Fracture Density Prediction of Basement Metamorphic Rocks Using Gene Expression Programming

Abstract

1. Introduction

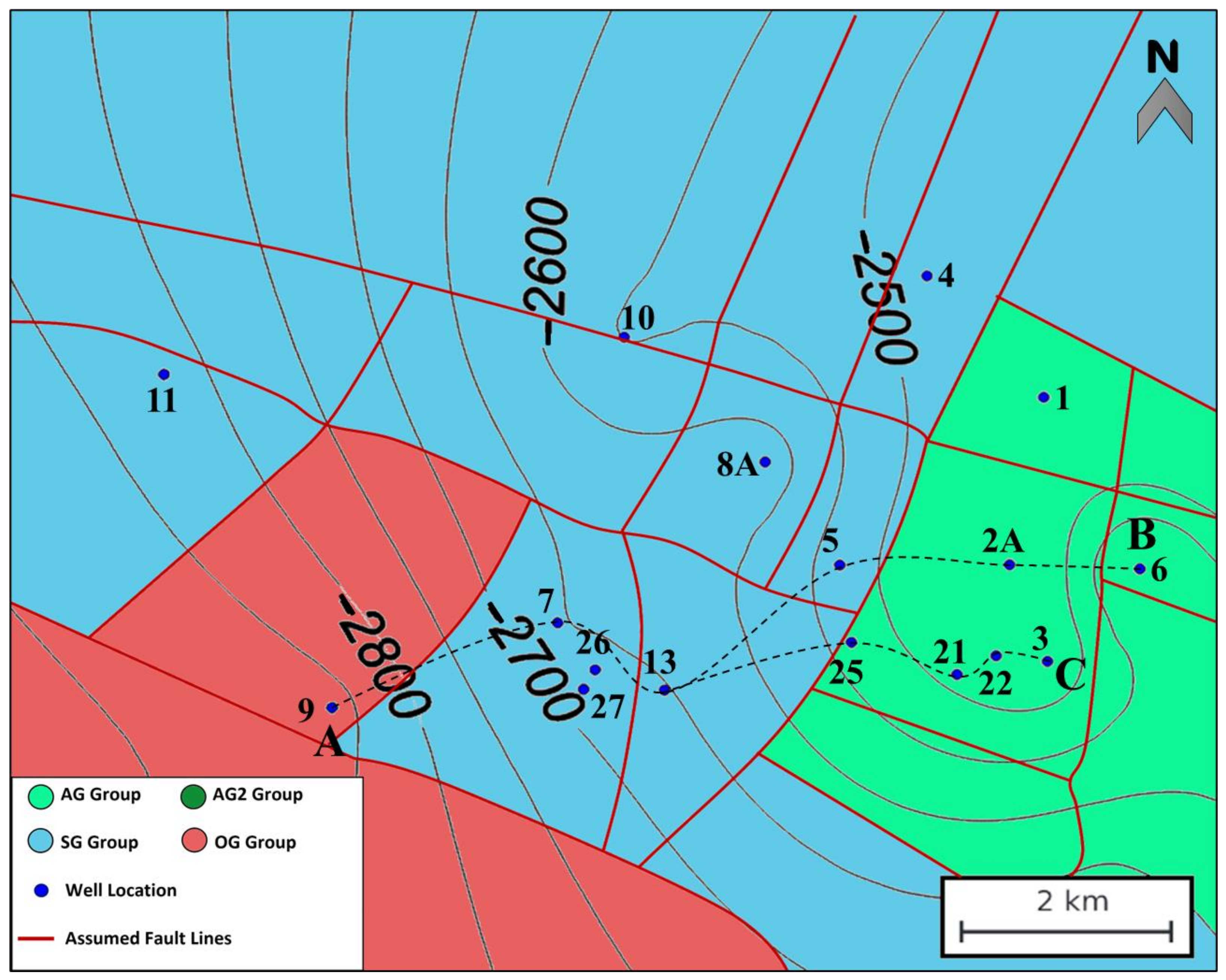

2. Geological Setting

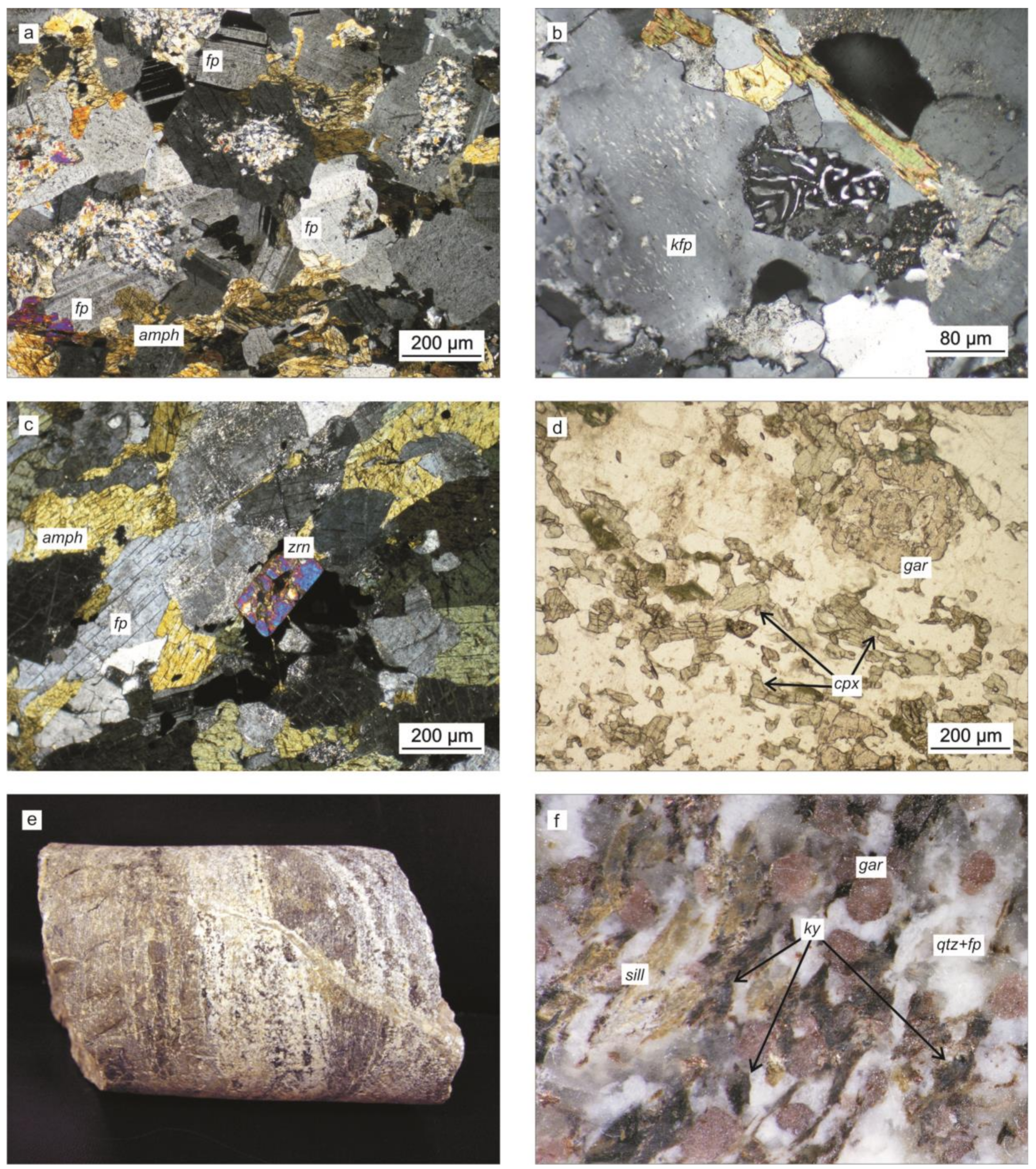

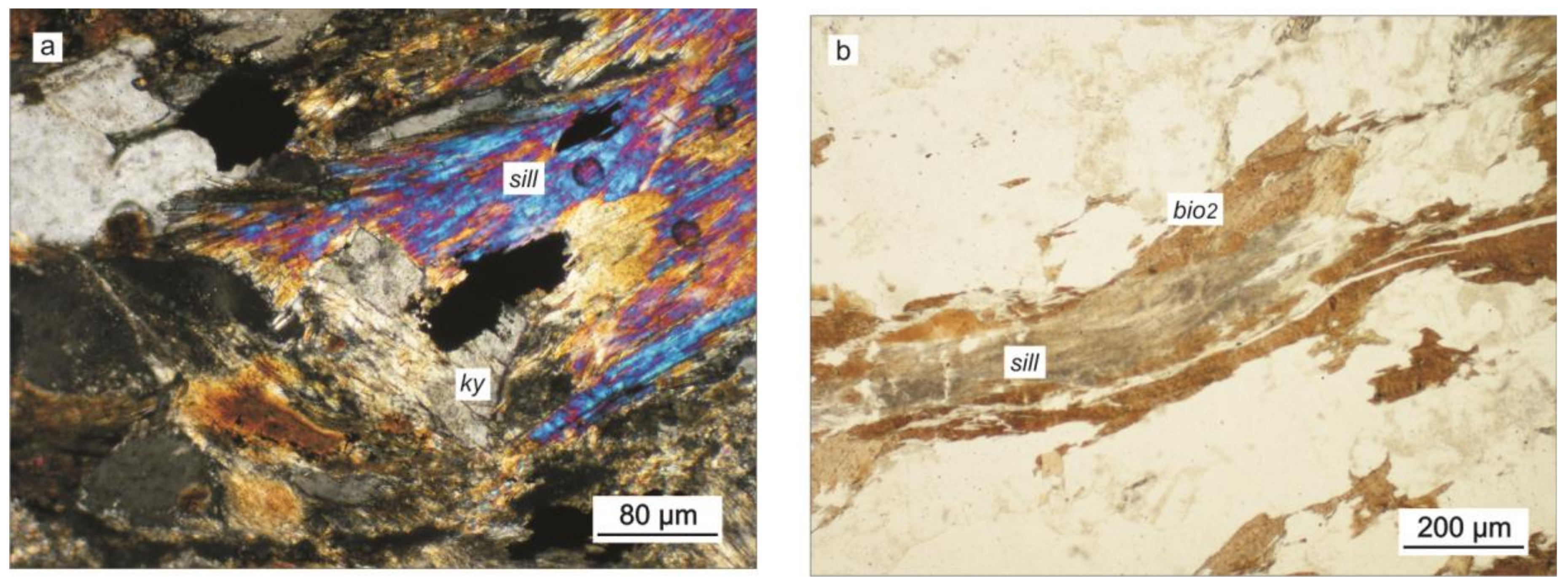

Petrography of the Rock Bodies

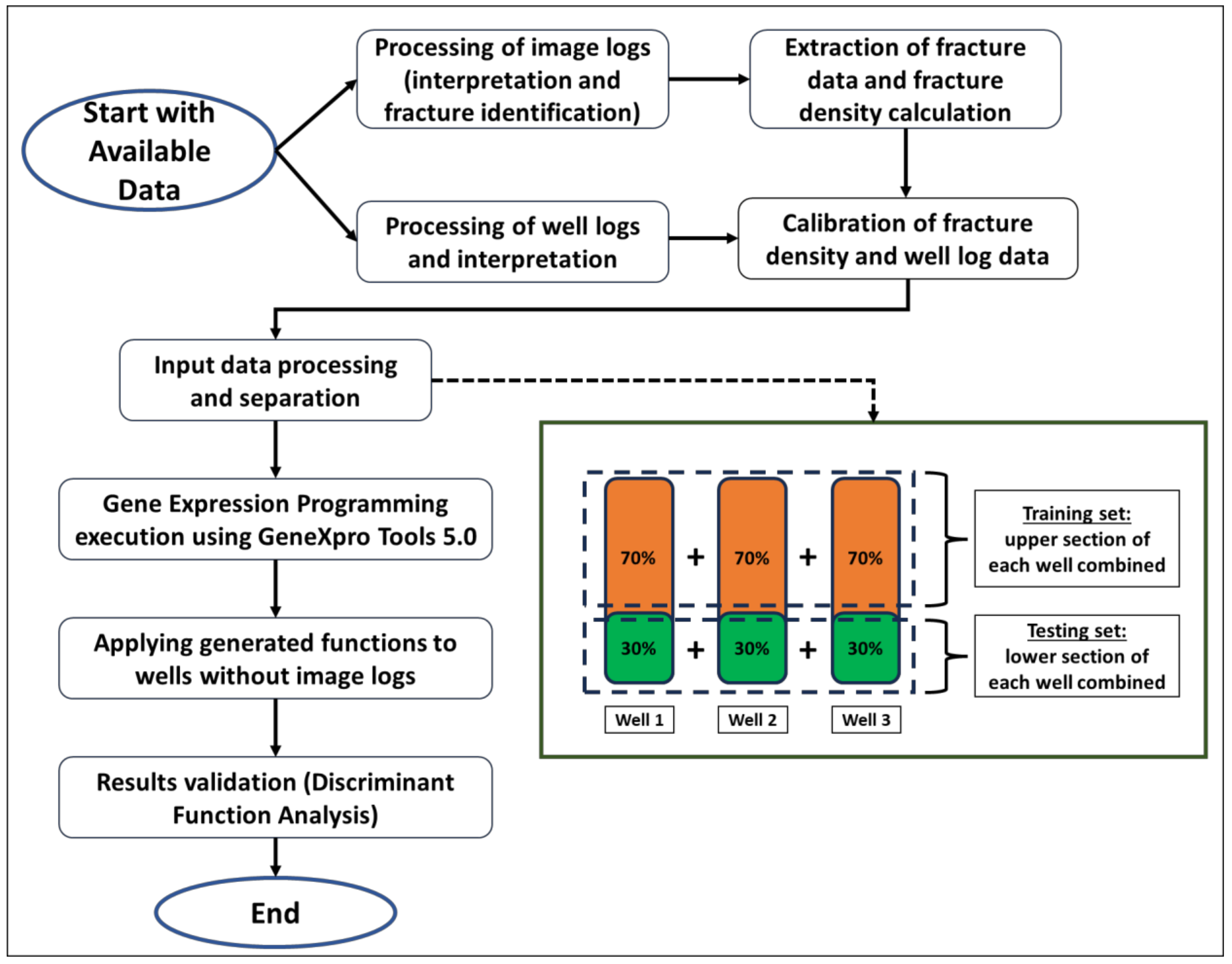

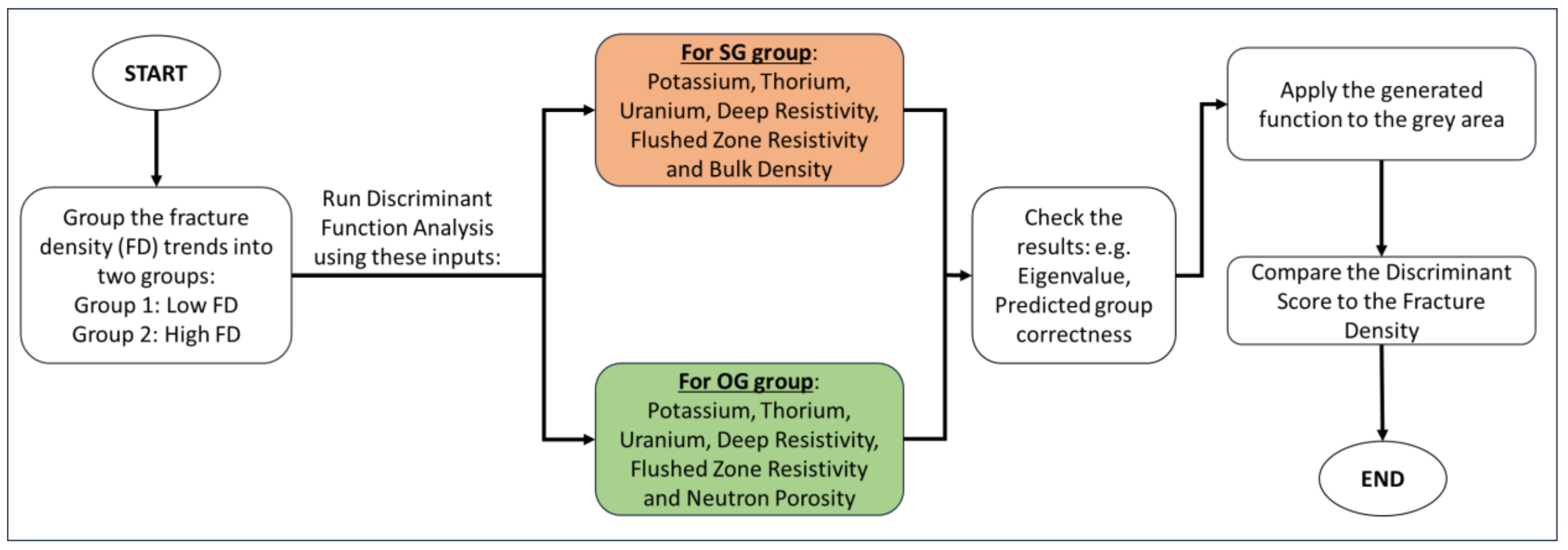

3. Samples and Methods

4. Results

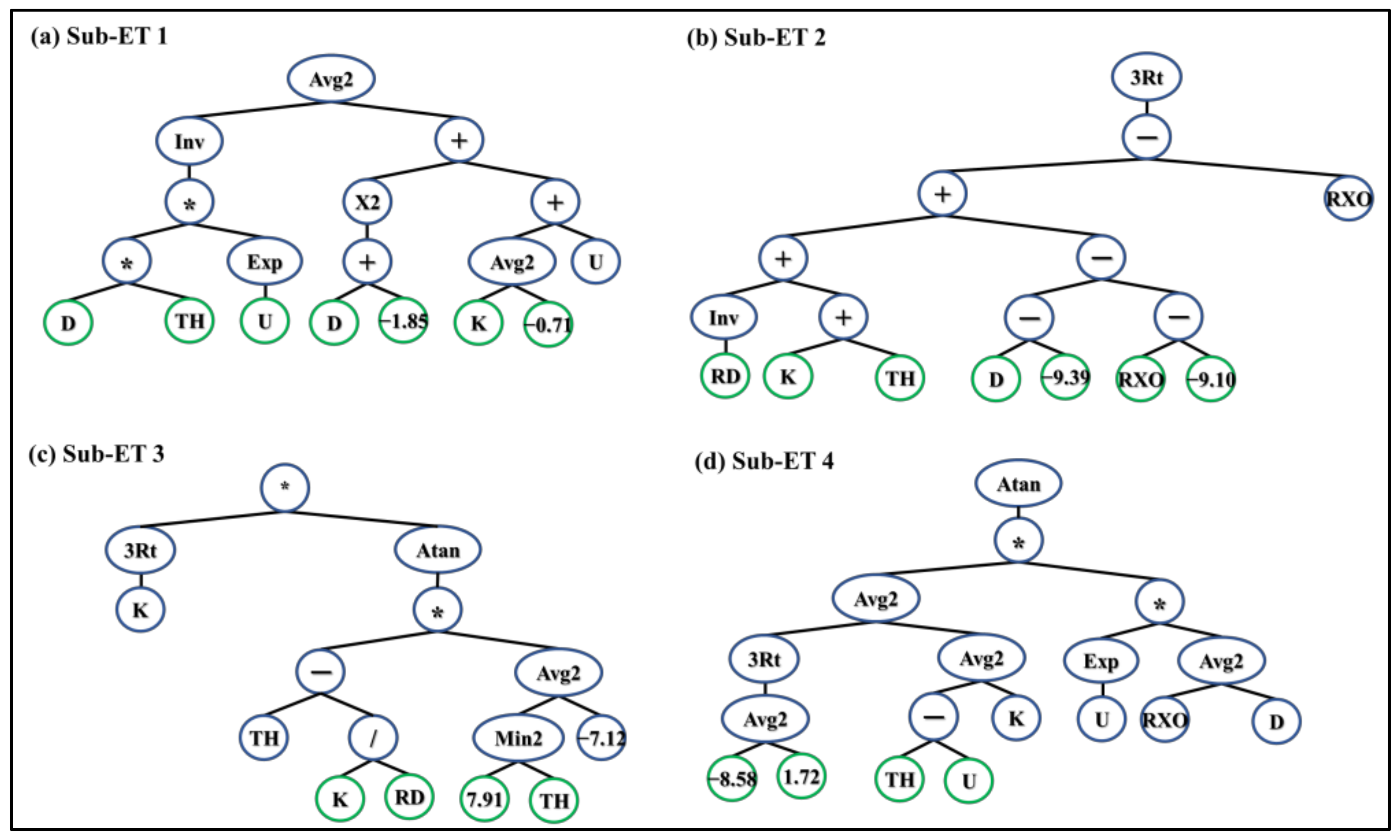

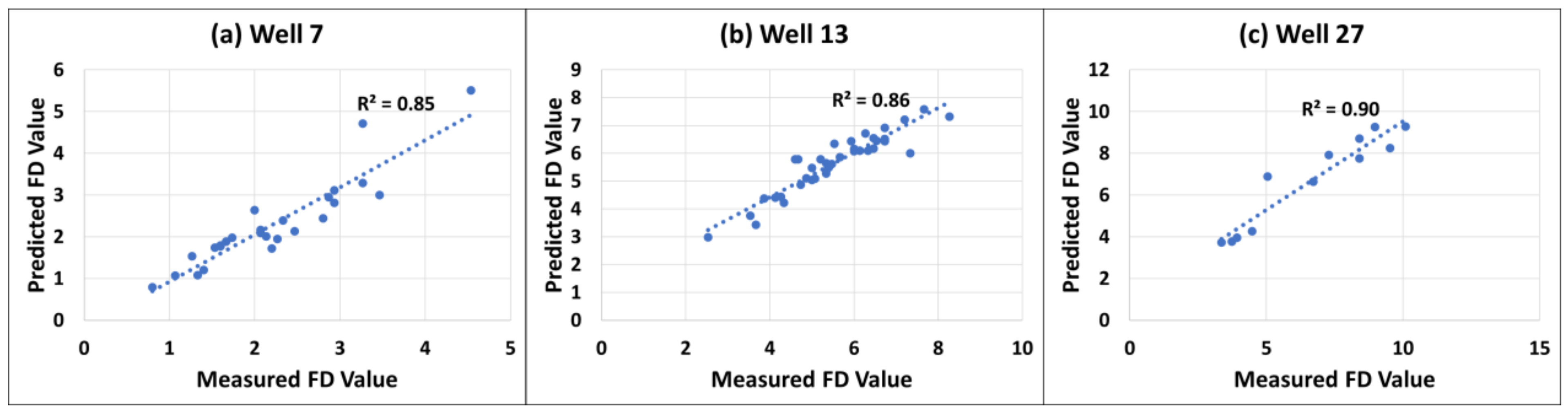

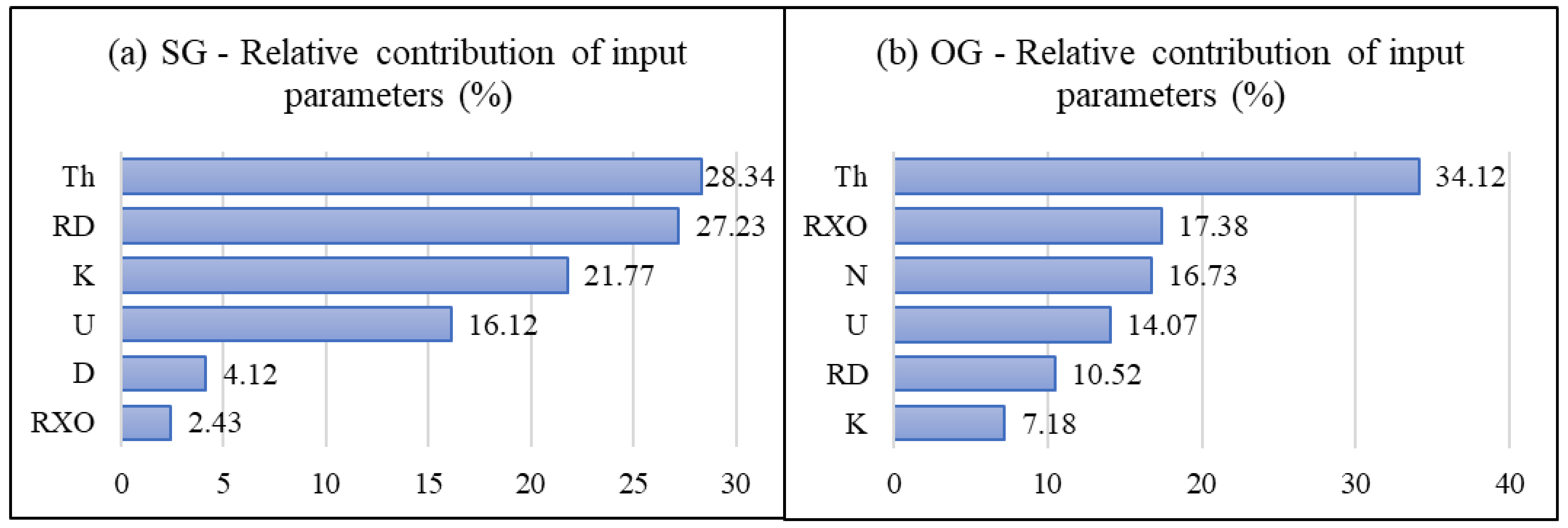

4.1. Training and Testing for SG Rock Column

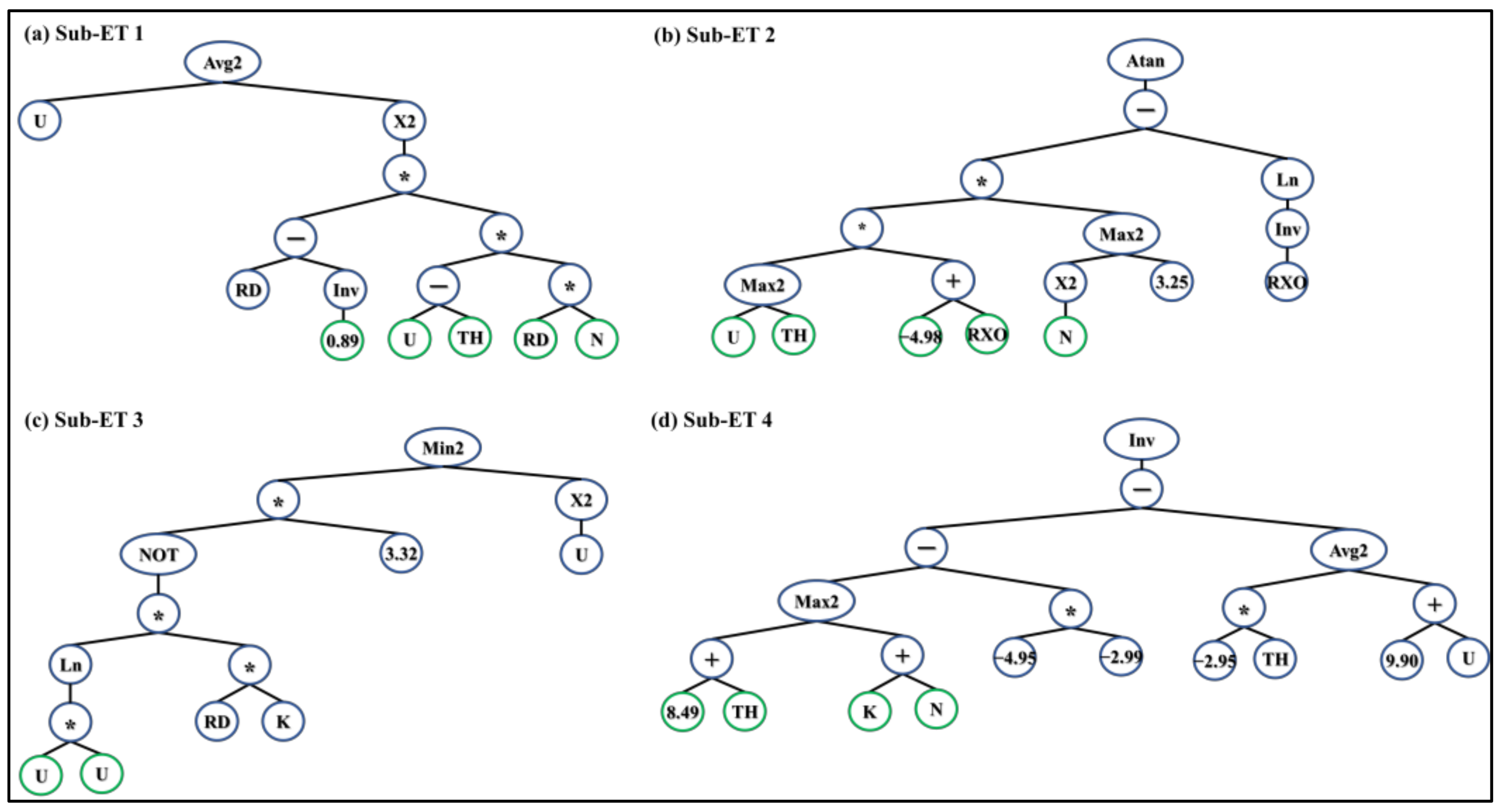

4.2. Training and Testing for OG Rock Column

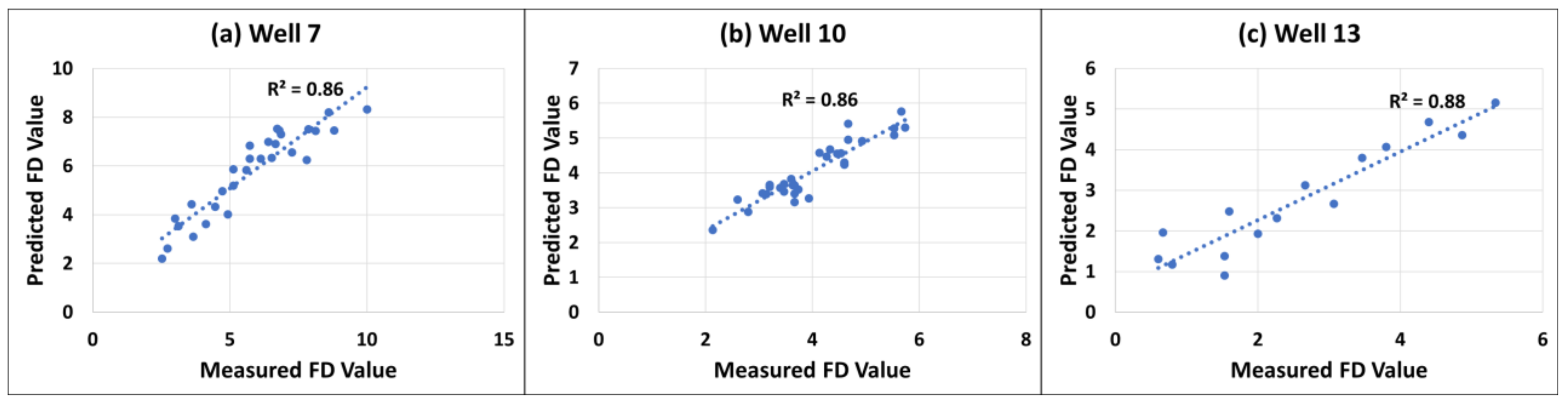

4.3. Performance Evaluation of GEP Models

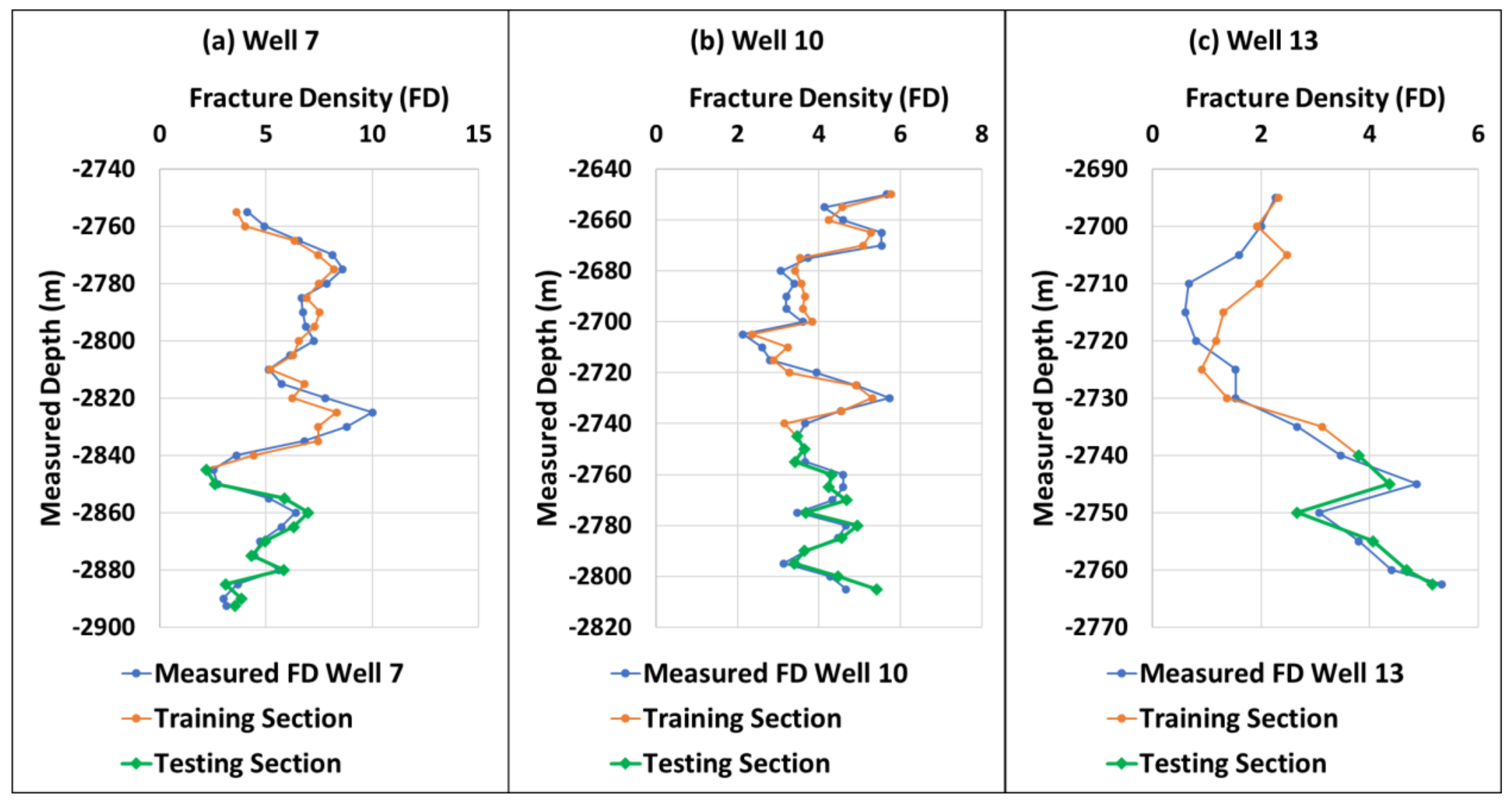

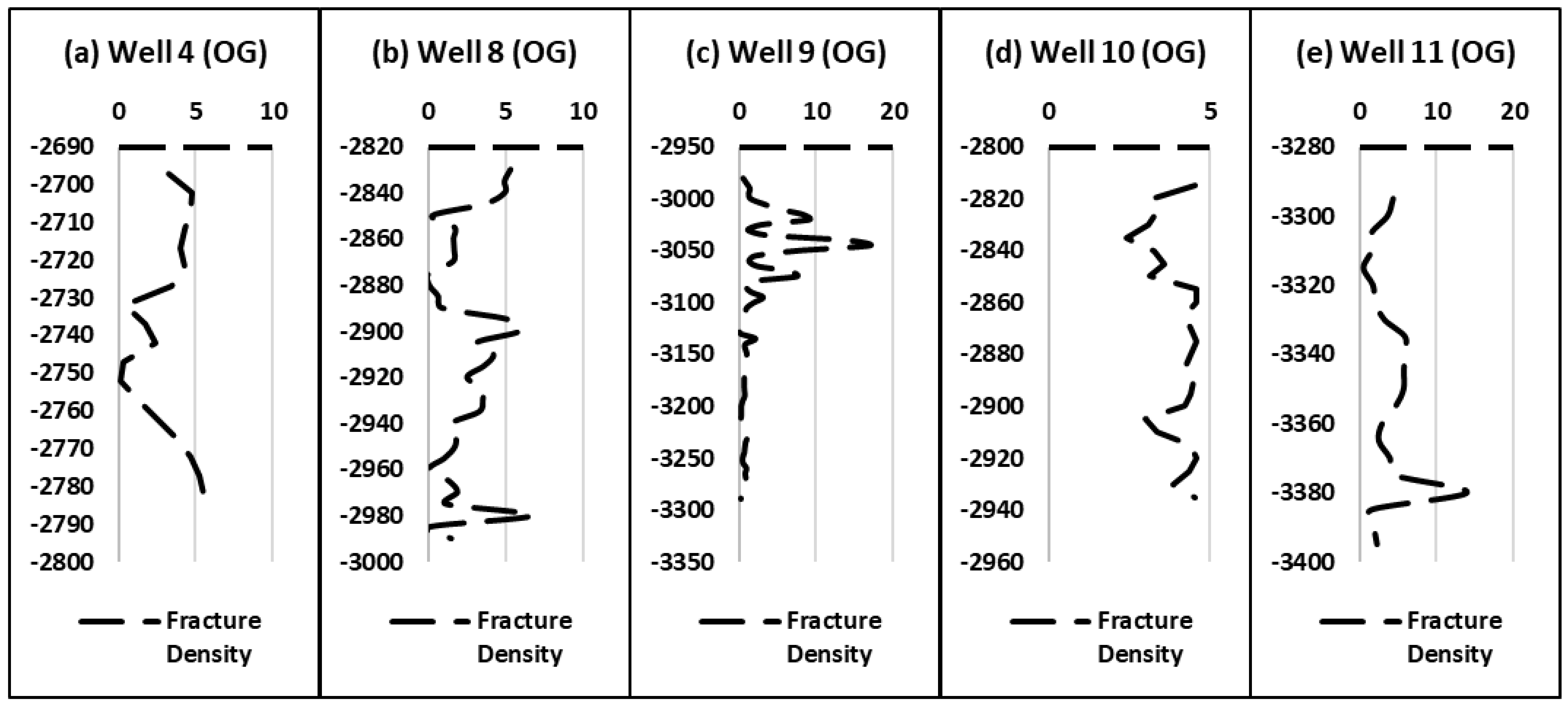

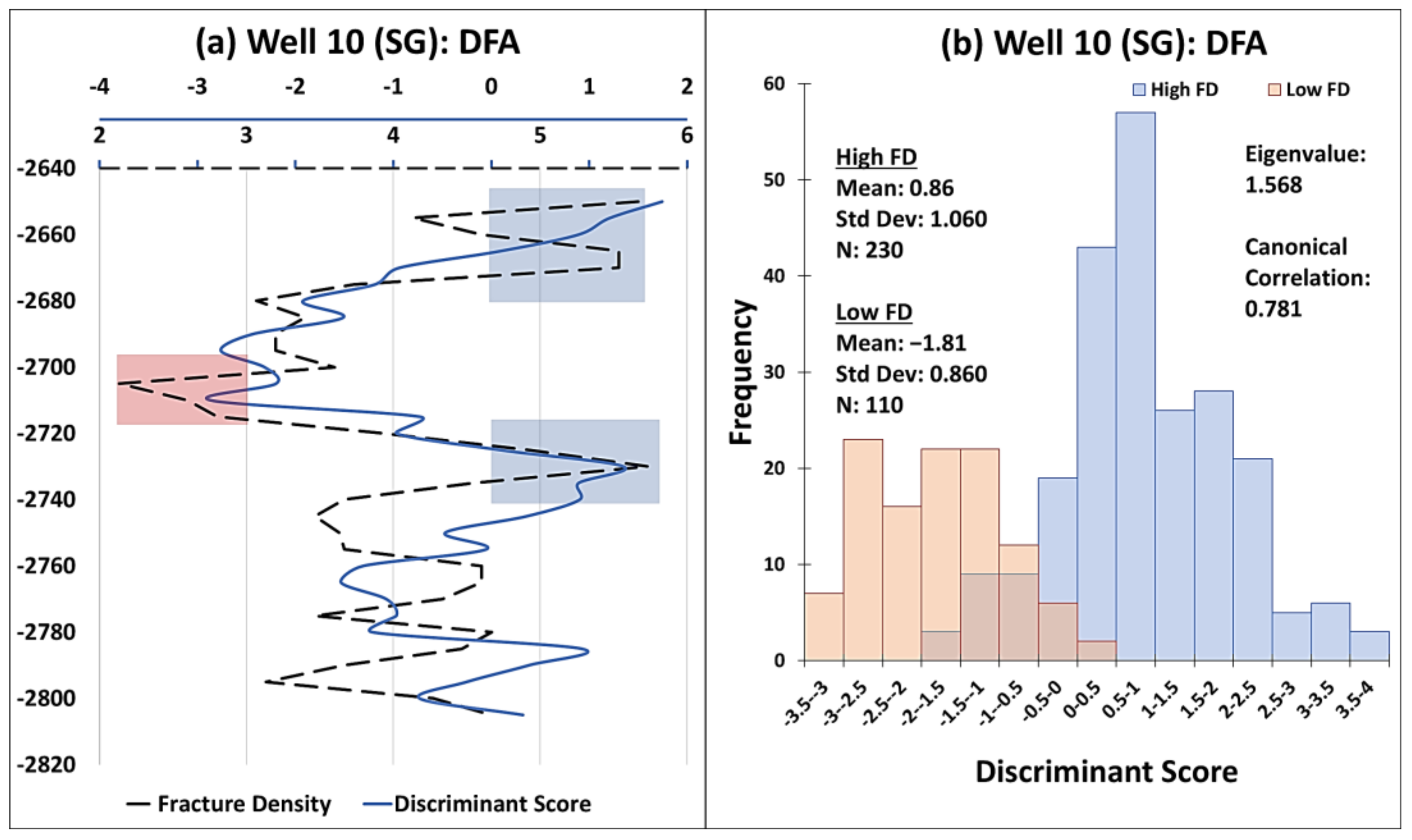

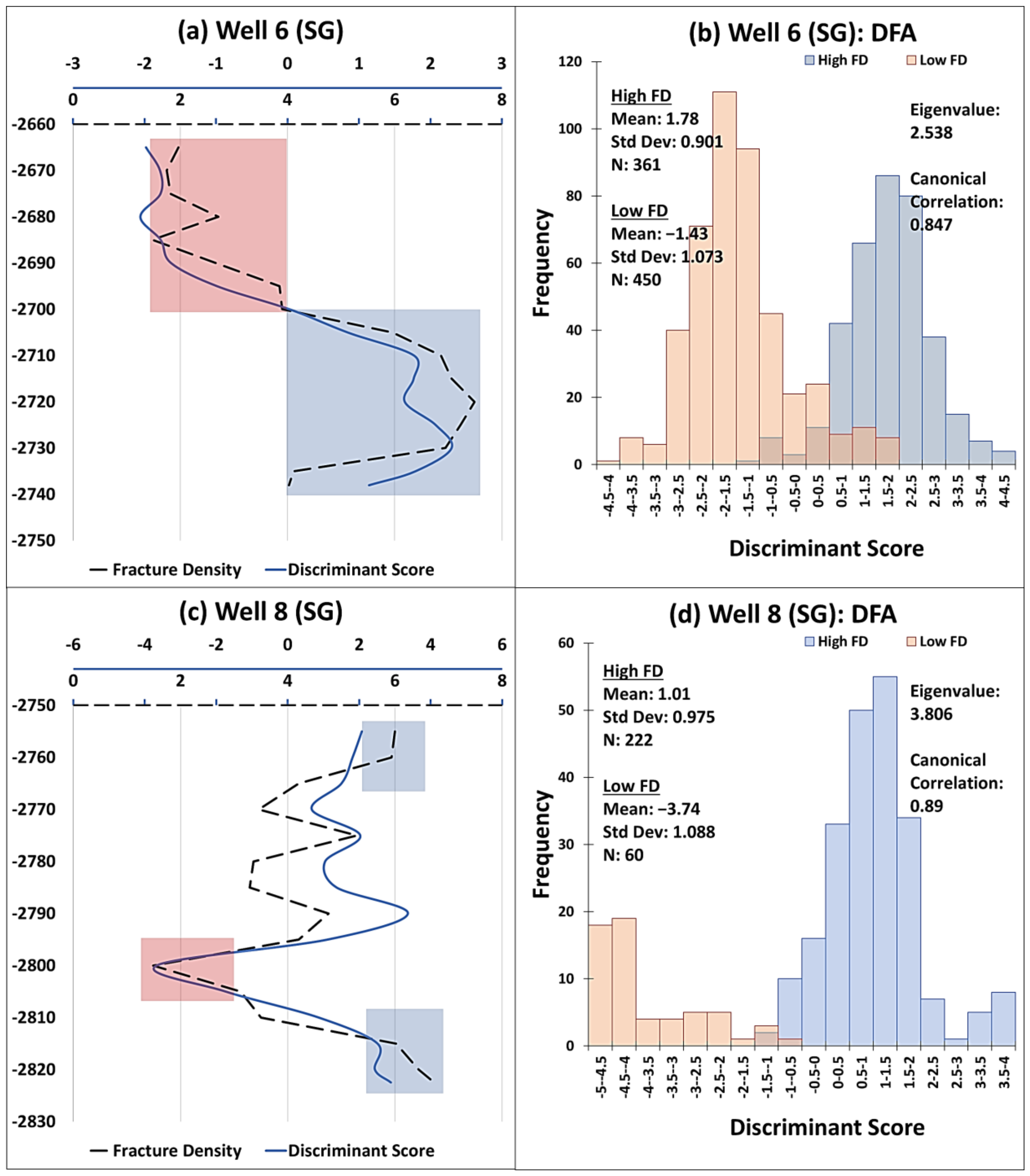

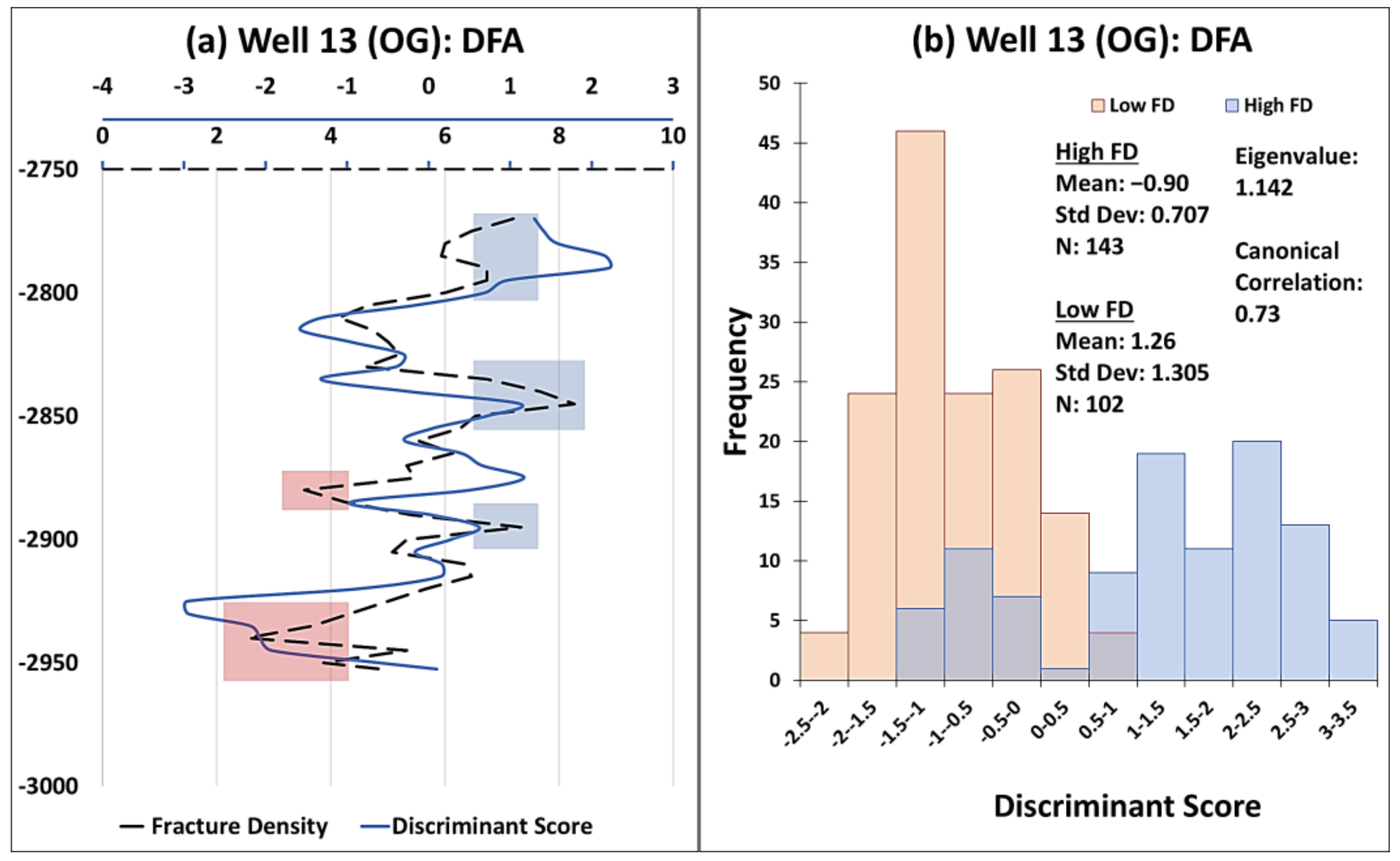

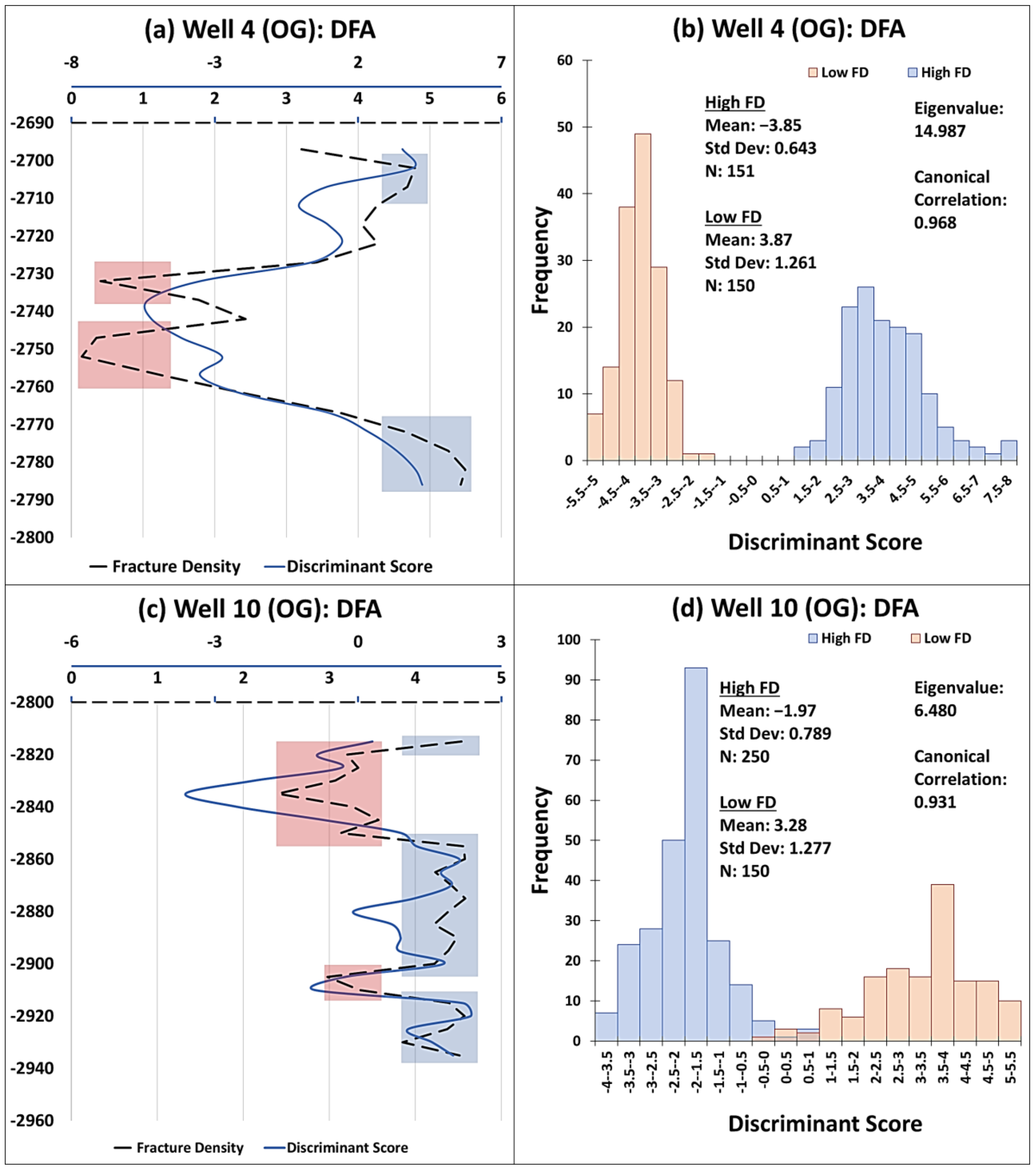

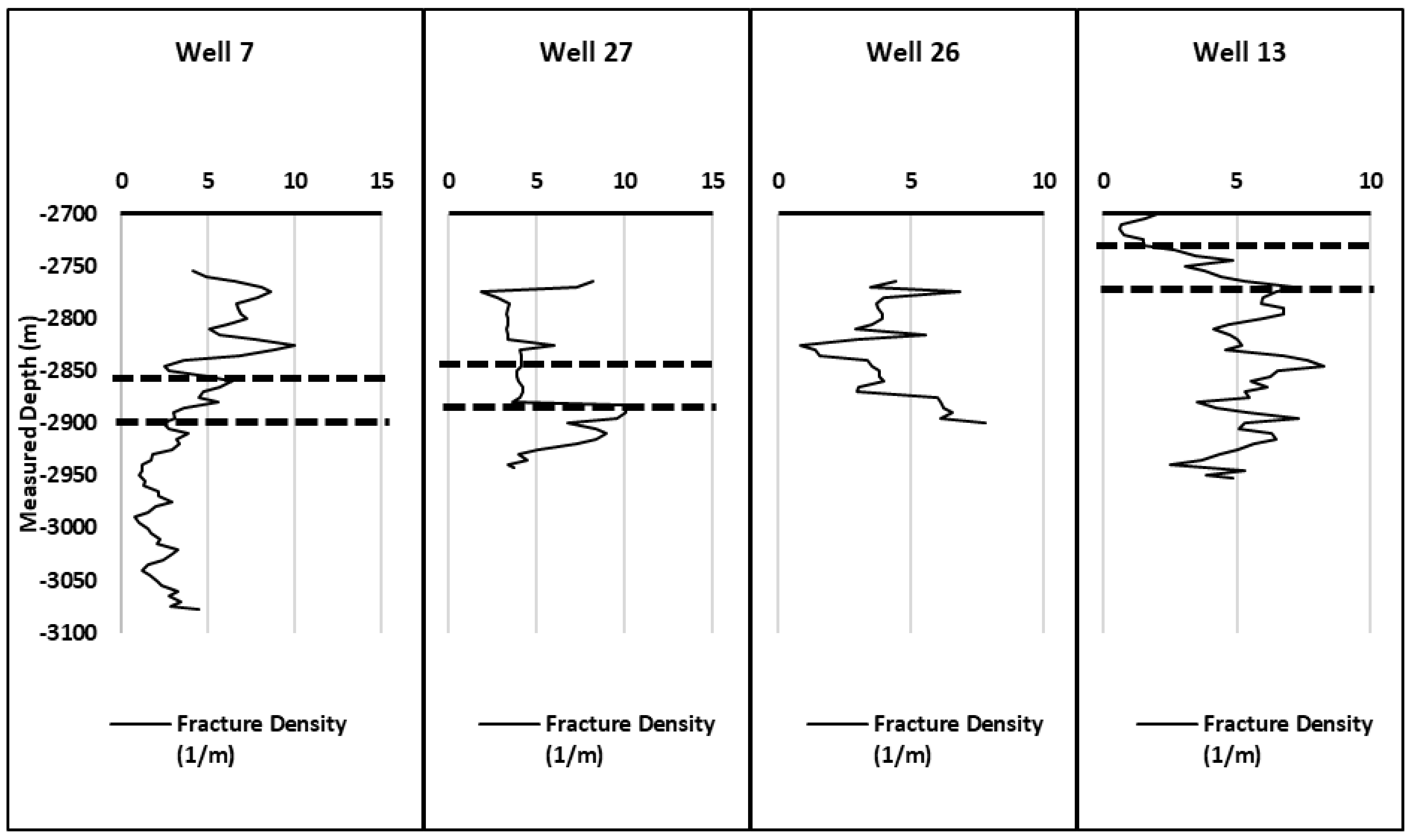

4.4. Validation of Fracture Density Predictions

5. Discussion

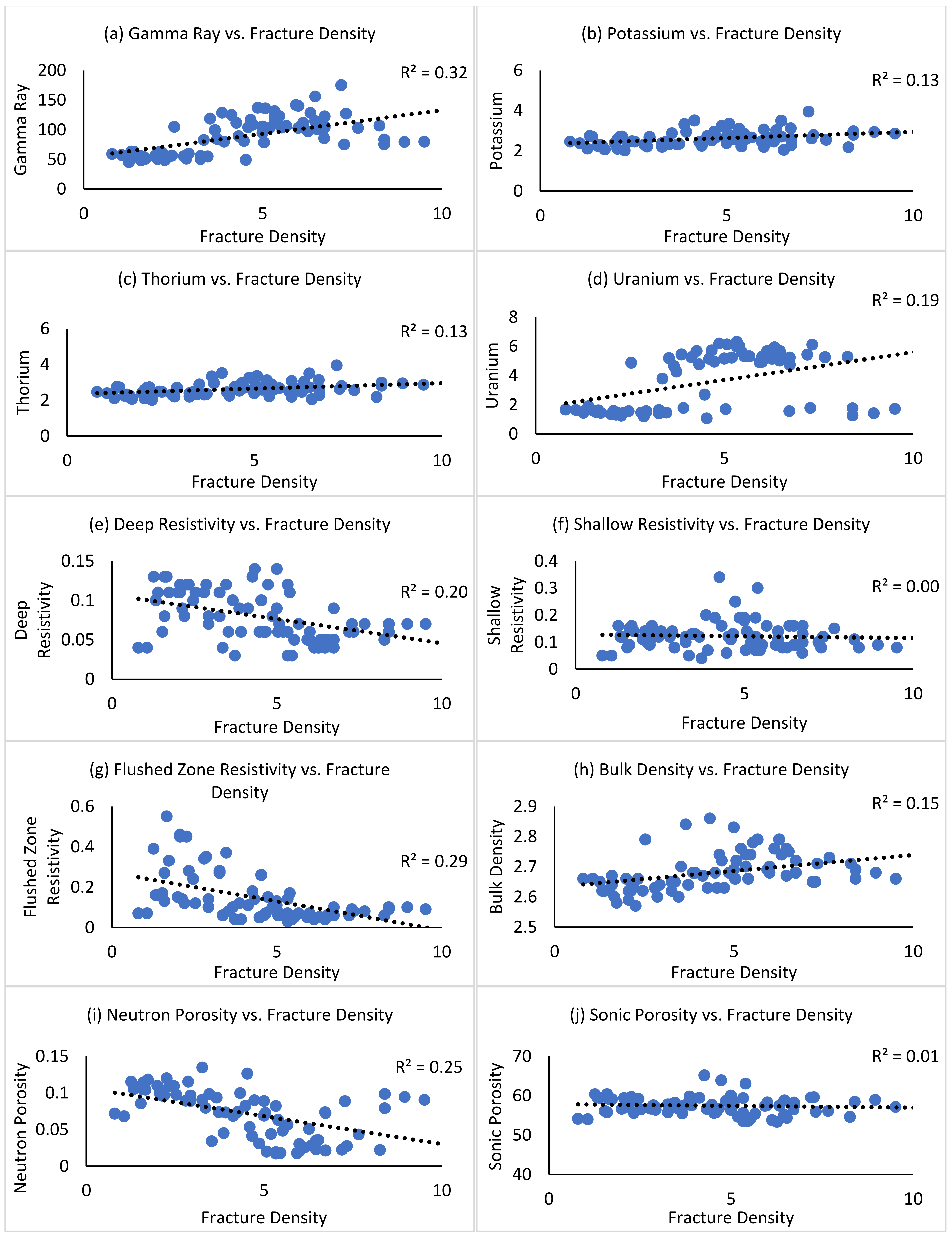

5.1. Well-Log Responses towards Fracture Characteristics

5.2. Theoretical Concept of the Fracture Network of the Studied Area

6. Conclusions

- The results from GEP modelling show that the fracture density prediction between SG and OG rock bodies has no significant difference regarding the well-log responses. The significant parameters for SG are K, TH, U, RD, RXO, and D, while the significant parameters for OG are K, TH, U, RD, RXO, and N.

- The results of this study show that spectral gamma ray, composed of K, TH, and U, is one of the critical parameters for FD predictions in a metamorphic rock body. The results confirmed and were consistent with the previous studies that GR alone did not contribute as much to fracture detection. However, it is one of the most helpful well-log parameters for lithology identification.

- GEP modelling could be used to predict FD in cases where image logs and core samples are unavailable. The GEP method has been proven helpful in this prediction by using only conventional well-logs as input data. This shows that the nonlinear method could solve a nonlinear and complex problem.

- The prediction of FD to wells without image logs can be validated by comparing the well-log pattern of wells with image logs. In this case, an analysis of all fracture indications from conventional well-logs was carried out, and the results were consistent throughout all wells, either with or without image logs.

- The study also proposes a method to validate the FD predictions using the statistical analysis method of discriminant function analysis (DFA). The results from GEP modelling were used as inputs for the DFA, and the results show the consistency of the results between wells with image logs and wells without image logs in terms of patterns and trends.

- There are limitations to this study. The study used samples from the basement metamorphic rocks. Although the application of the GEP method seemed to work in the case of this study, the generated functions and methods cannot be generalized for all other fractures since each fracture and rock acts differently. However, this study provides evidence that in the case of two different gneisses, predicting FD without core samples and image logs but using conventional well logs is possible.

- There are many advanced methods that have been developed that utilise the advantages of different machine learning methods. This study proposes that an extended study could be carried out in a similar manner by employing these different methods. However, it is also safe to say that although these model predictions could work, these methods could not replace geophysical analysis, especially image logs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, H.; Pan, H.; Wu, A.; Luo, M.; Konaté, A.A.; Meng, Q. Application of well logs integration and wavelet transform to improve fracture zones detection in metamorphic rocks. J. Pet. Sci. Eng. 2017, 157, 716–723. [Google Scholar] [CrossRef]

- Barthélémy, J.F.; Guiton, M.L.; Daniel, J.M. Estimates of fracture density and uncertainties from well data. Int. J. Rock Mech. Min. Sci. 2009, 46, 590–603. [Google Scholar] [CrossRef][Green Version]

- Rashid, F.; Hussein, D.; Lawrence, J.A.; Khanaqa, P. Characterization and impact on reservoir quality of fractures in the Cretaceous Qamchuqa Formation, Zagros folded belt. Mar. Pet. Geol. 2020, 113, 104117. [Google Scholar] [CrossRef]

- Hu, S.; Wang, X.; Wang, J.; Wang, L. Quantitative evaluation of fracture porosity from dual laterlog based on deep learning method. Energy Geosci. 2023, 4, 100064. [Google Scholar] [CrossRef]

- Khoshbakht, F.; Rasaie, M.R.; Shekarifard, A. Investigating induction log response in the presence of natural fractures. J. Pet. Sci. Eng. 2016, 145, 357–369. [Google Scholar] [CrossRef]

- Aghli, G.; Moussavi-Harami, R.; Mohammadian, R. Reservoir heterogeneity and fracture parameter determination using electrical image logs and petrophysical data (a case study, carbonate Asmari Formation, Zagros Basin, SW Iran). Pet. Sci. 2020, 17, 51–69. [Google Scholar] [CrossRef]

- Pham, C.; Zhuang, L.; Yeom, S.; Shin, H.S. Automatic fracture characterization in CT images of rocks using an ensemble deep learning approach. Int. J. Rock Mech. Min. Sci. 2023, 170, 105531. [Google Scholar] [CrossRef]

- Cappuccio, F.; Toy, V.G.; Mills, S.; Adam, L. Three-dimensional separation and characterization of fractures in X-ray computed tomographic images of rocks. Front. Earth Sci. 2020, 8, 529263. [Google Scholar] [CrossRef]

- Zhuo, R.; Ma, X.; Zhang, S.; Ma, J.; Xiang, Y.; Sun, H. Classification and assessment of core fractures in a post-fracturing conglomerate reservoir using the AHP–FCE method. Energies 2022, 16, 418. [Google Scholar] [CrossRef]

- Dong, T.; Zhou, J.; Yan, Z.; Wu, Y.; Mao, T. Study on voids and seepage characteristics within rock fracture after shear dislocation viewing from CT test and numerical modeling. Appl. Sci. 2024, 14, 1013. [Google Scholar] [CrossRef]

- Liu, L.; Yao, J.; Sun, H.; Zhang, L.; Zhang, K. Digital rock analysis on the influence of coarse micro-fractures on petrophysical properties in tight sandstone reservoirs. Appl. Sci. 2023, 13, 5237. [Google Scholar] [CrossRef]

- Ameen, M.S.; MacPherson, K.; Al-Marhoon, M.I.; Rahim, Z. Diverse fracture properties and their impact on performance in conventional and tight-gas reservoirs, Saudi Arabia: The Unayzah, South Haradh case study. AAPG Bull. 2012, 96, 459–492. [Google Scholar] [CrossRef]

- Lyu, W.; Zeng, L.; Liu, Z.; Liu, G.; Zu, K. Fracture responses of conventional logs in tight-oil sandstones: A case study of the Upper Triassic Yanchang Formation in southwest Ordos Basin, China. AAPG Bull. 2016, 100, 1399–1417. [Google Scholar] [CrossRef]

- Bagheri, H.; Falahat, R. Fracture permeability estimation utilizing conventional well logs and flow zone indicator. Pet. Res. 2022, 7, 357–365. [Google Scholar] [CrossRef]

- Qiu, X.; Tan, C.; Lu, Y.; Yin, S. Evaluation of fractures using conventional and FMI logs, and 3D seismic interpretation in continental tight sandstone reservoir. Open Geosci. 2022, 14, 530–543. [Google Scholar] [CrossRef]

- Aghli, G.; Moussavi-Harami, R.; Tokhmechi, B. Integration of sonic and resistivity conventional logs for identification of fracture parameters in the carbonate reservoirs (A case study, Carbonate Asmari Formation, Zagros Basin, SW Iran). J. Pet. Sci. Eng. 2020, 186, 106728. [Google Scholar] [CrossRef]

- Tabasi, S.; Tehrani, P.S.; Rajabi, M.; Wood, D.A.; Davoodi, S.; Ghorbani, H.; Mohamadian, N.; Alvar, M.A. Optimized machine learning models for natural fractures prediction using conventional well logs. Fuel 2022, 326, 124952. [Google Scholar] [CrossRef]

- Gamal, M.; El-Araby, A.A.; El-Barkooky, A.N.; Hassan, A. Detection and characterization of fractures in the Eocene Thebes formation using conventional well logs in October field, Gulf of Suez, Egypt. Egypt. J. Pet. 2022, 31, 1–9. [Google Scholar] [CrossRef]

- Hussein, H.S. Carbonate fractures from conventional well log data, Kometan Formation, Northern Iraq case study. J. Appl. Geophys. 2022, 206, 104810. [Google Scholar] [CrossRef]

- Laongsakul, P. Characterization of Reservoir Fractures Using Conventional Geophysical Logging. Doctoral Dissertation, Prince of Songkla University Faculty of Science (Geophysics), Hat Yai, Thailand, 2010. [Google Scholar]

- Tokhmechi, B.; Memarian, H.; Noubari, H.A.; Moshiri, B. A novel approach proposed for fractured zone detection using petrophysical logs. J. Geophys. Eng. 2009, 6, 365–373. [Google Scholar] [CrossRef]

- Shalaby, M.R.; Islam, M.A. Fracture detection using conventional well logging in carbonate Matulla Formation, Geisum oil field, southern Gulf of Suez, Egypt. J. Pet. Explor. Prod. Technol. 2017, 7, 977–989. [Google Scholar] [CrossRef]

- Laongsakul, P.; Dürrast, H. Characterization of reservoir fractures using conventional geophysical logging. Songklanakarin J. Sci. Technol. 2011, 33, 237–246. [Google Scholar]

- Rashid, M.; Luo, M.; Ashraf, U.; Hussain, W.; Ali, N.; Rahman, N.; Hussain, S.; Aleksandrovich Martyushev, D.; Vo Thanh, H.; Anees, A. Reservoir quality prediction of gas-bearing carbonate sediments in the Qadirpur Field: Insights from advanced machine learning approaches of SOM and cluster analysis. Minerals 2023, 13, 29. [Google Scholar] [CrossRef]

- Ma, T.; Liu, K.; Su, X.; Chen, P.; Ranjith, P.G.; Martyushev, D.A. Investigation on the Anisotropy of Meso-Mechanical Properties of Shale Rock Using Micro-Indentation. Bull. Eng. Geol. Environ. 2023, 83, 29. [Google Scholar] [CrossRef]

- Tóth, E.; Hrabovszki, E.; Tóth, T.M. Using geophysical log data to predict the fracture density in a claystone host rock for storing high-level nuclear waste. Acta Geod. Geophys. 2023, 58, 35–51. [Google Scholar] [CrossRef]

- Sahimi, M.; Hashemi, M. Wavelet identification of the spatial distribution of fractures. Geophys. Res. Lett. 2001, 28, 611–614. [Google Scholar] [CrossRef]

- Zhang, X.F.; Pan, B.Z.; Wang, F.; Han, X. A study of wavelet transforms applied for fracture identification and fracture density evaluation. Appl. Geophys. 2011, 8, 164–169. [Google Scholar] [CrossRef]

- Yousef, A.N.; Behzad, T.; Abolghasem, K.R.; Shahram, S.; Kaveh, K.; Amin, J. A combined Parzen-wavelet approach for detection of vuggy zones in fractured carbonate reservoirs using petrophysical logs. J. Pet. Sci. Eng. 2014, 119, 1–7. [Google Scholar] [CrossRef]

- Tokhmechi, B.; Memarian, H.; Rasouli, V.; Noubari, H.A.; Moshiri, B. Fracture detection from water saturation log data using a Fourier–wavelet approach. J. Pet. Sci. Eng. 2009, 69, 129–138. [Google Scholar] [CrossRef][Green Version]

- Taherdangkoo, R.; Abdideh, M. Application of wavelet transform to detect fractured zones using conventional well logs data (Case study: Southwest of Iran). Int. J. Pet. Eng. 2016, 2, 125–139. [Google Scholar] [CrossRef]

- Martyushev, D.A.; Yurikov, A. Evaluation of Opening of Fractures in the Logovskoye Carbonate Reservoir, Perm Krai, Russia. Pet. Res. 2021, 6, 137–143. [Google Scholar] [CrossRef]

- Xue, Y.; Cheng, L.; Mou, J.; Zhao, W. A new fracture prediction method by combining genetic algorithm with neural network in low-permeability reservoirs. J. Pet. Sci. Eng. 2014, 121, 159–166. [Google Scholar] [CrossRef]

- Pei, J.; Zhang, Y. Prediction of Reservoir Fracture Parameters Based on the Multi-Layer Perceptron Machine-Learning Method: A Case Study of Ordovician and Cambrian Carbonate Rocks in Nanpu Sag, Bohai Bay Basin, China. Processes 2022, 10, 2445. [Google Scholar] [CrossRef]

- Afrasiabian, B.; Eftekhari, M. Prediction of mode I fracture toughness of rock using linear multiple regression and gene expression programming. J. Rock Mech. Geotech. Eng. 2022, 14, 1421–1432. [Google Scholar] [CrossRef]

- Ari, D.; Alagoz, B.B. A differential evolutionary chromosomal gene expression programming technique for electronic nose applications. Appl. Soft Comput. 2023, 136, 110093. [Google Scholar] [CrossRef]

- Aydogan, M.S.; Alacali, S.; Arslan, G. Prediction of moment redistribution capacity in reinforced concrete beams using gene expression programming. Structures 2023, 47, 2209–2219. [Google Scholar] [CrossRef]

- Chu, H.H.; Khan, M.A.; Javed, M.; Zafar, A.; Khan, M.I.; Alabduljabbar, H.; Qayyum, S. Sustainable use of fly-ash: Use of gene-expression programming (GEP) and multi-expression programming (MEP) for forecasting the compressive strength geopolymer concrete. Ain Shams Eng. J. 2021, 12, 3603–3617. [Google Scholar] [CrossRef]

- Ferreira, C. Gene expression programming: A new adaptive algorithm for solving problems. Complex Syst. 2001, 13, 87–129. [Google Scholar] [CrossRef]

- Kaushik, V.; Kumar, M. Sustainable gene expression programming model for shear stress prediction in nonprismatic compound channels. Sustain. Energy Technol. Assess. 2023, 57, 103229. [Google Scholar] [CrossRef]

- Tari, G.; Dövényi, P.; Dunkl, I.; Horváth, F.; Lenkey, L.; Stefanescu, M.; Szafian, P.; Tóth, T. Lithospheric structure of the Pannonian basin derived from seismic, gravity and geothermal data. Geol. Soc. Lond. Spec. Publ. 1999, 156, 215–250. [Google Scholar] [CrossRef]

- Horváth, F.; Musitz, B.; Balázs, A.; Végh, A.; Uhrin, A.; Nádor, A.; Koroknai, B.; Pap, N.; Tóth, T.; Wórum, G. Evolution of the Pannonian basin and its geothermal resources. Geothermics 2015, 53, 328–352. [Google Scholar] [CrossRef]

- Tóth, T.M.; Fiser-Nagy, Á.; Kondor, H.; Molnár, L.; Schubert, F.; Vargáné Tóth, I.; Zachar, J. The Metamorphic Basement of the Great Hungarian Plain: From Zwischengebirge Towards A Variegated Mosaic. Földtani Közlöny 2021, 151, 3–26, (in Hungarian with English abstract). [Google Scholar] [CrossRef]

- Molnár, L.; Tóth, T.M.; Schubert, F. Structural controls on petroleum migration and entrapment within the faulted basement blocks of Szeghalom Dome (Pannonian Basin, SE Hungary). Geol. Croat. 2015, 68, 247–259. [Google Scholar] [CrossRef]

- Juhász, A.; Tóth, T.M.; Ramseyer, K.; Matter, A. Connected fluid evolution in the fractured crystalline basement and overlying sediments, Pannonian Basin, SE Hungary. Chem. Geol. 2002, 182, 91–120. [Google Scholar] [CrossRef]

- Schubert, F.; Diamond, L.W.; Tóth, T.M. Fluid-inclusion evidence of petroleum migration through a buried metamorphic dome in the Pannonian Basin, Hungary. Chem. Geol. 2007, 244, 357–381. [Google Scholar] [CrossRef]

- Kovács, Z.; Zilahi-Sebess, L. Evaluation of the trends of secondary and tertiary hydrocarbon migration processes based on oil density–reservoir depths relationship in Hungary. Cent. Eur. Geol. 2018, 61, 16–33. [Google Scholar] [CrossRef]

- Selmeczi, I. Hydrocarbon Exploration Areas in Hungary–Bihar. In Hydrocarbons in Hungary; Kovács, Z., Ed.; Hungarian Energy and Public Utility Regulatory Authority: Budapest, Hungary, 2018; pp. 165–178. [Google Scholar]

- Koroknai, B.; Wórum, G.; Tóth, T.; Koroknai, Z.; Fekete-Németh, V.; Kovács, G. Geological deformations in the Pannonian Basin during the neotectonic phase: New insights from the latest regional mapping in Hungary. Earth-Sci. Rev. 2020, 211, 103411. [Google Scholar] [CrossRef]

- Molnár, L.; Vásárhelyi, B.; Tóth, T.M.; Schubert, F. Integrated petrographic–rock mechanic borecore study from the metamorphic basement of the Pannonian Basin, Hungary. Open Geosci. 2015, 7, 20150004. [Google Scholar] [CrossRef]

- Tóth, T.M.; Molnár, L.; Körmös, S.; Czirbus, N.; Schubert, F. Localisation of Ancient Migration Pathways inside a Fractured Metamorphic Hydrocarbon Reservoir in South-East Hungary. Appl. Sci. 2020, 10, 7321. [Google Scholar] [CrossRef]

- Tóth, T.M.; Zachar, J. Petrology and deformation history of the metamorphic basement in the Mezősas-Furta crystalline high (SE Hungary). Acta Geol. Hung. 2006, 49, 165–188. [Google Scholar] [CrossRef]

- Hasan, M.L.; Tóth, T.M. Localization of potential migration pathways inside a fractured metamorphic hydrocarbon reservoir using well log evaluation (Mezősas field, Pannonian Basin). Geoenergy Sci. Eng. 2023, 225, 211710. [Google Scholar] [CrossRef]

- Tóth, T.M.; Schubert, F. Evolution of the arc-derived orthogneiss recorded in exotic xenoliths of the Koros Complex (Tisza Megaunit, SE Hungary). J. Geosci. 2018, 63, 21–46. [Google Scholar] [CrossRef]

- Baouche, R.; Sen, S.; Chaouchi, R.; Ganguli, S.S. Modeling In-Situ Tectonic Stress State and Maximum Horizontal Stress Azimuth in the Central Algerian Sahara—A Geomechanical Study from El Agreb, El Gassi and Hassi Messaoud Fields. J. Nat. Gas. Sci. Eng. 2021, 88, 103831. [Google Scholar] [CrossRef]

- Lai, J.; Pang, X.; Xiao, Q.; Shi, Y.; Zhang, H.; Zhao, T.; Chen, J.; Wang, G.; Qin, Z. Prediction of Reservoir Quality in Carbonates via Porosity Spectrum from Image Logs. J. Pet. Sci. Eng. 2019, 173, 197–208. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, S.; Cao, J.-T.; Li, M.; Pang, X.; Han, C.; Fan, X.; Yang, L.; He, Z.; et al. A Review on the Applications of Image Logs in Structural Analysis and Sedimentary Characterization. Mar. Pet. Geol. 2018, 95, 139–166. [Google Scholar] [CrossRef]

- Khoshbakht, F.; Memarian, H.; Mohammadnia, M. Comparison of Asmari, Pabdeh and Gurpi Formation’s Fractures, Derived from Image Log. J. Pet. Sci. Eng. 2009, 67, 65–74. [Google Scholar] [CrossRef]

- Nian, T.; Wang, G.; Xiao, C.; Zhou, L.; Deng, L.; Li, R. The in Situ Stress Determination from Borehole Image Logs in the Kuqa Depression. J. Nat. Gas Sci. Eng. 2016, 34, 1077–1084. [Google Scholar] [CrossRef]

- Egbue, O.; Kellogg, J.; Aguirre, H.; Torres, C. Evolution of the Stress and Strain Fields in the Eastern Cordillera, Colombia. J. Struct. Geol. 2014, 58, 8–21. [Google Scholar] [CrossRef]

- Aleardi, M.; Mazzotti, A.; Tognarelli, A.; Ciuffi, S.; Casini, M. Seismic and Well Log Characterization of Fractures for Geothermal Exploration in Hard Rocks. Geophys. J. Int. 2015, 203, 270–283. [Google Scholar] [CrossRef][Green Version]

- Algaifi, H.A.; Alqarni, A.S.; Alyousef, R.; Bakar, S.A.; Ibrahim, M.W.; Shahidan, S.; Ibrahim, M.; Salami, B.A. Mathematical prediction of the compressive strength of bacterial concrete using gene expression programming. Ain Shams Eng. J. 2021, 12, 3629–3639. [Google Scholar] [CrossRef]

- Jafari, S.; Mahini, S.S. Lightweight Concrete Design Using Gene Expression Programing. Constr. Build. Mater. 2017, 139, 93–100. [Google Scholar] [CrossRef]

- Beheshti Aval, S.B.; Ketabdari, H.; Asil Gharebaghi, S. Estimating Shear Strength of Short Rectangular Reinforced Concrete Columns Using Nonlinear Regression and Gene Expression Programming. Structures 2017, 12, 13–23. [Google Scholar] [CrossRef]

- Mahmoodzadeh, A.; Nejati, H.R. An optimized equation based on the gene expression programming method for estimating tunnel construction costs considering a variety of variables and indexes. Appl. Soft Comput. 2023, 147, 110749. [Google Scholar] [CrossRef]

- Zhang, R.; Xue, X.; Deng, C. Investigation of motion characteristics of catastrophic landslide using material point method and gene expression programming. Int. J. Rock Mech. Min. Sci. 2023, 170, 105507. [Google Scholar] [CrossRef]

- Alzara, M.; Rehman, M.F.; Farooq, F.; Ali, M.; Beshr, A.A.; Yosri, A.M.; El Sayed, S.A. Prediction of building energy performance using mathematical gene-expression programming for a selected region of dry-summer climate. Eng. Appl. Artif. Intell. 2023, 126, 106958. [Google Scholar] [CrossRef]

- Taleshi, M.M.; Tajik, N.; Mahmoudian, A.; Yekrangnia, M. Prediction of Pull-out Behavior of Timber Glued-in Glass Fiber Reinforced Polymer and Steel Rods under Various Environmental Conditions Based on ANN and GEP Models. Case Stud. Constr. Mater. 2024, 20, e02842. [Google Scholar] [CrossRef]

- Waqas, H.A.; Bahrami, A.; Sahil, M.; Poshad Khan, A.; Ejaz, A.; Shafique, T.; Tariq, Z.; Ahmad, S.; Özkılıç, Y.O. Performance Prediction of Hybrid Bamboo-Reinforced Concrete Beams Using Gene Expression Programming for Sustainable Construction. Materials 2023, 16, 6788. [Google Scholar] [CrossRef] [PubMed]

- Leon, L.P.; Gay, D. Gene Expression Programming for Evaluation of Aggregate Angularity Effects on Permanent Deformation of Asphalt Mixtures. Constr. Build. Mater. 2019, 211, 470–478. [Google Scholar] [CrossRef]

- Peng, H.; Li, L.; Mei, C.; Deng, C.; Yue, X.; Wu, Z. Gene expression programming with dual strategies and neighborhood search for symbolic regression problems. Appl. Soft Comput. 2023, 145, 110616. [Google Scholar] [CrossRef]

- Zhu, Y.-J.; Nie, X.; Ma, H.; Su, L.-C. Prediction Model for Load Effective Distribution Width of Slab in Composite Box Girders Using Gene Expression Programming. Eng. Struct. 2022, 255, 113930. [Google Scholar] [CrossRef]

- Murad, Y.; Tarawneh, A.; Arar, F.; Al-Zu’bi, A.; Al-Ghwairi, A.; Al-Jaafreh, A.; Tarawneh, M. Flexural Strength Prediction for Concrete Beams Reinforced with FRP Bars Using Gene Expression Programming. Structures 2021, 33, 3163–3172. [Google Scholar] [CrossRef]

- Azimi-Pour, M.; Eskandari-Naddaf, H. ANN and GEP Prediction for Simultaneous Effect of Nano and Micro Silica on the Compressive and Flexural Strength of Cement Mortar. Constr. Build. Mater. 2018, 189, 978–992. [Google Scholar] [CrossRef]

- Shahmansouri, A.A.; Akbarzadeh Bengar, H.; Jahani, E. Predicting Compressive Strength and Electrical Resistivity of Eco-Friendly Concrete Containing Natural Zeolite via GEP Algorithm. Constr. Build. Mater. 2019, 229, 116883. [Google Scholar] [CrossRef]

- Gholampour, A.; Gandomi, A.H.; Ozbakkaloglu, T. New Formulations for Mechanical Properties of Recycled Aggregate Concrete Using Gene Expression Programming. Constr. Build. Mater. 2017, 130, 122–145. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Roke, D.A. Assessment of Artificial Neural Network and Genetic Programming as Predictive Tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Güllü, H. Function Finding via Genetic Expression Programming for Strength and Elastic Properties of Clay Treated with Bottom Ash. Eng. Appl. Artif. Intell. 2014, 35, 143–157. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H.; Gandomi, M.; Kazemi, S. Formulation of Shear Strength of Slender RC Beams Using Gene Expression Programming, Part II: With Shear Reinforcement. Measurement 2017, 95, 367–376. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Liu, Q.; Azim, I.; Zhu, X.; Yang, J.; Javed, M.F.; Rauf, M. Prediction of Mechanical Properties of Green Concrete Incorporating Waste Foundry Sand Based on Gene Expression Programming. J. Hazard. Mater. 2020, 384, 121322. [Google Scholar] [CrossRef] [PubMed]

- Babanajad, S.K.; Gandomi, A.H.; Alavi, A.H. New Prediction Models for Concrete Ultimate Strength under True-Triaxial Stress States: An Evolutionary Approach. Adv. Eng. Softw. 2017, 110, 55–68. [Google Scholar] [CrossRef]

- Ali Khan, M.A.; Zafar, A.; Akbar, A.; Javed, M.F.; Mosavi, A. Application of Gene Expression Programming (GEP) for the Prediction of Compressive Strength of Geopolymer Concrete. Materials 2021, 14, 1106. [Google Scholar] [CrossRef] [PubMed]

- Fisher, R.A. The use of multiple measurements in taxonomic problems. Ann. Eugen. 1936, 7, 179–188. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, G.; Zhao, X.; Zhou, L.; Zhou, S.; Jiang, W.; Wang, Z. Oil-Source Correlation in the Slope of the Qikou Depression in the Bohai Bay Basin with Discriminant Analysis. Mar. Pet. Geol. 2019, 109, 641–657. [Google Scholar] [CrossRef]

- Konaté, A.A.; Pan, H.; Ma, H.; Cao, X.; Yevenyo Ziggah, Y.; Oloo, M.; Khan, N. Application of Dimensionality Reduction Technique to Improve Geophysical Log Data Classification Performance in Crystalline Rocks. J. Pet. Sci. Eng. 2015, 133, 633–645. [Google Scholar] [CrossRef]

- EsMAEl, M.; Bagheri, A.; Navid, S.M.; Mansourian, D.; Ayub, E.; Pedram, N.; Martyushev, D.A. An Efficient and Comprehensive Poroelastic Analysis of Hydrocarbon Systems Using Multiple Data Sets through Laboratory Tests and Geophysical Logs: A Case Study in an Iranian Hydrocarbon Reservoir. Carbonates Evaporites 2023, 38, 37. [Google Scholar] [CrossRef]

- Petrik, A.; Vahle, C.; Gianotten, I.P.; Trøan, L.I.; Rojo, L.; Galbraith, K. Quantitative Characterisation of Fracture Connectivity from High-Resolution Borehole Image Logs. Mar. Pet. Geol. 2023, 155, 106405. [Google Scholar] [CrossRef]

- Khoshbakht, F.; Azizzadeh, M.; Memarian, H.; Nourozi, G.H.; Moallemi, S.A. Comparison of electrical image log with core in a fractured carbonate reservoir. J. Pet. Sci. Eng. 2012, 86, 289–296. [Google Scholar] [CrossRef]

- Camanni, G.; Vinci, F.; Tavani, S.; Ferrandino, V.; Mazzoli, S.; Corradetti, A.; Parente, M.; Iannace, A. Fracture density variations within a reservoir-scale normal fault zone: A case study from shallow-water carbonates of southern Italy. J. Struct. Geol. 2021, 151, 104432. [Google Scholar] [CrossRef]

- Pontes, C.C.; Bezerra, F.H.; Bertotti, G.; La Bruna, V.; Audra, P.; De Waele, J.; Auler, A.S.; Balsamo, F.; De Hoop, S.; Pisani, L. Flow pathways in multiple-direction fold hinges: Implications for fractured and karstified carbonate reservoirs. J. Struct. Geol. 2021, 146, 104324. [Google Scholar] [CrossRef]

- Ammari, A.; Abbes, C.; Abida, H. Geometric properties and scaling laws of the fracture network of the Ypresian carbonate reservoir in central Tunisia: Examples of Jebels Ousselat and Jebil. J. Afr. Earth Sci. 2022, 196, 104718. [Google Scholar] [CrossRef]

| Well (Unit) | GR (API) | K (%) | Th (ppm) | U (ppm) | RD (ohm·m) | RS (ohm·m) | RXO (ohm·m) | D (g/cc) | N (v/v) | S (us/f) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 (n = 92) | Min | 60.97 | 2.19 | 3.08 | 1.98 | 0.06 | 0.06 | 0.07 | 2.49 | 4.17 | 57.83 |

| (2746 m | Max | 122.12 | 4.16 | 10.69 | 4.20 | 0.14 | 0.18 | 0.42 | 2.69 | 15.41 | 65.88 |

| – | Mean | 78.47 | 2.80 | 5.49 | 2.70 | 0.10 | 0.12 | 0.20 | 2.63 | 10.55 | 61.33 |

| 2896.5 m) | SD | 14.50 | 0.41 | 1.79 | 0.64 | 0.02 | 0.03 | 0.09 | 0.05 | 2.40 | 1.94 |

| 10 (n = 114) | Min | 83.90 | 1.85 | 5.79 | 2.33 | 0.10 | 0.08 | 0.10 | 2.59 | 10.00 | 60.31 |

| (2641 m | Max | 176.61 | 3.46 | 15.24 | 5.33 | 0.18 | 0.23 | 0.21 | 2.81 | 19.00 | 68.03 |

| – | Mean | 115.09 | 2.74 | 9.53 | 3.52 | 0.14 | 0.16 | 0.16 | 2.68 | 14.09 | 63.34 |

| 2813 m) | SD | 19.93 | 0.45 | 1.99 | 0.76 | 0.02 | 0.04 | 0.03 | 0.06 | 2.47 | 2.15 |

| 13 (n = 96) | Min | 63.29 | 1.29 | 2.23 | 4.29 | 0.12 | 0.18 | 0.12 | 2.63 | 3.49 | 58.60 |

| (2690 m | Max | 153.39 | 3.95 | 11.38 | 5.59 | 0.30 | 0.44 | 0.33 | 2.89 | 15.48 | 74.44 |

| - | Mean | 104.78 | 2.52 | 5.98 | 4.97 | 0.20 | 0.31 | 0.21 | 2.73 | 10.65 | 66.09 |

| 2769.8 m) | SD | 29.42 | 1.01 | 2.60 | 0.34 | 0.06 | 0.08 | 0.07 | 0.08 | 3.70 | 5.27 |

| All wells (7, 10, 13) | Min | 60.97 | 1.29 | 2.23 | 1.98 | 0.06 | 0.06 | 0.07 | 2.49 | 3.49 | 57.83 |

| Max | 176.61 | 4.16 | 15.24 | 5.59 | 0.30 | 0.44 | 0.42 | 2.89 | 19.00 | 74.44 | |

| Mean | 97.81 | 2.68 | 7.14 | 3.45 | 0.14 | 0.17 | 0.18 | 2.67 | 12.00 | 62.86 | |

| SD | 28.00 | 0.58 | 2.98 | 1.06 | 0.05 | 0.08 | 0.07 | 0.07 | 3.29 | 3.62 |

| Well (Unit) | GR (API) | K (%) | Th (ppm) | U (ppm) | RD (ohm·m) | RS (ohm·m) | RXO (ohm·m) | D (g/cc) | N (v/v) | S (us/f) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 (n = 78) | Min | 45.56 | 2.02 | 2.29 | 1.06 | 0.04 | 0.05 | 0.07 | 2.57 | 6.79 | 54.00 |

| (2896.5 m | Max | 63.22 | 2.75 | 3.47 | 1.90 | 0.13 | 0.16 | 0.55 | 2.67 | 13.45 | 60.35 |

| – | Mean | 55.30 | 2.40 | 3.10 | 1.48 | 0.10 | 0.12 | 0.26 | 2.63 | 10.29 | 57.55 |

| 3080 m) | SD | 4.84 | 0.23 | 0.34 | 0.17 | 0.03 | 0.03 | 0.13 | 0.03 | 1.53 | 1.83 |

| 13 (n = 122) | Min | 89.42 | 2.05 | 2.48 | 4.65 | 0.03 | 0.07 | 0.03 | 2.63 | 1.71 | 53.36 |

| (2769.8 m | Max | 175.25 | 3.95 | 16.64 | 6.30 | 0.14 | 0.34 | 0.18 | 2.86 | 9.97 | 65.14 |

| – | Mean | 116.66 | 2.73 | 6.77 | 5.38 | 0.07 | 0.14 | 0.08 | 2.72 | 4.59 | 57.20 |

| 2955 m) | SD | 17.74 | 0.43 | 3.18 | 0.46 | 0.03 | 0.06 | 0.04 | 0.06 | 2.62 | 2.77 |

| 27 (n = 46) | Min | 75.01 | 2.35 | 4.22 | 1.26 | 0.03 | 0.04 | 0.04 | 2.64 | 7.25 | 56.47 |

| (2885 m | Max | 85.66 | 3.13 | 6.18 | 4.27 | 0.08 | 0.10 | 0.12 | 2.69 | 10.85 | 59.59 |

| - | Mean | 80.07 | 2.77 | 5.16 | 2.13 | 0.06 | 0.07 | 0.08 | 2.66 | 8.44 | 57.96 |

| 2945 m) | SD | 3.62 | 0.23 | 0.70 | 0.95 | 0.01 | 0.02 | 0.03 | 0.02 | 1.16 | 0.86 |

| All wells (7, 13, 27) | Min | 45.56 | 2.02 | 2.29 | 1.06 | 0.03 | 0.04 | 0.03 | 2.57 | 1.71 | 53.36 |

| Max | 156.13 | 3.51 | 14.44 | 6.30 | 0.14 | 0.34 | 0.55 | 2.86 | 13.45 | 65.14 | |

| Mean | 88.23 | 2.57 | 4.99 | 3.55 | 0.08 | 0.12 | 0.14 | 2.68 | 7.10 | 57.29 | |

| SD | 29.07 | 0.33 | 2.15 | 1.96 | 0.03 | 0.05 | 0.13 | 0.06 | 3.36 | 2.38 |

| SG | OG | |||

|---|---|---|---|---|

| Training | Testing | Training | Testing | |

| RMSE | 0.63 | 0.4 | 0.55 | 0.42 |

| MAE | 0.49 | 0.34 | 0.38 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, M.L.; Tóth, T.M. Fracture Density Prediction of Basement Metamorphic Rocks Using Gene Expression Programming. Minerals 2024, 14, 366. https://doi.org/10.3390/min14040366

Hasan ML, Tóth TM. Fracture Density Prediction of Basement Metamorphic Rocks Using Gene Expression Programming. Minerals. 2024; 14(4):366. https://doi.org/10.3390/min14040366

Chicago/Turabian StyleHasan, Muhammad Luqman, and Tivadar M. Tóth. 2024. "Fracture Density Prediction of Basement Metamorphic Rocks Using Gene Expression Programming" Minerals 14, no. 4: 366. https://doi.org/10.3390/min14040366

APA StyleHasan, M. L., & Tóth, T. M. (2024). Fracture Density Prediction of Basement Metamorphic Rocks Using Gene Expression Programming. Minerals, 14(4), 366. https://doi.org/10.3390/min14040366