Characterization and Separation Studies of a Fine Sedimentary Phosphate Ore Slime

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

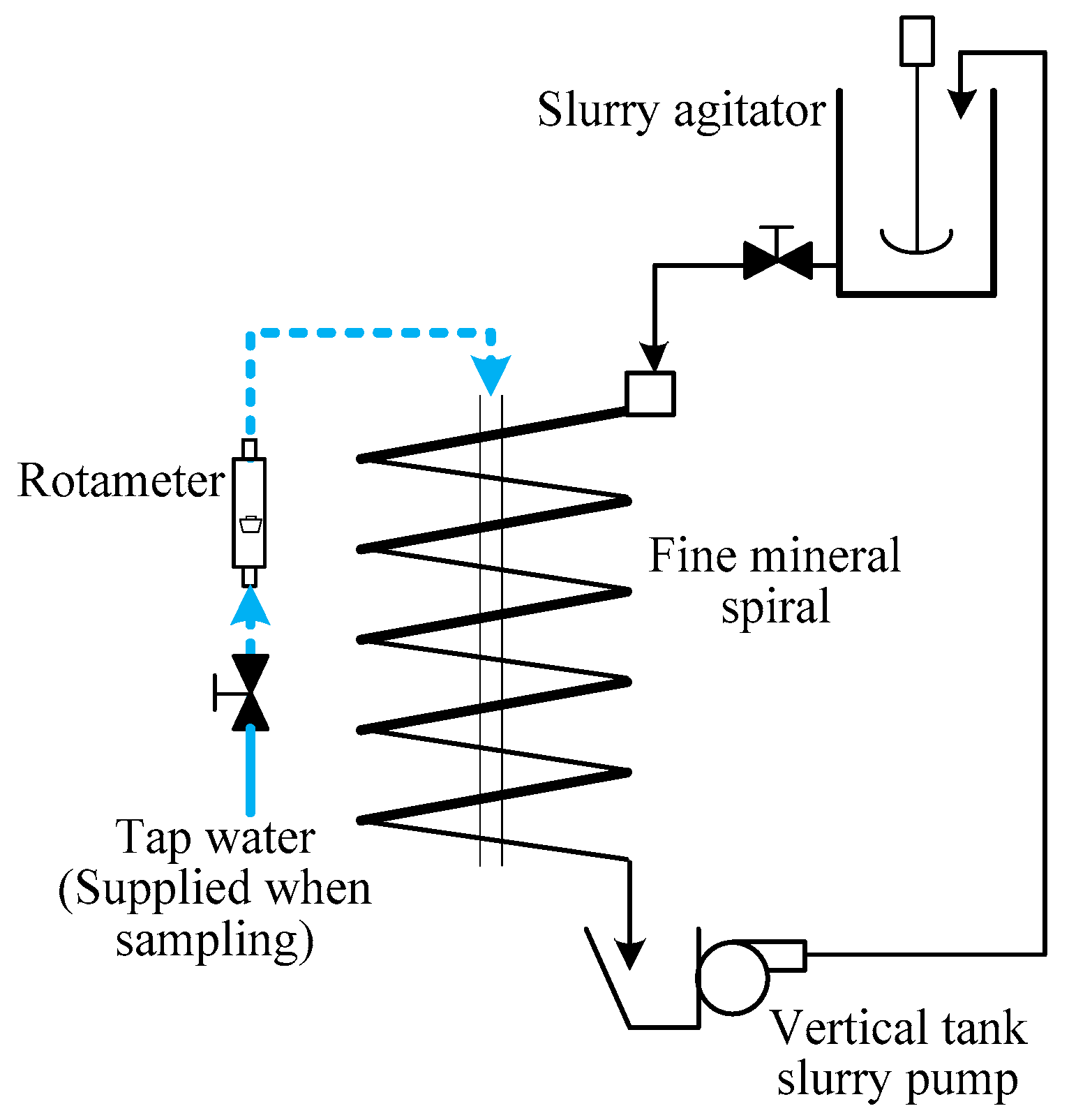

2.2.1. Gravity Separation Tests

2.2.2. Flotation Separation Tests

3. Results and Discussion

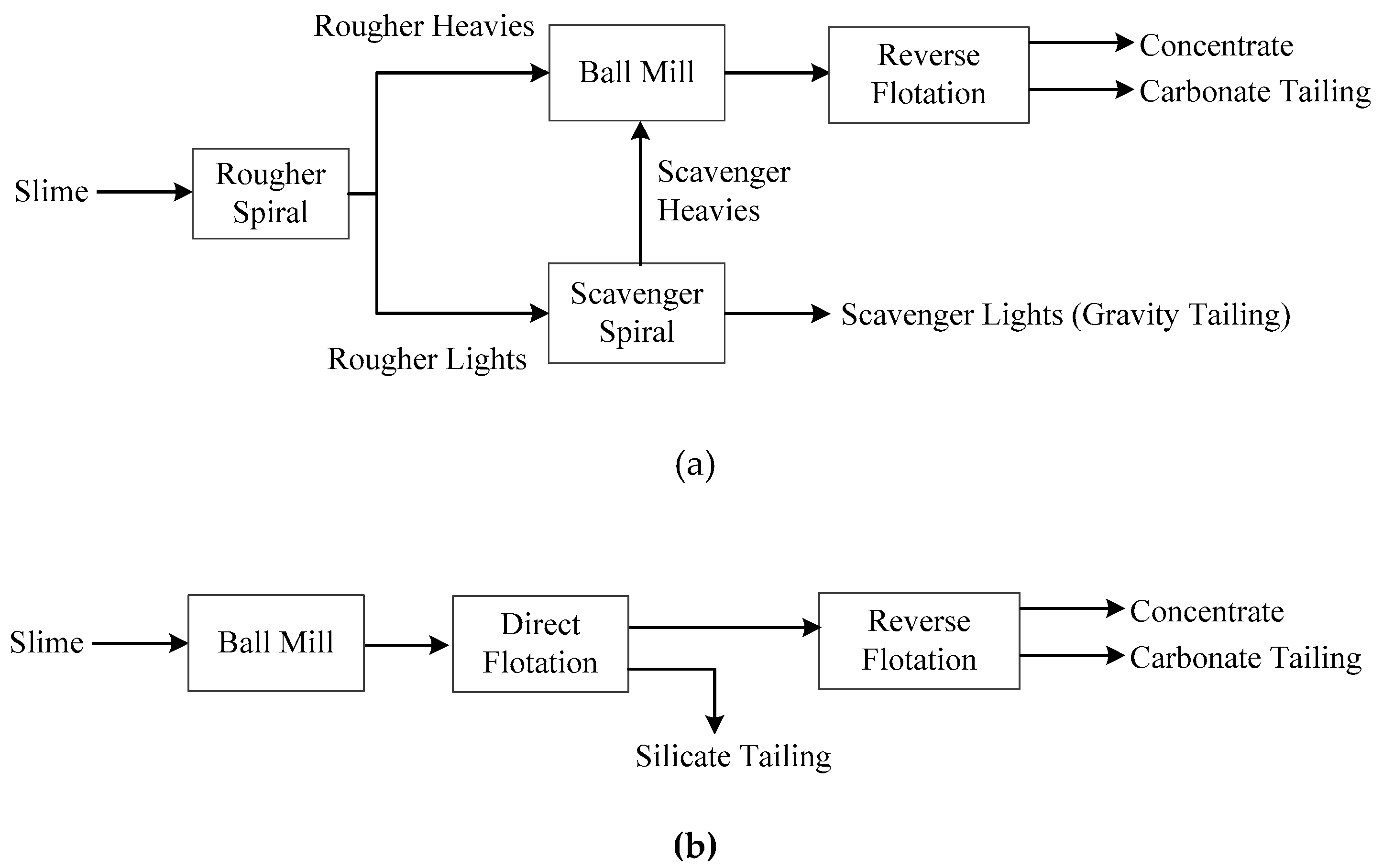

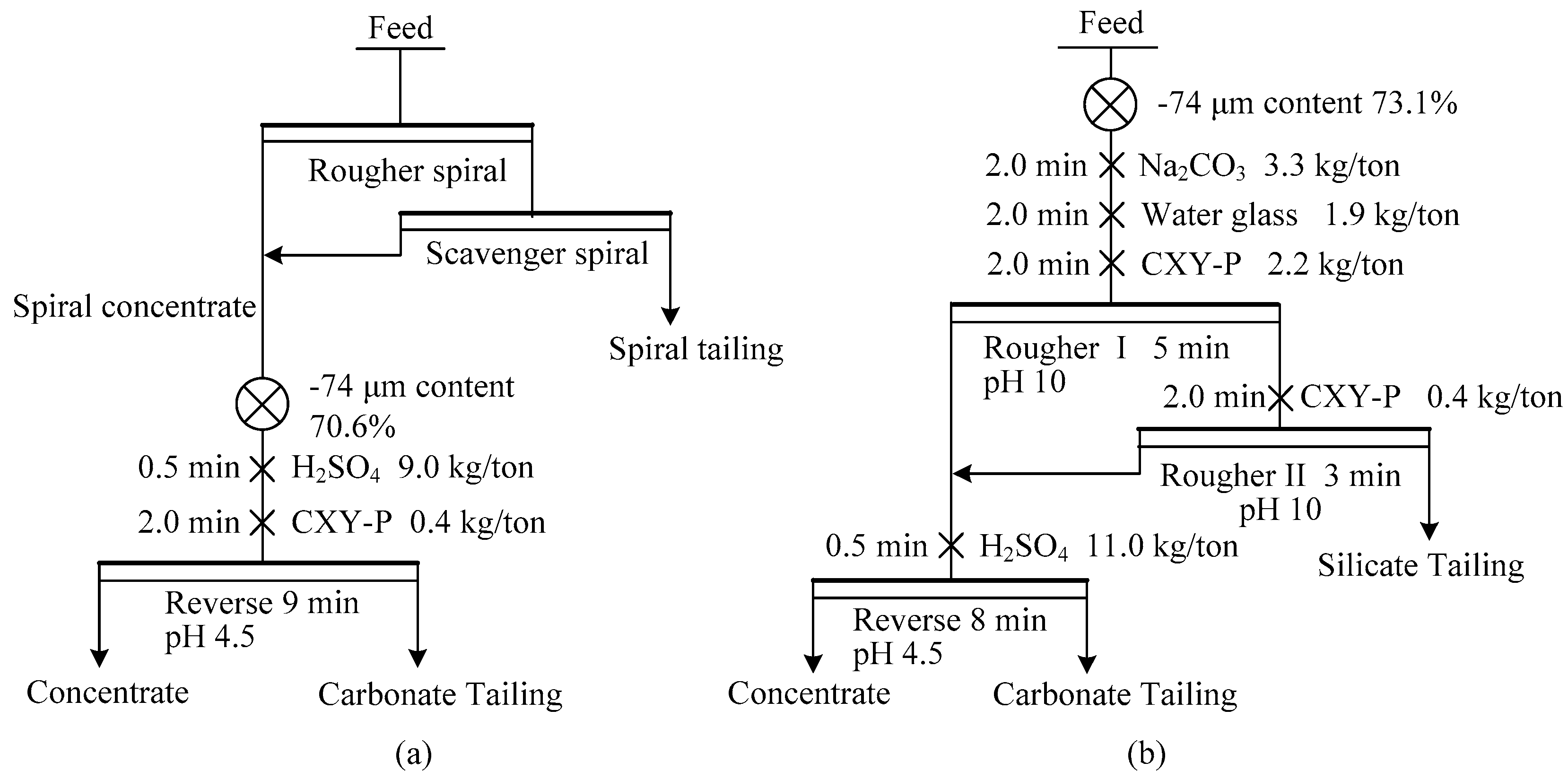

3.1. Gravity-Flotation Flowsheet

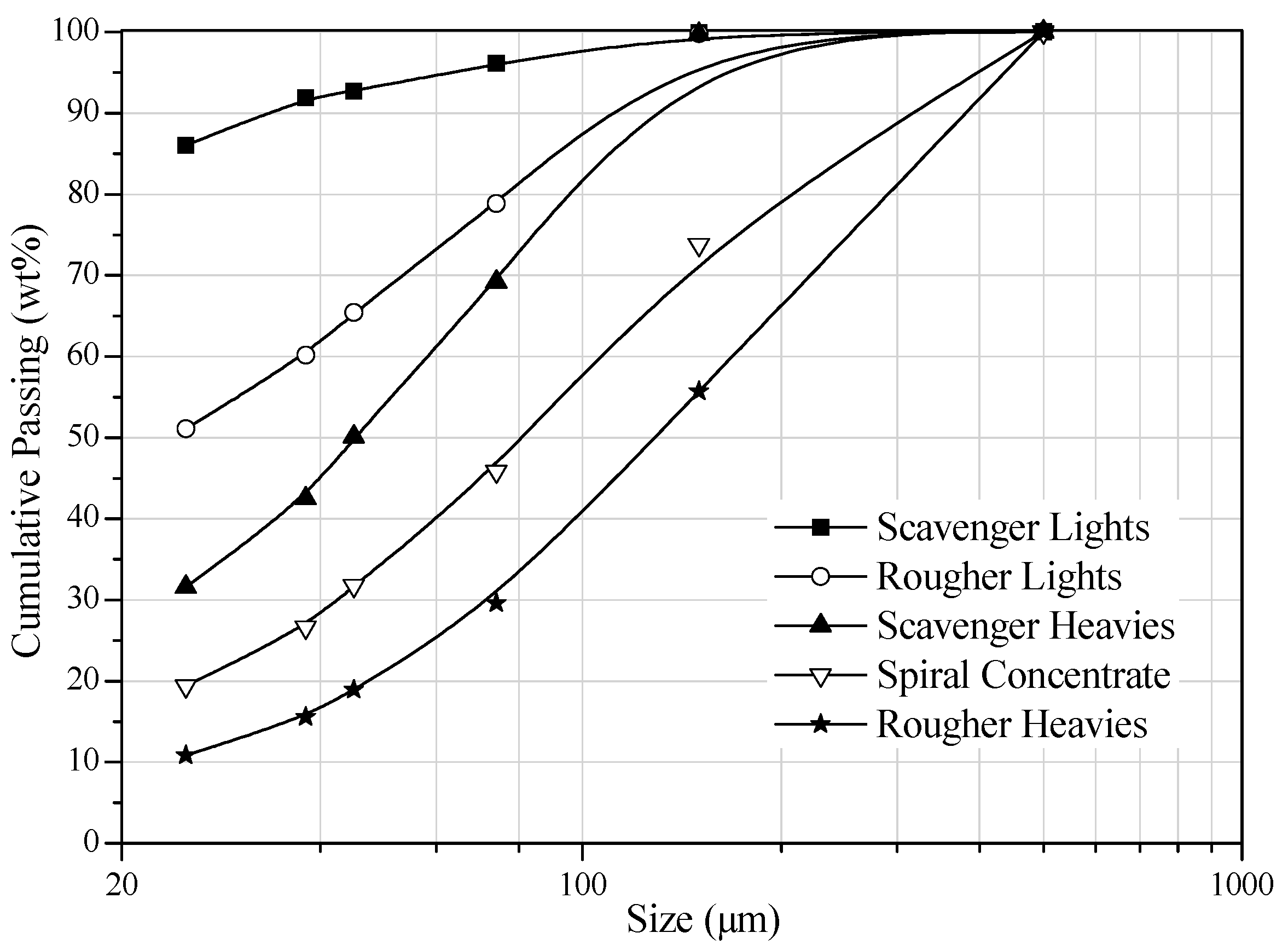

3.1.1. Gravity Separation Tests results

3.1.2. Reverse Flotation Tests Results

3.2. Direct-Reverse Flowsheet

3.3. Comparative Analysis of Flowsheets

4. Conclusions

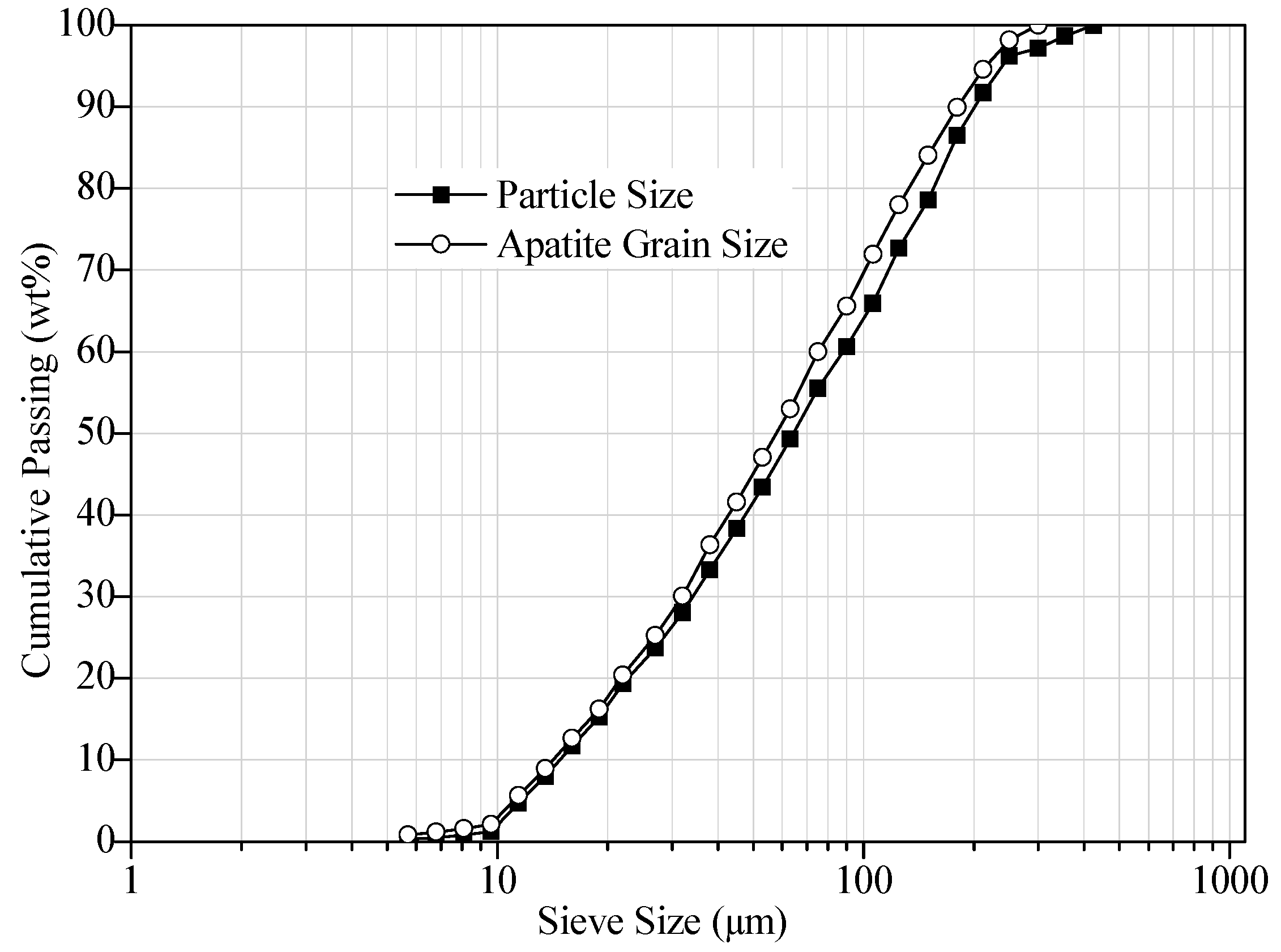

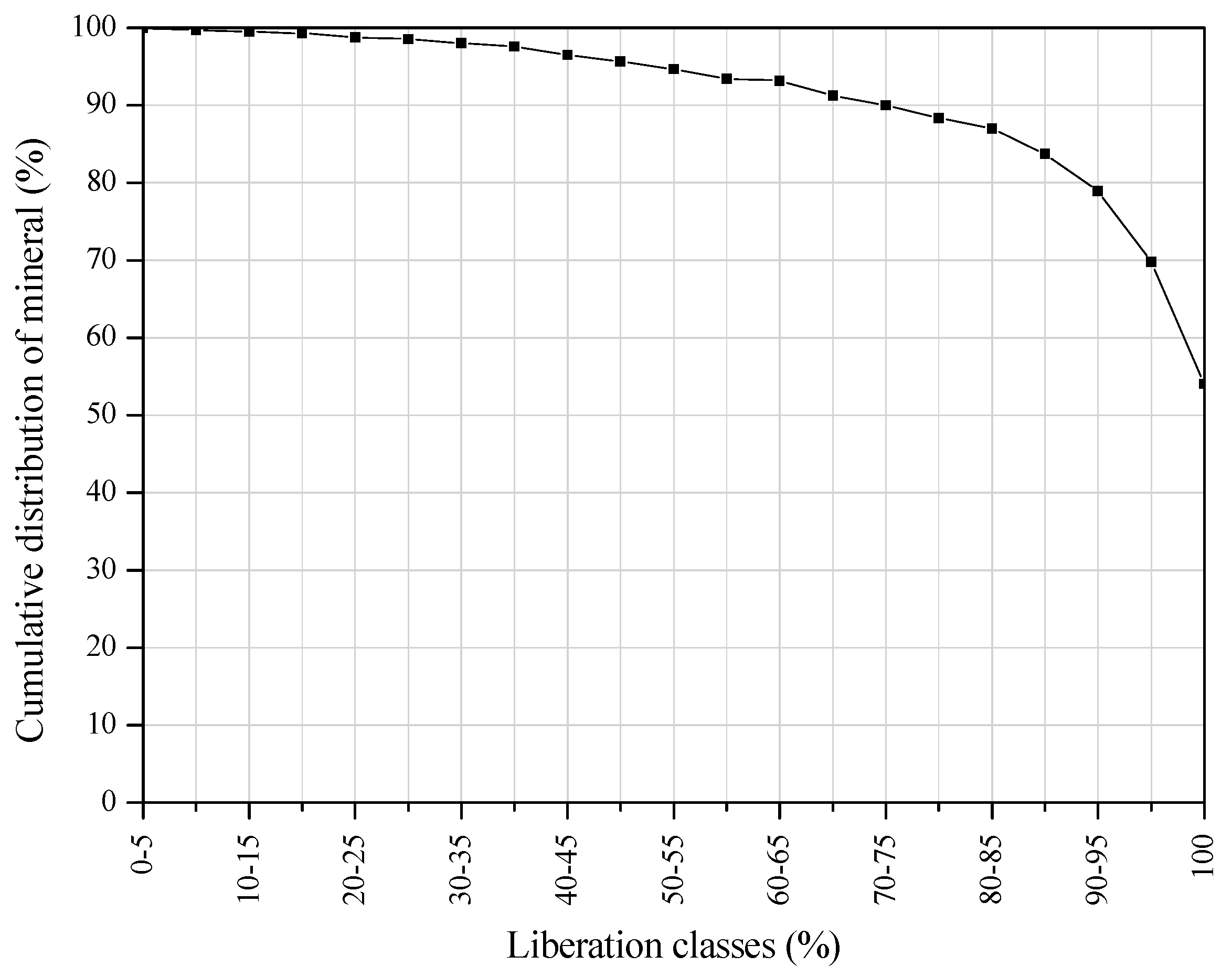

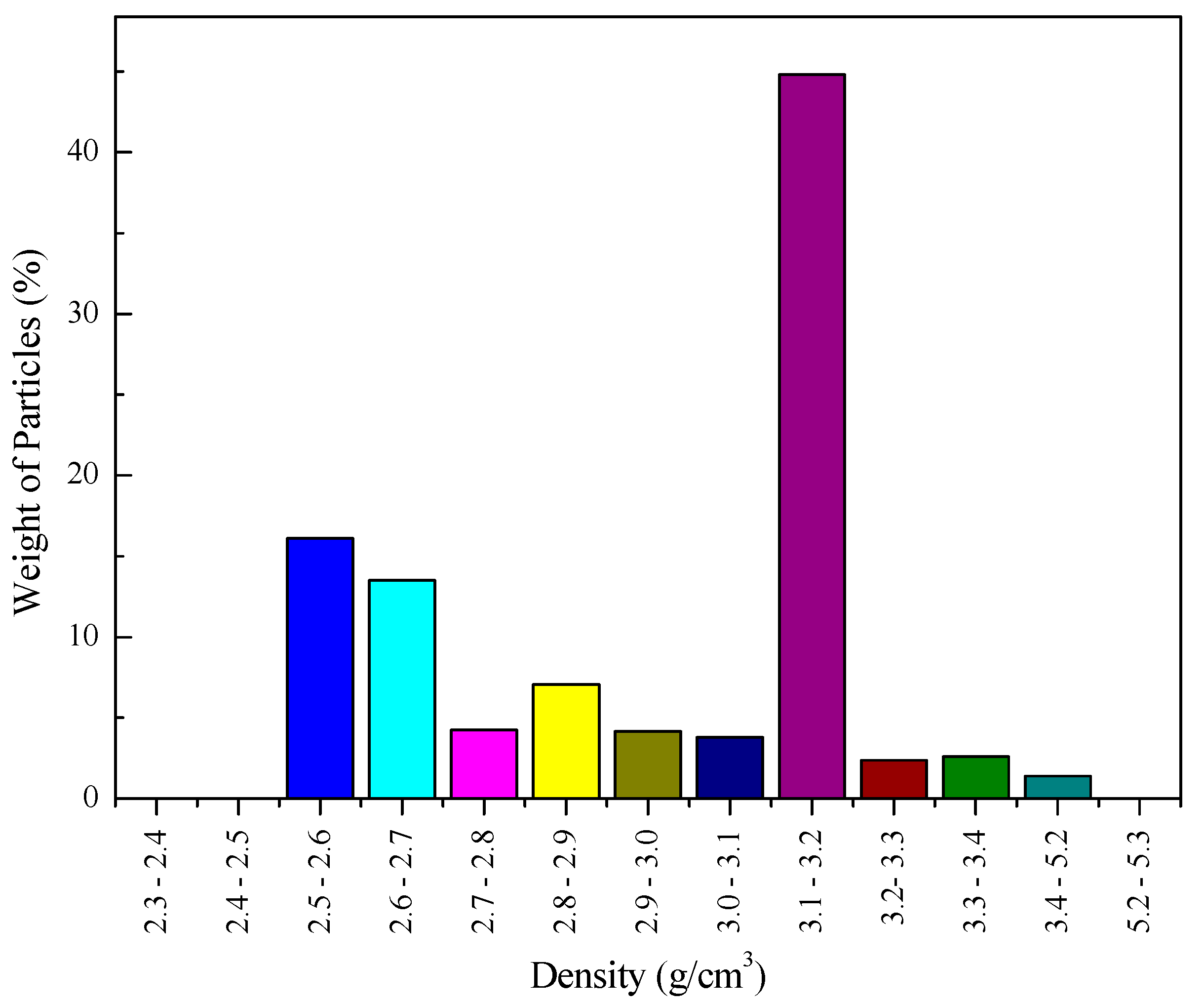

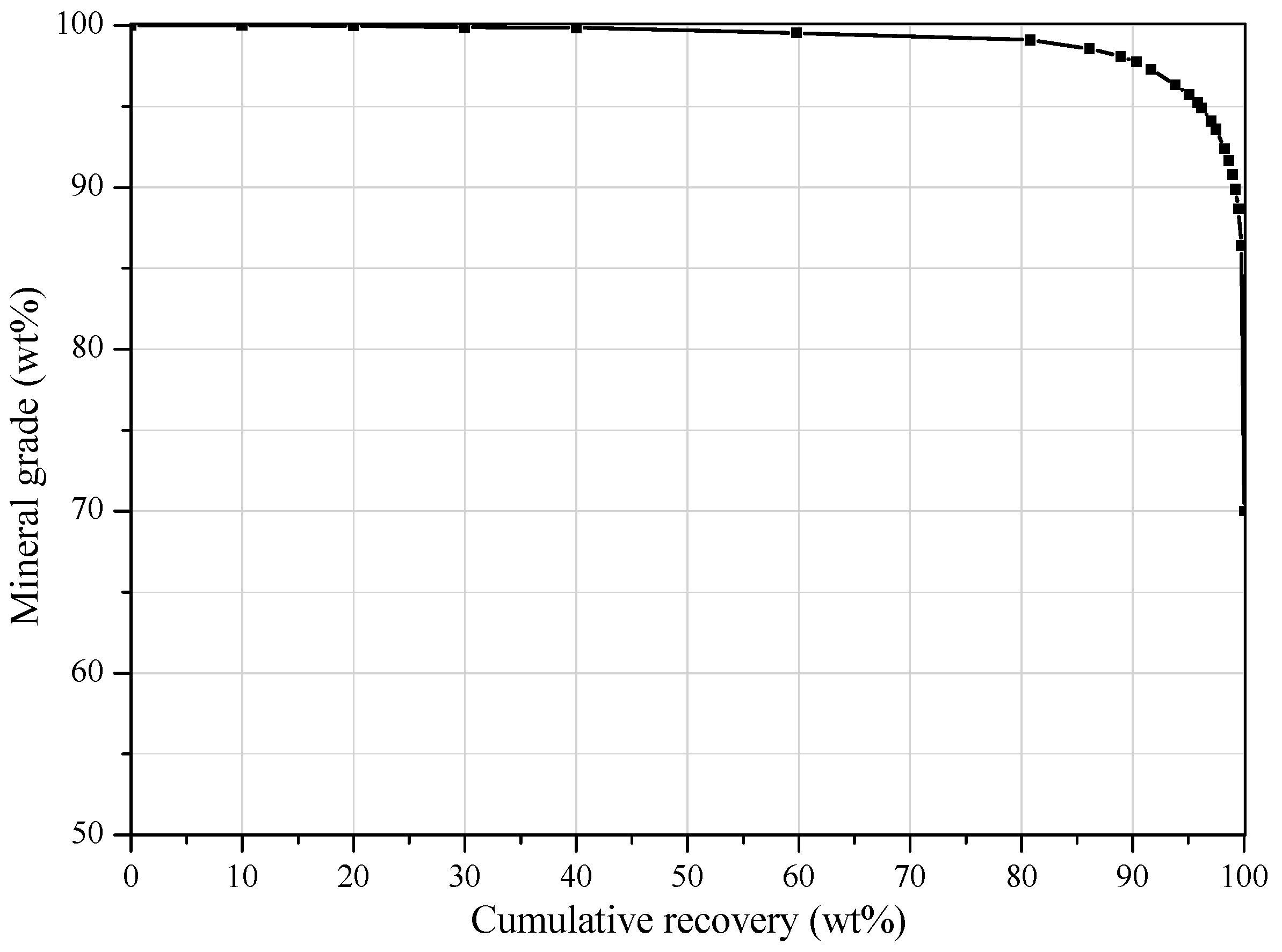

- (1)

- The generation of phosphate ore slime was about 14% from the heavy medium cyclone gravity process in the Yichang region. The slime contained 24.30% P2O5, 2.64% MgO, and 25.17% SiO2. Although the particle size of the slime was fine in distribution with d50 of 65 μm, nearly 80% of the apatite particles were liberated (above 90% liberation class), and the density of gangue minerals were mostly distributed at 2.5–2.7 g/cm3, which was lower than apatite mineral density of 3.1–3.2 g/cm3. It was concluded that the phosphate ore slime has a certain gravity separability.

- (2)

- Two different flowsheets were studied to recover the apatite. The first flowsheet comprised of the gravity concentration and reverse flotation, which produced of the concentrate assaying of 30.51% P2O5 and 0.59% MgO. Moreover, the second flowsheet comprised of the direct flotation and reverse flotation, which produced a concentrate assaying of 32.86% P2O5 and 0.59% MgO. Although in the second flowsheet, the product quality was enriched to higher than 32% P2O5, the reagent consumption was high, which may not be adopted from the economical of view. Compared to the direct-reverse flotation flowsheet, the reagent cost decreased from 56.7 CNY to 14.0 CNY for producing 1 t concentrate when using the gravity-flotation flowsheet, which is an optimal processing methods.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, N.F. Analysis and proposal about rational utilization of middle-low grade phosphate rock in Hubei province. Ind. Miner. Process. 2005, 11, 1–4. (In Chinese) [Google Scholar]

- Zafar, Z.I.; Anwar, M.M.; Pritchard, D.W. A new route for the beneficiation of low grade calcareous phosphate rocks. Fertil. Res. 1996, 44, 133–142. [Google Scholar] [CrossRef]

- Ge, Y.Y.; Gan, S.P.; Zeng, X.B.; Yu, Y.F. Double reverse flotation process of collophanite and regulating froth action. Trans. Nonferr. Met. Soc. China 2008, 18, 449–453. [Google Scholar] [CrossRef]

- Abouzeid, A.-Z.M. Physical and thermal treatment of phosphate ores-An overview. Int. J. Miner. Process. 2008, 85, 59–84. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, L.; Xu, Z.; Liu, Q.; Chi, R. Reactive oily bubble technology for flotation of apatite, dolomite and quartz. Int. J. Miner. Process. 2015, 134, 74–81. [Google Scholar] [CrossRef]

- Yu, J.; Ge, Y.Y.; Guo, X.L.; Guo, W.B. The depression effect and mechanism of NSFC on dolomite in the flotation of phosphate ore. Sep. Purif. Technol. 2016, 161, 88–95. [Google Scholar] [CrossRef]

- Lin, J. Application of double reverse flotation process in commercial production of difficult separated collophane in Yichang. Ind. Miner. Process. 2013, 8, 30–31. (In Chinese) [Google Scholar]

- Le, H.; Shao, T. Promoting of heavy medium cyclone and new technology application. Coal Sci. Technol. 2008, 5, 5–9. [Google Scholar]

- Tan, M.; Wei, M. Progress in beneficiation of phosphorite ores. Min. Metall. 2010, 4, 1–6. (In Chinese) [Google Scholar]

- Boulos, T.R.; Yehia, A.; Ibrahim, S.S.; Yassin, K.E. A modification in the flotation process of a calcareous–siliceous phosphorite that might improve the process economics. Miner. Eng. 2014, 69, 97–101. [Google Scholar] [CrossRef]

- Al-Thyabat, S. Empirical evaluation of the role of sodium silicate on the separation of silica from Jordanian siliceous phosphate. Sep. Purif. Technol. 2009, 67, 289–294. [Google Scholar] [CrossRef]

- Chen, J.; Chu, K.W.; Zou, R.P.; Yu, A.B.; Vince, A.; Barnett, G.D.; Barnett, P.J. Systematic study of the effect of particle density distribution on the flow and performance of a dense medium cyclone. Powder Technol. 2016, 314, 510–523. [Google Scholar] [CrossRef]

- Wei, X.S.; Huang, Q.S.; Li, Y.X. Study on dense media separation and its’ application in Huaguoshu phosphorite deposit. Geol. Chem. Miner. 2010, 3, 186–188. (In Chinese) [Google Scholar]

- Luo, H.H.; Liu, L.K.; Zhu, D.P.; Qu, D.J.; Miao, H.J.; Hu, X.C.; Hu, Z.; Zhang, Z.L. Recovery of fine-grain and low-grade collophane from gravity tailings of Yichang phosphate by flotation. Multipurp. Util. Miner. Resour. 2016, 3, 67–70. (In Chinese) [Google Scholar]

- Luo, H.H.; Shu, C.; Tong, Y.L.; Qu, D.J.; Miao, H.J.; Hu, X.C.; Hu, Z.; Zhang, Z.L. Recovery of Yichang phosphate by heavy fluid-separation and flotation combined process. Ind. Miner. Process. 2016, 7, 6–8. (In Chinese) [Google Scholar]

- Zhang, L.Y.; Hong, W.; Qiu, Y.S.; Song, Y.H. Experimental study on flotation of fine low grade collophane. Non-Met. Mines 2012, 2, 21–23. (In Chinese) [Google Scholar]

- Wu, C.B.; Duan, X.X. Studies on processing phosphorus ores in China. Yunnan Metall. 2000, 163, 19–22. (In Chinese) [Google Scholar]

- Liu, X.; Zhang, Y.M.; Liu, T.; Cai, Z.L.; Chen, T.J.; Sun, K. Beneficiation of a sedimentary phosphate ore by a combination of spiral gravity and direct-reverse flotation. Minerals 2016, 6, 38. [Google Scholar] [CrossRef]

- Sun, K.; Liu, T.; Zhang, Y.M.; Liu, X.; Wang, B.; Xu, C.B. Application and mechanism of anionic collector sodium dodecyl sulfate (SDS) in phosphate beneficiation. Minerals 2017, 7, 29. [Google Scholar] [CrossRef]

- Sandmann, D.; Gutzmer, J. Use of mineral liberation analysis (MLA) in the characterization of lithium-bearing micas. Miner. Mater. Charact. Eng. 2013, 1, 285–292. [Google Scholar] [CrossRef]

| Component | P2O5 | SiO2 | Al2O3 | Fe2O3 | MgO | CaO |

|---|---|---|---|---|---|---|

| Content (%) | 24.25 | 25.17 | 3.66 | 1.03 | 2.64 | 40.31 |

| Mineral | Apatite | Quartz | Clay | Dolomite | Calcite | Pyrite | Feldspar | Other |

|---|---|---|---|---|---|---|---|---|

| Content (%) | 57.5 | 12.5 | 9.2 | 14.8 | 2.1 | 1.0 | 0.5 | 2.4 |

| Size Fraction (μm) | Yield (%) | Grade (%) | Distribution (%) | ||

|---|---|---|---|---|---|

| P2O5 | MgO | P2O5 | MgO | ||

| +150 | 21.32 | 27.86 | 2.26 | 24.50 | 17.98 |

| −150 + 74 | 23.43 | 27.97 | 2.36 | 27.03 | 20.64 |

| −74 + 45 | 12.10 | 24.76 | 2.91 | 12.36 | 13.14 |

| −45 + 38 | 4.32 | 24.48 | 3.08 | 4.36 | 4.97 |

| −38 + 25 | 7.00 | 22.68 | 3.42 | 6.55 | 8.94 |

| −25 | 31.83 | 19.20 | 2.89 | 25.21 | 34.33 |

| Feed | 100 | 24.25 | 2.68 | 100.00 | 100.00 |

| Separation Units | Height | Pitch (P) | Outer Diameter (D) | P/D | Radial Width | Trough Slope Angle (θ) |

|---|---|---|---|---|---|---|

| Rougher | 920 mm | 160 mm | 400 mm | 0.40 | 184 mm | 8°~9° |

| Scavenger | 850 mm | 144 mm | 400 mm | 0.36 | 184 mm | 8°~9° |

| Products | Yield (%) | Grade (%) | Recovery (%) | ||

|---|---|---|---|---|---|

| P2O5 | MgO | P2O5 | MgO | ||

| Feed | 100.00 | 24.25 | 2.68 | 100.00 | 100.00 |

| Rougher heavies | 47.88 | 28.08 | 2.51 | 55.44 | 45.70 |

| Rougher lights | 52.12 | 20.73 | 2.74 | 44.56 | 54.30 |

| Scavenger heavies | 33.43 | 26.06 | 2.49 | 35.93 | 31.65 |

| Scavenger lights | 18.69 | 11.20 | 3.19 | 8.63 | 22.65 |

| Spiral concentrate | 81.31 | 27.25 | 2.50 | 91.37 | 77.35 |

| Products | Yield (%) | Grade (%) | Recovery (%) | ||

|---|---|---|---|---|---|

| P2O5 | MgO | P2O5 | MgO | ||

| Concentrate | 87.00 | 30.51 | 0.59 | 97.41 | 20.52 |

| Carbonate tailing | 13.00 | 5.43 | 15.30 | 2.59 | 79.48 |

| Spiral concentrate | 100.00 | 27.25 | 2.50 | 100.00 | 100.00 |

| Products | Yield (%) | Grade (%) | Recovery (%) | ||

|---|---|---|---|---|---|

| P2O5 | MgO | P2O5 | MgO | ||

| Concentrate | 66.86 | 32.76 | 0.55 | 89.65 | 14.43 |

| Carbonate tailing | 10.96 | 7.12 | 16.10 | 3.36 | 72.94 |

| Silicate tailing | 22.18 | 6.87 | 1.44 | 6.28 | 12.63 |

| Total | 100.00 | 24.08 | 2.53 | 100.00 | 100.00 |

| Process | Products | Yield (%) | Grade (%) | Recovery (%) | ||

|---|---|---|---|---|---|---|

| P2O5 | MgO | P2O5 | MgO | |||

| Gravity-flotation | Concentrate | 70.74 | 30.51 | 0.59 | 89.00 | 15.87 |

| Carbonate tailing | 10.57 | 5.43 | 15.30 | 2.37 | 61.48 | |

| Spiral tailing | 18.69 | 11.20 | 3.19 | 8.63 | 22.65 | |

| Total | 100.00 | 24.25 | 2.50 | 100.00 | 100.00 | |

| Direct-reverse | Concentrate | 66.36 | 32.76 | 0.55 | 89.65 | 14.43 |

| Carbonate tailing | 11.46 | 7.12 | 16.10 | 3.36 | 72.94 | |

| Silicate tailing | 22.18 | 6.87 | 1.44 | 6.28 | 12.63 | |

| Total | 100.00 | 24.08 | 2.53 | 100.00 | 100.00 | |

| Process | The Optimum Reagent Dosages (kg/t) | |||

|---|---|---|---|---|

| Sodium Carbonate | Water Glass | Sulfuric Acid | Collector | |

| Gravity-flotation | 0 | 0 | 9.0 | 0.4 |

| Direct-reverse | 3.3 | 1.9 | 11.0 | 2.6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, Y.; Liu, T.; Cai, Z.; Sun, K. Characterization and Separation Studies of a Fine Sedimentary Phosphate Ore Slime. Minerals 2017, 7, 94. https://doi.org/10.3390/min7060094

Liu X, Zhang Y, Liu T, Cai Z, Sun K. Characterization and Separation Studies of a Fine Sedimentary Phosphate Ore Slime. Minerals. 2017; 7(6):94. https://doi.org/10.3390/min7060094

Chicago/Turabian StyleLiu, Xin, Yimin Zhang, Tao Liu, Zhenlei Cai, and Kun Sun. 2017. "Characterization and Separation Studies of a Fine Sedimentary Phosphate Ore Slime" Minerals 7, no. 6: 94. https://doi.org/10.3390/min7060094

APA StyleLiu, X., Zhang, Y., Liu, T., Cai, Z., & Sun, K. (2017). Characterization and Separation Studies of a Fine Sedimentary Phosphate Ore Slime. Minerals, 7(6), 94. https://doi.org/10.3390/min7060094