The Utilization of Slag, Steel Slag, and Desulfurization Gypsum as Binder Systems in UHPC with Iron Tailings and Steel Fibers—A Review

Abstract

1. Introduction

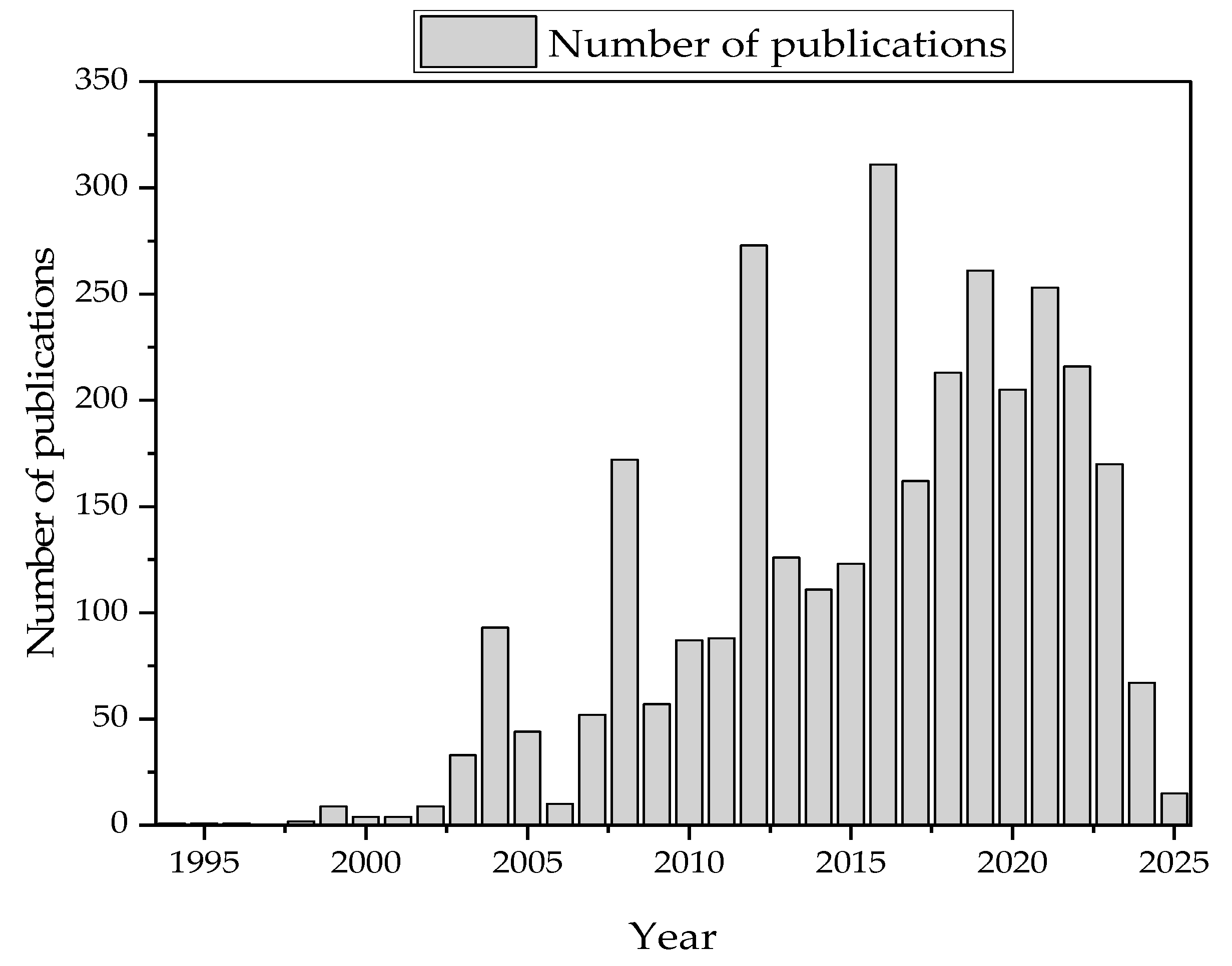

2. The Development of UHPC

2.1. The Performance of UHPC

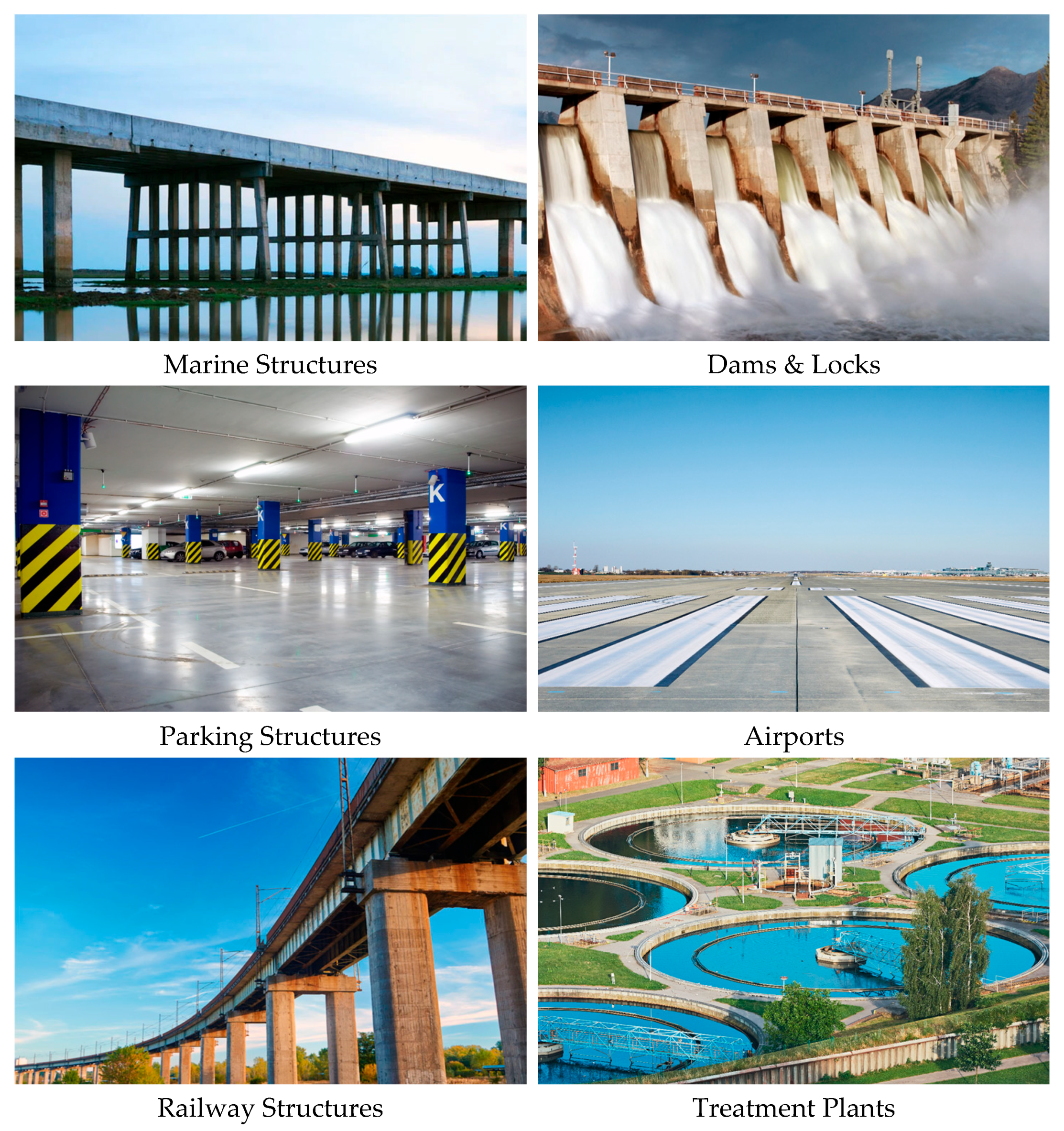

2.2. The Application of UHPC

2.3. The Preparation Processes of UHPC

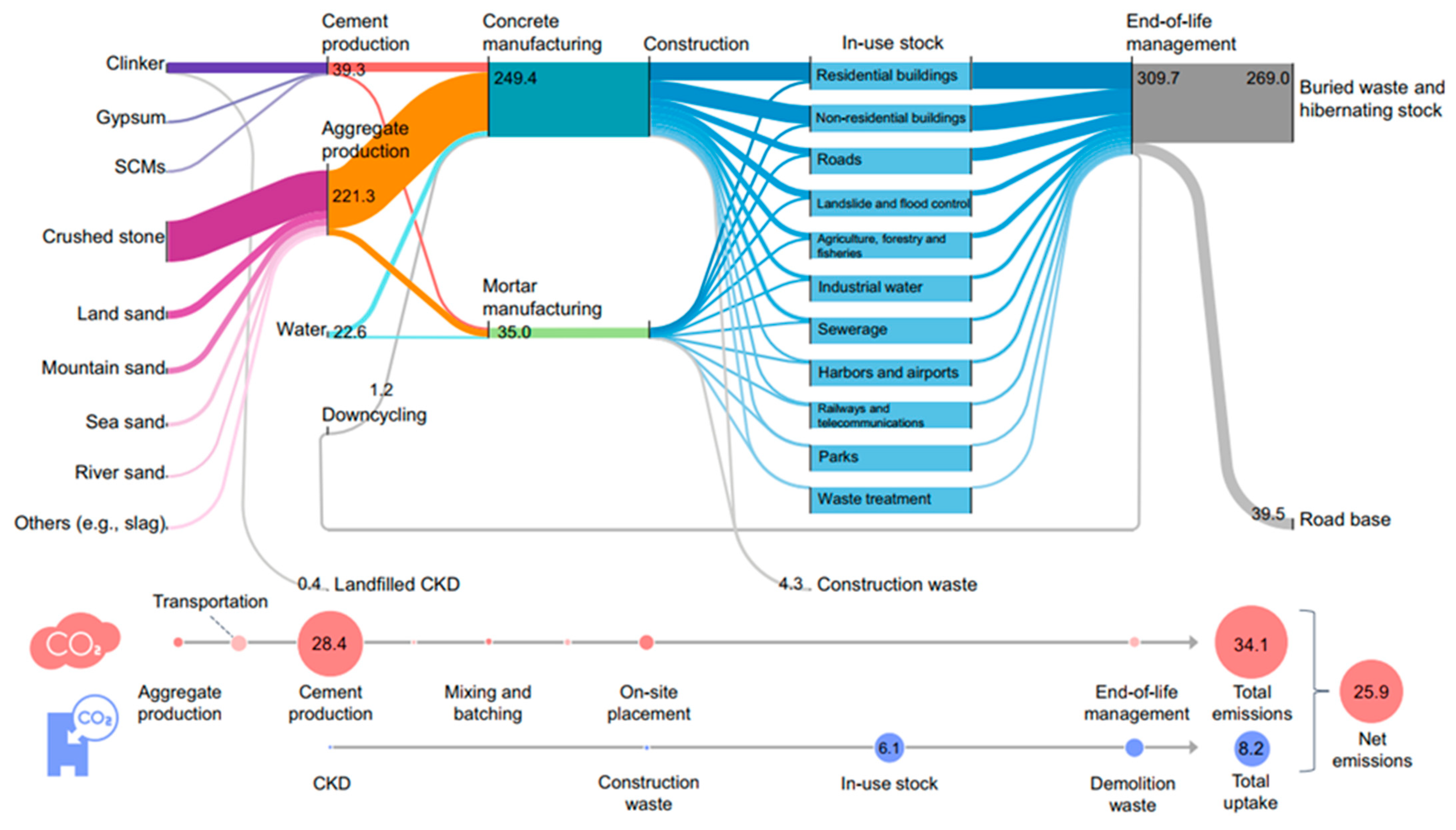

2.4. Contribution of UHPC to Sustainable Development Goals (SDGs)

- (1)

- SDG 9—Industry, Innovation, and Infrastructure

- (2)

- SDG 12—Responsible Consumption and Production

- (3)

- SDG 13—Climate Action

- (4)

- SDG 11—Sustainable Cities and Communities

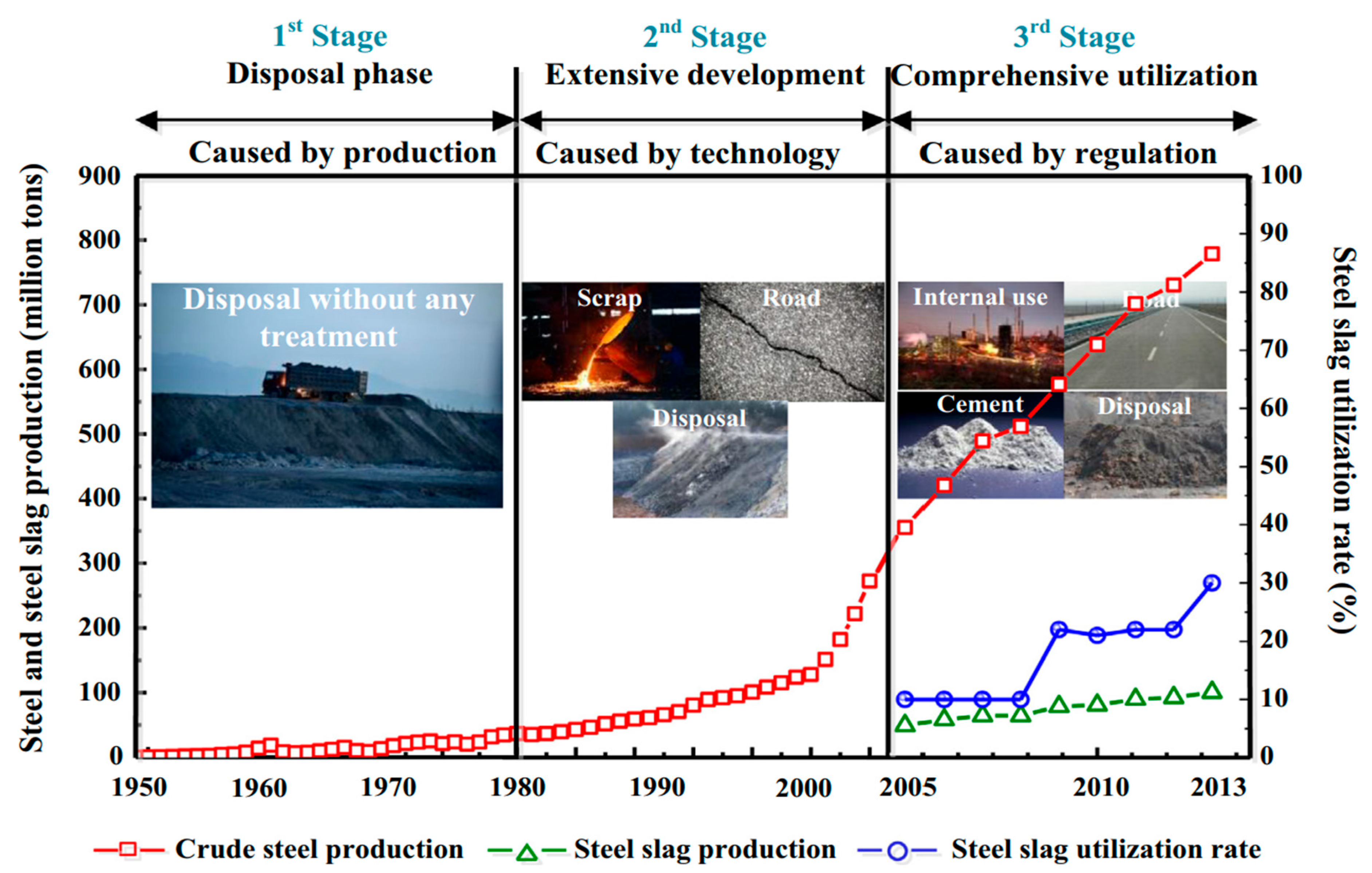

2.5. Industrial By-Products in UHPC: Uses and Benefits

- (1)

- Steel Slag as a Fine Aggregate

- (2)

- Iron Tailings as a Fine Aggregate

- (3)

- Desulfurization Gypsum as Supplementary Cementitious Material (SCM)

- (4)

- Other Potential Industrial By-Products

2.6. Main Components of UHPC with Industrial By-Product Binders

- (1)

- Binder Materials

- (2)

- Aggregates

- (3)

- Admixtures

- (4)

- Steel Fibers

- (5)

- Microstructural Characteristics

- (6)

- Applications

3. The Application of Mine Tailings as the Aggregate of UHPC

| Study | Key Findings | Remarks | |

|---|---|---|---|

| Mechanical Properties | Lv et al. (2022) [65] | Up to 25% IOT enhances strength: compressive, +12%; tensile, +18%; flexural, +13%. | Optimal at 25% IOT. Excessive amounts reduce effectiveness. |

| Shettimaet al. (2016) [66] | Strength is improved with 25% IOT: compressive, +12.90%; tensile +20.50%. | Finer particles enhance performance. Too much IOT can affect workability. | |

| Liu et al. (2023) [67] | Optimal strength at 25% IOT: compressive, +7.4%–10.1%; tensile, +5.30 to 9.90%; flexural, +9.1 to 12.6%. | Adjust workability for best results. Optimal at 25% IOT. | |

| Fiber Reinforced Concrete | Y. Li et al. (2024) [68] | IOT with carbon fiber enhances strength: +17% with 30% IOT and 0.6% fiber. | Synergistic effect. Up to 30% IOT recommended. |

| C. Wang et al. (2024) [69] | Significant gains with IOT fine aggregates and fibers: +42% strength with 50% IOT; +93% with 0.5% PVA fibers. | Fibers counteract brittleness. Improves overall performance. | |

| Zhao et al. (2023) [70] | Fiber addition mitigates IOT’s negative effects; improved strength with 1.5% fiber. | IOT decreases performance. Fiber addition is essential for maintaining mechanical properties. | |

| Ultra-High-Performance Concrete | H. Heraiz et al. (2024) [38] | IOT with 2% of steel fiber enhances the compressive strength by 19%. | Effective in high-performance concrete. |

| Zhanget al. (2020) [71] | Compressive strength is improved with 40% IOT by +14.3%. | Effective in high-performance concrete. | |

| Carrasco et al. (2017) [72] | Evaluated Young’s modulus indicates potential for high-performance mixes with IOT. | Promising for high-performance applications. | |

| Shi et al. (2024) [73] | Replacement with 100% IOT reduces properties compared to quartz sand. | Inferior performance as a complete substitute. Limited effectiveness in ultra-high-performance concrete. |

4. Innovative Solid Waste Binders in UHPC: Performance and Mechanisms

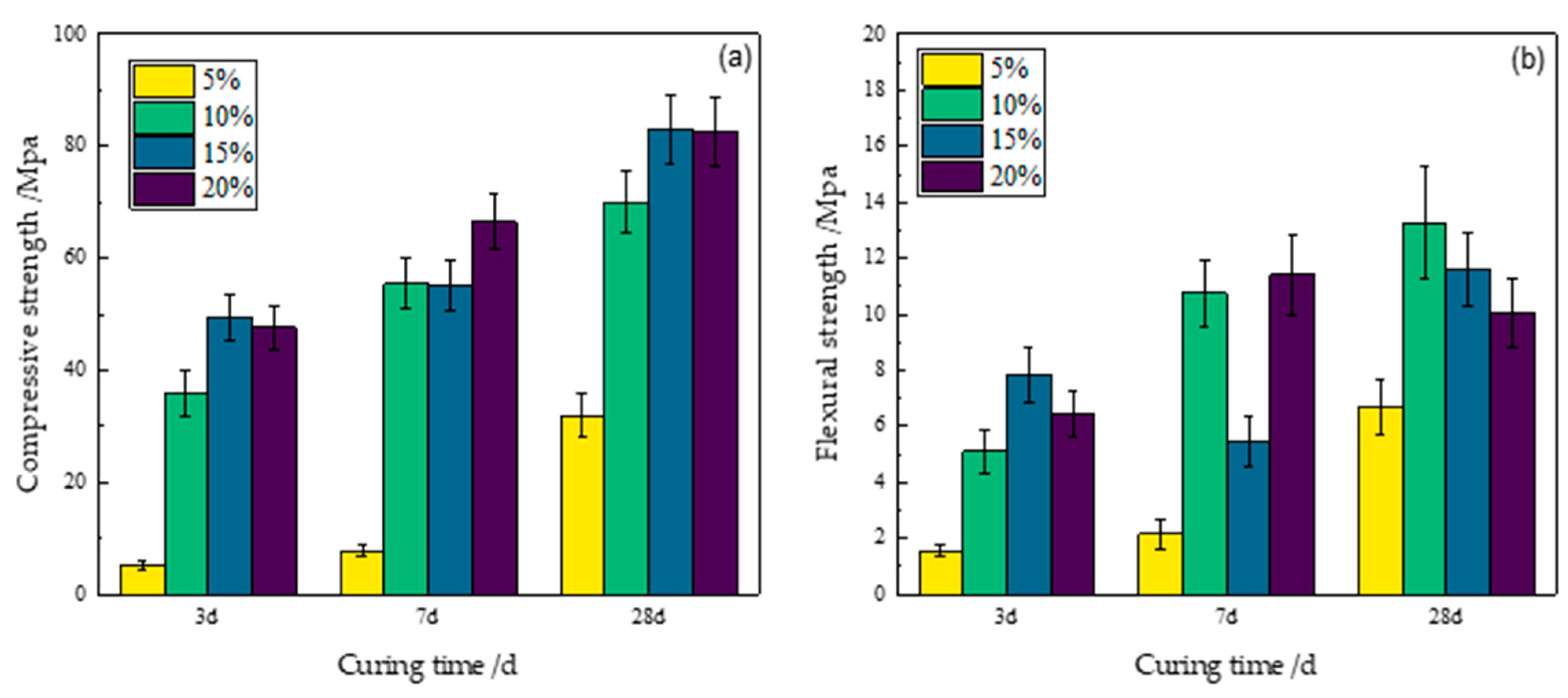

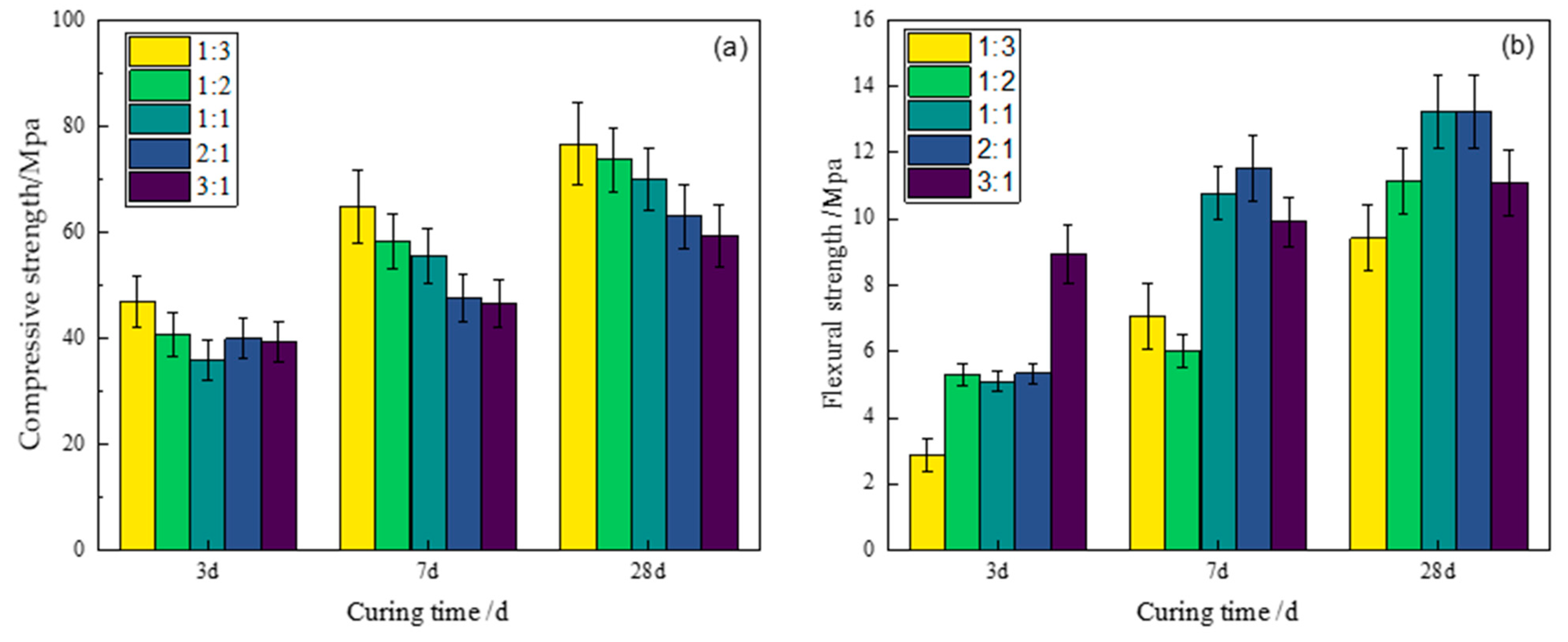

4.1. Supplementary Cementitious Materials Used in Ultra-High-Performance Concrete

4.2. Current State of Solid Waste Binders (Slag–Steel Slag–Desulfurization Gypsum) and Iron Tailings as Fine Aggregates

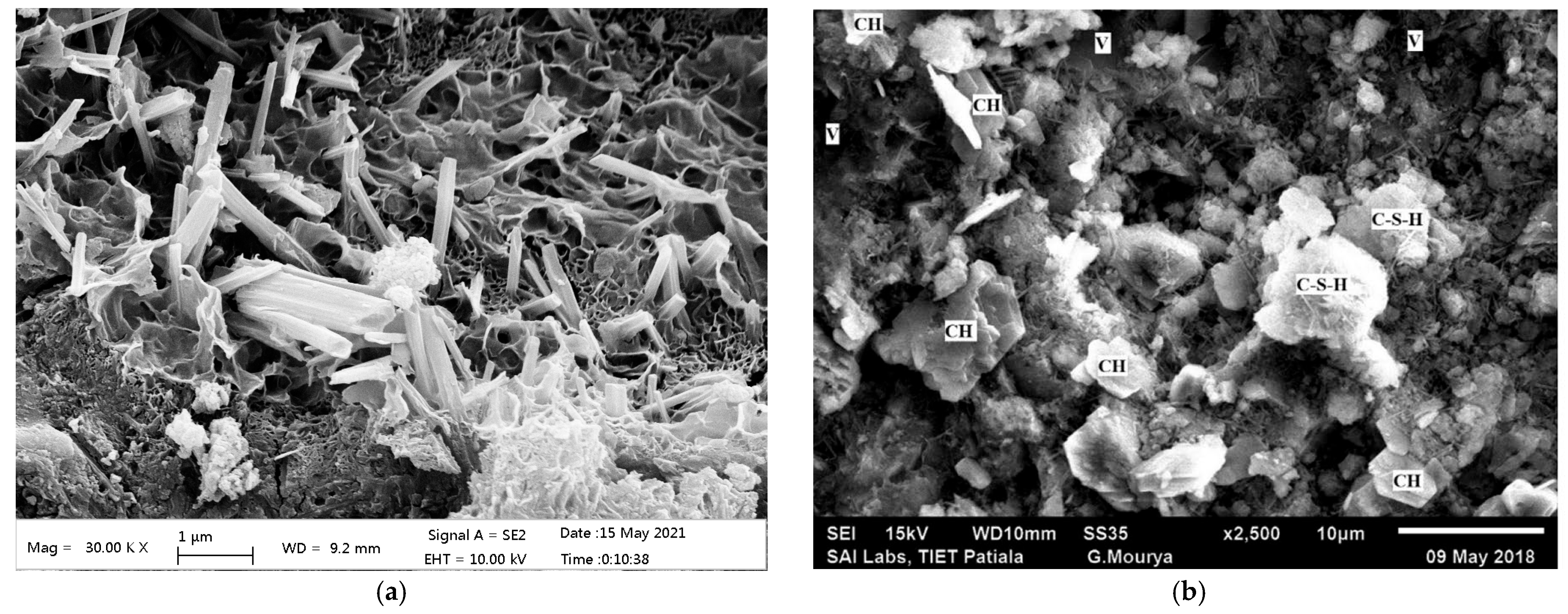

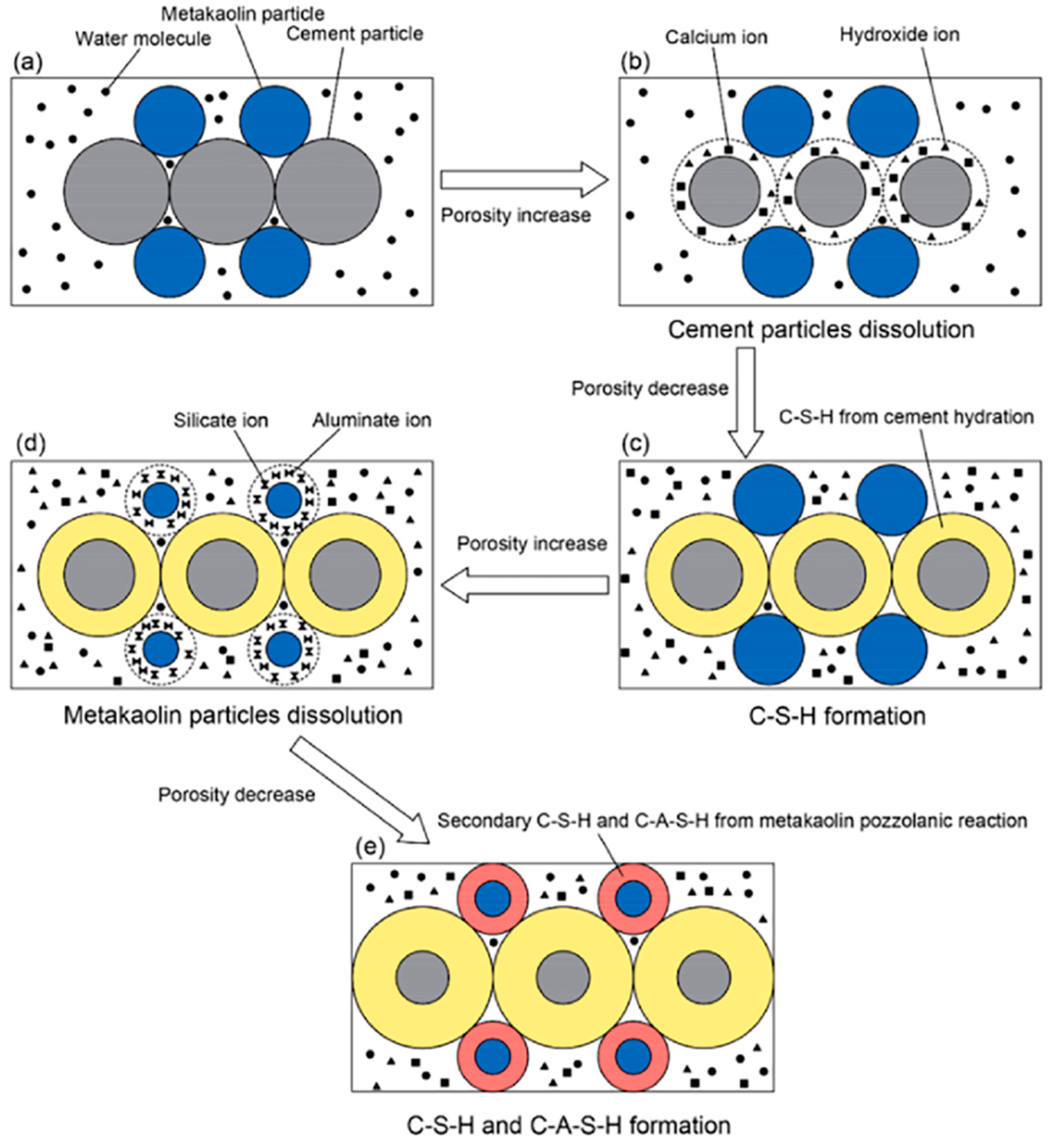

4.3. Microstructural Development in UHPC

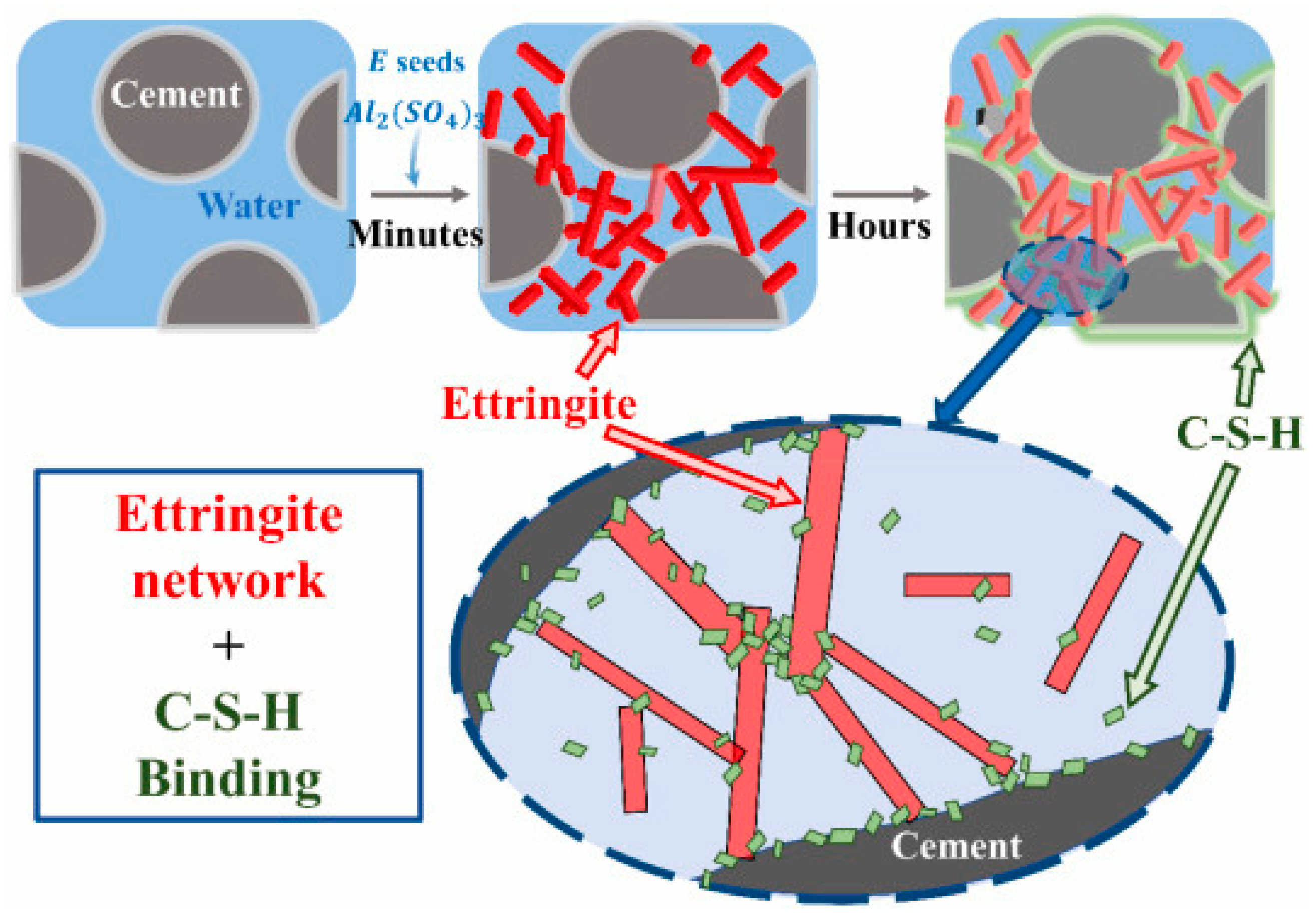

4.3.1. Formation of C-S-H Gel and Ettringite in Hybrid Binder Systems

4.3.2. Pore Structure Refinement and Durability Enhancement

4.3.3. Hydration Mechanisms and Early-Age Strength Development

4.3.4. Synergistic Effects of Portland Cement and Supplementary Cementitious Materials

4.4. Environmental and Economic Implications of Reducing Portland Cement Content

4.5. Challenges and Outlook

5. Reinforcement Synergy: Role of Steel Fibers in Waste-Based UHPC

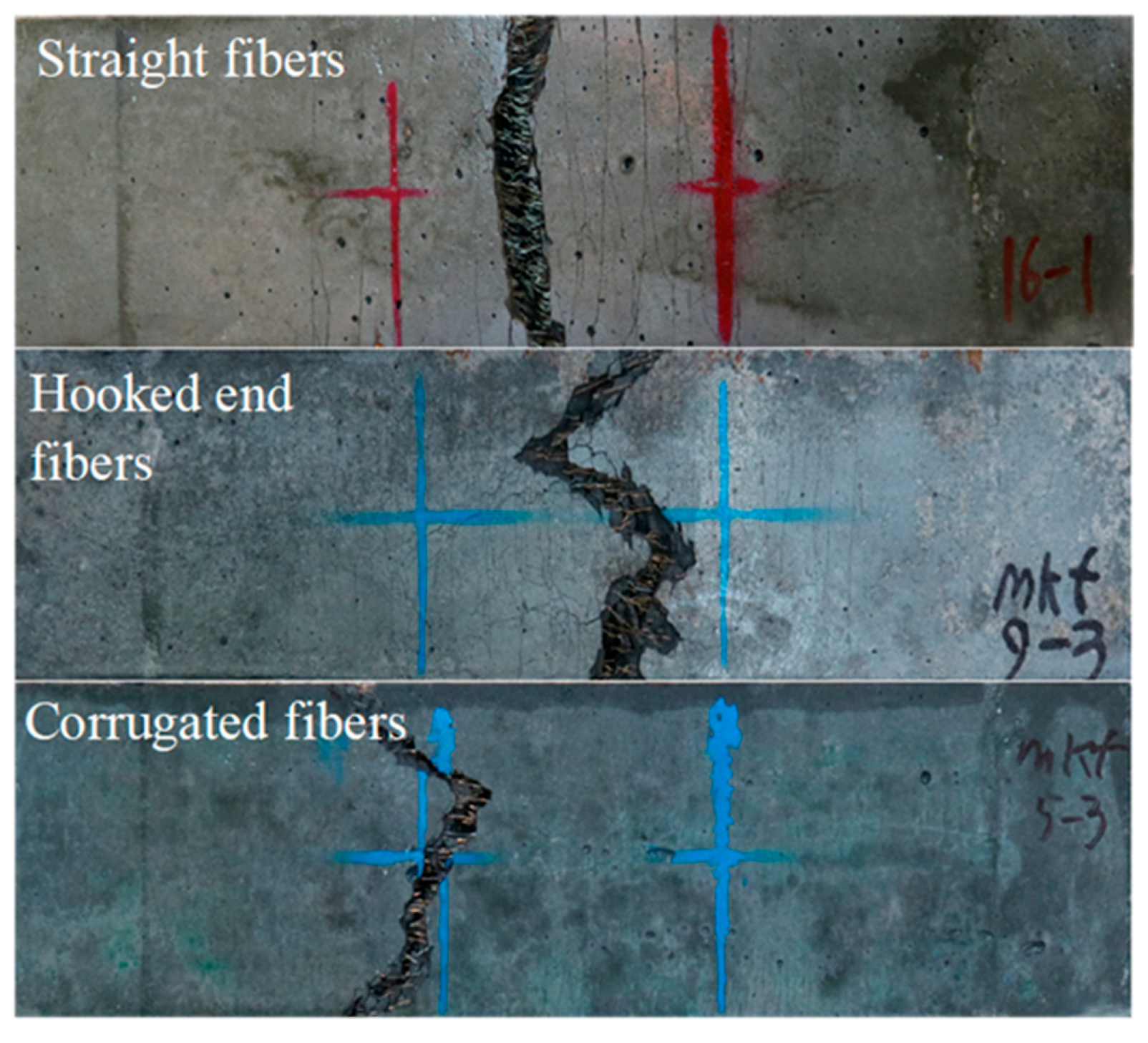

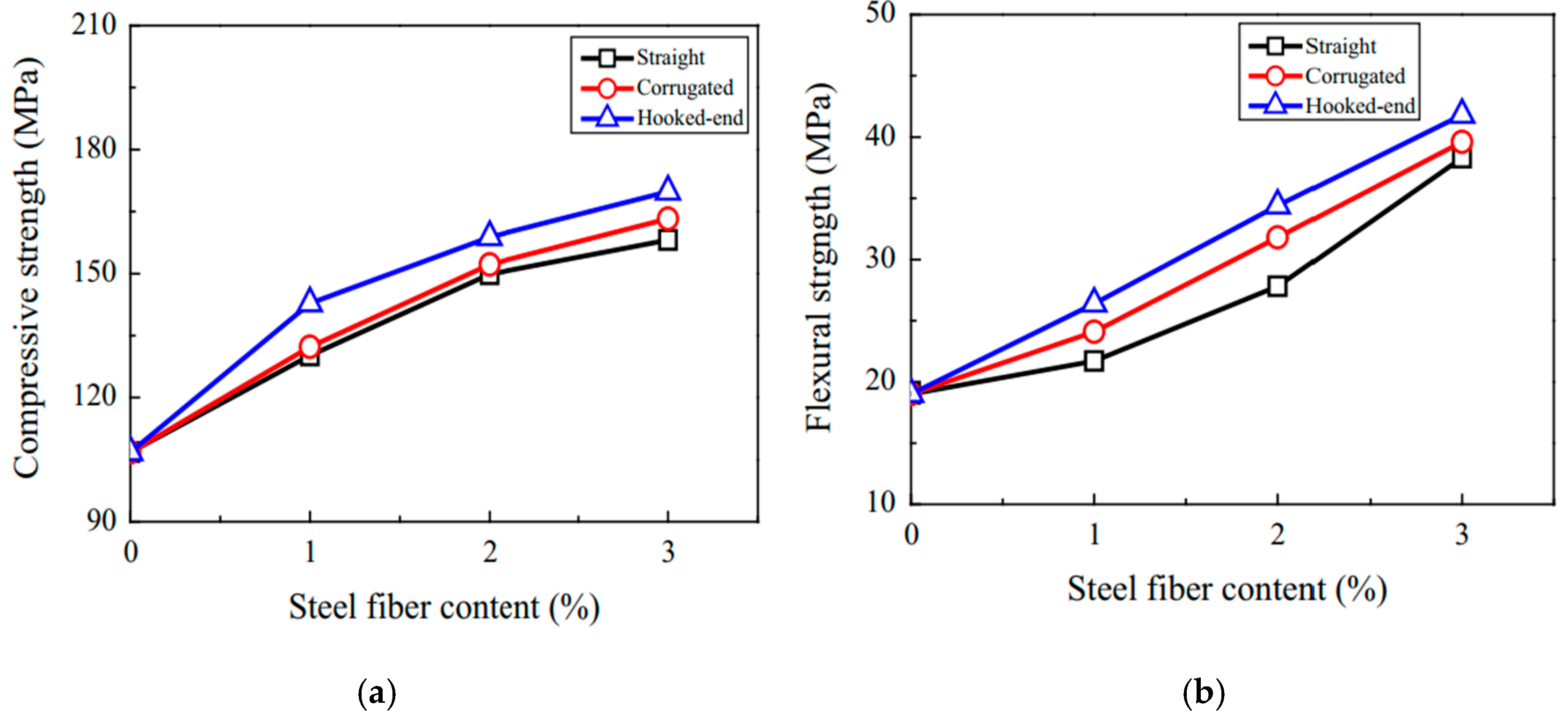

5.1. Influence of Fiber Shape on Crack Bridging and Load Transfer

5.1.1. Straight Fibers

5.1.2. Hooked-End Fibers

5.1.3. Corrugated Fibers

5.2. Effects of Fiber Volume Fraction on Workability and Strength

5.2.1. Impact on Workability

5.2.2. Effect on Mechanical Strength

5.2.3. Trade-Offs Between Workability and Strength

5.3. Economic and Practical Considerations for Fiber-Reinforced UHPC

5.3.1. Cost–Benefit Analysis of Different Fiber Types

- (1)

- Straight Fibers

- (2)

- Hooked-End Fibers

- (3)

- Corrugated Fibers

5.3.2. Applications of Fiber-Reinforced UHPC in Civil Infrastructure

6. Sustainability and Environmental Impacts of UHPC Production

- (1)

- Key challenges in waste utilization include the following:

- (2)

- Variable chemical compositions of industrial by-products.

- (3)

- Potential Impacts on early-age strength development.

- (4)

- Limited availability in some regions.

7. Standardization Challenges and Future Directions

- (1)

- Incorporation of Sustainable Materials

- Recycled Aggregates: future UHPC formulations may include a higher proportion of recycled aggregates, such as crushed concrete from demolition, to lessen the reliance on natural raw materials.

- Industrial by-products, such as fly ash, slag, silica fume, and rice husk ash, serve as alternatives to traditional cement, helping to reduce the carbon footprint of UHPC production. These materials lower emissions and enhance UHPC’s specific performance properties.

- Bio-based Additives: innovations in bio-based polymers or fibers could replace synthetic additives, providing a more sustainable and environmentally friendly method to enhance UHPC’s performance.

- (2)

- Reduction of Cement Content

- (3)

- Energy-Efficient Manufacturing Processes

- (4)

- Life Cycle Assessment and Circular Economy Integration

- (5)

- Optimized Durability and Longevity

- (6)

- Carbon Capture and Storage (CCS) Technologies

- (7)

- Hybrid UHPC Systems

- (8)

- Three-dimensional Printing of UHPC

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SS | Steel slag |

| FGDG | Flue gas desulfurization gypsum |

| SCM | Supplementary cementitious material |

| ITs | Iron tailings |

| HRWR | High-range water reducer |

| UHPC | Ultra-high-performance concrete |

| 3D | Three-dimensional (printing) |

| SDG | Sustainable development goals |

| SCMs | Supplementary cementitious materials |

| GBFS | ground granulated blast furnace slag |

| BOFS | Basic oxygen furnace slag |

References

- Wang, W.; Liu, J.; Agostini, F.; Davy, C.A.; Skoczylas, F.; Corvez, D. Durability of an ultra high performance fiber reinforced concrete (UHPFRC) under progressive aging. Cem. Concr. Res. 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Kodur, V.; Bhatt, P.; Soroushian, P.; Arablouei, A. Temperature and stress development in ultra-high performance concrete during curing. Constr. Build. Mater. 2016, 122, 63–71. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Guo, W.; Xi, B.; Huang, C.; Li, J.; Tang, Z.; Li, W.; Ma, C.; Wu, W. Solid waste management in China: Policy and driving factors in 2004–2019. Resour. Conserv. Recycl. 2021, 173, 105727. [Google Scholar] [CrossRef]

- Mor, S.; Ravindra, K. Municipal solid waste landfills in lower-and middle-income countries: Environmental impacts, challenges and sustainable management practices. Process Saf. Environ. Prot. 2023, 174, 510–530. [Google Scholar] [CrossRef]

- Shan, Z. The State of Treatment Technique and Comprehensive Utilization to Steel-Slag in China and Abroad. Indust. Saf. Dust. Contr. 2000, 78, 27–32. [Google Scholar]

- Cai, W.; Bai, M.; Davey, H. Implementing environmental protection tax in China: An alternative framework. Pac. Account. Rev. 2022, 34, 479–513. [Google Scholar] [CrossRef]

- Hu, Q.; Gu, Y. Mineral resources and the green economy: A blueprint for sustainable development and innovation. Resour. Policy 2024, 88, 104461. [Google Scholar] [CrossRef]

- Wen, H.; Liang, W.; Lee, C.-C. China’s progress toward sustainable development in pursuit of carbon neutrality: Regional differences and dynamic evolution. Environ. Impact Assess. Rev. 2023, 98, 106959. [Google Scholar] [CrossRef]

- Beraud, J.-J.D.; Zhao, X.; Wu, J. Revitalization of Chinese’s manufacturing industry under the carbon neutral goal. Environ. Sci. Pollut. Res. 2022, 29, 66462–66478. [Google Scholar] [CrossRef] [PubMed]

- Zuo, L.; Wang, C.; Corder, G.D.; Sun, Q. Future trends and strategies of recycling high-tech metals from urban mines in China: 2015–2050. Resour. Conserv. Recycl. 2019, 149, 261–274. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Zhou, J.; Huang, J.; Wang, Q. Application of Industrial Solid Waste in Preparation of Recycled Concrete: A Review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Wang, L.; Lv, Y.; Huang, S.; Liu, Y.; Li, X. The Evolution of Research on C&D Waste and Sustainable Development of Resources: A Bibliometric Study. Sustainability 2023, 15, 9141. [Google Scholar] [CrossRef]

- Bache, H.H. Densified Cement Ultra-Fine Particle-Based Materials; Based Materials; 1981. Available online: https://www.osti.gov/etdeweb/biblio/10168064 (accessed on 16 May 2025).

- De Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Pandya, H.; Semler, A.; Selle, K.; Lomboy, G. Effect of Binder and Aggregate Fineness on Ultra-High Performance Concrete. In International Interactive Symposium on Ultra-High Performance Concrete; Iowa State University Digital Press: Ames, IA, USA, 2019. [Google Scholar]

- Karbhari, V. Fabrication, quality and service-life issues for composites in civil engineering. In Durability of Composites for Civil Structural Applications; Elsevier: Amsterdam, The Netherlands, 2007; pp. 13–30. [Google Scholar]

- Rokugo, K.; Kanda, T.; Yokota, H.; Sakata, N. Applications and recommendations of high performance fiber reinforced cement composites with multiple fine cracking (HPFRCC) in Japan. Mater. Struct. 2009, 42, 1197–1208. [Google Scholar] [CrossRef]

- Gu, C.; Ye, G.; Sun, W. Ultrahigh performance concrete-properties, applications and perspectives. Sci. China Technol. Sci. 2015, 58, 587–599. [Google Scholar] [CrossRef]

- Xue, J.; Briseghella, B.; Huang, F.; Nuti, C.; Tabatabai, H.; Chen, B. Review of ultra-high performance concrete and its application in bridge engineering. Constr. Build. Mater. 2020, 260, 119844. [Google Scholar] [CrossRef]

- Chen, X.; Wan, D.-w.; Jin, L.-z.; Qian, K.; Fu, F. Experimental studies and microstructure analysis for ultra high-performance reactive powder concrete. Constr. Build. Mater. 2019, 229, 116924. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R.; Bharatkumar, B.H. Influence of curing regime and steel fibres on the mechanical properties of UHPC. Mag. Concr. Res. 2015, 67, 988–1002. [Google Scholar] [CrossRef]

- Trinh, B.P.; Van Chanh, N. Study on the properties of ultra high performance fiber reinforced concrete. Adv. Mater. Res. 2012, 383, 3305–3312. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Andrade, C. Reactive powder concrete: Durability and applications. Appl. Sci. 2021, 11, 5629. [Google Scholar] [CrossRef]

- Atlı, I.; Ipek, M. Investigation of the Mechanical Behaviors of Sustainable Green Reactive Powder Concrete Produced Using Ferrochrome Slag and Waste Fiber. Sustainability 2024, 16, 4714. [Google Scholar] [CrossRef]

- Popa, M.; Corbu, O.; Kiss, Z.; Zagon, R. Achieving mixtures of ultra-high performance concrete. ConstructII 2013, 14, 40. [Google Scholar]

- Hamad, M.A.; Nasr, M.; Shubbar, A.; Al-Khafaji, Z.; Al Masoodi, Z.; Al-Hashimi, O.; Kot, P.; Alkhaddar, R.; Hashim, K. Production of ultra-high-performance concrete with low energy consumption and carbon footprint using supplementary cementitious materials instead of silica fume: A review. Energies 2021, 14, 8291. [Google Scholar] [CrossRef]

- Graybeal, B. UHPC in the US Highway Infrastructure. Des. Build. UHPFRC 2011, 15, 221–234. [Google Scholar]

- Hakeem, I.Y.; Hosen, M.A.; Tayeh, B.A.; Alhamami, A. Innovative Ultra-High Performance Concrete (UHPC) Incorporating oil ash and electric arc furnace dust. Case Stud. Constr. Mater. 2023, 18, e01843. [Google Scholar] [CrossRef]

- Khan, M.I.; Abbas, Y.M.; Abellan-Garcia, J.; Castro-Cabeza, A. Eco-efficient ultra-high-performance concrete formulation utilizing electric arc furnace slag and recycled glass powder–advanced analytics and lifecycle perspectives. J. Mater. Res. Technol. 2024, 32, 362–377. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Makul, N.; Tang, W.; Alluqmani, A.E. Sustainable development of eco-friendly ultra-high performance concrete (UHPC): Cost, carbon emission, and structural ductility. Constr. Build. Mater. 2023, 398, 132477. [Google Scholar] [CrossRef]

- Mu, X.; Zhang, S.; Ni, W.; Xu, D.; Li, J.; Du, H.; Wei, X.; Li, Y. Performance optimization and hydration mechanism of a clinker-free ultra-high performance concrete with solid waste based binder and steel slag aggregate. J. Build. Eng. 2023, 63, 105479. [Google Scholar] [CrossRef]

- Guo, Y.; Xie, J.; Zheng, W.; Li, J. Effects of steel slag as fine aggregate on static and impact behaviours of concrete. Constr. Build. Mater. 2018, 192, 194–201. [Google Scholar] [CrossRef]

- Heraiz, H.; Mu, X.; Li, J.; Lei, B.; Zhang, S.; Li, Y.; Zhu, S.; Ni, W.; Hitch, M. Optimization of Ultra-High-Performance Concrete Using a Clinker-Free Binder and Iron Mine Tailings Aggregate. Minerals 2024, 15, 28. [Google Scholar] [CrossRef]

- Li, J.; Wang, C.; Ni, W.; Zhu, S.; Mao, S.; Jiang, F.; Zeng, H.; Sun, X.; Huang, B.; Hitch, M. Orthogonal test design for the optimization of preparation of steel slag-based carbonated building materials with ultramafic tailings as fine aggregates. Minerals 2022, 12, 246. [Google Scholar] [CrossRef]

- Li, J.; Cao, S.; Yilmaz, E. Characterization of macro mechanical properties and microstructures of cement-based composites prepared from fly ash, gypsum and steel slag. Minerals 2021, 12, 6. [Google Scholar] [CrossRef]

- Park, S.; Wu, S.; Liu, Z.; Pyo, S. The role of supplementary cementitious materials (SCMs) in ultra high performance concrete (UHPC): A review. Materials 2021, 14, 1472. [Google Scholar] [CrossRef]

- Xu, C.; Ni, W.; Li, K.; Zhang, S.; Li, Y.; Xu, D. Hydration mechanism and orthogonal optimisation of mix proportion for steel slag–slag-based clinker-free prefabricated concrete. Constr. Build. Mater. 2019, 228, 117036. [Google Scholar] [CrossRef]

- Li, Q.; Li, J.; Zhang, S.; Huang, X.; Wang, X.; Wang, Y.; Ni, W. Research progress of low-carbon cementitious materials based on synergistic industrial wastes. Energies 2023, 16, 2376. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, B.; Zhou, M. The Influences of Iron Ore Tailings as Fine Aggregate on the Strength of Ultra-High Performance Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 412878. [Google Scholar] [CrossRef]

- Torres, A.; Aguayo, F.; Allena, S.; Ellis, M. The effect of various superplasticizers on ultra high strength concrete. In Proceedings of the International Conference of Sustainable Production and Use of Cement and Concrete: ICSPCC 2019; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Walkley, B.; Geddes, D.A.; Matsuda, T.; Provis, J.L. Reversible adsorption of polycarboxylates on silica fume in high pH, high ionic strength environments for control of concrete fluidity. Langmuir 2022, 38, 1662–1671. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Yu, F.; Qiu, L.; Guo, Y.; Wang, J.; Han, B. Effect of steel fibers on tensile properties of ultra-high-performance concrete: A review. Materials 2024, 17, 1108. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Chen, G.; Yang, R.; Yu, R.; Xiao, R.; Wang, Z.; Xie, G.; Cheng, J. Hydration kinetics and microstructure development of Ultra-High Performance Concrete (UHPC) by high volume of phosphorus slag powder. Cem. Concr. Compos. 2023, 138, 104978. [Google Scholar] [CrossRef]

- Ge, W.; Zhu, S.; Yang, J.; Ashour, A.; Zhang, Z.; Li, W.; Jiang, H.; Cao, D.; Shuai, H. Mechanical Properties and Durability of Sustainable UHPC Using Industrial Waste Residues and Sea/Manufactured Sand. J. Test. Eval. 2024, 52, 1064–1094. [Google Scholar] [CrossRef]

- Ren, Z.; Li, D. Uniaxial compressive behavior study of normal-strength concrete using waste steel slag aggregate through laboratory tests and numerical simulation. J. Build. Eng. 2024, 85, 108720. [Google Scholar] [CrossRef]

- Liu, J.; Xu, J.; Liu, Q.; Wang, S.; Yu, B. Steel slag for roadway construction: A review of material characteristics and application mechanisms. J. Mater. Civil Eng. 2022, 34, 03122001. [Google Scholar] [CrossRef]

- Carmignano, O.R.; Vieira, S.S.; Teixeira, A.P.C.; Lameiras, F.S.; Brandão, P.R.G.; Lago, R.M. Iron ore tailings: Characterization and applications. J. Braz. Chem. Soc. 2021, 32, 1895–1911. [Google Scholar] [CrossRef]

- Chen, H.; Shen, W.; Shan, L.; Xiong, C.; Su, Y.; Liu, B.; Rao, J. Situation of discharge and comprehensive utilization of iron tailings domestic and abroad. Hunningtu (Concrete) 2012, 2, 88–92. [Google Scholar]

- Gayana, B.; Chandar, K.R. Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements-A review. Adv. Concr. Constr. 2018, 6, 221. [Google Scholar]

- Bing, L.; Zhongying, Z.; Biao, T.; Hongbo, L.; Hanchi, C.; Zhen, M. Comprehensive utilization of iron tailings in China. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Owolabı, A.; Ajiboye, G.; Ikumapayi, C.; Akande, S. Assessment of iron tailings as replacement for fine aggregate in engineering application. J. Sustain. Constr. Mater. Technol. 2023, 8, 20–26. [Google Scholar] [CrossRef]

- Alhassan, A.; Yusuf, K.O.; Abdulazeez, A.A.; Usman, S. Iron ore tailings as partial replacement for fine aggregate in concrete production-Review. Int. Eng. Manag. Res. 2022, 12, 64–71. [Google Scholar]

- Zhang, G.D.; Zhang, X.Z.; Zhou, Z.H.; Cheng, X. Preparation and properties of concrete containing iron tailings/manufactured sand as fine aggregate. Adv. Mater. Res. 2014, 838, 152–155. [Google Scholar] [CrossRef]

- Zhang, X.; Fu, B.; Liu, J.; Zhou, Z. Preparation and properties of high performance concrete based on the iron tailing mixed manufactured sand. Concrete 2014, 3, 116–123. [Google Scholar]

- Feng, X.X.; Xi, X.L.; Cai, J.W.; Chai, H.J.; Song, Y.Z. Investigation of drying shrinkage of concrete prepared with iron mine tailings. Key Eng. Mater. 2011, 477, 37–41. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Yin, S.; Yu, L. Utilization of iron tailings sand as an environmentally friendly alternative to natural river sand in high-strength concrete: Shrinkage characterization and mitigation strategies. Materials 2020, 13, 5614. [Google Scholar] [CrossRef]

- Hamiruddin, N.; Razak, R.A.; Muhamad, K.; Zahid, M.M.; Aziz, C.C.A. The Effect of Different Sand Gradation with Ultra High Performance Concrete (UHPC). Solid State Phenom. 2018, 280, 476–480. [Google Scholar] [CrossRef]

- Zhao, S.; Fan, J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- Jayasimha, N.; Sujini, B.; Annapurna, B. A study on durability and strength properties of high strength concrete with partial replacement of iron ore tailings with fine aggregates. Mater. Today Proc. 2022, 65, 1922–1929. [Google Scholar] [CrossRef]

- Lv, Z.; Jiang, A.; Liang, B. Development of eco-efficiency concrete containing diatomite and iron ore tailings: Mechanical properties and strength prediction using deep learning. Constr. Build. Mater. 2022, 327, 126930. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Liu, K.; Wang, S.; Quan, X.; Jing, W.; Xu, J.; Zhao, N.; Liu, B.; Ying, H. Industrial byproduct Iron ore tailings as ecofriendly materials in the utilization of cementitious composites. Constr. Build. Mater. 2023, 372, 130813. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Q.; Xu, G.; Shi, Y.; Su, Y. Influence of macro-synthetic fiber on the mechanical properties of iron ore tailing concrete. Constr. Build. Mater. 2023, 367, 130293. [Google Scholar] [CrossRef]

- Li, C.; Zhang, S.; Liu, P.; Li, H.; Lin, S.; Si, J.; Chen, W.; Hao, H. Influence of key design variables on dynamic material properties of iron tailing porous concrete under impact loading. Dev. Built Environ. 2024, 18, 100401. [Google Scholar] [CrossRef]

- Wang, C.; Ji, Y.; Qie, R.; Wang, J.; Wang, D. Mechanical performance investigation on fiber strengthened recycled iron tailings concrete. Case Stud. Constr. Mater. 2024, 20, e02734. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, X.; Qiu, J.; Liu, J.; Zhao, Y.; Li, X. Effects of iron ore tailings on the compressive strength and permeability of ultra-high performance concrete. Constr. Build. Mater. 2020, 260, 119917. [Google Scholar] [CrossRef]

- Carrasco, E.; Magalhaes, M.; Santos, W.; Alves, R.; Mantilla, J. Characterization of mortars with iron ore tailings using destructive and nondestructive tests. Constr. Build. Mater. 2017, 131, 31–38. [Google Scholar] [CrossRef]

- Shi, J.; Pan, W.; Kang, J.; Yu, Z.; Sun, G.; Li, J.; Zheng, K.; Shen, J. Properties of Ultra-High Performance Concrete incorporating iron tailings powder and iron tailings sand. J. Build. Eng. 2024, 83, 108442. [Google Scholar] [CrossRef]

- He, Z.-h.; Du, S.-G.; Chen, D. Microstructure of ultra high performance concrete containing lithium slag. J. Hazard. Mater. 2018, 353, 35–43. [Google Scholar] [CrossRef]

- Pyo, S.; Tafesse, M.; Kim, B.-J.; Kim, H.-K. Effects of quartz-based mine tailings on characteristics and leaching behavior of ultra-high performance concrete. Constr. Build. Mater. 2018, 166, 110–117. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, J.; Liu, J.; Ke, J.; Wang, F. Properties and microstructure of reactive powder concrete having a high content of phosphorous slag powder and silica fume. Constr. Build. Mater. 2015, 101, 482–487. [Google Scholar] [CrossRef]

- Edwin, R.S.; Gruyaert, E.; Dils, J.; De Belie, N. Influence of intensive vacuum mixing on the compressive strength of RPC containing secondary slag as cementitious material. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Yazıcı, H.; Yiğiter, H.; Karabulut, A.Ş.; Baradan, B. Utilization of fly ash and ground granulated blast furnace slag as an alternative silica source in reactive powder concrete. Fuel 2008, 87, 2401–2407. [Google Scholar] [CrossRef]

- Li, S.; Cheng, S.; Mo, L.; Deng, M. Effects of steel slag powder and expansive agent on the properties of ultra-high performance concrete (UHPC): Based on a case study. Materials 2020, 13, 683. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, S.; Liu, Z.; Wang, F. Utilization of steel slag in ultra-high performance concrete with enhanced eco-friendliness. Constr. Build. Mater. 2019, 214, 28–36. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, G.; Zheng, Y.; Zhang, K.; Ye, P.; Cui, X. Study on the preparation of high performance concrete using steel slag and iron ore tailings. J. New Mater. Electrochem. Syst. 2019, 22, 217–223. [Google Scholar] [CrossRef]

- Li, Y.; Huang, M.; Li, J.; Zhang, S.; Yang, G.; Chen, X.; Du, H.; Ni, W.; Song, X.; Hitch, M. Performance Assessment of All-Solid-Waste High-Strength Concrete Prepared from Waste Rock Aggregates. Materials 2025, 18, 624. [Google Scholar] [CrossRef]

- Liu, J.; Liu, B.; Ge, X.; Tian, Y.; Song, G.; Liu, K.; Wang, Y. Analysis of Hydration Mechanism of Steel Slag-Based Cementitious Materials under Saline–Alkaline-Coupled Excitation. Buildings 2024, 14, 597. [Google Scholar] [CrossRef]

- Juenger, M.C.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Zhang, J.; Zhao, Y. The mechanical properties and microstructure of ultra-high-performance concrete containing various supplementary cementitious materials. J. Sustain. Cem.-Based Mater. 2017, 6, 254–266. [Google Scholar] [CrossRef]

- Liu, J.; Farzadnia, N.; Shi, C. Effects of superabsorbent polymer on interfacial transition zone and mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2020, 231, 117142. [Google Scholar] [CrossRef]

- Singh, M.; Sidddique, R.; Setia, S.S.; Singh, G. Recycling of waste bagasse ash in concrete for sustainable construction. Asian J. Civil Eng. 2021, 22, 831–842. [Google Scholar] [CrossRef]

- Tang, S.; Wang, Y.; Geng, Z.; Xu, X.; Yu, W.; Hubao, A.; Chen, J. Structure, fractality, mechanics and durability of calcium silicate hydrates. Fractal Fract. 2021, 5, 47. [Google Scholar] [CrossRef]

- Xu, C.; Ni, W.; Li, K. Effect of ammonia-soda residue on the strength and chloride-resistance performance of steel slag-granulated blast furnace slag-based concrete after immersion in artificial seawater. Materials 2021, 14, 6048. [Google Scholar] [CrossRef] [PubMed]

- Sandybay, S.; Shon, C.S.; Tukaziban, A.; Syzdykov, D.; Orynbassarov, I.; Zhang, D.; Kim, J.R. Blended basic oxygen furnace (BOF) slag with ground granulated blast furnace slag (GGBFS) as a pozzolanic material. Mater. Sci. Forum 2022, 1053, 331–337. [Google Scholar] [CrossRef]

- Gan, L.; Wang, H.-F.; Li, X.-P.; Qi, Y.-H.; Zhang, C.-X. Strength activity index of air quenched basic oxygen furnace steel slag. J. Iron Steel Res. Int. 2015, 22, 219–225. [Google Scholar] [CrossRef]

- Kraft, B.; Achenbach, R.; Ludwig, H.-M.; Raupach, M. Hydration and carbonation of alternative binders. Corros. Mater. Degrad. 2022, 3, 19–52. [Google Scholar] [CrossRef]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Tang, P.; Wen, J.; Fu, Y.; Liu, X.; Chen, W. Improving the early-age properties of eco-binder with high volume waste gypsum: Hydration process and ettringite formation. J. Build. Eng. 2024, 86, 108988. [Google Scholar] [CrossRef]

- Franus, W.; Panek, R.; Wdowin, M. SEM investigation of microstructures in hydration products of portland cement. In Proceedings of the 2nd International Multidisciplinary Microscopy and Microanalysis Congress: Proceedings of InterM, Oludeniz, Turkey, 16–19 October 2014; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Snellings, R. Assessing, understanding and unlocking supplementary cementitious materials. RILEM Tech. Lett. 2016, 1, 50–55. [Google Scholar] [CrossRef]

- Wang, H.; Feng, P.; Liu, X.; Shi, J.; Wang, C.; Wang, W.; Li, H.; Hong, J. The role of ettringite seeds in enhancing the ultra-early age strength of Portland cement containing aluminum sulfate accelerator. Compos. Part B Eng. 2024, 287, 111856. [Google Scholar] [CrossRef]

- Lu, D.; Tang, Z.; Zhang, L.; Zhou, J.; Gong, Y.; Tian, Y.; Zhong, J. Effects of combined usage of supplementary cementitious materials on the thermal properties and microstructure of high-performance concrete at high temperatures. Materials 2020, 13, 1833. [Google Scholar] [CrossRef]

- Ndahirwa, D.; Zmamou, H.; Lenormand, H.; Leblanc, N. The role of supplementary cementitious materials in hydration, durability and shrinkage of cement-based materials, their environmental and economic benefits: A review. Clean. Mater. 2022, 5, 100123. [Google Scholar] [CrossRef]

- Miller, S.A.; John, V.M.; Pacca, S.A.; Horvath, A. Carbon dioxide reduction potential in the global cement industry by 2050. Cem. Concr. Res. 2018, 114, 115–124. [Google Scholar] [CrossRef]

- Habert, G.; Bouzidi, Y.; Chen, C.; Jullien, A. Development of a depletion indicator for natural resources used in concrete. Resour. Conserv. Recycl. 2010, 54, 364–376. [Google Scholar] [CrossRef]

- Shi, C.; Zheng, K. A review on the use of waste glasses in the production of cement and concrete. Resour. Conserv. Recycl. 2007, 52, 234–247. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kang, S.-T.; Yoon, Y.-S. Effect of fiber length and placement method on flexural behavior, tension-softening curve, and fiber distribution characteristics of UHPFRC. Constr. Build. Mater. 2014, 64, 67–81. [Google Scholar] [CrossRef]

- Lee, B.Y.; Kim, J.-K.; Kim, J.-S.; Kim, Y.Y. Quantitative evaluation technique of Polyvinyl Alcohol (PVA) fiber dispersion in engineered cementitious composites. Cem. Concr. Compos. 2009, 31, 408–417. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Sharif, A.M.; Ahmad, S.; Adekunle, S.K.; Al-Huri, M.; Sharif, A.M. Effect of hybridization of straight and hooked steel fibers and curing methods on the key mechanical properties of UHPC. J. Mater. Res. Technol. 2021, 15, 3222–3239. [Google Scholar] [CrossRef]

- Ma, R.-Y.; Yang, J.; Peng, G.-F. Influence of steel fiber types on residual mechanical properties and explosive spalling of hybrid fiber reinforced ultra-high performance concrete: Optimization and evaluations. Case Stud. Constr. Mater. 2023, 19, e02538. [Google Scholar] [CrossRef]

- Wu, F.; Yu, Q.; Chen, X. Effects of steel fibre type and dosage on abrasion resistance of concrete against debris flow. Cem. Concr. Compo. 2022, 134, 104776. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, M.J.; Kim, S.-W.; Park, J.-J. Development of cost effective ultra-high-performance fiber-reinforced concrete using single and hybrid steel fibers. Constr. Build. Mater. 2017, 150, 383–394. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, S. Comparative pullout behavior of half-hooked and commercial steel fibers embedded in UHPC under static and impact loads. Cem. Concr. Compo. 2019, 97, 89–106. [Google Scholar] [CrossRef]

- Hung, C.-C.; El-Tawil, S.; Chao, S.-H. A review of developments and challenges for UHPC in structural engineering: Behavior, analysis, and design. J. Struct. Eng. 2021, 147, 03121001. [Google Scholar] [CrossRef]

- Graybeal, B.; Brühwiler, E.; Kim, B.-S.; Toutlemonde, F.; Voo, Y.L.; Zaghi, A. International perspective on UHPC in bridge engineering. J. Bridge Eng. 2020, 25, 04020094. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, J.; Zhou, J.; Yan, K.; Zhang, Z.; Zou, Y. Strengthening of existing stone arch bridges using UHPC: Theoretical analysis and case study. Structures 2022, 43, 805–821. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Bae, Y.; Pyo, S. Ultra high performance concrete (UHPC) sleeper: Structural design and performance. Eng. Struct. 2020, 210, 110374. [Google Scholar] [CrossRef]

- Zheng, H.; Lu, J.; Shen, P.; Sun, L.; Poon, C.S.; Li, W. Corrosion behavior of carbon steel in chloride-contaminated ultra-high-performance cement pastes. Cem. Concr. Compos. 2022, 128, 104443. [Google Scholar] [CrossRef]

- Yu, F.; Dong, S.; Li, L.; Ashour, A.; Ding, S.; Han, B.; Ou, J. Developing a sustainable ultrahigh-performance concrete using seawater and sea sand in combination with superfine stainless wires. J. Mater. Civil Eng. 2023, 35, 04023368. [Google Scholar] [CrossRef]

- Kravanja, G.; Mumtaz, A.R.; Kravanja, S. A comprehensive review of the advances, manufacturing, properties, innovations, environmental impact and applications of Ultra-High-Performance Concrete (UHPC). Buildings 2024, 14, 382. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R. Ultra-high-performance fiber-reinforced concrete. Part IV: Durability properties, cost assessment, applications, and challenges. Case Stud. Constr. Mater. 2022, 17, e01271. [Google Scholar] [CrossRef]

- Carbone, C.; Ferrario, D.; Lanzini, A.; Stendardo, S.; Agostini, A. Evaluating the carbon footprint of cement plants integrated with the calcium looping CO2 capture process. Front. Sustain. 2022, 3, 809231. [Google Scholar] [CrossRef]

- Prem, P.R.; Ambily, P.S.; Vankudothu, B.; Bharatkumar, B.H. Sustainable production of high performance concrete. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Oxford, UK, 2020; pp. 527–536. [Google Scholar]

- Wang, J.; Zheng, C.; Mo, L.; GangaRao, H.; Liang, R. Assessment of recycling use of GFRP powder as replacement of fly ash in geopolymer paste and concrete at ambient and high temperatures. Ceram. Int. 2022, 48, 14076–14090. [Google Scholar] [CrossRef]

- Ansari, M.A.; Shariq, M.; Mahdi, F. Geopolymer concrete for clean and sustainable construction–A state-of-the-art review on the mix design approaches. Structures 2023, 55, 1045–1070. [Google Scholar] [CrossRef]

- Lupton, R.C.; Allwood, J.M. Hybrid Sankey diagrams: Visual analysis of multidimensional data for understanding resource use. Resour. Conserv. Recycl. 2017, 124, 141–151. [Google Scholar] [CrossRef]

- French Standard NF P 18-470; Concrete—Ultra-High Performance Fibre-Reinforced Concretes—Specifications, Performance, Production and Conformity. AFNOR: La Plaine Saint-Denis, France, 2016.

- JG/T 398-2012; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. The Grouting Coupler for Rebars Splicing. Standards Press of China: Beijing, China, 2012.

| Scenario | Recommended Fiber | Rationale |

|---|---|---|

| Budget-constrained projects | Straight | Lowest cost and adequate for static loads. |

| High seismic zones | Hooked end | Superior crack resistance and worth 40% cost premium |

| Pumped UHPC applications | Corrugated | Balanced performance and flowability. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heraiz, H.; Li, J.; Pan, Z.; Zhang, D.; Hu, Y.; Mu, X.; Baras, A.; Liu, J.; Ni, W.; Hitch, M. The Utilization of Slag, Steel Slag, and Desulfurization Gypsum as Binder Systems in UHPC with Iron Tailings and Steel Fibers—A Review. Minerals 2025, 15, 538. https://doi.org/10.3390/min15050538

Heraiz H, Li J, Pan Z, Zhang D, Hu Y, Mu X, Baras A, Liu J, Ni W, Hitch M. The Utilization of Slag, Steel Slag, and Desulfurization Gypsum as Binder Systems in UHPC with Iron Tailings and Steel Fibers—A Review. Minerals. 2025; 15(5):538. https://doi.org/10.3390/min15050538

Chicago/Turabian StyleHeraiz, Hocine, Jiajie Li, Ziping Pan, Dongdong Zhang, Yingxi Hu, Xinli Mu, Amer Baras, Jinhai Liu, Wen Ni, and Michael Hitch. 2025. "The Utilization of Slag, Steel Slag, and Desulfurization Gypsum as Binder Systems in UHPC with Iron Tailings and Steel Fibers—A Review" Minerals 15, no. 5: 538. https://doi.org/10.3390/min15050538

APA StyleHeraiz, H., Li, J., Pan, Z., Zhang, D., Hu, Y., Mu, X., Baras, A., Liu, J., Ni, W., & Hitch, M. (2025). The Utilization of Slag, Steel Slag, and Desulfurization Gypsum as Binder Systems in UHPC with Iron Tailings and Steel Fibers—A Review. Minerals, 15(5), 538. https://doi.org/10.3390/min15050538