth, mm.

2.3. Simulation Model Building

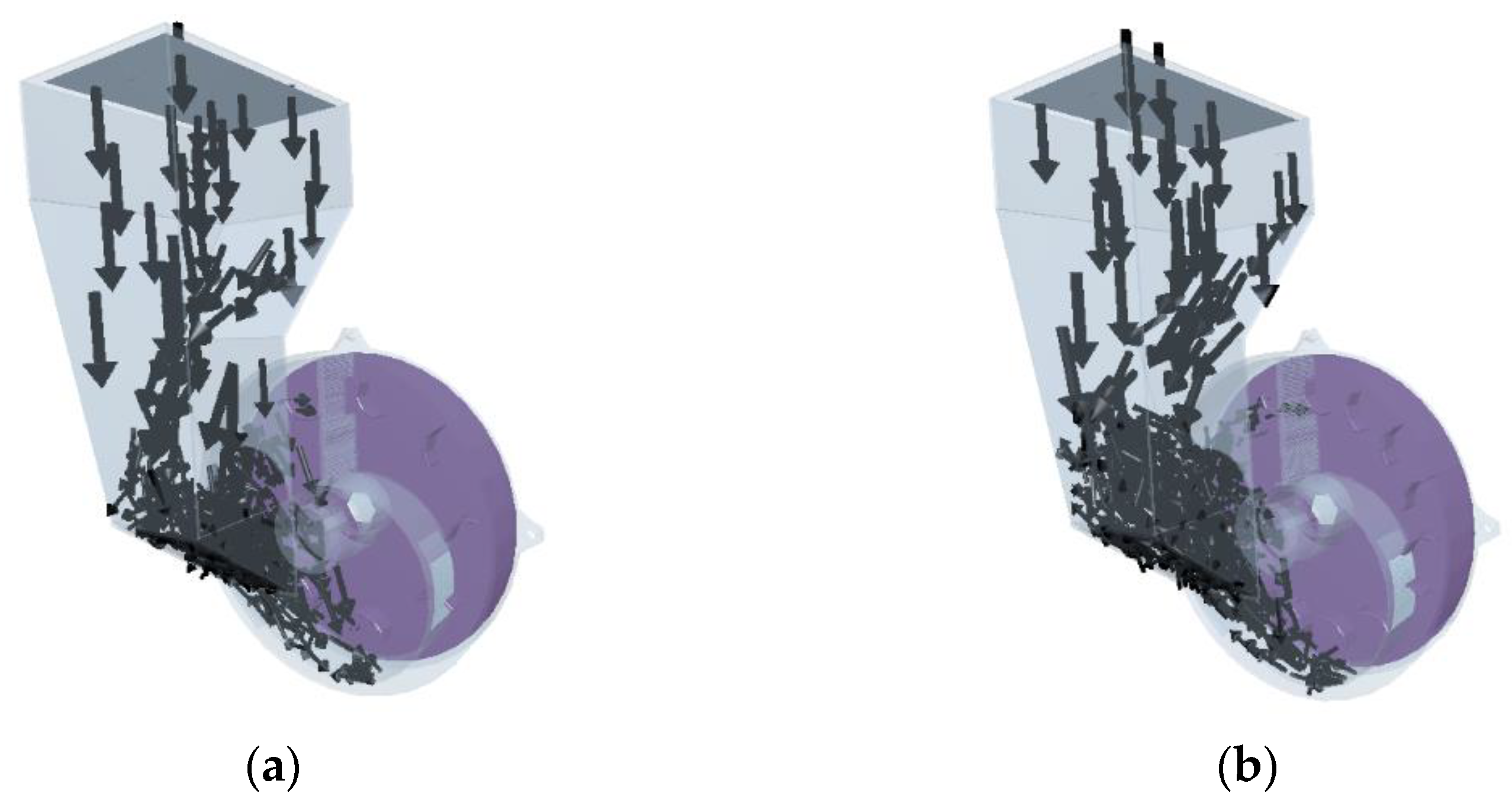

2.3.1. Analysis of Seed-Disturbing Tooth Auxiliary Perturbation Seed

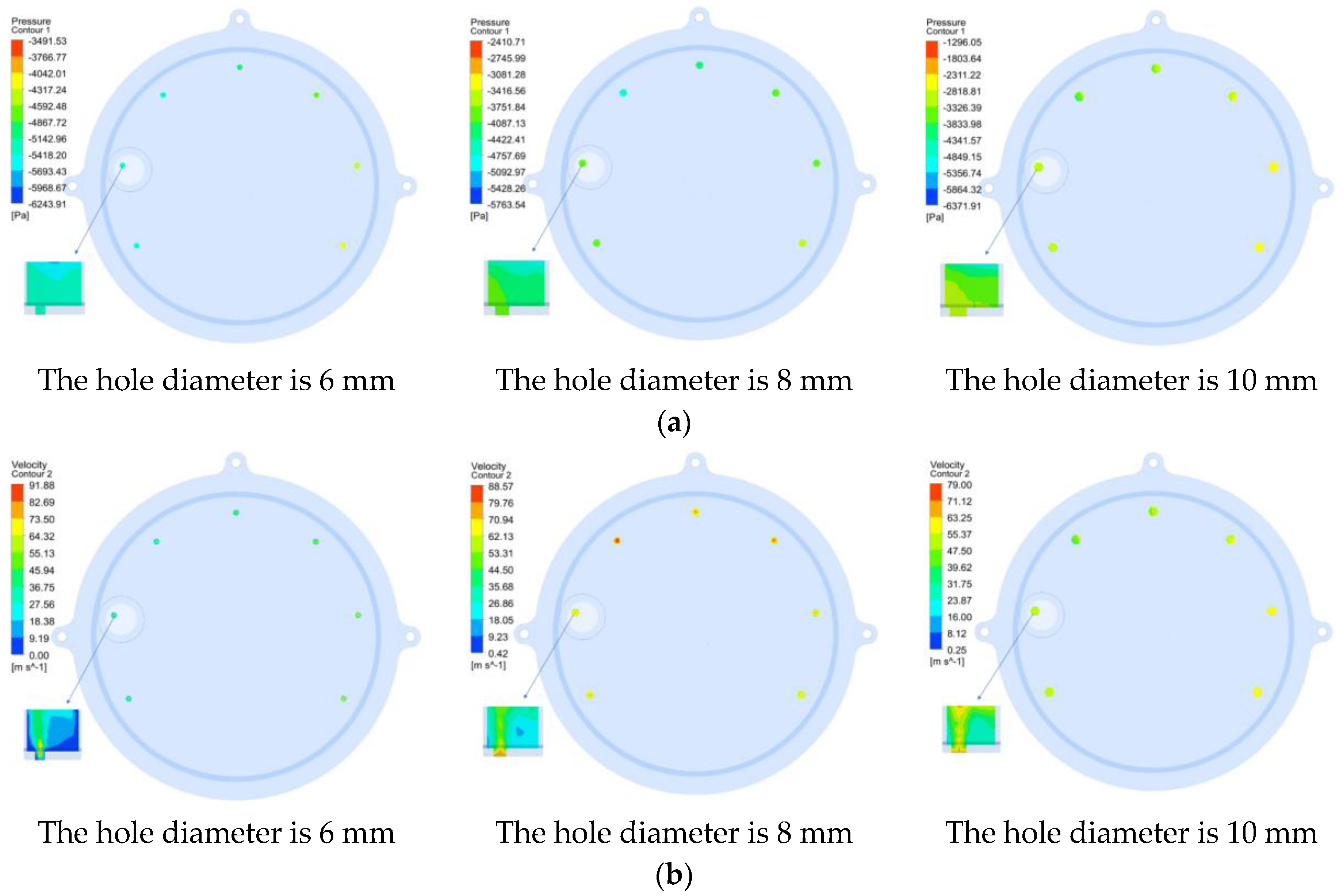

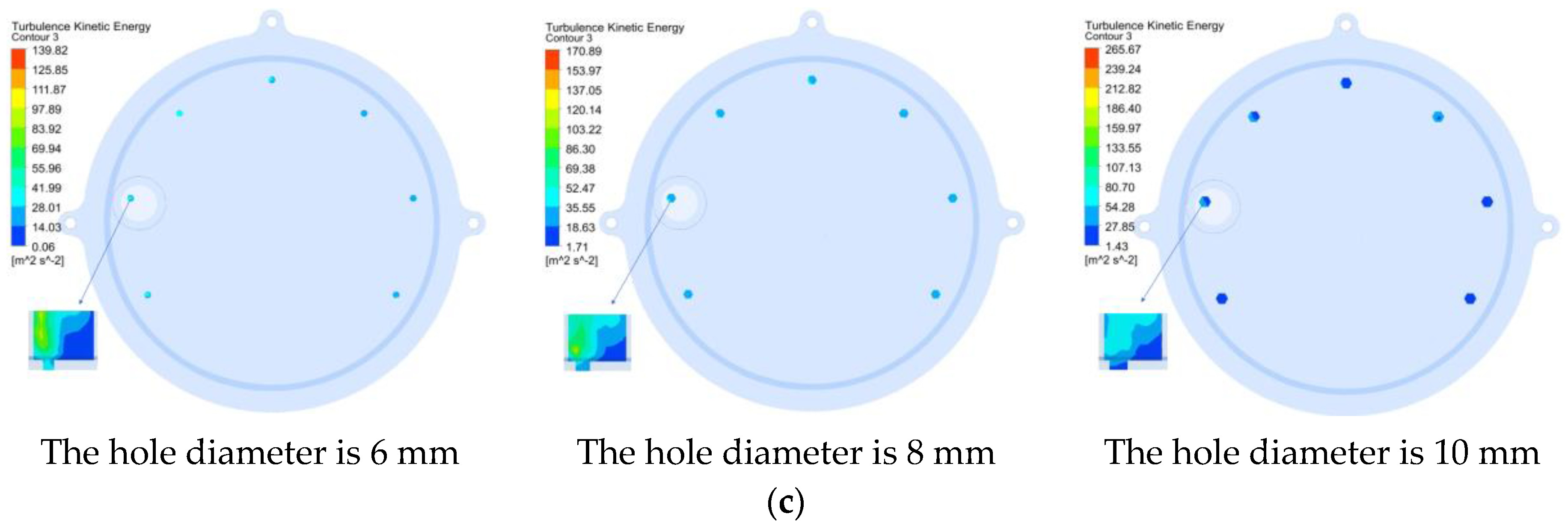

2.3.2. Analysis of Hole-Adsorbed Seed

- —Adsorption force of airflow on garlic seeds, N;

- —Air resistance coefficient;

- —Garlic seed contact area, m2. This is the area of the hole;

- —Relative velocity of airflow, m/s;

- —Air density, kg/m3. Constant at a low relative velocity of airflow.

2.4. Experimental Design and Evaluation Methods

- —Pass seeding rate, %;

- —Missed seeding rate, %;

- —Number of garlic seeds where the distance between two adjacent garlic seeds is greater than 1.5 times the theoretical plant distance;

- —Number of garlic seeds where the distance between two adjacent garlic seeds is greater than 0.5 times the theoretical plant distance;

- —The total number of garlic species counted in this paper is 250.

3. Results and Discussion

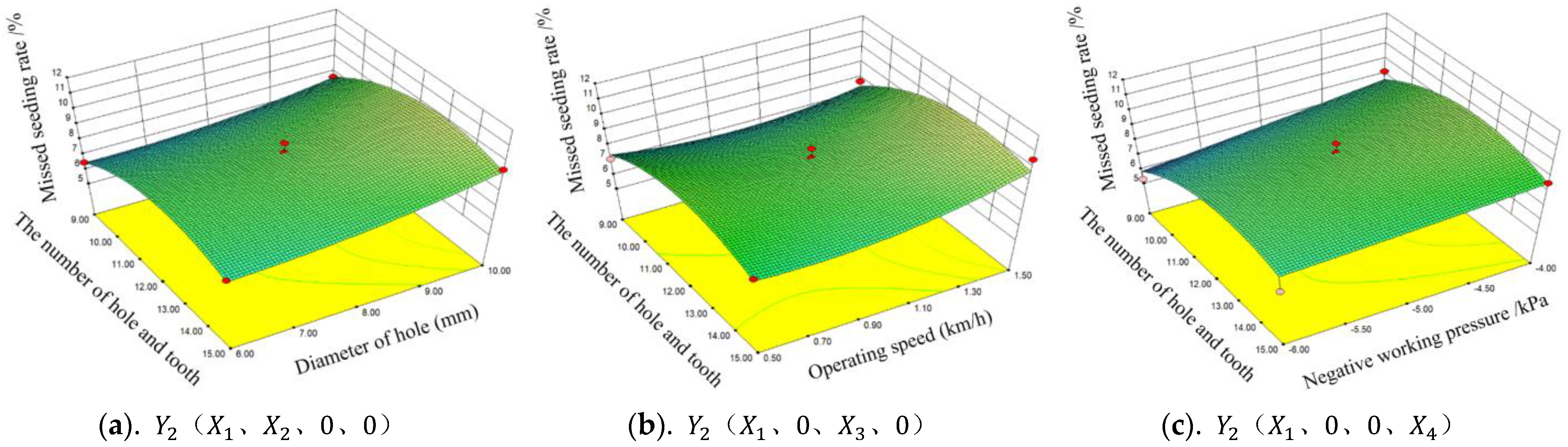

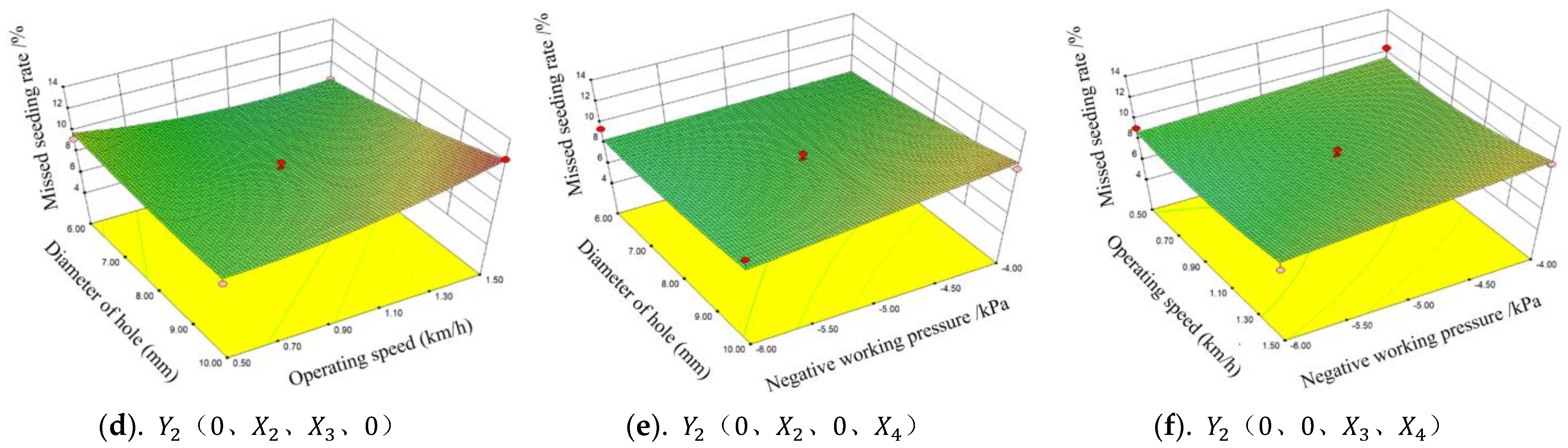

3.1. Effect of Factors on the Effectiveness of Seeding

- (1)

- The influence of the hole diameter

- (2)

- The influence of the number of tooth and hole combinations

- (3)

- The influence of operating speed

- (4)

- The influence of negative working pressure

3.2. Parameter Optimization and Validation

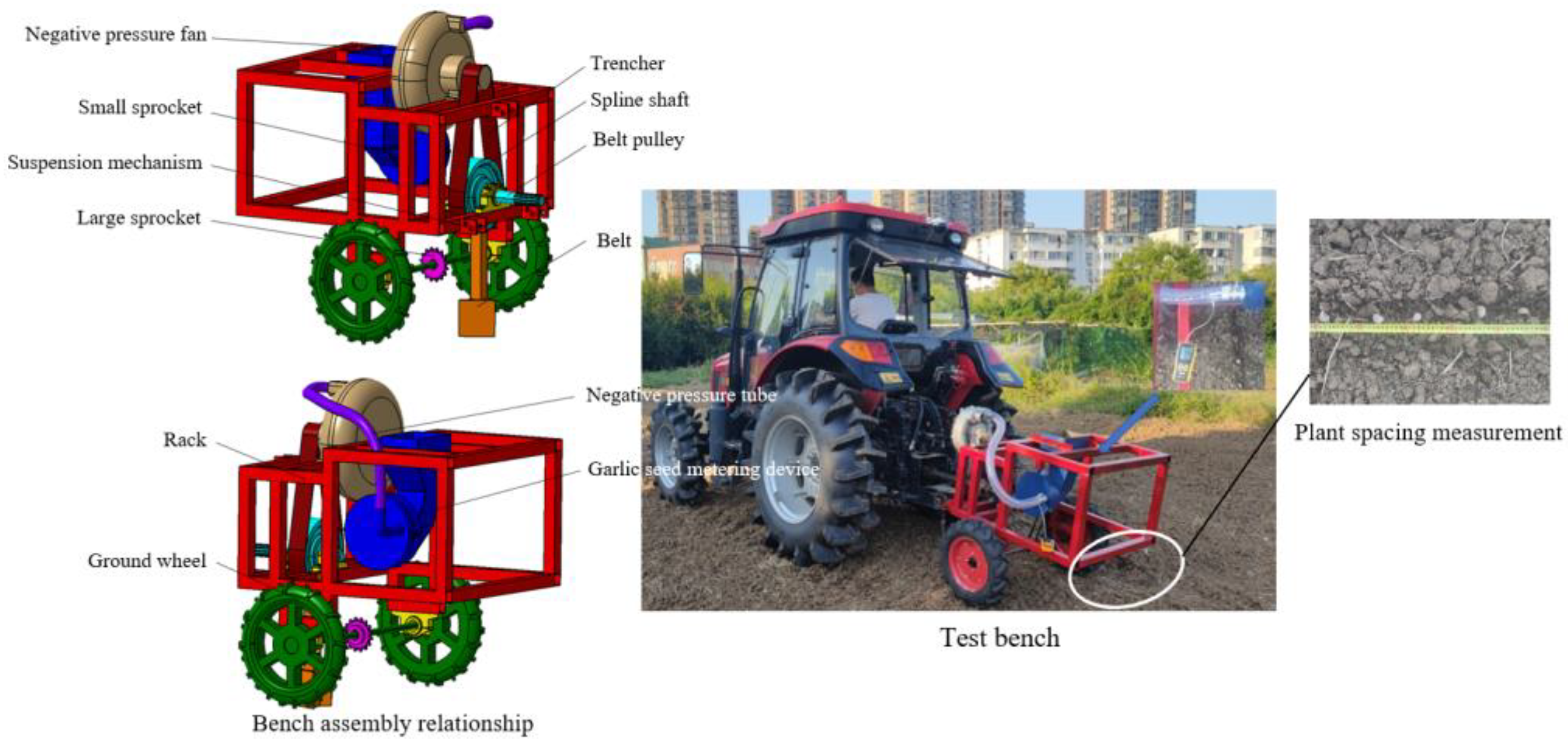

3.3. Field Trails

4. Conclusions

- (1)

- An air suction garlic seed metering device with disturbance assistance was designed in order to improve garlic metering quality. Through the curve fitting of garlic seed profile and static analysis, the initial dimensions of the critical components were determined. Among them, the diameter and number of holes were 6, 8, and 10 mm, and 9, 12, and 15, respectively.

- (2)

- Based on discrete element simulation results, when the simulated seed metering device was at a forward speed of 0.5, 1.0 and 1.5 km/h, the population disturbance was best with 9 shaped holes. On this basis, fluid dynamics simulation was conducted to determine the effect of adsorption in different diameters of shaped holes. The simulation results showed that the airflow distribution of an 8 mm diameter hole is better for the adsorption of garlic seeds

- (3)

- Based on a bench test and parameters’ optimization results, the optimal parameter combination was as follows: the diameter of holes was 7.24 mm, the operating forward speed was 1.04 km/h and the negative pressure was −5.53 kPa. The qualified seeding index and miss seeding index were 88.54% and 6.34% respectively under the above combination parameters. The error between field test results and bench test results were 0.71% and 0.51%, which showed the air suction garlic seed metering device was within a reasonable range and could be used for actual seeding operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, C.; Xue, S.; Li, S. Experimental study on garlic bulb direction recognition. Agric. Mech. Res. 2010, 10, 136–138. [Google Scholar]

- Cui, R.; Huang, J.; Zhang, Z.; Wang, X.; Jian, S. Title of the chapter. Research status of garlic mechanized seeding technology. Agric. Equip. Veh. Eng. 2018, 56, 54–56. [Google Scholar]

- Wang, J.; Tang, H.; Wang, Q.; Zhou, W.; Yang, W. Numerical simulation and experiment on seeding performance of pickup finger precision seed-metering device based on EDEM. Trans. Chin. Soc. Agric. Eng. 2015, 31, 43–50. [Google Scholar]

- Cui, R.; Jian, S.; Yang, J.; Wang, X.; Ma, J. Optimal design and experiment of spoon-chain garlic seed extractor. Agric. Mech. Res. 2017, 39, 99–107. [Google Scholar]

- Maheshwarr, T.K.; Varma, M.R. Modification and performance evaluation of garlic planter. Agric. Eng. Today 2007, 31, 11–14. [Google Scholar]

- Bakhtiari, M.R.; Loghavi, M. Development and evaluation of an innovative garlic clove precision planter. J. Agric. Sci. Technol. 2009, 11, 125–136. [Google Scholar]

- Choi, D.K.; Park, W.K.; Kang, T.G.; Park, S.H.; Kim, H.J.; Kwak, T.Y.; Kim, Y.K. Garlic Upright-Positioning and Planting Device. U.S. Patent No. 6,619,219, 16 September 2003. [Google Scholar]

- Zhang, C.L.; Wu, X.Q.; Xie, D.B.; Wang, Q.Q.; Zhang, J.; Chen, L.Q. Design and Experiment of Electro hydraulic Mixed Garlic Planter. Trans. Chin. Soc. Agric. Mach. 2021, 52, 166–174. [Google Scholar]

- Li, T.H.; Zhang, H.K.; Han, X.L.; Li, Y.H.; Hou, J.L.; Shi, G.Y. Design and experiment of missing seed detection and the reseeding device for spoon chain garlic seeders. Trans. Chin. Soc. Agric. Eng. 2022, 38, 24–32. [Google Scholar]

- Zhang, D.Q.; Wu, Y.J.; Zhang, C.K. Vertical planting structure design for planter. Appl. Mech. Mater. 2014, 654, 87–90. [Google Scholar] [CrossRef]

- Guo, H.; Cao, Y.; Song, W.; Zhang, J.; Wang, C.; Wang, C.; Yang, F.; Zhu, L. Design and simulation of a garlic seed metering mechanism. Agriculture 2021, 11, 1239. [Google Scholar] [CrossRef]

- Lv, J.; Yang, Y.; Li, Z.; Shang, Q.; Li, J.; Liu, Z. Design and experiment of an air-suction potato seed metering device. Int. J. Agric. Biol. Eng. 2016, 9, 33–42. [Google Scholar]

- Xing, H.; Wang, Z.; Luo, X.; Zang, Y.; He, S.; Xu, P.; Liu, S. Design and experimental Analysis of rice pneumatic seeder with adjustable seeding rate. Int. J. Agric. Biol. Eng. 2021, 14, 113–122. [Google Scholar] [CrossRef]

- Zhang, G.; Zang, Y.; Luo, X.; Wang, Z.; Zhang, Q.; Zhang, S. Design and indoor simulated experiment of pneumatic rice seed metering device. Int. J. Agric. Biol. Eng. 2015, 8, 10–18. [Google Scholar]

- Liang, K.X.; Liang, C.Y.; Li, Y.H. A Kind of Garlic Single Seed Extraction Device. CN201621160238, 25 October 2016. [Google Scholar]

- Xie, D.B.; Zhang, C.L.; Wu, X.Q.; Wang, W.W.; Liu, L.C.; Chen, L.Q. Design and Test of Garlic Seed Placer with Seed Disturbing Tooth Assisted Air Suction. Trans. Chin. Soc. Agric. Mach. 2022, 53, 47–57. [Google Scholar]

- Yu, C.; Zhu, D.; Gao, Y.; Xue, K.; Zhang, S.; Liao, J.; Liu, J. Optimization and experiment of counter-rotating straw returning cultivator based on discrete element method. J. Adv. Mech. Des. Syst. 2020, 14, JAMDSM0097. [Google Scholar] [CrossRef]

- Huang, Y.L. Lai’an Garlic. Chi. Veg. 1991, 4, 48. [Google Scholar]

- Li, W. Design of Mechanical-Pneumatic Combined Metering Device for Potato. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2019. [Google Scholar]

- Xie, D.; Chen, L.; Liu, L.; Chen, L.; Wang, H. Actuators and Sensors for Application in Agricultural Robots: A Review. Machines 2022, 10, 913. [Google Scholar] [CrossRef]

- Qi, B.B. Study on Pneumatic Spoon Type Peanut Precision Seed-Metering Device. Master’s Thesis, Shihezi University, Shihezi, China, 2020. [Google Scholar]

- Department of Theoretical Mechanics, Harbin Institute of Technology. Theoretical Mechanics, 8th ed.; Higher Education Press: Beijing, China, 2016; p. 317. [Google Scholar]

- Yan, B.X.; Zhang, D.X.; Yang, L.; Cui, T.; Zhong, X.J.; Li, Y.H. Performance Analysis of Gravity Assist Filling Precision Seed-metering Device with Synchronously Rotating Seed Plate and Vacuum Chamber. Trans. Chin. Soc. Agric. Mach. 2018, 49, 117–124. [Google Scholar]

- Li, Z.D.; Yang, W.C.; Zhang, T.; Wang, W.W.; Zhang, S.; Chen, L.Q. Design and suction performance test of sucking-seed plate combined with groove-tooth structure on high speed precision metering device of rapeseed. Trans. Chin. Soc. Agric. Eng. 2019, 35, 11–22. [Google Scholar]

- Chinese Academy of Agricultural Machinery Research. Handbook of Agricultural Machinery, 1st ed.; China Agricultural Science and Technology Press: Beijing, China, 2007; Volume 1. [Google Scholar]

- Liu, L.; Pan, Y.J.; Chen, Z.J.; Wang, Y.W.; Li, Y.W.; Chen, L.Q. Inter-rows Navigation Method for Corn Crop Protection Vehicles under High Occlusion Environment. Trans. Chin. Soc. Agric. Mach. 2020, 51, 11–17. [Google Scholar]

- Wang, Q.; Bai, Z.; Li, Z.; Xie, D.; Chen, L.; Wang, H. Straw/Spring Teeth Interaction Analysis of Baler Picker in Smart Agriculture via an ADAMS-DEM Coupled Simulation Method. Machines 2021, 9, 296. [Google Scholar] [CrossRef]

- Yu, C.; Liu, J.; Zhang, J.; Xue, K.; Zhang, S.; Liao, J.; Zhu, D. Design and optimization and experimental verification of a segmented double-helix blade roller for straw returning cultivators. J. Chin. Inst. Eng. 2021, 44, 379–387. [Google Scholar] [CrossRef]

- Song, W.Y. Design and Experimental Research on Key Components of Garlic Seeder. Master’s Thesis, Northwest Agriculture and Forestry University, Xianyang, China, 2020. [Google Scholar]

- Zhang, J.W.; Zhu, L.; Chen, P.; Wu, Q.M.; Wei, M.; Yin, C.L.; Li, G.L. Flowing interaction between cutting edge of plough breast with soil in shifting tillage operations. Eng. Appl. Comp. Fluid 2020, 14, 1404–1415. [Google Scholar]

- Chen, L.; Ma, P.; Tian, J.; Liang, X. Prediction and optimization of lubrication performance for a transfer case based on computational fluid dynamics. Eng. Appl. Comp. Fluid. 2019, 13, 1013–1023. [Google Scholar] [CrossRef]

- Zhu, L.; Ge, J.R.; Cheng, X.; Peng, S.S.; Qi, Y.Y.; Zhang, S.W.; Zhu, D.Q. Modeling of share/soil interaction of a horizontally reversible plow using computational fluid dynamics. J. Terramech. 2017, 72, 1–8. [Google Scholar] [CrossRef]

- GB/T6973-2005; China National Standard. Testing Methods of Single Seed Drills (Precision Drills). Standardization Administration of the PR China: Beijing, China; General Administration of Quality Supervision, Inspection and Quarantine of the PR China: Beijing, China, 2005.

- Cao, Y.; Yao, J.; Li, J.; Chen, X.; Wu, J. Optimization of microbial oils production from kitchen garbage by response surface methodology. J. Renew. Sustain. Energy 2013, 5, 53105. [Google Scholar] [CrossRef]

- Da, Q.; Li, D.; Zhang, X.; Guo, W.; He, D.; Huang, Y.; He, G. Research on Performance Evaluation Method of Rice Thresher Based on Neural Network. Actuators 2022, 11, 257. [Google Scholar] [CrossRef]

- Zhang, C.L.; Xia, J.F.; Zhang, J.M.; Zhou, H.; Zhu, Y.H.; Wang, J.W. Design and Experiment of Knife Roller for Six-head Spiral Straw Returning Cultivator. Trans. Chin. Soc. Agric. Mach. 2019, 50, 25–34. [Google Scholar]

| Name | Numerical Selection |

|---|---|

| The number of hole and tooth | 9, 12, 15 |

| the diameter of the hole (mm) | 6, 8, 10 |

| Materials | Poisson’s Ratio | Shear Modulus/Pa | Density kg/m3 |

|---|---|---|---|

| Garlic seeds | 0.25 | 1 × 108 | 1080 |

| Resin material (the seed tray and seedbox) | 0.36 | 1.2 × 108 | 1420 |

| Polyurethane PU elastic sheet (seed disturbing teeth) | 0.33 | 2.21 × 108 | 1072 |

| Contact Form | Crash Recovery Factor | Static Friction Coefficient | Coefficient of Dynamic Friction |

|---|---|---|---|

| Garlic seeds—Garlic seeds | 0.487 | 0.503 | 0.108 |

| Garlic seeds—Resin material | 0.36 | 0.34 | 0.06 |

| Garlic seeds—Polyurethane PU elastic sheet | 0.32 | 0.21 | 0.11 |

| Operating Speed | The Number of Teeth Is 15 | The Number of Teeth Is 12 | The Number of Teeth Is 9 |

|---|---|---|---|

| 0.5 km/h | 6 rpm | 7.5 rpm | 10 rpm |

| 1 km/h | 12 rpm | 15 rpm | 20 rpm |

| 1.5 km/h | 18 rpm | 22.5 rpm | 30 rpm |

| Serial Number | Factors | Response Values | ||||

|---|---|---|---|---|---|---|

| The Number of Tooth and Hole | Diameter of Hole | Operating Speed | Negative Working Pressure | Pass Rate | Missed Seeding Rate | |

| 1 | 1 | 1 | 0 | 0 | 88.2 | 6.5 |

| 2 | −1 | 1 | 0 | 0 | 86.7 | 7.8 |

| 3 | 1 | −1 | 0 | 0 | 87.5 | 7.7 |

| 4 | −1 | −1 | 0 | 0 | 83.4 | 9.5 |

| 5 | 0 | 0 | 1 | 1 | 79.4 | 10.5 |

| 6 | 0 | 0 | −1 | 1 | 81.3 | 10.6 |

| 7 | 0 | 0 | 1 | −1 | 81.5 | 9.2 |

| 8 | 0 | 0 | −1 | −1 | 82.7 | 8.4 |

| 9 | 1 | 0 | 0 | 1 | 87.6 | 8.2 |

| 10 | −1 | 0 | 0 | 1 | 81.4 | 8.6 |

| 11 | 1 | 0 | 0 | −1 | 89.3 | 5.3 |

| 12 | −1 | 0 | 0 | −1 | 85.7 | 6.8 |

| 13 | 0 | 1 | 1 | 0 | 81.8 | 9.3 |

| 14 | 0 | −1 | 1 | 0 | 80.4 | 8.6 |

| 15 | 0 | 1 | −1 | 0 | 82.8 | 8.5 |

| 16 | 0 | −1 | −1 | 0 | 81.5 | 12.2 |

| 17 | 1 | 0 | 1 | 0 | 84.6 | 7.1 |

| 18 | −1 | 0 | 1 | 0 | 78.4 | 8.2 |

| 19 | 1 | 0 | −1 | 0 | 85.4 | 7.8 |

| 20 | −1 | 0 | −1 | 0 | 82.3 | 10.5 |

| 21 | 0 | 1 | 0 | 1 | 87.6 | 8.1 |

| 22 | 0 | −1 | 0 | 1 | 82.6 | 10.5 |

| 23 | 0 | 1 | 0 | −1 | 87.3 | 9.5 |

| 24 | 0 | −1 | 0 | −1 | 84.1 | 9.8 |

| 25 | 0 | 0 | 0 | 0 | 87.5 | 8.8 |

| 26 | 0 | 0 | 0 | 0 | 86.9 | 8.7 |

| 27 | 0 | 0 | 0 | 0 | 87.9 | 8.9 |

| 28 | 0 | 0 | 0 | 0 | 86.1 | 9.5 |

| 29 | 0 | 0 | 0 | 0 | 87.6 | 8.5 |

| Source of Variance | Pass Rate | Missed Seeding Rate | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degree of Freedom | F-Value | p-Value | Sum of Squares | Degree of Freedom | F-Value | p-Value | |

| Models | 246.68 | 14 | 19.29 | ** | 47.28 | 14 | 5.72 | ** |

| 50.84 | 1 | 55.66 | ** | 6.45 | 1 | 10.93 | ** | |

| 18.50 | 1 | 20.25 | ** | 6.16 | 1 | 10.44 | ** | |

| 8.17 | 1 | 8.94 | ** | 2.17 | 1 | 3.67 | ||

| 9.54 | 1 | 10.44 | ** | 4.69 | 1 | 7.94 | * | |

| 1.69 | 1 | 1.85 | 0.063 | 1 | 0.11 | |||

| 2.40 | 1 | 2.63 | 0.64 | 1 | 1.08 | |||

| 1.69 | 1 | 1.85 | 0.30 | 1 | 0.51 | |||

| 2.500 × 10−3 | 1 | 2.737 × 10−3 | 4.84 | 1 | 8.20 | * | ||

| 0.81 | 1 | 0.89 | 1.10 | 1 | 1.87 | |||

| 0.12 | 1 | 0.13 | 0.20 | 1 | 0.34 | |||

| 0.029 | 1 | 0.032 | 12.83 | 1 | 21.74 | ** | ||

| 3.73 | 1 | 4.08 | 0.76 | 1 | 1.29 | |||

| 145.33 | 1 | 159.10 | ** | 3.23 | 1 | 5.47 | * | |

| 9.08 | 1 | 9.94 | ** | 6.167 × 10−3 | 1 | 0.01 | ||

| Residuals | 12.79 | 14 | 8.27 | 14 | ||||

| Loss of proposed items | 10.75 | 10 | 2.11 | 0.2461 | 7.70 | 10 | 5.42 | 0.0588 |

| Error | 2.04 | 4 | 0.57 | 4 | ||||

| Total | 259.47 | 28 | 55.55 | 28 | ||||

| Serial Number | Passing Rate | Missed Seeding Rate |

|---|---|---|

| 1 | 88.5 | 6.3 |

| 2 | 88.8 | 6.7 |

| 3 | 89.3 | 5.9 |

| 4 | 87.7 | 6.2 |

| 5 | 88.4 | 6.6 |

| Average value | 88.54 | 6.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhang, X.; Zheng, Z.; Xie, X.; Liu, L.; Chen, L. Numerical Simulation and Test of the Disturbance Air Suction Garlic Seed Metering Device. Machines 2022, 10, 1127. https://doi.org/10.3390/machines10121127

Zhang C, Zhang X, Zheng Z, Xie X, Liu L, Chen L. Numerical Simulation and Test of the Disturbance Air Suction Garlic Seed Metering Device. Machines. 2022; 10(12):1127. https://doi.org/10.3390/machines10121127

Chicago/Turabian StyleZhang, Chunling, Xinyi Zhang, Zihao Zheng, Xiaodong Xie, Lichao Liu, and Liqing Chen. 2022. "Numerical Simulation and Test of the Disturbance Air Suction Garlic Seed Metering Device" Machines 10, no. 12: 1127. https://doi.org/10.3390/machines10121127

APA StyleZhang, C., Zhang, X., Zheng, Z., Xie, X., Liu, L., & Chen, L. (2022). Numerical Simulation and Test of the Disturbance Air Suction Garlic Seed Metering Device. Machines, 10(12), 1127. https://doi.org/10.3390/machines10121127