Damping Characteristics of Cantilever Beam with Obstacle Grid Particle Dampers

Abstract

1. Introduction

2. Experimental Setup and Measurement System

3. Experimental Results

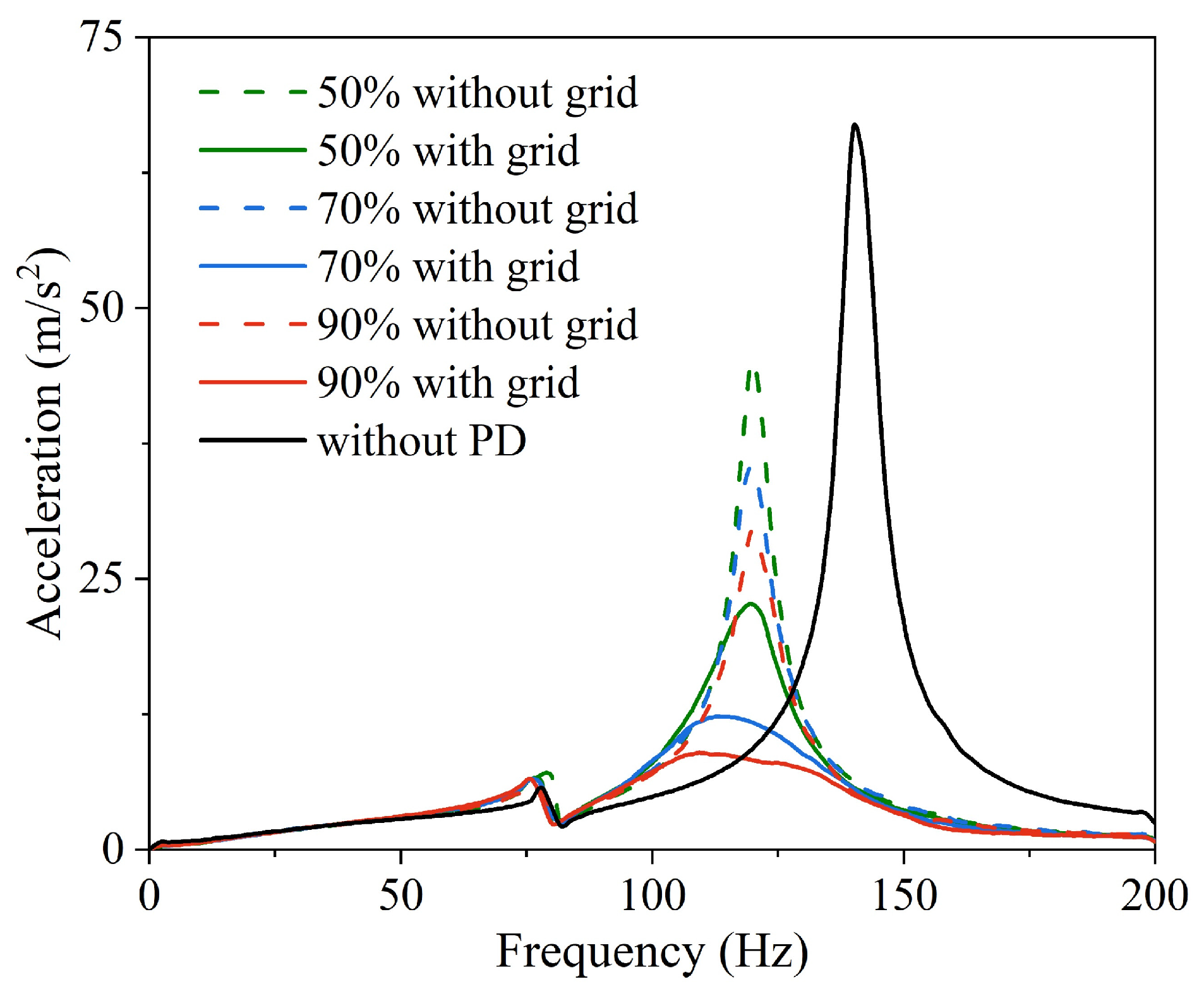

3.1. Effect of Filling Ratio on the Vibration Characteristics of Cantilever Beam Subsection

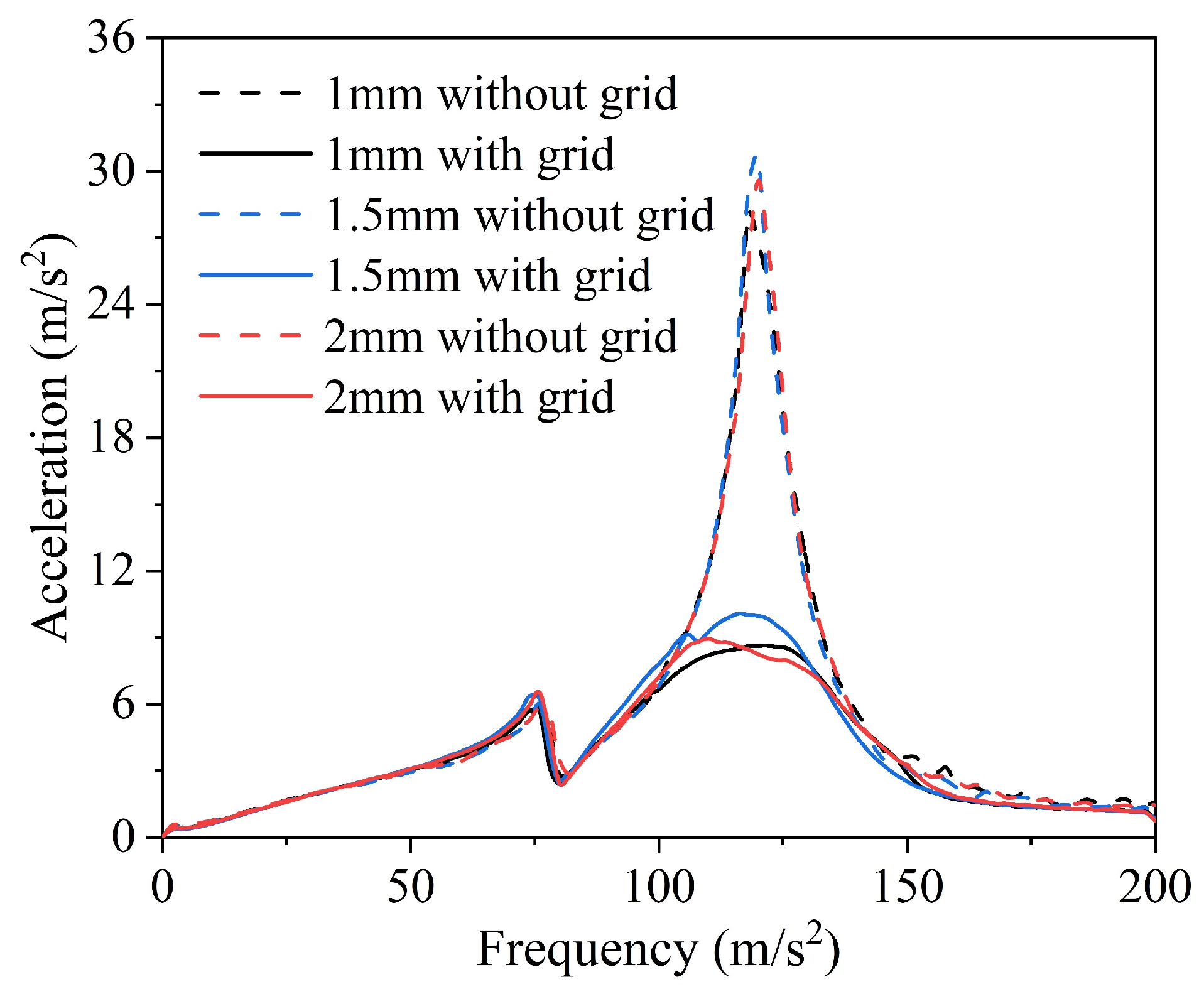

3.2. Effect of Particle Size on Vibration Characteristics of Cantilever Beam

3.3. Effect of Particle Material on Vibration Characteristics of Cantilever Beam

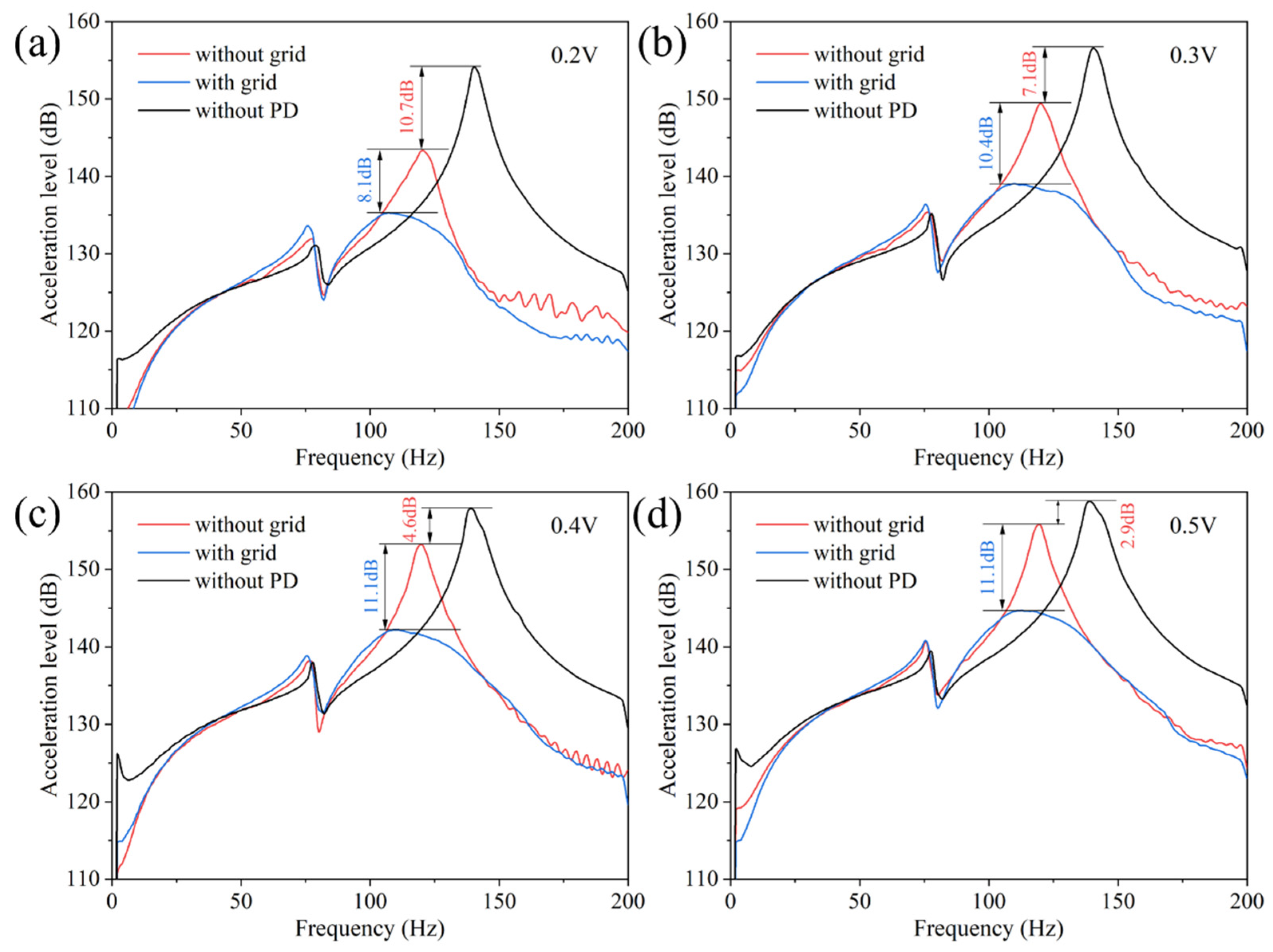

3.4. Effect of Excitation Amplitude on Vibration Characteristics of Cantilever Beam

4. Analysis and Discussion

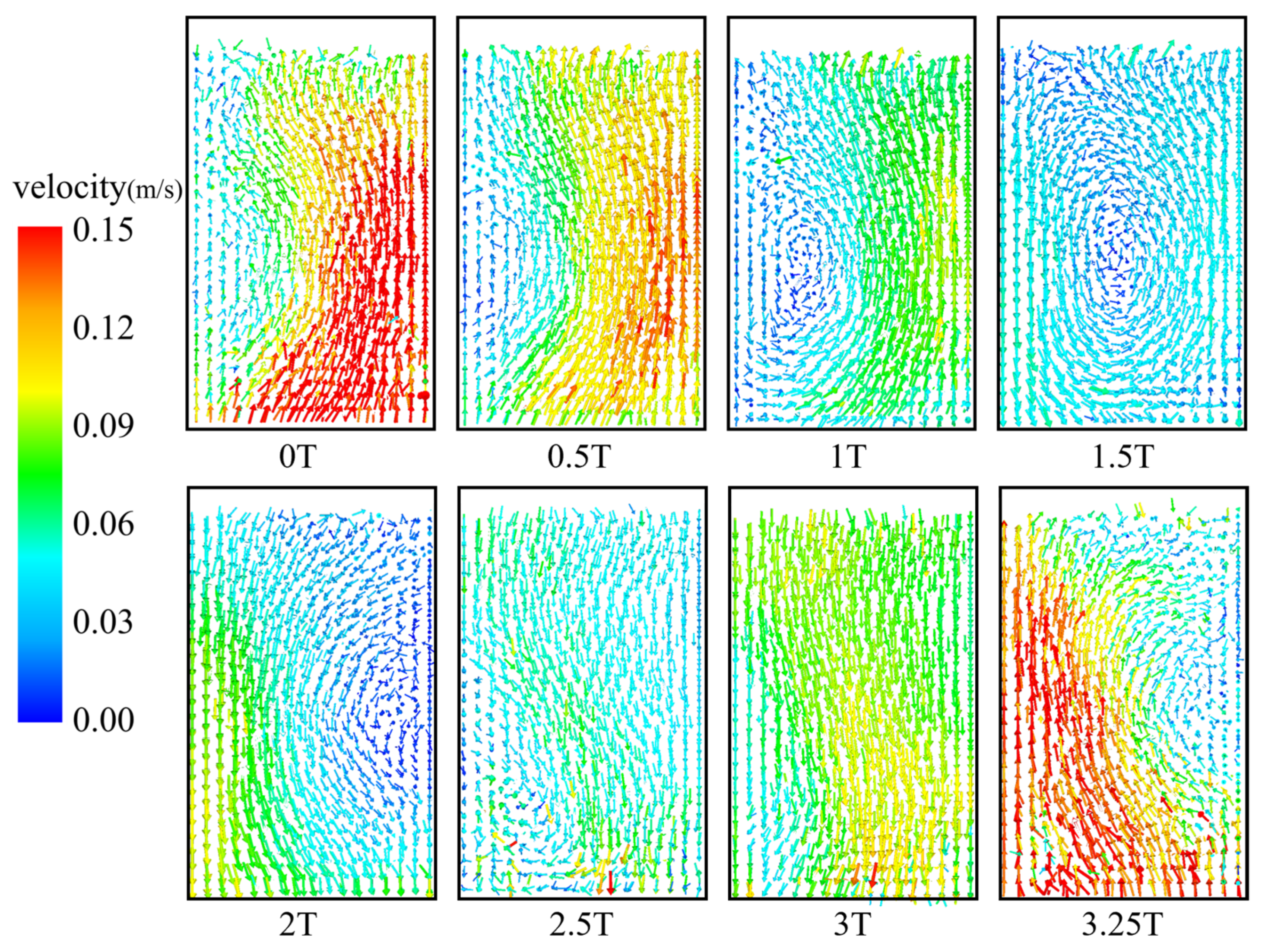

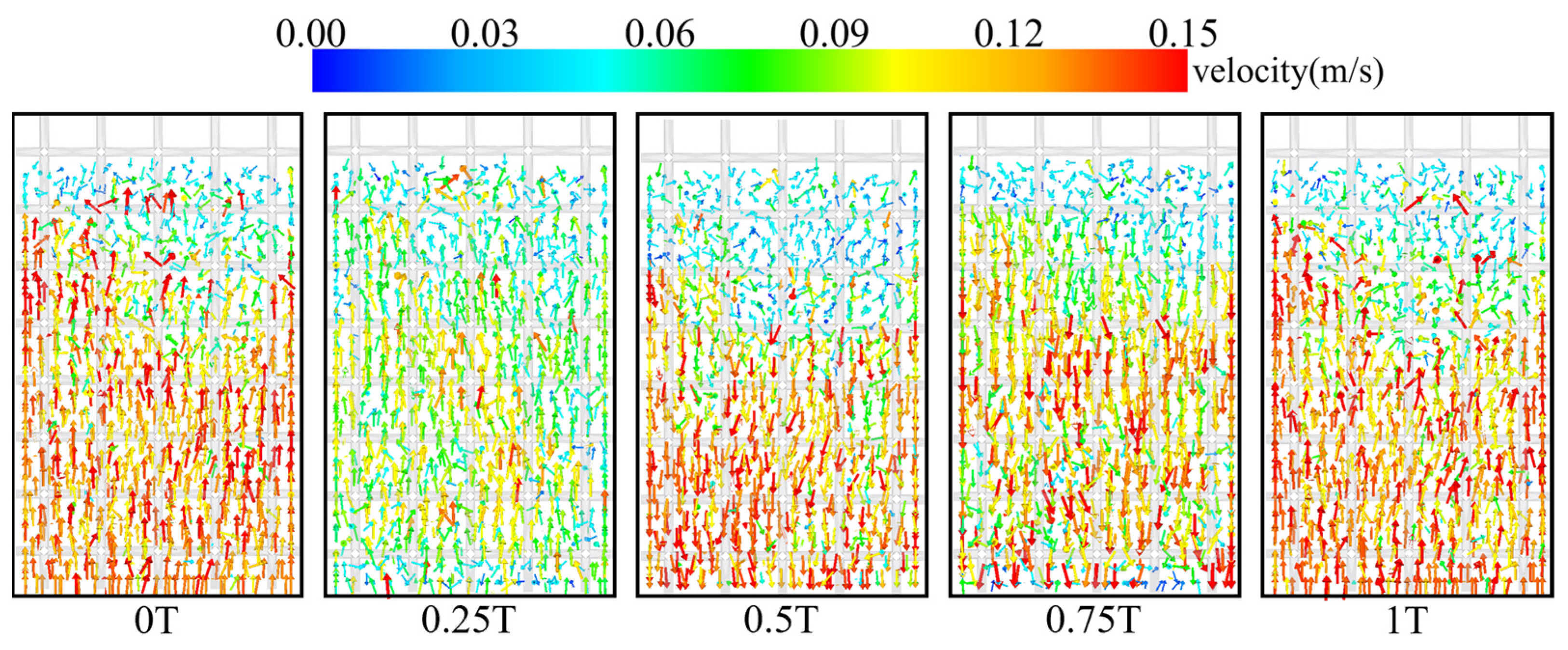

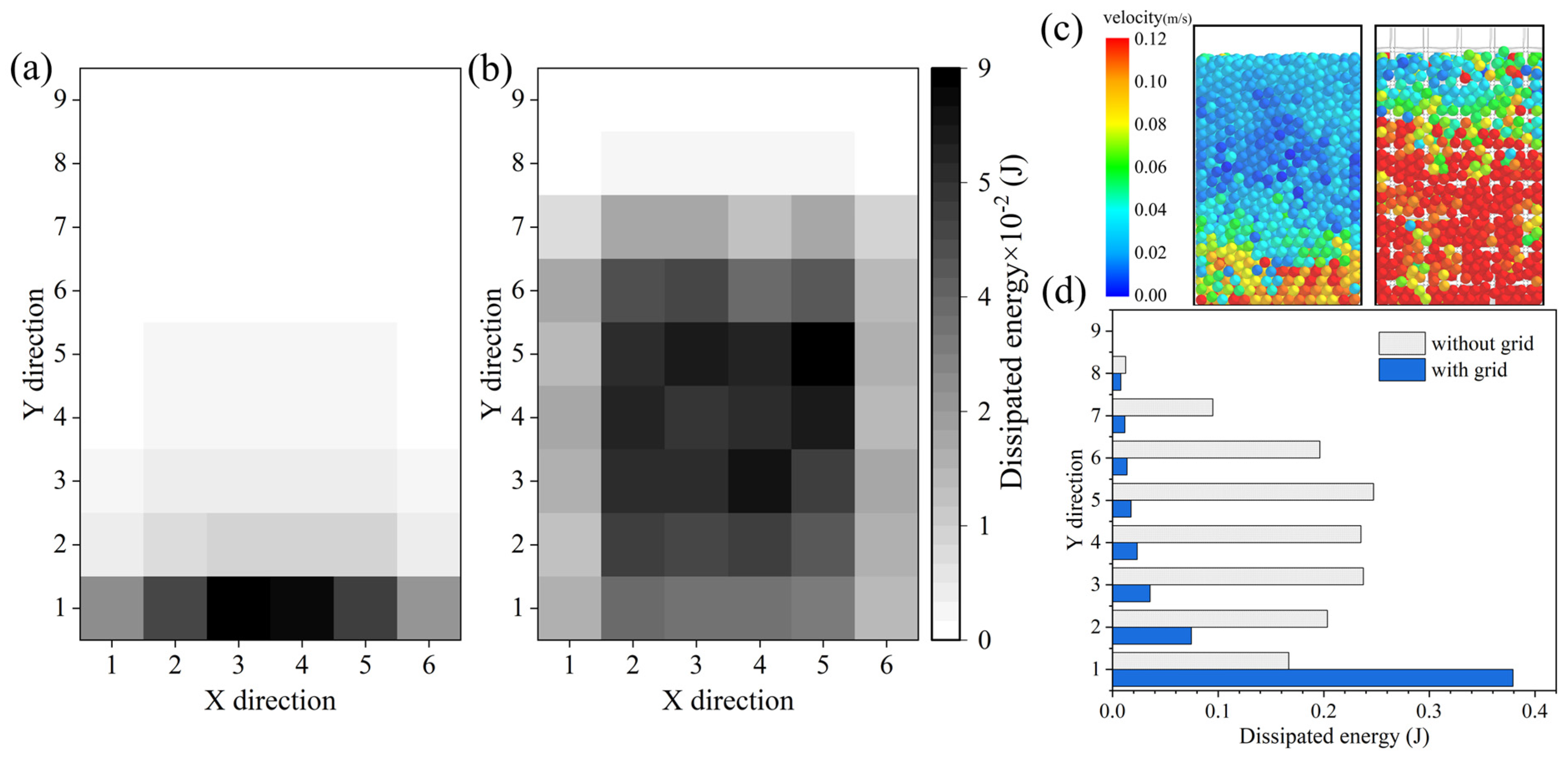

4.1. Damping Energy Dissipation Characteristics of the Particle Dampers with Obstacle Grid

4.2. Effect of Excitation Amplitude on Particle Damping Energy Dissipation

5. Conclusions

- (1)

- As the filling ratio increases, the effect of the obstacle grid particle damper on the cantilever beam vibration suppression becomes more and more obvious. At the filling ratio of 90%, the acceleration amplitude of the cantilever beam with grid particle dampers decreased by 69.8% compared to the cantilever beam without grid particle dampers with additional grid particle dampers. The best damping effect was achieved when the particle dampers were filled with 1 mm particle size, followed by 2 mm and 1.5 mm particles.

- (2)

- The particle material has a large impact on the damping performance of the particle damper. Among the five materials, aluminum balls have the worst damping effect, followed by zirconium oxide particles. In the traditional particle dampers filled with stainless steel particles, damping effect is more significant. The damping effect of copper and lead balls is between zirconia and stainless steel, and the damping effect of copper balls is slightly better than that of lead balls. The difference between the damping effect of stainless steel, Cu, and Pb in the particle dampers with obstacle grid is small.

- (3)

- With the increase of excitation amplitude, the damping effect of traditional particle damper is 10.7 dB, 7.1 dB, 4.6 dB, and 2.9 dB, respectively, while the damping effect of obstacle grid particle damper decreases 8.1 dB, 10.4 dB, 11.1 dB, and 11.1 dB, respectively. The particle damper with grid still has good damping characteristics.

- (4)

- Conventional particle dampers reduce the level of vibration energy transfer and dissipation due to fluidization of particles. The energy transfer area of the particle dampers is increased, and the energy dissipation of the particle dampers is enhanced by embedding the obstacle grid energy to hinder the generation of particle fluidization.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Veeramuthuvel, P.; Shankar, K.; Sairajan, K.K. Application of particle damper on electronic packages for spacecraft. Acta Astronaut. 2016, 127, 260–270. [Google Scholar] [CrossRef]

- Jin, G.; Zhao, Z. Design of a particle damper and experimental study on vibration damping of the pipeline. Adv. Mech. Eng. 2021, 13, 16878140211044923. [Google Scholar] [CrossRef]

- Lei, X.; Wu, C.; Wu, H. A novel composite vibration control method using double-decked floating raft isolation system and particle damper. J. Vib. Control 2018, 24, 4407–4418. [Google Scholar] [CrossRef]

- Xiao, W.; Xu, Z.; Bian, H.; Li, Z. Lightweight heavy-duty CNC horizontal lathe based on particle damping materials. Mech. Syst. Signal Process. 2021, 147, 107127. [Google Scholar] [CrossRef]

- Wang, M.; Xu, H.; He, D.; Wang, T.; Zhang, J. Design of a damped vibration absorber to control the resonant vibration of roll. Mech. Syst. Signal Process. 2022, 178, 109262. [Google Scholar] [CrossRef]

- Xiao, W.; Lu, D.; Song, L.; Guo, H.; Yang, Z. Influence of particle damping on ride comfort of mining dump truck. Mech. Syst. Signal Process. 2020, 136, 106509. [Google Scholar] [CrossRef]

- Jin, J.; Kim, H.; Koh, H.I.; Park, J. Railway noise reduction by periodic tuned particle impact damper with bounce and pitch-coupled vibration modes. Compos. Struct. 2022, 284, 115230. [Google Scholar] [CrossRef]

- Zhao, C.; Shi, D.; Zheng, J.; Niu, L.; Wang, P. New floating slab track isolator for vibration reduction using particle damping vibration absorption and bandgap vibration resistance. Constr. Build. Mater. 2022, 336, 127561. [Google Scholar] [CrossRef]

- Prasad, B.B.; Duvigneau, F.; Juhre, D.; Woschkeet, E. Application of Particle Dampers on a Scaled Wind Turbine Generator to Improve Low-Frequency Vibro-Acoustic Behavior. Appl. Sci. 2022, 12, 671. [Google Scholar] [CrossRef]

- Lu, Z.; Liao, Y.; Huang, Z. Stochastic response control of particle dampers under random seismic excitation. J. Sound Vib. 2020, 481, 115439. [Google Scholar] [CrossRef]

- Gagnon, L.; Morandini, M.; Ghiringhelli, G.L. A review of particle damping modeling and testing. J. Sound Vib. 2019, 459, 114865. [Google Scholar] [CrossRef]

- Mao, K.; Wang, M.Y.; Xu, Z.; Chen, T. Simulation and characterization of particle damping in transient vibrations. J. Vib. Acoust. 2004, 126, 202–211. [Google Scholar] [CrossRef]

- Mao, K.; Wang, M.Y.; Xu, Z.; Chen, T. DEM simulation of particle damping. Powder Technol. 2004, 142, 154–165. [Google Scholar] [CrossRef]

- Wong, C.X.; Daniel, M.C.; Rongong, J.A. Energy dissipation prediction of particle dampers. J. Sound Vib. 2009, 319, 91–118. [Google Scholar] [CrossRef]

- Biondani, F.; Morandini, M.; Ghiringhelli, G.L.; Terraneo, M.; Cordisco, P. Efficient Discrete Element Modeling of Particle Dampers. Processes 2022, 10, 1247. [Google Scholar] [CrossRef]

- Wu, C.J.; Liao, W.H.; Wang, M.Y. Modeling of granular particle damping using multiphase flow theory of gas-particle. J. Vib. Acoust. 2004, 126, 196–201. [Google Scholar] [CrossRef]

- Xia, Z.; Mao, K.; Wei, S.; Wang, X.; Fang, Y.; Yang, S. Application of genetic algorithm-support vector regression model to predict damping of cantilever beam with particle damper. J. Low Freq. Noise Vib. Act. Control 2017, 36, 138–147. [Google Scholar] [CrossRef]

- Ye, X.; Ni, Y.Q.; Sajjadi, M.; Wang, Y.; Lin, C. Physics-guided, data-refined modeling of granular material-filled particle dampers by deep transfer learning. Mech. Syst. Signal Process. 2022, 180, 109437. [Google Scholar] [CrossRef]

- Bai, X.M.; Keer, L.M.; Wang, Q.J.; Snurr, R.Q. Investigation of particle damping mechanism via particle dynamics simulations. Granul. Matter 2009, 11, 417–429. [Google Scholar] [CrossRef]

- Masmoudi, M.; Job, S.; Abbes, M.S.; Tawfiq, I.; Haddar, M. Experimental and numerical investigations of dissipation mechanisms in particle dampers. Granul. Matter 2016, 18, 71. [Google Scholar] [CrossRef]

- Pourtavakoli, H.; Parteli, E., Jr.; Pöschel, T. Granular dampers: Does particle shape matter? New J. Phys. 2016, 18, 073049. [Google Scholar] [CrossRef]

- Koch, S.; Duvigneau, F.; Orszulik, R.; Gabbert, U.; Woschke, E. Partial filling of a honeycomb structure by granular materials for vibration and noise reduction. J. Sound Vib. 2017, 393, 30–40. [Google Scholar] [CrossRef]

- Romdhane, M.B.; Bouhaddi, N.; Trigui, M.; Foltete, E.; Haddar, M. The loss factor experimental characterisation of the non-obstructive particles damping approach. Mech. Syst. Signal Process. 2013, 38, 585–600. [Google Scholar] [CrossRef]

- Meyer, N.; Seifried, R. Numerical and experimental investigations in the damping behavior of particle dampers attached to a vibrating structure. Comput. Struct. 2020, 238, 106281. [Google Scholar] [CrossRef]

- Meyer, N.; Seifried, R. Toward a design methodology for particle dampers by analyzing their energy dissipation. Comput. Part. Mech. 2021, 8, 681–699. [Google Scholar] [CrossRef]

- Meyer, N.; Schwartz, C.; Morlock, M.; Seifried, R. Systematic design of particle dampers for horizontal vibrations with application to a lightweight manipulator. J. Sound Vib. 2021, 510, 116319. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, T.; Wang, X.; Fang, J. Rheology behavior and optimal damping effect of granular particles in a non-obstructive particle damper. J. Sound Vib. 2016, 364, 30–43. [Google Scholar] [CrossRef]

- Yin, Z.; Su, F.; Zhang, H. Investigation of the energy dissipation of different rheology behaviors in a non-obstructive particle damper. Powder Technol. 2017, 321, 270–275. [Google Scholar] [CrossRef]

- Meyer, N.; Seifried, R. Energy dissipation in horizontally driven particle dampers of low acceleration intensities. Nonlinear Dyn. 2022, 108, 3009–3024. [Google Scholar] [CrossRef]

- Jadhav, T.A.; Awasare, P.J. Enhancement of particle damping effectiveness using multiple cell enclosure. J. Vib. Control 2016, 22, 1516–1525. [Google Scholar] [CrossRef]

- Yao, B.; Chen, Q.; Xiang, H.Y.; Gao, X. Experimental and theoretical investigation on dynamic properties of tuned particle damper. Int. J. Mech. Sci. 2014, 80, 122–130. [Google Scholar] [CrossRef]

- Zhang, K.; Xi, Y.; Chen, T.; Ma, Z. Experimental studies of tuned particle damper: Design and characterization. Mech. Syst. Signal Process. 2018, 99, 219–228. [Google Scholar] [CrossRef]

- Hamed, Y.S.; el Shehry, A.; Sayed, M. Nonlinear modified positive position feedback control of cantilever beam system carrying an intermediate lumped mass. Alex. Eng. J. 2020, 59, 3847–3862. [Google Scholar] [CrossRef]

- Sayed, M.; Mousa, A.A.; Alzaharani, D.Y. Bifurcation analysis of a composite cantilever beam via 1: 3 internal resonance. J. Egypt. Math. Soc. 2020, 28, 1–21. [Google Scholar] [CrossRef]

- Sayed, M.; Mousa, A.A.; Mustafa, I. Stability and bifurcation analysis of a buckled beam via active control. Appl. Math. Model. 2020, 82, 649–665. [Google Scholar] [CrossRef]

- Arumugam, A.B.; Subramani, M.; Dalakoti, M. Dynamic characteristics of laminated composite CNT reinforced MRE cylindrical sandwich shells using HSDT. Mech. Based Des. Struct. 2021, 1–17. [Google Scholar] [CrossRef]

- Shareef, S.S.; Rajeshkumar, S.; Rauf, H.L. A Numerical Study on Forced Vibration Analysis and Optimum Design of Rotating Composite Multiwalled Carbon Nanotubes-Reinforced Smart Sandwich Plate. Int. J. Struct. Stab. Dyn. 2022, 22, 2250009. [Google Scholar] [CrossRef]

- Ferreyra, M.V.; Gómez-Paccapelo, J.M.; Suarez, R.; Pugnaloni, L.A. Avoiding chaos in granular dampers. In EPJ Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 249, p. 15003. [Google Scholar]

- Yao, B.; Chen, Q. Investigation on zero-gravity behavior of particle dampers. J. Vib. Control 2015, 21, 124–133. [Google Scholar] [CrossRef]

- Gnanasambandham, C.; Fleissner, F.; Eberhard, P. Enhancing the dissipative properties of particle dampers using rigid obsta-cle-grids. J. Sound Vib. 2020, 484, 115522. [Google Scholar] [CrossRef]

- Liu, W.; Tomlinson, G.R.; Rongong, J.A. The dynamic characterisation of disk geometry particle dampers. J. Sound Vib. 2005, 280, 849–861. [Google Scholar] [CrossRef]

- Sánchez, M.; Pugnaloni, L.A. Effective mass overshoot in single degree of freedom mechanical systems with a particle damper. J. Sound Vib. 2011, 330, 5812–5819. [Google Scholar] [CrossRef]

- Xia, R.; Li, B.; Wang, X.; Li, T.; Yang, Z. Measurement and calibration of the discrete element parameters of wet bulk coal. Measurement 2019, 142, 84–95. [Google Scholar] [CrossRef]

| Mass | Shell (g) | Grid (g) | Filling Ratio 50% (g) | Filling Ratio 70% (g) | Filling Ratio 90% (g) |

|---|---|---|---|---|---|

| Without grid | 122 | / | 105 | 147 | 189 |

| With grid | 122 | 3.3 | 85 | 119 | 153 |

| Filling Ratios | 50% | 60% | 70% | 80% | 90% | Without PD |

|---|---|---|---|---|---|---|

| Without grid | 45.4 m/s2 | 38.6 m/s2 | 35.5 m/s2 | 32.5 m/s2 | 29.6 m/s2 | 66.5 m/s2 |

| With grid | 22.7 m/s2 | 16.2 m/s2 | 12.2 m/s2 | 11.6 m/s2 | 8.9 m/s2 |

| Particle Sizes | 1 mm | 1.5 mm | 2 mm |

|---|---|---|---|

| Without grid | 27.9 m/s2 | 30.7 m/s2 | 29.6 m/s2 |

| With grid | 8.6 m/s2 | 10 m/s2 | 8.9 m/s2 |

| Materials | Al | ZrO | Steel | Cu | Pb |

|---|---|---|---|---|---|

| Without grid | 47.4 m/s2 | 36.1 m/s2 | 29.6 m/s2 | 32.5 m/s2 | 33.2 m/s2 |

| With grid | 22.5 m/s2 | 11.4 m/s2 | 8.9 m/s2 | 9 m/s2 | 8.9 m/s2 |

| Components | Density (kg/m3) | Poisson’s Ratio | Young’s Modulus (Pa) | Coefficient of Restitution | Coefficient of Static Friction | Coefficient of Rolling Friction |

|---|---|---|---|---|---|---|

| Particle | 7930 | 0.3 | 2.06 × 1011 | 0.74 | 0.2 | 0.01 |

| Shell | 1190 | 0.32 | 3.3 × 109 | 0.3 | 0.154 | 0.01 |

| Grid | 1120 | 0.23 | 2.46 × 109 | 0.7 | 0.3 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Hu, Y.; Jiang, J.; Zan, H. Damping Characteristics of Cantilever Beam with Obstacle Grid Particle Dampers. Machines 2022, 10, 989. https://doi.org/10.3390/machines10110989

Zhang J, Hu Y, Jiang J, Zan H. Damping Characteristics of Cantilever Beam with Obstacle Grid Particle Dampers. Machines. 2022; 10(11):989. https://doi.org/10.3390/machines10110989

Chicago/Turabian StyleZhang, Junlong, Yin Hu, Jie Jiang, and Hao Zan. 2022. "Damping Characteristics of Cantilever Beam with Obstacle Grid Particle Dampers" Machines 10, no. 11: 989. https://doi.org/10.3390/machines10110989

APA StyleZhang, J., Hu, Y., Jiang, J., & Zan, H. (2022). Damping Characteristics of Cantilever Beam with Obstacle Grid Particle Dampers. Machines, 10(11), 989. https://doi.org/10.3390/machines10110989