Fibrous Platinum-Group Minerals in “Floating Chromitites” from the Loma Larga Ni-Laterite Deposit, Dominican Republic

Abstract

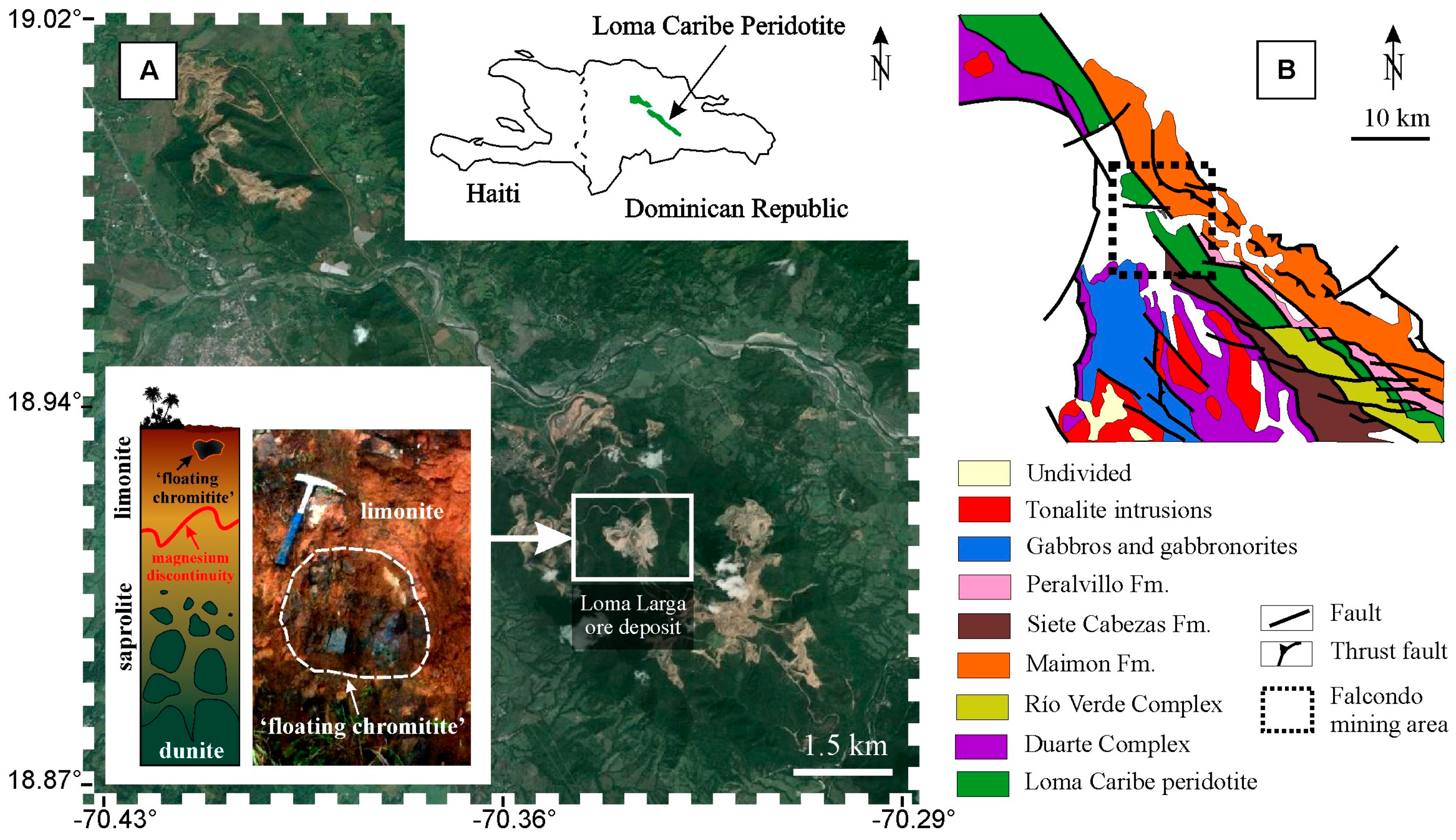

:1. Introduction

2. Sample Material and Methods

3. Mineralogy of Fibrous PGM

3.1. Detailed Investigation of One Fibrous PGM

3.1.1. Field Emission Scanning Electron Microscopy (FE-SEM)

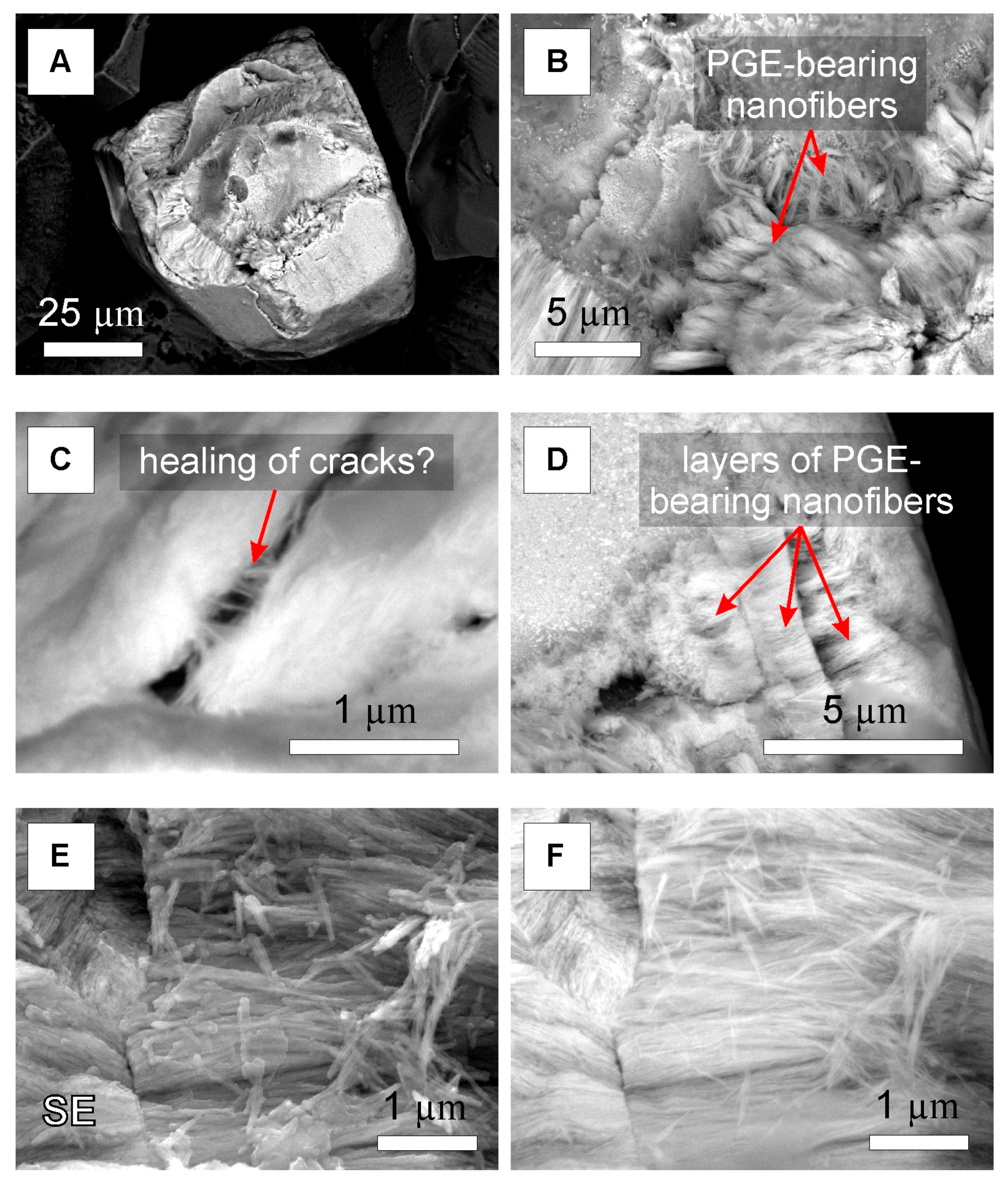

- the structure of the grain suggests an interdependency of PGM nanoparticles and nanofiber-bundles which are oriented orthogonal to the grain’s surface (Figure 3A,B,G,H);

- nanofibers occur within layers of nanofiber-bundles as well as within open spaces suggesting either in situ growth (“healing of cracks”) or misalignments (Figure 3C,D);

- comparison of BSE images and secondary electron (SE) images suggests that elements of high atomic number (PGE) are present in the central part of the nanofibers (bright in BSE images), whereas the outer part of the nanofibers appears to consist of elements with lower atomic numbers (e.g., Si) (Figure 3E,F);

- at the endings of nanofiber-bundles, a thin layer of a homogenous film occurs that host PGM nanoparticles (Figure 3G–J);

- within the central part of the grain a Si-rich, crater-like texture is present which occurs dark in BSE images (Figure 3A). This “crater” measures approximately 5 µm × 7 µm in diameter and hosts a great number of homogenously distributed PGM nanoparticles. At its periphery an Ir-rich accumulation (~1 µm in diameter) with a rather irregular shape is observed (Figure 3K);

- around the crater-like texture, PGM nanoparticles occur, which are characterized by ragged morphologies resembling sponge spicules. Interestingly, the Si-rich crater-like texture hosts smaller PGM nanoparticles than its Si-depleted immediate vicinity (Figure 3K);

- on plain walls at the upper part of the grain (Figure 3A), which represent the backside of nanofiber-bundles and therefore most likely film material, oval forms (~500 nm at the long axes) with included PGM nanoparticles occur, resembling observations by [21] in experiments with PGE reducing bacteria (Figure 3L).

3.1.2. X-ray Diffraction (XRD)

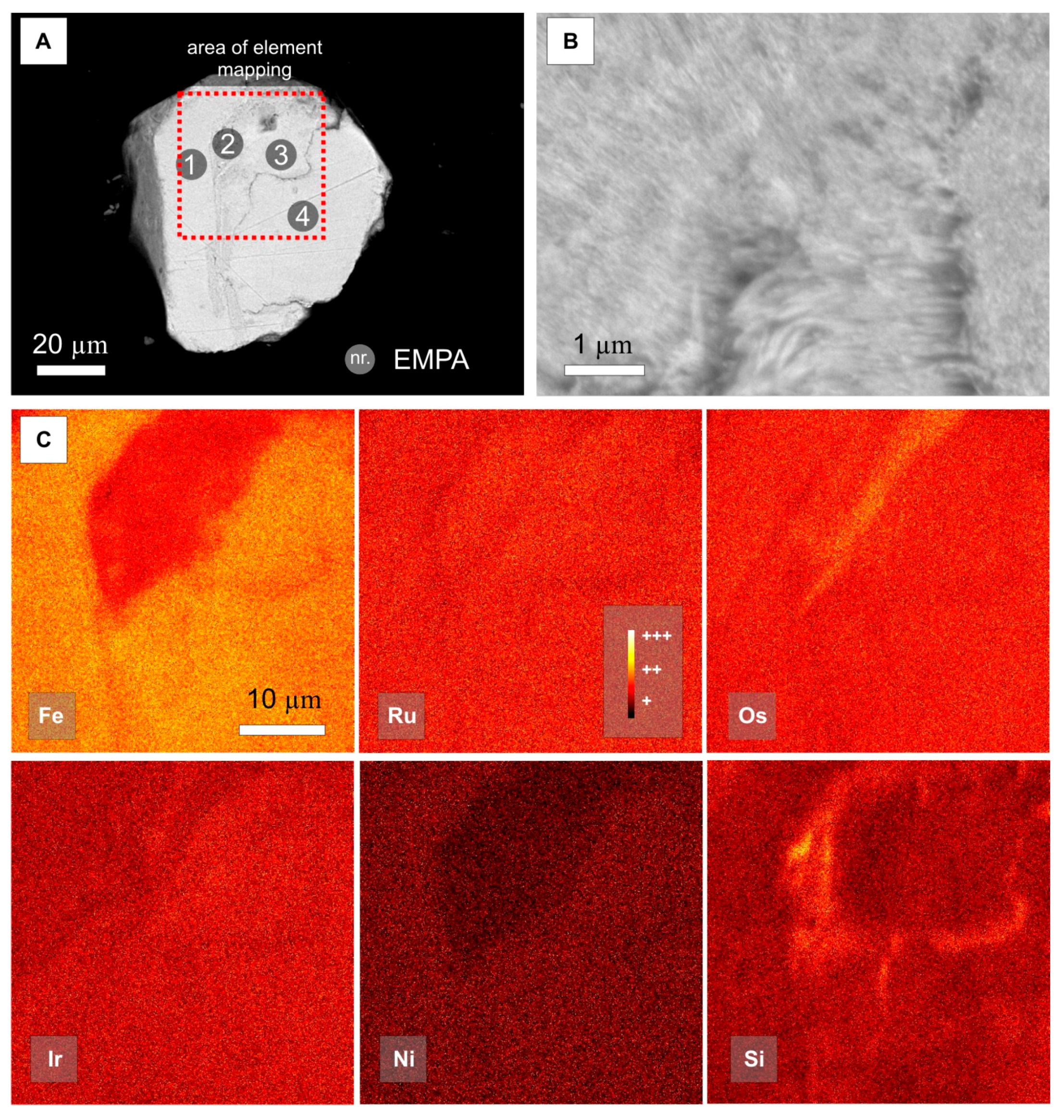

3.1.3. Electron Microprobe Analysis (EMPA)

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- European Commission (EC). Report on Critical Raw Materials for the EU; Report of the Ad-Hoc Working Group in Defining Critical Raw Materials; EC: Brussels, Belgium, 2014. [Google Scholar]

- United States Geological Survey (USGS). Mineral Commodity Summaries 2015. Available online: http://minerals.usgs.gov/minerals/pubs/commodity/platinum/mcs-2015-plati.pdf (accessed on 19 January 2016).

- Wilde, A.; Edwards, A.; Yakubchuk, A. Unconventional deposits of Pt and Pd: A review with implications for exploration. SEG Newsl. 2003, 52, 1 and 10–18. [Google Scholar]

- Gray, J.D.; Schorin, K.H.; Butt, C.R.M. Mineral associations of platinum and palladium in lateritic regolith, Ora Banda Sill, Western Australia. J. Geochem. Explor. 1996, 57, 245–255. [Google Scholar] [CrossRef]

- Maier, W.D.; Barnes, S.J.; Bandyayera, D.; Livesey, T.; Li, C.; Ripley, E. Early Kibaran rift-related mafic-ultramafic magmatism in western Tanzania and Burundi: Petrogenesis and ore potential of the Kapalagulu and Musongati layered intrusions. Lithos 2008, 101, 24–53. [Google Scholar] [CrossRef]

- Aiglsperger, T.; Proenza, J.A.; Lewis, J.F.; Labrador, M.; Svojtka, M.; Rojas-Purón, A.; Longo, F.; Ďurišová, J. Critical metals (REE, Sc, PGE) in Ni-laterites from Cuba and the Dominican Republic. Ore Geol. Rev. 2016, 73, 127–147. [Google Scholar] [CrossRef]

- Aiglsperger, T.; Proenza, J.A.; Font-Bardia, M.; Baurier-Amat, S.; Galí, S.; Lewis, J.F.; Longo, F. Supergene neoformation of Pt-Ir-Fe-Ni alloys: Multistage grains explain nugget formation in Ni-laterites. Miner. Depos. 2016. [Google Scholar] [CrossRef]

- Aiglsperger, T.; Proenza, J.A.; Zaccarini, F.; Lewis, J.F.; Garuti, G.; Labrador, M.; Longo, F. Platinum group minerals (PGM) in the Falcondo Ni-laterite deposit, Loma Caribe peridotite (Dominican Republic). Miner. Depos. 2015, 50, 105–123. [Google Scholar] [CrossRef]

- Reith, F.; Zammit, C.M.; Shar, S.S.; Etschmann, B.; Bottrill, R.; Southam, G.; Ta, C.; Kilburn, M.; Oberthür, T.; Ball, A.S.; et al. Biological role in the transformation of platinum-group-mineral grains. Nat. Geosci. 2016, 9, 294–298. [Google Scholar] [CrossRef]

- Redwood, S. Gold surge Mining is booming in the Dominican Republic as investors follow the gold rush. Min. J. 2014, 24, 23–27. [Google Scholar]

- Villanova-de-Benavent, C.; Proenza, J.A.; Galí, S.; García-Casco, A.; Tauler, E.; Lewis, J.F.; Longo, F. Garnierites and garnierites: Textures, mineralogy and geochemistry of garnierites in the Falcondo Ni-laterite deposit, Dominican Republic. Ore Geol. Rev. 2014, 58, 91–109. [Google Scholar] [CrossRef]

- Lewis, J.F.; Draper, G.; Proenza, J.A.; Espaillat, J.; Jiménez, J. Ophiolite-related ultramafic rocks (serpentinites) in the Caribbean region: A review of their occurrence, composition, origin, emplacement and nickel laterite soils. Geol. Acta 2006, 4, 237–263. [Google Scholar]

- Tauler, E.; Proenza, J.; Galí, S.; Lewis, J.; Labrador, M.; García-Romero, E. Ni-sepiolite-falcondite in garnierite mineralisation from the Falcondo Ni-laterite deposit, Dominican Republic. Clay Miner. 2009, 44, 435–454. [Google Scholar] [CrossRef]

- Villanova-de-Benavent, C.; Nieto, F.; Viti, C.; Proenza, J.A.; Galí, S.; Roqué-Rosell, J. Ni-phyllosilicates (garnierites) from the Falcondo Ni-laterite deposit (Dominican Republic): Mineralogy, nanotextures, and formation mechanisms by HRTEM and AEM. Am. Mineral. 2016, 101, 1460–1473. [Google Scholar] [CrossRef]

- Proenza, J.A.; Zaccarini, F.; Lewis, J.F.; Longo, F.; Garuti, G. Chromian spinel composition and the Platinum Group Minerals of the PGE-rich Loma Peguera chromitites, Loma Caribe peridotite, Dominican Republic. Can. Mineral. 2007, 45, 631–648. [Google Scholar] [CrossRef]

- Baurier-Aymat, S.; Aiglsperger, T.; Proenza, J.A.; Lewis, J.F.; Longo, F. Chromian spinel composition, PGE geochemistry and PGE mineralogy of different chromitites from the Loma Caribe peridotite, Dominican Republic. In Proceedings of the 13th SGA Biennial Meeting, Nancy, France, 24–27 August 2015; Volume 3, pp. 889–892.

- Bowin, C.O. Geology of the central Dominican Republic (a case history of part of an island arc). In Caribbean Geological Studies; Hess, H., Ed.; Geological Society of America: Boulder, CO, USA, 1966; Volume 98, pp. 11–84. [Google Scholar]

- Escuder-Viruete, J.; Pérez-Estaún, A.; Contreras, F.; Joubert, M.; Weis, D.; Ullrich, T.D.; Spadea, P. Plume mantle source heterogeneity through time: Insights from the Duarte Complex, Hispaniola, northeastern Caribbean. J. Geophys. Res. 2007, 112, B04203. [Google Scholar] [CrossRef]

- TOPAS. General Profile and Structure Analysis for Powder Diffraction Data, version 4.2; Bruker AXS GmbH: Karlsruhe, Germany, 2009. [Google Scholar]

- Aiglsperger, T.; Proenza, J.A.; Galí, S.; Rius, J.; Longo, F.; Domènech, C. The supergene origin of Ruthenian Hexaferrum in Ni-laterites. Terra Nova 2016. accepted. [Google Scholar]

- Konishi, Y.; Ohno, K.; Saitoh, N.; Nomura, T.; Nagamine, S.; Hishida, H.; Takahashi, Y.; Uruga, T. Bioreductive deposition of platinum nanoparticles on the bacterium Shewanella algae. J. Biotechnol. 2007, 128, 648–653. [Google Scholar] [CrossRef] [PubMed]

- Mochalov, A.G.; Dmitrenko, G.G.; Rudashevsky, N.S.; Zhernovsky, I.V.; Boldyreva, M.M. Hexaferrum (Fe,Ru), (Fe,Os), (Fe,Ir)—A new mineral. Zap Vseross Miner. Obshch 1998, 127, 41–51. (In Russian) [Google Scholar]

- Urashima, Y.; Wakabayashi, T.; Masaki, T.; Terasaki, Y. Ruthenium, a new mineral from Horokanai, Hokkaldo, Japan. Miner. J. (Jpn.) 1974, 7, 438–444. [Google Scholar] [CrossRef]

- Swanson, H.E.; Fuyat, R.K.; Ugrinic, G.M. Standard X-ray diffraction powder patterns. Natl. Bur. Stand. (U.S.) 1955, IV, 8. [Google Scholar]

- McDonald, A.M.; Proenza, J.A.; Zaccarini, Z.; Rudashevsky, N.S.; Cabri, L.J.; Stanley, C.J.; Rudashevsky, V.N.; Melgarejo, J.C.; Lewis, J.F.; Longo, F. Garutiite, (Ni,Fe,Ir), a new hexagonal polymorph of native Ni from Loma Peguera, Dominican Republic. Eur. J. Mineral. 2010, 22, 293–304. [Google Scholar] [CrossRef]

- Garuti, G.; Zaccarini, F. In situ alteration of platinum-group minerals at low temperature: Evidence from serpentinized and weathered chromitite of the Vourinos complex, Greece. Can. Miner. 1997, 35, 611–626. [Google Scholar]

- Uysal, I.; Zaccarini, F.; Sadiklar, M.B.; Bernhardt, H.-J.M.; Bigi, S.; Garuti, G. Occurrence of rare Ru-Fe-Os-Ir–oxide and associated Platinum-group minerals (PGM) in the chromitite of Mugla ophiolite, SW-Turkey. Neues Jahrb. Mineral. (Abh.) 2009, 185, 323–333. [Google Scholar] [CrossRef]

| Fibrous PGM | Ruthenian Hexaferrum 1 | Hexaferrum (PDF 54-0704) | Ruthenium (PDF 00-06-0663) | Osmium (PDF 00-041-0601) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Imeas | dmeas(Å) | hkl | Imeas | dmeas(Å) | hkl | Imeas | dmeas(Å) | hkl | Imeas | dmeas(Å) | hkl | Imeas | dmeas(Å) | hkl |

| 20 | 2.3097 | 100 | 20 | 2.3068 | 100 | 50 | 2.28 | 100 | 40 | 2.343 | 100 | 80 | 2.363 | 100 |

| 25 | 2.1181 | 002 | 20 | 2.1250 | 002 | 60 | 2.10 | 002 | 35 | 2.142 | 002 | 30 | 2.166 | 002 |

| 100 | 2.0279 | 101 | 100 | 2.0274 | 101 | 100 | 2.006 | 101 | 100 | 2.056 | 101 | 100 | 2.071 | 101 |

| 30 | 1.5611 | 102 | 25 | 1.5629 | 102 | 30 | 1.549 | 102 | 25 | 1.5808 | 102 | 40 | 1.594 | 102 |

| 35 | 1.3335 | 110 | 40 | 1.3318 | 110 | 30 | 1.316 | 110 | 25 | 1.3530 | 110 | 60 | 1.364 | 110 |

| 40 | 1.2047 | 103 | 50 | 1.2072 | 103 | 30 | 1.195 | 103 | 25 | 1.2189 | 103 | 20 | 1.232 | 103 |

| 10 | 1.1534 | 200 | 6 | 1.1715 | 200 | 10 | 1.180 | 200 | ||||||

| 50 | 1.1285 | 112 | 60 | 1.1285 | 112 | 20 | 1.118 | 112 | 25 | 1.1434 | 112 | 50 | 1.153 | 112 |

| 35 | 1.1142 | 201 | 40 | 1.1131 | 201 | 20 | 1.108 | 201 | 20 | 1.1299 | 201 | 40 | 1.039 | 201 |

| 4 | 1.0705 | 004 | 1 | 1.080 | 004 | |||||||||

| 5 | 1.0278 | 202 | 10 | 1.035 | 202 | |||||||||

| 6 | 0.9738 | 104 | 5 | 0.9835 | 104 | |||||||||

| 16 | 0.9056 | 203 | 40 | 0.9135 | 203 | |||||||||

| 6 | 0.8857 | 210 | 10 | 0.8929 | 210 | |||||||||

| 25 | 0.8673 | 211 | 50 | 0.8737 | 211 | |||||||||

| 18 | 0.8395 | 114 | 20 | 0.8472 | 114 | |||||||||

| 10 | 0.8185 | 212 | 20 | 0.8252 | 212 | |||||||||

| 16 | 0.8043 | 105 | 20 | 0.8123 | 105 | |||||||||

| 5 | 0.7974 | 204 | ||||||||||||

| 10 | 0.7866 | 300 | ||||||||||||

| Fibrous PGM | Ruthenian hexaferrum 1 | Hexaferrum 2 | Ruthenium 3 | Osmium 4 | Garutiite 5 | |

|---|---|---|---|---|---|---|

| Chem. Formula | (Ru,Os,Ir,Fe,Si,Al,Mn) | Ru0.4(Os,Ir)0.1Fe0.5 | (Fe,Os,Ru,Ir) | (Ru,Ir,Os) | (Os,Ir,Ru) | (Ni,Fe,Ir) |

| Crystal System | Hexagonal | Hexagonal | Hexagonal | Hexagonal | Hexagonal | Hexagonal |

| Group Unit cell | P63/mmc | P63/mmc | P63/mmc | P63/mmc | P63/mmc | P63/mmc |

| a | 2.6670 (13) | 2.664 (1) | 2.64 (1) | 2726 | 2726 | 2.6939 (5) |

| c (Å) | 4.2361 (18) | 4.250 (2) | 4.20 (2) | 4326 | 4326 | 4.2732 (6) |

| V (Å3) | 26.095 (27) | 26.12 (3) | 25.35 | 27.84 | 27.84 | 26.86 (1) |

| Z | 2 | 2 | 2 | 2 | 2 | 2 |

| wt % | ||||||||||||||||||

| S | As | Os | Ir | Ru | Rh | Pt | Pd | Fe | Ni | Cu | Co | Si | Al | Mg | Sb | Mn | Total | |

| 1 | 0.04 | 0.15 | 17.95 | 5.32 | 42.96 | bdl | bdl | bdl | 16.64 | 0.33 | 0.09 | 0.13 | 0.54 | 0.62 | 0.05 | bdl | 0.59 | 85.54 |

| 2 | 0.12 | 0.15 | 17.78 | 5.04 | 40.94 | 0.12 | bdl | bdl | 11.36 | 0.17 | 0.09 | 0.07 | 0.82 | 0.44 | 0.03 | 0.15 | 0.86 | 78.14 |

| 3 | 0.06 | 0.10 | 16.34 | 7.78 | 43.03 | bdl | bdl | bdl | 14.59 | 0.29 | 0.06 | 0.14 | 0.47 | 0.59 | 0.06 | bdl | 0.76 | 84.29 |

| 4 | 0.03 | 0.09 | 17.31 | 7.81 | 41.56 | bdl | bdl | bdl | 16.50 | 0.36 | 0.10 | 0.10 | 0.47 | 0.60 | 0.04 | bdl | 0.58 | 85.55 |

| at % | ||||||||||||||||||

| S | As | Os | Ir | Ru | Rh | Pt | Pd | Fe | Ni | Cu | Co | Si | Al | Mg | Sb | Mn | ||

| 1 | 0.14 | 0.22 | 10.33 | 3.03 | 46.54 | 0.00 | 0.00 | 0.00 | 32.63 | 0.62 | 0.16 | 0.25 | 2.11 | 2.50 | 0.23 | 0.00 | 1.17 | |

| 2 | 0.47 | 0.25 | 11.62 | 3.26 | 50.35 | 0.14 | 0.00 | 0.00 | 25.29 | 0.35 | 0.18 | 0.15 | 3.63 | 2.05 | 0.16 | 0.15 | 1.94 | |

| 3 | 0.20 | 0.15 | 9.76 | 4.60 | 48.38 | 0.00 | 0.00 | 0.00 | 29.69 | 0.56 | 0.10 | 0.28 | 1.92 | 2.49 | 0.29 | 0.00 | 1.57 | |

| 4 | 0.10 | 0.13 | 10.10 | 4.51 | 45.63 | 0.00 | 0.00 | 0.00 | 32.79 | 0.69 | 0.17 | 0.18 | 1.85 | 2.48 | 0.19 | 0.00 | 1.18 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aiglsperger, T.; Proenza, J.A.; Longo, F.; Font-Bardia, M.; Galí, S.; Roqué, J.; Baurier-Aymat, S. Fibrous Platinum-Group Minerals in “Floating Chromitites” from the Loma Larga Ni-Laterite Deposit, Dominican Republic. Minerals 2016, 6, 126. https://doi.org/10.3390/min6040126

Aiglsperger T, Proenza JA, Longo F, Font-Bardia M, Galí S, Roqué J, Baurier-Aymat S. Fibrous Platinum-Group Minerals in “Floating Chromitites” from the Loma Larga Ni-Laterite Deposit, Dominican Republic. Minerals. 2016; 6(4):126. https://doi.org/10.3390/min6040126

Chicago/Turabian StyleAiglsperger, Thomas, Joaquín A. Proenza, Francisco Longo, Mercè Font-Bardia, Salvador Galí, Josep Roqué, and Sandra Baurier-Aymat. 2016. "Fibrous Platinum-Group Minerals in “Floating Chromitites” from the Loma Larga Ni-Laterite Deposit, Dominican Republic" Minerals 6, no. 4: 126. https://doi.org/10.3390/min6040126

APA StyleAiglsperger, T., Proenza, J. A., Longo, F., Font-Bardia, M., Galí, S., Roqué, J., & Baurier-Aymat, S. (2016). Fibrous Platinum-Group Minerals in “Floating Chromitites” from the Loma Larga Ni-Laterite Deposit, Dominican Republic. Minerals, 6(4), 126. https://doi.org/10.3390/min6040126