Production of Graphitic Carbon from Renewable Lignocellulosic Biomass Source

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Development of Pinecone-Derived Graphitic Carbon

2.2.2. Characterization of Graphitic Carbon

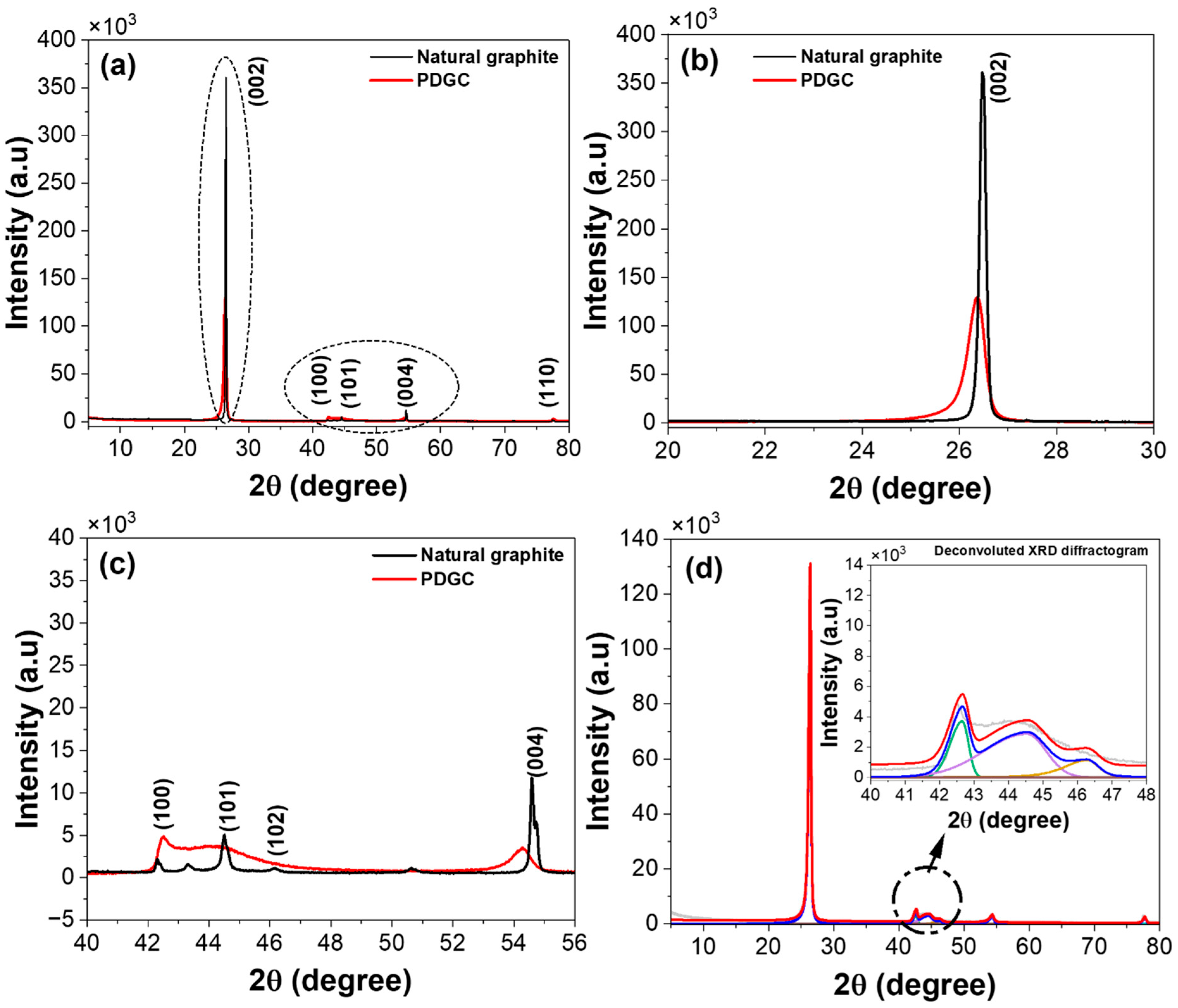

X-Ray Diffraction Analysis

Transmission Electron Microscopy Imaging

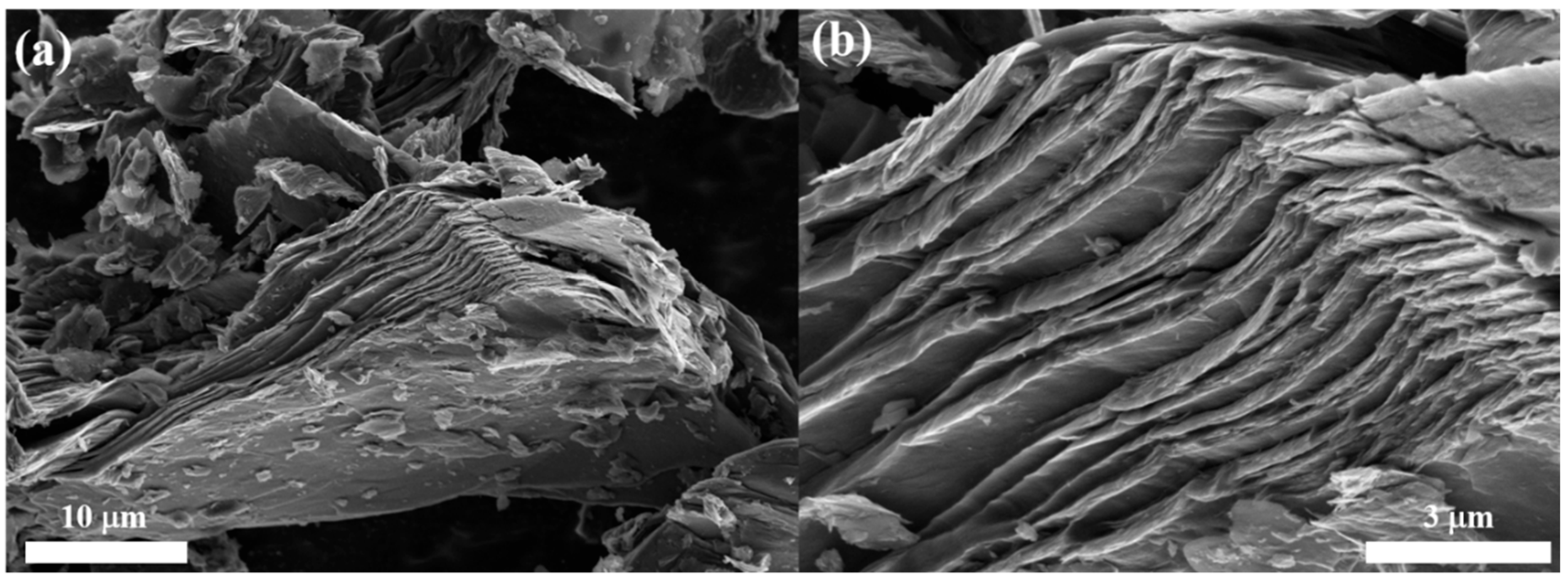

Scanning Electron Microscopy Imaging

3. Results and Discussion

3.1. Bulk Study of PDGC Material

3.2. Morphological and Microstructural Analysis

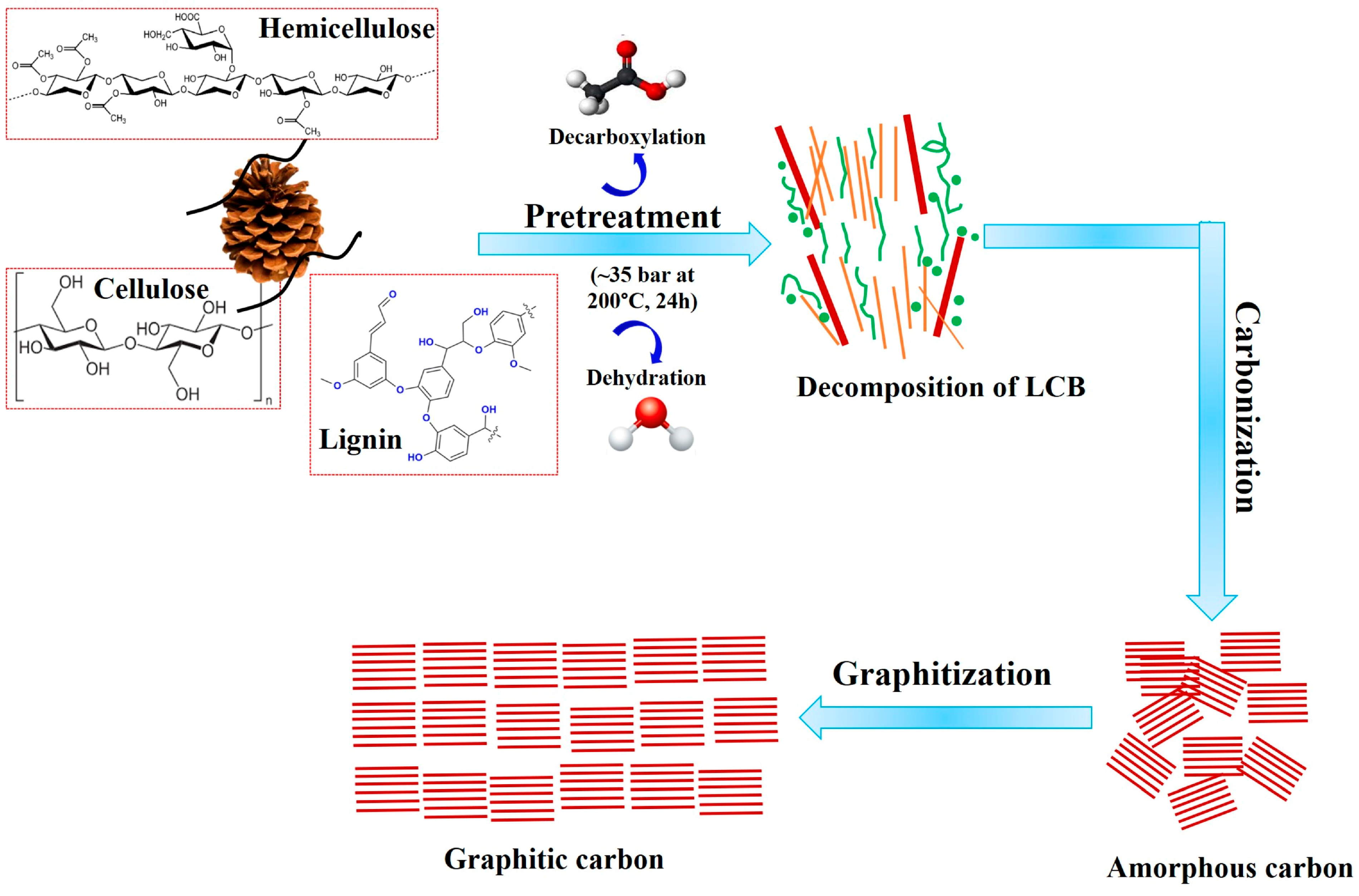

3.3. Graphitization Mechanism for the Formation of Pinecone-Derived Graphitic Carbon

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Y.; Tang, Z.; Zhou, S.; Wang, H.; Tang, Y.; Sun, D.; Wang, H. Renewable waste biomass-derived carbon materials for energy storage. J. Phys. D Appl. Phys. 2022, 55, 313002. [Google Scholar] [CrossRef]

- Antil, B.; Kumar, L.; Das, M.R.; Deka, S. N-doped graphene modulated N-rich carbon nitride realizing a promising all-solid-state flexible supercapacitor. J. Energy Storage 2022, 52, 104731. [Google Scholar] [CrossRef]

- Yan, D.; Song, L.; Kang, F.; Mo, X.; Lv, Y.; Sun, J.; Tang, H.; Zhou, X.; Zhang, Q. In Situ Growth of Covalent Organic Frameworks on Carbon Nanotubes for High-Performance Potassium-Ion Batteries. Angew. Chem. 2025, e202422851. [Google Scholar] [CrossRef]

- Yuan, Y.; Hu, R.; Wang, W.; Wang, Y.; Zhang, T.; Wang, Z. Design and fabrication of high-performance multilayer silicon-carbon composite anodes for lithium-ion batteries via femtosecond laser. J. Energy Storage 2025, 110, 115362. [Google Scholar] [CrossRef]

- Olhan, S.; Behera, B.K. Development of GNP nanofiller based textile structural composites for enhanced mechanical, thermal, and viscoelastic properties for automotive components. Adv. Compos. Hybrid. Mater. 2024, 7, 25. [Google Scholar] [CrossRef]

- Olhan, S.; Antil, B.; Behera, B.K. Synergistic effect of different high-performance fibers on the microstructural evolution and mechanical performance of novel hybrid metal matrix composites produced via friction stir processing for automotive applications. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 239, 236–249. [Google Scholar] [CrossRef]

- Chen, G.; Wang, M.; Jiao, M.; Kong, X.; Zhao, L. Rapid Joule-heating synthesis of oxide nanoparticles on carbon cloth as electrodes for supercapacitors. J. Power Sources 2025, 629, 235963. [Google Scholar] [CrossRef]

- Bhat, Y.; Adeosun, W.A.; Prenger, K.; Samad, Y.A.; Liao, K.; Naguib, M.; Mao, S.; Qurashi, A. Frontiers of MXenes-based hybrid materials for energy storage and conversion applications. Adv. Compos. Hybrid. Mater. 2025, 8, 52. [Google Scholar] [CrossRef]

- Olhan, S.; Khatkar, V.; Behera, B.K. Mechanical Behavior of Natural Fiber Based 3D woven Structural Composites for Automotive applications. In Proceedings of the 47th Textile Research Symposium (TRS), Liberec, Czech Republic, 19–21 June 2019; pp. 65, 120. [Google Scholar]

- Wang, J.; Zhang, X.; Li, Z.; Ma, Y.; Ma, L. Recent progress of biomass-derived carbon materials for supercapacitors. J. Power Sources 2020, 451, 227794. [Google Scholar] [CrossRef]

- Zhai, Z.; Zhang, L.; Du, T.; Ren, B.; Xu, Y.; Wang, S.; Miao, J.; Liu, Z. A review of carbon materials for supercapacitors. Mater. Des. 2022, 221, 111017. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, J.; Fan, Z. Carbon materials for high volumetric performance supercapacitors: Design, progress, challenges and opportunities. Energy Environ. Sci. 2016, 9, 729–762. [Google Scholar] [CrossRef]

- Borenstein, A.; Hanna, O.; Attias, R.; Luski, S.; Brousse, T.; Aurbach, D. Carbon-based composite materials for supercapacitor electrodes: A review. J. Mater. Chem. A 2017, 5, 12653–12672. [Google Scholar] [CrossRef]

- Zhang, L.L.; Zhao, X.S. Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 2009, 38, 2520. [Google Scholar] [CrossRef]

- Hoang, V.C.; Hassan, M.; Gomes, V.G. Coal derived carbon nanomaterials—Recent advances in synthesis and applications. Appl. Mater. Today 2018, 12, 342–358. [Google Scholar] [CrossRef]

- Li, S.; Jin, B.; Zhai, X.; Li, H.; Jiang, Q. Review of Carbon Materials for Lithium-Sulfur Batteries. ChemistrySelect 2018, 3, 2245–2260. [Google Scholar] [CrossRef]

- Lee, S.-M.; Kang, D.-S.; Roh, J.-S. Bulk graphite: Materials and manufacturing process. Carbon Lett. 2015, 16, 135–146. [Google Scholar] [CrossRef]

- Singh, M.; Vander Wal, R.L. Carbon Composites—Graphene-Oxide-Catalyzed Sugar Graphitization. C 2022, 8, 15. [Google Scholar] [CrossRef]

- Chew, J.J.; Doshi, V. Recent advances in biomass pretreatment—Torrefaction fundamentals and technology. Renew. Sustain. Energy Rev. 2011, 15, 4212–4222. [Google Scholar] [CrossRef]

- Morgan, H.M.; Bu, Q.; Liang, J.; Liu, Y.; Mao, H.; Shi, A.; Lei, H.; Ruan, R. A review of catalytic microwave pyrolysis of lignocellulosic biomass for value-added fuel and chemicals. Bioresour. Technol. 2017, 230, 112–121. [Google Scholar] [CrossRef]

- Mohamed, A.R.; Mohammadi, M.; Darzi, G.N. Preparation of carbon molecular sieve from lignocellulosic biomass: A review. Renew. Sustain. Energy Rev. 2010, 14, 1591–1599. [Google Scholar] [CrossRef]

- Kumar Mishra, R.; Singh, B.; Acharya, B. A comprehensive review on activated carbon from pyrolysis of lignocellulosic biomass: An application for energy and the environment. Carbon Resour. Convers. 2024, 7, 100228. [Google Scholar] [CrossRef]

- Khan, T.A.; Saud, A.S.; Jamari, S.S.; Rahim, M.H.A.; Park, J.-W.; Kim, H.-J. Hydrothermal carbonization of lignocellulosic biomass for carbon rich material preparation: A review. Biomass Bioenergy 2019, 130, 105384. [Google Scholar] [CrossRef]

- Olhan, S.; Antil, B.; Behera, B.K. Repair technologies for structural polymeric composites: An automotive perspective. Compos. Struct. 2025, 352, 118711. [Google Scholar] [CrossRef]

- Titirici, M.-M.; White, R.J.; Brun, N.; Budarin, V.L.; Su, D.S.; del Monte, F.; Clark, J.H.; MacLachlan, M.J. Sustainable carbon materials. Chem. Soc. Rev. 2015, 44, 250–290. [Google Scholar] [CrossRef]

- Luo, X.; Chen, S.; Hu, T.; Chen, Y.; Li, F. Renewable biomass-derived carbons for electrochemical capacitor applications. SusMat 2021, 1, 211–240. [Google Scholar] [CrossRef]

- Antil, B.; Elkasabi, Y.; Strahan, G.D.; Vander Wal, R.L. Development of graphitic and non-graphitic carbons using different grade biopitch sources. Carbon 2025, 232, 119770. [Google Scholar] [CrossRef]

- Yu, S.; Wang, L.; Li, Q.; Zhang, Y.; Zhou, H. Sustainable carbon materials from the pyrolysis of lignocellulosic biomass. Mater. Today Sustain. 2022, 19, 100209. [Google Scholar] [CrossRef]

- Harris, P.J.F. New Perspectives on the Structure of Graphitic Carbons. Crit. Rev. Solid State Mater. Sci. 2005, 30, 235–253. [Google Scholar] [CrossRef]

- Sharma, S. Glassy Carbon: A Promising Material for Micro- and Nanomanufacturing. Materials 2018, 11, 1857. [Google Scholar] [CrossRef]

- Franklin, R.E. The structure of graphitic carbons. Acta Crystallogr. 1951, 4, 253–261. [Google Scholar] [CrossRef]

- Joo, J.B.; Kim, P.; Kim, W.; Kim, J.; Kim, N.D.; Yi, J. Simple preparation of hollow carbon sphere via templating method. Curr. Appl. Phys. 2008, 8, 814–817. [Google Scholar] [CrossRef]

- Tam, N.T.M.; Liu, Y.-G.; Bashir, H.; Zhang, P.; Liu, S.-B.; Tan, X.; Dai, M.-Y.; Li, M.-F. Synthesis of Porous Biochar Containing Graphitic Carbon Derived From Lignin Content of Forestry Biomass and Its Application for the Removal of Diclofenac Sodium From Aqueous Solution. Front. Chem. 2020, 8, 274. [Google Scholar] [CrossRef]

- Gai, L.; Li, J.; Wang, Q.; Tian, R.; Li, K. Evolution of biomass to porous graphite carbon by catalytic graphitization. J. Environ. Chem. Eng. 2021, 9, 106678. [Google Scholar] [CrossRef]

- Lower, L.; Dey, S.C.; Vook, T.; Nimlos, M.; Park, S.; Sagues, W.J. Catalytic Graphitization of Biocarbon for Lithium-Ion Anodes: A Minireview. ChemSusChem 2023, 16, e202300729. [Google Scholar] [CrossRef]

- Fathy, N.A. Carbon nanotubes synthesis using carbonization of pretreated rice straw through chemical vapor deposition of camphor. RSC Adv. 2017, 7, 28535–28541. [Google Scholar] [CrossRef]

- Pan, Q.; Li, B.; Liu, S.; Yang, Y.; Tang, X.; Liu, H.; Huang, R.; Wang, J. Flower-like graphitic carbon derived from biomass for anode of potassium ion battery. Chem. Eng. Sci. 2025, 304, 121043. [Google Scholar] [CrossRef]

- Demir, M.; Kahveci, Z.; Aksoy, B.; Palapati, N.K.R.; Subramanian, A.; Cullinan, H.T.; El-Kaderi, H.M.; Harris, C.T.; Gupta, R.B. Graphitic Biocarbon from Metal-Catalyzed Hydrothermal Carbonization of Lignin. Ind. Eng. Chem. Res. 2015, 54, 10731–10739. [Google Scholar] [CrossRef]

- Trifol, J.; Marin Quintero, D.C.; Moriana, R. Pine Cone Biorefinery: Integral Valorization of Residual Biomass into Lignocellulose Nanofibrils (LCNF)-Reinforced Composites for Packaging. ACS Sustain. Chem. Eng. 2021, 9, 2180–2190. [Google Scholar] [CrossRef]

- Creteanu, A.; Lungu, C.N.; Lungu, M. Lignin: An Adaptable Biodegradable Polymer Used in Different Formulation Processes. Pharmaceuticals 2024, 17, 1406. [Google Scholar] [CrossRef]

- Kongpanya, J.; Hussaro, K.; Teekasap, S. Influence of Reaction Temperature and Reaction Time on Product from Hydrothermal Treatment of Biomass Residue. Am. J. Environ. Sci. 2014, 10, 324–335. [Google Scholar] [CrossRef]

- Patterson, A.L. The Scherrer Formula for X-Ray Particle Size Determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Rogalinski, T.; Ingram, T.; Brunner, G. Hydrolysis of lignocellulosic biomass in water under elevated temperatures and pressures. J. Supercrit. Fluids 2008, 47, 54–63. [Google Scholar] [CrossRef]

- Franklin, R.E. Crystallite growth in graphitizing and non-graphitizing carbons. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1951, 209, 196–218. [Google Scholar]

- Alcaraz, L.; Díaz-Guerra, C.; Calbet, J.; López, M.L.; López, F.A. Obtaining and Characterization of Highly Crystalline Recycled Graphites from Different Types of Spent Batteries. Materials 2022, 15, 3246. [Google Scholar] [CrossRef]

- Sun, J.; Sun, Y.; Oh, J.A.S.; Gu, Q.; Zheng, W.; Goh, M.; Zeng, K.; Cheng, Y.; Lu, L. Insight into the structure-capacity relationship in biomass derived carbon for high-performance sodium-ion batteries. J. Energy Chem. 2021, 62, 497–504. [Google Scholar] [CrossRef]

- Kumar, U.; Wu, J.; Sharma, N.; Sahajwalla, V. Biomass Derived High Areal and Specific Capacity Hard Carbon Anodes for Sodium-Ion Batteries. Energy Fuels 2021, 35, 1820–1830. [Google Scholar] [CrossRef]

- Kim, Y.S.; Hanif, A.; Song, H.; Kim, S.; Cho, Y.; Ryu, S.-K.; Kim, H.G. Wood-Derived Graphite: A Sustainable and Cost-Effective Material for the Wide Range of Industrial Applications. Crystals 2024, 14, 309. [Google Scholar] [CrossRef]

- Oka, H.; Setoyama, N.; Matsuhara, S. Gas adsorption analysis for quantifying the edge sites of graphite. Carbon 2024, 230, 119664. [Google Scholar] [CrossRef]

- Popova, A.N. Crystallographic analysis of graphite by X-Ray diffraction. Coke Chem. 2017, 60, 361–365. [Google Scholar] [CrossRef]

- Seehra, M.S.; Pavlovic, A.S. X-Ray diffraction, thermal expansion, electrical conductivity, and optical microscopy studies of coal-based graphites. Carbon 1993, 31, 557–564. [Google Scholar] [CrossRef]

- Montagna, L.S.; Fim, F.d.C.; Galland, G.B.; Basso, N.R.d.S. Synthesis of Poly(propylene)/Graphite Nanocomposites by in Situ Polymerization. Macromol. Symp. 2011, 299–300, 48–56. [Google Scholar] [CrossRef]

- Tekin, K.; Karagöz, S.; Bektaş, S. A review of hydrothermal biomass processing. Renew. Sustain. Energy Rev. 2014, 40, 673–687. [Google Scholar] [CrossRef]

| Lattice Parameter|Sample | PDGC | Natural Graphite |

|---|---|---|

| d002 [Å] | 3.37 | 3.354 |

| FWHM (deg) | 0.36 | ~0.1 |

| Lc (using 002) [nm] | 20.4 | 24.6 |

| La (using100) [nm] | 28.4 | 28.6 |

| La (using 110) [nm] | 44.4 | ~100 |

| g (degree of graphitization) | 0.7 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antil, B.; Olhan, S.; Vander Wal, R.L. Production of Graphitic Carbon from Renewable Lignocellulosic Biomass Source. Minerals 2025, 15, 262. https://doi.org/10.3390/min15030262

Antil B, Olhan S, Vander Wal RL. Production of Graphitic Carbon from Renewable Lignocellulosic Biomass Source. Minerals. 2025; 15(3):262. https://doi.org/10.3390/min15030262

Chicago/Turabian StyleAntil, Bindu, Sandeep Olhan, and Randy L. Vander Wal. 2025. "Production of Graphitic Carbon from Renewable Lignocellulosic Biomass Source" Minerals 15, no. 3: 262. https://doi.org/10.3390/min15030262

APA StyleAntil, B., Olhan, S., & Vander Wal, R. L. (2025). Production of Graphitic Carbon from Renewable Lignocellulosic Biomass Source. Minerals, 15(3), 262. https://doi.org/10.3390/min15030262