Geometallurgical Modeling of Influence of Mineral Composition of Sulfide Copper Ore (Southwest Poland) on Enrichment Selectivity

Abstract

1. Introduction

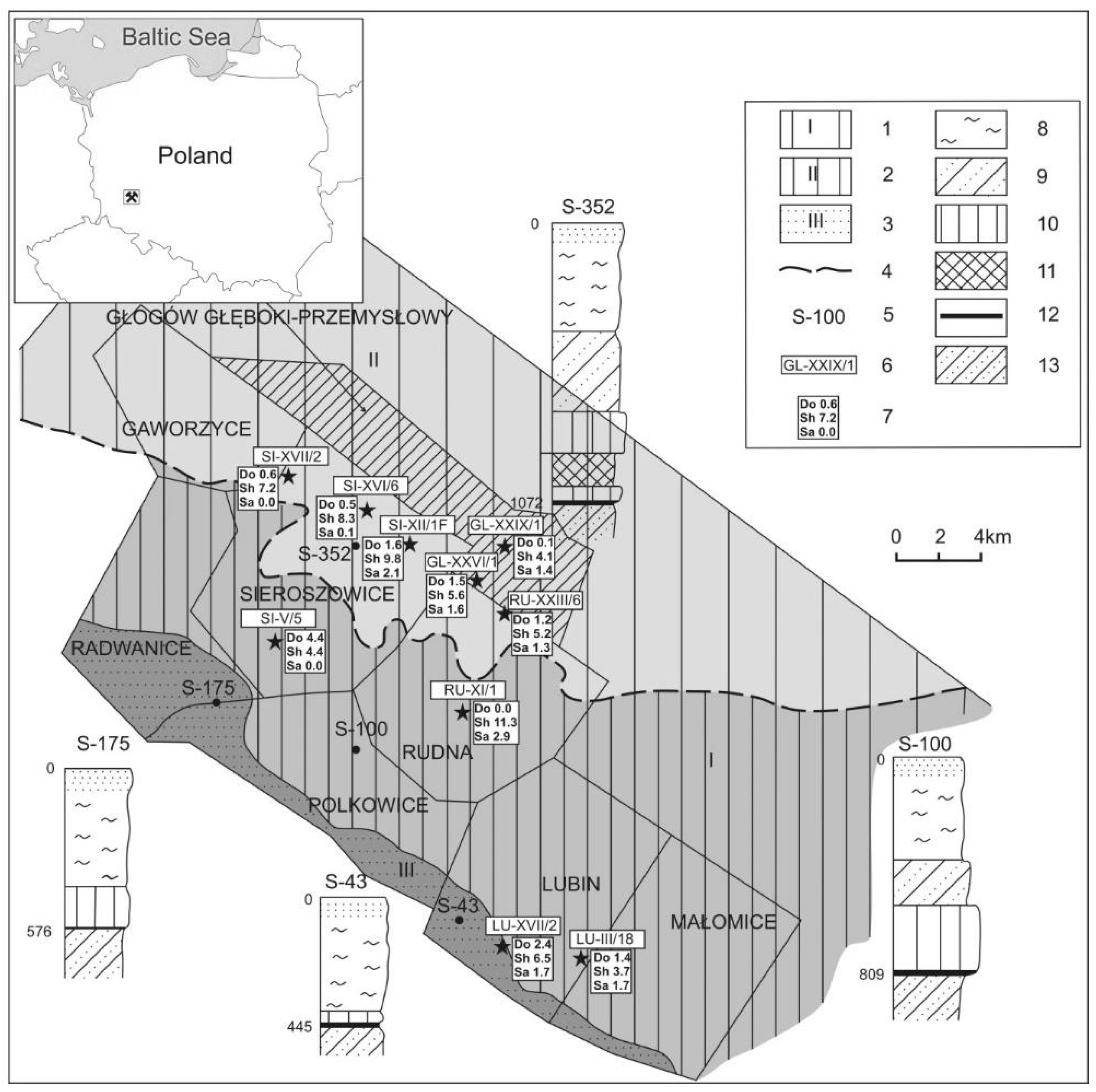

Characteristics of Stratiform Copper Ore from Legnica-Glogow Copper Basin (LGCB)

2. Materials and Methods

- Sampling and collecting representative samples for the comminution test—preparation of averaged mixtures of pure lithological types and their comminution for the flotation process (wet grinding);

- Conducting 120 flotation tests;

- Performing chemical and mineralogical analyses of the feed and of the enrichment product;

- Identifying parameters affecting enrichment process, together with the effectiveness of the enrichment process;

- Developing the geometallurgical model’s equation and verifying it for consistency with the actual data.

2.1. Sampling

2.2. Feed Sample Preparation for Flotation

2.3. Flotation Test Methodology

2.4. Metallurgical Investigation and Model Development

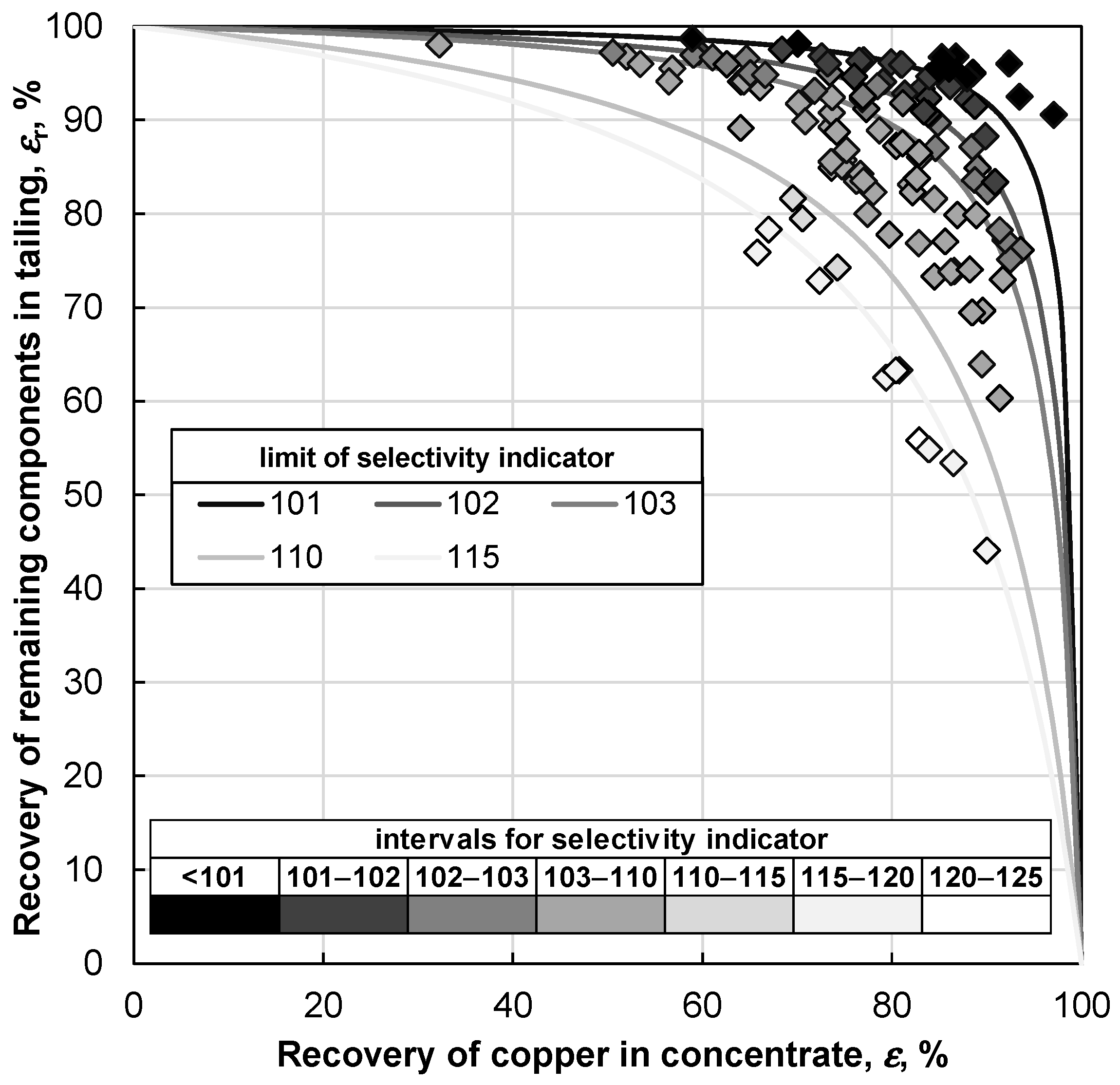

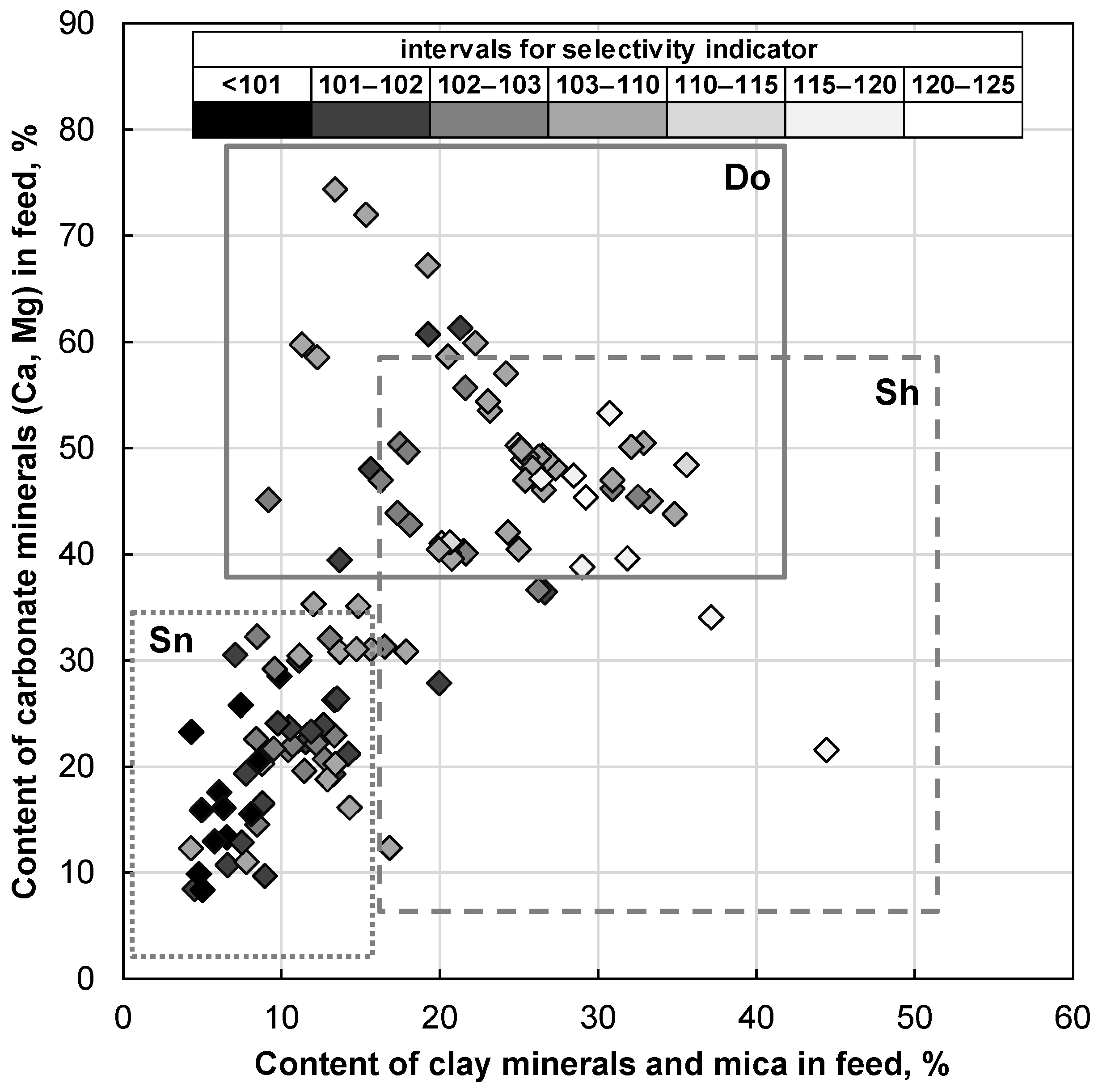

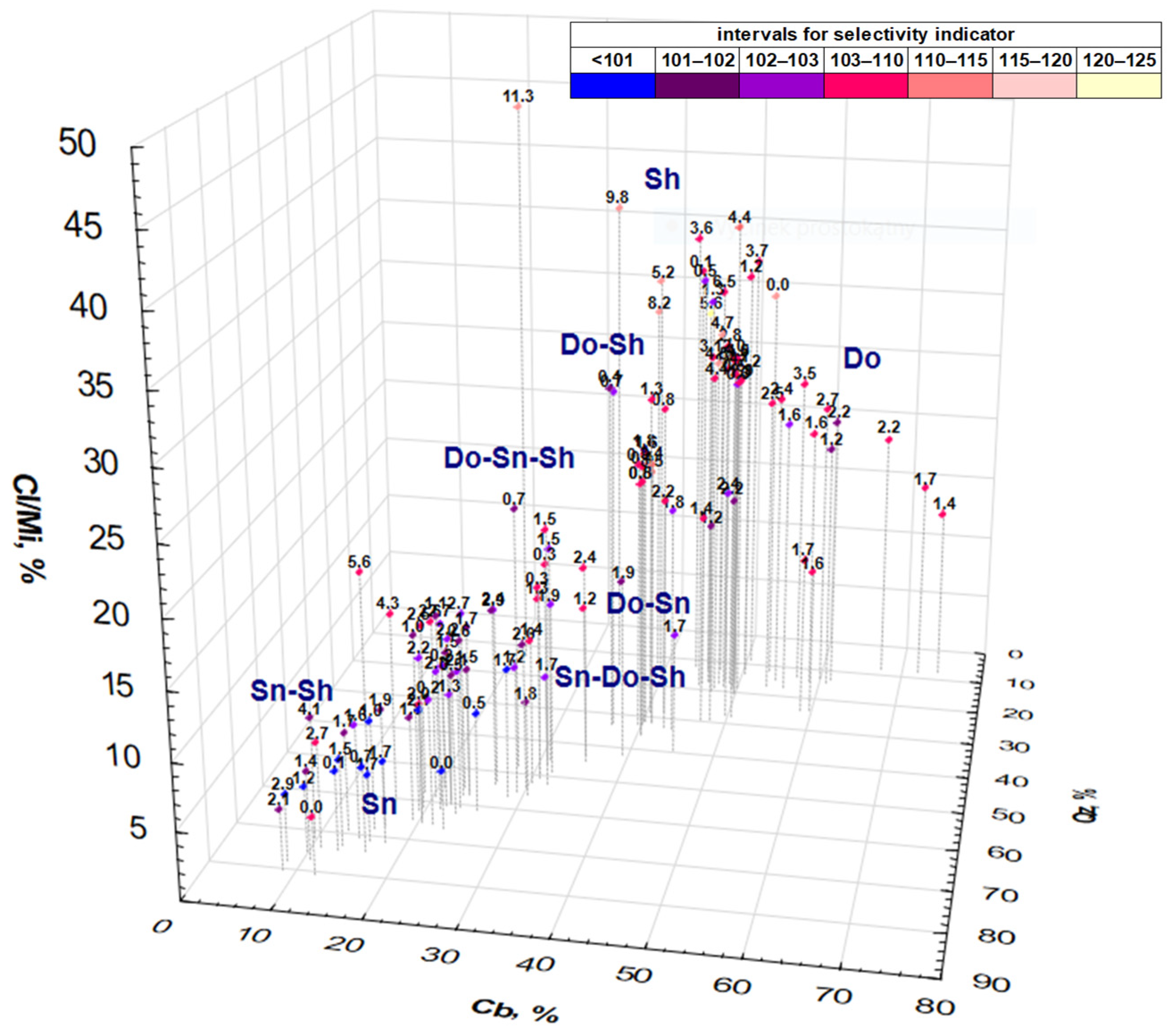

3. Test Results and Discussion

| Sample Collection Location | Mixture No. | αCu | αQz | αCb | αCl/Mi | εCu | εr | a | Sample Collection Location | Mixture No. | αCu | αQz | αCb | αCl/Mi | εCu | εr | a |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LU III/18 | 1 | 1.4 | 8.1 | 74.4 | 13.4 | 86.6 | 73.9 | 105.8 | LU-XVII/2 | 1 | 2.2 | 13.3 | 61.3 | 21.3 | 79.1 | 94.0 | 101.7 |

| 2 | 3.7 | 8.9 | 50.5 | 32.9 | 89.5 | 63.9 | 107.1 | 2 | 6.5 | 12.9 | 47.0 | 30.9 | 86.3 | 73.8 | 106.0 | ||

| 3 | 1.6 | 71.5 | 15.9 | 5.0 | 86.7 | 96.7 | 100.5 | 3 | 1.7 | 71.5 | 17.6 | 6.1 | 92.4 | 96.0 | 100.3 | ||

| 4 | 1.6 | 39.8 | 45.1 | 9.2 | 84.6 | 87.0 | 102.8 | 4 | 1.9 | 42.4 | 39.4 | 13.7 | 79.9 | 96.1 | 101.0 | ||

| 5 | 1.6 | 23.9 | 59.8 | 11.3 | 82.0 | 83.1 | 104.7 | 5 | 2.2 | 27.8 | 50.4 | 17.5 | 78.5 | 93.6 | 101.9 | ||

| 6 | 1.8 | 55.7 | 30.5 | 7.1 | 83.1 | 93.3 | 101.5 | 6 | 1.7 | 56.9 | 28.5 | 9.9 | 85.3 | 96.7 | 100.6 | ||

| 7 | 2.2 | 8.3 | 67.2 | 19.2 | 76.3 | 83.5 | 106.6 | 7 | 3.5 | 13.2 | 57.0 | 24.2 | 84.5 | 81.6 | 104.3 | ||

| 8 | 1.7 | 8.1 | 72.0 | 15.3 | 77.4 | 79.9 | 107.9 | 8 | 2.7 | 13.3 | 59.9 | 22.3 | 83.0 | 86.0 | 103.4 | ||

| 9 | 2.4 | 52.7 | 26.3 | 13.3 | 89.1 | 84.9 | 102.2 | 9 | 2.9 | 53.9 | 26.4 | 13.5 | 89.9 | 88.3 | 101.5 | ||

| 10 | 1.8 | 65.3 | 19.3 | 7.8 | 88.0 | 92.2 | 101.2 | 10 | 2.1 | 65.6 | 20.5 | 8.6 | 93.5 | 92.5 | 100.6 | ||

| 11 | 1.7 | 52.5 | 32.2 | 8.5 | 88.5 | 87.1 | 102.0 | 11 | 2.0 | 54.0 | 30.0 | 11.1 | 81.1 | 95.9 | 101.0 | ||

| 12 | 1.7 | 24.0 | 58.6 | 12.3 | 74.9 | 85.7 | 105.9 | 12 | 2.4 | 27.8 | 49.7 | 18.0 | 76.9 | 92.2 | 102.6 | ||

| GL-XXVI/1 | 1 | 1.5 | 17.9 | 49.3 | 26.5 | 66.1 | 93.5 | 103.7 | SI-V/5 | 1 | 4.4 | 20.1 | 47.0 | 25.4 | 82.2 | 82.3 | 104.9 |

| 2 | 5.6 | 13.0 | 45.4 | 29.2 | 82.9 | 55.8 | 119.5 | 2 | 4.4 | 10.3 | 48.4 | 35.6 | 74.3 | 74.2 | 113.7 | ||

| 3 | 1.5 | 73.4 | 13.3 | 6.5 | 88.6 | 95.0 | 100.7 | 3 | 0.0 | 66.8 | 23.3 | 4.3 | 70.1 | 98.1 | 100.8 | ||

| 4 | 1.5 | 45.6 | 31.3 | 16.5 | 73.4 | 95.0 | 101.9 | 4 | 2.4 | 43.4 | 35.1 | 14.9 | 64.1 | 89.1 | 107.3 | ||

| 5 | 1.6 | 31.8 | 40.3 | 21.5 | 64.1 | 94.1 | 103.6 | 5 | 3.5 | 31.8 | 41.0 | 20.1 | 70.6 | 79.5 | 112.1 | ||

| 6 | 1.5 | 59.5 | 22.3 | 11.5 | 80.9 | 95.9 | 101.0 | 6 | 1.2 | 55.1 | 29.2 | 9.6 | 62.6 | 95.9 | 102.6 | ||

| 7 | 2.8 | 16.4 | 48.1 | 27.3 | 84.5 | 73.3 | 107.2 | 7 | 4.7 | 17.2 | 47.4 | 28.5 | 65.8 | 75.8 | 119.8 | ||

| 8 | 2.0 | 17.4 | 48.9 | 26.8 | 73.7 | 84.9 | 106.8 | 8 | 4.5 | 19.1 | 47.1 | 26.4 | 67.0 | 78.3 | 115.8 | ||

| 9 | 2.7 | 55.3 | 22.9 | 13.3 | 93.6 | 76.1 | 102.2 | 9 | 1.3 | 49.8 | 30.8 | 13.7 | 80.5 | 87.2 | 103.7 | ||

| 10 | 1.9 | 67.4 | 16.5 | 8.8 | 88.8 | 91.5 | 101.2 | 10 | 0.5 | 61.1 | 25.8 | 7.4 | 86.8 | 95.1 | 100.8 | ||

| 11 | 1.7 | 56.5 | 23.9 | 12.7 | 83.9 | 92.3 | 101.6 | 11 | 1.4 | 52.3 | 30.4 | 11.1 | 74.2 | 88.7 | 104.6 | ||

| 12 | 1.7 | 31.5 | 40.1 | 21.6 | 77.3 | 91.2 | 102.9 | 12 | 3.4 | 31.3 | 41.1 | 20.6 | 69.5 | 81.6 | 111.0 | ||

| GL-XXIX/1 | 1 | 0.1 | 18.6 | 45.0 | 33.3 | 52.0 | 96.7 | 103.2 | SI-XVII/2 | 1 | 0.6 | 20.7 | 49.8 | 25.2 | 71.8 | 93.1 | 103.0 |

| 2 | 4.1 | 13.9 | 48.9 | 25.3 | 86.5 | 53.4 | 115.7 | 2 | 7.2 | 13.6 | 50.3 | 24.9 | 83.9 | 54.8 | 118.7 | ||

| 3 | 1.4 | 77.5 | 10.7 | 6.6 | 84.0 | 94.6 | 101.1 | 3 | 0.0 | 81.1 | 12.3 | 4.3 | 32.3 | 98.0 | 104.4 | ||

| 4 | 0.7 | 48.0 | 27.9 | 20.0 | 72.6 | 96.8 | 101.3 | 4 | 0.3 | 50.9 | 31.1 | 14.7 | 73.6 | 85.5 | 106.5 | ||

| 5 | 0.4 | 33.3 | 36.4 | 26.6 | 73.2 | 96.0 | 101.5 | 5 | 0.5 | 35.8 | 40.4 | 20.0 | 70.9 | 89.8 | 104.9 | ||

| 6 | 1.0 | 62.7 | 19.3 | 13.3 | 77.0 | 96.4 | 101.1 | 6 | 0.2 | 66.0 | 21.7 | 9.5 | 66.7 | 94.8 | 102.8 | ||

| 7 | 1.3 | 17.2 | 46.2 | 30.9 | 92.5 | 75.1 | 102.8 | 7 | 2.9 | 18.6 | 49.9 | 25.1 | 82.9 | 76.8 | 106.6 | ||

| 8 | 0.5 | 18.1 | 45.4 | 32.5 | 88.7 | 83.6 | 102.6 | 8 | 1.3 | 20.0 | 49.8 | 25.2 | 77.0 | 83.5 | 106.3 | ||

| 9 | 2.2 | 58.4 | 22.2 | 12.2 | 92.0 | 77.2 | 102.6 | 9 | 2.1 | 60.8 | 23.7 | 10.5 | 91.4 | 78.2 | 102.7 | ||

| 10 | 1.6 | 71.1 | 14.5 | 8.5 | 84.9 | 89.7 | 102.1 | 10 | 0.7 | 74.3 | 16.1 | 6.3 | 97.1 | 90.5 | 100.3 | ||

| 11 | 1.1 | 59.6 | 21.2 | 14.2 | 81.4 | 92.8 | 101.8 | 11 | 0.5 | 62.6 | 23.6 | 10.5 | 86.1 | 93.6 | 101.1 | ||

| 12 | 0.6 | 33.1 | 36.6 | 26.2 | 84.0 | 90.5 | 102.0 | 12 | 0.8 | 35.5 | 40.4 | 19.9 | 78.7 | 88.9 | 103.5 | ||

| SI-XII/1F | 1 | 1.6 | 17.3 | 55.7 | 21.6 | 64.7 | 96.5 | 102.0 | RU-XXIII/6 | 1 | 1.2 | 14.3 | 60.7 | 19.3 | 68.4 | 97.5 | 101.2 |

| 2 | 9.8 | 14.2 | 34.0 | 37.2 | 79.4 | 62.5 | 118.5 | 2 | 5.2 | 15.5 | 39.6 | 31.9 | 80.4 | 63.3 | 116.5 | ||

| 3 | 2.1 | 80.7 | 8.5 | 4.5 | 59.6 | 97.3 | 101.9 | 3 | 1.2 | 75.6 | 9.9 | 4.8 | 85.0 | 95.5 | 100.8 | ||

| 4 | 1.9 | 49.0 | 32.1 | 13.1 | 59.1 | 96.9 | 102.3 | 4 | 1.2 | 44.9 | 35.3 | 12.0 | 81.1 | 87.5 | 103.4 | ||

| 5 | 1.8 | 33.1 | 43.9 | 17.3 | 61.1 | 96.6 | 102.3 | 5 | 1.2 | 29.6 | 48.0 | 15.6 | 76.1 | 94.6 | 101.8 | ||

| 6 | 2.0 | 64.9 | 20.3 | 8.8 | 64.4 | 94.1 | 103.6 | 6 | 1.3 | 60.2 | 22.6 | 8.4 | 76.9 | 92.5 | 102.5 | ||

| 7 | 4.0 | 16.4 | 49.2 | 26.3 | 74.7 | 85.1 | 106.3 | 7 | 2.4 | 14.7 | 54.4 | 23.0 | 79.7 | 77.8 | 107.8 | ||

| 8 | 2.5 | 17.0 | 53.5 | 23.2 | 73.6 | 89.3 | 104.5 | 8 | 1.6 | 14.4 | 58.6 | 20.5 | 85.6 | 77.0 | 105.3 | ||

| 9 | 4.3 | 60.8 | 16.1 | 14.3 | 78.1 | 82.3 | 106.4 | 9 | 2.5 | 57.5 | 18.8 | 12.9 | 82.7 | 83.7 | 104.2 | ||

| 10 | 2.7 | 74.1 | 11.0 | 7.8 | 73.7 | 90.7 | 103.8 | 10 | 1.7 | 69.6 | 12.8 | 7.5 | 83.8 | 90.7 | 102.0 | ||

| 11 | 2.3 | 61.5 | 21.5 | 10.4 | 65.1 | 95.0 | 102.9 | 11 | 1.5 | 57.2 | 24.1 | 9.8 | 83.4 | 90.9 | 102.0 | ||

| 12 | 2.2 | 33.0 | 42.8 | 18.1 | 70.2 | 91.7 | 104.0 | 12 | 1.4 | 29.7 | 47.0 | 16.3 | 82.9 | 86.5 | 103.3 | ||

| SI-XVI/6 | 1 | 0.5 | 19.0 | 49.2 | 25.5 | 56.8 | 95.5 | 103.7 | RU-XI/1 | 1 | 0.0 | 11.7 | 53.3 | 30.7 | 72.4 | 72.8 | 116.6 |

| 2 | 8.2 | 12.5 | 38.8 | 29.0 | 80.8 | 63.3 | 116.0 | 2 | 11.3 | 13.2 | 21.6 | 44.4 | 90.0 | 44.0 | 116.3 | ||

| 3 | 0.1 | 74.4 | 13.0 | 5.8 | 59.0 | 98.7 | 101.0 | 3 | 2.9 | 78.4 | 8.4 | 5.0 | 86.1 | 95.5 | 100.8 | ||

| 4 | 0.3 | 46.7 | 31.1 | 15.7 | 56.5 | 94.1 | 105.1 | 4 | 1.5 | 45.1 | 30.8 | 17.9 | 89.6 | 69.6 | 105.3 | ||

| 5 | 0.4 | 32.9 | 40.1 | 20.6 | 53.4 | 96.0 | 103.8 | 5 | 0.8 | 28.4 | 42.1 | 24.3 | 86.9 | 79.8 | 104.0 | ||

| 6 | 0.2 | 60.6 | 22.0 | 10.7 | 50.5 | 97.2 | 102.9 | 6 | 2.2 | 61.7 | 19.6 | 11.4 | 81.2 | 91.8 | 102.1 | ||

| 7 | 3.0 | 17.1 | 46.0 | 26.6 | 76.7 | 84.2 | 106.0 | 7 | 3.6 | 12.2 | 43.8 | 34.8 | 91.4 | 60.3 | 106.6 | ||

| 8 | 1.4 | 18.4 | 48.1 | 25.9 | 75.2 | 86.7 | 105.3 | 8 | 1.2 | 11.9 | 50.1 | 32.1 | 88.5 | 69.4 | 106.1 | ||

| 9 | 2.7 | 55.8 | 20.7 | 12.7 | 90.1 | 82.4 | 102.4 | 9 | 5.6 | 58.9 | 12.3 | 16.8 | 91.7 | 73.0 | 103.5 | ||

| 10 | 0.9 | 68.2 | 15.5 | 8.1 | 87.9 | 94.4 | 100.8 | 10 | 4.1 | 71.9 | 9.7 | 9.0 | 90.9 | 83.3 | 102.0 | ||

| 11 | 0.6 | 57.5 | 23.3 | 11.9 | 76.6 | 96.3 | 101.2 | 11 | 2.6 | 58.5 | 20.3 | 13.4 | 88.9 | 79.9 | 103.2 | ||

| 12 | 0.9 | 32.5 | 39.6 | 20.8 | 73.7 | 92.4 | 103.0 | 12 | 1.3 | 28.5 | 40.5 | 25.0 | 88.2 | 74.0 | 104.9 |

4. Conclusions

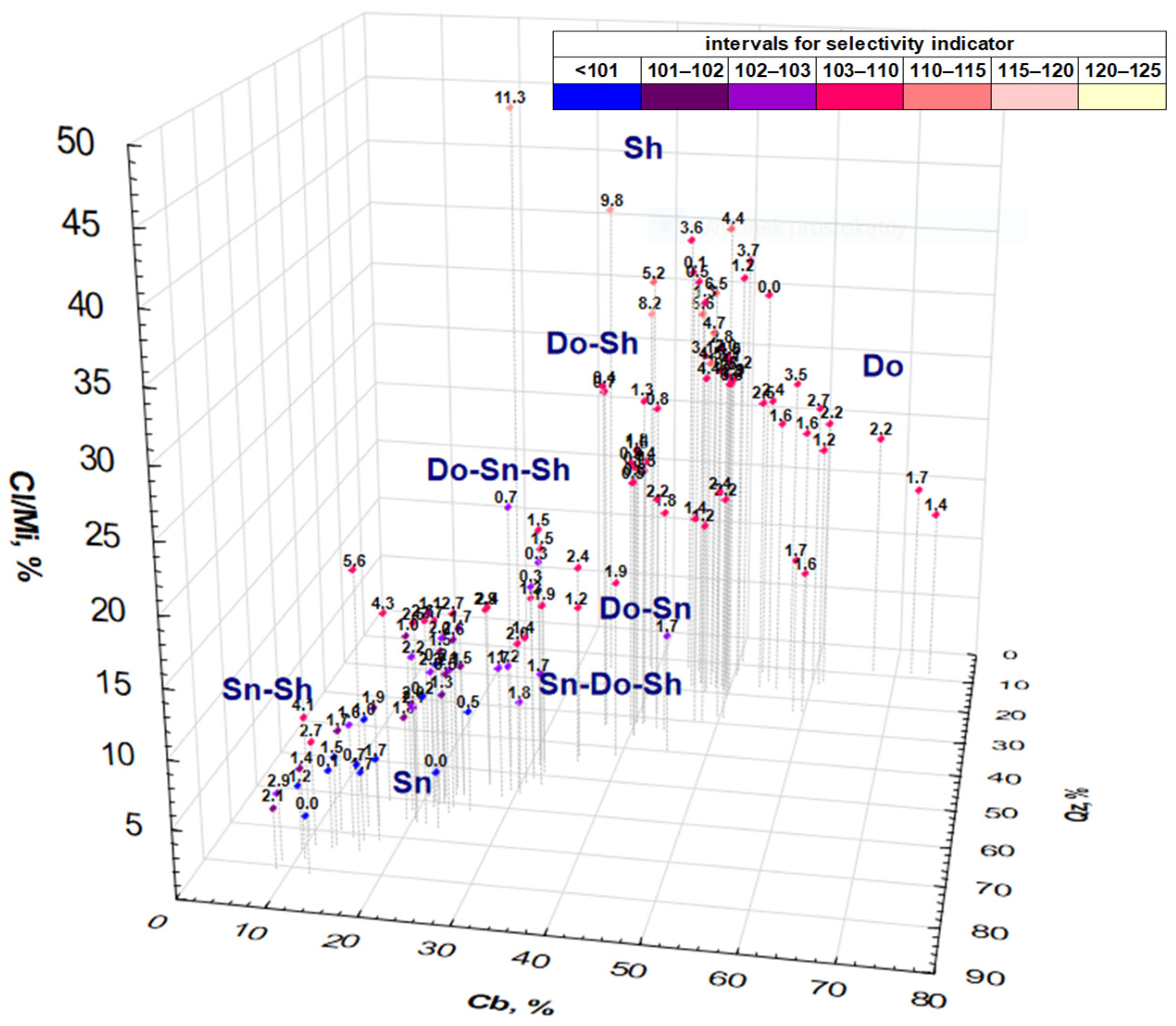

- The metallurgical effectiveness of the enrichment process of individual lithological compositions depends mainly on two factors: sulfide mineralization, which has a major influence on the quality of the feed and the concentrate (contents of the main metals), and the relationship between the content of carbonate and clay minerals in the feed, which affects enrichment selectivity.

- Dolomitic–shale mixtures with high contents of clay minerals and low contents of carbonate minerals show the lowest metallurgical enrichment effectiveness (and this being despite the high copper content in the feed). The highest enrichment selectivity was found for sandstone–shale mixtures in which shale represented 10% of the mixture mass; these were mixtures with low contents of carbonate minerals and high contents of quartz,

- In the case of three-component mixtures, higher enrichment effectiveness was observed for the feed mixtures in which quartz was the dominating component (sandstone ore) than for the mixtures in which carbonate minerals dominated (dolomitic ore).

- The proposed equation performs quick and effective predictions of the copper ore enrichment results from its mineral and chemical composition. It also allows quick and effective control of the performance of the enrichment process, based only on the results of the carbonate and clay minerals and the copper content in the feed of the flotation process. In addition, the derived equation is universal and allows control of the enrichment process depending on the quality parameters of the feed that enters enrichment plants. It also allows this system to be controlled in case of problems during the enrichment process, for example, by changing the lithological composition of the feed entering the process. The use and consideration of this information during enrichment under technological conditions can improve the selectivity of enrichment by effectively monitoring and controlling the composition of the feed entering the enrichment process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dobby, G.; Bennett, C.; Bulled, D.; Kosick, G. Geometallurgical modeling-The new approach to plant design and production forecasting/planning, and Mine/Mill Optimization. In Proceedings of the 36th Annual Meeting of the Canadian Mineral Processors, Ottawa, ON, Canada, 20–22 January 2004; Paper 15. [Google Scholar]

- Dunham, S.; Vann, J. Geometallurgy, geostatistics and project value–does your block model tell you what you need to know. In Proceedings of the Project Evaluation Conference, Melbourne, Australia, 19–20 June 2007; pp. 1–9. [Google Scholar]

- Jackson, J.; Mcfarlane, A.J.; Hoal, K.O. Geometallurgy—Back to the future: Scoping and communicating geomet. In Proceedings of the First AusIMM International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; pp. 125–131. [Google Scholar]

- Parian, M.; Lamberg, P.; Möckel, R.; Rosenkranz, J. Analysis of mineral grades for geometallurgy: Combined element-to-mineral conversion and quantitative X-ray diffraction. Miner. Eng. 2015, 82, 25–35. [Google Scholar] [CrossRef]

- Dominy, S.C.; O’Connor, L.; Parbhakar-Fox, A.; Glass, H.J.; Purevgerel, S. Geometallurgy—A route to more resilient mine operations. Minerals 2018, 8, 560. [Google Scholar] [CrossRef]

- Mu, Y.; Salas, J.C. Data-Driven Synthesis of a Geometallurgical Model for a Copper Deposit. Processes 2023, 11, 1775. [Google Scholar] [CrossRef]

- Celik, I.B.; Can, N.M.; Sherazadishvili, J.O.H.N. Influence of process mineralogy on improving metallurgical performance of a flotation plant. Miner. Process. Extr. Metall. Rev. 2010, 32, 30–46. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Yang, X.; Wang, Z.; Chen, W. Process mineralogy assisted iso-floatability of copper-zinc-lead minerals from iron tailings at marcona iron ore mine. Miner. Process. Extr. Metall. Rev. 2023, 46, 129–142. [Google Scholar] [CrossRef]

- Michaux, S.; O’Connor, L. How to Set Up and Develop a Geometallurgical Program; GTK Open Work File Report 72/2019; Economic Minerals Unit, Geological Survey of Finland: Espoo, Finland, 2020; pp. 1–245. [Google Scholar]

- Bulled, D.; McInnes, C. Flotation plant design and production planning through geometallurgical modelling. SGS Miner. Serv. Tech. Bull. Publ. Ser. 2005, 3, 809–814. [Google Scholar]

- Lamberg, P. Particles–the bridge between geology and metallurgy. In Proceedings of the Mineral Engineering, Luleå, Sweden, 8–9 February 2011; pp. 8–9. [Google Scholar]

- Lishchuk, V.; Koch, P.H.; Ghorbani, Y.; Butcher, A.R. Towards integrated geometallurgical approach: Critical review of current practices and future trends. Miner. Eng. 2020, 145, 106072. [Google Scholar] [CrossRef]

- Lund, C.; Lamberg, P.; Lindberg, T. Development of a geometallurgical framework to quantify mineral textures for process prediction. Miner. Eng. 2015, 82, 61–77. [Google Scholar] [CrossRef]

- Hoal, K.O. Getting the Geo into Geomet. SEG Discov. 2008, 73, 1–15. [Google Scholar] [CrossRef]

- Mwanga, A.; Rosenkranz, J.; Lamberg, P. Testing of ore comminution behavior in the geometallurgical context—A review. Minerals 2015, 5, 276–297. [Google Scholar] [CrossRef]

- Babel, B.; Penz, M.; Schach, E.; Boehme, S.; Rudolph, M. Reprocessing of a Southern Chilean Zn Tailing by Flotation—A Case Study. Minerals 2018, 8, 295. [Google Scholar] [CrossRef]

- Büttner, P.; Osbahr, I.; Zimmermann, R.; Leißner, T.; Satge, L.; Gutzmer, J. Recovery potential of flotation tailings assessed by spatial modelling of automated mineralogy data. Miner. Eng. 2018, 116, 143–151. [Google Scholar] [CrossRef]

- Bowell, R.; Brough, C.; Barnes, A.; Vardanyan, A. Geometallurgy of Trace Elements in the Hrazdan Iron Deposit. Minerals 2021, 11, 1085. [Google Scholar] [CrossRef]

- Yenial-Arslan, U.; Jefferson, M.; Curtis-Morar, C.; Forbes, E. Pathway to Prediction of Pyrite Floatability from Copper Ore Geological Domain Data. Minerals 2023, 13, 801. [Google Scholar] [CrossRef]

- Navarra, A.; Grammatikopoulos, T.; Waters, K. Incorporation of geometallurgical modelling into long-term production planning. Miner. Eng. 2018, 120, 118–126. [Google Scholar] [CrossRef]

- Wackernagel, H. Multivariate Geostatistics An Introduction with Applications; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar] [CrossRef]

- Garrido, M.; Ortiz, J.M.; Sepúlveda, E.; Farfán, L.; Townley, B. An overview of good practices in the use of geometallurgy to support mining reserves in copper sulfides deposits. In Proceedings of the 15th International Conference on Mineral Processing and the 6th International Seminar on Geometallurgy, Santiago, Chile, 20–22 November 2019. [Google Scholar]

- Johnson, R.A.; Wichern, D.W. Applied Multivariate Statistical Analysis; Prentice Hall: New York, NY, USA, 2007. [Google Scholar]

- Napier-Munn, T.J. Statistical methods to compare batch flotation grade-recovery curves and rate constants. Miner. Eng. 2012, 34, 70–77. [Google Scholar] [CrossRef]

- Tumidajski, T. Aktualne tendencje w opisie i modelowaniu matematycznym procesow przerobki materialow uziarnionych [Actual tendencies in description and mathematical modeling of mineral processing]. Gospod. Surowcami Miner.—Miner. Resour. Manag. 2010, 26, 111–121. (In Polish) [Google Scholar]

- Tumidajski, T.; Saramak, D.; Foszcz, D.; Niedoba, T. Methods of modeling and optimization of work effects for chosen mineral processing systems. Acta Montan. Slovaca 2005, 1, 115–120. [Google Scholar]

- Konieczny, A.; Pawlos, W.; Jach, M.; Pepkowski, R.; Krzeminska, M.; Kaleta, R. Zastosowanie systemu wizualizacji do sterowania parametrami pracy maszyn flotacyjnych w KGHM Polska Miedz S.A. Oddzial Zaklady Wzbogacania Rud [Application of visualisation system for controlling operating parameters of flotation machines in KGHM Polska Miedz S.A. Division of concentrators]. Gor. i Geologia 2011, 6, 61–71. (In Polish) [Google Scholar]

- Borg, G.; Piestrzynski, A.; Bachmann, G.; Püttmann, W.; Walther, S.; Fiedler, M. An Overview of the European Kupferschiefer Deposits. Soc. Econ. Geol. Inc. Spec. Publ. 2012, 16, 455–486. [Google Scholar] [CrossRef]

- Rydzewski, A.; Sliwinski, W. Litologia skal zlozowych. In Monografia KGHM Polska Miedz S.A.; A. Piestrzynski, A., Ed.; KGHM Cuprum CBR: Wroclaw, Poland, 2007. [Google Scholar]

- Oszczepalski, S.; Speczik, S.; Zielinski, K.; Chmielewski, A. The Kupferschiefer Deposits and Prospects in SW Poland: Past, Present and Future. Minerals 2019, 9, 592. [Google Scholar] [CrossRef]

- Chmielewski, T. Development of a hydrometallurgical technology for production of metals from KGHM Polska Miedz S.A. concentrates. Physicochem. Probl. Miner. Process. 2015, 51, 335–350. [Google Scholar] [CrossRef]

- KGHM Report. Integrated Report of KGHM Polska Miedz S.A. and the KGHM Polska Miedz S.A. Group for 2022. 2022. Available online: https://kghm.com/sites/default/files/2024-01/kghm-integrated-report-2022_7.pdf (accessed on 1 January 2024).

- Bakalarz, A.; Duchnowska, M. Analysis of the Possibility of Copper Recovery from Flotation Stratiform Copper Ore Tailings. Miner. Process. Extr. Metall. Rev. 2024, 45, 943–949. [Google Scholar] [CrossRef]

- Kijewski, P.; Leszczynski, R. Wegiel organiczny w rudach miedzi—Znaczenie i problemy [Organic carbon in copper ores—Importance and problems]. In The Bulletin of the Mineral and Energy Economy Research Institute of the Polish Academy of Sciences (Zeszyty Naukowe Instytutu Gospodarki Surowcami Mineralnymi i Energia Polskiej Akademii Nauk); Mineral and Energy Economy Research Institute of the Polish Academy of Sciences: Kraków, Poland, 2010; Volume 79, pp. 131–146. (In Polish) [Google Scholar]

- Luszczkiewicz, A.; Duchnowska, M.; Drzymala, J.; Konopacka, Z.; Henc, T.; Laskowski, J.; Karwowski, P. Okreslenie Granicznej Wzbogacalnosci Urobku Przerabianego w O/ZWR Rejon Lubin [Determination of the Limiting Enrichment of Ore Processed in the Lubin Concentrator Plant (KGHM)]; Report Nr I-11/2012/S-28; Instytut Gornictwa Politechniki Wroclawskiej: Wroclaw, Poland, 2012. unpublished data (In Polish) [Google Scholar]

- Kaczmarek, W.; Twardowski, M.; Wasilewska-Blaszczyk, M. Praktyczne aspekty modelowania litologicznych typow rud w zlozach Cu-Ag LGOM (Legnicko-Glogowskiego Okregu Miedziowego) [Practical aspects of lithological types modelling in Cu-Ag ore LGOM deposit (Legnica-Glogow Copper District)]. Biul. Panstw. Inst. Geol. 2017, 468, 209–226. (In Polish) [Google Scholar] [CrossRef]

- Luszczkiewicz, A.; Wieniewski, A. Kierunki rozwoju technologii wzbogacania rud w krajowym przemysle miedziowym [Directions in development of ore processing technology in Polish copper industry]. Gor. i Geoinzynieria 2006, 30, 181–196. (In Polish) [Google Scholar]

- Konieczny, A.; Kasinska-Pilut, E.; Pilut, R. Problemy technologiczne i techniczne procesu przerobki mechanicznej rud miedzi w swietle dzialalnosci i roli Oddzialu Zaklady Wzbogacania Rud KGHM Polska Miedz S.A. [Technological and technical problems in mineral processing of Polish copper ores at division of concentrators KGHM Polska Miedz SA]. Cuprum Czas. Nauk.-Tech. Gor. Rud 2009, 1–2, 31–46. (In Polish) [Google Scholar]

- Pawlos, W.; Poznar, E.; Krzeminska, M. The effect of lithological diversity of feed on process efficiency indexes in KGHM Polska Miedz S.A. Concentrator Plants. Biul. Panstw. Inst. Geol. 2017, 469, 67–74. [Google Scholar] [CrossRef]

- Sawlowicz, Z. Organic Matter and its Significance for the Genesis of the Copper-Bearing Shales (Kupferschiefer) from the Fore-Sudetic Monocline (Poland). In Bitumens in Ore Deposits. Special Publication of the Society for Geology Applied to Mineral Deposits, 9; Parnell, J., Kucha, H., Landais, P., Eds.; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar] [CrossRef]

- Oszczepalski, S. Origin of the Kupferschiefer polymetallic mineralization in Poland. Miner. Depos. 1999, 34, 599–613. [Google Scholar] [CrossRef]

- Hitzman, M.W.; Selley, D.; Bull, S. Formation of sedimentary rock-hosted stratiform copper deposits through Earth history. Econ. Geol. 2010, 105, 627–639. [Google Scholar] [CrossRef]

- Tomaszewski, J. Problems of a rational utilization of copper-polymetallic ores from the Foresudetic Monocline deposits. Physicochem. Probl. Miner. Process. 1985, 17, 131–141. Available online: https://www.journalssystem.com/ppmp/pdf-80391-35434?filename=The%20problems%20of%20the.pdf (accessed on 1 January 2024). (In Polish).

- Konstantynowicz-Zielinska, J. Petrografia i geneza lupkow miedzionosnych monokliny przedsudeckiej. Rudy Met. Niezelaz. 1990, 35, 128–137. (In Polish) [Google Scholar]

- Kucha, H. Mineralogia kruszcowa i geochemia ciala rudnego zloza Lubin-Sieroszowice. Biul. Panstw. Inst. Geol. 2007, 423, 77–94. (In Polish) [Google Scholar]

- Skorupska, B.; Wieniewski, A.; Kubacz, N. Mozliwosci produkcji koncentratow miedziowych o zroznicowanej zawartosci skladnikow organicznych [Possibility of copper concentrates production of different organic elements content]. Gor. i Geologia 2011, 6, 201–216. (In Polish) [Google Scholar]

- Wasilewska-Blaszczyk, M.; Twardowski, M.; Mucha, J.; Kaczmarek, W. Model litologiczny 3D przy zastosowaniu technik interpolacyjnych i symulacji geostatystycznej (na przykladzie zloza Cu-Ag Legnicko-Glogowskiego Okregu Miedziowego) [3D lithological model using by interpolation and simulation methods on an example of the Cu-Ag deposit, Legnica-Głogow Copper District]. Biul. Panstw. Inst. Geol. 2017, 468, 237–246. (In Polish) [Google Scholar] [CrossRef]

- Twardowski, M.; Kaczmarek, W.; Rozek, R. Trzeci wymiar geologii zloza rud miedzi [The third dimension of the geology of copper ore deposit]. Prz. Geol. 2020, 68, 886–893. (In Polish) [Google Scholar]

- Bakalarz, A.; Duchnowska, M.; Luszczkiewicz, A. Ongoing monitoring of the quality of extracted ore in terms of its geometallurgical properties based on a 3D deposit model. Stage 2. Raporty Wydzialu Geoinzynierii, Gornictwa i Geologii Politechniki Wroclawskiej. Report no. 6. 2021; unpublished data. (In Polish) [Google Scholar]

- Kubik, R. Creation and development of QEMSCAN®®® analysis procedure based on Polish copper ores investigation. Int. Multidiscip. Sci. GeoConference SGEM Surv. Geol. Min. Ecol. Manag. 2018, 18, 59–66. [Google Scholar]

- Kijewski, P.; Lis., J. Warunki geologiczno–inzynierskie w obszarze Zloza [Geological and engineering conditions in the Deposit area]. In Monografia KGHM Polska Miedz S.A.; KGHM Cuprum Sp. z o.o. CBR: Lubin, Poland, 1996; pp. 164–168. (In Polish) [Google Scholar]

- Drzymala, J.; Ahmed, H.A.M. Mathematical equations for approximation of separation results using the Fuerstenau upgrading curves. Int. J. Miner. Process. 2005, 76, 55–65. [Google Scholar] [CrossRef]

- Duchnowska, M.; Drzymala, J. Self-similarity of upgrading parameters used for evaluation of separation results. Int. J. Miner. Process. 2012, 106, 50–57. [Google Scholar] [CrossRef]

- Foszcz, D.; Duchnowska, M.; Niedoba, T.; Tumidajski, T. Accuracy of separation parameters resulting from errors of chemical analysis, experimental results and data approximation. Physicochem. Probl. Miner. Process. 2016, 52, 98–111. [Google Scholar]

- Duchnowska, M.; Drzymala, J. Transformation of equation y = a(100 − x)/(a − x) for approximation of separation results plotted as Fuerstenau’s upgrading curve for application in other upgrading curves. Physicochem. Probl. Miner. Process. 2011, 47, 123–130. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R. Multivariate Data Analysis, 6th ed.; Prentice Hall: Upper Sadle River, NJ, USA, 2006. [Google Scholar]

| Mass of mined ore, tons | 30,500,000 |

| Average Cu content in ore, % | 1.45 |

| Average Cu content in concentrate, % | 22.36 |

| Mass of Cu in ore, tons | 442,700 |

| Concentrate mass, tons | 1,755,000 |

| Mass of Cu in concentrate, tons | 392,500 |

| Total final Cu recovery, % | 88.75 |

| Flotation tailings mass, tons | 28,717,443.57 |

| Location of Sample Collection | Lithology Type | Content, % | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Ore Minerals | Cct/Dg/Dj | Bn | Ccp | Cv | Tnt/Ttr | Eng | Py/Mrc | Gn | Sp | Qz | Cb | Cl/Mi | ||

| LU III/18 | S | 1.65 | 2.00 | 0.92 | 0.41 | 0.07 | 0.25 | 0.09 | 0.01 | 0.25 | 0.00 | 0.00 | 71.54 | 15.89 | 4.96 |

| Sh | 3.73 | 5.60 | 2.07 | 1.96 | 0.24 | 0.39 | 0.09 | 0.01 | 0.82 | 0.00 | 0.00 | 8.87 | 50.48 | 32.88 | |

| D | 1.41 | 2.48 | 0.84 | 0.77 | 0.31 | 0.16 | 0.00 | 0.00 | 0.41 | 0.00 | 0.00 | 8.06 | 74.37 | 13.40 | |

| LU-XVII/2 | S | 1.69 | 1.40 | 1.26 | 0.02 | 0.01 | 0.10 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 71.46 | 17.57 | 6.07 |

| Sh | 6.47 | 6.77 | 5.92 | 0.38 | 0.02 | 0.43 | 0.01 | 0.00 | 0.02 | 0.00 | 0.00 | 12.91 | 46.97 | 30.91 | |

| D | 2.17 | 2.59 | 1.62 | 0.29 | 0.25 | 0.19 | 0.00 | 0.00 | 0.22 | 0.00 | 0.00 | 13.29 | 61.32 | 21.29 | |

| GL-XXVI/1 | S | 1.53 | 2.51 | 0.30 | 1.43 | 0.18 | 0.12 | 0.01 | 0.00 | 0.35 | 0.01 | 0.12 | 73.40 | 13.32 | 6.54 |

| Sh | 5.56 | 9.05 | 0.37 | 7.72 | 0.24 | 0.28 | 0.00 | 0.00 | 0.28 | 0.03 | 0.14 | 13.03 | 45.36 | 29.23 | |

| D | 1.48 | 2.72 | 0.02 | 1.68 | 0.63 | 0.06 | 0.00 | 0.00 | 0.32 | 0.00 | 0.00 | 17.88 | 49.28 | 26.49 | |

| GL-XXIX/1 | S | 1.38 | 2.37 | 0.46 | 0.72 | 0.17 | 0.20 | 0.04 | 0.00 | 0.52 | 0.04 | 0.22 | 77.45 | 10.72 | 6.60 |

| Sh | 4.08 | 8.89 | 0.19 | 4.77 | 2.48 | 0.13 | 0.02 | 0.00 | 0.65 | 0.43 | 0.23 | 13.89 | 48.88 | 25.28 | |

| D | 0.09 | 1.45 | 0.00 | 0.00 | 0.18 | 0.00 | 0.00 | 0.00 | 0.96 | 0.14 | 0.16 | 18.60 | 45.01 | 33.32 | |

| SI-XII/1F | S | 2.10 | 1.78 | 0.51 | 0.43 | 0.08 | 0.50 | 0.02 | 0.00 | 0.22 | 0.00 | 0.03 | 80.73 | 8.47 | 4.51 |

| Sh | 9.81 | 11.34 | 8.53 | 1.43 | 0.03 | 1.14 | 0.02 | 0.00 | 0.02 | 0.03 | 0.14 | 14.21 | 34.04 | 37.15 | |

| D | 1.62 | 2.23 | 0.64 | 0.66 | 0.27 | 0.30 | 0.00 | 0.00 | 0.35 | 0.00 | 0.00 | 17.27 | 55.68 | 21.61 | |

| SI-XVI/6 | S | 0.07 | 0.28 | 0.00 | 0.00 | 0.09 | 0.01 | 0.00 | 0.00 | 0.17 | 0.01 | 0.00 | 74.40 | 12.96 | 5.78 |

| Sh | 8.25 | 15.71 | 2.27 | 7.41 | 3.53 | 2.28 | 0.05 | 0.01 | 0.15 | 0.01 | 0.00 | 12.49 | 38.79 | 28.99 | |

| D | 0.54 | 1.75 | 0.01 | 0.26 | 0.58 | 0.04 | 0.00 | 0.00 | 0.86 | 0.00 | 0.00 | 19.02 | 49.15 | 25.52 | |

| SI-V/5 | S | 0.03 | 0.05 | 0.01 | 0.02 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 66.76 | 23.26 | 4.30 |

| Sh | 4.39 | 4.05 | 3.73 | 0.05 | 0.00 | 0.27 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 10.35 | 48.41 | 35.59 | |

| D | 4.44 | 5.08 | 4.64 | 0.05 | 0.00 | 0.38 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 20.12 | 46.97 | 25.40 | |

| SI-XVII/2 | S | 0.01 | 0.02 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 81.05 | 12.30 | 4.28 |

| Sh | 7.16 | 9.58 | 4.92 | 3.60 | 0.22 | 0.59 | 0.08 | 0.01 | 0.05 | 0.09 | 0.02 | 13.56 | 50.26 | 24.92 | |

| D | 0.62 | 2.12 | 0.00 | 0.61 | 0.46 | 0.04 | 0.00 | 0.00 | 0.47 | 0.51 | 0.02 | 20.73 | 49.80 | 25.19 | |

| RU-XXIII/6 | S | 1.25 | 1.99 | 0.20 | 1.19 | 0.10 | 0.15 | 0.02 | 0.00 | 0.32 | 0.00 | 0.01 | 75.56 | 9.87 | 4.78 |

| Sh | 5.22 | 8.73 | 1.72 | 5.10 | 0.30 | 0.95 | 0.01 | 0.00 | 0.56 | 0.01 | 0.08 | 15.48 | 39.60 | 31.85 | |

| D | 1.17 | 1.87 | 0.28 | 0.87 | 0.25 | 0.13 | 0.00 | 0.00 | 0.28 | 0.00 | 0.06 | 14.30 | 60.73 | 19.27 | |

| RU-XI/1 | S | 2.94 | 2.64 | 2.16 | 0.01 | 0.00 | 0.47 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 78.42 | 8.37 | 5.01 |

| Sh | 11.29 | 16.84 | 13.10 | 0.86 | 0.14 | 0.80 | 0.00 | 0.00 | 0.75 | 0.76 | 0.44 | 13.22 | 21.56 | 44.43 | |

| D | 2.94 | 1.42 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | 0.66 | 0.18 | 0.58 | 11.75 | 53.29 | 30.73 | |

| Sample No. | Lithology Content in the Sample, % | ||

|---|---|---|---|

| Dolomite | Shale | Sandstone | |

| 1 | 100 | 0 | 0 |

| 2 | 0 | 100 | 0 |

| 3 | 0 | 0 | 100 |

| 4 | 50 | - | 50 |

| 5 | 75 | - | 25 |

| 6 | 25 | - | 75 |

| 7 | 70 | 30 | - |

| 8 | 90 | 10 | - |

| 9 | - | 30 | 70 |

| 10 | - | 10 | 90 |

| 11 | 25 | 5 | 70 |

| 12 | 70 | 5 | 25 |

| Summary of Variable-Dependent Regression | |||||||

|---|---|---|---|---|---|---|---|

| R= 0.777, R2 = 0.604, Corrected R2 = 0.600 | |||||||

| F(3.116) = 58.844, p < 0.0000, Standard Estimation Error: 2.897 | |||||||

| Variable | Standardized Coefficient b* | Partial Correlation | Semi-Partial Correlation | Tolerance | R-Squared | T-Value | Probability Value p |

| αCb, % | 0.163 | 0.189 | 0.121 | 0.550 | 0.450 | 2.067 | 0.041 |

| αCl/Mi, % | 0.292 | 0.291 | 0.191 | 0.430 | 0.570 | 3.272 | 0.001 |

| αCu, % | 0.525 | 0.572 | 0.439 | 0.699 | 0.301 | 7.502 | 0.000 |

| Standardized coefficient b* | St. err. of b* | Unstandardized coefficient b | St. err. of b | t-value | probability value p | ||

| Free term | 97.468 | 0.715 | 136.332 | 0.000 | |||

| αCb, % | 0.163 | 0.079 | 0.048 | 0.023 | 2.067 | 0.041 | |

| αCl/Mi, % | 0.292 | 0.089 | 0.151 | 0.046 | 3.272 | 0.001 | |

| αCu, % | 0.525 | 0.070 | 1.295 | 0.173 | 7.502 | 0.000 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duchnowska, M.; Bakalarz, A. Geometallurgical Modeling of Influence of Mineral Composition of Sulfide Copper Ore (Southwest Poland) on Enrichment Selectivity. Minerals 2025, 15, 432. https://doi.org/10.3390/min15040432

Duchnowska M, Bakalarz A. Geometallurgical Modeling of Influence of Mineral Composition of Sulfide Copper Ore (Southwest Poland) on Enrichment Selectivity. Minerals. 2025; 15(4):432. https://doi.org/10.3390/min15040432

Chicago/Turabian StyleDuchnowska, Magdalena, and Alicja Bakalarz. 2025. "Geometallurgical Modeling of Influence of Mineral Composition of Sulfide Copper Ore (Southwest Poland) on Enrichment Selectivity" Minerals 15, no. 4: 432. https://doi.org/10.3390/min15040432

APA StyleDuchnowska, M., & Bakalarz, A. (2025). Geometallurgical Modeling of Influence of Mineral Composition of Sulfide Copper Ore (Southwest Poland) on Enrichment Selectivity. Minerals, 15(4), 432. https://doi.org/10.3390/min15040432