Abstract

Cavitation is a destructive hydraulic phenomenon; it causes damage to small hydraulic machinery and large water-conservancy projects, and cavitation and cavitation corrosion problems are long-standing problems for hydraulic machinery experts. Micro-textures are often machined onto the end face near the indirect contact point to increase the oil film bearing capacity and reduce the transfer torque in hydraulic machinery, but the pressure disturbance caused by the texture dimple and boundary can induce cavitation. To delay or eliminate cavitation on the textured surface of equipment such as mechanical seals and dynamic bearings, the cavitation effect of a cylindrical texture on a rotating frictional pair was investigated from theoretical, imitational, and experimental perspectives. Low pressure is extremely important for inducing cavitation; once cavitation conditions are met, a full bubble can be formed in about 0.015 s. Cavitation mainly occurs at the outer radius of the rotating end face, i.e., in the high-speed region. There is a mutual mass transfer between gas and liquid phases when cavitation occurs, but the generation of cavitation bubbles is faster than its collapse, thus causing an increasing cavitation region.

1. Introduction

Cavitation has only been known and studied for a hundred years. Cavitation is a part of hydrodynamics research; simultaneously, it is an interdisciplinary discipline that integrates fluid mechanics, physics, acoustics, and materials science, etc. Cavitation has been widely used in engineering applications, and its performance is of significance in ship engineering [1], water armament [2], hydraulic engineering [3], and hydraulic machinery [4]. Cavitation is also gaining attention and focus in the fields of environmental engineering [5], pharmaceutical engineering [6,7], aerospace engineering [8,9,10], and nuclear engineering [11,12,13].

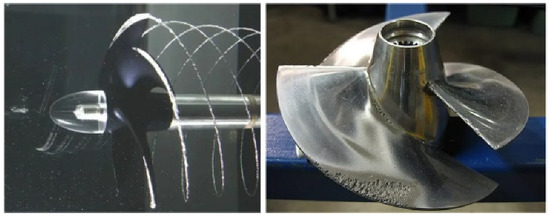

People’s understanding of cavitation has improved with the advancement of microelectronics and fluid drive and control technology [14]. Cavitation is a phenomenon in which water is violently vaporized at a certain temperature when the local pressure is reduced below the saturated vapor pressure, and a cavitation bubble is created [15,16,17,18,19]. To create a cavity or bubble inside water, it is necessary to pull the water apart. It has been estimated that if the liquid state is viewed as a pseudo-crystal, it may require a tensile force of 0.405 MPa to 10.133 MPa to rupture the liquid. Thus, homogeneous, continuous, pure water hardly produces cavitation [1]. However, natural water contains a large number of invisible (to the naked eye), very small insoluble microbubbles; that is, a free gas nucleus, with a diameter of approximately 10−6–10−3 cm. The cavitation phenomenon occurs when the local pressure in water flow is very low, causing the free gas nucleus to expand and become visible, resulting in bubbles in the water [20]. In 1754, Euler first proposed the possibility of water cavitation in the low-pressure region when he studied the theory of hydraulic turbines [21]. After the examination, several perforations were found in the propeller (Figure 1). Hydrodynamic cavitation is a phase change process and a very complex transient microscopic phenomenon [22]. Most of the effects of cavitation on hydrodynamic machinery are derogatory; when a cavitation bubble collapses, it can release huge amounts of energy into the surrounding fluid [23], generate local high temperatures [24] (2300 k~4600 k) and high pressures [25] (1000 bar), generate shock waves [26], damage mechanical surfaces [27], corrode flow channels, and affect the service life of hydrodynamic machinery.

Figure 1.

Cavitation erosion on propeller [20].

Studies on flow fields between rotating disk systems are abundant in hydromechanics. When fluid flows along uneven surfaces, it can form secondary flow vortexes with opposite rotation directions; the center of the vortex is frequently a low-pressure area, which can induce cavitation inception. Schouveiler et al. [28] studied the oil flow between stationary and rotating disks and found that when the Reynolds number value was high, turbulent flow broke the periodicity of oil flow, and a secondary flow phenomenon appeared at the outer diameter. Subsequently, Soong et al. [29] used the paraffin fluorescence method to analyze the oil flow structure between disks and found that when the Reynolds number was increased at the same speed as both disks, the flow field changed from stable to complex to stable, which verified the secondary flow found by Schouveiler. Pahlovy et al. [30,31] established a mathematical model of the band-row torque under a disk friction pair, analyzed the effects of parameters such as speed difference and friction pair gap on band-row torque, built a visualization test rig, and photographed and collected flow morphology of the friction pair, and found that the theoretical results were in general agreement with the trend of the experimental results. Gostia investigated the hydrodynamic performance of a new fixed-disk hydrodynamic cavitation rotary generator and compared it with a sawtooth disk variant. The experimental results showed that the nail-head disk produced more intense cavitation than the sawtooth disk for a given speed and fluid flow rate [32]. S. Klingl et al. [33] demonstrated that the boundary layer of different types of rotating disks is absolutely unstable, and the instability of the boundary layer is an inevitable factor in cavitation.

Many studies have proven that the surface texture of a friction pair can effectively improve lubrication performance and increase the load-carrying capacity. Niket investigated the effectiveness of micro-textures in reducing sliding friction on contact surfaces. Micro-texture structures in the shape of tough nests were machined on the notch and edge side of the drill bit using laser micromachining technology. The micro-texture enhanced tribological properties even at higher rotational speeds [34]. Bei established a texturized, non-parallel, two-dimensional, slider-bearing model and investigated the effect of oil film thickness on the load-bearing capacity of woven and non-textured surfaces. The results showed that the efficiency of the surface structure’s load-bearing capacity increased and then decreased with the increase in the oil film thickness, and the surface texture decreased the efficiency of the load-bearing capacity when the oil film thickness was significant [35]. Ran established a three-dimensional, finite-element flow model of a thrust bearing and found that a surface micro-texture structure increases the bearing capacity. Thus, the stability of the bearing was improved [36].

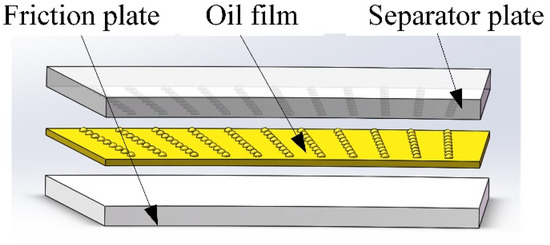

A summary of the previous research results shows that most studies have focused on improving lubrication performance using texture, but the cavitation phenomenon resulting from the change in flow field pressure via the texture is a problem that must be considered in engineering applications. Many studies have documented the detrimental results of cavitation on machinery, but the microscopic mechanisms have not been explored deeply. The surface texture structure of mechanical seals or dynamic load bearings is dominated by tiny grooves, and the cavitation effect caused by cylindrical texture has been analyzed less. Therefore, in this paper, the cavitation process is analyzed from the perspectives of the texture ratio, pressure distribution, and mass exchange between gas and liquid phases. As shown in Figure 2, our research object is a pair of simplified cylindrical texture friction pairs, and simulation and experimental analysis are conducted.

Figure 2.

Simplified model of friction pair.

2. Governing Equations

2.1. Homogeneous Equilibrium Model

In the CFX software, there are two main multiphase flow models: the homogeneous equilibrium model and the non-homogeneous flow model. In a non-homogeneous flow, the flow between different phases is considered independently and is also made more complicated by solving separate momentum equations for each fluid in the flow region. However, the former treats the gas–liquid two-phase mixture as a homogeneous substance, and its flow parameters, such as temperature and turbulence, are taken as the weighted average of the corresponding parameters of two phases, so that each phase shares the same flow field and, therefore, can reach interphase equilibrium quickly. In the cavitation calculation, the homogeneous flow model ignores the difference between the gas–liquid two-phase flow parameters, so it is easier to converge [37], and treats the gas–liquid two-phase as a single-phase flow, as shown in Figure 3, where R is the radius of bubbles, and N2 is the number.

Figure 3.

Schematic diagram of homogeneous model [38].

The homogeneous flow model is based on two basic assumptions: (1) the two phases are in thermal equilibrium; (2) the two phases have equal linear velocities. Additionally, it is assumed that the parameter transport of each phase is the same except for the volume fraction [39,40]:

where φ is a general scalar of the flow field, χ is a different phase of fluid and is generally used as a subscript, ρ is the fluid density in kg/m3, NP is the phase number in the fluid, λ is the volume fraction of each phase, U is the vector velocity in m/s, Г is the phase diffusion ability in kg/(m·s), and SM is the mass source in kg/(m3·s).

2.2. Turbulence Equations

Numerous research findings have shown that turbulence exists in viscous flow when the Reynolds number is high [41,42]. In rotating disc systems, turbulent flow with a high Reynolds number occurs at the moving disc’s surface, and the transition from laminar to turbulent flow occurs at the stationary disc’s surface [43,44]. Oil flow into the dimple generates vortex flow [45,46], so the turbulence model is chosen in the CFX simulation. The friction pair involved in this paper is in a near-contact state with a low film thickness, and since the SST model [46,47,48] has good applicability to the boundary layer and a free-shear layer in the thin-film flow field, the shear stress transport SST model is chosen. Its turbulent viscosity equation, k-equation, ω-equation, and weighting function equation are shown in [48].

where ωh is the turbulence frequency; Pk is the incidence of turbulence caused by viscous forces in kg/(m·s3); μt and μ are turbulent viscosity and dynamic viscosity, respectively, in kg/(m·s); υ is the kinematic viscosity in m2/s; y is the distance to the wall in m; Pkb and Pωb are buoyant turbulence terms; S΄ is the strain rate; and the other constants are β″ = 0.09, β′ = 0.075, α = 5/9, σk = σω =2, and σω2 =1/0.856.

2.3. Cavitation Equations

In multiphase flow fields, there is an exchange of mass, momentum, and energy between phases, so the interphase transport model is crucial in calculations [49]. Cavitation flow causes the convective exchange of mass and volume fractions between the gas and liquid phases in the flow field, where the transport equation for the volume content of the vapor phase is:

where λv is the volume fraction of gas, ρv is the gas density in kg/m3, u is the vector velocity of the gas phase in m/s, and is the source term for evaporation and condensation.

The Rayleigh–Plesset equation describes the growth of bubbles:

where RB is the cavitation bubble radius in m, pv is the pressure (saturated vapor pressure of the liquid) in the cavitation bubble in Pa, p is the liquid pressure around the cavitation bubble in Pa, ρf and ρv are the liquid and vapor density in kg/m3, and τ is the coefficient of the surface tension between the liquid and vapor in N∙m.

Ignoring the second derivative term and the surface tension term, Equation (11) can be simplified as:

The change rates of bubble volume and mass can be calculated as follows:

If the number of bubbles per unit volume in the fluid is NB, then the volume fraction of vapor in the fluid λv can be expressed as:

and the total mass transfer rate between different phases (evaporation or condensation) per unit volume is:

where F is the empirical correction coefficient, which means the difference in evaporation or condensation rate. Generally, evaporation is faster than condensation. Empirically, evaporation mainly occurs at the nucleation point and decreases the density at this location. Therefore, the mass-transfer rate equation of the evaporation process needs to be modified.

where λnuc is the volume fraction in the nucleation center.

The evaporation process for when p ≤ pv is shown in Equation (12). The condensation process for when p ≥ pv is shown in Equation (11). In the CFX simulation, the model empirical coefficients are all set according to the literature as: RB = 2 μm, λnuc = 5 × 10−4, Fvap = 50, Fcoud = 0.01 [50].

2.4. Fluid Mechanics Equations

Our research aims to analyze the shear cavitation phenomenon of the flow field between a pair of rotating friction disks, and the simplified model is shown in Figure 4.

Figure 4.

Simplified model for friction pair.

As the working medium is a viscous hydraulic fluid, the calculation is simplified by assuming that the fluid is a Newtonian fluid with constant viscosity. Assumptions are made as follows [45]:

- (1)

- There is no relative slippage on the contact surface of fluid oil and friction disks.

- (2)

- The disks are always parallel to each other without bias grinding, the oil film thickness is always greater than 0, and there is no convex peak contact.

- (3)

- The flow field flow is laminar flow.

- (4)

- The effect of volume force and inertia terms are neglected and only the effect of centrifugal terms is considered.

- (5)

- Neglecting the axial movement of oil.

Based on the assumptions stated above, the Reynolds equation for the flow of oil between frictional pairs can be obtained [51]:

where, p is pressure, Pa; μ is oil dynamic viscosity, Pa·s; h is oil film thickness, m; ω is angular velocity, rad/s.

3. Model Analysis

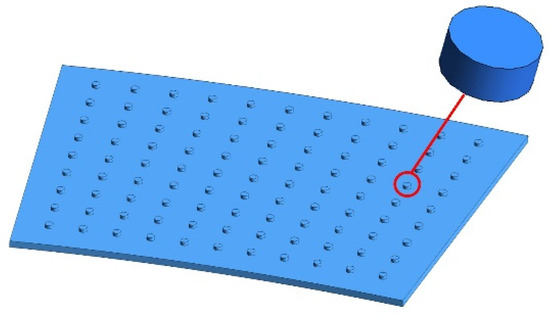

3.1. Geometric Model

Our objective is to determine the oil film between the friction pair using SolidWorks to establish a 3D model of the oil film flow, as shown in Figure 5. A 1/30 model was established to save time for simulation calculation. After the disk was machined with micro-dimples, the corresponding oil film surface appeared to have an orderly arrangement in the form of a micro-hump, as shown in Figure 6. The parameters are shown in Table 1.

Figure 5.

Schematic diagram of friction pair structure.

Figure 6.

Schematic diagram of oil film with cylindrical texture.

Table 1.

Structure parameters of friction pairs.

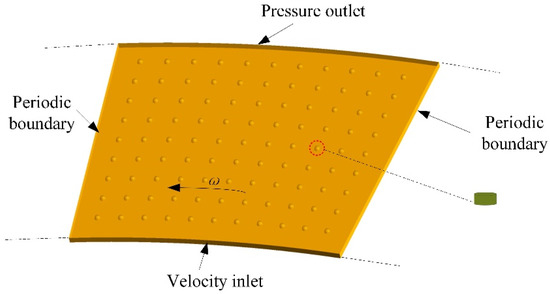

3.2. CFD Model

The computational domain boundary conditions are set as shown in Figure 7. The whole flow field is a rotating domain, as the cavitation phenomenon mainly occurs at a high rotational speed. We can set the speed to n = 6000 rpm, inlet pressure to P0 = 0.08 MPa, and the default oil temperature to T0 = 293 K. We can set the inner diameter surface for the velocity inlet; the oil volume fraction at the inlet is one, and the gas volume fraction is zero. In order to be consistent with the experimental conditions, a relative static pressure of zero is applied at the outlet boundary, i.e., no additional pressure is applied other than atmospheric pressure.

Figure 7.

Boundary condition of flow field.

The transient simulation of the flow field needs a specified time step. Since cavitation is a transient phenomenon unique to liquids and disappears extremely rapidly from generation to disappearance, the total time for transient simulation is set to 0.1 s, the time step is 0.001 s, the total number of calculation steps is 100, and the maximum number of iterative steps in each time step is 10.

3.3. Mesh Model

In CFD simulations, more than 90% of the time is spent on mesh preprocessing in ICEM, so the computational model was simplified to reduce the computational time and the steps of finite-element preprocessing. Due to the complex structure of the cylindrical texture, the mesh division of the texture region with an O-grid was chosen, and the mesh encryption of the texture region was also processed, as shown in Figure 8.

Figure 8.

Structural grid of oil film.

When numerical calculation is based on the finite volume method, the mesh nodes are the objects of numerical calculation, so the mesh quality directly affects the calculation accuracy and time. To test the influence of grid division quality on the accuracy of calculation results, different grid-division schemes were selected. The total volume fraction of cavitation of a single oil film under default operating conditions was calculated using the CFX steady-state simulation method; the results are shown in Table 2. It is worth noting that in this study, steady-state simulations were used to verify grid independence, while a transient simulation strategy was used to simulate the cavitation process. During the simulation, the results of the transient and steady-state simulations were compared for time-saving purposes, and it was discovered that the steady-state simulation was effective in verifying grid independence.

Table 2.

Independence test of mesh division.

Schemes 1–3 utilize numerous axially divided layers, Schemes 2–5 utilize various circumferentially divided layers, and Schemes 4–7 employ different radially divided layers. The results show that increasing the number of axial layers too much causes simulation divergence, and the inaccuracy of the calculation results corresponding to different circumferential layer divisions was smaller.

The selected meshing parameters in this paper are as follows: 121 layers in the weaving region, 124 layers in the non-weaving region, and 11 layers in the O-grid, and eventually the total number of elements in the mesh division was 1,607,374.

3.4. Viscosity–Temperature Relationship

The flow media in the calculation domain are oil and vapor, and the material properties of both at room temperature are shown in Table 3. Considering the great influence of temperature on oil viscosity, a linear-interpolation function was used in CFX software to define the relationship between oil viscosity and temperature [40].

where μx = 0.18 × 10−3 Pa·s, T is the temperature in Celsius, and μ40 is the dynamic oil viscosity with a temperature of 40 °C in Pa∙s.

Table 3.

Parameters of working medium.

4. Simulation Analysis

4.1. Cavitation at Different Texture Rates

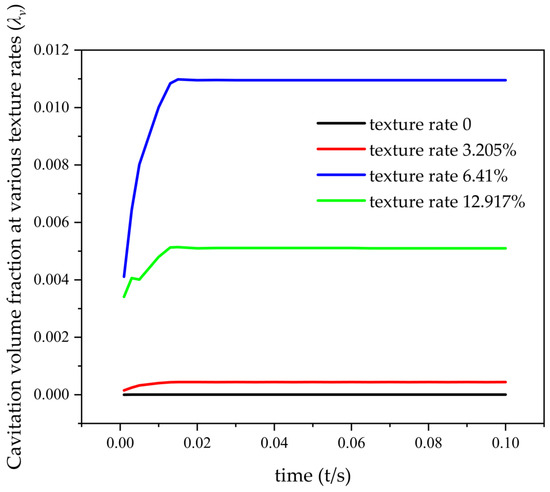

Generally, cavitation does not occur on absolutely smooth surfaces. The cavitation of oil film was investigated at texture rates of 3.205%, 6.41%, and 12.917%, respectively. We used the cavitation volume fraction to measure the intensity of cavitation; that is, when the texture rate is zero, the cavitation volume fraction is zero, i.e., no cavitation occurs. A slight degree of cavitation was produced at a weave rate of 3.205%, and vapor volume fraction was finally stabilized at 0.00044051. The cavitation volume fraction stabilized at 0.01095 at a 6.41% weave rate; however, when the texture rate increased to 12.917%, the cavitation volume fraction decreased to 0.0051. Therefore, we can assume that the cavitation intensity and the surface texture rate on the friction disk are not directly proportional, but there is an optimal texture rate to reduce the cavitation effect and increase the oil film load capacity simultaneously.

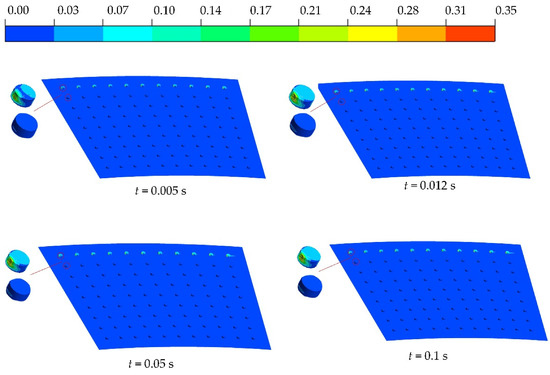

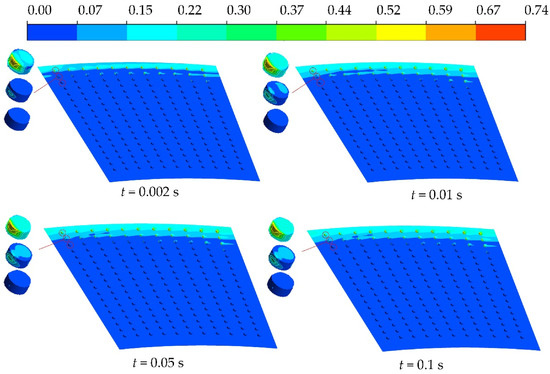

According to Figure 9, it can be seen that cavitation occurs extremely fast. The texture rates of the three friction disks are different, but all reach their maximum within 0.015 s. Figure 10 shows the morphological changes of cavitation at 0.1 s when the texture rate is 3.205%. According to Newton’s law of internal friction, when the fluid flows into the dimple, it will be subject to stronger shear, so the oil film is more likely to cavitate. At 0.005 s, the cavitation mainly appeared inside the texture dimple. The cavitation volume fraction increased with time, and the cavitation area was still concentrated inside the texture dimples distributed at the outer diameter. As shown in Figure 11, when the texture rate was 6.41%, the cavitation was not only confined to the texture dimple but started to extend along the texture region to the non-texture region, with a large area of sheet-like cavitation areas. As shown in Figure 12, when the texture rate increased to 12.917%, the cavitation was still concentrated at the outer radius, but the cavitation area decreased. The cavitation development maintained a similar morphology and therefore is not repeatedly described.

Figure 9.

Cavitation volume fraction at various texture rates.

Figure 10.

Cavitation morphology evolution when texture rate is 3.205%.

Figure 11.

Cavitation morphology evolution when texture rate is 6.41%.

Figure 12.

Cavitation morphology evolution when texture rate is 12.917%.

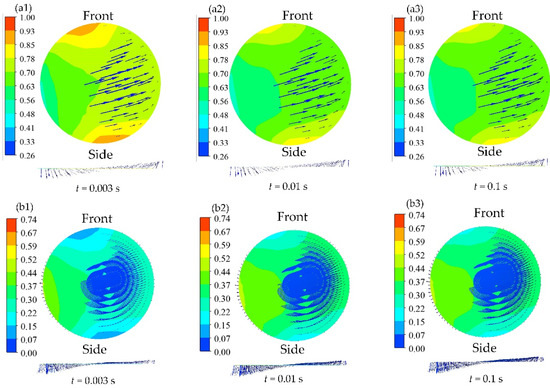

4.2. Cavitation Velocity Field Analysis

To analyze the instantaneous relative velocities of oil and cavitation vapor in the texture dimple, an oil film with a texture rate of 6.41% was selected and enlarged in the local area in the upper left corner of the sample. As shown in Figure 13, when n = 6000 rpm, t = 0.1 s, a1, a2, and a3 are the velocity vector diagrams of the oil at different times. In the non-texture region, the oil was in centrifugal motion, so the oil flowed smoothly. The ripples on the circles mean that when the oil entered the cylindrical dimple, it caused a significant flow field disturbance, and the flow field tended to smooth out at the outflow dimple. Correspondingly, b1, b2, and b3 are the velocity vector diagrams of the cavitation vapor at the same position; it can be seen that the oil and vapor flowed in the same direction, the vapor followed the oil flow, and the oil flowed much faster than the vapor.

Figure 13.

Vector diagram of local oil flow velocity ((a1) is velocity vectors of oil when t = 0.002 s; (a2) is velocity vectors of oil when t = 0.01 s; (a3) is velocity vectors of oil when t = 0.1 s; (b1) is velocity vectors of gas when t = 0.002 s; (b2) is velocity vectors of gas when t = 0.01 s; (b3) is velocity vectors of gas when t = 0.1 s).

Figure 14 shows the velocity vectors in the cross-section at time points, where “front” is the top view of the velocity vector of oil flowing through the plane, and the corresponding “side” is the side view of the same position. According to a1, a2, and a3, the oil velocity increases with time, and according to the vector arrows, the oil flowed in and out from the cross-section simultaneously—which may be due to the strong retention effect of the cylindrical dimple—and the vortex was generated after the oil entered the cylindrical dimples. Upon combining Figure 13 and Figure 14, it can be inferred that the cavitation vapor originated from the oil phase change due to a shear effect.

Figure 14.

Velocity vector diagram of oil flow overlaid by the contours of oil volume fractions ((a1) is velocity vectors of oil when t = 0.003 s; (a2) is velocity vectors of oil when t = 0.01 s; (a3) is velocity vectors of oil when t = 0.1 s; (b1) is velocity vectors of gas when t = 0.003 s; (b2) is velocity vectors of gas when t = 0.01 s; (b3) is velocity vectors of gas when t = 0.1 s).

4.3. Cavitation Pressure Field Analysis

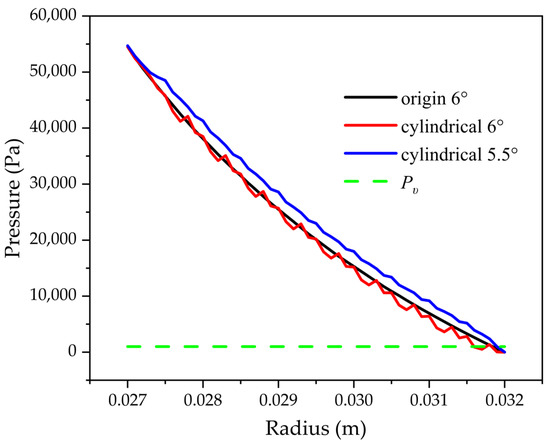

The pressure pulsation caused by texture dimples and their boundary can induce cavitation. It can assume that the oil saturation vapor pressure pv is 1000 Pa, i.e., cavitation occurs when the pressure is below 1000 Pa. The radial flow was mainly driven by the inlet pressure and centrifugal force, the flow velocity increased along the radial direction, and according to Bernoulli’s principle, the pressure distribution and the velocity distribution appeared to have opposite trends. The circumferential angle θ of the model is 12° when θ = 6° is on the center line of the radial texture dimple. As shown in Figure 15, in the non-textured oil film, the pressure decreased uniformly along the radial direction, and the pressure curve was smooth (origin at 6°). In the textured oil film, the pressure curve was smooth in the non-textured area, and the pressure fluctuated in the texture area when the oil flowed into the crater, thus creating a wave-like curve (cylindrical at 6°).

Figure 15.

Radial pressure distribution along radial direction.

The pressure distribution in a single texture dimple was analyzed. Figure 16 shows the pressure distribution at different speeds considering the cavitation effect (where 0.9~1.1° is the textured region, and 0.8~0.9° and 1.1~1.2° are the non-textured regions). Due to the strong shearing effect of the texture and the barrier effect of the textured wall, the oil was squeezed near the root, which caused a huge pressure pulsation, and peak pressure was greatly increased. Figure 17 shows the pressure distribution at different speeds while ignoring the cavitation effect; comparing Figure 16 and Figure 17, it can be seen that the pressure distribution had the same pattern when the speed was 1000 rpm, 2000 rpm, and 3000 rpm, respectively. However, as the speed increased, the peak in the high-pressure region, where the cavitation effect was ignored, did not increase much with speed, but the peak in the low-pressure region was greatly increased. Therefore, the cavitation effect partially weakened the fluid’s dynamic pressure.

Figure 16.

Pressure distribution in a single textured dimple with the cavitation effect at different rotational speeds.

Figure 17.

Pressure distribution in a single textured dimple without the cavitation effect at different rotational speeds.

4.4. Mass-Transfer Analysis

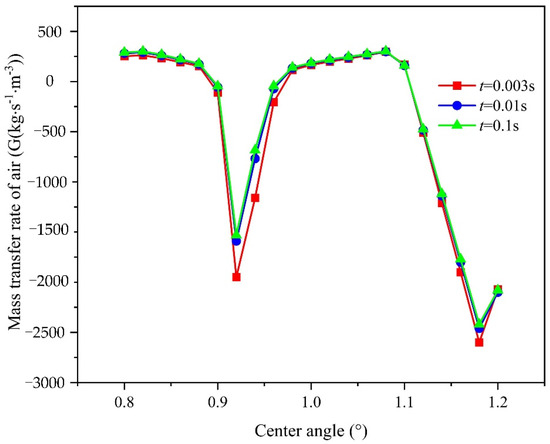

As can be seen in the above analysis, cavitation is generated when the pressure is lower than the saturated vapor pressure, and the cavitation bubble gradually disappears when the pressure increases over pv. Using the pressure-distribution law in the oil film, the gas–liquid mass-transfer rate was analyzed. It can assume that the gas phase mass-generation rate is negative, and the gas phase mass-dissipation rate is positive, to analyze the mass transfer between gas and liquid phases when cavitation is generated.

As can be seen in Figure 18, cavitation develops rapidly when t = 0~0.01 s. The maximum value of the gas phase mass-generation rate was t = 0.003 s. Subsequently, the value gradually decreased; the gas phase mass-dissipation rate virtually remained the same. The gas phase generation and dissipation were conducted simultaneously, i.e., the process of cavitation development was accompanied by collapse, and the peak of the disappearance rate was smaller than the generation rate, so the cavitation area increased gradually with time.

Figure 18.

Mass-transfer rate of air at different times in a single cylindrical textured dimple.

5. Experiment Analysis

5.1. Experiment Design

To visually analyze cavitation morphology, as shown in Figure 19, a laser marking machine was used to texture the friction disk’s surface, and a VK-X250 laser scanning confocal microscope was used to measure the variation in different pulse counts versus the dimple depth.

Figure 19.

(a) Laser marking machine; (b) VK-X250 laser scanning microscope.

Some of the parameters of the laser marking machine were set as shown in Table 4. The laser processing speed is 500 mm/s; spot diameter is 0.05 mm, and after determining the values of the other parameters, the laser marking machine is used to process the friction disk.

Table 4.

Laser processing parameters.

After several calibrations, the equipment parameters were determined, and friction disks with a texture rate of 6% were processed, as shown in Figure 20.

Figure 20.

Surface texture of friction disk.

To illustrate the clear cavitation morphology, we built a visualized transparent test bench, including a transparent host and hydraulic system. In this system, the transparent host is the main object of the power input and output and oil film morphology observation, which is loaded, controlled, and transmitted using power and is mainly composed of an inverter, asynchronous motor, sensor, torque tachometer, and loading device. As shown in Figure 21, the speed of the asynchronous motor is controlled by an inverter, and the asynchronous motor is connected to the active shaft of the clutch through coupling. The output shaft of the host is connected to the torque tachometer, which is used to measure the output torque and speed of the host, and the clamping device or magnetic powder brake is used as the loading device for the load.

Figure 21.

Design of transparent test platform (1 = high-speed camera; 2 = lens; 3 = computer; 4 = fill light; 5 = host; 6 = motor; 7 = data collection unit; 8 = magnet powder brake; 9 = torque sensor; 10 = coupling; 11 = base). The hydraulic system provides lubricating fluid to the transparent host and cools the system, as shown in Figure 22. The system comprises a pressure gauge, relief valve, gear pump, oil tank, speed control valve, flow meter, and cooler, etc. The gear pump sends the lubricating fluid into the transparent host to fill the gap of the friction pair and then flows back into the oil tank through the return port at the bottom.

Figure 22.

Design of hydraulic system (1 = pressure gauge; 2 = relief valve; 3 = gear pump; 4 = oil tank; 5 = flow meter; 6 = speed control valve; 7 = cooler).

5.2. Experiment Results

The experiment has the advantage of using a transparent acrylic plate to produce the transparent host case, which allows for clear observation of the internal oil movement. Oil film cavitation is a transient phenomenon, and the friction disk is in a high-speed rotating state, so the high-speed camera is used to record the oil film flow pattern images. The high-speed camera model is the Thousand Eyes Wolf 5F01, its resolution is 2320 × 1720, shooting speed is 500~52,000 frames per second, supporting USB 3.0 and Gigabit Ethernet dual interface.

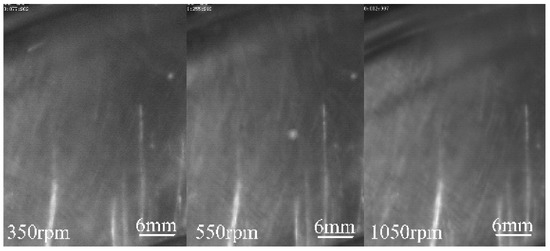

The non-textured friction disk was selected for the control experiment, and three sets of rotational speeds were created using the frequency converter: from 300 rpm to 1200 rpm, increasing by 50 rpm each time. The model was scaled down in the simulation (inner radius is 27 mm and outer radius is 32 mm) to reduce modeling difficulty and save computational time. As the tangential speed has a significant effect on cavitation, the simulation rotations range from 1000 rpm to 6000 rpm; in experiment, the manufactured friction disk is more in line with the size of engineering applications (inner radius is 86 mm and outer radius is 120 mm), so the rotations must be reduced when the friction disk size is larger. Finally, 350 rpm, 550 rpm, and 1050 rpm were chosen to represent the lower, medium, and higher speeds, in that order. The cavitation phenomenon is gradually obvious at the above speed variations.

As shown in Figure 23, despite the speed being increased gradually, the oil film remained intact at all times and no cavitation occurred. Therefore, it is believed that the pressure pulsation caused by the texture dimple or boundary is an important factor in cavitation.

Figure 23.

Cavitation morphology of oil film without texture.

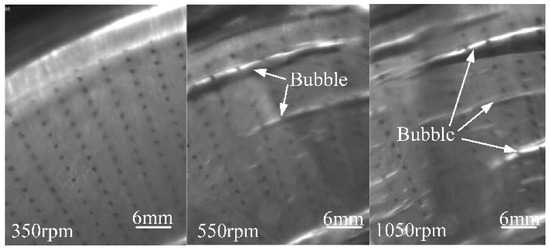

Subsequently, a friction disk with a texture rate of 6% was mounted on a transparent bench. As shown in Figure 24, When the speed was 350 rpm, the oil film remained intact throughout the test without cavitation, and when the speed was increased to 550 rpm, the circumferential velocity of the oil increased, and significant cavitation occurred. When the speed was increased to 1050 rpm, the bubbles increased, the number of narrow bubbles increased in comparison with the speed at 550 rpm, and the cavitation area at the outer diameter increased and moved toward the inner diameter simultaneously. Thus, according to the results of this experimental study, the change in cavitation morphology is consistent with the simulation study.

Figure 24.

Cavitation morphology of oil film without texture.

6. Conclusions

The oil film between a cylindrical textured friction pair was the object of this research, and a hydrodynamic wetting model was established considering the cavitation effect and the viscous shear heat generated. The control equations for solving the cavitation model were analyzed using the finite-unit method. The cavitation effect and the effect on pressure under high-speed conditions were studied, and the mechanism of cavitation flow was revealed. A visualized experimental test platform was built to catch the cavitation morphology in the flow field. The research work and summary are as follows.

After selecting appropriate governing equations, the oil film cavitation phenomenon and mechanism in the cylindrical textured friction pair were analyzed using an ANSYS CFX simulation. It found that the cavitation bubbles preferentially appeared inside the texture dimples, and cavitation developed along textured dimples toward the non-textured region as the speed or the texture rate was increased, and always occurred at the outer diameter of the friction disk. Severe cavitation can lead to poor load-bearing performance, tribological performance, and fluid film stability. Therefore, it is important to avoid creating a texture at the outer diameter of the disk, which can effectively avoid cavitation and be applied in engineering practice.

By counting data derived from commercial fluid-analysis software, it can be found that the cavitation effect reduced the low-pressure peak at the boundary, and it can be assumed that vigorous cavitation can weaken the bearing capacity. However, the increase in the texture rate and cavitation volume fraction is not proportional, and we believe that there is an optimal texture rate which can simultaneously increase the beneficial lubrication friction effect and reduce the cavitation effect. The cavitation equation chosen in this paper is accurate, stable, and efficient.

Cavitation cannot occur without low pressure and nuclear cavitation, and this study verifies that uneven surfaces are the key causative factors for cavitation. The simulation results show that cavitation does not occur on absolutely smooth surfaces. The velocity vectors of liquid and gas phases maintain the same direction while there is a mass transfer between the two phases, verifying that cavitation gas originates from the phase change of oil and liquid. An experimental bench was designed and built for the end-face visualization mechanism, and the oil film cavitation was observed in real time. We found that cavitation was mainly related to the rotational speed, and cavitation bubbles appeared at the inner diameter of the friction disk as the rotational speed gradually increased.

7. Patents

The patent number is CN201810435987.8.

Author Contributions

Conceptualization, J.S.; methodology, J.S.; software, J.S.; validation, L.C., B.Z. and P.Q.; formal analysis, J.S.; investigation, J.S.; resources, J.S.; writing—original draft preparation, J.S.; writing—review and editing, J.S.; visualization, J.S.; supervision, L.C.; project administration, B.Z.; funding acquisition, B.Z. and P.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (51805215, 51605194), in part by the Starting Foundation of Jiangsu University Advanced Talent (14JDG048), in part by the Open Foundation of the State Key Laboratory of Fluid Power and Mechatronic Systems (GZKF-201819), and in part by the Youth Talent Development Program of Jiangsu University.

Data Availability Statement

The data that support the findings in this study are available from the author, J.S., upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Brennan, C.E. Cavitation and Bubble Dynamics; Oxford University Press: New York, NY, USA, 1995; pp. 122–125. [Google Scholar]

- Suryanarayana, C.; Satyanarayana, B.; Ramji, K. Cavitation studies on axi-symmetric underwater body with pump jet propulsor in cavitation tunnel. Int. J. Nav. Arch. Ocean 2010, 2, 85–194. [Google Scholar]

- Knapp, R.T.; Daily, J.W.; Hammitt, F.G. Cavitation; McGraw-Hill Companies: New York, NY, USA, 1970; p. 50. [Google Scholar]

- Iosif, A.; Sarbu, I. Numerical modeling of cavitation characteristics and sensitivity curves for reversible hydraulic machinery. Eng. Anal. Bound. Elem. 2014, 41, 18–27. [Google Scholar] [CrossRef]

- Tatsuya, Y.; Keita, A. Low-intensity ultrasound induced cavitation and streaming in oxygen-supersaturated water: Role of cavitation bubbles as physical cleaning agents. Ultrason. Sonochem. 2019, 52, 268–279. [Google Scholar]

- Robin, J.; Maria, E.K.; Mark, B.; Morgan, S.; Maria, F.M.; Elisa, E.K. Cavitation-modulated inflammatory response following focused ultrasound blood-brain barrier opening. J. Control. Release 2021, 337, 458–471. [Google Scholar]

- Arijana, F.; Tadeja, L.; Katarina, B.; Maja, R.; Meta, J.; Tamara, K.; Martin, P.; Mojca, Z.; Matevž, D.; Ion, G.A. Hydrodynamic cavitation efficiently inactivates potato virus Y in water. Ultrason. Sonochem. 2022, 82, 105898. [Google Scholar]

- Chunmin, W.; Le, X.; Yonghua, T.; Hui, C.; Kaifu, X. Experimental investigation of thermal effect on cavitation characteristics in a liquid rocket engine turbopump inducer. Chin. J. Aeronaut. 2021, 34, 48–57. [Google Scholar]

- Yogen, U.; Jiongyang, W.; Guoyo, W.; Wei, S. Recent progress in modeling of cryogenic cavitation for liquid rocket propulsion. Prog. Aerosp. Sci. 2005, 41, 558–608. [Google Scholar]

- Liang, T.; Cai, G.; Wang, J.; Gu, X.; Zhuo, L.; Cao, L. A hydrogen peroxide electric pump for throttleable hybrid rocket motor. Acta Astronaut. 2022, 192, 409–417. [Google Scholar] [CrossRef]

- Zhenhua, W.; Yuefeng, W. Cavitation erosion and its effect on corrosion resistance of nuclear-grade Z3CN20–09M stainless steel. Mater. Design 2022, 221, 2–3. [Google Scholar]

- Lee, M.W.; Kim, Y.K.; Oh, Y.M.; Kim, Y.; Lee, S.H.; Hong, H.S. Study on the cavitation erosion behavior of hardfacing alloys for nuclear power industry. Wear 2003, 255, 157–161. [Google Scholar] [CrossRef]

- An, C.; Zhu, R.; Long, Y.; Wang, X.; Lu, Y.; Chen, Y. The cavitation performance analysis of the RCP under LBLOCA at inlet-sciencedirect. Ann. Nucl. Energy 2020, 148, 6–8. [Google Scholar] [CrossRef]

- Qian, P.; Pu, C.; Liu, L.; Li, X.; Zhang, B.; Gu, Z.; Meng, D. Development of a new high-precision friction test platform and experimental study of friction characteristics for pneumatic cylinders. Meas. Sci. Technol. 2022, 33, 2–3. [Google Scholar] [CrossRef]

- Hong, S.; Son, G. Numerical modelling of acoustic cavitation threshold in water with non-condensable bubble nuclei. Ultrason. Sonochem. 2022, 83, 1–12. [Google Scholar] [CrossRef]

- Lee, G.L.; Law, M.C. Numerical modelling of single-bubble acoustic cavitation in water at saturation temperature. Chem. Eng. J. 2022, 430, 1–13. [Google Scholar] [CrossRef]

- Ty, A.; Nn, A.; Dh, A.; Mi, B. Sonoluminescence from ultra-high temperature and pressure cavitation produced by a narrow water jet. Heliyon 2021, 7, 1–20. [Google Scholar]

- Masataka, I.; Naoki, O.; Shun, O.; Takayuki, O.; Shoichi, K.; Yoshimura, T. Characteristics of oxide film formed on cavitation-treated steel surface in water. J. Mater. Res. Technol. 2022, 19, 897–1905. [Google Scholar]

- Pipp, P.; Hoevar, M.; Dular, M. Challenges of numerical simulations of cavitation reactors for water treatment–an example of flow simulation inside a cavitating microchannel. Ultrason. Sonochem. 2021, 77, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.S. Physical Mechanism of Cavitation; National Defense Industry Press: Beijing, China, 2013; pp. 6–7. [Google Scholar]

- Kassanos, I.; Anagnostopoulos, I. Cavitation and Bubble Dynamics; Academic Press: Salt Lake City, UT, USA, 2021; pp. 173–209. [Google Scholar]

- Yong, W.; Pan, Z.Y. Cavitation and Bubble Dynamics; Jiangsu University Press: Zhenjiang, China, 2013; pp. 12–13. [Google Scholar]

- Brotchie, A.; Grieser, F.; Ashokkumar, M. Characterization of acoustic cavitation bubbles in different sound fields. J. Phys. Chem. B 2010, 114, 11010–11016. [Google Scholar] [CrossRef]

- Rae, J.; Ashokkumar, M.; Eulaerts, O.; Sonntag, C.V.; Grieser, F. Estimation of ultrasound induced cavitation bubble temperatures in aqueous solutions. Ultrason. Sonochem. 2005, 12, 325–329. [Google Scholar] [CrossRef]

- Sun, X.; Jia, X.; Liu, J.; Wang, G.; Zhao, S.; Ji, L.; Yoon, J.Y.; Chen, S. Investigation on the characteristics of an advanced rotational hydrodynamic cavitation reactor for water treatment—Sciencedirect. Sep. Purif. Technol. 2020, 251, 1–15. [Google Scholar] [CrossRef]

- Lee, H.; Gojani, A.B.; Han, T.H.; Yoh, J.J. Dynamics of laser-induced bubble collapse visualized by time-resolved optical shadowgraph. J. Visual. 2011, 14, 331–337. [Google Scholar] [CrossRef]

- Choi, J.W.; Choi, Y.D.; Kim, C.G.; Lee, Y.H. Flow uniformity in a multi-intake pump sump model. J. Mech. Sci. Technol. 2010, 24, 1389–1400. [Google Scholar] [CrossRef]

- Schouveiler, L.; Le Gal, P.; Chauve, M.P. Stability of a traveling roll system in a rotating disk flow. Phys. Fluids 1998, 10, 2695–2697. [Google Scholar] [CrossRef]

- Soong, C.Y.; Wu, C.C.; Liu, T.P.; Liu, T.P. Flow structure between two co-axial disks rotating independently. Exp. Therm. Fluid Sci. 2003, 27, 295–311. [Google Scholar] [CrossRef]

- Pahlovy, S.A.; Mahmud, S.F.; Masamitsu, K.; Makoto, O.; Norio, T. New development of a gas cavitation model for evaluation of drag torque characteristics in disengaged wet clutches. SAE Int. J. Engines 2016, 9, 1910–1915. [Google Scholar] [CrossRef]

- Shahjada, P.; Faria, M.S.; Masamitsu, K.; Makoto, O.; Norio, T. Multiphase drag modeling for prediction of the drag torque characteristics in disengaged wet clutches. SAE Int. J. Commer. Veh. 2014, 7, 441–447. [Google Scholar]

- Gostia, J.; Irok, B.; Repinc, S.K.; Levstek, M.; Zupanc, M. Performance evaluation of a novel pilot-scale pinned disc rotating generator of hydrodynamic cavitation. Ultrason. Sonochem. 2021, 72, 1–23. [Google Scholar]

- Klingl, S.; Lecheler, S.; Pfitzner, M. Absolute and convective stability of flow between closely spaced co-rotating disks with imposed throughflow. Eur. J. Mech. B Fluid 2022, 91, 226–232. [Google Scholar] [CrossRef]

- Niketh, S.; Samuel, G.L. Surface texturing for tribology enhancement and its application on drill tool for the sustainable machining of titanium alloy. J. Clean. Prod. 2017, 167, 253–270. [Google Scholar] [CrossRef]

- Bei, G.; Ma, C.; Wang, X.; Sun, J.; Ni, X. Study on Tribological Characteristics of Textured Surface under Convergent Oil Film Gap. Lubricants 2022, 10, 183. [Google Scholar] [CrossRef]

- Ran, H.; Dai, P.; Yan, S.; Wang, F.; Yao, X.; Wang, J.; Zuo, G. Flow Mechanisms and Lubrication Performance of Water-Lubricated Thrust Bearings with Herringbone Grooves. Lubricants 2022, 10, 182. [Google Scholar] [CrossRef]

- Giorgi, M.D.; Bello, D.; Ficarella, A. An artifificial neural network approach to investigate cavitating flow regime at different temperatures. Measurement 2014, 47, 971–981. [Google Scholar] [CrossRef]

- Sun, J.; Chen, L.; Zhang, B.; Huang, H.; Qian, P. Cavitation Morphology Study between Hemispherical Textured Rotating Friction Pairs. Lubricants 2022, 10, 249. [Google Scholar] [CrossRef]

- Li, P.F.; Xu, M.Y.; Wang, F.F. Proficient in CFD Engineering Simulation and Case Practice; People’s Posts and Telecommunications Press: Beijing China, 2011; pp. 67–69. [Google Scholar]

- Hu, K.; Li, Z.B. ANSYS ICEM CFD Engineering Examples; People’s Posts and Telecommunications Press: Beijing, China, 2014; pp. 112–113. [Google Scholar]

- Klebanoff, P.S. Characteristics of turbulence in a boundary layer with zero pressure gradient. NACA Tech. 1954, 3178, 23–24. [Google Scholar]

- Taylor, G.I. The transport of vorticity and heat through fluids in turbulent motion. Proc. R. Soc. Lond. 1932, 135, 685–702. [Google Scholar]

- Itoh, M.; Yamada, Y.; Nagata, H. Characteristics of instabilities and transition processes of the flow between a rotating disk and the casing. Trans. Jpn. Soc. Mech. Eng. B 1988, 54, 1236–1243. [Google Scholar] [CrossRef][Green Version]

- Itoh, M.; Yamada, Y.; Imao, S. Experiments on turbulent flow due to an enclosed rotating disk. Exp. Therm. Fluid Sci. 1992, 5, 359–368. [Google Scholar] [CrossRef]

- Watanabe, T.; Oyama, T. Magnetohydrodynamic boundary layer flow over a rotating disk. ZAMM-Z. Angew. Math. Mech. 1991, 71, 522–524. [Google Scholar] [CrossRef]

- Stewartson, K. On the flow between two rotating coaxial disks. Math. Proc. Camb. 1953, 49, 333–341. [Google Scholar] [CrossRef]

- Menter, F.R. Zonal two-equation k-ω turbulence models for aerodynamic flows. AIAA Pap. 1993. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Heat Mass Transf. 2003, 4, 1–8. [Google Scholar]

- Jen, T.C.; Daniel, J.N. Thermal analysis of a wet-disk clutch subjected to a constant energy engagement. Int. J. Heat Mass Transf. 2008, 51, 1757–1769. [Google Scholar] [CrossRef]

- Zwart, P.J.; Gerber, A.G.; Belamri, T. A Two-Phase Flow Model for Predicting Cavitation Dynamics. In Proceedings of the International Conference on Multiphase Flow, Jokohama, Japan, 30 May–3 June 2004. [Google Scholar]

- Meng, Q.R.; Hou, Y.F.; Wang, Y. Finite element analysis of oil film pressure field of liquid viscous drive based on Matlab. Min. Mach. 2007, 9, 121–124. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).