Abstract

Process capability index (PCI) is a convenient and useful tool of process quality evaluation that allows a company to have a complete picture of its manufacturing process in order to prevent defective products while ensuring the product quality is at the required level. The aim of this study was to develop a control chart for process incapability index , which differentiates between information related to accuracy and precision. Index measures process inaccuracy as the degree to which the mean departs from the target value, while index measures imprecision in terms of process variation. The most important advantage of using these control charts of , , and is that practitioners can monitor and evaluate both the quality of the process and the differences in process capability. The and charts were instead of Shewhart’s and chart since the process target values and tolerances can be incorporated in the charts for evaluation as a whole, which makes the charts capable of monitoring process stability and quality simultaneously. The proposed , , and control charts enable practitioners to monitor and evaluate process quality as well as differences in process capability. The control charts are defined using probability limits, and operating characteristic (OC) curves used to detect shifts in process quality. The method proposed in this study can easily and accurately determine the process quality capability and a case is used to illustrate the application of control charts of , , and .

MSC:

62P30

1. Introduction

A control chart is used to monitor the stability of product quality produced within a specific manufacturing process, rather than evaluating the quality of the process itself. The and S control charts are commonly used in the industry; however, they are not applicable to the monitoring of process quality or estimating process capability in real time. In a fiercely competitive market, it is crucial for firms to prioritize the improvement of product quality and continually grasp the evolving needs of their customers. In other words, product specifications must be derived from the needs of customers and designers [1,2,3]. Determining the quality of a given process requires management to determine the corresponding target values and tolerances before assessing process capability, because products vary in specifications and units [4]. The process capability index (PCI) is the most widely used process quality evaluation tool in the industry [5].

The process capability indices and are pivotal tools for characterizing a process’s capability to manufacture a product that conforms to specified requirements [6]. In [7], experts provided a detailed review of PCIs. More details on PCIs can be read in [8]. In addition, the PCI provides an easy-to-use criterion to evaluate the entire process. Kane [9] reported that the and indices are the most widely used PCIs in industry. They are defined as follows:

where USL and LSL are the upper and lower specification limits, respectively, μ is the process mean, σ is the process standard deviation, is the mid-point of the specification interval, and is half the length of the specification interval. The author [6] pointed out that the definitions of and are based on the process yield. However, the fact that neither is associated with target value T means that they are not able to reflect the degree to which a given process deviates from the target value. Based on the Taguchi loss function, experts [10] proposed , which is defined as follows:

where T is the target value, and , is the expected value of the Taguchi loss function. In [11], experts modified in the development of process incapability index, , which is the square of the reciprocal of expressed as = (1/)2. The definition is shown below:

where is the inaccuracy index , and is imprecision index . Thus, . In [12], the author proposed a loss ratio based on the same idea. Therefore, it is safe to say that makes things easier for a company in terms of process management by assessing process precision and accuracy. Experts [13] argued that is superior to .

Unfortunately, little research is available concerning capability indices. In [14], when and S control charts are in statistical control, the control charts of process capability indices can be used to monitor the quality of process. It based the chart on the conventional and S charts and and R charts for the monitoring of process variations during stable operating conditions [14]. Another expert [15] studied how to monitor the capability index using an EWMA approach. Paper [16] optimally assesses the detection power between the chart and the S chart while associating in-control and out-of-control process conditions with the process capability index, . A control chart using one-sided capability indices for the evaluation of process stability and capability was developed in [17]. The author proposed using the family of capability indices with a logarithmic transformation in the form of an EWMA capability chart [18]. That system proved effective in the monitoring of unstable processes through the detection of variations in capability level. In [19], experts investigated the efficiency of the EWMA capability chart in terms of average run length (ARL). In [20], the process capability control charts used one-sided capability indices based on UMVUEs, using the estimators of the parameters of the quality characteristics obtained from the corresponding and charts.

The process incapability index, , includes and [11]. A statistical test for is used to determine whether a given process is capable of meeting the demands of customers [13]; however, that method does not provide an effective means of monitoring actual processes. This fact was instrumental in the development of estimation by [1] and process capability monitoring by [14]. , , and were used to develop the upper control limits (UCL) and lower control limits (LCL) for the control chart in order to enable real-time monitoring of process capability. In this study, the software used is MATLAB, and the objective was to obtain a clear understanding of process quality and stability in order to initiate corrective actions and minimize occurrences of defective products.

The rest of this paper is organized as follows. In the next section, , , and are used to develop control charts. Next, the proposed chart shows how this new approach efficiently monitors capable processes by detecting changes in the capability level, followed by an illustrative example in manufacturing. Then, operating characteristic (OC) curves of these control charts to detect shifts in process quality are evaluated. The last section contains some concluding remarks.

2. Process Capability Control Charts

Control charts are an important tool of statistical process control for monitoring the process mean, dispersion, or both to enhance customer confidence and the quality of the production process [21]. The fact that is used for the evaluation of process accuracy and is used for process precision makes it possible to incorporate and within a control chart simply by expanding the and S control charts and introducing the idea of process capability. This allows for the direct monitoring of process stability as well as precision and accuracy.

Let X denote a process characteristic, let denote the process mean, and let denote the process variance. Let , i = 1, 2, 3, …, m, be the m subgroups, and j = 1, 2, …, n, be the measurements of X arranged in sample size n. Assume that for each i, is a random sample from a normal distribution with the mean and standard deviation . Let be the mean of the ith sample, and let be the standard deviation of the ith sample. denotes the average standard deviation of the m subgroups, and the average of the m subgroups, are estimators of process mean and process standard deviation , respectively. The and S control charts are based directly on and . For our purposes, it was necessary to use process capability indices , , and as an alternative to classical sample statistics, such as and . For the estimation of indices , , and , Greenwich and Jahr-Schaffrath [11] considered unbiased, consistent point estimators for , , and , which are defined as follows:

Chen [1] developed , , and as uniformly minimum variance unbiased estimators (UMVUE) of , , and , respectively.

2.1. Process Capability Control Chart Based on

The and charts were introduced as an alternative to Shewhart’s and S chart, due to their ability to incorporate process target values and tolerances and thereby enable the simultaneous monitoring of process stability and quality. In cases where the and charts indicate stable process quality, the implication is that the process mean and variance are stable. The and charts give no indication of how well a given process actually works. Therefore, we developed the chart for the monitoring of process capability. Rewriting the expression of index , we obtain the following:

Let , , so and Greenwich and Jahr-Schaffrath [11] obtained . Hence, .

Spiring [14] reported that is distributed as , where is non-central chi-square distribution with n degrees of freedom and is a non-centrality parameter. Thus, the control limits of the process capability control chart of are given by the following:

The control limits used with the control chart based on index are obtained as follows:

where can be replaced by .

To establish the constants and , the value that convert according to and . In addition, is set to α = 0.05 and 0.002 as shown in Table 1 and Table 2. It can be seen that when n and α are given, will increase as increases, but will decrease as increases. When n and are given, will increase as increases, but will decrease as α increases.

Table 1.

Values of the constants and for , , .

Table 2.

Values of the constants and for , , .

2.2. Process Capability Control Chart Based on

The control limits for index are based on the sample . Chen [1] showed that follows a non-central chi-square distribution with one degree of freedom, and non-centrality parameter . To obtain the control limits for index , Y can be rewritten as

Similar to the method proposed by Spiring [14], the upper control limit (UCL) and lower control limit (LCL) for index are as follows:

The control limits and centerline (CL) of the control chart of index are defined as

where and can be replaced by and , respectively.

To establish the constants and the value that converts according to n = 3(1)10 and where is set to α = 0.05 and 0.002 as shown in Table 3 and Table 4. It can be seen that when n and α are given, and increase as increases. However, given arbitrary values for ξ and α, will increase as n increases and will decrease as n increases. When α = 0.002, is close to 0 at any ξ and n.

Table 3.

Values of the constants and for , , .

Table 4.

Values of the constants and for , , .

2.3. Process Capability Control Chart Based on

The control chart is used to monitor variations in process quality and precision. The centerline of the control chart is designated as , whereas the control limits are determined according to .

Obviously, is distributed as , where has a chi-square distribution with n−1 degrees of freedom. The control limits of the control chart of index are obtained as follows:

The control limits of the control chart of index are given by

where can be replaced by .

To establish the constants and , the value converts according to where

α = 0.05 and 0.002 as shown in Table 5 and Table 6. It can be seen that given arbitrary values for α, and will increase as increases. However, giving arbitrary values for n, will increase as α increases and will decrease as α increases.

Table 5.

Values of the constants and for n = 3(1)10, α = 0.05.

Table 6.

Values of the constants and for n = 3(1)10, α = 0.002.

3. Capability indices for Process Monitoring

3.1. Model Schema for Process Monitoring

To evaluate the monitoring of process capability and performance, we outline the steps used in the implementation of , , and charts in the following:

- Step 1.

- Collection of data

Select quality characteristic X; determine sample size, n, and number of subgroups, m; and determine the significance level .

- Step 2.

- Calculation of , , and and , , and

Tabulate the data, as shown in Table 7; and calculate , , and .

Table 7.

m subgroup observations with sample size n.

- Step 3.

- Calculation of control limits

Table 8 presents the equations used to determine the control limits for each of the charts. It is preferable to begin with the chart when establishing the charts, due to the fact that the control limits of are subject to process variance and is subject to . . These limits are meaningful only when process variation is under control.

Table 8.

Control limit equations and criteria used in process evaluation for index control charts.

- Step 4.

- Plotting control limits and connecting the dots

Plot the values of , , and in the charts and connect the dots; and plot the control limits in the control charts.

- Step 5.

- Breakdown of control charts

After plotting the charts, the control status is evaluated based on analysis of any points that fall above or below a control limit as an indication of instability in the production process. Break down the chart: The estimated variance of values within each sample. The chart control limits are derived from the values. If the chart’s values are out of control, the chart control limits are inaccurate. Thus, the stability of the chart must be studied first. Break down the chart: When the chart is under control, the in-group variance is considered stable. The mean of each group can be analyzed to identify any significant time-dependent variations in the process center. In cases where the process is not under control, the source of instability in the process center must be identified. Break down the chart: The control limits need to be recalculated in order to remove the (corrected) effects of process instability on the estimation of limits before seeking to verify whether the dots on the charts are under control. The steps of verification, correction, and recalculation are repeated as necessary.

- Step 6.

- Breakdown of the process

When the charts indicate that a process is under control (i.e., stable), it is necessary to evaluate the process capability in order to determine whether the specifications of the product and underlying process quality meet the needs of clients and designer. Limitations related to the control charts indicate whether the available processes can deliver sufficient precision consistently. Table 8 presents the criteria used in the evaluation of manufacturing processes by [13]. It is favorable to begin the evaluation of process capability using the chart. In cases where process capability is poor, the and charts can be used to identify the causes. The chart is used to determine the accuracy that can be achieved using a given process, while the chart is used to determine precision and the reasons for process variation in order to formulate a plan for improvement.

- Step 7.

- Extension of control limits

If a process is under stable control and the processes are able to deliver the necessary accuracy and precision, the control limits can be extended to initiate control.

3.2. An Example

The data used in this example were obtained from a semiconductor manufacturer in Hsinchu, Taiwan. The wafer building process involves the placement of a large number of microcircuits on silicon-based wafers. The required critical dimension is 2 ± 0.4 μm; i.e., target value T = 2.00 μm with USL = 2.4 μm and LSL = 1.6 μm. Our objective was to build a model for monitoring adherence to the critical dimensions under mass production conditions. A breakdown of the steps is presented in the following:

- Step 1.

- Collection of data

Select quality characteristic X: the critical dimensions of the wafer (m) is a quality characteristic of this process. Determine the size of the sample (n = 5), and number of subgroups is 20, and determine the significance level (= 0.0027).

- Step 2.

- Calculation of , , and

According to Formulas (12), (17), and (18), ,, and are calculated as shown in Table 9.

Table 9.

Data and , , and values.

- Step 3.

- Calculation of control limits

Using the data in Table 9, we obtained the following control limits for the chart: , , and The control limits for the chart are as follows: , , and . The control limits for the chart are as follows: , , and .

- Step 4.

- Plotting the control limits and connecting the dots

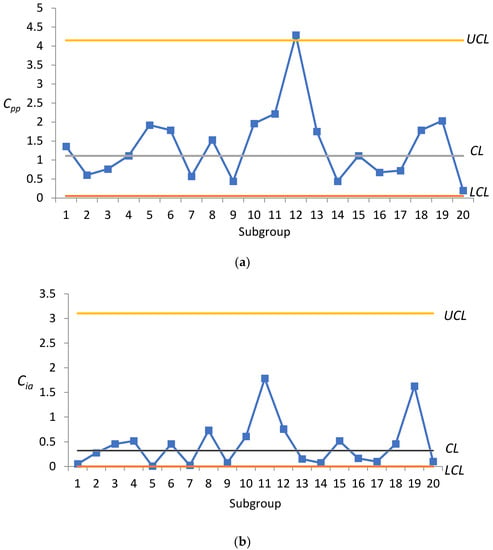

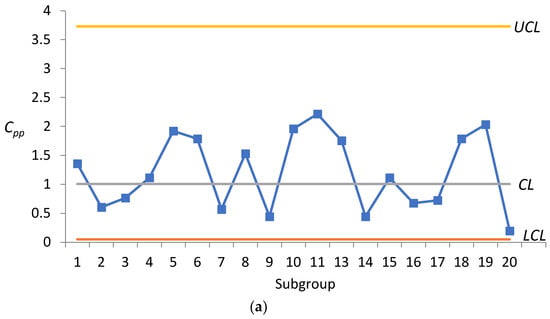

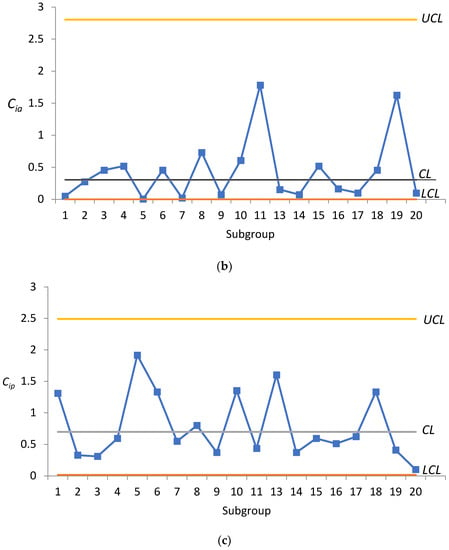

Figure 1 presents the control limits for the index control chart along with the , , and values obtained for various samples. Figure 1a,c indicates that point 12 exceeds the UCL, which necessitates an investigation into the assignable causes.

Figure 1.

Process capability control charts for microcircuits. (a) C_pp chart. (b) C_ia chart. (c) C_ip chart.

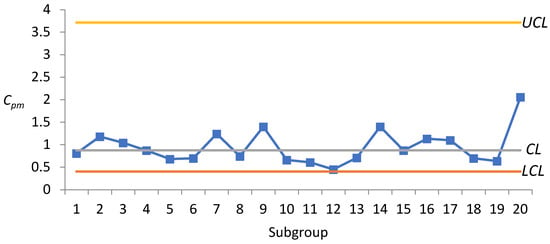

Compared with [14], is presented in Table 9. The control limits of are drawn in Figure 2 where , , and . It can be seen from Figure 2 that each is within the upper and lower limits of the control, indicating that there is no abnormality in this process. Compared with the control chart proposed by this study, it can be found that point 12 exceeds the UCL in Figure 1a,c, and the process can be improved immediately.

Figure 2.

Process capability control charts of .

- Step 5.

- Breakdown of control charts

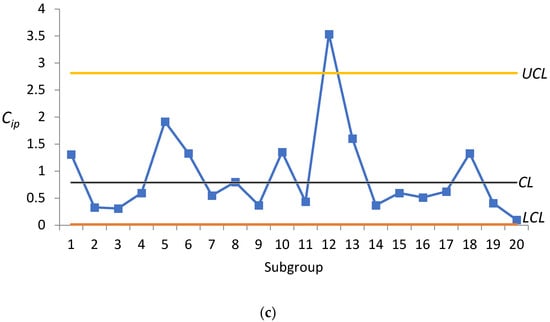

Figure 1 presents the , , and charts. The Cia chart presents all of the points located within the control limits in Figure 1b, indicating that the process accuracy is under control. The and charts indicate that point 12 exceeds the UCL in Figure 1a,c, thereby necessitating an investigation into assignable causes. Our subsequent investigation revealed that the problem with point 12 was a delay in the feeding of materials. We removed point 12 and re-calculated , , and which resulted in mean values of 1.0061, , and . The control limits for the chart are as follows: , , and . The control limits for the chart are as follows: , , and . The control limits for the chart are as follows: , , and . Figure 3 presents the control limits and the re-plotting of the charts. In Figure 3, all of the points fall within the control limits, thereby indicating that the process is under control.

Figure 3.

Improved process capability control charts for microcircuits. (a) chart. (b) chart. (c) chart.

- Step 6.

- Breakdown of the process

The chart clearly shows that the process capability for this product is substandard. The and charts provide a picture of process accuracy and precision. In Figure 3a, the plotted points 1, 5, 6, 8, 10, 11, 13, 18, and 19 are outside of = 1, it indicates their is higher than 1 but not more than 4, indicating the process capability is not poor. The rest of the points are all less than 1, which also means that the capabilities of these processes are considered to be satisfactory. If it is expected that the process capability can better meet the needs of the industry, researchers can learn from Figure 3b,c from the plotted points 1, 5, 6, 10, 13, and 18; they indicates that their must be higher than their . When , the process precision is not capable. Thus, reducing their process variance has higher priority than reducing the process departure.

For the plotted points 11 and 19, their must be higher than their . , the quality improvement efforts for these processes should be first focused on, reducing the departure of process mean from the target value.

In plotted point 8, the values of and are similar, which indicates that the variability of those processes is contributed equally by the mean departure and process variance.

- Step 7.

- Extension of control limits

The process was deemed to be under control and the process capability appeared to be up to standard. Thus, the control limits were extended to initiate control in order to enhance process stability and monitor process precision and accuracy.

The proposed model in this example allows businesses to have real-time understanding of the quality and stability of the manufacturing process. This enables real-time monitoring of process precision and accuracy. If the quality does not meet the standards or deteriorates, businesses can promptly make improvements to prevent the production of faulty products. This allows businesses to have continuous awareness of the quality and stability of the process. It eliminates the need for relying on control charts to determine process stability. The evaluation of process capability based on product specifications and target values can assess process drift and stability.

4. Operating Characteristic Curves for Control Charts for , , and

The efficacy of the , , and charts to detect shifts in process quality is described by their OC curves. The OC curves for the process capability control charts of , , and are as follows:

is the cumulative distribution function (cdf) of noncentral chi-square distribution for each of the values in u using the corresponding degrees of freedom in v and positive noncentrality parameters in . The noncentral chi-square cdf is rendered as follows:

is the cumulative distribution function (cdf) of a chi-square distribution for a given value u with v degrees of freedom: i.e.,

where is the Gamma function.

For these control charts, we assigned probability control limits of 0.00135 to each tail, such that the probability of a Type I error would be 0.0027 when the process is under control. Assume that the in-control process mean and variance are and , respectively, where USL = 13, LSL = 7, and T = 10. k is defined as the mean shift from to . If r is defined as the shift size of the standard deviation , then the shift amount of standard deviation is . The following three cases make it possible to study shifts in process quality: (1) Only a shift in the mean values; (2) only a shift in the standard deviation; (3) shifts in both the mean values and standard deviation.

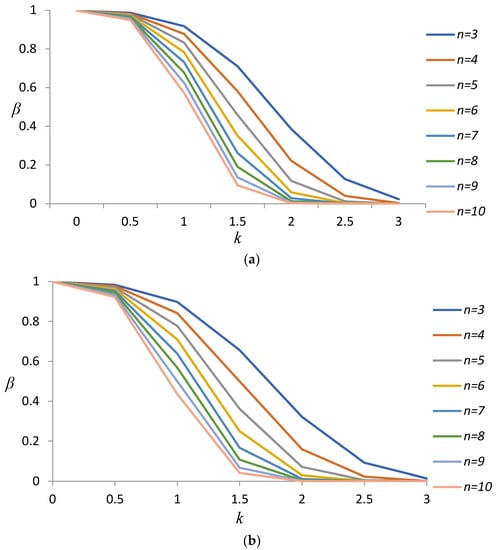

In case 1, the values of k are 0(0.5)3. The chart could not determine the effects of different mean shifts. Thus, to construct the OC curve for the and charts, we plot the -risk against the magnitude of the shift we wish to detect, as expressed in units of standard deviation for samples of various size . The OC curves for the and charts are shown in Figure 4a and Figure 4b, respectively. As shown in Figure 4a, when k is fixed, an increase in n reduces the probability of Type II errors. When n is fixed, an increase in k reduces the probability of Type II errors. Consequently, similar results were obtained for the chart (shown in Figure 4b). To summarize, an increase in n reduces the probability of Type II errors for the same k, whereas an increase in k reduces the probability of Type II errors for the same n.

Figure 4.

OC curves for index control charts, where process mean shifts by . (a) chart. (b) chart.

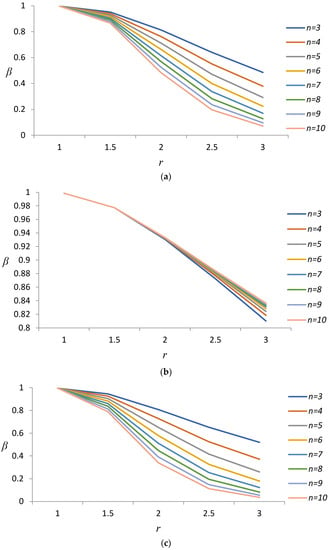

In case 2, the value of r is 1(0.5)3. To construct OC curves for the , , and charts, we plot the probability of Type II errors against the magnitude of the shift we wish to detect, which is expressed in units of standard deviation for samples of various size . The OC curves for the , , and are presented in Figure 5a, Figure 5b and Figure 5c, respectively. An examination of Figure 5b indicates that the chart is not particularly effective in detecting process shifts when dealing with samples of various sizes. Furthermore, Figure 5a,c indicates that these and charts are not particularly effective in detecting process shifts in small samples due to a negligible shift in standard deviation.

Figure 5.

OC curves for index control charts, where process standard deviation shifts by . (a) chart. (b) chart. (c) chart.

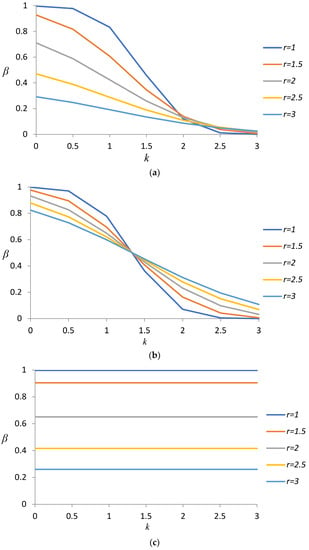

Case 3 presents shifts in the mean as well as the standard deviation. The values of k are 0(0.5)3, and the values of r are 1(0.5)3. The OC curves for the control charts of , , and with are presented in Figure 6a, Figure 6b and Figure 6c, respectively. As shown in Figure 6a,c, when mean shift k is fixed, -risk decreases with an increase in r. As shown in Figure 6a,b, when r is fixed, the probability of Type II errors decreases with an increase in k. This indicates that the newly developed process capability control charts are more sensitive to larger shifts than to smaller ones. As shown in Figure 6c, when r is fixed, the probability of Type II errors does not vary with a change in k. As shown in Figure 6b, when mean shift k is fixed, the probability of Type II errors decreases with an increase in r when k ≤ 1, and the probability of Type II errors decreases with a decrease in r when k ≥ 1.5.

Figure 6.

OC curves for index control charts with , where both process the mean and standard deviation shifts. (a) chart. (b) chart. (c) chart.

5. Conclusions

Manufacturers are constantly striving to improve process stability and quality in order to meet the evolving needs of clients. In the past, determining the stability of manufacturing processes involved the use of a control chart. Manufacturing processes must be kept under strict control in order to determine the capability of a given process in consistently achieving target specifications. In this study, we sought to combine control charts and process capability indices in the development of a monitoring model using indexed control charts to facilitate the control of system parameters in order to maintain a stable level of quality. We used the indices , , and to establish upper and lower limits of control charts in order to facilitate the monitoring of process capability, accuracy, and precision. The objective was to provide a framework by which to guide actions aimed at improving manufacturing processes when quality fails to meet the set criteria, thereby minimizing the production of defective products. A practical example was outlined to illustrate the application of the proposed monitoring model. In this example, the chart shows that the process is operating normally, without any unusual situation. However, both the and charts indicate that there is a problem with one of the processes, and it is important to investigate the specific reasons behind this issue. The proposed method aims to show how well a company’s processes meet customer needs. These charts not only highlight what customers want but also offer valuable information for process managers to make improvements.

Author Contributions

Conceptualization, T.-I.K.; methodology, T.-I.K. and T.-L.C.; software, T.-I.K.; validation, T.-L.C.; formal analysis, T.-I.K. and T.-L.C.; resources, T.-I.K. and T.-L.C.; visualization, T.-L.C.; writing—original draft, T.-I.K. and T.-L.C.; writing—review and editing, T.-I.K. and T.-L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, K.S. Estimation of the process incapability index. Commun. Stat. Theory Methods 1998, 27, 1263–1274. [Google Scholar] [CrossRef]

- Chen, K.S. Incapability index with asymmetric tolerances. Stat. Sin. 1998, 8, 253–262. [Google Scholar]

- Davis, R.; Kaminsky, F. Statistical measures of process capability and their relationship to non-conforming products. In Proceedings of the Third Biennial International Manufacturing Technology Research Forum, Chicago, IL, USA, 29–30 August 1989. [Google Scholar]

- Deleryd, M.; Vännman, K. Process capability plots—A quality improvement tool. Qual. Reliab. Eng. Int. 1999, 15, 213–227. [Google Scholar] [CrossRef]

- Chen, K.-S.; Li, F.-C.; Lai, K.-K.; Lin, J.-M. Green Outsourcer Selection Model Based on Confidence Interval of PCI for SMT Process. Sustainability 2022, 14, 16667. [Google Scholar] [CrossRef]

- Boyles, R.A. The Taguchi capability index. J. Qual. Technol. 1991, 23, 17–26. [Google Scholar] [CrossRef]

- Kotz, S.; Johnson, N.L. Process capability indices—A review, 1992–2000. J. Qual. Technol. 2002, 34, 2–19. [Google Scholar] [CrossRef]

- Wu, C.-W.; Pearn, W.; Kotz, S. An overview of theory and practice on process capability indices for quality assurance. Int. J. Prod. Econ. 2009, 117, 338–359. [Google Scholar] [CrossRef]

- Kane, V.E. Process capability indices. J. Qual. Technol. 1986, 18, 41–52. [Google Scholar] [CrossRef]

- Chan, L.K.; Cheng, S.W.; Spiring, F.A. A new measure of process capability: Cpm. J. Qual. Technol. 1988, 20, 162–175. [Google Scholar] [CrossRef]

- Greenwich, M.; Jahr-Schaffrath, B.L. A process incapability index. Int. J. Qual. Reliab. Manag. 1995, 12, 58–71. [Google Scholar] [CrossRef]

- Phillips, G.P. Target ratio simplifies capability index system, makes it easy to use Cpm. Qual. Eng. 1994, 7, 299–313. [Google Scholar] [CrossRef]

- Pearn, W.L.; Chen, K.L.; Chen, K.S. An application of the incapability index Cpp. J. Manag. Syst. 1999, 6, 177–190. [Google Scholar]

- Spiring, F.A. Process capability: A total quality management tool. Total Qual. Manag. 1995, 6, 21–33. [Google Scholar] [CrossRef]

- Castagliola, P. How to monitor capability index Cm using EWMA. Int. J. Reliab. Qual. Saf. Eng. 2001, 8, 191–204. [Google Scholar] [CrossRef]

- Wu, Z.; Xie, M.; Tian, Y. Optimization Design of the &S Charts for Monitoring Process Capability. J. Manuf. Syst. 2002, 21, 83–92. [Google Scholar]

- Chen, K.S.; Huang, H.L.; Huang, C.T. Control Charts for One-sided Capability Indices. Qual. Quant. 2007, 41, 413–427. [Google Scholar] [CrossRef]

- Castagliola, P.; Vännman, K. Monitoring capability indices using EWMA approach. Qual. Reliab. Eng. Int. 2007, 23, 769–790. [Google Scholar] [CrossRef]

- Castagliola, P.; Vännman, K. Average Run Length When Monitoring capability indices using EWMA. Qual. Reliab. Eng. Int. 2008, 24, 941–955. [Google Scholar] [CrossRef]

- Chatterjee, M.; Chakraborty, A.K. Distributions and process capability control charts for Cpu and Cpl using subgroup information. Commun. Stat. Theory Methods 2015, 44, 4333–4353. [Google Scholar] [CrossRef]

- Aslam, M.; Rao, G.S.; AL-Marshadi, A.H.; Ahmad, L.; Jun, C.-H. Control Charts for Monitoring Process Capability Index Using Median Absolute Deviation for Some Popular Distributions. Processes 2019, 7, 287. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).