5.1. Flotation Model: First-Order Rate Equation

The objective of a flotation model is to predict the recovery rate (rate of mass flow of useful minerals collected from a flotation cell). Following Koh and Schwarz [

13], we model the flotation kinetics as a first-order rate process, which is given by the fundamental equation:

where

is the particle number concentration (number of particles per unit volume) of free particles (not attached to bubbles),

is the number concentration of bubbles available for attachment (not fully loaded bubbles),

is the number of particle-bubble aggregates (bubbles that cannot accept more particles but can lose particles),

is the average particle-bubble attachment rate constant, and

is the average particle-bubble detachment rate constant. We note the difference in the dimensions (units) of

(m

3/s) and

(1/s). The total particle number concentration

is:

where

is the number concentration of particles attached to bubbles. All number concentrations are functions of time and location in a flotation cell. A bubble is either fully loaded (cannot accept more particles) or clean (no particles attached). The number of particle-bubble aggregates is proportional to the total number of bubbles,

where

is an average loading parameter, which varies with time and position. The number of clean bubbles (those available for attachment) is

The rate equation can now be written as:

The number of particles (

S) that can be attached to a bubble is given by the ratio of surface area of the bubble to the projected area of the particle.

Such an estimation is not realistic. In Koh and Schwarz [

13] work, only half of that number is assumed as a first approximation.

5.3. Collision Kernel

The collision kernel

is perhaps the most important ingredient of the attachment rate constant

. For turbulent flows, two classical models are in use. The first is Saffman and Turner model [

14], which is applicable in the limit of zero Stokes particle number. The second is Abrahamson model [

8] which is applicable in the limit of infinite particle Stokes number. The form of the later model is usually written (Schubert and Bischofberger 1979) [

15] as:

where

and

are the turbulent (

) fluctuating velocities of the particles and bubbles relative to the carrier liquid, respectively. Leipe and Mockel’s [

16] formula (not the original formula by Abrahamson) is used for these velocities,

where

is dissipation rate of the turbulent kinetic energy per unit mass (w/kg),

and

are the kinematic viscosity and density of the liquid, respectively.

and

are the density and diameter of the colliding particles,

for particles and

for bubbles. The mass density for a bubble is assumed to be equal 0.5

, as if the bubble mass is the virtual mass of a spherical bubble. This equation implies that high dissipation results in higher collisions rates between bubbles and particles, and in this regard high dissipation has favorable effects on flotation. Schubert [

15] model have been developed for very high inertia particles. In minerals, flotation particles have a wide spectrum of inertia. Therefore, application of Schubert collisions model results in over prediction of collision kernel as discussed by Fayed [

17].

Zaichik

et al. [

9] developed another statistical model for the collisions kernel for particles and bubbles. The model applies to arbitrary values of density ratio and particle sizes. This model has been validated by Fayed and Ragab [

18] to study its limitation and it provides more accurate prediction for collisions kernel than Schubert model [

15]. The model is not presented here because of the space and interested reader is referred to Zaichik

et al. [

9] and Fayed [

17] where the model has been presented and discussed extensively. In this paper, comparison between Schubert model [

15] and Zaichik

et al. model [

9] is presented to show the over-estimation of collision kernel by the former model. Hence, Zaichik

et al. model [

9] has been used herein for more accurate prediction of collision kernel.

5.4. Flotation Probabilities

Process of minerals flotation involves two main events which are collisions of particles with bubbles and attachment of the colliding particles with bubbles. The first event happens under turbulent flow conditions where particles and bubbles sizes and turbulent velocity

rms fluctuations are the main variables that control this event. Upon collision, useful minerals particles have to attach to the bubble and then transported to the froth phase by buoyancy of bubbles. The attachment process is due to the adhesive forces between particles and bubbles and then stabilization of the particle-bubble aggregates. An accurate model for collisions frequency of particles and bubbles has been used in this work [

9] to estimate kernel collisions. The second step is to model for the probability of particles’ attachment to a bubble. In the literature, considerable efforts have been made to model for the probabilities of collisions, adhesion and stabilization. The concept of probability of collisions has been developed under laminar flow conditions which do not exist in minerals flotation. In this section, we summarize and present models for probabilities of collisions, adhesion and stabilization developed by other authors. These models have been used in our CFD-flotation model to predict pulp recovery rate of a flotation cell. Hopefully, some validation work will be completed on a fundamental level in future to study the limitations of these models and their accuracy.

The probability (efficiency) of collision

Pc is given by a formula due to Yoon and Luttrell [

10],

where the bubble Reynolds number is defined by

. In the actual calculations

is limited to a maximum of 1.

The expression for probability of adhesion

Pa is also derived by Yoon and Luttrell [

10],

where

is the induction time, which is determined by an empirical formula due to Dai

et al. [

19]:

where

is measured in seconds,

is particle-bubble contact angle in degrees, and

is the particle diameter in meters.

The formula proposed by Schulze [

20] and modified by Bloom and Heindel [

12] for the probability of stabilization

is used:

where the modified Bond number is defined by:

where

As = 0.5 is an empirical constant suggested by Bloom and Heindel [

12], where

is the surface tension (N/m),

, and g is the gravitational acceleration.

5.6. Particle Size Distribution

Particles in the feed slurry to a flotation machine have a particle size distribution. Several models in the literature have been developed to account for different particles properties in the feed slurry. These models predict the global rate constant of a flotation cell and classified into three groups—discrete rate constant distribution, continuous rate constant distribution and mean rate constant. Several discrete rate constant models have been developed but they differ in the number of fractions (Morris [

21], Kelsall [

22], Cutting [

23], Jowett [

24], Imaizumi [

25]). Two fraction discrete models developed by (Kelsall [

22]) are named as fast float and slow float fractions. Continuous rate constant models assume that rate constants are distributed as a continuous distribution represented by a Gamma-distribution function (Harris [

26], Woodburn [

27], Loveday [

28], Kappur [

29]). The mean rate constant model has been proposed by Chen (Chen Z.M. [

30,

31]). However, prediction of rate constant in all flotation models is strongly affected by operating conditions as well as particles and bubbles properties on a local basis. Flotation modeling using CFD enables more accurate prediction of rate constant and helps to assess the performance of a flotation cell.

The attachment rate

as given above is mainly a function of bubble size, particle size, air/water surface tension and contact angle. An effective pulp recovery rate constant proposed here is defined by:

We recognize the factor

as the local number concentration of bubbles, and the factor

is included so that in a region of high air volume fraction (

the recovery rate should drop to zero. The local number concentration of particles

depends on slurry loading, and we expect it to be proportional to the local water volume fraction, (

). We believe that including the factor (

) gives a better figure of merit that can be used to evaluate different designs in the absence of

distribution. The machine average rate constant is obtained by integration over the machine volume,

where

is a froth recovery factor.

Minerals particles in the feed slurry have a size distribution and this distribution has great impact on recovery rate. Let

denote the pdf of particle size distribution. Particle size distribution depends on the grinding process and metallurgical properties of the minerals particles. The current CFD-based flotation kinetic model can be used to determine pulp recovery rate for both bubble size and particle size distributions. We assume a Gamma-distribution for the particles number density function.

where

is the minimum possible particle diameter and

is the Gamma function. In this paper, we used

and

. To obtain different particles number distributions, we assign different values for

starting from 1.0–15, incremented by one. This also changes the mean diameter. The pseudo rate constant for particle size distribution

is computed:

and

are the minimum and maximum particle diameters present in the feed slurry.

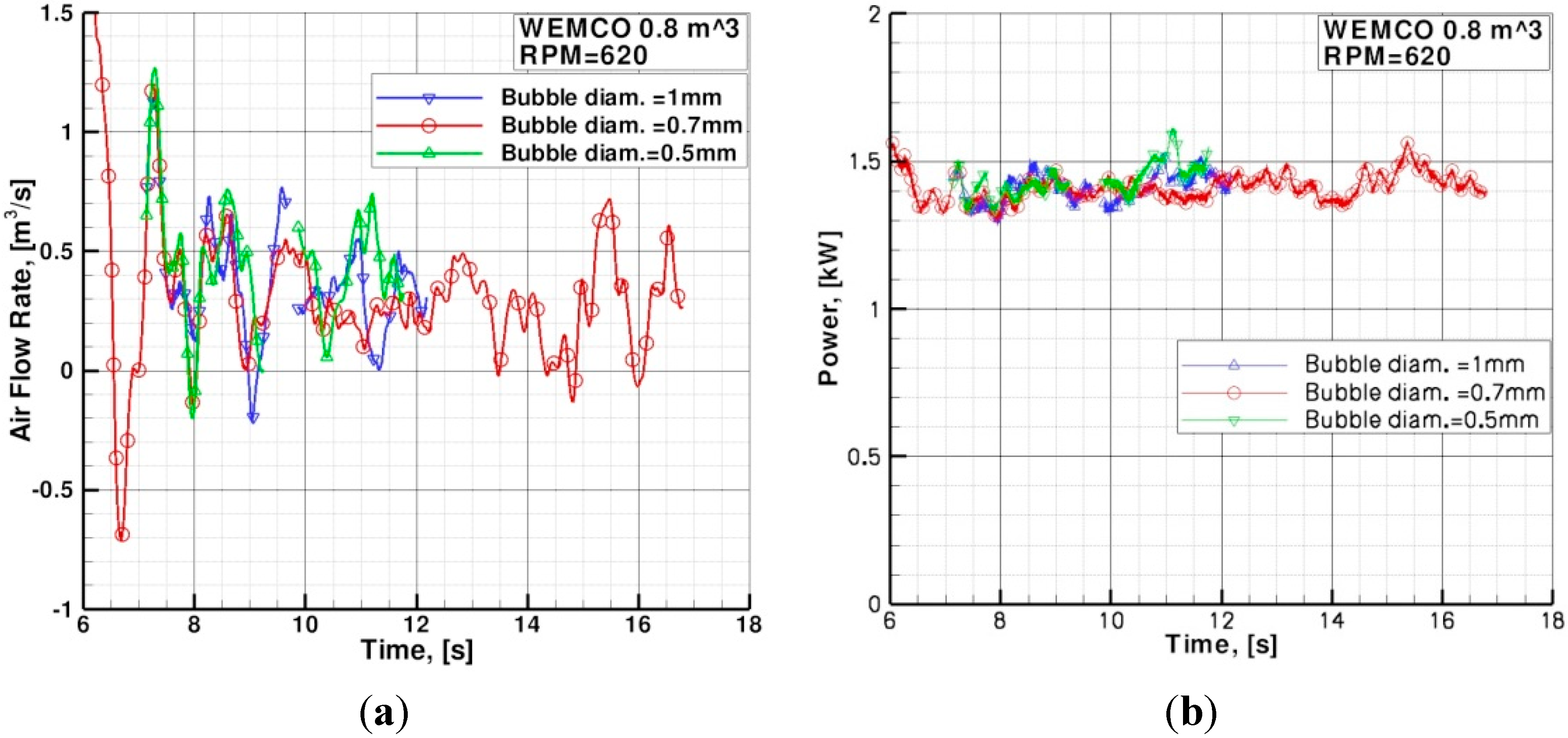

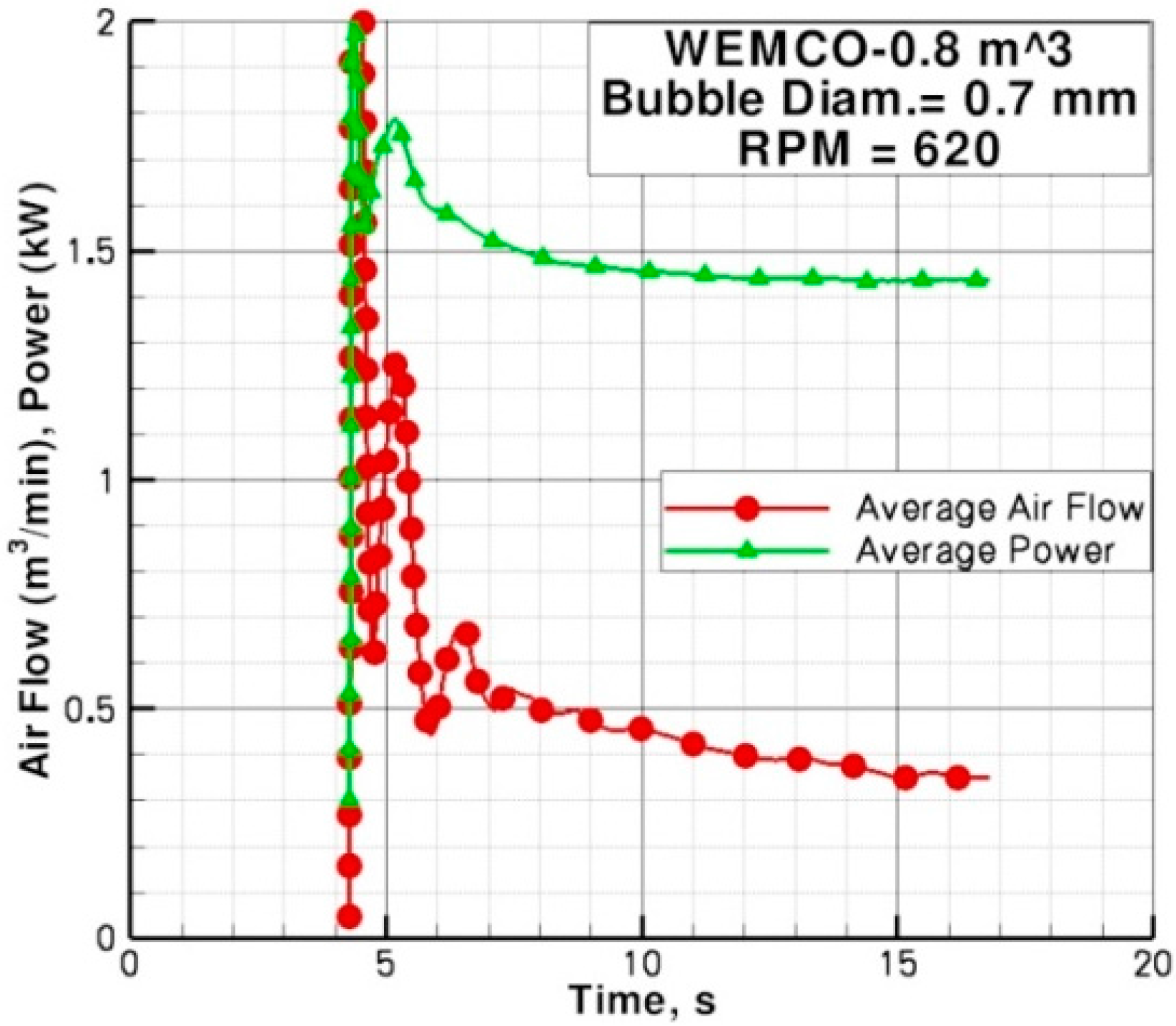

5.7. Flotation Results

In this section, we demonstrate the viability of CFD-based flotation model as a tool to evaluate the performance of flotation machines and provide detailed hydrodynamic and kinetics data that can help improve the design of such machines. Ragab and Fayed [

32] developed a CFD-based flotation model, and used it to determine the effects of particle size on the rate constant. We use particle specific gravity

, contact angle

, and surface tension

as input parameters to the flotation model. Two-phase hydrodynamic simulations provided spatial distributions of dissipation rate,

, and air volume fraction,

(also called void fraction). The number concentration of bubbles is

, where

is the bubble volume and spherical bubbles are assumed. Particles-bubbles collisions rate has been estimated using Zaichik

et al.’s model [

9]. Zaichik

et al.’s model and probabilities models rely on velocity fluctuations, bubble diameter, particle diameter, particle density, air void fraction, contact angle and air-water surface tension coefficient. Velocity fluctuation,

has been estimated from the local eddy viscosity and dissipation rate. Local air void fraction is obtained from the CFD results of the two-phase flow. Other parameters are user input. CFD-based flotation kinetics model is a post processing program to the two-phase simulations runs of flotation cells such as Wemco 0.8 m

3. Effects of particles size distribution on pulp recovery rate are presented here.

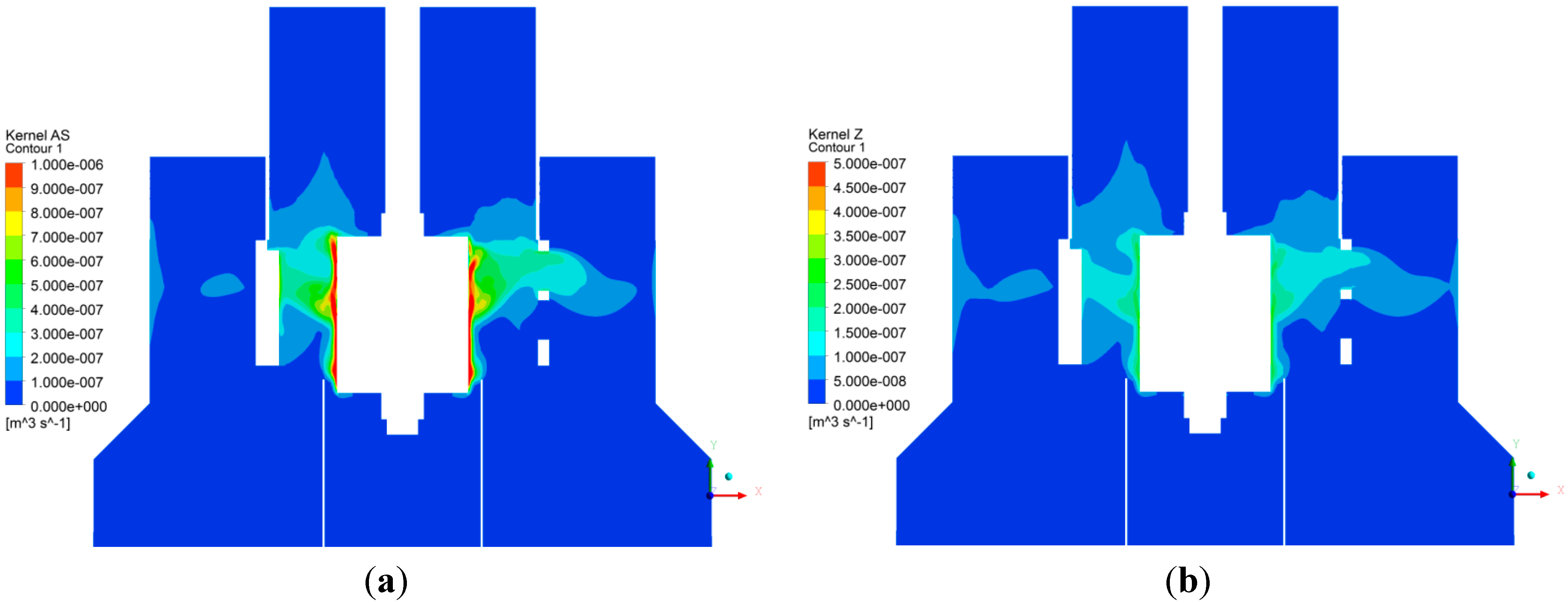

As described above, accurate estimation of particle-bubble collision rate is essential for accurate modeling of rate constant. Fayed and Ragab [

18] validated Zaichik

et al. model [

9] and recommended it for use in flotation modeling. A comparison between collisions kernel by Schubert model [

15] and Zaichik

et al. model [

9] are shown in

Figure 10a,b. Schubert model overestimates the collisions kernel by an order of magnitude when compared to that of Zaichik

et al. model. Based on these results, we recommend Zaichik

et al. model in flotation kinetics.

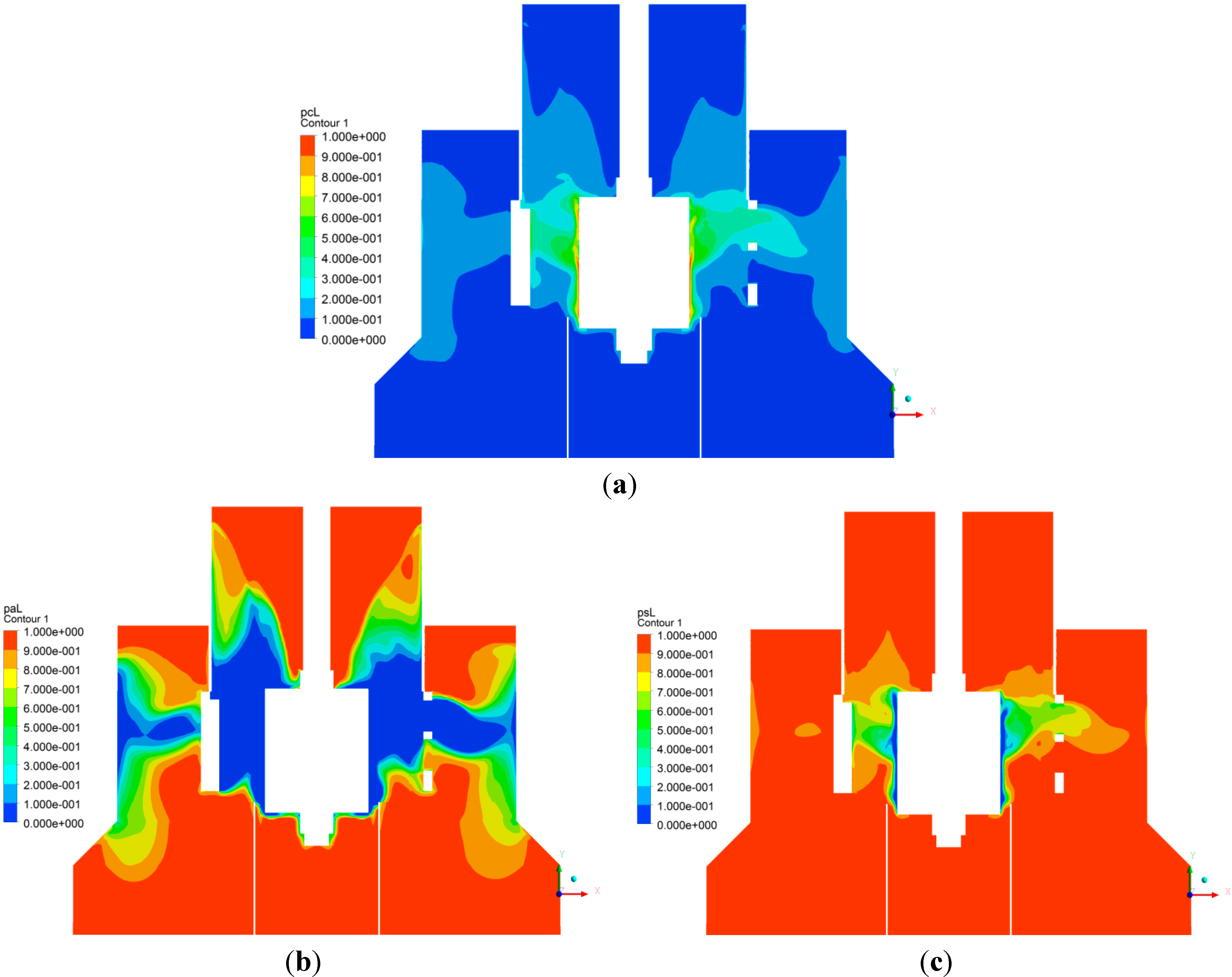

Figure 11a–c shows the spatial distribution of probabilities of collision, adhesion and stabilization in a vertical plane that passes through the machine axis.

Figure 11a,b shows the favorable effects of turbulent dissipation rate where higher collisions rate and higher probability of collisions in the region between rotor and disperser and within the jet region. However, high local dissipation rates have adverse effects on the probabilities of adhesion and stabilization where low values are observed in the regions between rotor and disperser and within the jet. As described above, flotation process is mainly due to two events—collisions of particles and bubbles and particles attachment to a bubble. That is to say, we can achieve high dissipation rate regions that cause a high collisions rate but lower rates of attachment are obtained which results in a lower rate constant. Therefore, the presented CFD-based flotation model in this paper is a useful tool to optimize for rate constant in flotation machines.

Figure 10.

(

a) Abrahmson-Schubert [

6] collisions kernel for

dp = 100 micron; (

b) Zaichik

et al. [

9] collisions kernel for

dp = 100 micron.

Figure 10.

(

a) Abrahmson-Schubert [

6] collisions kernel for

dp = 100 micron; (

b) Zaichik

et al. [

9] collisions kernel for

dp = 100 micron.

Figure 11.

(a) Probability of collisions for dp = 100 micron; (b) Probability of adhesion for dp = 100 micron; (c) Probability of stabilization for dp = 100 micron.

Figure 11.

(a) Probability of collisions for dp = 100 micron; (b) Probability of adhesion for dp = 100 micron; (c) Probability of stabilization for dp = 100 micron.

The product of collision kernel and probabilities of collision, adhesion and stabilization gives the local attachment rate

. An effective pulp recovery rate constant (in the absence of detachment) is defined here by

, and corresponding contours are depicted in

Figure 12a–d. The factor

is included in this definition so that in a region of 100% air (

) the local recovery rate should be zero. The spatial distribution of

, which is zero if

or

and maximum if

(50% void fraction), implies that the local recovery rate is maximized when the air is well dispersed throughout the machine. The actual recovery rate will depend on the balance between the favorable effects of dissipation rate

in increasing the collision frequency against its adverse effects on reducing the attachment rate and increasing detachment rate. Therefore, knowing the spatial distributions of both

and

throughout the machine is essential in understanding the effectiveness of different components (rotor, stator or disperser, jets) on the flotation efficiency. Only through CFD of two-phase simulations (or elaborate experimental measurements) one can determine those spatial distributions. This is a clear advantage of CFD-based flotation models in comparison with models that treat the entire cell as one unit which assumes a single value for

determined by the consumed power and single value for

that is equal to the gas holdup.

Figure 12.

(a) Pulp recovery rate

for 40 μm particle diameter; (b) Pulp recovery rate

for 100 μm particle diameter; (c) Pulp recovery rate

for 200 μm particle diameter; (d) Pulp recovery rate

for 300 μm particle diameter.

Figure 12.

(a) Pulp recovery rate

for 40 μm particle diameter; (b) Pulp recovery rate

for 100 μm particle diameter; (c) Pulp recovery rate

for 200 μm particle diameter; (d) Pulp recovery rate

for 300 μm particle diameter.

Particle diameter has significant effects on distribution of the pulp rate constant

throughout the Wemco machine. Contours of

in a vertical mid plane are shown in

Figure 12a–d, for particle diameters of 40, 100, 200, and 300

m. Fine particles

are efficiently recovered in the high dissipation region between the rotor and disperser. For a medium particle diameter of

, recovery happens in the jets out of the disperser. For coarse particles

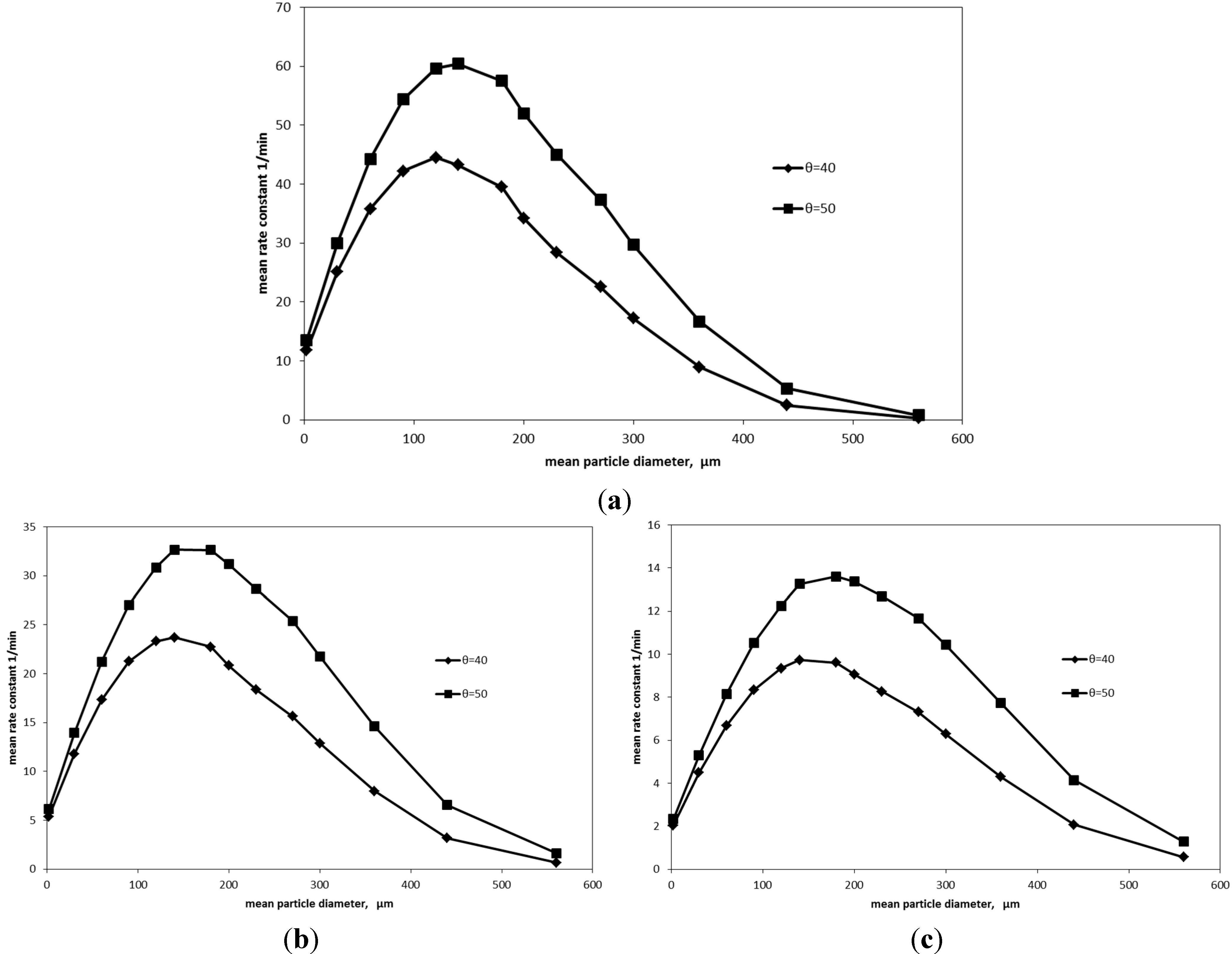

pulp recovery is more efficient in the moderate dissipation regions outside the disperser below, above and between the disperser jets. In the present work, the pseudo rate constant is computed as a function of particle diameter for two values of contact angle (

and

). Values for rate constant are obtained for different uniform bubble size and different uniform particle size. Average flotation rate constant

can be defined according to the Equation (24) where

is a froth recovery factor. We assumed

and

for a fully unloaded bubble and studied the effects of bubble diameter, particle diameter, and contact angle on

. The results are shown in

Figure 13a–c. As expected, rate constant increases with the increase of contact angle. Also, higher rate constant is observed for smaller bubble size (

) because air holdup increases for smaller bubble diameter, and hence higher bubble concentration number, as well as a lower rate constant for larger bubble diameter due to the decreases in the air holdup (

i.e., local bubbles number concentration). The maximum recovery rate shifts to higher particle diameter with the increase in bubble diameter. The recovery rate shown in these figures is very high relative to experimental data reported in literature because of the assumed values of

and

. Maximum rate constant for bubble sizes of 0.5, 0.7 and 1.0 mm occur at particle size of 125, 150 and 175 μm, respectively. This reveals that fact that smaller bubbles sizes (

db < 0.5 mm) are needed to float very tiny particles (

dp < 100 μm).

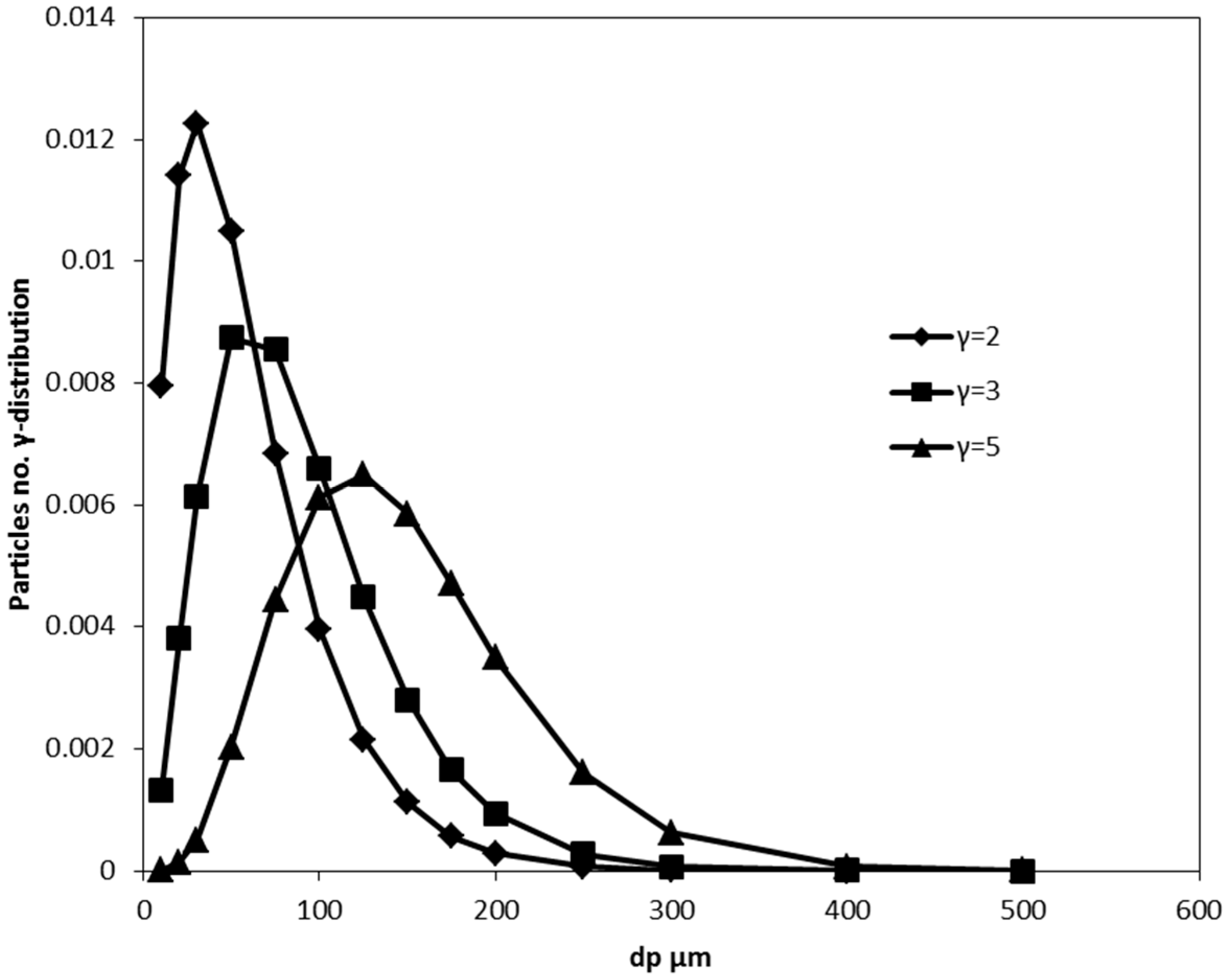

Next, we study the effects of particles size distribution on the mean flotation rate constant. As shown in

Figure 13a–c, rate constant is dramatically affected by particle sizes and the feed slurry to a flotation cell contains a wide spectrum of particles sizes. Therefore, modeling for rate constant with particle size distribution is more realistic and useful. Samples of assumed particles’ number distribution are shown in

Figure 14 for

B = 30 and three different values for γ (γ = 2, 3 and 5). Changing values for γ changes the size distribution and mean diameter of the particles. In real samples, this distribution depends on the grinding process as well as metallurgical properties of the ore. The procedure herein is to apply the present CFD flotation model for a single particle size and uniform bubble diameter in the postprocessor of the used CFD package (CFX). Using Equation (23), we obtain the local rate constant for a specific particle size. We used particles sizes ranging from 10–500 μm to be within the practical particle sizes. We used Equation (24) to obtain the average rate constant over the pulp volume and from Equation (26) we calculate the average pulp rate constant for a specific distribution. This process yields a single value for the rate constant that we attribute to the mean value of the proposed particle size. Different particle number distributions pdfs are used (each has different mean diameter) to plot rate constant

versus particles mean diameter. This deterministic method in the calculation of rate constant for certain particle size distribution is more robust than the other probabilistic models [

26,

27,

28,

29]. This is because the effects of all variables such as surface tension, contact angle, bubbles size and particles size are explicitly included in the model.

Figure 13.

(a) Average rate constant for 0.5 mm bubble diameter and for single particle sizes; (b) average rate constant for 0.7 mm bubble diameter and for single particle sizes; (c) average rate constant for 1.0 mm bubble diameter and for single particle sizes.

Figure 13.

(a) Average rate constant for 0.5 mm bubble diameter and for single particle sizes; (b) average rate constant for 0.7 mm bubble diameter and for single particle sizes; (c) average rate constant for 1.0 mm bubble diameter and for single particle sizes.

Figure 14.

Assumed particles number distribution, B = 30.

Figure 14.

Assumed particles number distribution, B = 30.

The effect of particles size distribution on the rate constant has been studied also by an assumed γ-particle number distribution. Effects of different size distribution on mean rate constant are depicted in

Figure 15a–c for different bubbles sizes.

Figure 15a shows that the maximum rate constant is around the mean particle diameter of 140 μm for a contact angle of 50°, and the particle diameter of 120 μm for a contact angle of 40° where, increasing contact angle increases the possibilities of floating larger particles. A considerable mean rate constant for very small mean diameter (

dmean = 5 μm) is observed for bubble size of 0.5 mm while very low rate constant exists for the larger bubble size (

dmean = 0.7 and 1.0 mm) at the same particle mean diameter. Maximum mean rate constant for bubble size (

dmean = 0.7 mm) is also observed to be around particle mean diameter 140 and 180 μm for bubble size (

dmean = 1.0 mm) as shown in

Figure 15b,c.

Figure 15.

(a) Average rate constant for 0.5 mm bubble diameter and for particle no. γ-distribution; (b) average rate constant for 0.7 mm bubble diameter and for particle no. γ-distribution; (c) average rate constant for 1.0 mm bubble and diameter for particle no. γ-distribution.

Figure 15.

(a) Average rate constant for 0.5 mm bubble diameter and for particle no. γ-distribution; (b) average rate constant for 0.7 mm bubble diameter and for particle no. γ-distribution; (c) average rate constant for 1.0 mm bubble and diameter for particle no. γ-distribution.