Response Surface Methodology for Optimization of Copper Leaching from Refractory Flotation Tailings

Abstract

:1. Introduction

2. Experimental Section

2.1. Description of Samples and Apparatus

2.2. Methods

2.3. Experimental Design

2.4. Evaluation Methods

3. Results and Discussions

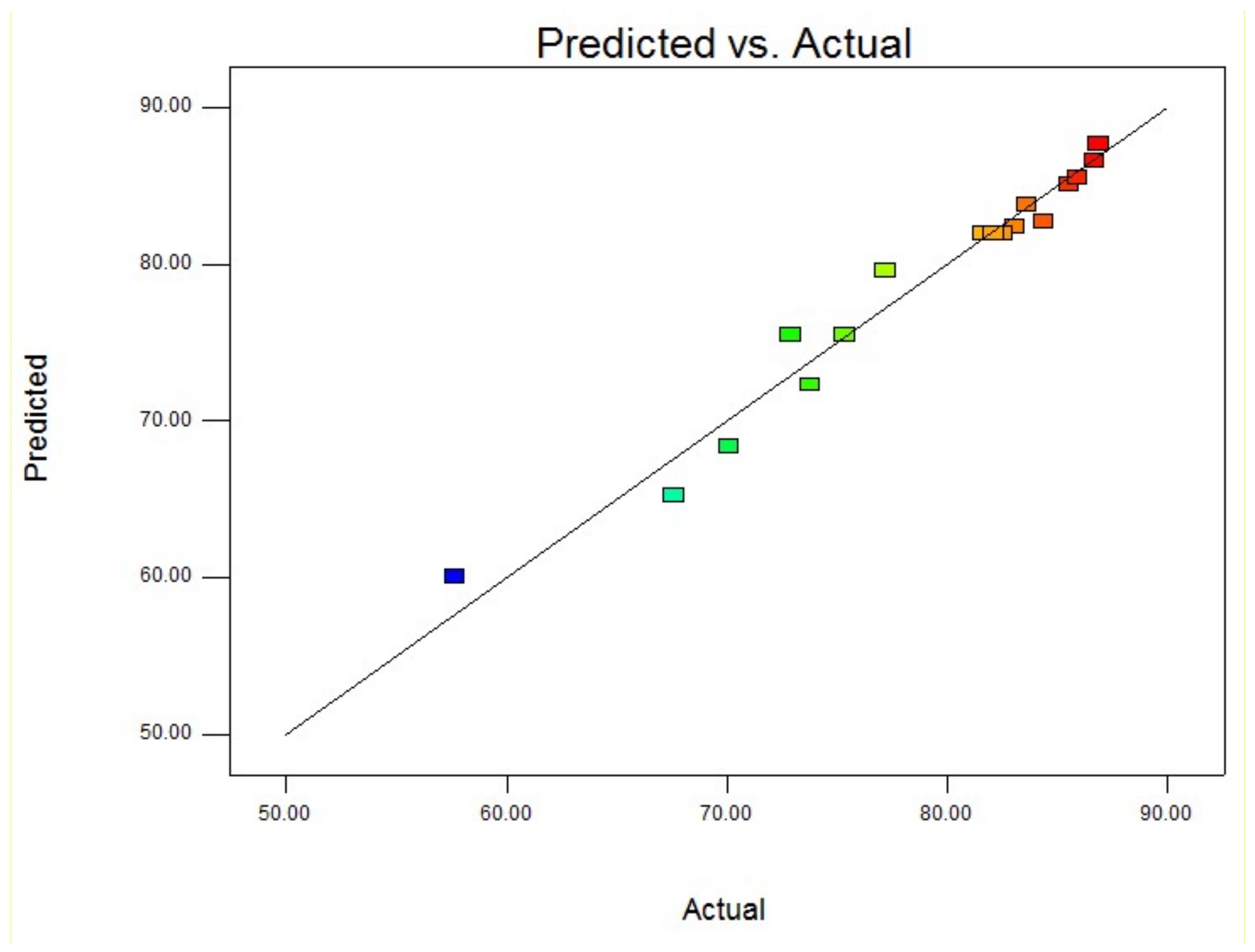

3.1. Response Analysis and Interpretation

3.2. Relevant Chemical Reactions in the Leaching Process

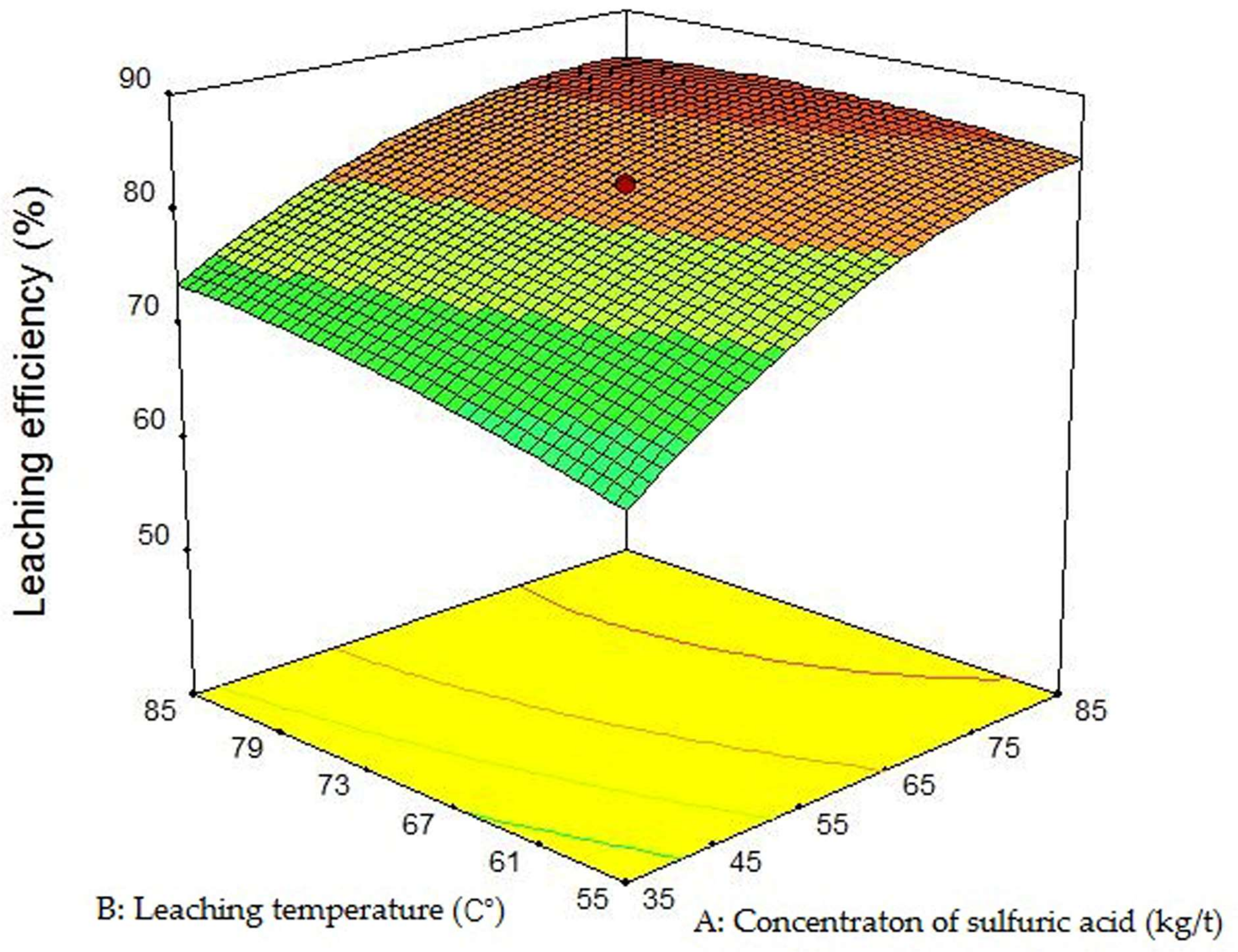

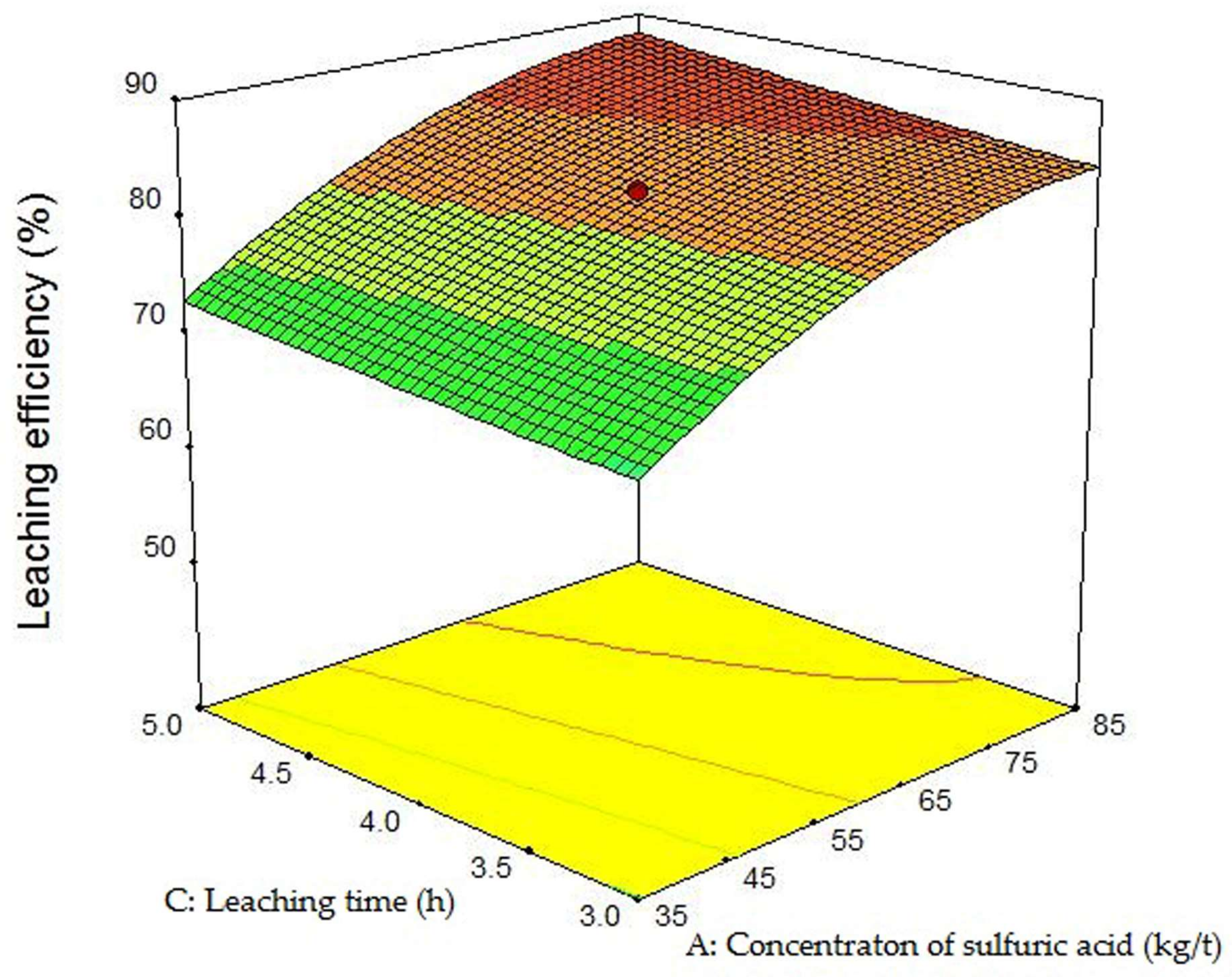

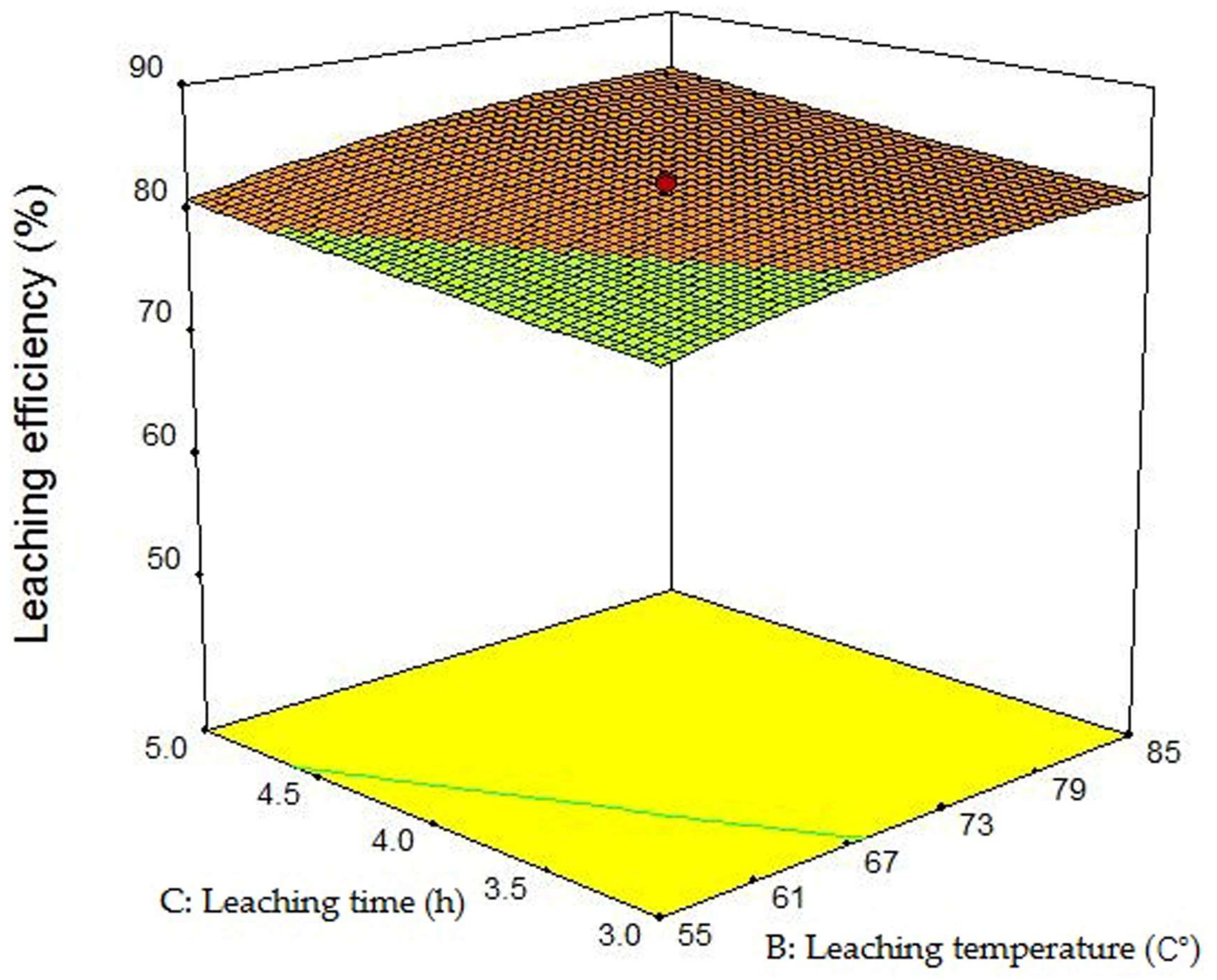

3.3. Interactions among Key Parameters

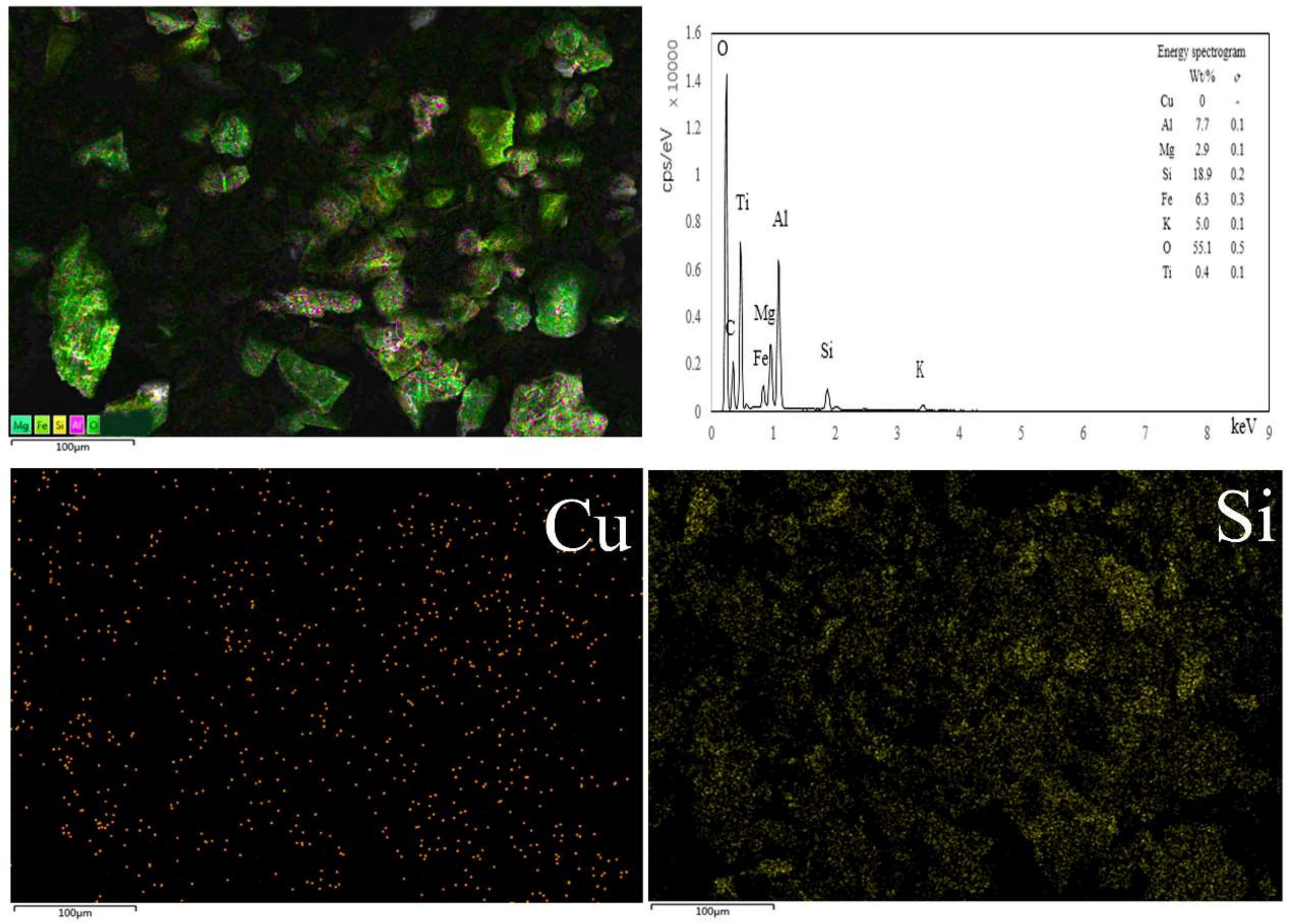

3.4. Process Optimization and Analysis of Leaching Residue

5. Conclusions

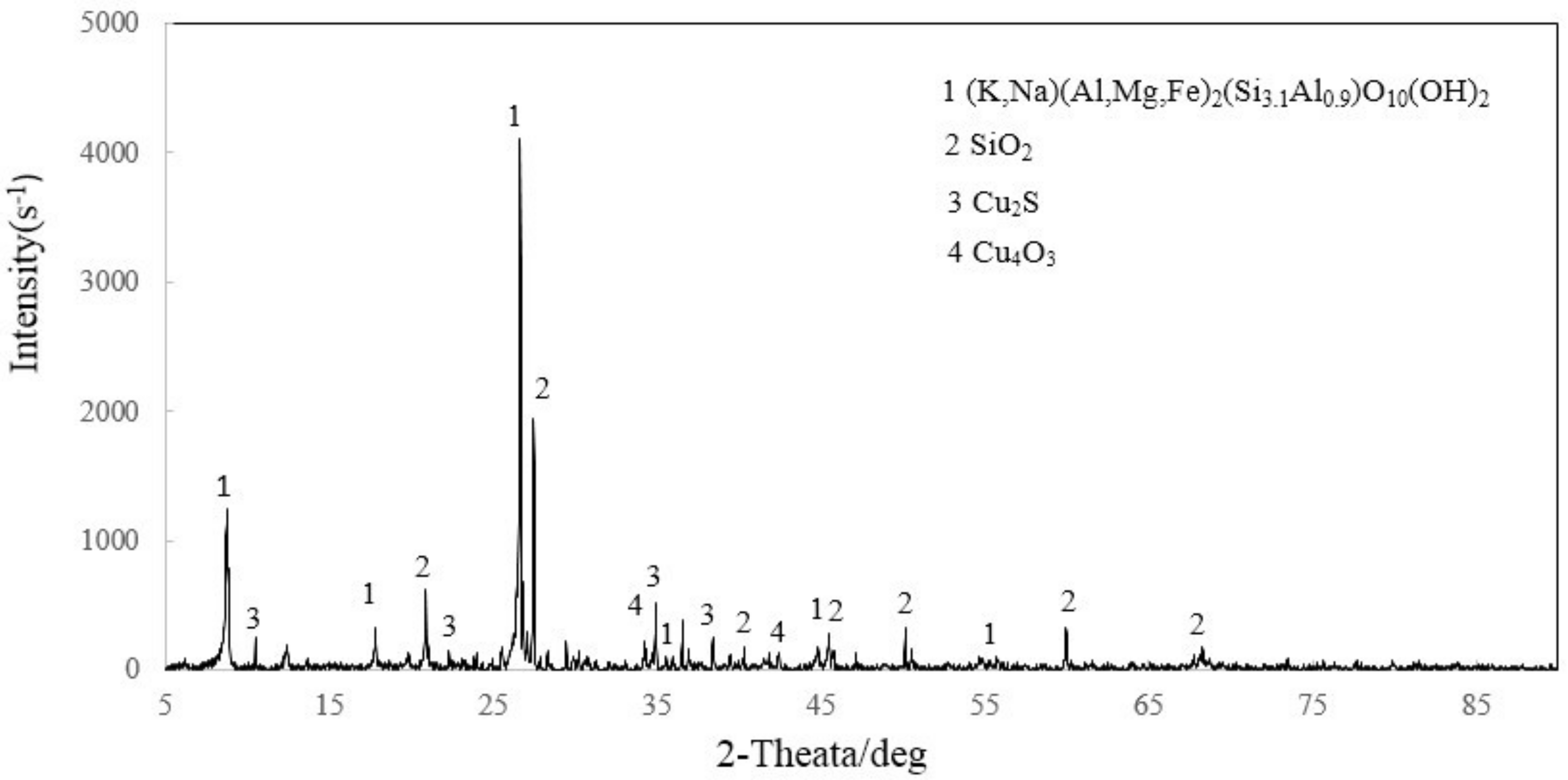

- The main copper oxide minerals in flotation tailings are malachite and chrysocolla, and the main gangue minerals, quartz and biotite, are wrapped around the copper oxide minerals. They are symbiotic with each other. The proportion of copper oxide is relatively high (93.41%). Moreover, the proportion of refractory copper oxide is 64.84%, which causes handling difficulties.

- The results of the response surface methodology show that the amount of concentrated sulfuric acid and the leaching temperature are both significant factors affecting the leaching efficiency of flotation tailings. High temperatures can destroy the gangue mineral structure and cause the sulfuric acid to react with copper oxide. Therefore, a large amount of concentrated sulfuric acid is required to obtain a high leaching efficiency.

- Optimal leaching conditions are as follows: the amount of concentrated sulfuric acid is 85 kg/t, the leaching temperature is 68.51 °C, and the leaching time is 4.36 h. This combination leads to an actual leaching efficiency of 85.86% (the predicted leaching efficiency is 86.79%). The actual measured value is consistent with the model prediction. We successfully used the response surface methodology to minimize the sulfuric acid concentration and heating costs, save energy, and reduce the negative environmental impacts of the technology.

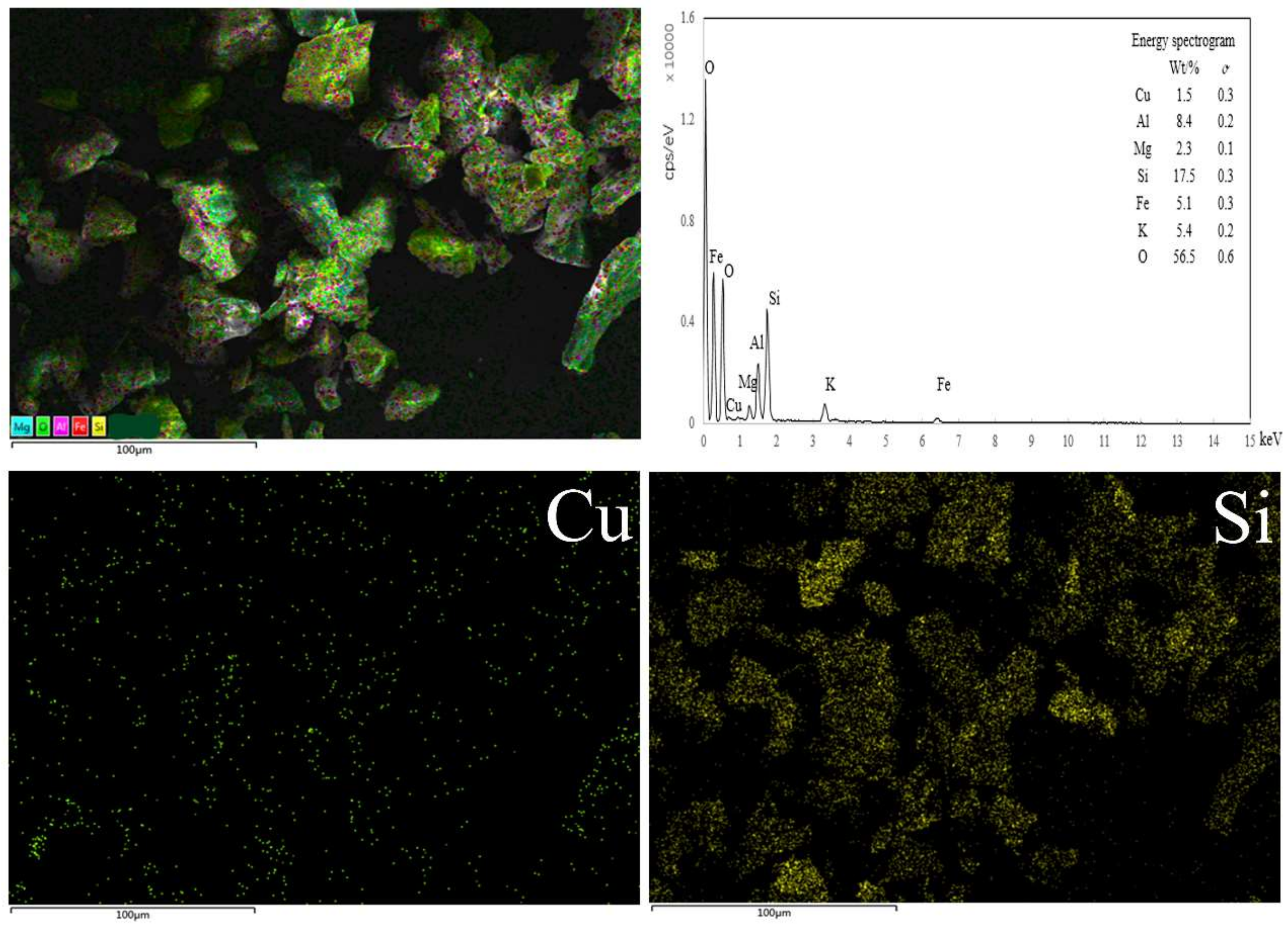

- We assessed the leaching processes using SEM and EDS surface scan analyses. These analyses visually observe the content and distribution of the main element, allowing us to develop effective methods for treating low-grade oxide ores.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Feng, Q.C.; Zhao, W.J.; Wen, S.M.; Cao, Q.B. Activation mechanism of lead ions in cassiterite flotation with salicylhydroxamic acid as collector. Sep. Purif. Technol. 2017, 178, 193–199. [Google Scholar] [CrossRef]

- Feng, Q.C.; Zhao, W.J.; Wen, S.M. Surface modification of malachite with ethanediamine and its effect on sulfidization flotation. Appl. Surf. Sci. 2018, 436, 823–831. [Google Scholar] [CrossRef]

- Feng, Q.C.; Wen, S.M.; Deng, J.S.; Zhao, W.J. Combined DFT and XPS investigation of enhanced adsorption of sulfide species onto cerussite by surface modification with chloride. Appl. Surf. Sci. 2017, 425, 8–15. [Google Scholar] [CrossRef]

- Rucker, D.F.; Zaebst, R.J.; Gillis, J.; Cain, C., IV; Teague, B. Drawing down the remaining copper inventory in a leach pad by way of subsurface leaching. Hydrometallurgy 2017, 169, 382–392. [Google Scholar] [CrossRef]

- Han, J.W.; Xiao, J.; Qin, W.Q.; Chen, D.X.; Liu, W. Copper Recovery from Yulong Complex Copper Oxide Ore by Flotation and Magnetic Separation. JOM 2017, 69, 1563–1569. [Google Scholar] [CrossRef]

- Deng, D.; Xu, L.H.; Tian, J.; Hu, Y.H.; Han, Y.X. Flotation and Adsorption of a New Polysaccharide Depressant on Pyrite and Talc in the Presence of a Pre-Adsorbed Xanthate Collector. Minerals 2017, 7, 40. [Google Scholar] [CrossRef]

- Haghighi, H.K.; Moradkhani, D.; Sedaghat, B.; Najafabadi, M.R.; Behnamfard, A. Production of copper cathode from oxidized copper ores by acidic leaching and two-step precipitation followed by electrowinning. Hydrometallurgy 2013, 133, 111–117. [Google Scholar] [CrossRef]

- Turan, M.; Arslanoglu, H.; Altundogan, H.S. Optimization of the leaching conditions of chalcopyrite concentrate using ammonium persulfate in an autoclave system. J. Taiwan Inst. Chem. Eng. 2015, 50, 49–55. [Google Scholar] [CrossRef]

- Mao, Y.B.; Wen, S.M.; Deng, J.S.; Fang, J.J. Response surface modeling and optimization of process parameters for leaching of zinc oxide ore with ammonia and ammonium bicarbonate solutions followed by flotation. Przem. Chem. 2015, 7, 1000–1008. [Google Scholar]

- Awe, S.A.; Khoshkhoo, M.; Kruger, P.; Sandström, Å. Modelling and process optimisation of antimony removal from a complex copper concentrate. Trans. Nonferrous Met. Soc. China 2012, 22, 675–685. [Google Scholar] [CrossRef]

- Kul, M.; Oskay, K.O.; Şimşir, M.; Sübütay, H.; Kirgezen, H. Optimization of selective leaching of Zn from electric arc furnace steelmaking dust using response surface methodology. Trans. Nonferrous Met. Soc. China. 2015, 25, 2753–2762. [Google Scholar] [CrossRef]

- Lambert, A.; Drogui, P.; Daghrir, R.; Zaviska, F.; Benzaazoua, M. Removal of copper in leachate from mining residues using electrochemical technology. J. Environ. Manag. 2014, 133, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Behbahani, M.; Seo, Y. Investigation on haloacetic acid (HAA) degradation by iron powder: Application of response surface methodology. Process Saf. Environ. 2016, 103, 153–162. [Google Scholar] [CrossRef]

- Goh, K.H.; Lim, T.T.; Chui, P.C. Evaluation of the effect of dosage, pH and contact time on high-dose phosphate inhibition for copper corrosion control using response surface methodology (RSM). Corros. Sci. 2008, 50, 918–927. [Google Scholar] [CrossRef]

- Fattahi, A.; Rashchi, F.; Abkhoshk, E. Reductive leaching of zinc, cobalt and manganese from zinc plant residue. Hydrometallurgy 2016, 161, 185–192. [Google Scholar] [CrossRef]

- Helle, S.; Jerez, O.; Kelm, U.; Pincheira, M.; Varela, B. The influence of rock characteristics on acid leach extraction and re-extraction of Cu-oxide and sulfide minerals. Miner. Eng. 2010, 23, 45–50. [Google Scholar] [CrossRef]

- Liu, J.; Wen, S.M.; Liu, D.; Lv, M.Y. Response surface methodology for optimization of copper leaching from a low-grade flotation middling. Miner. Metall. Proc. 2011, 28, 139–145. [Google Scholar]

- Aguirre, C.L.; Toro, N.; Carvajal, N.; Watling, H.; Aguirre, C. Leaching of chalcopyrite (CuFeS2) with an imidazolium-based ionic liquid in the presence of chloride. Miner. Eng. 2016, 99, 60–66. [Google Scholar] [CrossRef]

- Rosales, G.D.; Pinna, E.G.; Suarez, D.S.; Rodriguez, M.H. Recovery Process of Li, Al and Si from Lepidolite by Leaching with HF. Minerals 2017, 7, 36. [Google Scholar] [CrossRef]

- Somasundaram, M.; Saravanathamizhan, R.; Basha, C.A.; Nandakumar, V.; Begum, S.N.; Kannadasan, T. Recovery of copper from scrap printed circuit board: Modelling and optimization using response surface methodology. Powder Technol. 2014, 266, 1–6. [Google Scholar] [CrossRef]

- Shabani, M.A.; Irannajad, M.; Azadmehr, A.R. Investigation on leaching of malachite by citric acid. Int. J. Min. Met. Mater. 2012, 19, 782–786. [Google Scholar] [CrossRef]

- Bingöla, D.; Canbazoğlub, M. Dissolution kinetics of malachite in sulphuric acid. Hydrometallurgy 2004, 72, 159–165. [Google Scholar] [CrossRef]

- Dorfling, C.; Akdogan, G.; Bradshaw, S.M.; Eksteen, J. Modelling of an autoclave used for high pressure sulphuric acid/oxygen leaching of first stage leach residue. Part 1: Model development. Miner. Eng. 2013, 53, 220–227. [Google Scholar] [CrossRef]

| Name | Free Oxide Copper | Combination Oxide Copper | Sulfides and Others | Total Copper |

|---|---|---|---|---|

| Content | 0.26 | 0.59 | 0.06 | 0.91 |

| Proportion | 28.57 | 64.84 | 6.59 | 100 |

| Symbols | Levels and Rangs | ||||||

|---|---|---|---|---|---|---|---|

| Independent variables | Uncoded | Coded | −1.682 | −1 | 0 | 1 | +1.682 |

| Sulfuric concentration, kg/t | λ1 | X1 | 17.96 | 35 | 60 | 85 | 102.04 |

| Leaching temperature, °C | λ2 | X2 | 44.77 | 55 | 70 | 85 | 95.23 |

| Leaching time, h | λ3 | X3 | 2.32 | 3 | 4 | 5 | 5.68 |

| Variables | ||||

|---|---|---|---|---|

| Experimental Runs | Concentrated Sulfuric Acid, kg/t | Leaching Temperature, °C | Leaching Time, h | Leaching Efficiency, % |

| 1 | 60 | 70 | 4 | 82.20 |

| 2 | 35 | 55 | 5 | 70.09 |

| 3 | 60 | 70 | 5.68 | 85.89 |

| 4 | 60 | 70 | 4 | 81.73 |

| 5 | 60 | 70 | 2.32 | 77.17 |

| 6 | 17.96 | 70 | 4 | 57.66 |

| 7 | 85 | 85 | 5 | 86.85 |

| 8 | 35 | 55 | 3 | 67.58 |

| 9 | 60 | 70 | 4 | 82.53 |

| 10 | 60 | 70 | 4 | 82.26 |

| 11 | 60 | 95.23 | 4 | 83.05 |

| 12 | 35 | 85 | 5 | 75.34 |

| 13 | 60 | 70 | 4 | 82.11 |

| 14 | 35 | 85 | 3 | 73.77 |

| 15 | 102.04 | 70 | 4 | 85.50 |

| 16 | 85 | 85 | 3 | 83.58 |

| 17 | 85 | 55 | 3 | 84.37 |

| 18 | 60 | 44.77 | 4 | 72.88 |

| 19 | 85 | 55 | 5 | 86.65 |

| 20 | 60 | 70 | 4 | 81.65 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Values Prob > F |

|---|---|---|---|---|---|

| Model | 1045.91 | 9 | 116.21 | 34.19 | <0.0001 |

| λ1 | 754.23 | 1 | 754.23 | 221.87 | <0.0001 |

| λ2 | 57.22 | 1 | 57.22 | 16.83 | 0.0021 |

| λ3 | 43.22 | 1 | 43.22 | 12.71 | 0.0051 |

| λ1λ2 | 18.09 | 1 | 18.09 | 5.32 | 0.0437 |

| λ1λ3 | 0.27 | 1 | 0.27 | 0.08 | 0.7838 |

| λ2λ3 | 0.00 | 1 | 0.00 | 0.00 | 0.9925 |

| λ12 | 159.83 | 1 | 159.83 | 47.02 | <0.0001 |

| λ22 | 16.59 | 1 | 16.59 | 4.88 | 0.0517 |

| λ32 | 0.51 | 1 | 0.51 | 0.15 | 0.7074 |

| Residual | 33.99 | 10 | 3.40 | - | - |

| Pure Error | 0.56 | 5 | 0.11 | - | - |

| Sulfuric Concentration, λ1, kg/t | Leaching Temperature, λ, °C | Leaching time, λ3, h | Leaching Efficiency, % | |

|---|---|---|---|---|

| Predicted | Experimental | |||

| 85 | 68.51 | 4.36 | 86.79 | 85.86 |

| Name | Cu | Fe | CaO | MgO | Al2O3 | S | SiO2 |

|---|---|---|---|---|---|---|---|

| Flotation tailings | 0.91 | 4.34 | 0.62 | 5.62 | 14.62 | 0.035 | 58.46 |

| Leach residue | 0.125 | 3.87 | 0.70 | 5.41 | 14.49 | 0.035 | 61.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, X.; Wen, S.; Liu, J.; Lin, Y. Response Surface Methodology for Optimization of Copper Leaching from Refractory Flotation Tailings. Minerals 2018, 8, 165. https://doi.org/10.3390/min8040165

Bai X, Wen S, Liu J, Lin Y. Response Surface Methodology for Optimization of Copper Leaching from Refractory Flotation Tailings. Minerals. 2018; 8(4):165. https://doi.org/10.3390/min8040165

Chicago/Turabian StyleBai, Xu, Shuming Wen, Jian Liu, and Yilin Lin. 2018. "Response Surface Methodology for Optimization of Copper Leaching from Refractory Flotation Tailings" Minerals 8, no. 4: 165. https://doi.org/10.3390/min8040165

APA StyleBai, X., Wen, S., Liu, J., & Lin, Y. (2018). Response Surface Methodology for Optimization of Copper Leaching from Refractory Flotation Tailings. Minerals, 8(4), 165. https://doi.org/10.3390/min8040165