Abstract

Processing complex ore remains a challenge due to energy-intensive grinding and complex beneficiation and pyrometallurgical treatments that consume large amounts of water whilst generating significant waste and polluting the environment. Sensor-based ore sorting, which separates ore particles based on their physical or chemical properties before downstream processing, is emerging as a transformative technology in mineral processing. However, its application to complex and heterogeneous ores remain limited by the constraints of single-sensor systems. In addition, existing hybrid sensor strategies are fragmented and a consolidated framework for implementation is lacking. This review explores these challenges and underscores the potential of multimodal sensor integration for complex ore pre-concentration. A multi-sensor framework integrating machine learning and computer vision is proposed to overcome limitations in handling complex ores and enhance sorting efficiency. This approach can improve recovery rates, reduce energy and water consumption, and optimize process performance, thereby supporting more sustainable mining practices that contribute to the United Nations Sustainable Development Goals (UNSDGs). This work provides a roadmap for advancing efficient, resilient, and next-generation mineral processing operations.

1. Introduction

Demand for minerals is increasing due to population growth, technological advancement, and the transition to Industry 4.0 [1]. The global push for energy transition policies has caused a global supply crisis of critical minerals. By 2030, mining companies are projected to meet only about 70% of the global copper demand [2]. This shortfall is expected to deepen, as global copper demand by 2050 could rise by as much as 83% compared to 2015 [3]. Copper and other energy transition metals, including lithium, cobalt, and rare earth elements, are found within complex geological structures, suggesting that they are obtained from complex ores. Complex ores refer to ores with two or more targeted metals/minerals interwoven with gangues and are often difficult to treat due to their heterogeneous properties, including texture, mineralogy, and chemical characteristics. In most cases, complex ores are polymetallic with varying grades that require systematic beneficiation for metal recovery. Their liberation usually produces fine particles, which complicate subsequent mineral separation and result in the production of a large volume of tailings, thereby contributing to environmental degradation and posing health and safety risks. Furthermore, comminution of such ores requires considerable energy input, significantly increasing operational costs. Subsequent processing stages further require large volumes of water and chemical reagents, intensifying resource consumption. These challenges are further compounded by the global decline in ore grades [4]. This combination of energy intensity, resource consumption, and environmental burden underscores the urgent need for innovative processing technologies and sustainable practices in handling complex ores.

Pre-concentration of ore through sorting has been described as a promising technique to solve some of these challenges [5]. Ore sorting is the process by which targeted minerals are pre-concentrated by rejecting the gangue minerals without further processing, leading to energy and operation cost savings. The prerequisite for ore sorting is that minerals to be sorted must have different physical properties, and target particles should be liberated from gangue [6]. When middlings result from inefficient sorting or poor liberation of target particles, a milling step can be introduced prior to the next sorting process. Among the sorting techniques is hand-sorting, which is the oldest form of pre-concentration of complex ore, such as sulfides [7]. By observing the color of the ore, minerals can be hand-separated from each other. This approach was used in the late nineteenth century to separate complex sulfide ore into (i) chalcopyrite (nearly pure), (ii) pyrite (nearly pure), (iii) mixed chalcopyrite-pyrite with predominant chalcopyrite, (iv) mixed chalcopyrite-pyrite with predominant pyrite, (v) pyritiferous milling rock, and (vi) pyrite-chalcopyrite-galena-sphalerite [7]. After this stage, the product (6) was cobbed and further sorted to yield new products till all minerals were sorted out [7]. By the early 1970s, hand-sorting became impractical and uneconomical due to declining ore grade, leading to advanced innovative technology for ore sorting.

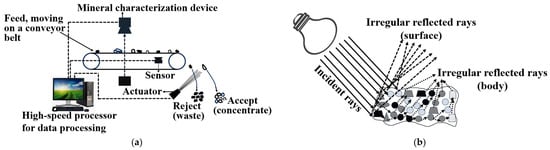

Due to technological advancements, automatic sorters (electronic sorters) were developed to discriminate targeted minerals from gangue. Electronic mineral sorting (using electronic sensors) became a reality in the early 1970s [8]. Such automatic sorters include sensors connected with programmable high-speed processors to identify and sort targeted minerals from the gangues (Figure 1a) using predefined criteria, such as density, conductivity, diffusivity, color, texture, dielectric, magnetic and radioactivity properties of the ore [9]. The electronic sensors detect mineral-specific properties under different electromagnetic (EM) waves, including radio, infrared, light, ultraviolet, X-ray and gamma-ray, allowing for classification and separation of target elements/minerals from gangue. Different sensors for ore sorting, however, work at various ranges of the electromagnetic spectrum (Table 1), and their effectiveness depends on many factors, such as material properties, distribution of minerals/elements among particles, sensor selectivity, and economic considerations for sustainable mining [10]. Detected ore particles are classified into target minerals, intermediate products, and waste by an interpreter and electro-mechanical sorting device [11], facilitating ore pre-concentration.

Figure 1.

(a) Sensor-based sorting configuration. (b) Surface and volumetric (body) electromagnetic wave reflectance.

Table 1.

Electromagnetic (EM) waves and corresponding ore sensors.

It is crucial to note that some sensors classify ores based on surface properties, while others may be employed for volumetric (body) ore classifications. Volumetric sensors generally provide more accurate sorting, as they consider the entire ore particle rather than just its surface (Figure 1b). In such an approach, the scattered EM waves from the ore particles’ interior provide a physical or chemical representation of the minerals/elements of interest to be sorted. Surface-based sensors, by contrast, rely on the surface properties such as reflectance, brightness, and color of the ore particles for ore classifications, without assessing the entire particle (Figure 1b). Irrespective of the approach, the sensor detection threshold is determined by the EM wave intensity received at each sensing pixel [13]. The effectiveness of ore sorting depends on the liberation of rocks with distinct physical properties, mostly at coarser particle sizes [14]. Ore sorting can be implemented as bulk sorting or particle-by-particle sorting: bulk sorting is applied immediately after excavation or on a conveyor belt and is suited for processing large volumes of rock. Meanwhile, particle-based sorting, on the other hand, evaluates individual ore particles, usually on a conveyor, using mechanical levers or air ejectors to separate targeted minerals from waste. In both cases, some rejected ore may be used as blending material for metallurgical control and optimization.

Despite the number of research studies conducted over the years to improve ore sorting techniques and efficiency (Section 2), to the best of our knowledge, a systematic review focusing on the complexity in the sensor-based ore sorting and its implications for sustainability is largely lacking from the existing literature. This paper addresses this gap by providing an overview of ore sensors and their application for enhanced sorting in support of sustainable mining. This review aims to guide sensor selection for various complex ores, and to promote efficient, sustainable sorting processes that maximize resource recovery, reduces operational cost and comminution energy, and minimizes environmental impact and risk associated with processing of complex ores. Exempted from this review are easy-to-treat ores, including free-milling gold ore, bauxite, hematite, barite, and uranium ores.

2. Review Methods and Related Work

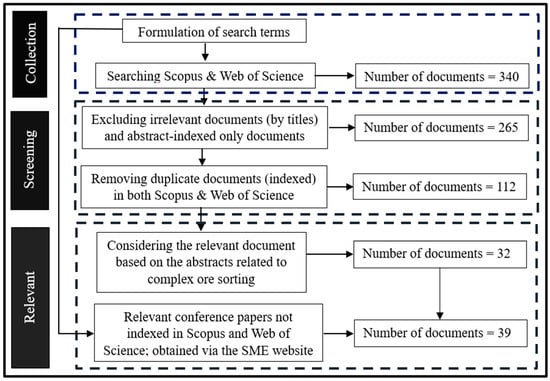

Ore sorting has been a hot topic in the literature for decades [8]. Researchers used different terminologies to represent the process, including “ore sorting”, “sensor-based sorting”, and “electronic ore sorting”. To gather scattered published work (only documents published in English were considered) and established terminologies in the literature on ore sorting technology, “electronic ore sorting” was searched using Scopus and Web of Science (WoS) databases—comprehensive and trusted citation databases mostly used for review works [5]. The methodology employed for literature acquisition is presented in Figure 2. Due to different terminologies used in the literature, various search terms were employed to acquire documents for this study. The “electronic ore sorting” was searched using the Scopus database. This produced only two documents. When the search term was changed to electronic AND “ore sorting”, the number of documents increased to three. Automatic AND “ore sorting” was also searched using the same database, producing five documents. Then we changed the search term to sensor-based AND “ore sorting”, which produced 43 documents. To obtain more documents, we refined the search term to “ore sorting,” which yielded 178 documents. Since “ore sorting” produced the highest number of documents in the Scopus database, the term was used to find documents using the WoS. The total documents obtained using Scopus and WoS databases, conference papers, and screening criteria are presented in Figure 2. While 39 documents primarily related to sorting complex ores were identified, additional industrial case studies and published results from ore sensor manufacturers were also included in the critical review.

Figure 2.

Documents acquisition process (SME: Society of Mining, Metallurgy and Exploration).

All the review articles identified among the 112 screened documents (Figure 2) are briefly presented. In addition, review articles found using the Google search engine, mostly conference papers (acquired via the Society for Mining, Metallurgy and Exploration (SME) website; OneMine Digital Library), were also included in this section. We ensured that any paper presented at a conference and later published in a journal was considered only once. In such a case, only the journal publication was considered, and the conference paper was discarded from the analysis.

The review of electronic sorting and other pre-concentration methods in the 1970s and 1980s, when sensor-based sorting was in developmental stages, has been presented in the literature [7,15,16]. Subsequent advancements including the sorting of industrial minerals and the emergence of sorters for metalliferous ores in the early 2000s are also well presented [17,18]. Additionally, the historical perspective and detailed review of sensor technologies tailored for the recycling industry, with applications in paper [19], glass and scrap metal sorting have been extensively covered [20]. Sensor-based sorting was widely adopted in the mining industry in the late 1990s, mainly for industrial minerals, after it had been used in the recycling and diamond industries for many decades [20]. Duffy et al. presented the benefits of bulk ore sorting with case studies focusing on reducing cut-off grade, increasing production and reducing ore loss and dilution [21]. Gryshan and Kulish presented the sensor-based technology for ferromanganese, ferroalloy, and slag [22]. Bearman et al. reviewed the uptake of sensor-based technology for gold preconcentration and provided decision support to increase the uptake of the technology for improved gold production [23].

Klein et al. envisioned that sensor-based sorting would be crucial in future invisible mining operations—that is, mining activities that will have less impact on the environment in terms of tailing and mining wastes [24]. Recently, equipment development for intelligent ore sorting, focusing on algorithms to improve the sorting process, has been presented [25]. Kinnunen et al. opined that gangue minerals could be sorted out of targeted minerals at a coarse particle size to avoid processing minerals below the cut-off grade—the discussed technique focused on reducing tailings in downstream operations [26]. Amar et al. briefly reviewed sensor sorting for phosphate reprocessing for sustainable reserves [27]. Kundu et al. discussed sorting as one of the beneficiation techniques for recovering lithium from spodumene-bearing pegmatites [14]. However, the work was not a comprehensive review of the ore sorting process; it only briefly presented the possibility of applying ore sorting in spodumene-bearing pegmatite processing. Hilscher et al. provided a technical review of precious metals ore sorting with four case studies, showcasing the successful implementation of sensor-based sorting for improved metal recovery [11]. This interesting review was limited to only four cases (on precious metal sorting only). Since its publication in 2017, a substantial body of literature has emerged, expanding the scope and depth of research in this area. Another review of sensor-based sorting was presented at the 28th International Mining Congress and Exhibition, Turkey [28]. The review work focused on platinum group metals, gold, and silver. It was reported that sensor-based technology has not been well adopted for the pre-concentration of precious ores, due to their low targeted metal concentration. This called for advanced sensor technology for low-grade ore sorting applications. Robben et al. explored the sensor-based sorting for gold beneficiation [29]. Their work is among the few that discussed ore sorting from a sustainability perspective. However, its focus was limited to gold processing and technology advancement, and more innovative research has since been published.

Santos et al. reviewed sensor-based sorting techniques and flotation pre-concentration specifically used for sulfide ores [30]. It was reported that among the studied sensors for sulfide sorting, X-ray sensors are widely used; however, integrated sensors (laser and PGNAA) provided enhanced sulfide sorting. Other review articles presented general overviews of sensor sorting in mineral processing [5,31,32]. The summary of sensor-based methods for ore sorting is presented in Table 2. As illustrated in Figure 1b and presented in Table 2, sensor-based methods are generally grouped based on penetration or measurement techniques. Based on the former, they are categorized as surface or body (Table 2), while by the latter, they are grouped as direct or indirect methods. Direct measurement methods, including XRF (X-ray fluorescence), XRL (X-ray luminescence), LIF (laser-induced fluorescence), LISB (laser-induced breakdown spectrometry), and PGNAA (Prompt gamma neutron activation analysis). These methods provide information that is explicitly related to the elemental or mineralogical composition of the ore. Meanwhile, indirect methods such as NIR (Near-infrared), XRT (X-ray transmission), and DE-XRT (Dual-energy X-ray transmission) rely on physical or spectral representations that correlate with mineral composition but do not measure it directly. Indirect methods are fast and cost-effective, making them widely applied in high-throughput ore sorting.

Table 2.

Sorting methods and applications: Color (VIS—visible light); radiometric—RM; prompt gamma neutron activation analysis—PGNAA; photometric—PM; X-ray transmission—XRT; dual-energy X-ray transmission—DE-XRT; X-ray fluorescence—XRF; X-ray luminescence—XRL; near-infrared—NIR; microwave-infrared—M-IR; laser-induced breakdown spectrometry—LIBS; laser-induced fluorescence—LIF; microwave imaging—MIW.

This paper presents the first holistic review of ore sorting as a strategy for the pre-concentration of complex ores to support sustainable mining practices. These ores include some sulfides, porphyry copper deposits, and refractory ores. The study also examines sorting applications for low-grade ores previously considered uneconomical and stored in stockpiles, which were classified here as complex due to their processing difficulties. Frameworks that integrate multiple sensors for sorting complex ores are proposed, a potential paradigm shift in mineral processing.

3. Complex Ores

Geological structures exhibit complexity due to multiple formation phases, leading to heterogeneous characteristics. However, some ores are a bit more complex. Otsuki et al. defined complex ores as ores that are difficult to treat using the “conventional metallurgical unit operations” [50]. Their complexity is associated with their mineralogy variability, which requires multiple comminution stages for effective mineral liberation. Comprehensive characterization is therefore crucial, designing processing circuits, often requiring a combination of methods. Detailed characterization methodology for complex ores can be found in the literature [50]. In this paper, we extend the conventional definition of complex ores to include ores with massive mineralization containing gangue inclusion, narrow ore veins, and deposits with excessive dilution due to complex geology that makes selective mining difficult. This is because diluted ores can benefit from sensor-based sorting, reducing haulage, comminution, and processing operations. However, highly disseminated complex ores are difficult to sort due to the fine grains, making sorting difficult [51]. Such ores often require sorting at multiple particle sizes and involve complex comminution operations, but the increased liberation of minerals can significantly improve the head grade.

Sensor-based sorters have been explored for sorting various complex ores. A critical consideration in effective sensor-based ore pre-concentration, especially for complex ore, is sensor selection. A decision needs to be made whether to select a direct or indirect method for complex ore sorting. A direct elemental method, such as XRF, may be used when elements of interest are clearly detectable. The main limitation of this approach is that the overlapping in metal content among mineral phases (e.g., iron content in hematite, magnetite, and sulfides) may be difficult to identify. Conversely, the direct mineralogical method identifies mineral phases (even when elements overlap) in ore rather than elemental content—it provides useful information on ore liberation characteristics, which is critical to mineral processing. The approach has no direct link to ore grade, making it difficult to be solely employed for grade control. For complex ore sorting, integration of mineralogical and elemental methods provides data for effective sorting operations.

3.1. Copper Ores

Complex copper ores require systematic processing to extract valuable minerals. Copper ores are the source of copper, which has been classified as a critical mineral in many countries, including the United States. This is due to its wide usage in electronics, aircraft, wires, military gadgets, and green energy applications. Different sensing technologies have been explored for copper ore sorting as a pre-concentration technique due to declining ore grades. Among the techniques used is the microwave-infrared (M-IR) sensor, which can effectively distinguish target minerals from waste [52]. In this method, ore is subjected to microwave radiation while moving on a conveyor belt, with provision for microwave shielding. The source of radiation could be from a series of waveguide antennae, and the resulting thermal response of the particles is captured by an infrared (IR) camera. The data are processed and transmitted to a fluid-blast ejector, which separates particles into accept and reject streams (Figure 1a).

Sorting performance of porphyry copper ore has been noted to improve with larger ore fragments [53]. Detailed studies indicated that particle size ranges 76.2 + 50.8 mm and 50.8 + 25.4 mm, sorted better than 25.4 + 12.7 mm, when using the M-IR method. The poor results at smaller sizes have been attributed to particle clustering on the conveyor belt. To avoid loss of valuable minerals to waste, comminution should achieve a size range that enables economic sorting while minimizing clustering. Ore sorting at finer particle sizes might still be profitable if there is a sizable liberation of the constituent minerals, and particle clustering is controlled. A crucial issue of consideration when applying M-IR is the ore mineralogy, since microwave-active minerals can cause neighboring non-active neighboring minerals to heat, leading to the creation of misleading signals. The magnetic properties of the ore further influence this behavior due to reorientation under a magnetic field [54]. Practical tests of monazite ore (mainly containing feldspar, quartz, andradite, iron, and copper-bearing minerals) confirmed that ore fragments with higher magnetic content induced heating in less magnetic particles when exposed to microwave radiation [55]. It is therefore recommended to remove magnetic particles prior to sorting to reduce misclassification [54]. A recent study showed that sorting copper sulfide is feasible using the M-IR method [55].

For the first time, pilot-scale microwave sorting technology was tested on porphyry copper ores [56]. To achieve the high heating rate required, a belt-based microwave cavity delivering 100 kW of power was designed [56], which is consistent with previous findings that large scale pretreatment demands high power density [57]. Sixteen representative porphyry copper ore samples, each weighing 200–500 kg were used in the study. The samples were microwave-treated, and their thermal response was monitored using an IR detector. The microwave radiation energy dose (power: 10–55 kW, energy dose: 0.1–1 kWh/t) had a significant effect on the average temperature experienced by the fragment ores; consequently, influencing the sorting performance. Higher energy dose was noted to improve sortability. In contrast, the study revealed that belt speed (0.3–1 m/s), belt mass loading (7–40 kg/m), and thermal equilibration time (20–120 s) had no significant effect on the ore sorting [56]. Sorting based on the rejection of low-temperature fragments (−50.8 + 25.4 mm) resulted in a 25% by mass rejection while achieving 90% copper recovery [57]. These results led to 233 pilot trials at mine sites in the United Kingdom [53]. However, despite these successes, the M-IR method has not yet received industrial adoption. This may be likely due to the challenges associated in integrating the system with existing processing circuits.

With the intent to develop new technology for sorting complex copper ores, the near-infrared (NIR) method was tested, using 150 porphyry copper ore samples [44]. The results suggested that copper-bearing minerals could not be directly identified using NIR spectroscopy. However, the NIR active gangue minerals in the ore could be used to classify the ore grades indirectly. This approach can be useful for the identification of sub-economic copper ores through developing a logistic regression model using NIR active-mineral data. Understanding the role of NIR active minerals in copper ore is therefore crucial for ore classification and consequently for sorting. Key parameters such as absorption features and wavelength positions are important indicators for NIR based sorting [58]. Surface contamination, moisture content, and data representativeness may influence the results of NIR spectroscopy [44]. Since the NIR active functional groups are H2O, -OH, and CO32−, the best strategy is to classify minerals containing these functional groups (e.g., carbonates and hydroxy-bearing minerals) as waste, while treating the remaining minerals as target miner [59]. Similar findings have been reported by other researchers who correlated NIR spectra with the assays of copper in ores containing carbonate gangue [60].

Sorting of complex Cu-Zn-Sn ore has been studied using the X-ray Transmission (XRT) sensor [61]. The aim was to lower costs associated with transportation during mineral processing. The mine employed two-stream processing plants to recover Cu first, followed by Zn and Sn. An XRT sensor (Comex CXR-1000; with 1 m belt — Comex, Krakow, Poland) was used in a two-stage sorting process for the selective recovery of Cu, Zn, and Sn. The results indicated that the enrichment of Cu increased from 0.404% to 1.258%, after sorting, at 85.65% recovery. This resulted in the reduction in the mass of material sent to the second stream by 27.52%. The Zn and Sn were upgraded from 0.832% and 0.255% to 2.249% and 0.655%, at recoveries of 76.48% and 72.72%, respectively. Economic analysis revealed that XRT sorting reduced capital and operating costs by up to 20% [61]. Dual-Energy X-ray Transmission (DE-XRT) was employed for sorting two selected copper sulfide ores (3 × 1 cm fragments) from Arizona, United States, using micro-X-ray computed tomography for assay validation [62]. Results suggested that one of the selected samples was highly dispersed, making sorting difficult to achieve. However, the second sample was amenable to DE-XRT sorting. At pilot scale (using a sample 10 × 1 cm, fragments), 90% copper recovery was achieved while rejecting 31% waste, which included 0.08% Cu [62].

Prompt gamma neutron activation analysis (PGNAA) is well known for bulk coal and cement sorting [63] and has been studied recently for sorting complex copper–gold ores [64]. PGNAA uses a neutron source such as Californium-252 (Cf-252) to irradiate the particles with neutrons as they move over the conveyor belt. When the nuclei of these particles absorbs the irradiated neutrons, they become excited, leading to the emission of gamma rays characteristic of the specific elements present. A sensor (detector) array measures the excitation energy of the nucleus at specified peaks in the form of spectra, with each peak representing a particular element. Bulk measurements are typically reported within 2 s to 3 s [64]. It is essential to note that this process requires a properly shielded environment to contain gamma radiation and ensure safety for the operators. As presented in Table 2, beyond the surface of the particles, the method is also able to detect moisture content; hence, a moisture monitoring system must be used to correct for its effect on the PGNAA spectra. Although PGNAA has been used for decades for process optimization, its application in ore sorting is relatively recent. Investigations have revealed that 30 s is the appropriate time required for the copper–gold ore sorting using this method [64].

PGNAA and X-ray fluorescence (XRF) sensors have also been incorporated into the New Afton block cave mine (in British Columbia, Canada) for the sorting of porphyry copper ore. These methods have demonstrated improved ore production by removing waste typically associated with block and panel caving mining methods [39]. Key factors to be considered in adopting sorting in a caving mining operation are outlined in the literature [65]. In addition, sensors have been suggested for installation in loading buckets during underground ore production to enable grade control and sorting [66]. This approach helps address the challenges of ore grade underestimation associated with conventional drawpoints, thereby improving downstream ore processing. Intelligent sorting of porphyry copper ore using the XRF method [67]. Researchers were able to correlate XRF spectra of selected samples with ore grades, achieving a positive Pearson’s correlation coefficient of 0.86 and regression analysis results with R2 values between 0.95 and 1.0. Repeat of the whole process using low-grade copper ore suggested that multiple linear regression is required to obtain good results that can be used for the sorting process [67]. Besides the reduction in material to be processed due to the early removal of some waste, using sorting techniques, there is an additional benefit in terms of reduction in greenhouse gas emissions. For instance, optical sorting of copper ore has the potential to reduce greenhouse gas emissions by approximately 13 kg CO2/t of copper ore processed [68]. One major challenge with the XRF sorting algorithms as well as other conventional algorithms is misclassification, which reduces sorting efficiency. To address this, the Receiver Operating Characteristic (ROC) was developed as a more effective approach to eliminate/minimize misclassification during XRF-based sorting [51]. Irrespective of the sorting method used, assessing the heterogeneity of the ore is essential to determine the economic potential of incorporating sorting in block cave mining [69]. In doing so, statistical analysis of the heterogeneity must be carried out, and optimization models such as fractal and multifractal may be developed to improve accuracy. Research has shown that the multifractal model delivers more accurate predictions compared to the fractal model [70]. Recently, multi-sensor synergy has been proposed as a way to improve porphyry copper ore sorting, combining technologies such as PGNAA and Magnetic Resonance (MR) [71]. Findings have revealed that the multi-sensor approaches outperform single sensor sorting systems. A similar conclusion was reported for integrated XRT and MW-IR sensor sorting for porphyry copper ore [72]. While on-site trials have been recommended for multi-sensor sorting, no such trials have been reported in the literature. However, MR based sorting has been installed at the Kansanshi copper mine, Zambia [73]. In this operation the low-grade copper ore particles were identified and diverted to stockpile while on a conveyor belt, working at 2800 tph. Up to 10,000 tons of low-grade copper ore particles were diverted for later processing, which improved flotation performance [73].

To improve the sortability performance of complex copper–gold ores, researchers have proposed the use of machine learning (ML) to develop more effective sorting algorithms [74]. The selected ore for the study consisted of gold as an inclusion within pyrite, while copper occurred in minerals such as bornite, chalcopyrite, chalcocite, and covellite. The authors explored the hyperspectral imaging in the visible to near-infrared (VNIR) and short-wave infrared (SWIR) regions combined with ML models—specifically Random Forest (RF) and Support Vector Machine (SVM). The results demonstrated that both RF and SVM could accurately predict sorting outcomes based on VNIR and SWIR imaging data. At a copper recovery of 90%, RF had no misclassification out of 24 samples, while SVM recorded one misclassification. When the recovery rate increased to 95%, RF and SVM recorded 3 and 2 misclassifications, respectively. Overall, RF achieved an accuracy of 72% to 100% while SVM ranged from 82% to 92% [74]. There is a need to improve the presented models using larger samples. In another study, Logistic Regression (LR) and SVM were employed to improve XRF based sorting of copper ore. Stepwise regression and Principal Component Analysis (PCA) were employed to identify significant features of the input XRF data. Comparison of the LR and SVM models revealed that the former outperformed the latter, with an accuracy of 0.95% [75]. Additionally, other machine learning models may be employed to further enhance sorting predictions. One of the main challenges of spectra-based imaging for ore sorting is the random spectra caused by interference in the reflectance and absorbance of constituent minerals. To address this, spectra filtration has been proposed to eliminate noisy or overlapping signals, allowing for clearer identification of each individual mineral or particle, and ultimately improving the sorting performance [41].

A techno-economic impact assessment of incorporating ore sorting into an existing copper processing circuit involving a crusher, two semi-autonomous grinding (SAG) mills, screen sets, and flotation equipment was studied [76]. Different scenarios and a sensitivity analysis were conducted. Results indicated that introducing a sorting operation into an existing processing circuit is economically viable, with an internal rate of return (IRR) ranging from 61% and 106%, and a payback period of approximately 20 months [76]. In another study, the techno-economic analysis of adopting sensor-based sorting at Phu Kham mine, an open pit operation with complex heterogeneous copper–gold ore was undertaken [77]. Due to the complexity in ore tonnage and grade, geo-statistical tools were employed to reduce uncertainty. Sorting was proposed as an addition to the existing beneficiation circuit, accounting for all factors such as handling costs, sorter cost per ton, and a 10% misclassification rate. Simulation results of various scenarios showed that annual metal production could increase by up to 40% if sorting were implemented, driven by higher mining throughput. However, it was reported that the required increased mining production was not feasible. Without additional sorters or changing the comminution circuit, implementing sorting was expected to increase the cash flow by 5%. If an additional SAG mill was added, the cash flow could increase by about 20%. Furthermore, optimizing the ore cut-off grade (determined as 0.10% Cu through an innovative methodology) was identified as a key factor for improving sorting efficiency and profitability.

A separate economic analysis compared lab-scale and industrial-scale XRF sorting using porphyry copper ore as a case study [78]. The lab-scale XRF sensor rejected 40% of the tested samples as waste, achieving a Cu recovery of 80% and an upgrade ratio of 1.4. However, the industrial-scale sensor achieved an upgrade ratio of 1.1, suggesting low pre-concentration of the studied ore. Economically, the industrial-scale application could result in a USD 7 million loss under the studied conditions, likely due to the small sample size (100 samples) used in testing. Future studies should evaluate larger samples under operating mine conditions to accurately determine the economic impact of industrial-scale XRF sorting [78].

3.2. Nickel Ores

The sorting of nickel–copper sulfide ore at Whistle Mine, Sudbury, Ontario, Canada, was studied to improve mineral recovery and reduce downstream beneficiation operations [79]. Due to the complexity of sulfide ore at Whistle Mine, testing of various sensors was performed in the 1980s, to reduce ore sent to the mill. The ore consists of a mix of minerals including pyrrhotite, chalcopyrite, copper sulfide, nickel sulfide, and pentlandite along with silicates such as chlorite, biotite, and talc. Magnetic separation was initially considered but faced significant challenges. Hexagonal pyrrhotite is nonmagnetic, and monoclinic pyrrhotite is magnetic, creating inconsistency. Moreover, other key minerals such as pyrrhotite, chalcopyrite, copper sulfide, nickel sulfide, and pentlandite are all nonmagnetic, meaning they would be incorrectly rejected as waste. Conductivity-based sorting of Whistle Mine ore was also tested but encountered technical limitations. Some targeted minerals were misclassified as waste, a problem linked to the distribution of sulfides in the tested samples, the location of the sulfide minerals during sorting, and the variations in particle size and shape.

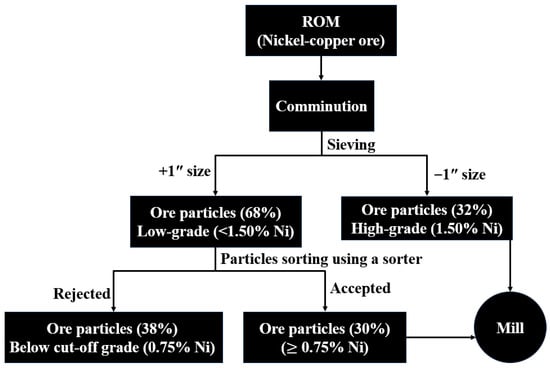

In another study, magnetic separation was employed to sort complex sulfide particles acquired from Whistle Mine, achieving a waste rejection rate of 38% (Figure 3). Processing this waste alongside targeted minerals would have led to increased operational costs due to unnecessary handling and treatment. Pre-concentration of the complex ore from Whistle Mine improved both nickel and copper recovery during downstream operations [79]. Electromagnetic sorting of nickel has also been reported. This automated sorting process uses sensors to detect particles as they are fed through the system. Scan and air reject units, then separate the material into two streams high-grade Ni (accept) and low-grade Ni (reject). The low-grade fraction can be further processed through comminution, followed by an additional round of electromagnetic sorting [80]. The use of ML may improve the sorting operation. The application of ML to multi-sensor nickel ore sorting was studied [72]. Two sensors were considered: MW-IR and XRT. The acquired data from both sensors was preprocessed, with Tensorflow used for object detection and segmentation of XRT data, while k-means clustering (pixel-wise quantification) was employed for the MW-IR data. Statistical analysis was then performed for feature extraction and to determine the intrinsic sortability. Logistic regression was then used to predict sorting performance under three scenarios: XRT only, MW-IR only, and combined multi-sensor. Findings indicated that the multi-sensor approach performed better than a single sensor for sorting targeted mineral (nickel) from gangue. At a mass recovery of 72.82%, the nickel recovery reached 99.89%, with the ML model achieving an accuracy of 0.976, with an absolute error of 0.023 [72].

Figure 3.

Sorting of complex sulfide (nickel-copper) ore at Whistle Mine using magnetic separation (information extracted from [79]).

3.3. Lead–Zinc Ores

Lead–zinc ore sorting has been explored using the M-IR technology. The finding showed that subjecting lead–zinc ore to microwave radiation at a particle size range of −19 + 13.2 mm enabled sorting possible using an IR detector, due to differential heating. This process allowed about 30% of the total rock samples to be sorted from the lead–zinc ore, achieving an efficiency of about 95% [33]. Such preconcentration has the potential to reduce comminution energy consumption, extend the lifespan of comminution equipment, lower grinding media usage and reduce overall processing costs. XRT sorting has also been explored to reduce processing challenges, improve water usage and enhance environmental sustainability [61]. In one study, an XRT sensor (Comex CXR-1000; with 1 m belt—Comex, Krakow, Poland) was tested against dense media separation (DMS), using the same feed material of 20–60 mm. Sorting was performed using the density of the samples, and the results were compared with the DMS method installed at the lead–zinc mine, Poland [61]. At 80% recovery, the Zn grades achieved by XRT sorting and DMS were 11% and 7.6%, respectively. Additionally, the recovery of Fe was reduced due to sorting, which improved the overall processing performance. These results demonstrate the potential of dry processing to lower costs and water usage [61].

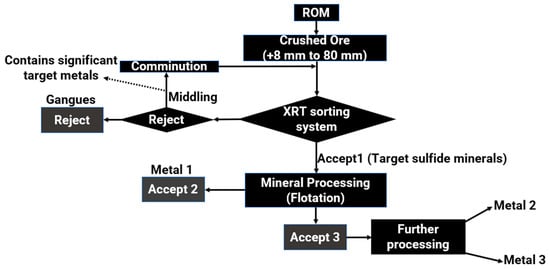

In another study, the amenability of silicate-zinc ore to XRT sorting was conducted and compared to other pre-concentration methods, such as heavy medium separation (HMS) and jig stratification [81]. XRT sorting achieved 93% recovery with a 30% waste rejection rate (particle size ranges: −50 + 19 mm and −25 + 8 mm). Under the same rejection rate, HMS (particle size range: −25 + 1.18 mm) achieved 97% Zn recovery, suggesting some Zn loss in XRT sorting [81]. A detailed techno-economic analysis is necessary to compare these approaches, considering all parameters, including water management associated with the HMS approach. Figure 4 illustrates a strategy used for sorting sulfide ore, containing copper, zinc, and lead, using an XRT sensor. This approach can upgrade copper grade by 20% to 100% while rejecting 20% to 45% of the material as waste [82]. The extent of metal recovery at different processing stages depends on the initial ore grade, flotation parameters, and techniques used.

Figure 4.

Sorting of sulfide ore to recover copper, zinc, and lead (information extracted from [82]); dashed arrow—additional information on material flow; solid arrow—process flow direction or products.

3.4. Lithium and Antimony Ores

Optical and NIR sensor-based sorters have been explored for lithium ore pre-concentration. As part of a feasibility study for the processing of lithium ore (spodumene) at Keliber Oy, Finland, two different processing circuits were evaluated—one incorporating sorting and the other without [83]. The ore deposit consisted of spodumene hosted in rocks such as amphibolite, plagioclase porphyrite, and mica schist, along with associated minerals including quartz, albite, K-feldspar, muscovite, and apatite. The gangue, especially mica, makes the recovery of lithium via flotation difficult. The flotation test conducted revealed that increasing dilution negatively impacted lithium recovery with a reduction of up to 5% at 15% dilution. Incorporating sorting into the processing circuit is an excellent way to remove the dilution. To improve lithium recovery and reduce processing cost, sorting via optical and NIR was investigated. An optical sensor was selected due to the color contrast between spodumene and its host rocks, allowing for an optical sorting opportunity to remove dilution before further processing. This approach was investigated as a clean technology solution aimed at reducing waste generation for environmental sustainability and lowering operational costs. In the study, 4.5 tons of ore were crushed to below a 100 mm sieve size, and an optical sensor was employed for the sorting process. The sensor effectively separated waste from lithium based on color, achieving a 12% mass rejection with only about 3% Li2O lost to the waste. Notably, 100% of the black waste rock was removed, significantly resulting in a reduction in the load on grinding, flotation and other downstream operations [83]. With the use of OreMet Optimizer (HSC Chemistry 9 software, Metso Outotec Corporation, Helsinki, Finland) for simulation of the whole process, it was estimated that the optical sorting could increase the annual revenue by USD 3.5 million [83]. In contrast to the optical sensor, an NIR sensor proved unfeasible, as some spodumene particles were rejected as waste.

The amenability of complex antimony ore (−35 + 10 mm) to sorting was investigated using VIS and NIR sensors [84]. The study employed a two-stage sorting process: VIS-based optical sorting to remove dark particles, while NIR-based sorting was used to target particles with low infrared radiation absorption. However, the maximum recovery of the antimony achieved through the sorting process was only 28%. The authors concluded that heavy medium separation might be the best pre-concentration method for antimony ore, provided that a proper water management strategy is implemented to ensure resource efficiency and environmental sustainability [84].

3.5. Gold Ores

Gold may be classified as a complex ore when selective extraction becomes difficult often due to its inclusion in sulfide minerals such as pyrite, arsenopyrite and chalcopyrite. When gold is finely disseminated in gangue minerals, cyanide consumption increases significantly and toxic by-products are generated, posing environmental challenges. This may lead to environmental, social and governance (ESG) issues and high corporate social responsibility (CSR) obligations such as providing social community benefits, compensating for land degradation, and excessive site reclamation costs. Adopting pre-concentration techniques to upgrade head grade can enhance gold processing, leading to high recovery, reduced operation costs and minimization of waste generation. An investigation on the use of optical sensors for gold sorting from gold waste dumps has been conducted [85]. Findings from the pilot studies at Kloof Gold Mine, South Africa, showed that optical sorting (feed size: –16 mm) can help recover lost gold in waste dumps by upgrading head grade from 0.29 to 3.12, at 70.27% gold recovery. Another pilot study conducted at Mintek, in South Africa, involved a mixture of 30 tons of waste and 5 tons of gold ore with particle sizes of –75 + 50 mm and –50 + 20 mm, processed using an optical sorter. Findings indicated that within the studied particle fractions, 40% of waste could be discarded while achieving 80% gold recovery [29].

Apart from optical sorting, DE-XRT sorting has been employed for the sorting of narrow-vein sulfide gold ore from Pilgrim’s Rest, South Africa [86]. Bench-scale trials using run-of-mine (ROM) and dense-medium-cyclone float fractions produced promising results, leading to a pilot studyat Pilgrim’s Rest. DE-XRT sorting improved the head grade of dense-medium-separation (DMS) from 0.3 g/t to 0.6 g/t. However, finer particles negatively affected sorting performance, and a recommendation was made to screen out finer particles to improve both sorting performance and production rate by about 45% [86]. Other sensor-based methods, including electromagnetic (EM) sorting and XRF sorting have also been studied for gold ores [11]. In one investigation, assays of 100 ROM ore samples were correlated with the EM and XRF data, and algorithms were developed for sorting waste from targeted precious metals. Both methods achieved comparable performance, with gold recovery rates up to 95% possible at 25% mass pull [11]. Despite the XRF’s surface-based detection limitation, it proved effective for precious metal sorting. The EM sorter further upgraded the ore grade from 0.97 g/t to 3.63 g/t, with only 5% gold loss to the waste, remaining well below the cut-off grade. Additional case studies using both EM and XRF for gold sorting in different locations have also been reported [11].

4. Sustainability of Sensor-Based Sorting System

The case studies reviewed in Table 3 demonstrate that sensor-based sorting technologies have become an important tool for improving mineral processing efficiency and sustainability. These technologies—such as X-ray transmission (XRT), near-infrared (NIR), visible spectrum (VIS), microwave-assisted infrared (MW-IR), and laser sorting—are applied across a variety of ore types, including copper, gold, tin, zinc–lead, and antimony. While copper ores dominate the research focus, this is likely due to their economic importance, large-scale production, and significant decline in ore grades, which has resulted in the highest global tailings generation.

Table 3.

Case studies of selected complex ore sorting operations.

Overall, sensor-based sorting delivers substantial benefits in terms of upgrading head grade and improving metal recovery. For example, a XRT sorting at San Rafael Mine upgraded tin ore from 0.6% to 2.8% at 90% recovery, while optical sorting in South Africa improved gold head grade from 0.29 to 3.12 g/t with 70.27% recovery [23]. Similar improvements were observed for copper and polymetallic ores, where recoveries above 85% were commonly reported. These results demonstrate the potential of sorting technologies to transform low-grade or waste materials into valuable feed, reducing the reliance on primary extraction.

In addition, as copper grades decline, more ore needs to be mined and processed to meet the market demand, which in turn results in huge energy demands for extraction, haulage, processing, and metallurgical operations. Although copper consumes substantial amounts of energy during comminution, its metallurgical energy demand is relatively low compared to other metals. Gold, for example, has the highest metallurgical energy requirement, followed by titanium, aluminum, and nickel [89]. Overall, comminution remains the most energy-intensive stage, accounting for up to 70% of the mining industry’s total energy use [4]. Beyond grade improvement, energy and cost savings represent a major advantage of sensor-based sorting. For instance, DE-XRT sorting of molybdenum ore reduced comminution energy by 61%, a critical achievement given that comminution accounts for up to 70% of the mining industry’s total energy consumption [4]. In addition, cost benefits can be significant; at the San Rafael Mine, XRT sorting paid back USD 24 million in capital expenditure within four months.

Sensor-based sorting also offers environmental and ESG benefits by removing waste at an early stage, reducing the amount of material subjected to energy- and water-intensive grinding and flotation circuits. This results in lower tailings generation, reduced chemical consumption (e.g., cyanide in gold processing), and smaller environmental footprints, aligning with the United Nations Sustainable Development Goals (UNSDGs). Table 4 presents the sustainability-related issues identified in ore sorting in alignment with the UNSDGs.

Table 4.

Challenges in mining and opportunities to adopt sensor-based sorting to achieve the United Nations SDGs.

Early-stage waste sorting using sensor-based ore sorting is expected to offer key sustainability benefits, including energy savings (responsible energy use), reduced tailings generation (environmental protection), water conservation, lower reagent consumption (sustainable resource use), and improved community acceptance (peaceful society). However, despite decades of research on sensor-based ore sorting (Section 2 and Section 3), most of the associated UNSDGs identified for the process (Table 4) have not been well quantitatively assessed (Table 5). However, sensor-based sorting has been projected to deliver cost savings of up to USD 10 per tonne, primarily through downstream benefits such as reduced energy and water consumption, lower grinding media and reagent requirements, and more efficient tailings management [91]. This projection lacks detailed analysis suggesting further studies to fully evaluate and quantify these benefits, considering the costs of the sorter, component change (e.g., X-ray source), indirect costs (especially for XRT and MW-IR—regulations, shielding, certification), compressed air costs (blow-out unit), energy, water, reagent, grinding media consumption, and tailing generation, must also be taken into account, in comparation to the conventional processing. Detailed techno-economic studies considering direct and indirect costs for various sensors and their sortability efficiency for different complex ore types are required to support broader adoption of sensor-based ore sorting in the mining industry. Generally, rigorous papers on case studies of sorting performance are lacking, especially for complex ores. This calls for intensive research on ore sorting performance.

Table 5.

Quantitative sustainability benefits of sensor-based ore sorting (Ref.: Reference).

While effective ore sorting contributes to key sustainability metrics when properly implemented, the integration of microwave processing can further enhance progress toward the UNSDGs. Ore pretreatment during excavation can improve ore fragmentation, saving on blasting costs and reducing the amount of ore requiring comminution. Differential heating liberates more gangue from the valuable minerals, allowing for more efficient sorting using techniques outlined in Section 3. If further grinding of sorted ore is needed, the induced cracks from microwave treatment reduce energy demand during comminution. These improvements also cut water and reagent consumption during downstream processing like flotation, hydrometallurgical, or bioleaching processing, thereby enhancing the overall performance and minimizing waste generation.

Techno-economic analysis has shown positive results of the combined microwave and ore sorting technologies [86]. For example, incorporating ore sorting alone into an existing semi-autonomous grinding (SAG) circuit delivered a profit of more than USD 4.5 million per year, with a payback period of 20 months [76]. Although field tests of microwave-assisted excavation have been conducted [92], comprehensive studies on its downstream effects, particularly on ore sorting, processing, and refining, are still needed.

Beyond microwave technology integration, laser-based sorting technology has achieved industrial success (Table 3). For instance, laser sorters efficiently separate quartz gangue from low-grade gold ore, reducing feed tonnes, plant operating hours, energy and water consumption, and labor, thereby supporting UNSDG targets, as presented in Table 4 [87]. XRT sorters have also demonstrated energy savings of up to 15 GWh annually in lithium processing operations [95]. Though XRT sorters were designed to reduce the effect of material blockage on conveyor belts, challenges may still occur due to inherent particle clustering on the belt. To solve this problem and improve the sustainability of sensor-based sorting, a ring-shaped XRT sorter was developed [93] which does not require a conveyor belt, thereby providing a better sorting experience without particle clustering. This sorter has about 330% sorting capacity than conventional sensor-based sorters, and it is more compact, saving about 75% floor space. A single ring-shaped XRT sorter can replace up to three conventional belt-type sorters, saving about 2/3 of the energy requirement. Apart from reducing environmental footprint, the technoeconomic analysis revealed USD 4.5 million/year economic benefit [93]. This is a game-changer for the mining industry to meet the UNSDG targets.

Despite advances in sensor-based ore sorting, several challenges remain, particularly regarding material characterization and misclassification in complex ores. Sorting performance is strongly influenced by particle size distribution, with efficiency decreasing in the presence of fines. Ores containing clay minerals are especially problematic due to slime formation and complex mineralogy, which reduce sensor response. Furthermore, each sensor technology has inherent limitations: XRF is surface-sensitive, NIR struggles with mineral mixtures, and MW-IR may require high energy input.

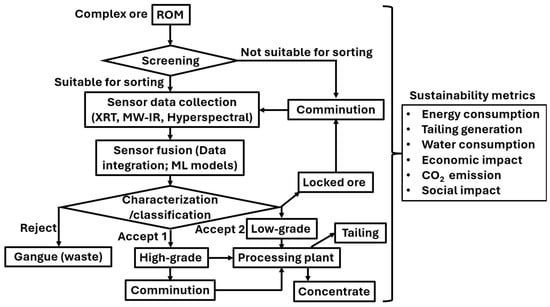

To address these challenges, a hybrid sensor-based approach (Figure 5) that integrates complementary technologies such as XRT, MW-IR, and hyperspectral imaging, supported by machine learning (ML) models, could improve classification accuracy and overall process sustainability. Such an approach enables the capture of a broader range of physical and chemical ore properties, facilitating improved ore characterization and enhanced beneficiation from complex deposits. For example, hyperspectral imaging can provide high-resolution information on ore texture and mineral composition, while MW-IR contributes insights into internal particle properties, complementing XRT’s bulk density characterization. Together, these sensors offer richer datasets that may overcome the shortcomings of traditional single-sensor systems.

Figure 5.

Proposed hybrid sorting technology with ML models for improved ore sorting.

Feature extraction methods such as neighborhood component analysis have demonstrated strong performance for hyperspectral data in copper sulfide applications [101]. For XRF, a combination of principal component analysis (PCA) and stepwise regression has been effective in reducing dimensionality while preserving relevant features [75]. These techniques ensure higher-quality inputs for ML models.

The success of this framework depends on effective data preprocessing and ML model selection. For accurate prediction capability, a multifractal model should be considered for metal content in complex ore, as this model, unlike the fractal model, captures the heterogeneous properties of the ore [70]. The data obtained using this model, when fed into an ML model, improves prediction accuracy. Further information on data preprocessing for sensor data fusion can be found in the literature [102].

ML algorithms offer different strengths depending on the data type. Convolutional neural networks (CNNs) are particularly well suited to hyperspectral imaging due to their ability to capture spatial-spectral correlations [103]. Ensemble methods such as random forests or gradient boosting perform robustly with fused tabular sensor data, while support vector machines are effective with smaller, high-dimensional datasets. Model training should include cross-validation to avoid overfitting, with the best-performing model further optimized for generalizability. The ML models to be developed for sorter fused data should continuously learn and adapt to the specific characteristics of the ore being processed. Although adaptive or continual learning approaches have been proposed to address variability in ore characteristics, their industrial implementation remains limited due to computational demands and data-labeling requirements.

Case studies on hybrid or multi-sensor data fusion are emerging but remain scarce. For example, studies have reported classification accuracy improvements of 7%–23% when combining VNIR and SWIR reflectance datasets compared with single-sensor models [104], and R2 values above 0.94 have been achieved using PLSR for fused MWIR and X-ray datasets [102]. While promising, these results are mostly derived from laboratory-scale experiments, and industrial-scale validation is lacking. This gap underscores the need for systematic pilot-scale trials and techno-economic analyses.

A further challenge is the computational intensity of processing large, fused datasets in real time. Algorithms must balance predictive accuracy with speed and resource efficiency. In this regard, model evaluation should consider not only accuracy but also simplicity, computational cost, and scalability. Integration with cloud-based monitoring and IoT infrastructure has been proposed to enable remote supervision of sorting operations [105], but such systems introduce additional requirements in terms of data security, latency, and cost.

Overall, while ML has been successfully applied to single-sensor datasets in ore sorting [106,107,108,109], its application to hybrid sensor fusion remains limited (Table 6) suggesting opportunities for further studies for effective ore sorting and decision making. The hybrid framework proposed here (Figure 5) should therefore be considered as a conceptual model that warrants further investigation. Detailed pilot-scale demonstrations, accompanied by rigorous techno-economic assessments, are required to validate its effectiveness for complex ores and to quantify its potential contributions to sustainable mining practices.

Table 6.

Hybrid/multi-sensor data fusion for ore sorting applications (SVR—support vector regression; SVC—support vector classification; PLSR—partial-least squares regression; PCR—principal component regression; MWIR—mid-wave infrared; LWIR—long-wave infrared; VNIR—visible-near infrared; SWIR—short-wave infrared; Ref.—Reference).

To reduce human interaction and improve sorting efficiency, AI-driven computer vision technology should be promoted. As discussed by Kuppa [90], combining laser and optical sensors with AI-based machine vision using multispectral, 3D, and X-ray imaging can significantly improve sorting efficiency, particularly for high-grade ore immediately after excavation. To handle both high-grade and low-grade complex ores, the proposed multi-sensor technology presented in Figure 5 needs to be developed. By integrating data from multi-sensor into an AI model for near-real time analysis and leveraging generative AI to produce instant insights in natural language, the system can deliver intelligent, adaptive sorting experience that responds to changing ore grades. This process, when integrated with the Internet of Things (IoT) and cloud-based monitoring, enables remote supervision of sorting operations. This strategy aligns with the growing industrial shift toward data-driven, automated mining practices [105].

The proposed framework (Figure 5), if properly developed, will likely reduce the impact of ore variability on the characterization and sorting process, using innovative sensor fusion technology. The sustainability (key performance indicators: KPIs) of the proposed technology should be evaluated based on the reduction in energy and water consumption, CO2 emission, economic and social impact, and tailing reduction resulting from the implementation of the proposed technology.

A key challenge for the proposed technology lies in its ability to adapt to different complex ores at diverse mining sites. Addressing this will require the development of modular ML and AI tools tailored to specific ore complexities and operational conditions. Achieving this goal will require cross-disciplinary collaboration among geologists, mining engineers, metallurgists, and software developers. In addition, a sortability index should be developed for different ore types to guide site specific adaptation. However, this remains difficult to accomplish due to limited data availability, as developing such an index requires extensive sorting tests for each ore type. Successful adoption of the technology will also require workforce upskilling and adjustments to existing mineral processing protocols. To support training and continuous learning, digitizing sorting operations through digital twin technology should be actively pursued. Finally, integrating the system with renewable energy sources will ensure continuous operation, reduce greenhouse gas emissions, and align the technology with the UNSDGs.

5. Conclusions

This paper presents a holistic review of complex ore sorting aimed at guiding best practices in mineral processing. It also offers a comprehensive discussion of sensor-based ore sorting and its potential contributions toward achieving the United Nations Sustainable Development Goals. Relevant documents were sourced from Scopus and Web of Science databases using targeted search terms complemented by conference papers and mining companies’ case studies. The review shows that several sensor-based methods—such as M-IR, NIR, SWIR, XRF, XRT, DE-XRT, MR, and PGNAA—have been explored for complex ore sorting. Among these, XRT, DE-XRT, PGNAA, and M-IR demonstrate significant potential with the ability to reduce grinding energy and lower operating costs. It must be noted that no single sorting system can be universally applied across different mines due to variations in ore complexity. Nevertheless, ore sorting remains a viable strategy for sustainable pre-concentration of complex ores. Investment in these ore sorting systems is strongly encouraged to support sustainable mineral processing. The findings from the study also suggest that multi-sensor-based ore sorting is more effective than single-sensor systems when dealing with complex ores. However, some technologies discussed have not yet progressed beyond laboratory-scale testing, highlighting the need for pilot scale trials. To improve sorting of complex ores, the study proposes a multi-sensor technology framework that integrates XRT, MW-IR, and hyperspectral sensors with advanced data fusion analysis powered by machine learning. When connected to the Internet of Things and supported by cloud servers, the system enables remote monitoring and control of sorting operations. Future research should focus on developing this framework into an efficient, autonomous sorting solution. Finally, a critical gap remains in the absence of a sortability index to assess the suitability of different ores for sensor-based sorting. Establishing such an index should be a key priority for future investigations.

Author Contributions

Conceptualization, S.O.A.; methodology, S.O.A.; formal analysis, S.O.A.; investigation, S.O.A.; resources, K.L., A.A. and S.N.; data curation, S.O.A.; writing—original draft preparation, S.O.A.; writing—review and editing, A.A., S.N., S.O.A. and K.L.; supervision, A.A., K.L. and S.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wellington, T.A.A.; Mason, T.E. The Effects of Population Growth and Advancements in Technology on Global Mineral Supply. Resour. Policy 2014, 42, 73–82. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global Critical Minerals Outlook 2024. Available online: https://www.iea.org/reports/global-critical-minerals-outlook-2024 (accessed on 8 July 2025).

- Klose, S.; Pauliuk, S. Sector-Level Estimates for Global Future Copper Demand and the Potential for Resource Efficiency. Resour. Conserv. Recycl. 2023, 193, 106941. [Google Scholar] [CrossRef]

- Adewuyi, S.O.; Ahmed, H.A.M.; Ahmed, H.M.A. Methods of Ore Pretreatment for Comminution Energy Reduction. Minerals 2020, 10, 423. [Google Scholar] [CrossRef]

- Peukert, D.; Xu, C.; Dowd, P. A Review of Sensor-Based Sorting in Mineral Processing: The Potential Benefits of Sensor Fusion. Minerals 2022, 12, 1364. [Google Scholar] [CrossRef]

- Gaft, M.; Reisfeld, R.; Panczer, G. Modern Luminescence Spectroscopy of Minerals and Materials; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-319-24765-6. ISSN 2366-1585. [Google Scholar]

- Salter, J.D.; Wyattt, N.P.G.; Process, M. Sorting in the Minerals Industry: Past, Present, and Future. Min. Eng. 1991, 4, 779–796. [Google Scholar] [CrossRef]

- Myman, R.A. Selective Electronic Mineral Sorting. In Mines Branch Monograph; Department of Energy, Mines and Resources: Ottawa, ON, Canada, 1972; pp. 1–67. [Google Scholar]

- Murphy, B.; van Zyl, J.; Domingo, G. Underground Preconcentration by Ore Sorting and Coarse Gravity Separation. In Proceedings of the Narrow Vein Mining Conference, Perth, WA, Australia, 26–27 March 2012; pp. 26–27. [Google Scholar]

- Lessard, J.; De Bakker, J.; McHugh, L. Development of Ore Sorting and Its Impact on Mineral Processing Economics. Min. Eng. 2014, 65, 88–97. [Google Scholar] [CrossRef]

- Hilscher, B.; Nayak, P.; Lorio, L.; Yoon, N. Technical Review and Evaluation of Ore Sorting Technologies on Precious Metals Operations. In Proceedings of the COM 2017, The Conference of Metallurgists hosting World Gold & Nickel Cobalt, Hyatt Regency Hotel, Vancouver, BC, Canada, 27–30 August 2017; Canadian Institute of Mining, Metallurgy and Petroleum: Westmount, QC, Canada, 2017; pp. 1–11, ISBN 978-1-926872-36-0. [Google Scholar]

- Qiu, J.; Zhang, Y.; Fu, C.; Yang, Y.; Ye, Y.; Wang, R.; Tang, B. Study on Photofluorescent Uranium Ore Sorting Based on Deep Learning. Min. Eng. 2024, 206, 108523. [Google Scholar] [CrossRef]

- Modise, E.G.; Zungeru, A.M.; Mtengi, B.; Ude, A.U. Sensor-Based Ore Sorting—A Review of Current Use of Electromagnetic Spectrum in Sorting. IEEE Access 2022, 10, 112307–112326. [Google Scholar] [CrossRef]

- Kundu, T.; Rath, S.S.; Das, S.K.; Parhi, P.K.; Angadi, S.I. Recovery of Lithium from Spodumene-Bearing Pegmatites: A Comprehensive Review on Geological Reserves, Beneficiation, and Extraction. Powder Technol 2023, 415, 118142. [Google Scholar] [CrossRef]

- Sivamohan, R.; Forssberg, E. Electronic Sorting and Other Preconcentration Methods. Min. Eng. 1991, 4, 797–814. [Google Scholar] [CrossRef]

- King, R.P. Automatic Sorting of Ores. Min. Sci. Eng. 1978, 10, 198–207. [Google Scholar]

- Wotruba, H. Sensor Sorting Technology—Is the Minerals Industry Missing a Chance? In Proceedings of the IMPC 2006—Proceedings of 23rd International Mineral Processing Congress Istanbul, Turkey, 3–8 September 2006; pp. 21–29. [Google Scholar]

- Cutmore, N.G.; Eberhardt, J.E. The Future of Ore Sorting in Sustainable Processing. In Proceedings of the Green Processing 2002—Proceedings: International Conference on the Sustainable Processing of Minerals, Cairns, Queensland, 29 May 2002; pp. 287–289. [Google Scholar]

- Rahman, M.O.; Hussain, A.; Basri, H. A Critical Review on Waste Paper Sorting Techniques. Int. J. Environ. Sci. Technol. 2014, 11, 551–564. [Google Scholar] [CrossRef]

- De Jong, T.P.R.; Kattentidt, H.U.R.; Dalmijn, W.L. Future Trends in Automatic Particle Sorting. In Proceedings of the IFAC Future Trends in Automation in Mineral and Metal Processing, Helsinki, Finland, 22–24 August 2000; pp. 307–312. [Google Scholar]

- Duffy, K.-A.; Valery, W.; Jankovic, A.; Holtham, P. Integrating Bulk Ore Sorting into a Mining Operation to Maximise Profitability. In Proceedings of the Metallurgical Plant Design and Operating Strategies (Perth 2015), Melbourne, VIC, Australia, 7–8 September 2015; pp. 273–287. [Google Scholar]

- Gryshan, D.; Kulish, A. Production Technologies and Operation Sensor-Based Technology for Ore and Slag Sorting. In Proceedings of the Energy efficiency and environmental friendliness are the future of the global Ferroalloy industry, The Fourteenth International Ferroalloys Congress, Kiev, Ukraine, 31 May–4 June 2015; pp. 184–189. [Google Scholar]

- Bearman, R.A.; Bowman, D.J.; Dunne, R. Decision Support for Ore Sorting and Preconcentration in Gold Applications. Miner. Process. Extr. Metall. Trans. Inst. Min. Metall. 2020, 129, 12–23. [Google Scholar] [CrossRef]

- Klein, B.; Bamber, A.; Altun, N.E.; Scoble, M. Towards Tomorrow’s ‘Smart Mine’—Embedded Sensor Telemetry and Sensor-Based Sorting. In Proceedings of the Second International Future Mining Conference Sydney, NSW, Australia, 22–23 November 2011. [Google Scholar]

- Luo, X.; He, K.; Zhang, Y.; He, P.; Zhang, Y. A Review of Intelligent Ore Sorting Technology and Equipment Development. Int. J. Miner. Metall. Mater. 2022, 29, 1647–1655. [Google Scholar] [CrossRef]

- Kinnunen, P.; Obenaus-Emler, R.; Raatikainen, J.; Guignot, S.; Guimerà, J.; Ciroth, A.; Heiskanen, K. Review of Closed Water Loops with Ore Sorting and Tailings Valorisation for a More Sustainable Mining Industry. J. Clean. Prod. 2021, 278, 123237. [Google Scholar] [CrossRef]

- Amar, H.; Benzaazoua, M.; Elghali, A.; Hakkou, R.; Taha, Y. Waste Rock Reprocessing to Enhance the Sustainability of Phosphate Reserves: A Critical Review. J. Clean. Prod. 2022, 381, 135151. [Google Scholar] [CrossRef]

- Klein, B.; Li, G.; Cetin, M.C.; Xu, Y. Sensor Based Bulk Ore Sorting of Precious Metal Ores. In Proceedings of the 28th International Mining Congress and Exhibition, Turkey, Antalya, Turkey, 28 November–1 December 2023; Chamber of Mining Engineers of Turkey; pp. 1–11. [Google Scholar]

- Robben, C.; Wotruba, H.; Robben, M.; Von Ketelhodt, L.; Kowalzcyk, M. Potential of Sensor-Based sorting for the Gold Mining Industry. Can. Inst. Min. Metall. Pet. 2013, 4, 191–200. [Google Scholar]

- Santos, E.G.; Brum, I.A.S.; Ambrós, W.M. Techniques of Pre-Concentration by Sensor-Based Sorting and Froth Flotation Concentration Applied to Sulfide Ores—A Review. Minerals 2025, 15, 350. [Google Scholar] [CrossRef]

- Robben, C.; Wotruba, H. Sensor-Based Ore Sorting Technology in Mining—Past, Present and Future. Minerals 2019, 9, 523. [Google Scholar] [CrossRef]

- Wotruba, H.; Robben, C. Sensor-Based Ore Sorting in 2020. De Gruyter 2020, 68, 231–238. [Google Scholar] [CrossRef]

- Tong, Y. Technical Amenability Study of Laboratory-Scale Sensor Based Ore Sorting on a Mississippi Valley Type Lead-Zinc Ore. Master of Applied Science Thesis, The University of British Columbia, Vancouver, BC, Canada, 2012. [Google Scholar]

- Tereshchenko, S.V.; Shibaeva, D.N.; Alekseeva, S.A. X-Ray Luminescence Separation of Khibiny Low-Grade Apatite Ore. J. Min. Sci. 2019, 55, 124–133. [Google Scholar] [CrossRef]

- Martino, N. Laser Induced Breakdown Spectroscopy to Quantify Penalty Elements in Iron Ore. Master of Applied Science Thesis, The University of British Colombia, Vancouver, BC, Canada, 2021. [Google Scholar]

- Gaft, M.; Megaw, P.K.M.; Lambeck, L.; Cantor, S. Luminescence Applications in Ore Geology, Mining, and Industry. Elements 2024, 20, 318–323. [Google Scholar] [CrossRef]

- Broicher, H.F. Bulk Sorting by LIF: Quality Control of Ores for Bulk Sorting and Blending by Laser-Induced Fluorescence Analysis. Min. Eng. (SME) 2000, 52, 24–28. [Google Scholar]

- Proctor, R.; Yusuf, S.; Miller, J.; Scott, C. Detectors for On-Line Prompt Gamma Neutron Activation Analysis. Nucl. Instrum. Methods Phys. Res. A 1999, 422, 933–937. [Google Scholar] [CrossRef]

- Nadolski, S.; Samuels, M.; Klein, B.; Hart, C.J.R. Evaluation of Bulk and Particle Sensor-Based Sorting Systems for the New Afton Block Caving Operation. Min. Eng. 2018, 121, 169–179. [Google Scholar] [CrossRef]

- Shatwell, D.G.; Murray, V.; Barton, A. Real-Time Ore Sorting Using Color and Texture Analysis. Int. J. Min. Sci. Technol. 2023, 33, 659–674. [Google Scholar] [CrossRef]

- Gülcan, E.; Gülsoy, Ö.Y. Evaluation of Complex Copper Ore Sorting: Effect of Optical Filtering on Particle Recognition. Min. Eng. 2018, 127, 208–223. [Google Scholar] [CrossRef]

- Keys, N.J.; Gordon, R.J.; Peverett, N.F. Photometric Sorting of Ore on a South African Gold Mine. J. S. Afr. Inst. Min. Metall. 1974, 75, 13–21. [Google Scholar]

- Dalm, M.; Buxton, M.W.N.; van Ruitenbeek, F.J.A. Ore–Waste Discrimination in Epithermal Deposits Using Near-Infrared to Short-Wavelength Infrared (NIR-SWIR) Hyperspectral Imagery. Math. Geosci. 2019, 51, 849–875. [Google Scholar] [CrossRef]

- Dalm, M.; Buxton, M.W.N.; Van Ruitenbeek, F.J.A.; Voncken, J.H.L. Application of Near-Infrared Spectroscopy to Sensor Based Sorting of a Porphyry Copper Ore. Min. Eng. 2014, 58, 7–16. [Google Scholar] [CrossRef]

- Böhme, R.C. The Development of a Radiometric Sorter for South African Gold Ores. Nucl. Geophys. 1983, 417–428. [Google Scholar] [CrossRef]

- Robben, C.; Condori, P.; Pinto, A.; Machaca, R.; Takala, A. X-Ray-Transmission Based Ore Sorting at the San Rafael Tin Mine. Min. Eng. 2020, 145, 105870. [Google Scholar] [CrossRef]

- Duan, B.; Bobicki, E.R.; Hum, S.V. Application of Microwave Imaging in Sensor-Based Ore Sorting. Min. Eng. 2023, 202, 108303. [Google Scholar] [CrossRef]

- Batchelor, A.R.; Ferrari-John, R.S.; Katrib, J.; Dimitrakis, G.; Dodds, C.; Kingman, S.W. Pilot-Scale Industrial Microwave-IR Sorting of Porphyry Copper Ores. In Proceedings of the IMPC 2016: XXVIII International Mineral Processing Conference Proceedings, Quebec, QC, Canada, 11–15 September 2016; Canadian Institute of Mining, Metallurgy and Petroleum: Westmount, QC, Canada, 2016; pp. 1–10. [Google Scholar]

- Genn, G.L. Novel Techniques in Ore Characterisation and Sorting. Doctoral Dissertation, The University of Queensland, St Lucia, QLD, Australia, 2013. [Google Scholar][Green Version]

- Otsuki, A.; Chen, Y.; Zhao, Y. Characterisation and Beneficiation of Complex Ores for Sustainable Use of Mineral Resources: Refractory Gold Ore Beneficiation as an Example. J. Soc. Mater. Eng. Resour. 2014, 20, 126–135. [Google Scholar] [CrossRef]

- Li, G.; Klein, B.; Sun, C.; Kou, J.; Yu, L. Development of a Bulk Ore Sorting Model for Sortability Assessment. Min. Eng. 2019, 141, 105856. [Google Scholar] [CrossRef]

- Nordin, L.; Salter, J.D. Sorting Method and Apparatus Using Microwave Phase-Shift Detection. U.S. Patent 4,933,075, 12 June 1990. pp. 1–4. [Google Scholar]

- Batchelor, A.R.; Buttress, A.J.; Jones, D.A.; Katrib, J.; Way, D.; Chenje, T.; Stoll, D.; Dodds, C.; Kingman, S.W. Towards Large Scale Microwave Treatment of Ores: Part 2—Metallurgical Testing. Min. Eng. 2016, 111, 5–24. [Google Scholar] [CrossRef]

- Jokovic, V.; Antonio, C.; Morrison, R. MW Heating of Rock Particles and Their Cross-Dependencies. Min. Eng. 2019, 141, 105834. [Google Scholar] [CrossRef]

- Naseh, R.; Sam, A. Microwave Infrared Ore Sorting of Screen Rejected Rocks Based on Their Content of Iron and Copper Sulfide in Sarcheshmeh Copper Complex, Iran, Kerman. Miner. Process. Extr. Metall. Trans. Inst. Min. Metall. 2019, 130, 416–424. [Google Scholar] [CrossRef]

- Batchelor, A.R.; Ferrari-John, R.S.; Katrib, J.; Udoudo, O.B.; Jones, D.A.; Dodds, C.; Kingman, S.W. Pilot Scale Microwave Sorting of Porphyry Copper Ores: Part 1: Laboratory Investigations. Min. Eng. 2016, 98, 303–327. [Google Scholar] [CrossRef]

- Jones, D.A.; Kingman, S.W.; Whittles, D.N.; Lowndes, I.S. The Influence of Microwave Energy Delivery Method on Strength Reduction in Ore Samples. Chem. Eng. Process. 2007, 46, 291–299. [Google Scholar] [CrossRef]

- Iyakwari, S.; Glass, H.J. Influence of Mineral Particle Size and Choice of Suitable Parameters for Ore Sorting Using near Infrared Sensors. Min. Eng. 2014, 69, 102–106. [Google Scholar] [CrossRef]

- Iyakwari, S. Application of near Infrared Sensors to Minerals Preconcentration. Ph.D. Thesis, University of Exeter, Exeter, UK, 2014. [Google Scholar]

- Phiri, T.; Glass, H.J.; Mwamba, P. Development of a Strategy and Interpretation of the NIR Spectra for Application in Automated Sorting. Min. Eng. 2018, 127, 224–231. [Google Scholar] [CrossRef]

- Kolacz, J. Advanced Separation Technologies for Pre-Concentration of Metal Ores and the Additional Process Control. E3S Web Conf. 2017, 18, 01001. [Google Scholar] [CrossRef]

- Jin, J.; Lin, C.L.; Miller, J.D.; Zhao, C.; Li, T. X-Ray Computed Tomography Evaluation of Crushed Copper Sulfide Ore for Pre-Concentration by Ore Sorting. Min. Met. Explor. 2022, 39, 13–21. [Google Scholar] [CrossRef]

- Frontier Technology Corporation (FTC). Everything You Need to Know About PGNAA (Prompt Gamma Neutron Activation Analysis). Available online: http://frontier-cf252.com/wp-content/uploads/eBook-Everything-You-Need-to-Know-About-PGNAA-Frontier-Technology-Corp.-8.27.pdf (accessed on 25 September 2025).

- Kurth, H. Suitability of On-Belt Elemental Analysis for Real-Time Ore Quality Measurement and Bulk Ore Sorting. In Proceedings of the COM 2017, The Conference of Metallurgists hosting World Gold & Nickel Cobalt, Hyatt Regency Hotel, Vancouver, BC, Canada, 27–30 August 2017; Canadian Institute of Mining, Metallurgy and Petroleum: Westmount, QC, Canada, 2017; pp. 1–9. [Google Scholar]

- Cetin, M.C.; Li, G.; Klein, B.; Futcher, W. Key Factors Determining the Bulk Ore Sorting Potential in a Caving Mine. Min. Eng. 2023, 201, 108237. [Google Scholar] [CrossRef]

- Cetin, M.C.; Klein, B.; Li, G.; Futcher, W.; Haest, M.; Welsh, A. Deployment of XRF Sensors Underground: An Opportunity for Grade Monitoring or Bulk Ore Sorting in Cave Mines. Minerals 2023, 13, 672. [Google Scholar] [CrossRef]

- Tong, L.; Cebeci, T.; Klein, B.; Khoshaba, B.; Bamber, A. Bench Scale X-Ray Fluorescence Sorting of Low Grade Copper Ores. In Proceedings of the IMPC 2016: XXVIII International Mineral Processing Congress Proceedings, Quebec, QC, Canada, 11–15 September 2016; Canadian Institute of Mining, Metallurgy and Petroleum: Westmount, QC, Canada, 2016; pp. 1–11. [Google Scholar]

- Norgate, T.; Haque, N. The Greenhouse Gas Impact of IPCC and Ore-Sorting Technologies. Min. Eng. 2013, 42, 13–21. [Google Scholar] [CrossRef]