Dynamic Modeling and Analysis of Nonlinear Compound Planetary System

Abstract

1. Introduction

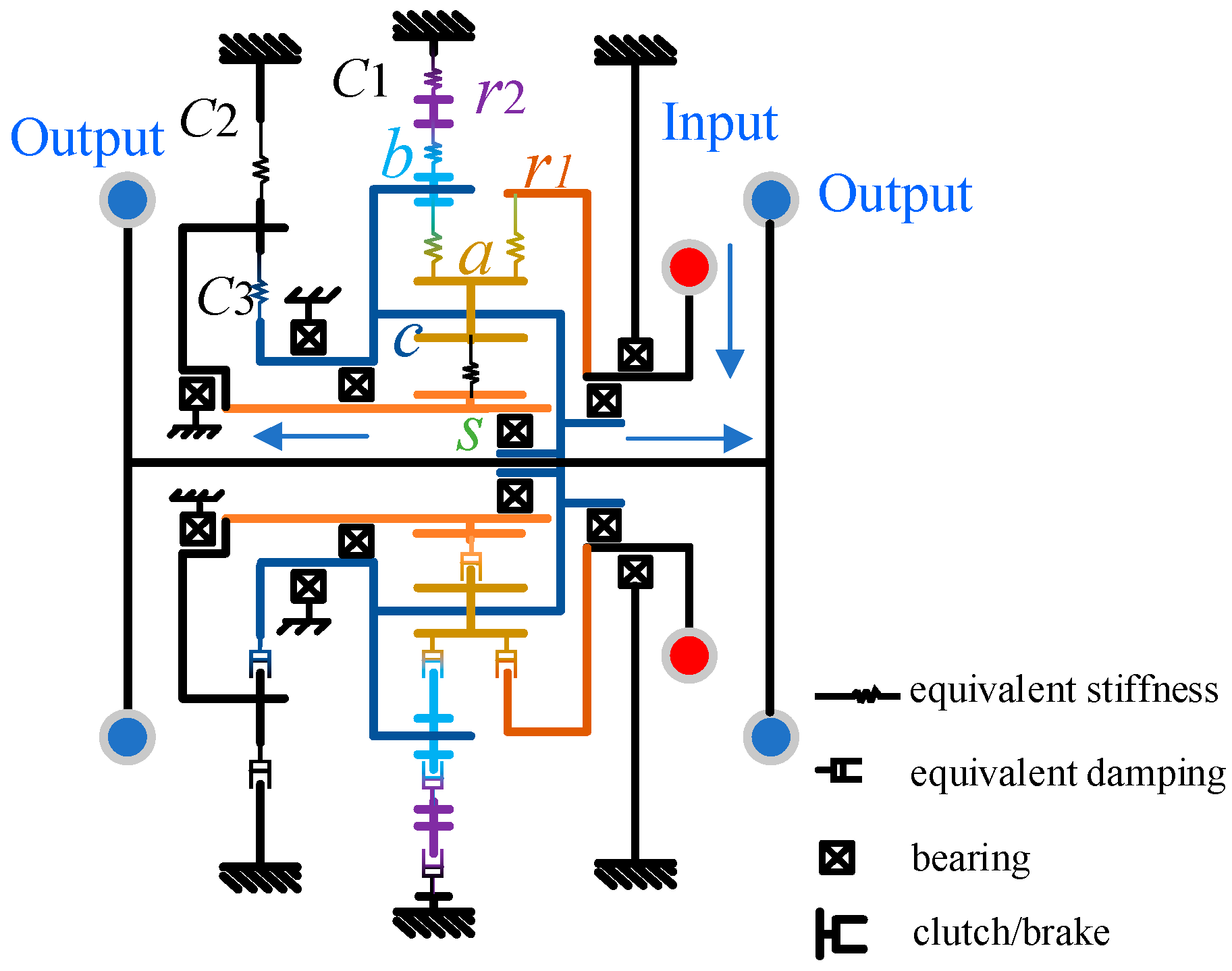

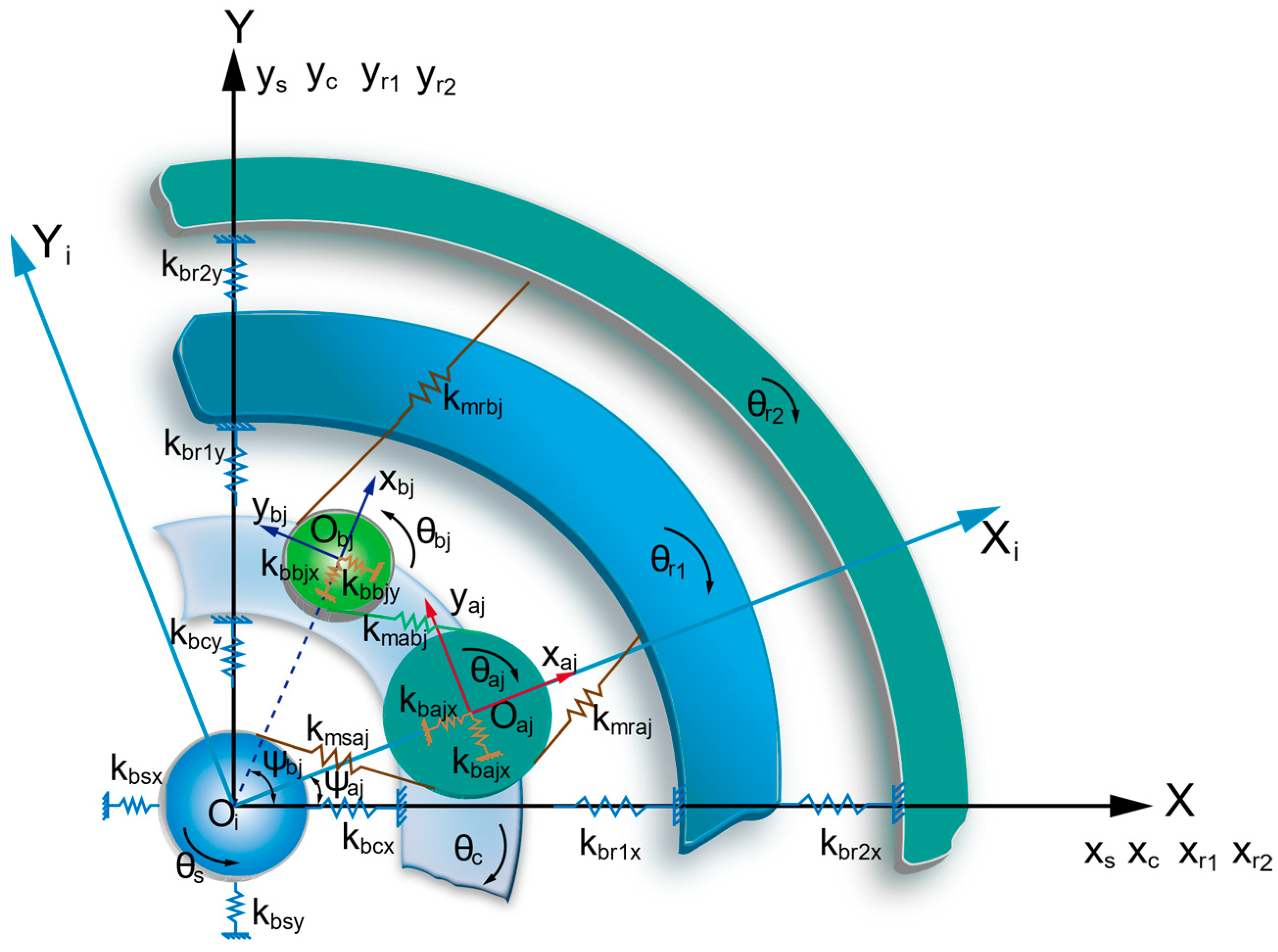

2. Dynamic Model for Compound Planetary System

2.1. Model Description

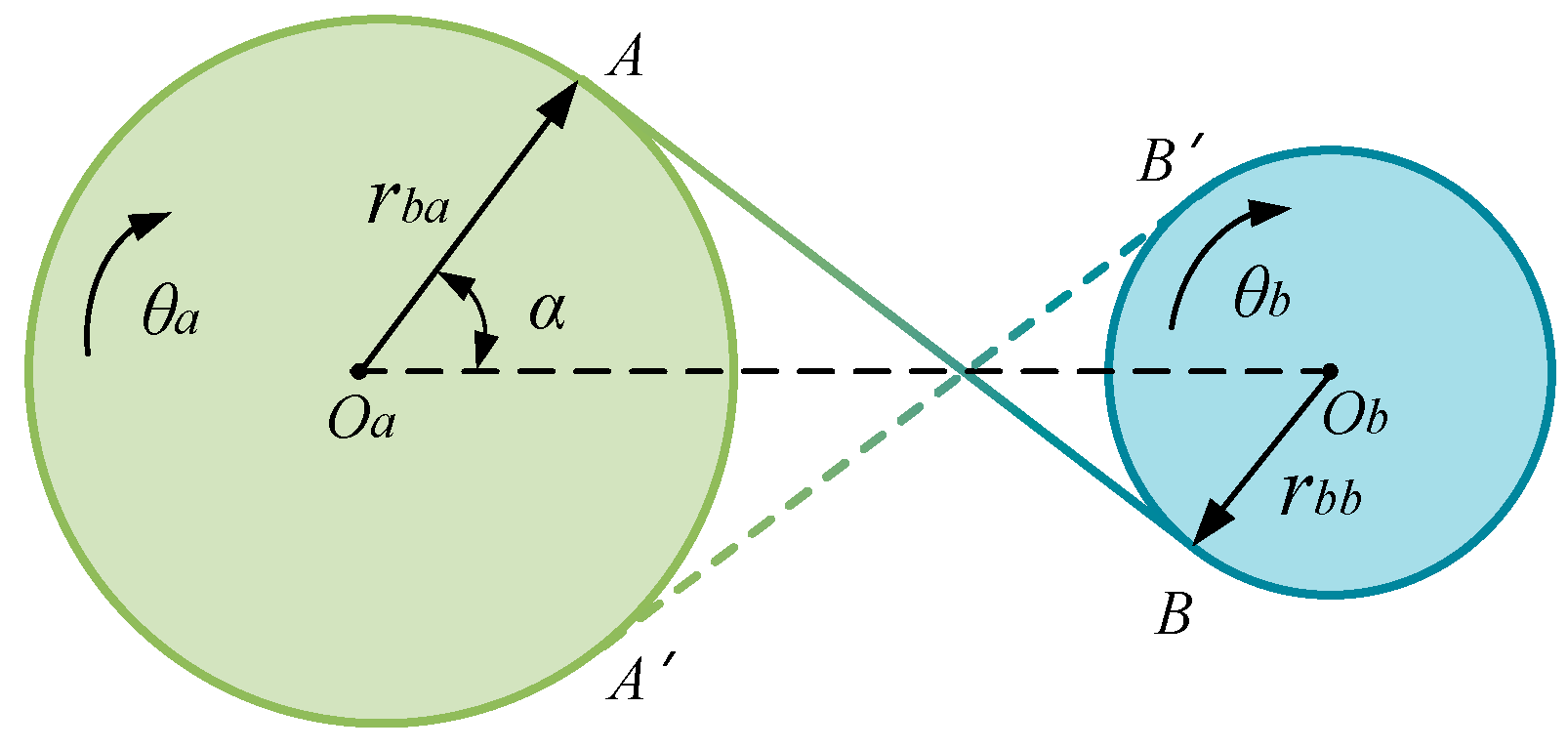

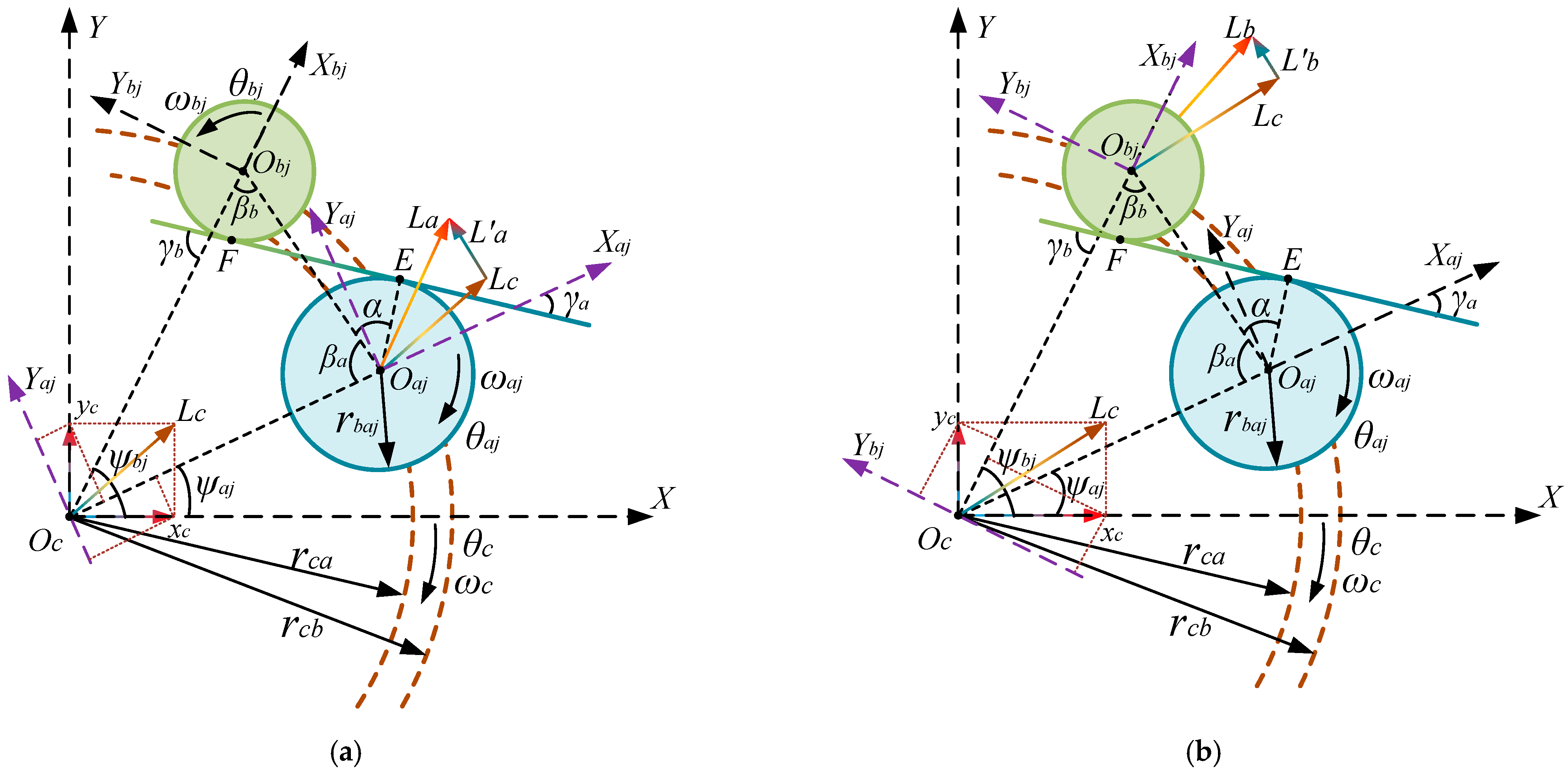

2.2. The Deformation of Meshing Planetary Gears

2.3. Internal Nonlinear Excitation

2.4. External Nonlinear Excitation

2.5. Nonlinear Flexural and Torsional Coupling Dynamics Equation of the System

3. Dynamic Characteristic Analysis

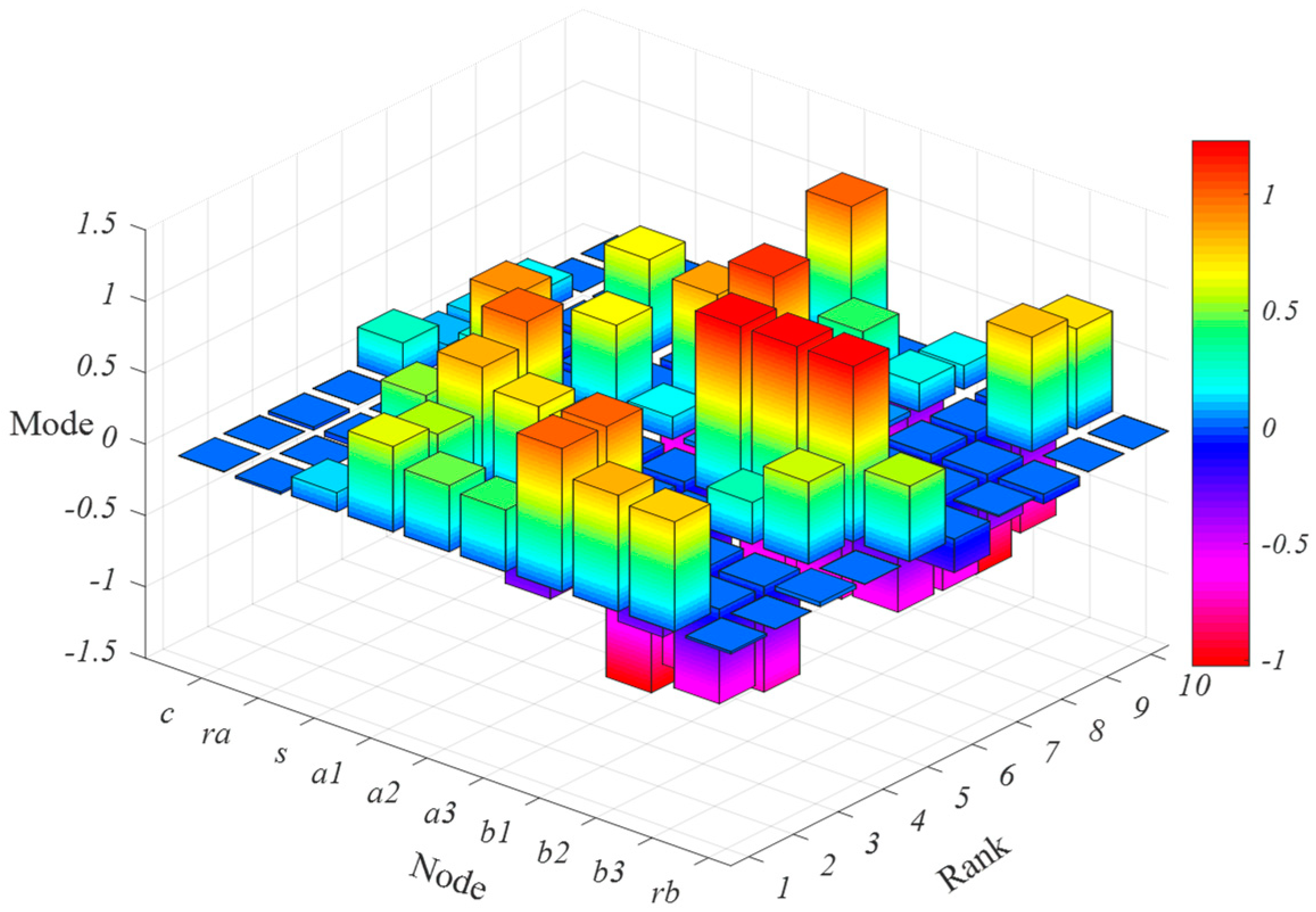

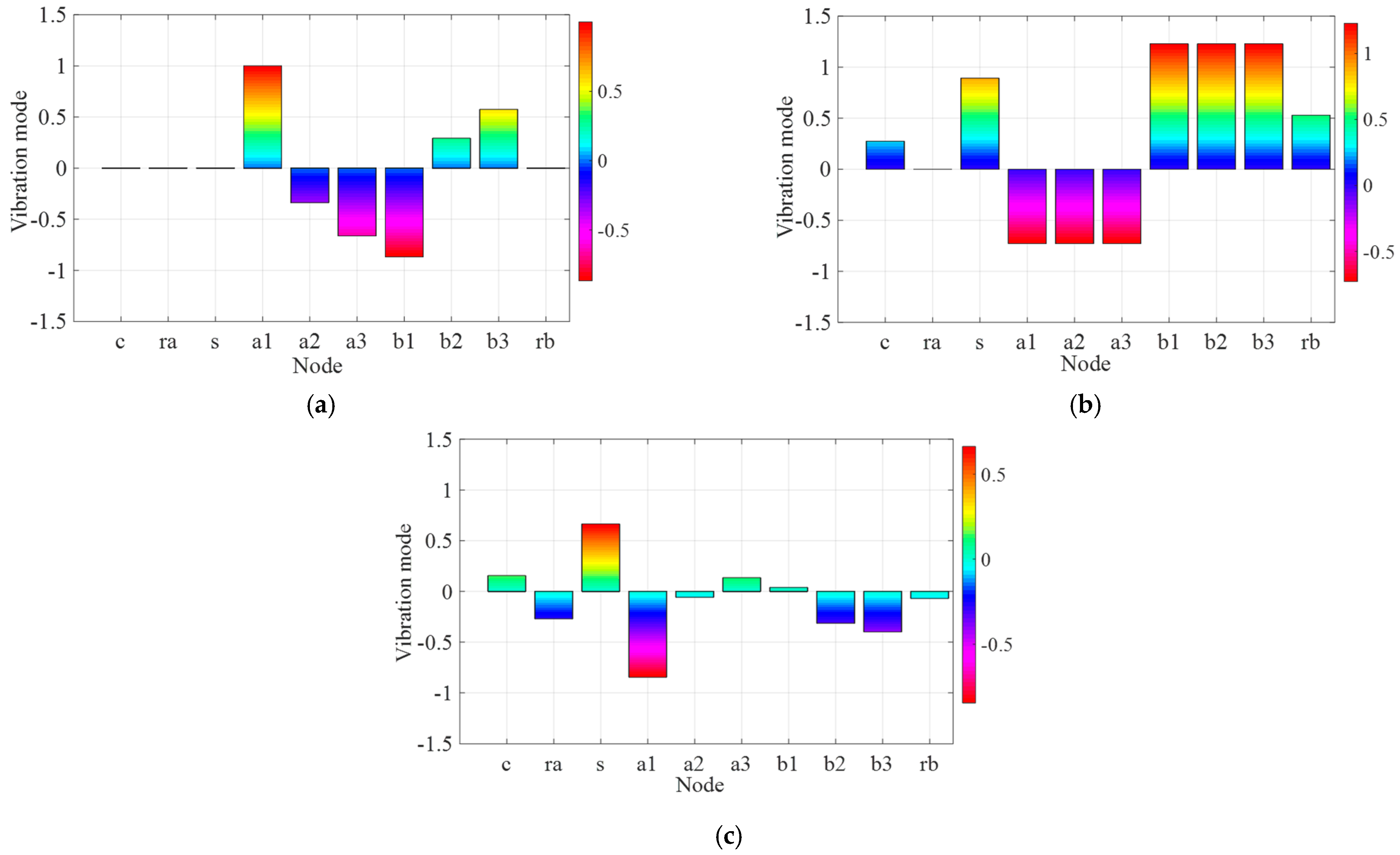

3.1. The Inherent Characteristics

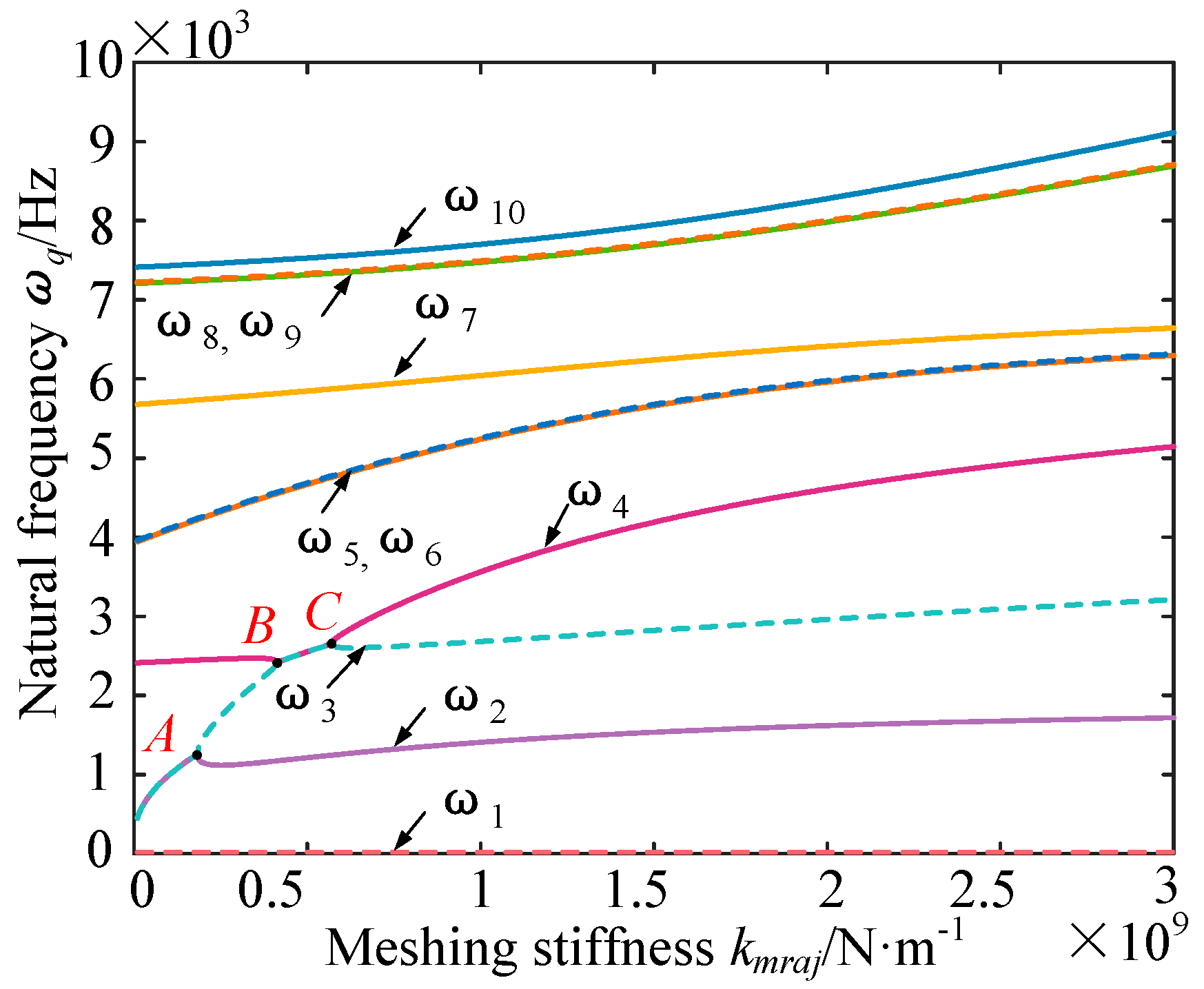

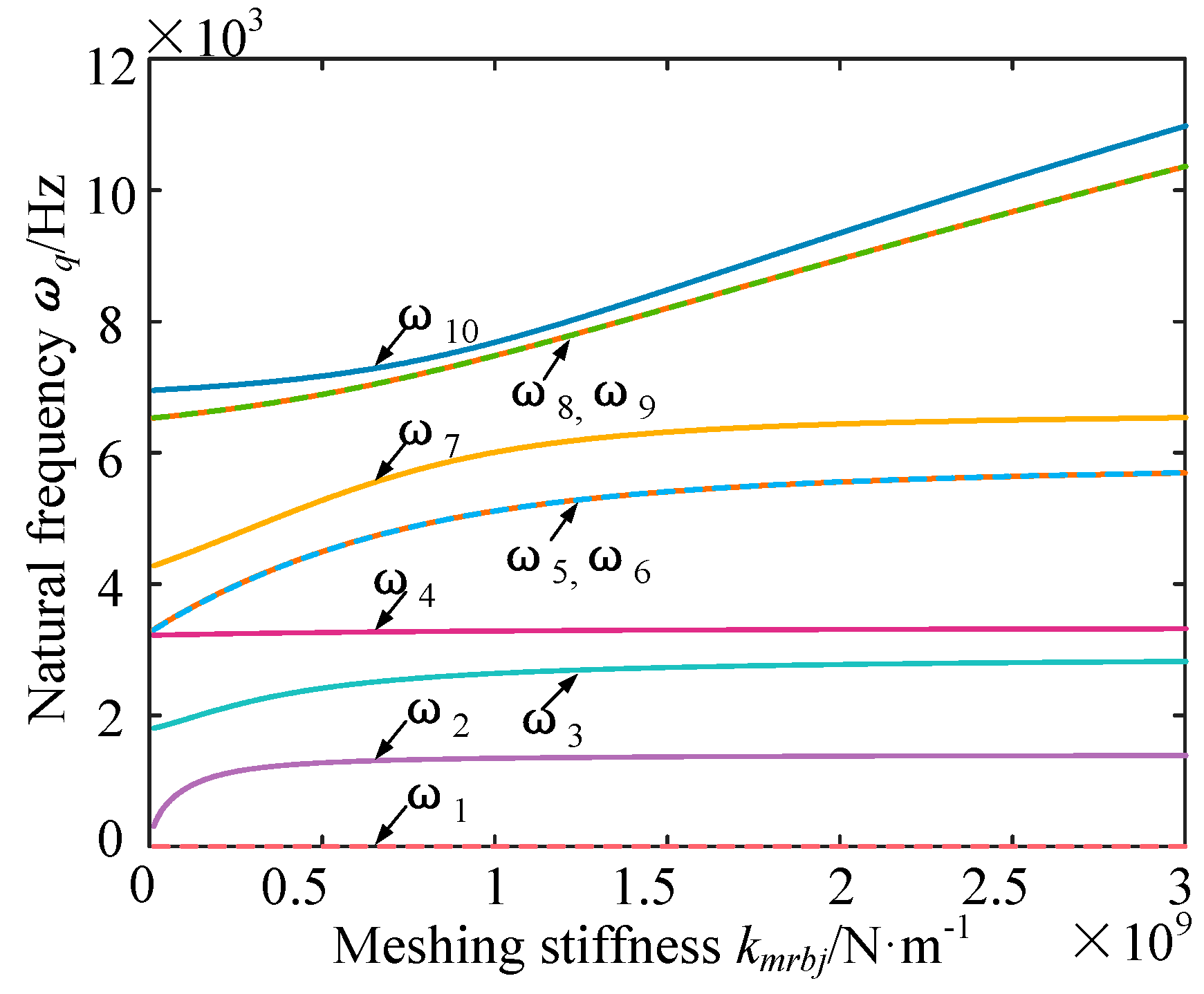

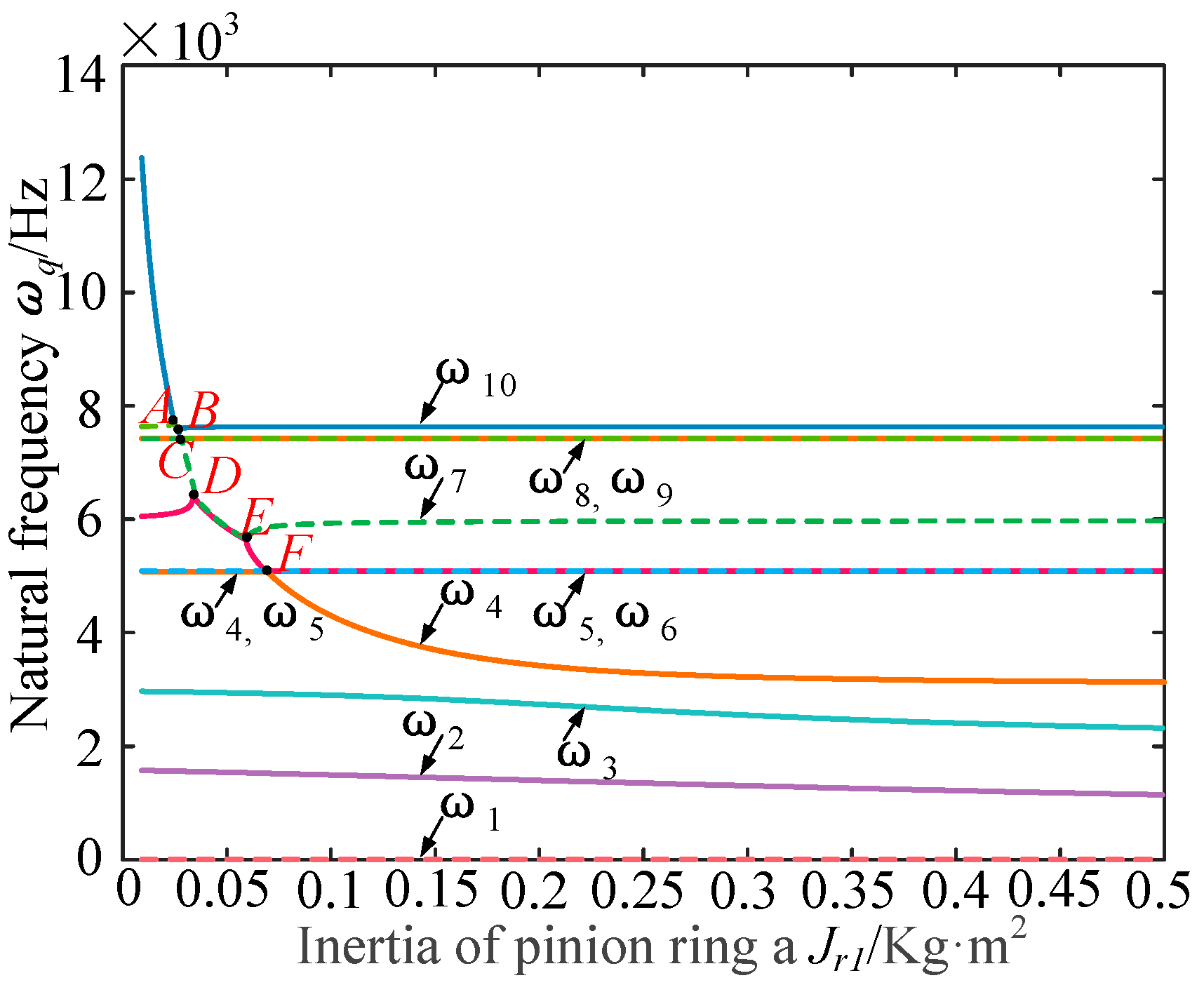

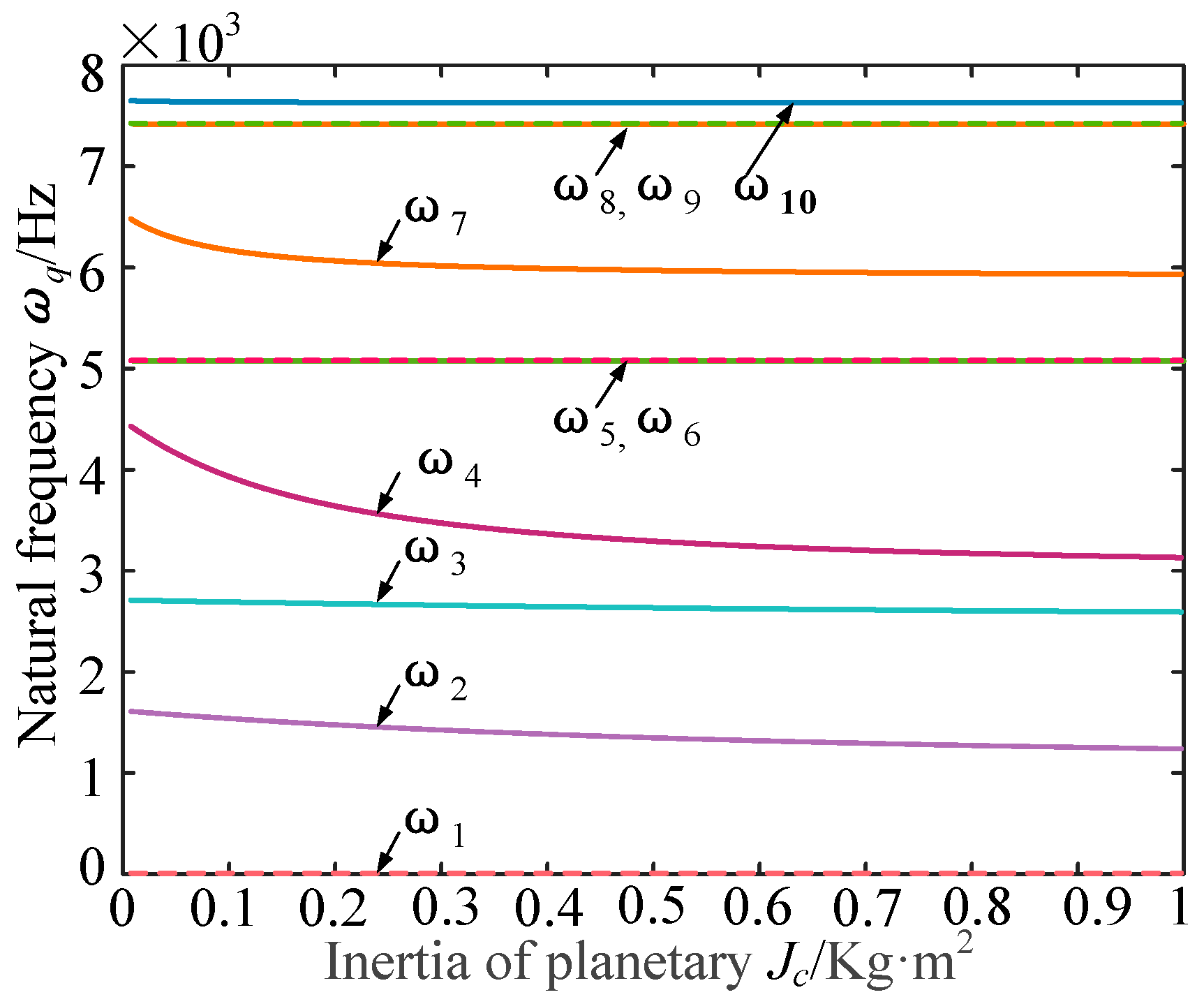

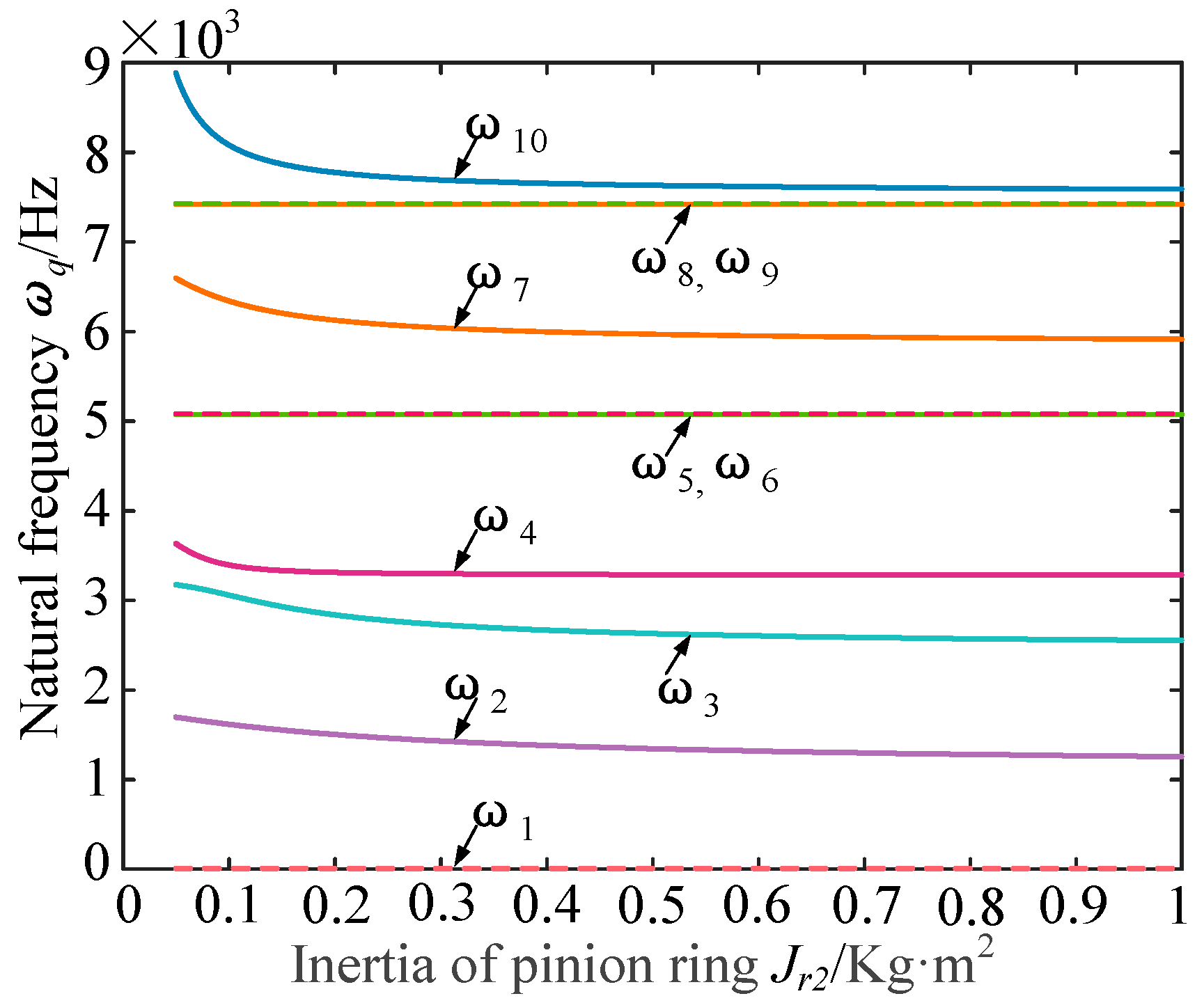

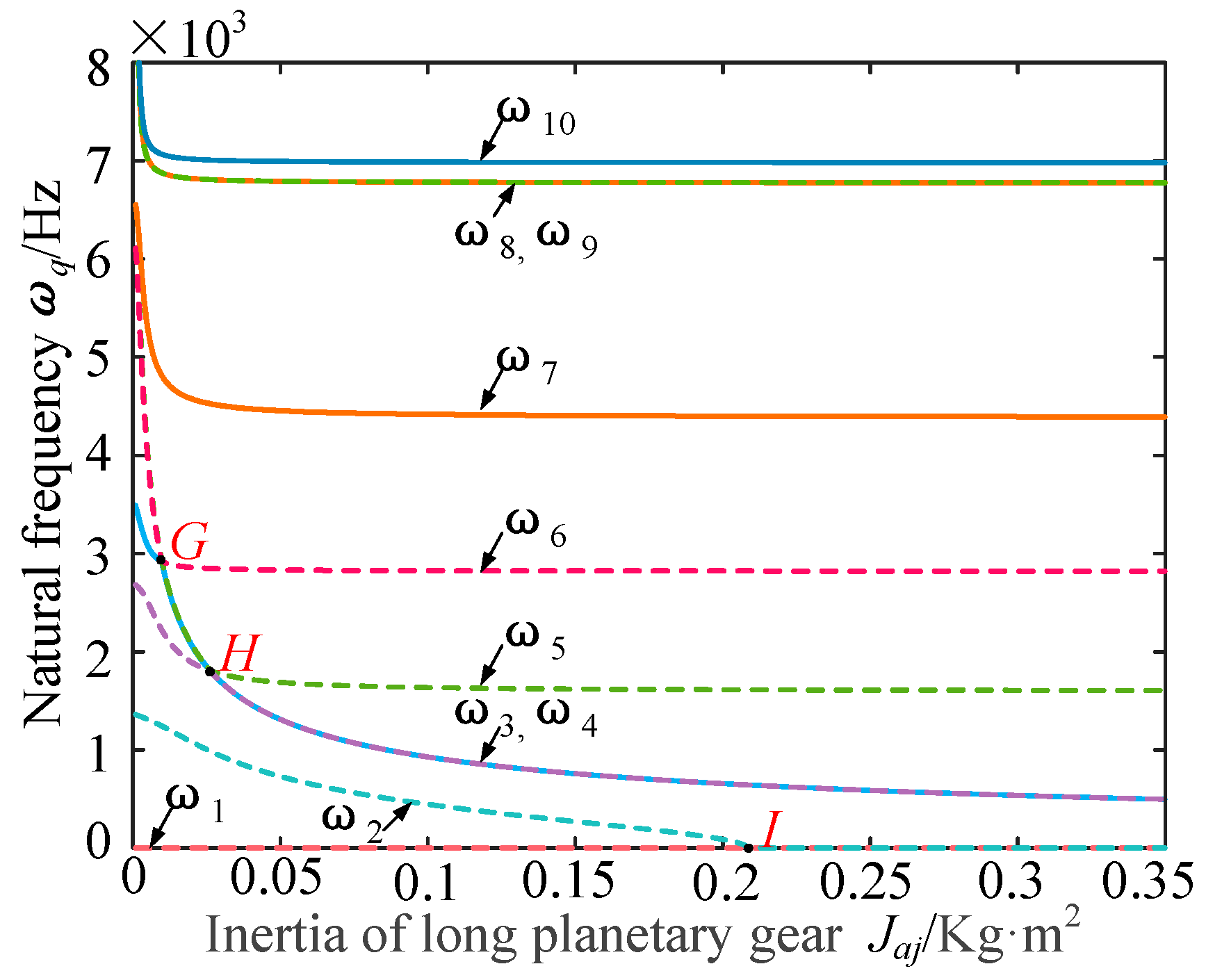

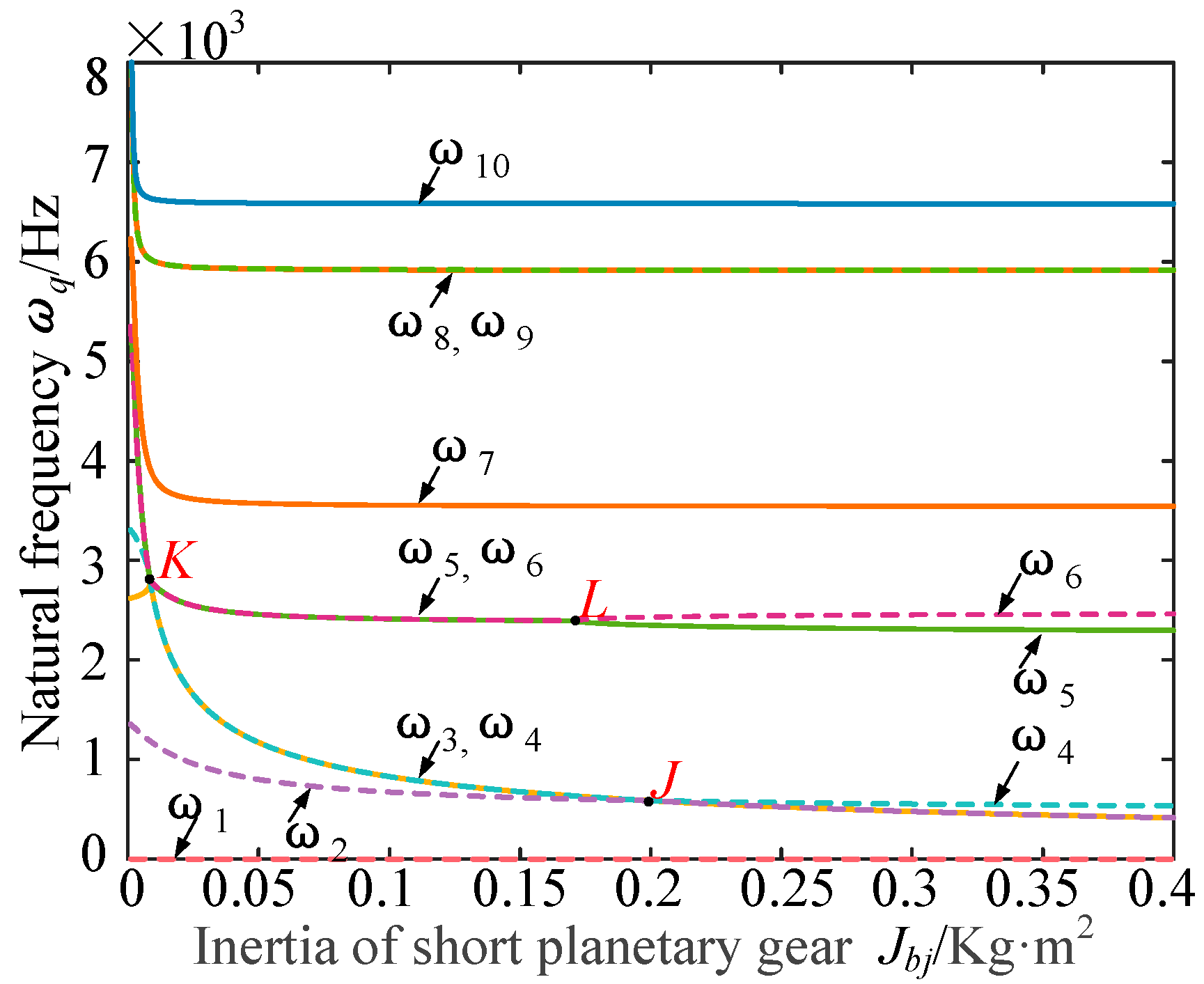

3.2. The Natural Frequency Varies with the Trajectory of Stiffness and Inertia

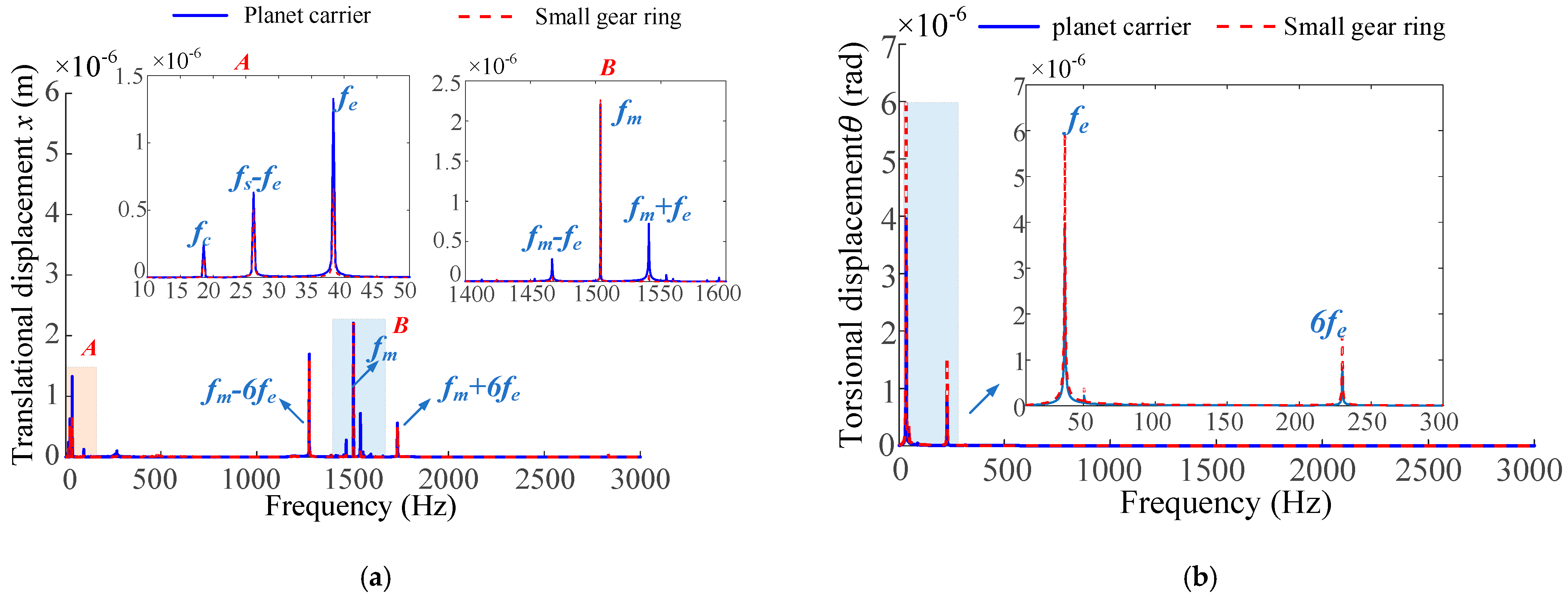

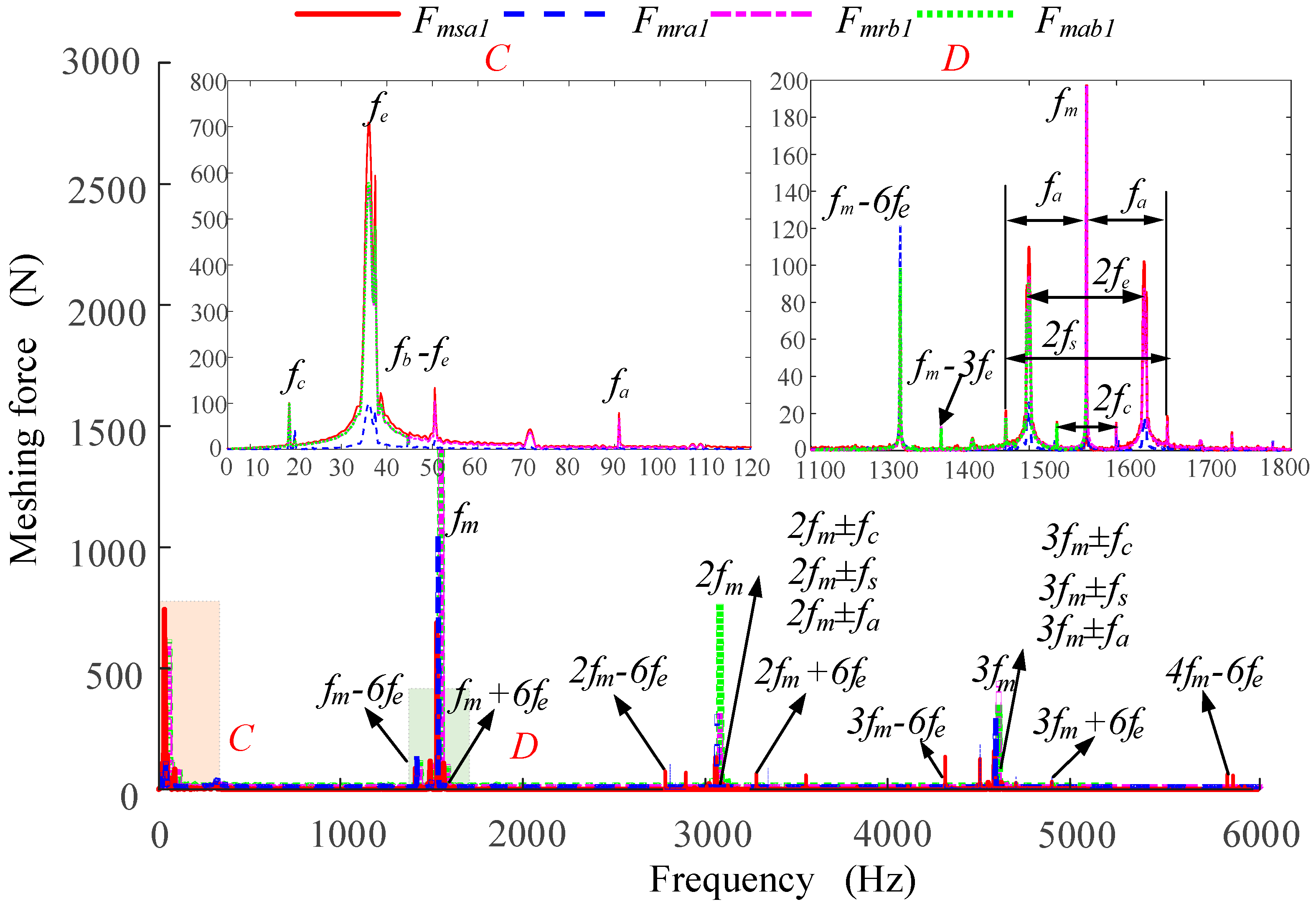

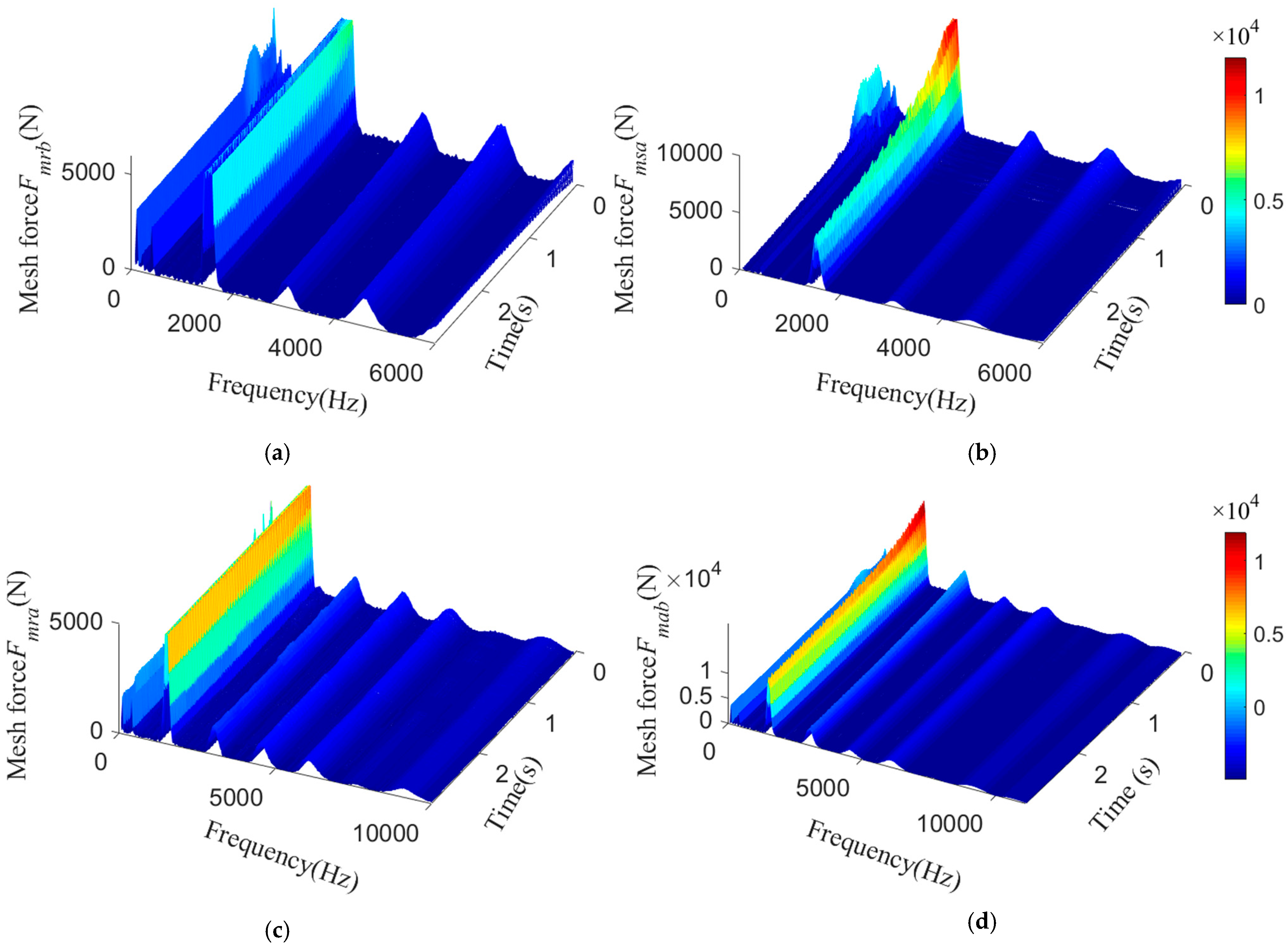

3.3. Time-Frequency Characteristic Analysis of System Coupling Response

4. Verification of Model Accuracy

4.1. Comparison of Natural Frequency

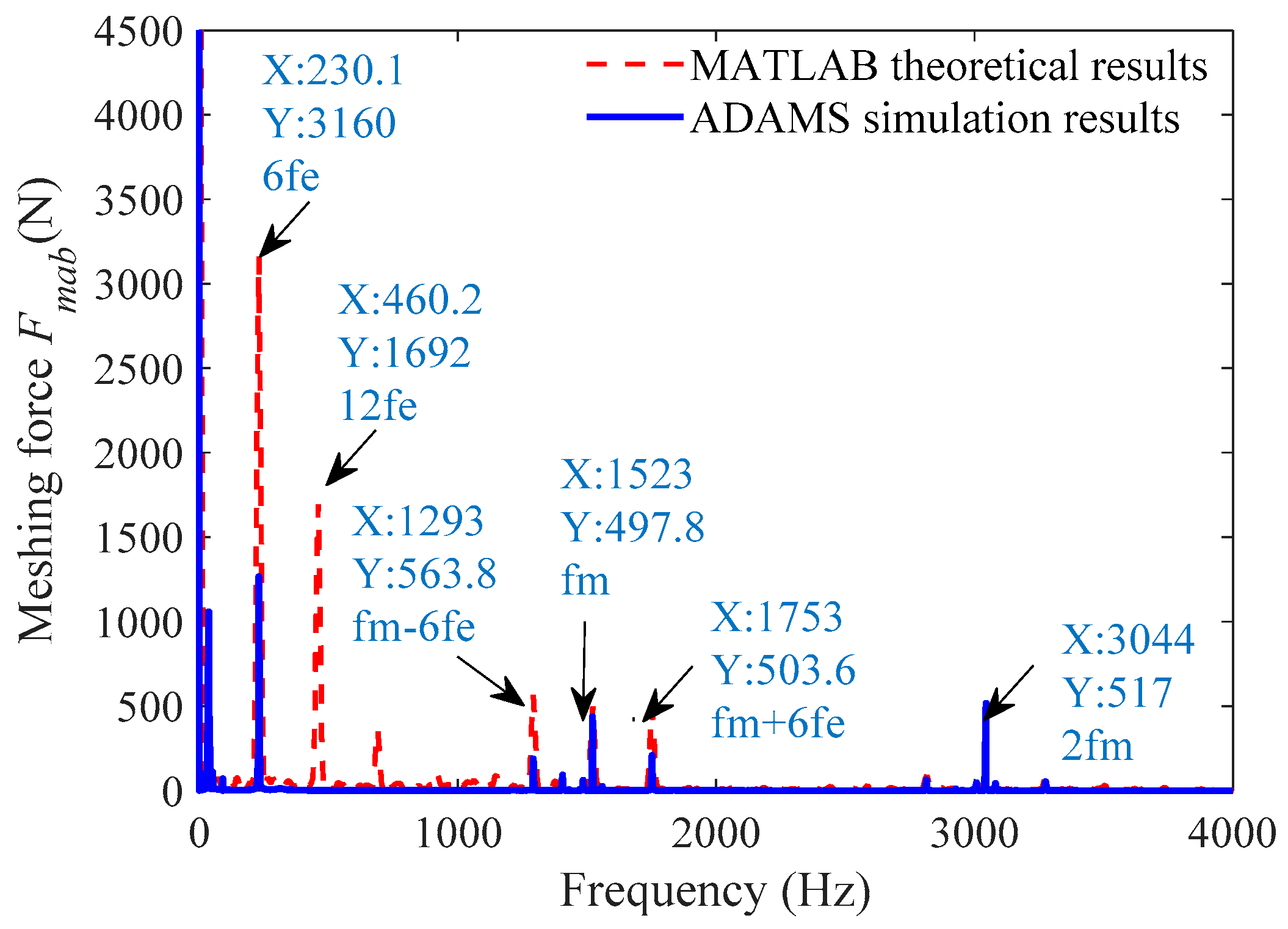

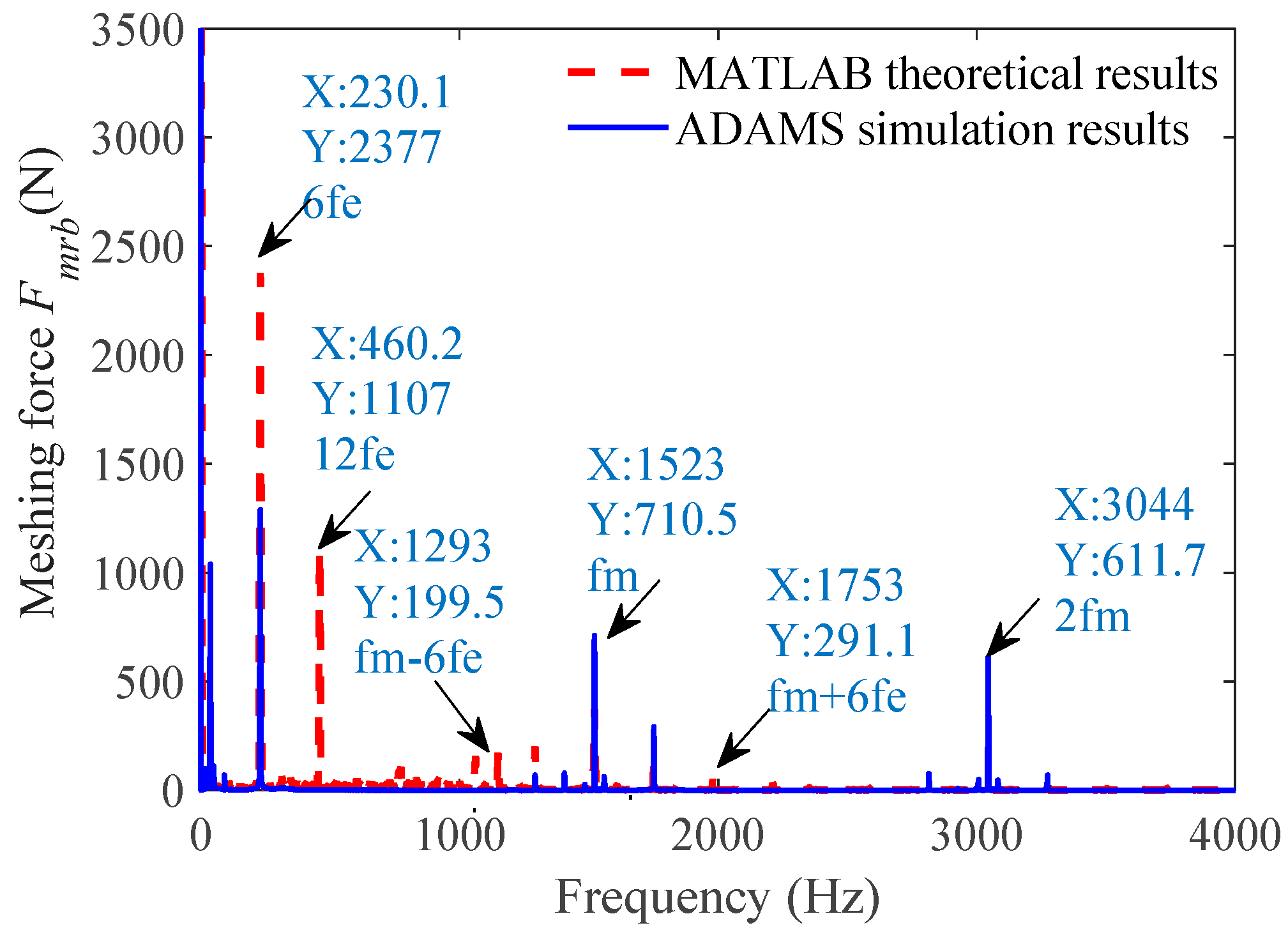

4.2. Comparison of Meshing Force

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ambarisha, V.K.; Parker, R.G. Nonlinear dynamics of planetary gears using analytical and finite element models. J. Sound Vib. 2007, 302, 577–595. [Google Scholar] [CrossRef]

- Sun, T.; Hu, H. Nonlinear dynamics of planetary gear transmission by harmonic balance method based on DFT. Chin. J. Mech. Eng. 2002, 38, 58–61. [Google Scholar] [CrossRef]

- Yi, G.; Parker, G.R. Dynamic modeling and analysis of a spur planetary gear involving tooth wedging and bearing clearance nonlinearity. Eur. J. Mech.-A/Solids 2010, 29, 1022–1033. [Google Scholar]

- Guo, Y.; Keller, J.; Parker, R.G. Nonlinear dynamics and stability of wind turbine planetary gear sets under gravity effects. Eur. J. Mech.-A/Solids 2014, 47, 45–57. [Google Scholar] [CrossRef]

- Woohyung Kim, J.Y.L.J. Dynamic analysis for a planetary gear with time-varying pressure angles and contact ratios. J. Sound Vib. 2012, 331, 883–901. [Google Scholar]

- Zhou, J.; Sun, W.; Cao, L.; Wen, G. Vibro-Impact characteristics of planetary gear transmission. J. Xi’an Jiaotong Univ. 2016, 50, 16–21. [Google Scholar]

- Liu, H.; Cai, Z.; Xiang, C. Frequency coupling and dynamic characteristics of nonlinear meshing force for two-stage planetary gears. J. Vib. Shock 2015, 34, 13–23. [Google Scholar]

- Liu, C.; Qin, D.; Lim, T.C.; Liao, Y. Dynamic characteristics of the herringbone planetary gear set during the variable speed process. J. Sound Vib. 2014, 333, 6498–6515. [Google Scholar] [CrossRef]

- Lin, J.; Parker, R.G. Analytical Characterization of the Unique Properties of Planetary Gear Free Vibration. J. Vib. Acoust. 1999, 121, 316–321. [Google Scholar] [CrossRef]

- Kahraman, A. Natural Modes of Planetary Gear Trains. J. Sound Vib. 1994, 173, 125–130. [Google Scholar] [CrossRef]

- Peng, D.; Smith, W.A.; Randall, R.B.; Peng, Z. Use of mesh phasing to locate faulty planet gears. Mech. Syst. Signal Process. 2019, 116, 12–24. [Google Scholar] [CrossRef]

- Qiu, X.; Han, Q.; Chu, F. Review on Dynamic Analysis of Wind Turbine Geared Transmission Systems. J. Mech. Eng. 2014, 50, 23–36. [Google Scholar] [CrossRef]

- Xiang, L.; Gao, N.; Tang, L.; Guo, P. Nonlinear dynamic features of wind turbine’s gear systems subjected to internal and external excitations. Zhendong Yu Chongji/J. Vib. Shock 2018, 37, 126–132. [Google Scholar]

- Bozca, M. Kinematic analysis of a semi-rigid-elastic multi-body torsional vibration model of gears system. In Proceedings of the 12th International Carpathian Control Conference (ICCC), Velké Karlovice, Czech Republic, 25–28 May 2011; pp. 37–41. [Google Scholar]

- Zhang, J.; Liu, X.; Jiao, Y.; Song, Y. Vibration Analysis of Planetary Gear Trains Based on a Discrete-continuum Dynamic Model. J. Mech. Eng. 2014, 50, 104–112. [Google Scholar] [CrossRef]

- Qin, D.; Long, W.; Yang, J.; Zhou, H. Dynamic characteristics of wind turbine transmission system under varying wind speed and operation control conditions. J. Mech. Eng. 2012, 48, 1–8. [Google Scholar] [CrossRef]

- Dou, Z.; Li, Y.; Zeng, Z.; Du, M.; Yang, Y. Frequency coupling and coupling resonance of a composite planetary transmission system under complex excitations. J. Vib. Shock 2019, 3, 16–23. [Google Scholar]

- Wu, S.; Ren, H.; Zhu, E.; Wang, X.; Xu, Q.; Qian, B. Research advances for dynamics of planetary gear trains. Eng. J. Wuhan Univ. 2010, 43, 398–403. [Google Scholar]

- Wang, J.; Qin, D.; Ding, Y. Dynamic behavior of wind turbine by a mixed flexible-rigid multi-body model. J. Syst. Des. Dyn. 2009, 3, 403–419. [Google Scholar] [CrossRef][Green Version]

- Li, G.; Li, F.; Zhu, Z. Simulation of dynamic characteristics of compound planetary gear trains. J. Cent. South Univ. (Sci. Technol.) 2015, 46, 1635–1640. [Google Scholar]

- Zhu, C.; Xu, X.; Lim, T.C.; Du, X.; Liu, M. Effect of flexible pin on the dynamic behaviors of wind turbine planetary gear drives. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2013, 227, 74–86. [Google Scholar] [CrossRef]

- Inalpolat, M.; Kahraman, A. A dynamic model to predict modulation sidebands of a planetary gear set having manufacturing errors. J. Sound Vib. 2010, 329, 371–393. [Google Scholar] [CrossRef]

- Chaari, F.; Fakhfakh, T.; Hbaieb, R.; Louati, J.; Haddar, M. Influence of manufacturing errors on the dynamic behavior of planetary gears. Int. J. Adv. Manuf. Technol. 2006, 27, 738–746. [Google Scholar] [CrossRef]

- Zhang, C.; Wei, J.; Wang, F.; Hou, S. Dynamic model and load sharing performance of planetary gear system with journal bearing. Mech. Mach. Theory 2020, 151, 1–22. [Google Scholar] [CrossRef]

- Gu, X.; Velex, P. A dynamic model to study the influence of plant position errors in planetary gears. J. Sound Vib. 2012, 331, 4554–4574. [Google Scholar] [CrossRef]

- Li, T.; Zhu, R.; Bao, H.; Xiang, C.; Liu, H. Nonlinear torsional vibration modeling and bifurcation characteristic study of a planetary gear train. J. Mech. Eng. 2011, 47, 76–83. [Google Scholar] [CrossRef]

- Ryali, L.; Talbot, D. A dynamic load distribution model of planetary gear sets. Mech. Mach. Theory 2020, 158, 104229. [Google Scholar] [CrossRef]

- Mo, S.; Zhang, T.; Jin, G.; Cao, X.; Gao, H. Analytical investigation on load sharing characteristics of herringbone planetary gear train with flexible support and floating sun gear. Mech. Mach. Theory 2020, 144, 1–27. [Google Scholar]

- Sanchez-Espiga, J.; Fernandez-Del-Rincon, A.; Iglesias, M.; Viadero, F. Planetary gear transmissions load sharing measurement from tooth root strains: Numerical evaluation of mesh phasing influence. Mech. Mach. Theory 2021, 163, 104370. [Google Scholar] [CrossRef]

- Iglesias, M.; Fernandez, D.; De-Juan, A.; Garcia, P.; Diez-Ibarbia, A.; Viadero, F. Planetary transmission load sharing: Manufacturing errors and system configuration study. Mech. Mach. Theory 2017, 111, 21–38. [Google Scholar] [CrossRef]

| Number of Teeth | Moment of Inertia (kg*m2) | Mass (kg) | |

|---|---|---|---|

| The small ring r1 | 77 | 0.2546 | 11.275 |

| The big ring r2 | 82 | 0.4977 | 14.434 |

| sun gear | 34 | 0.0140 | 6.323 |

| planet gear a | 21 | 0.0028 | 2.163 |

| planet gear b | 22 | 0.0017 | 1.094 |

| Ring Gear r1 (Input) | Sun Gear s | Planet Gear aj | Planet Gear bj | Planet Carrier c (Output) | |

|---|---|---|---|---|---|

| Theoretical values (r/min) | 2300 | 1572.5 | 5463.1 | 3235.4 | 1113.8 |

| Simulation values (r/min) | 2300 | 1574.2 | 5452.7 | 3234.0 | 1113.9 |

| Errors (%) | 0 | 0.11 | 0.19 | 0.045 | 0.0048 |

| Degree | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Theoretical values(Hz) | 0 | 1339.1 | 2624.2 | 3281.3 | 5075.0 | 7420.5 |

| Simulation values (Hz) | 0 | 1324.9 | 2508.0 | 3206.6 | 5092.7 | 6970.2 |

| Errors(%) | 0 | 1.06 | 4.43 | 2.28 | 0.35 | 6.07 |

| Mean Meshing Force | |||

|---|---|---|---|

| Theoretical values (N) | 4360.4 | 6204.6 | 6177.3 |

| Simulation values (N) | 4391.9 | 5916.4 | 6295.9 |

| Errors (%) | 0.72 | 4.64 | 1.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, T.; Li, Y.; Zan, C.; Chen, Y. Dynamic Modeling and Analysis of Nonlinear Compound Planetary System. Machines 2022, 10, 31. https://doi.org/10.3390/machines10010031

Cui T, Li Y, Zan C, Chen Y. Dynamic Modeling and Analysis of Nonlinear Compound Planetary System. Machines. 2022; 10(1):31. https://doi.org/10.3390/machines10010031

Chicago/Turabian StyleCui, Tingqiong, Yinong Li, Chenglin Zan, and Yuanchang Chen. 2022. "Dynamic Modeling and Analysis of Nonlinear Compound Planetary System" Machines 10, no. 1: 31. https://doi.org/10.3390/machines10010031

APA StyleCui, T., Li, Y., Zan, C., & Chen, Y. (2022). Dynamic Modeling and Analysis of Nonlinear Compound Planetary System. Machines, 10(1), 31. https://doi.org/10.3390/machines10010031