Advancing Smart Manufacturing in Europe: Experiences from Two Decades of Research and Innovation Projects

Abstract

:1. Introduction

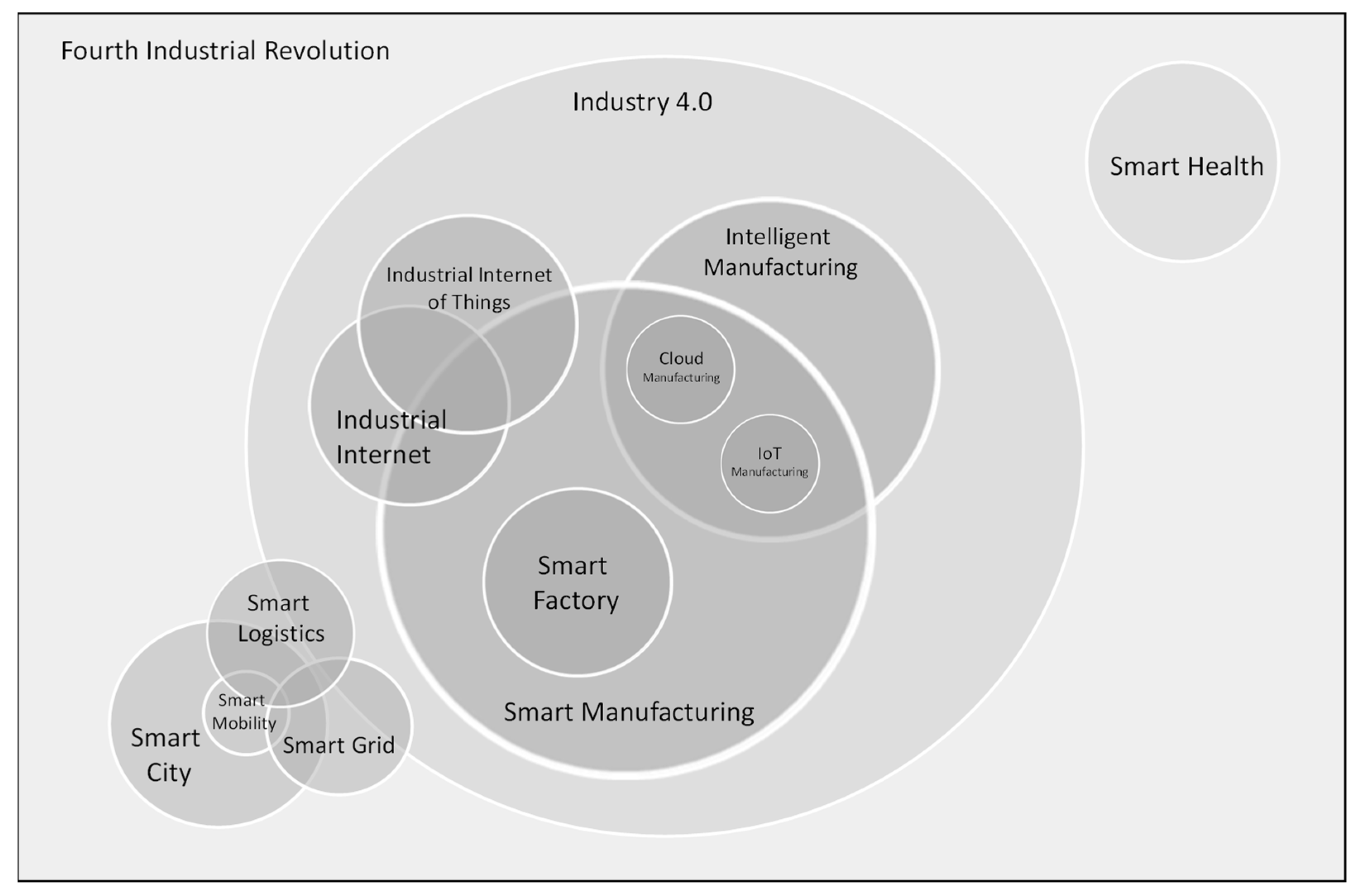

1.1. State of the Art in Smart Manufacturing

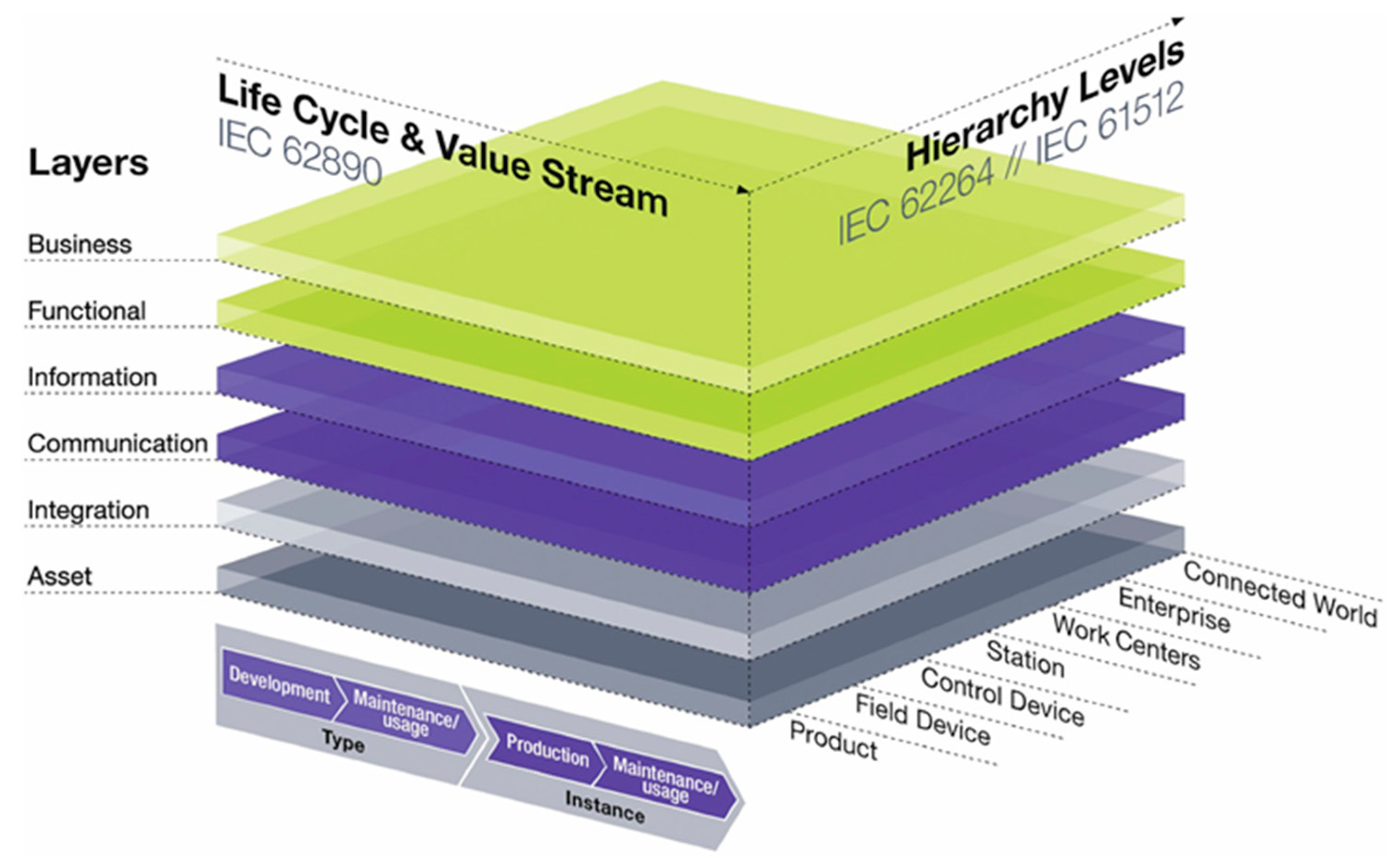

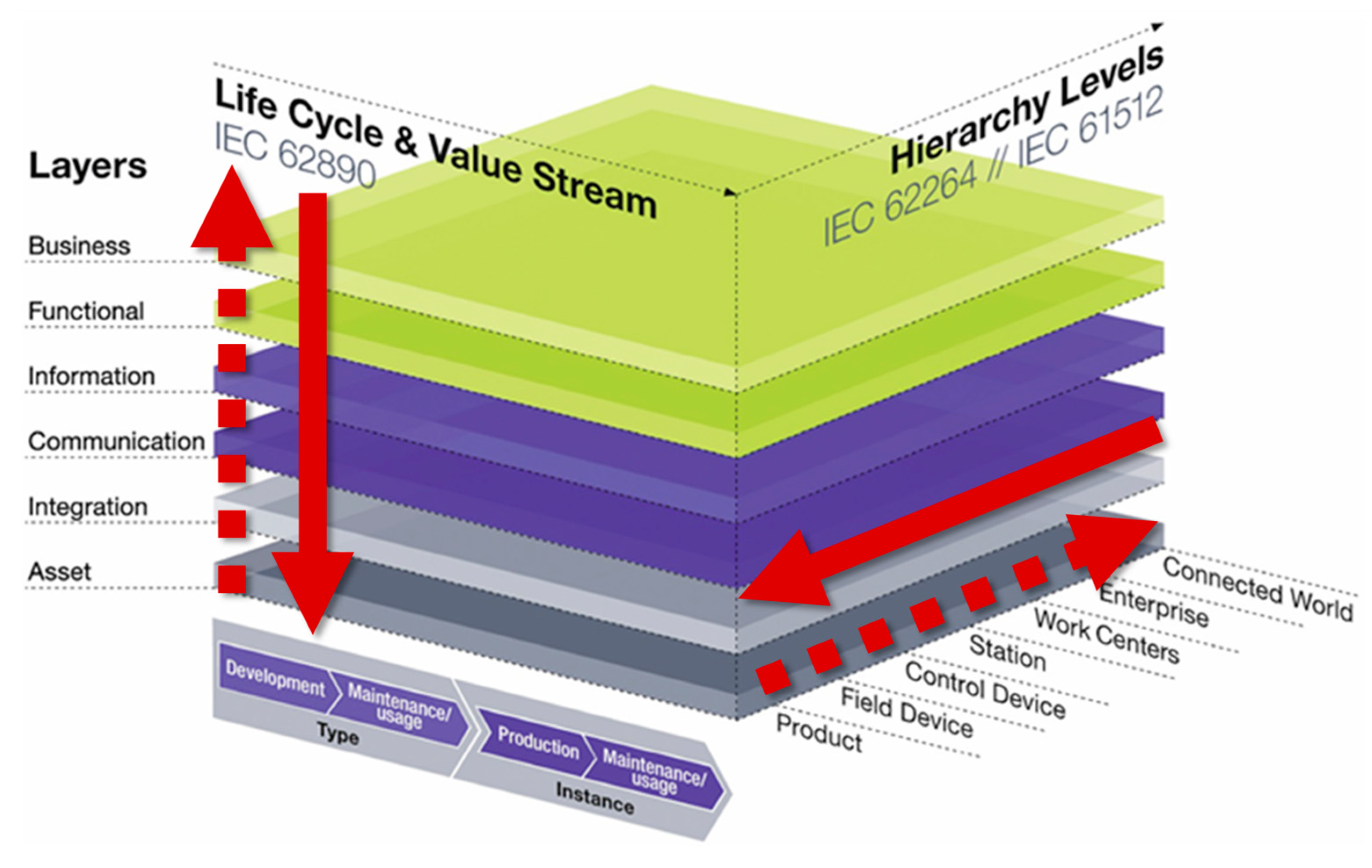

1.2. The RAMI4.0 Framework

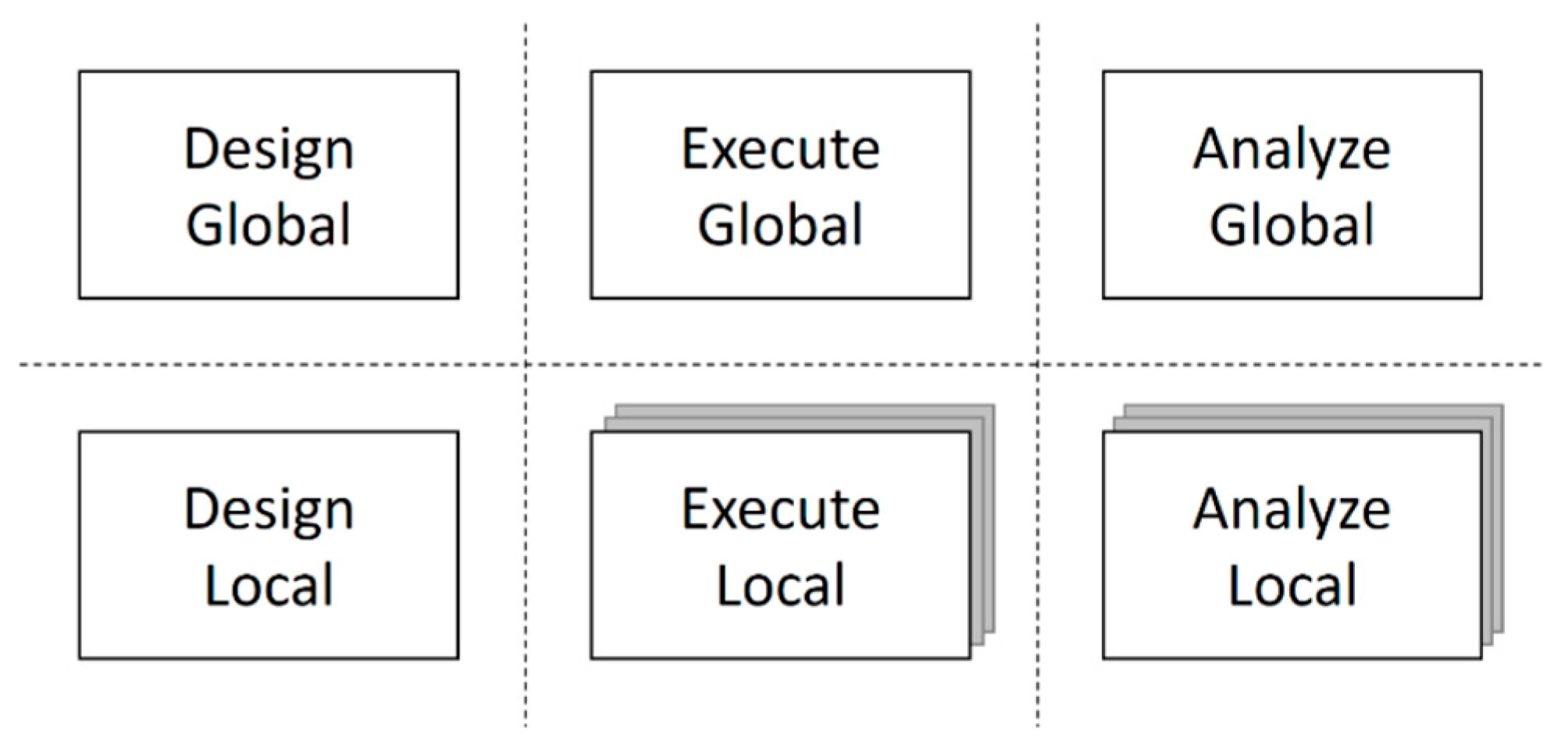

1.3. Method for Organizing the Content of This Paper

2. Two Decades of Research and Innovation Projects

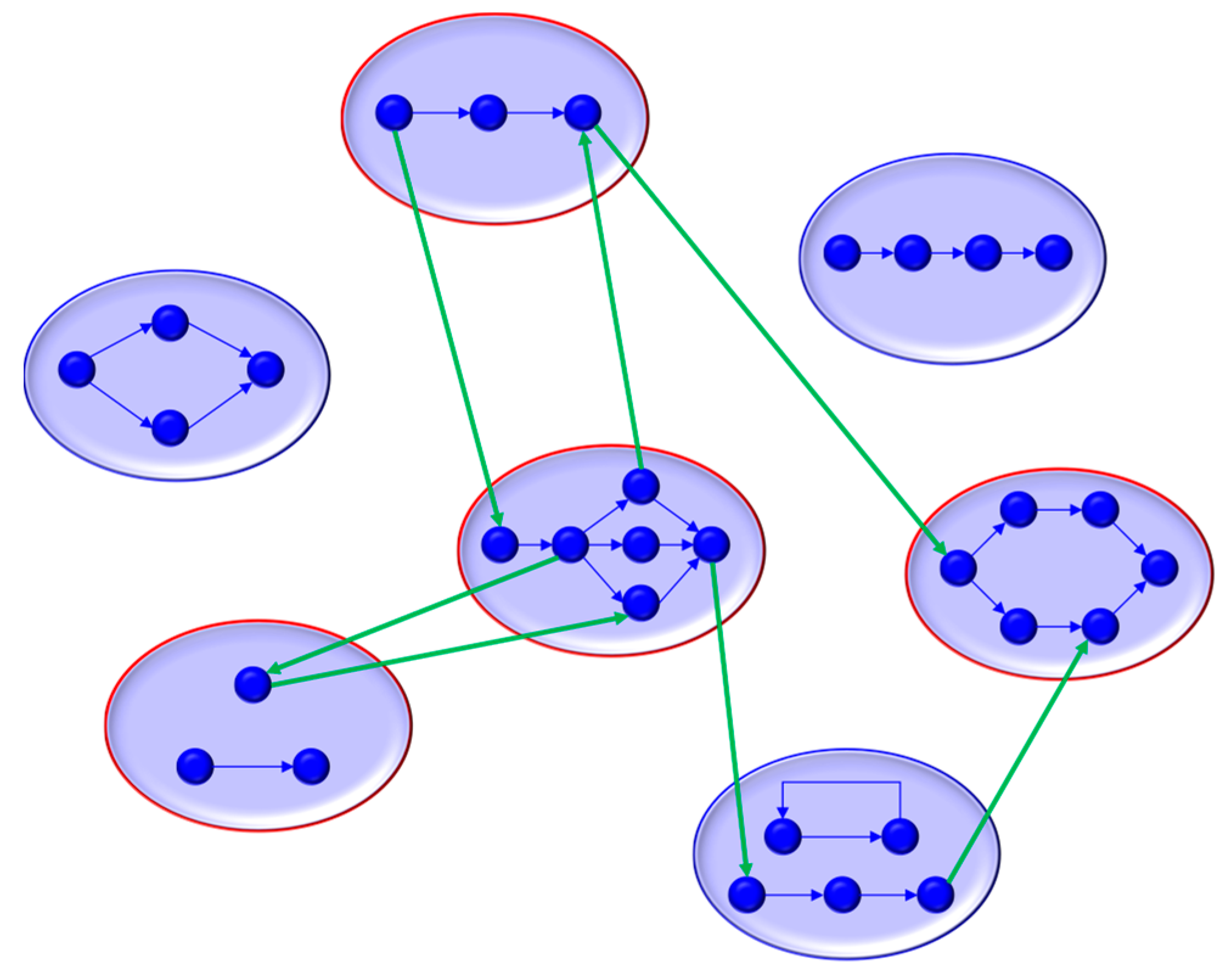

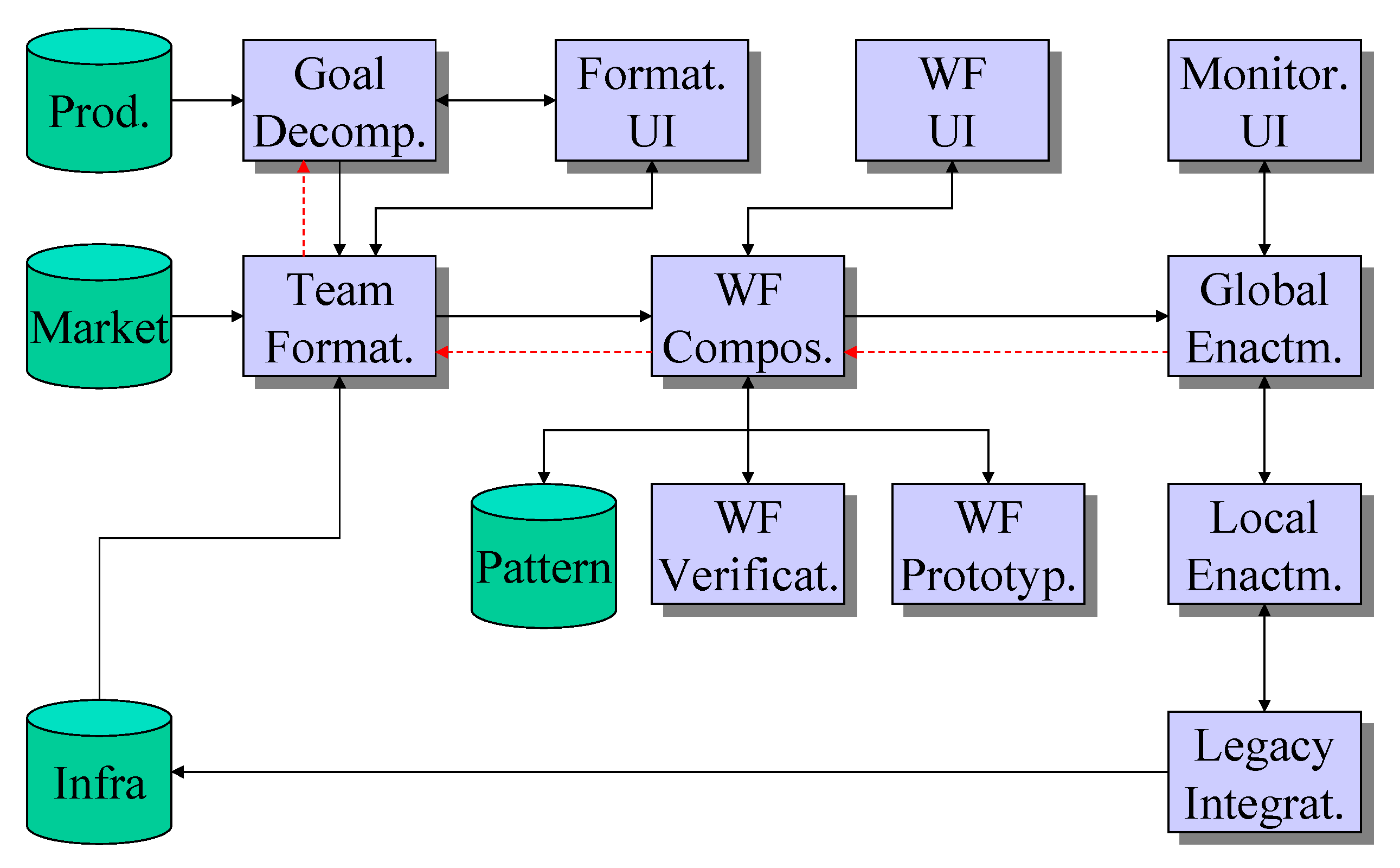

2.1. The CrossWork Project

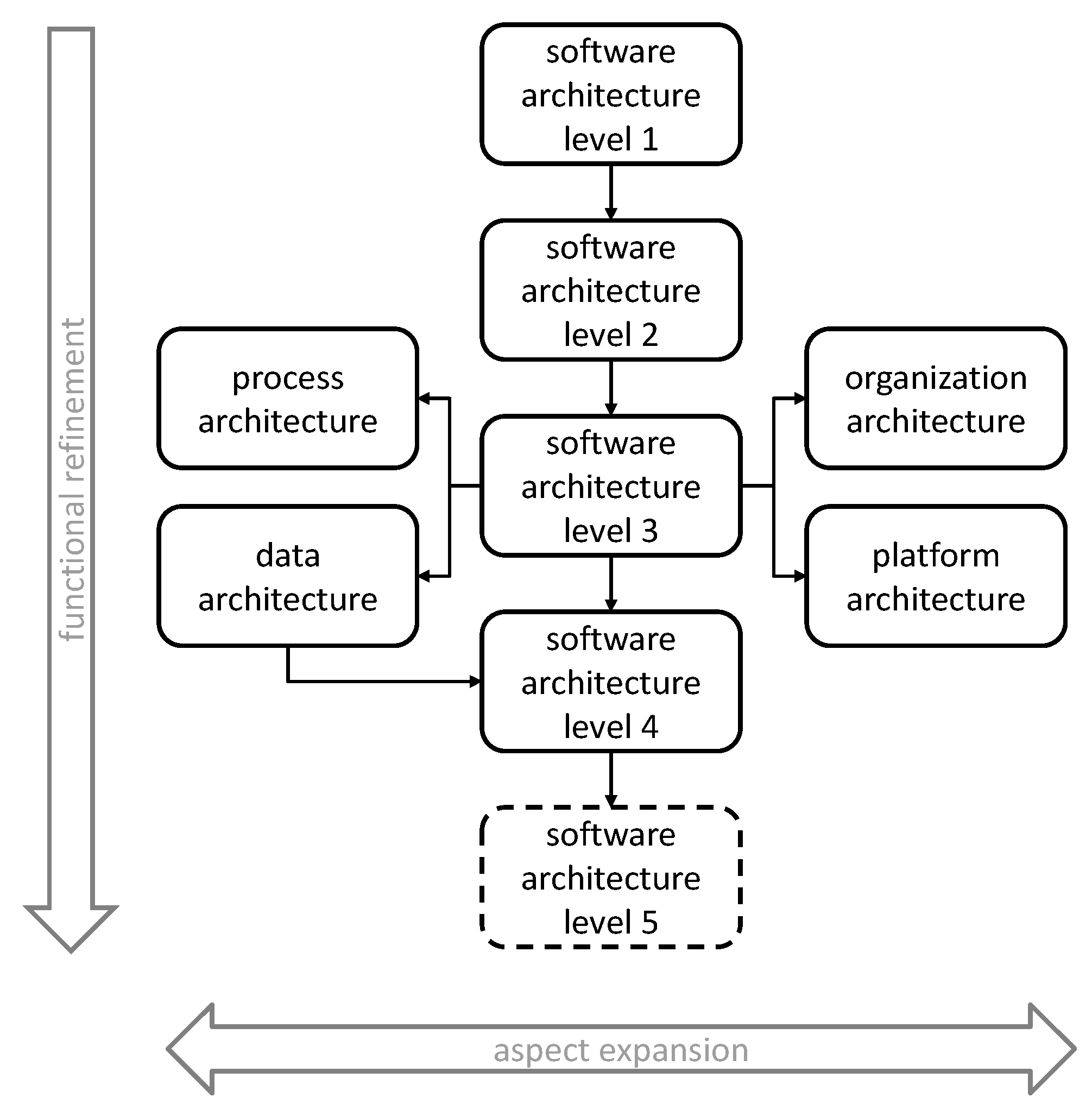

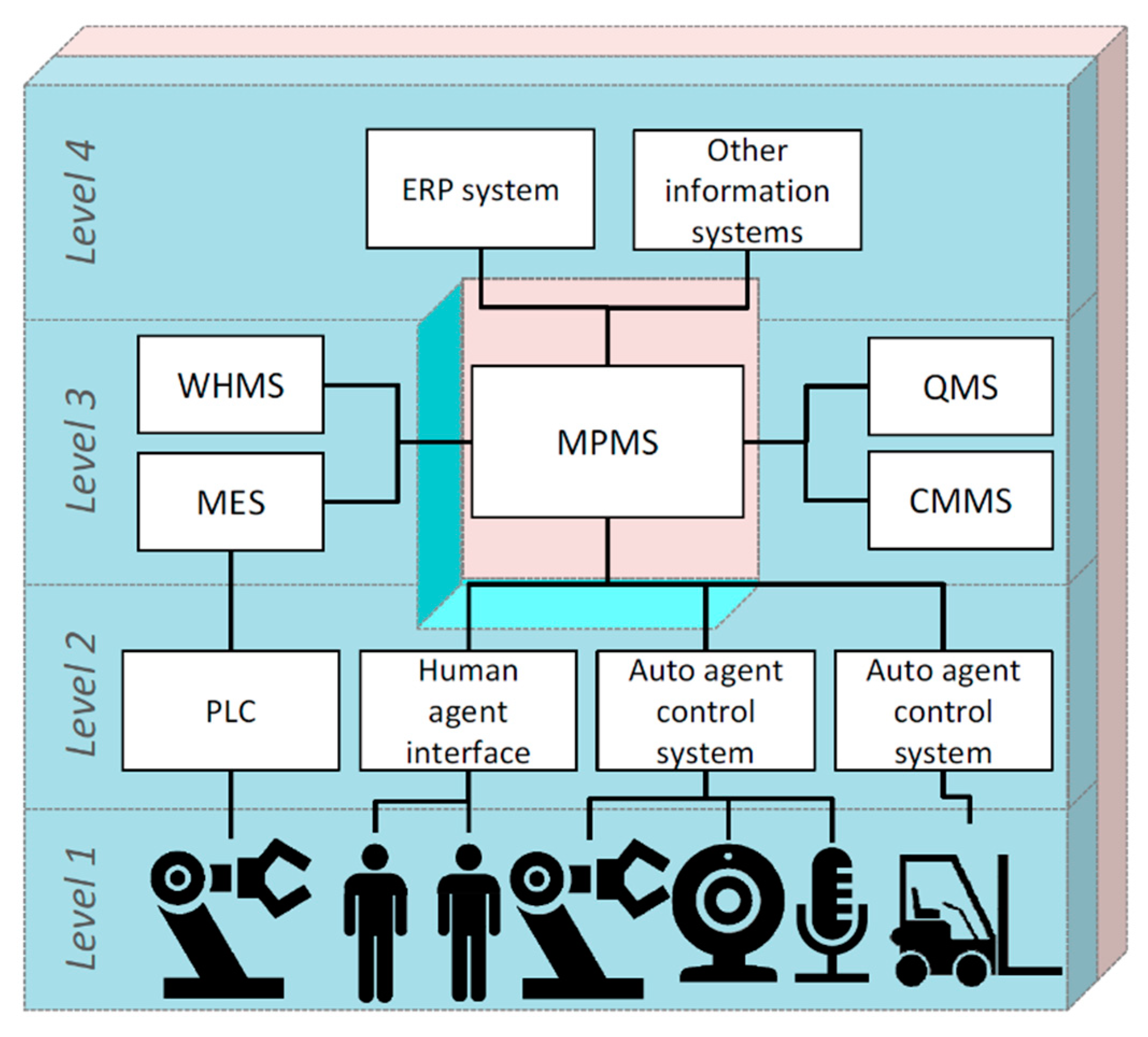

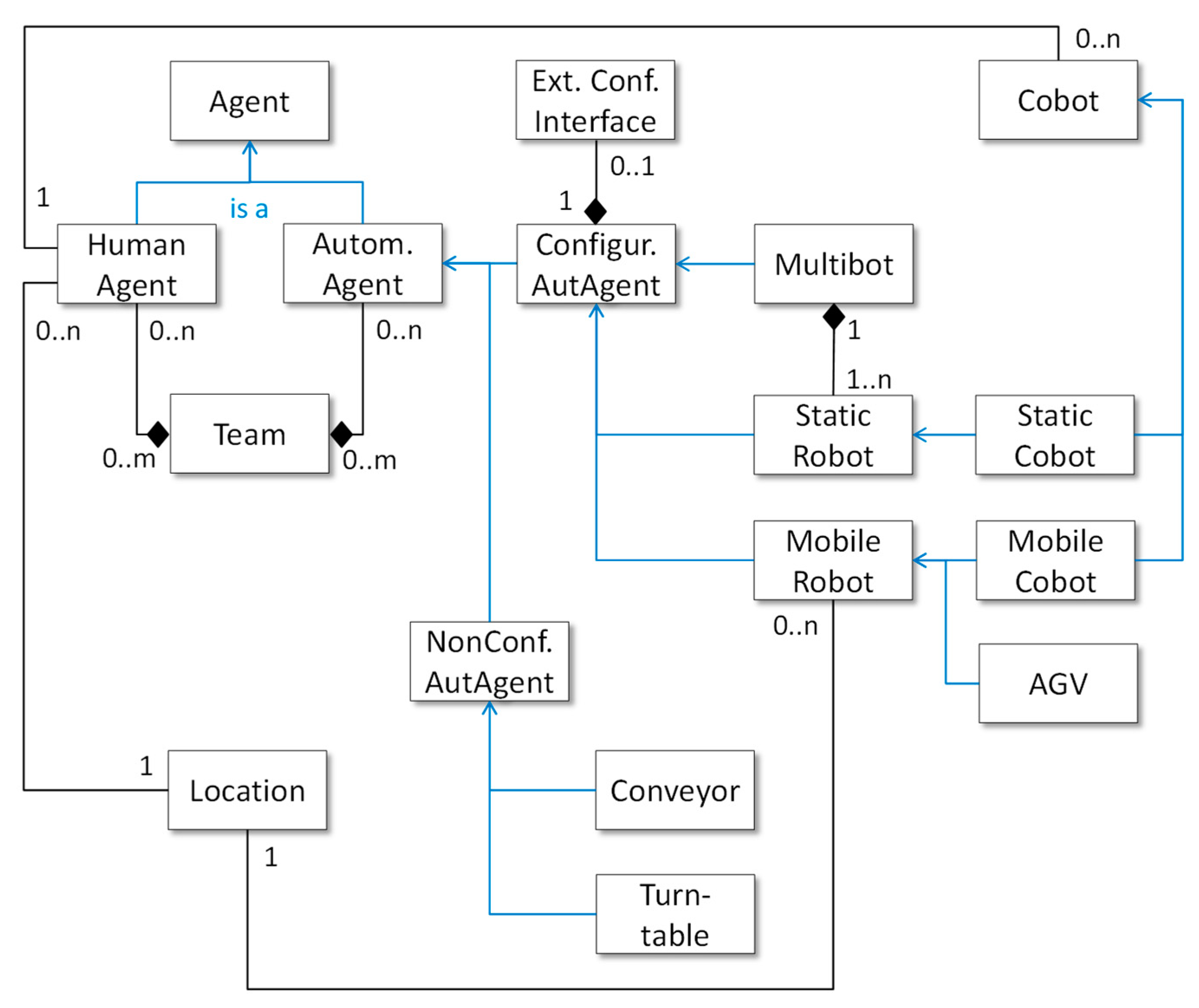

2.2. The HORSE Project

2.3. The OEDIPUS Project

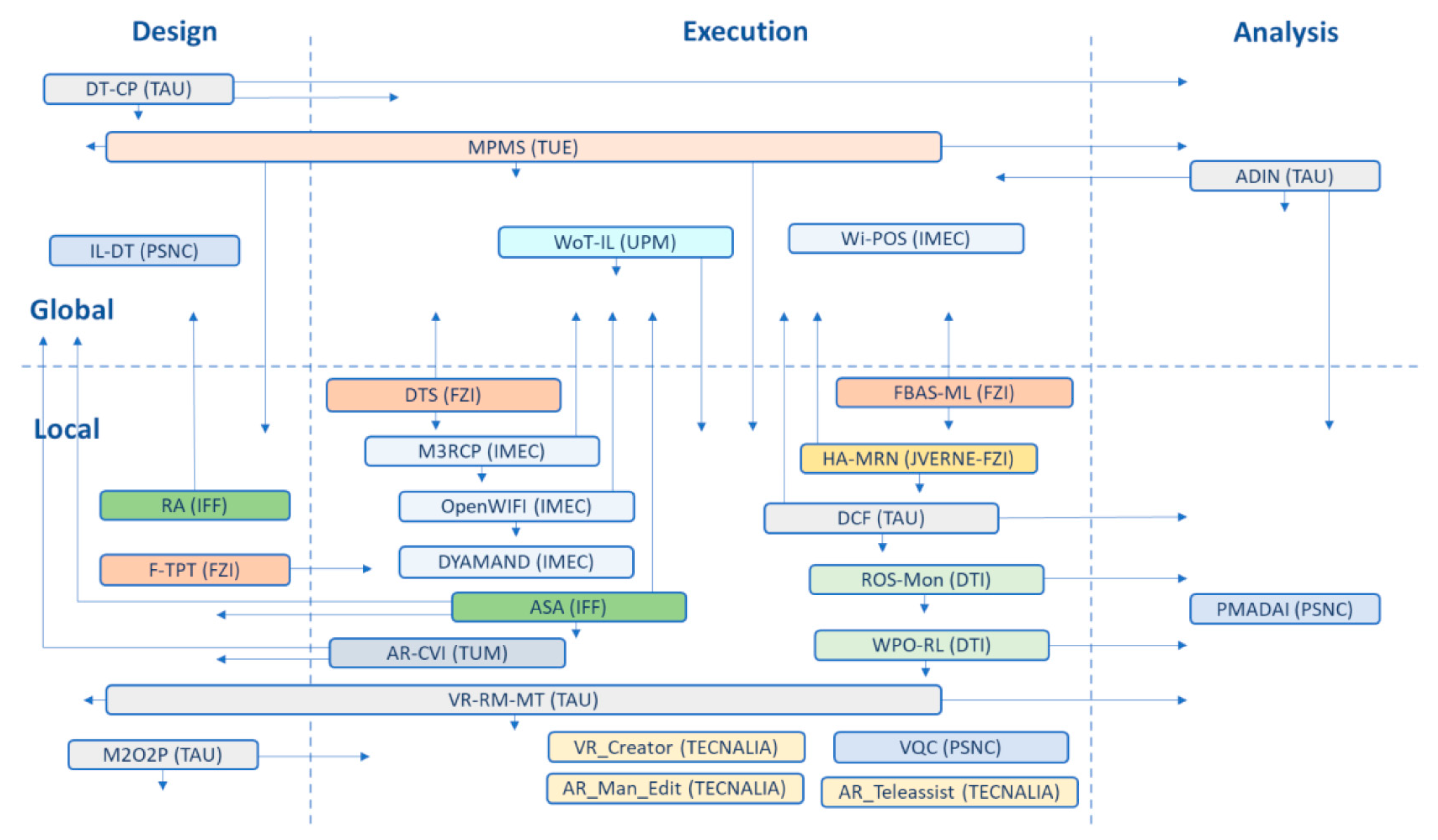

2.4. The SHOP4CF Project

3. The Layers Dimension Perspective

3.1. Internal Efficiency vs. Customer Value Perspective

3.2. The OT–IT Dichotomy

4. The Hierarchy Levels Dimension Perspective

4.1. Top-Down or Bottom-Up Design Strategy?

4.2. The Notion of Connected Factory

5. The Life Cycle and Value Stream Perspective

5.1. Unified Business Process Management as an Integrator

5.2. The Changing Role of Human Actors

6. Conclusions and Look Forward

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2017, 56, 508–517. [Google Scholar] [CrossRef]

- Industrie 4.0: Smart Manufacturing for the Future; Germany Trade & Invest: Berlin, Germany, 2014.

- Brouns, N. A New Industrial Era: Technologies, Characteristics, Frameworks and Applications; Eindhoven University of Technology: Eindhoven, The Netherlands, 2019. [Google Scholar]

- Urban Mobility in the Smart City Age—Smart Cities Cornerstone Series; Schneider Electric, ARUP, The Climate Group: London, UK, 2015.

- Jeschke, S.; Brecher, C.; Song, H.; Rawat, D. Industrial Internet of Things: Cybermanufacturing Systems; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Vasudevan, H.; Kottur, V.; Raina, A. Proceedings of International Conference on Intelligent Manufacturing and Automation; Springer Nature: Singapore, 2019. [Google Scholar]

- Evjemo, L.D.; Gjerstad, T.; Grøtli, E.I.; Sziebig, G. Trends in Smart Manufacturing: Role of Humans and Industrial Robots in Smart Factories. Curr. Robot. Rep. 2020, 1, 35–41. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Cecil, J. An Internet of Things (IoT)-based collaborative framework for advanced manufacturing. Int. J. Adv. Manuf. Technol. 2015, 84, 1141–1152. [Google Scholar] [CrossRef]

- Nee, A.Y.C.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Ann. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Smart manufacturing: Characteristics, technologies and enabling factors. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 233, 1342–1361. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Brox, J.A.; Fader, C. The set of just-in-time management strategies: An assessment of their impact on plant-level productivity and input-factor substitutability using variable cost function estimates. Int. J. Prod. Res. 2002, 40, 2705–2720. [Google Scholar] [CrossRef]

- Connerty, M.; Navales, E.; Kenney, C.; Bhatia, T. Manufacturing Companies Need to Sell Outcomes, Not Products. Harvard Business Review 2016. Available online: https://hbr.org/2016/06/manufacturing-companies-need-to-sell-outcomes-not-products (accessed on 29 October 2021).

- Grefen, P.; Wilbik, A.; Kuitems, F.; Blanken, M. Outcome-Based Business Design in IoT-Enabled Digital Supply Chain Trans-formation. In Proceedings of the IEEE International Conference on Internet of Things and Intelligence Systems, Bandung, Indonesia, 23–24 November 2021; IEEE: Piscataway, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Hankel, M.; Rexroth, B. The Reference Architectural Model Industrie 4.0 (RAMI4.0); German Electrical and Electronic Manufacturers’ Association: Frankfurt am Main, Germany, 2015. [Google Scholar]

- Enterprise-Control System Integration—Part 1: Models and Terminology, 2nd ed.; The International Electrotechnical Commission (IEC): Geneva, Switzerland, 2013.

- Cunningham, J.B. Case study principles for different types of cases. Qual. Quant. 1997, 31, 401–423. [Google Scholar] [CrossRef]

- Court, M.; Mills, A.; Durepos, G.; Wiebe, E. Encyclopedia of Case Study Research; Sage: Thousand Oaks, CA, 2010. [Google Scholar] [CrossRef]

- Baškarada, S. Qualitative Case Study Guidelines. Qual. Rep. 2014, 19, 1–18. [Google Scholar] [CrossRef]

- Grefen, P.; Mehandjiev, N.; Kouvas, G.; Weichhart, G.; Eshuis, R. Dynamic business network process management in instant virtual enterprises. Comput. Ind. 2009, 60, 86–103. [Google Scholar] [CrossRef]

- Grefen, P.; Eshuis, R.; Mehandjiev, N.; Kouvas, G.; Weichhart, G. Internet-based support for process-oriented instant virtual enterprises. IEEE Internet Comput. 2009, 13, 65–73. [Google Scholar] [CrossRef] [Green Version]

- Mehandjiev, M.; Grefen, P. Dynamic Business Process Formation for Instant Virtual Enterprises; Springer: London, UK, 2010. [Google Scholar]

- Grefen, P.; Mehandjiev, N.; Kouvas, G.; Weichhart, G.; Eshuis, R. Dynamic Business Network Process Management in Instant Virtual Enterprises; Beta Working Paper 198; Eindhoven University of Technology: Eindhoven, The Netherlands, 2007. [Google Scholar]

- HORSE. Available online: www.horse-project.eu (accessed on 5 November 2021).

- Traganos, K.; Grefen, P.; Vanderfeesten, I.; Erasmus, J.; Boultadakis, G.; Bouklis, P. The HORSE framework: A reference architecture for cyber-physical systems in hybrid smart manufacturing. J. Manuf. Syst. 2021, 61, 461–494. [Google Scholar] [CrossRef]

- Kruchten, P. Architectural Blueprints—The “4+1” View Model of Software Architecture. IEEE Softw. 1995, 12, 42–50. [Google Scholar] [CrossRef] [Green Version]

- Grefen, P.; Boultadakis, G. Designing an Integrated System for Smart Industry: The Development of the HORSE Architecture; In-dependently Published: Eindhoven, The Netherlands, 2021. [Google Scholar]

- Juelg, C.; Hermann, A.; Roennau, A.; Dillmann, R. Fast Online Collision Avoidance for Mobile Service Robots through Poten-tial Fields on 3D Environment Data Processed on GPUs. In Proceedings of the IEEE International Conference on Robotics and Biomimetics, Macao, China, 5–8 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 921–928. [Google Scholar]

- Erasmus, J.; Grefen, P.; Vanderfeesten, I.; Traganos, K. Smart Hybrid Manufacturing Control Using Cloud Computing and the Internet-of-Things. Machines 2018, 6, 62. [Google Scholar] [CrossRef] [Green Version]

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Keulen, R.; Grefen, P. The HORSE Project: The Application of Business Process Management for Flexibility in Smart Manufacturing. Appl. Sci. 2020, 10, 4145. [Google Scholar] [CrossRef]

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Grefen, P. Using business process models for the specification of manufacturing operations. Comput. Ind. 2020, 123, 103297. [Google Scholar] [CrossRef]

- Operate European Digital Industry with Products and Services; OEDIPUS Fact Sheet; EIT Digital: Brussels, Belgium, 2017.

- Traganos, K.; Vanderfeesten, I.; Grefen, P.; Erasmus, J.; Gerrits, T.; Verhofstad, W. End-to-End Production Process Orchestration for Smart Printing Factories: An Application in Industry. In Proceedings of the 2020 IEEE 24th International Enterprise Distributed Object Computing Conference (EDOC), Eindhoven, The Netherlands, 5–8 October 2020; pp. 155–164. [Google Scholar] [CrossRef]

- Traganos, K.; Spijkers, D.; Grefen, P.; Vanderfeesten, I. Dynamic Process Synchronization Using BPMN 2.0 to Support Buffering and (Un)Bundling in Manufacturing. In Business Process Management Forum; Springer: Cham, Switzerland, 2020; pp. 18–34. [Google Scholar] [CrossRef]

- SHOP4CF. Available online: https://shop4cf.eu/ (accessed on 20 October 2021).

- L4MS: Smart Logistics for Manufacturing. Available online: http://www.l4ms.eu/content/l4ms-project-home (accessed on 20 October 2021).

- Zimniewicz, M. SHOP4CF Architecture (SHOP4CF Public Deliverable D3.2); SHOP4CF Consortium: Munich, Germany, 2020. [Google Scholar]

- Grefen, P. Service-Dominant Business Engineering with BASE/X: Business Modeling Handbook; CreateSpace Independent Publishing Platform: Seattle, WA, USA, 2015; ISBN 978-1516942176. [Google Scholar]

- Turetken, O.; Grefen, P.; Gilsing, R.; Adali, O.E. Service-Dominant Business Model Design for Digital Innovation in Smart Mobility. Bus. Inf. Syst. Eng. 2018, 61, 9–29. [Google Scholar] [CrossRef] [Green Version]

- Kazantsev, N.; Martens, I. Industry 4.0 Digital Platforms: Collaborative Business Models for SMEs. In Digital Business Models in Industrial Ecosystems; Springer Nature: Cham, Switzerland, 2021. [Google Scholar]

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in Smart Manufacturing: Research Challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef] [Green Version]

- Steenstrup, K. Operational Technology Convergence with IT: Definitions; Gartner: Stamford, CT, USA, 2010. [Google Scholar]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Lu, Y.; Morris, K.C.; Frechette, S. Current Standards Landscape for Smart Manufacturing Systems; NISTIR 8107; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016; 39p. [Google Scholar] [CrossRef]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- The Connected Factory. Available online: https://www.manufacturingtomorrow.com/article/2018/01/the-connected-factory/10819 (accessed on 29 October 2021).

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Grefen, P. The Case for Unified Process Management in Smart Manufacturing. In Proceedings of the 2018 IEEE 22nd International Enterprise Distributed Object Computing Conference (EDOC), Stockholm, Sweden, 16–19 October 2018; pp. 218–227. [Google Scholar] [CrossRef]

- Erasmus, J. The Application of Business Process Management in Smart Manufacturing: Towards Dynamic Allocation of Manufacturing Resources; Eindhoven University of Technology: Eindhoven, The Netherlands, 2019. [Google Scholar]

- Drexl, A.; Kimms, A. Beyond Manufacturing Resource Planning (MRP II); Springer: Berlin, Germany, 1998. [Google Scholar]

- Chui, M.; Manyika, J.; Miremadi, M.; George, K. Human + Machine: A New Era of Automation in Manufacturing; McKinsey: San Francisco, CA, USA, 2017. [Google Scholar]

- El Zaatari, S.; Marei, M.; Li, W.; Usman, Z. Cobot programming for collaborative industrial tasks: An overview. Robot. Auton. Syst. 2019, 116, 162–180. [Google Scholar] [CrossRef]

- Vanderfeesten, I.; Grefen, P. Advanced Dynamic Role Resolution in Business Processes. In Advanced Information Systems Engineering Workshops; Springer: Cham, Switzerland, 2015; pp. 87–93. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-centric and Resilient European Industry. Policy Brief; R&I Paper Series; European Union: Luxembourg, 2021. [Google Scholar]

| Dimension | Aspect | Main Learnings |

|---|---|---|

| Layers | Balancing internal efficiency and external value | The emphasis is often too much on internal efficiency. Analyze business strategy and business model early in innovation projects. |

| Handling the OT–IT dichotomy | Systems are poorly vertically integrated. Connect them by shared concept and data models and a clear middleware approach. Use standards. | |

| Hierarchy levels | Choosing between top-down and bottom-up design | Both strategies have their pros and cons. Make explicit choices, led by a well-qualified, independent architect. |

| Understanding the concept of the connected factory | There are two different interpretations with OT and IT perspectives, respectively. Be innovative. Make choices clear and explicit in an innovation effort. | |

| Life cycle and value stream | Applying unified manufacturing process management | Functions are too separated. Consider unified business process management as an integrator, link to planning functions. |

| Dealing with the changing role of human actors in the factory | The gap between human and robotic actors is fading. Treat both types of actors in a common framework to enable flexibility. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grefen, P.; Vanderfeesten, I.; Traganos, K.; Domagala-Schmidt, Z.; van der Vleuten, J. Advancing Smart Manufacturing in Europe: Experiences from Two Decades of Research and Innovation Projects. Machines 2022, 10, 45. https://doi.org/10.3390/machines10010045

Grefen P, Vanderfeesten I, Traganos K, Domagala-Schmidt Z, van der Vleuten J. Advancing Smart Manufacturing in Europe: Experiences from Two Decades of Research and Innovation Projects. Machines. 2022; 10(1):45. https://doi.org/10.3390/machines10010045

Chicago/Turabian StyleGrefen, Paul, Irene Vanderfeesten, Kostas Traganos, Zuzanna Domagala-Schmidt, and Julia van der Vleuten. 2022. "Advancing Smart Manufacturing in Europe: Experiences from Two Decades of Research and Innovation Projects" Machines 10, no. 1: 45. https://doi.org/10.3390/machines10010045

APA StyleGrefen, P., Vanderfeesten, I., Traganos, K., Domagala-Schmidt, Z., & van der Vleuten, J. (2022). Advancing Smart Manufacturing in Europe: Experiences from Two Decades of Research and Innovation Projects. Machines, 10(1), 45. https://doi.org/10.3390/machines10010045