Assessment of Gravity Deportment of Gold-Bearing Ores: Gravity Recoverable Gold Test

Abstract

1. Introduction

2. Materials and Methods

2.1. Location: Zlaté Hory–Západ in the Czech Republic

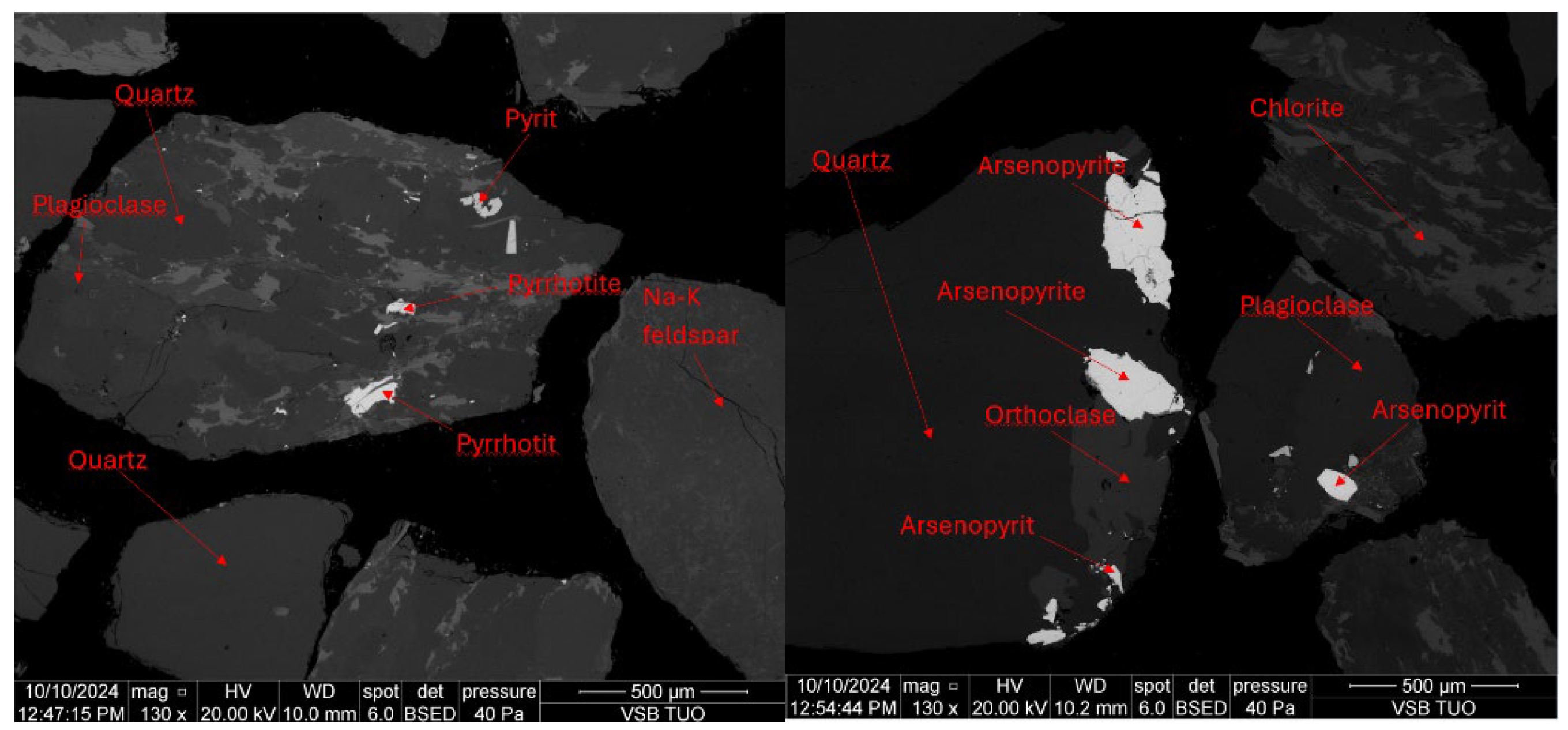

2.2. Location: Kašperské Hory in the Czech Republic

2.3. XRD Difraction

2.4. AAS

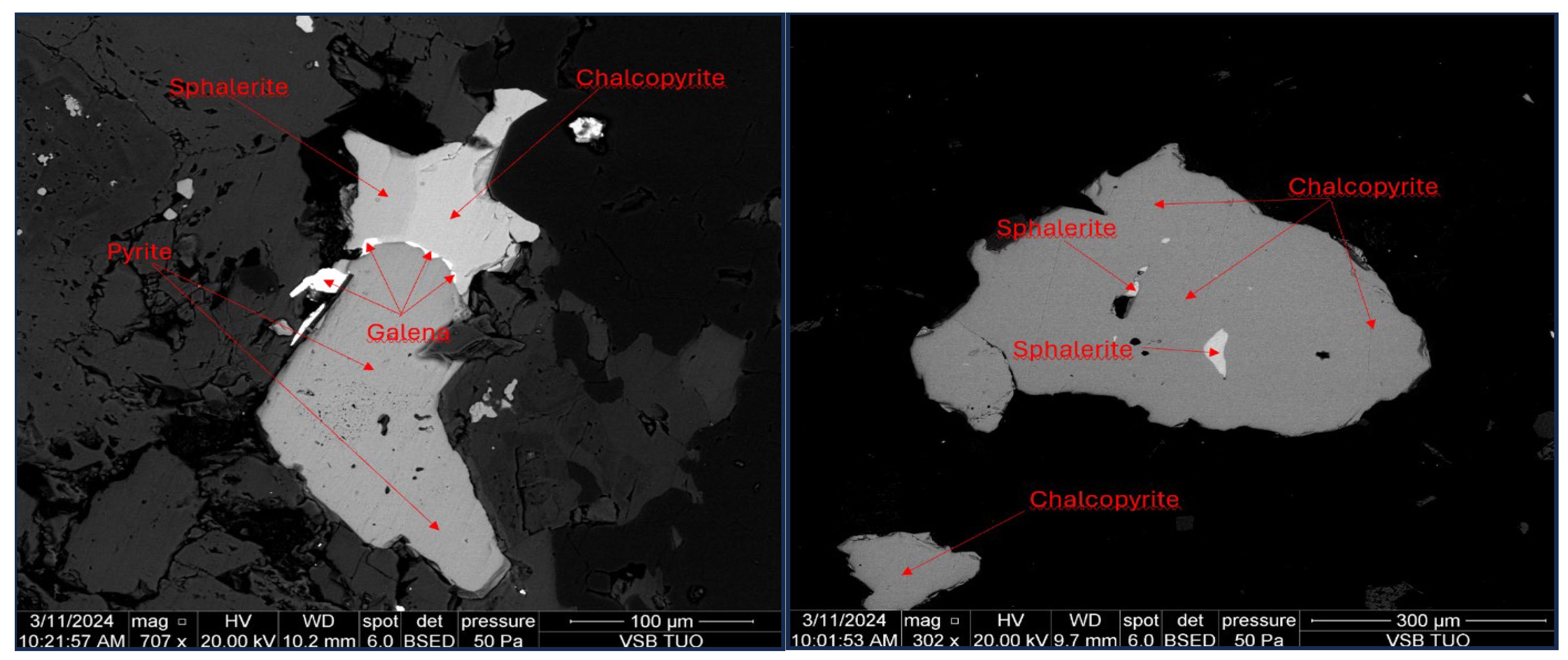

2.5. SEM Microscopy and Microanalysis

2.6. GRG Test

- First Step: Sample Preparation

- Second Step

- Third Step

3. Results

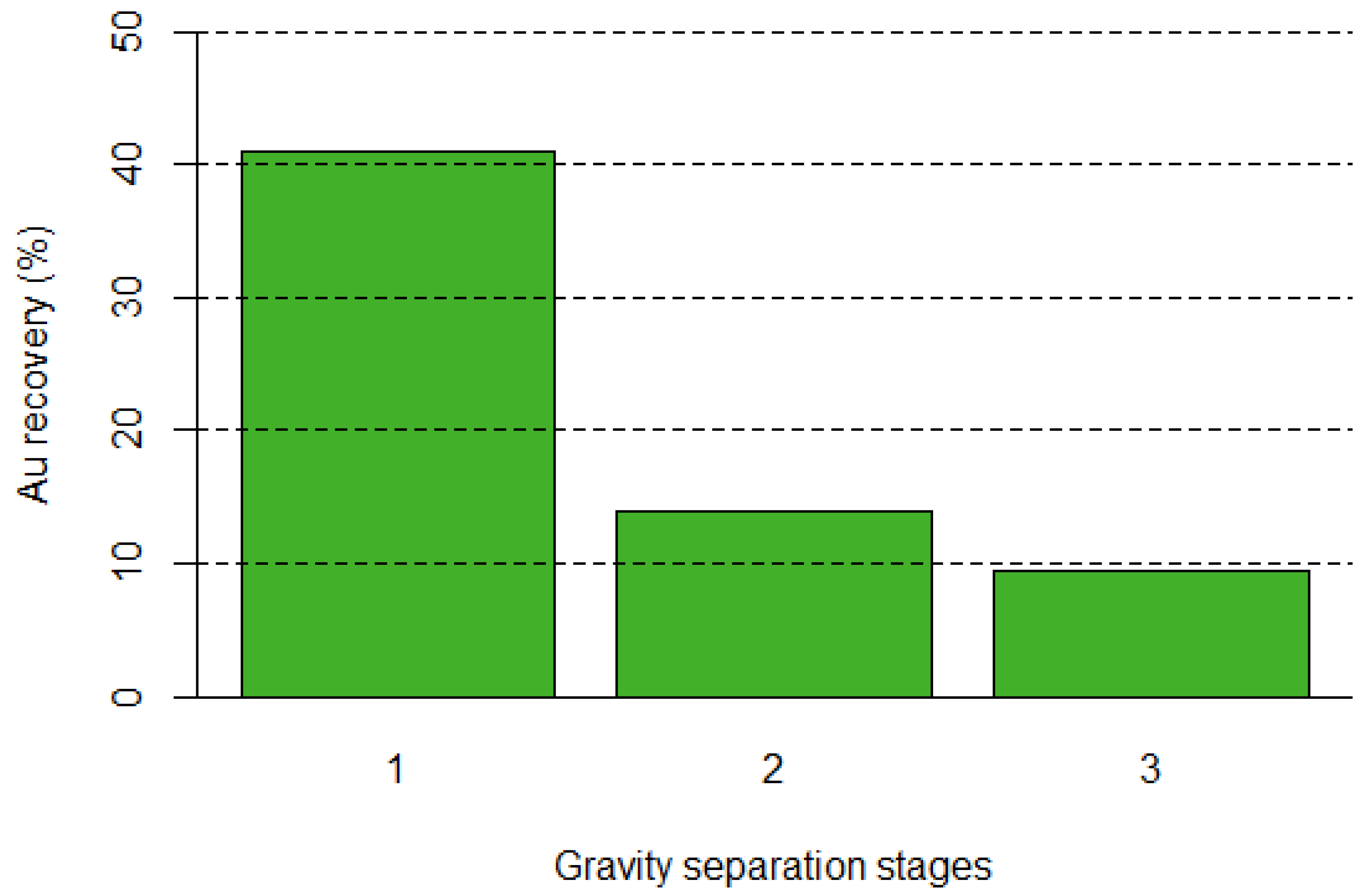

3.1. Sample from Kašperské Hory

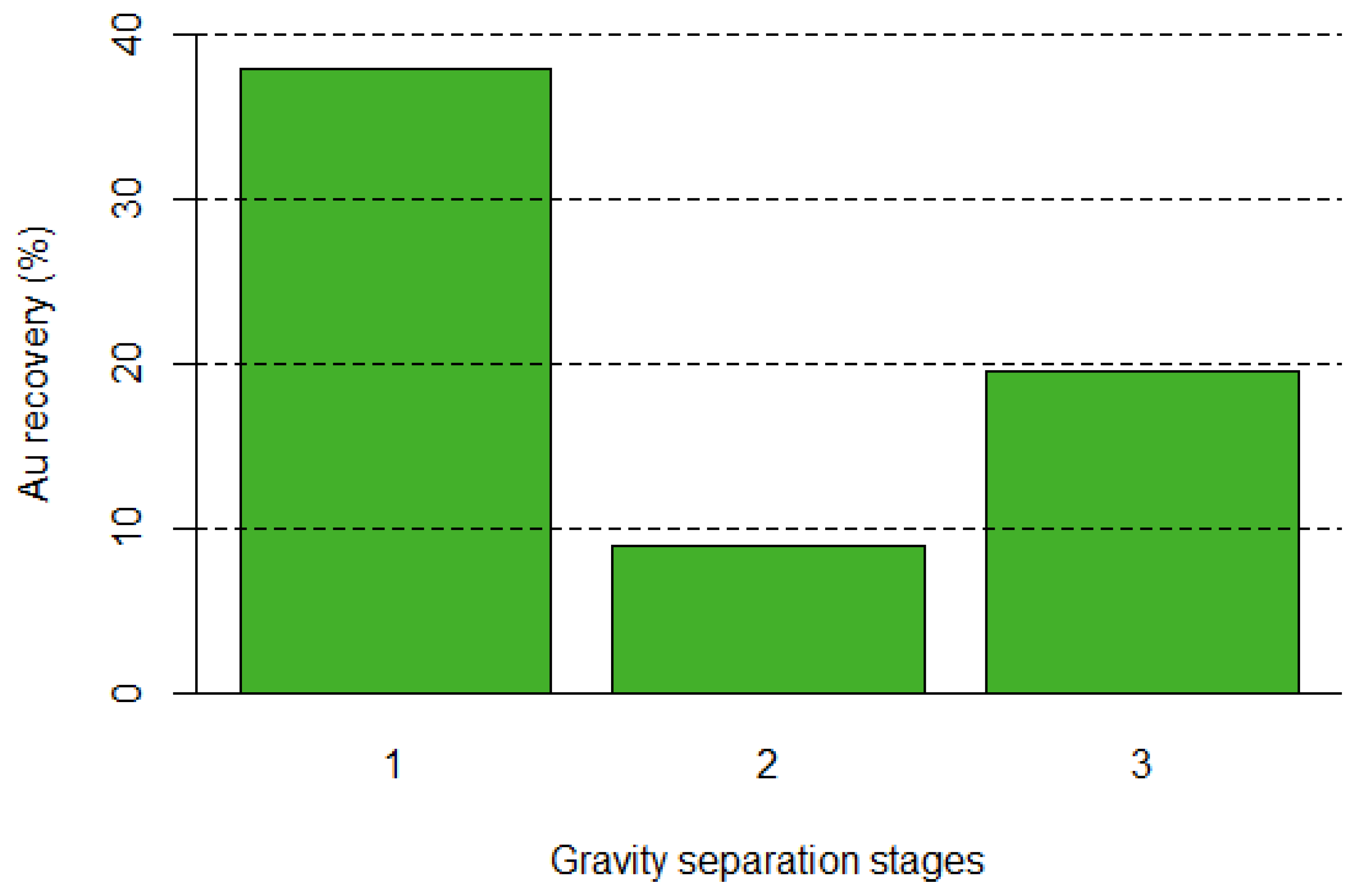

3.2. Sample from Zlaté Hory—Západ

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Petrova, V. Exploring the Opportunities for Sustainable Management of Critical Raw Materials in the Circular Economy. Eurasia Proc. Sci. Technol. Eng. Math. 2023, 26, 664–671. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, H.L.; Ma, L.W.; Li, Z. An Evaluation of Critical Raw Materials for China. Adv. Mater. Res. 2013, 773, 954–960. [Google Scholar] [CrossRef]

- Li, H.; Xiao, W.; Jin, J.; Han, Y. Oxidation Roasting of Fine-Grained Carbonaceous Gold Ore: The Effect of Aeration Rate. Minerals 2021, 11, 558. [Google Scholar] [CrossRef]

- Richmond, K.A.; Zanin, M.; Gascooke, J.; Skinner, W.; Addai-Mensah, J. Refractory Gold Ores and Concentrates Part 1: Mineralogical and Physico-Chemical Characteristics. Miner. Process. Extr. Metall. 2021, 130, 240–252. [Google Scholar] [CrossRef]

- Hool, A.; Helbig, C.; Wierink, G. Challenges and Opportunities of the European Critical Raw Materials Act. Min. Econ. 2024, 37, 661–668. [Google Scholar] [CrossRef]

- Tomala, J.; Urbaniec, M. Towards Sustainable Development in the European Union: A Critical Raw Materials Perspective. Econ. Environ. 2024, 88, 654. [Google Scholar] [CrossRef]

- Pommeret, A.; Ricci, F.; Schubert, K. Critical Raw Materials for the Energy Transition. Eur. Econ. Rev. 2022, 141, 103991. [Google Scholar] [CrossRef]

- Tkaczyk, A.H.; Bartl, A.; Amato, A.; Lapkovskis, V.; Petranikova, M. Sustainability Evaluation of Essential Critical Raw Materials: Cobalt, Niobium, Tungsten and Rare Earth Elements. J. Phys. D Appl. Phys. 2018, 51, 203001. [Google Scholar] [CrossRef]

- Chryssoulis, S.L.; McMullen, J. Mineralogical Investigation of Gold Ores. In Developments in Mineral Processing; Adams, M.D., Wills, B.A., Eds.; Advances in Gold Ore Processing; Elsevier: Amsterdam, The Netherlands, 2005; Volume 15, pp. 21–71. [Google Scholar]

- Zhou, M.; Kokkilic, O.; Langlois, R.; Waters, K. A Preliminary Investigation of Dry Gravity Separation with Low Specific Gravity Ores Using a Laboratory Knelson Concentrator. Physicochem. Probl. Miner. Process. 2023, 59, 165992. [Google Scholar] [CrossRef]

- Subasinghe, G.K.N. Performance Curve Approach to Optimising Fluidising Water for Knelson Concentrators. Miner. Process. Extr. Metall. 2012, 121, 205–210. [Google Scholar] [CrossRef]

- Laplante, A.; Gray, S. Advances in Gravity Gold Technology. In Developments in Mineral Processing; Adams, M.D., Wills, B.A., Eds.; Advances in Gold Ore Processing; Elsevier: Amsterdam, The Netherlands, 2005; Volume 15, pp. 280–307. [Google Scholar]

- Munganyinka, J.P.; Habinshuti, J.B.; Ndayishimiye, J.C.; Mweene, L.; Ofori-Sarpong, G.; Mishra, B.; Adetunji, A.R.; Tanvar, H. Potential Uses of Artisanal Gold Mine Tailings, with an Emphasis on the Role of Centrifugal Separation Technique. Sustainability 2022, 14, 8130. [Google Scholar] [CrossRef]

- Roostaei, H.; Kordparijaei, M.; Mesroghli, S. Iron Oxide Gold-Bearing Ore Processing Based on Ore Characterization: Gravity Pre-Concentration and Cyanide Dissolution. Preprint 2023. [Google Scholar]

- Lins, F.F.; Veiga, M.M.; Stewart, J.A.; Papalia, A.; Papalia, R. Performance of a new centrifuge (Falcon) in concentrating a gold ore from texada island, B.C., Canada. Miner. Eng. 1992, 5, 1113–1121. [Google Scholar] [CrossRef]

- Burt, R. The Role of Gravity Concentration in Modern Processing Plants. Miner. Eng. 1999, 12, 1291–1300. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, H.; Tong, L.; Niu, H.; Zhang, F.; Chen, G. Research and Application of a Knelson Concentrator: A Review. Miner. Eng. 2020, 152, 106339. [Google Scholar] [CrossRef]

- Veiga, M.; Gunson, A.J. Gravity Concentration in Artisanal Gold Mining. Minerals 2020, 10, 1026. [Google Scholar] [CrossRef]

- Sakuhuni, G.; Altun, N.E.; Klein, B.; Tong, L. A Novel Laboratory Procedure for Predicting Continuous Centrifugal Gravity Concentration Applications: The Gravity Release Analysis. Int. J. Miner. Process. 2016, 154, 66–74. [Google Scholar] [CrossRef]

- Rouchalova, D.; Rouchalova, K.; Janakova, I.; Cablik, V.; Janstova, S. Bioleaching of Iron, Copper, Lead, and Zinc from the Sludge Mining Sediment at Different Particle Sizes, pH, and Pulp Density Using Acidithiobacillus Ferrooxidans. Minerals 2020, 10, 1013. [Google Scholar] [CrossRef]

- Kovarikova, H.; Janakova, I.; Cablik, V.; Vrlikova, V. Bacterial Leaching of Polymetallic Ores from Zlatý Chlum Locality. Inżynieria Miner. 2019, 21, 145–148. [Google Scholar]

- Ghaffari, A.; Farzanegan, A. An Investigation on Laboratory Knelson Concentrator Separation Performance: Part 1: Retained Mass Modelling. Miner. Eng. 2017, 112, 57–67. [Google Scholar] [CrossRef]

- Surimbayev, B.; Bolotova, L.; Mishra, B.; Baikonurova, A. Intensive Cyanidation of Gold From Gravity Concentrates in a Drum-Type Apparatus. News Natl. Acad. Sci. Repub. Kazakhsta 2018, 431, 32–37. [Google Scholar] [CrossRef]

- Fedotov, P.S.; Fedotov, K.V.; Burdonov, A.E.; Senchenko, A.E. A Study of Gold Ore for Processability by Gravity Separation Techniques. Ore Met. 2021, 2, 8–16. [Google Scholar] [CrossRef]

- Oediyani, S.; Triana, T.; Ifzan, I.; Mamby, H.E. Centrifugal Concentration of Mandailing Natal North Sumatera Gold Ores Using Knelson Concentrator. World Chem. Eng. J. 2021, 5, 44–49. [Google Scholar] [CrossRef]

- Surimbayev, B.N.; Kanaly, E.S.; Bolotova, L.S.; Shalgymbayev, S.T. Assessment of Gravity Dressability of Gold Ore—GRG Test. Gorn. Nauk. I Tekhnologii = Min. Sci. Technol. 2020, 5, 92–103. [Google Scholar] [CrossRef]

- Zhou, M.; Paris, J.; Kökkılıç, O.; Langlois, R.; Waters, K.E. An Investigation into the Dry Processing of Low Specific Gravity Ores Using a Laboratory Knelson Concentrator. Can. Metall. Q. (Can. J. Metall. Mater. Sci.) 2024, 63, 508–529. [Google Scholar] [CrossRef]

- Fullam, M.; Watson, B.; Laplante, A.; Gray, S. Chapter 19—Advances in Gravity Gold Technology. In Gold Ore Processing, 2nd ed.; Adams, M.D., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 301–314. ISBN 978-0-444-63658-4. [Google Scholar]

- Koppalkar, S.; Bouajila, A.; Gagnon, C.; Noel, G. Understanding the Discrepancy between Prediction and Plant GRG Recovery for Improving the Gold Gravity Performance. Miner. Eng. 2011, 24, 559–564. [Google Scholar] [CrossRef]

- Myrzaliev, B.M.; Nogaeva, K.A.; Molmakova, M.S. Determination of Jamgyr Deposit Ore Gravity Concentration Feasibility. Ipolytech J. 2018, 22, 153–165. [Google Scholar] [CrossRef]

- Vávra, V. Největší Rudní Revír Zlata a Polymetalických Rud Na Moravě (Translate: The Largest Ore District of Gold and Polymetallic Ores in Moravia). Available online: http://pruvodce.geol.morava.sci.muni.cz/zlate_hory/taborske_skaly.html (accessed on 7 August 2024).

- Zelinger, O.; Grygárek, J. RD Jeseník 1958–1998; REP Tisk: Jeseník, Czech Republic, 1998; Translate Jeseník Ore District. [Google Scholar]

- Litochleb, J.; Sejkora, J.; Šrein, V.; Malec, J. Kašperskohorské Zlato (Šumava, Česká Republika). Bull. Miner.-Petrol. Odd. Nár. Muz. (Praha) 2009, 17, 1–13, Translate: Gold in the Kasperske Hory Mountain. [Google Scholar]

- Knelson. KC-MD3 User Manual Rev. 4.0. Scribd. 2017. Available online: https://www.scribd.com/document/615133333 (accessed on 7 August 2024).

- Mkandawire, N.P.; McGrath, T.; Bax, A.; Eksteen, J. Potential of the Dense Media Cyclone for Gold Ore Preconcentration. Miner. Process. Extr. Metall. 2020, 129, 87–95. [Google Scholar] [CrossRef]

- Marion, C.; Langlois, R.; Kökkılıç, O.; Zhou, M.; Williams, H.; Awais, M.; Rowson, N.A.; Waters, K.E. A Design of Experiments Investigation into the Processing of Fine Low Specific Gravity Minerals Using a Laboratory Knelson Concentrator. Miner. Eng. 2019, 135, 139–155. [Google Scholar] [CrossRef]

- Toktar, G.; Magomedov, D.R.; Koizhanova, A.K.; Abdyldaev, N.N.; Bakraeva, A.N. Extraction of Gold from Low-Sulfide Gold-Bearing Ores by Beneficiating Method Using a Pressure Generator for Pulp Microaeration. Kompleks. Ispolz. Miner. Syra = Complex Use Miner. Resour. 2023, 325, 62–71. [Google Scholar] [CrossRef]

- Sen, S. Gold Recovery by KC from Grinding Circuit of Bergama CIP Plant. Rem Rev. Esc. Minas 2010, 63, 539–545. [Google Scholar] [CrossRef]

- Wang, X.; Qin, W.; Jiao, F.; Yang, C.; Cui, Y.; Li, W.; Zhang, Z.; Song, H. Mineralogy and Pretreatment of a Refractory Gold Deposit in Zambia. Minerals 2019, 9, 406. [Google Scholar] [CrossRef]

- Win Tun, N.; Godirilwe, L.L.; Batnasan, A.; Haga, K.; Shibayama, A. Process Development for Gold Concentrate Recovery by Multi-Stage Flotation Using Optimized Conditions. Int. J. Soc. Mater. Eng. Resour. 2022, 25, 235–242. [Google Scholar] [CrossRef]

- Liu, Q.J.; Deng, R.D.; Yang, J.L. Using Plain Chute to Recovery Gold from Leaching Residue. Adv. Mater. Res. 2012, 530, 3–8. [Google Scholar] [CrossRef]

| Input Particle Size [µm] | Feed Rate [g/min] | Fluidization Flow Rate of Water [L/min] | |

|---|---|---|---|

| Step 1 | 90%–100% < 850 | 800–1000 | 3.5 |

| Step 2 | 45%–60% < 75 | 600–900 | 3.5 |

| Step 3 | 75%–80% < 75 | 400–600 | 3.5 |

| Mineral | Content [%] | Element | Content [g/t] |

|---|---|---|---|

| Quartz | 56.14 | Gold | 2.9 |

| Chlorite | 19.63 | ||

| Albite | 17.88 |

| Product | Weight | Assay | Recovery | |

|---|---|---|---|---|

| [g] | [%] | Au [g/t] | Au [%] | |

| Pan concentrate 1 | 200.0 | 1.1 | 59.0 | 15.75 |

| Pan tail 1 | 3766.0 | 19.9 | 5.0 | 25.14 |

| KC-MD3 concentrate 1 | 3966.0 | 21.0 | 7.7 | 40.89 |

| Pan concentrate 2 | 8.2 | 0.04 | 151.0 | 1.65 |

| Pan tail 2 | 1022.0 | 5.4 | 9.0 | 12.28 |

| KC-MD3 concentrate 2 | 1030.2 | 5.44 | 10.1 | 13.93 |

| Pan concentrate 3 | 6.5 | 0.03 | 46.0 | 0.39 |

| Pan tail 3 | 480.0 | 2.5 | 14.0 | 8.97 |

| KC-MD3 concentrate 3 | 486.5 | 2.5 | 14.4 | 9.37 |

| Total KC-MD3 concentrate 3 | 5482.7 | 29.0 | 8.7 | 64.21 |

| KC-MD3 tails | 13,404.0 | 71.0 | 2.0 | 35.79 |

| Calculated head | 18,886.7 | 100.0 | 3.9 | 100.00 |

| Assayed head | 2.9 | |||

| Mineral | Content [%] | Element | Content [g/t] |

|---|---|---|---|

| Pyrite | 2.13 | Gold | 59.0 |

| Chlorite | 0.54 | ||

| Quartz | 56.42 | ||

| Muscovite | 7.33 | ||

| Albite | 17.14 | ||

| Scheelite | 0.38 | ||

| Arsenopyrite | 10.50 | ||

| Biotite | 5.57 |

| Mineral | Content [%] | Element | Content [g/t] |

|---|---|---|---|

| Quartz | 60.93 | Gold | 6.0 |

| Chlorite | 13.26 | ||

| Dolomite | 7.74 | ||

| Pyrite | 6.45 | ||

| Albite | 5.21 | ||

| Chalcopyrite | 2.16 | ||

| Calcite | 2.14 | ||

| Muscovite | 2.11 |

| Product | Weight | Assay | Recovery | |

|---|---|---|---|---|

| [g] | [%] | Au [g/t] | Au [%] | |

| Pan concentrate 1 | 148.8 | 0.8 | 152.5 | 25.78 |

| Pan tail 1 | 1179.2 | 6.2 | 9.0 | 12.06 |

| KC-MD3 concentrate 1 | 1328.0 | 6.9 | 25.1 | 37.84 |

| Pan concentrate 2 | 345.0 | 1.8 | 11.0 | 4.31 |

| Pan tail 2 | 1017.6 | 5.3 | 4.0 | 4.62 |

| KC-MD3 concentrate 2 | 1362.6 | 7.1 | 5.8 | 8.93 |

| Pan concentrate 3 | 399.2 | 2.1 | 35.0 | 15.87 |

| Pan tail 3 | 1065.8 | 5.6 | 3.0 | 3.63 |

| KC-MD3 concentrate 3 | 1465.0 | 7.7 | 11.7 | 19.51 |

| Total KC-MD3 concentrate 3 | 4155.6 | 21.9 | 14.2 | 66.28 |

| KC-MD3 tails | 14,826.0 | 78.1 | 2.0 | 33.72 |

| Calculated head | 18,981.6 | 100.0 | 4.6 | 100.00 |

| Assayed head | 6.0 | |||

| Mineral | Content [%] | Element | Content [g/t] |

|---|---|---|---|

| Quartz | 16.88 | Gold | 152.5 |

| Chlorite | 0.18 | ||

| Dolomite | 9.53 | ||

| Pyrite | 67.93 | ||

| Calcite | 5.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šigut, O.; Široký, T.; Janáková, I.; Střelecký, R.; Čablík, V. Assessment of Gravity Deportment of Gold-Bearing Ores: Gravity Recoverable Gold Test. Minerals 2024, 14, 1279. https://doi.org/10.3390/min14121279

Šigut O, Široký T, Janáková I, Střelecký R, Čablík V. Assessment of Gravity Deportment of Gold-Bearing Ores: Gravity Recoverable Gold Test. Minerals. 2024; 14(12):1279. https://doi.org/10.3390/min14121279

Chicago/Turabian StyleŠigut, Oldřich, Tomáš Široký, Iva Janáková, Radek Střelecký, and Vladimír Čablík. 2024. "Assessment of Gravity Deportment of Gold-Bearing Ores: Gravity Recoverable Gold Test" Minerals 14, no. 12: 1279. https://doi.org/10.3390/min14121279

APA StyleŠigut, O., Široký, T., Janáková, I., Střelecký, R., & Čablík, V. (2024). Assessment of Gravity Deportment of Gold-Bearing Ores: Gravity Recoverable Gold Test. Minerals, 14(12), 1279. https://doi.org/10.3390/min14121279