Process Mineralogy Characteristics of Lijiagou Pegmatite Spodumene Deposit, Sichuan, China

Abstract

:1. Introduction

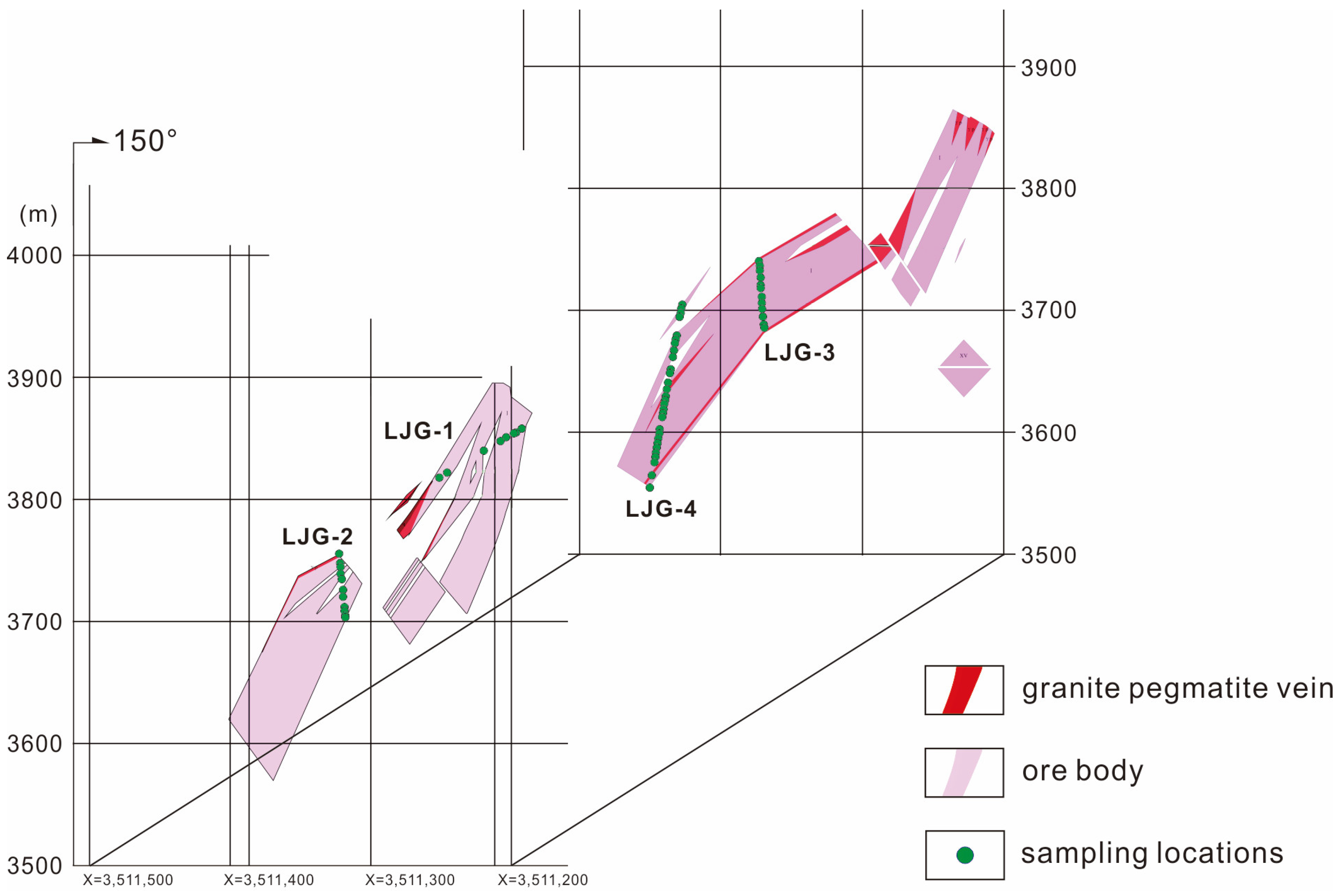

2. Geological Background

3. Sampling and Analytical Methods

3.1. Sample

3.2. Whole-Rock Analyses

3.3. Mineralogical Analyses

4. Results

4.1. Ore Material Composition

4.1.1. Chemical Composition

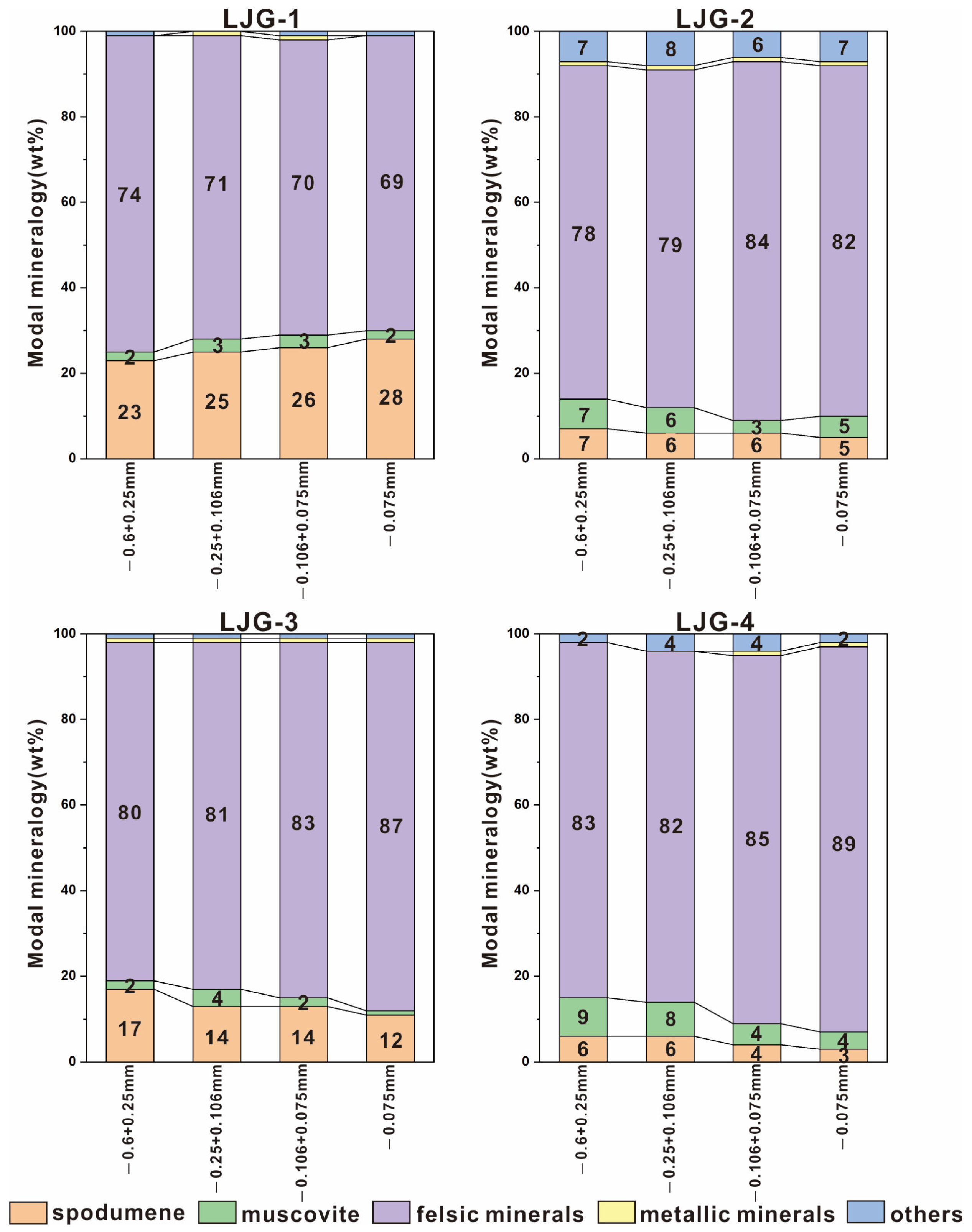

4.1.2. Mineralogical Composition

4.2. Elements Occurrence

4.3. Spodumene Mineral-Processing Properties

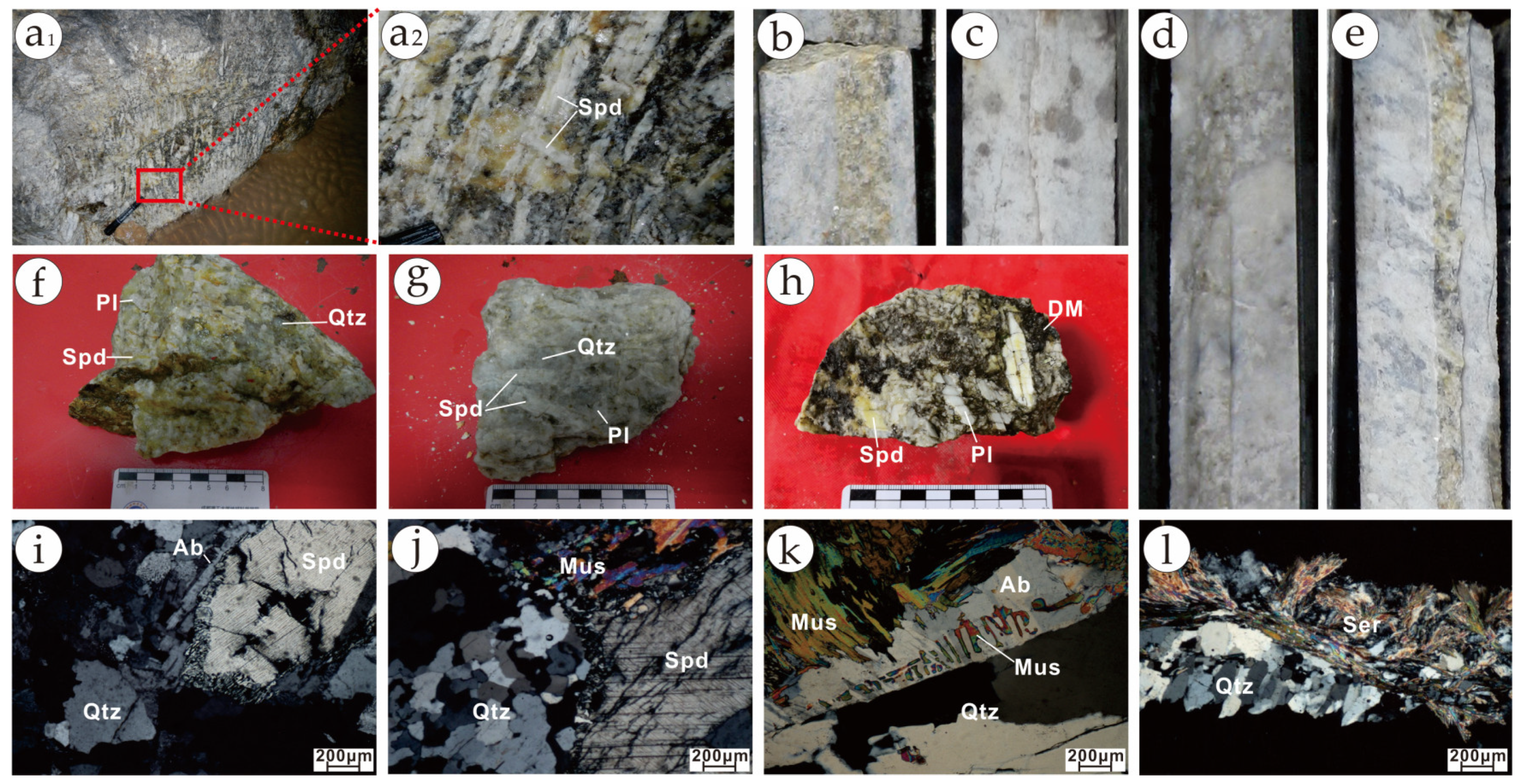

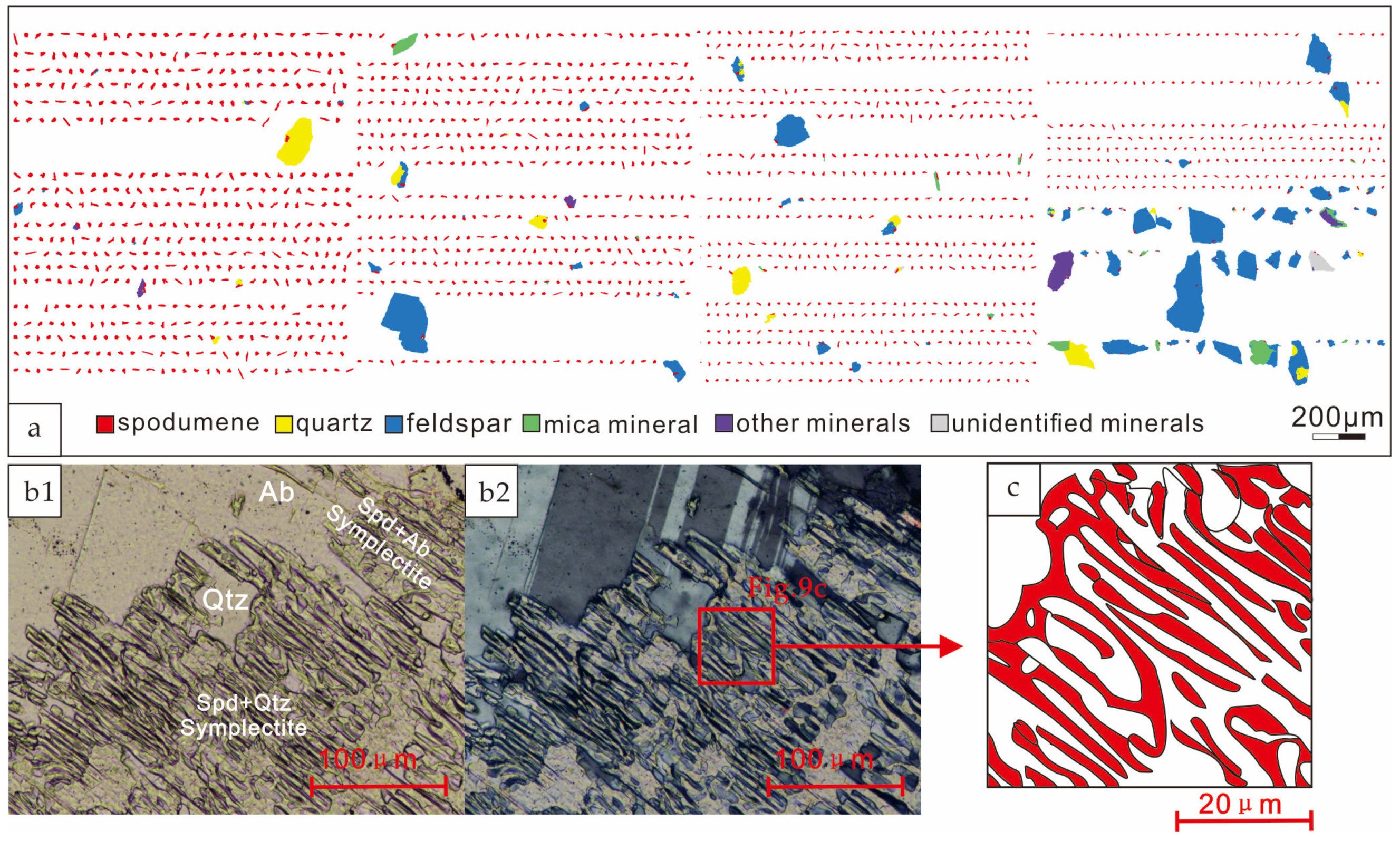

4.3.1. Texture and Interlink Characteristic of Spodumene

4.3.2. Chemical Composition of Spodumene

4.3.3. Particle Size Distribution

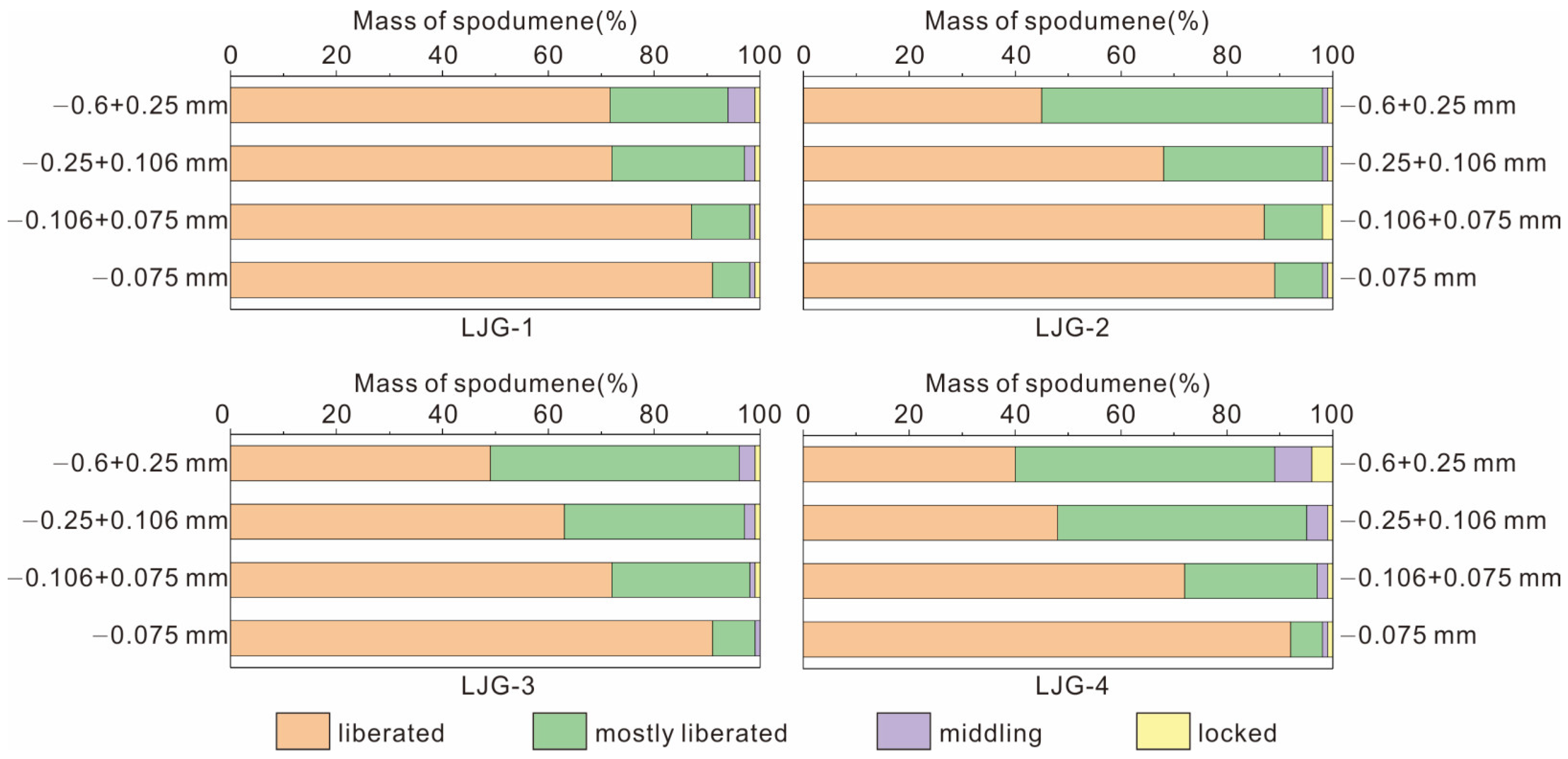

4.3.4. Spodumene Liberation

5. Discussion

6. Conclusions

- (1)

- Ljiagou spodumene deposit lithium ore grade is 0.86%, which is considered low-grade lithium ore. The theoretical grade of lithium concentrate is 6.4%.

- (2)

- Recovering Li from symplectitic spodumene–quartz intergrowths is hampered by considerable difficulties, as it is prone to being entrained in the tailings during the separation process.

- (3)

- The process characteristics of the ore are controlled by elevation and, overall, exhibit a heterogeneous nature. It is recommended to employ a multi-stage grinding and multi-stage beneficiation process, while also incorporating a desliming step. It is best to maintain the particle size of the first-stage grinding at around 0.15 mm, and, prior to entering the final flotation process, the material should be ground to a size of less than 0.075 mm.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. Geological Survey. Mineral Commodity Summaries 2022; U.S. Geological Survey: Reston, VA, USA, 2022; 202p. [Google Scholar]

- Wang, Q.S.; Yuan, C.H.; Xu, H. The global supply situation of lithium ore and suggestions on resources security in China. China Min. Mag. 2015, 24, 10–17, (In Chinese with English abstract). [Google Scholar]

- Sociedad Quimicay Minera de Chile S. A. 2017 Annual Report. Available online: http://www.sqm.com/aspx/Investor (accessed on 31 December 2017).

- Wang, D.H.; Liu, L.J.; Dai, H.Z.; Liu, S.B.; Hou, J.L.; Wu, X.S. Discussion on particularity and prospecting direction of large and super-large spodumene deposits. J. Earth Sci. 2017, 42, 2243–2257. [Google Scholar]

- Dai, H.Z.; Wang, D.H.; Liu, L.J.; Yu, Y.; Dai, J.J. Geochronology and geochemistry of Li(Be)-bearing granitic pegmatites from the Jiajika superlarge Li-polymetallic deposit in western Sichuan, China. J. Earth Sci. 2019, 30, 707–727. [Google Scholar] [CrossRef]

- Jirestig, J.A.; Forssberg, K.S.E. Magnetic separation in sulfide processing. Min. Metall. Explor. 1993, 10, 176–181. [Google Scholar] [CrossRef]

- Jirestig, J.A.; Forssberg, K.S.E. Dispersion of flotation concentrates before magnetic separation. Miner. Eng. 1994, 7, 1505–1516. [Google Scholar] [CrossRef]

- Amarante, M.M.; De Sousa, A.B.; Leite, M.M. Processing a spodumene ore to obtain lithium concentrates for addition to glass and ceramic bodies. Miner. Eng. 1999, 12, 433–436. [Google Scholar] [CrossRef]

- Li, C.X.; Wang, G.X.; Wang, C.L.; Dai, X.Y.; Rao, X.Y. Experimental research on comprehensive utilization of a multi-metallic ore containing lithium in Sichuan Province. Multipurp. Util. Miner. Resour. 2008, 6, 3–6, (In Chinese with English abstract). [Google Scholar]

- Li, C.X.; Cheng, R.J.; Liu, X. Research status and prospects of spodumene ore beneficiation technology in China. Multipurp. Util. Miner. Resour. 2021, 5, 1–8, (In Chinese with English abstract). [Google Scholar]

- Marino, S.L. The Flotation of Marginal Gibbsitic Bauxite Ores from Paragominas-Brazil. Ph.D. Thesis, University of Utah, Salt Lake City, UT, USA, 2012. [Google Scholar]

- Xu, L.; Hu, Y.; Jia, T.; Wu, H.Q.; Yang, X.H.; Zeng, X.B.; Wang, Z.; Wang, J.M. Selective flotation separation of spodumene from feldspar using new mixed anionic/cationic collectors. Miner. Eng. 2016, 89, 84–92. [Google Scholar] [CrossRef]

- Wang, D.H.; Huang, F.; Wang, Y.; He, H.H.; Li, X.M.; Liu, X.X.; Sheng, J.F.; Liang, T. Regional metallogeny of tungsten-tin-polymetallic deposits in Nanling region, south China. Ore Geol. Rev. 2020, 120, 103305. [Google Scholar] [CrossRef]

- Li, J.K.; Wang, D.H.; Fu, X.F. 40Ar/39Ar ages of the Ke’eryin pegmatite type rare metal deposit, Western Sichuan, and its tectonic significances. Acta Geol. Sin. 2006, 80, 843–848, (In Chinese with English abstract). [Google Scholar]

- Deng, Y.; Fei, G.C.; Li, J.; Tang, W.C.; Zhong, W.; Yang, G.B. Study of C-H-O isotopes and geochronology of the Lijiagou pegmatite spodumene deposit in Sichuan Province. J. Mineral. Petrol. 2018, 38, 40–47, (In Chinese with English abstract). [Google Scholar]

- Fei, G.C.; Menuge, J.F.; Li, Y.Q.; Yang, J.Y.; Deng, Y.; Chen, C.S.; Yang, Y.F.; Yang, Z.; Qin, L.Y.; Zheng, L.; et al. Petrogenesis of the Lijiagou spodumene pegmatites in Songpan-garze fold belt, west Sichuan, China: Evidence from geochemistry, zircon, cassiterite and coltan U-Pb geochronology and Hf isotopic compositions. Lithos 2020, 364, 105555. [Google Scholar] [CrossRef]

- Xu, J.B.; Fei, G.C.; Qin, L.Y.; Yang, J.Y.; Zheng, L.; Tang, W.C. LA-MC-ICP-MS U-Pb dating of cassiterite from the Lijiagou pegmatite-type rare-metal deposit in the Ke’eryin orefield, Sichuan province and its geological implication. Geol. Explor. 2020, 56, 346–358, (In Chinese with English abstract). [Google Scholar]

- Dittrich, T.; Seifert, T.; Schulz, B.; Hagemann, S.; Gerdes, A.; Pfänder, J. Archean Rare-Metal Pegmatites in Zimbabwe and Western Australia: Geology and Metallogeny of Pollucite Mineralisations; Springer: Berlin/Heidelberg, Germany, 2019; 125p. [Google Scholar] [CrossRef]

- Fei, G.C.; Li, B.; Yang, J. Geology, Fluid Inclusion Characteristics and H-O-C Isotopes of Large Lijiagou pegmatite spodumene deposit in Songpan-Garze fold belt, Eastern Tibet: Implications for ore Genesis. Resour. Geol. 2018, 68, 37–50. [Google Scholar] [CrossRef]

- Schulz, B.; Sandmann, D.; Gilbricht, S. Sem-based automated mineralogy and its application in geo-and material sciences. Minerals 2020, 10, 1004. [Google Scholar] [CrossRef]

- Yun, H.; Fei, G.C.; Zhu, H.P.; Tan, H.; Cai, Y.H.; Li, Y.G.; Chen, X.J.; Zhao, W.H.; Chen, Z.P.; Luo, X.L.; et al. Study on process mineralogy and occurrence state of lithium from No.VI vein of Dangba spodumene ore in Sichuan Province. Acta Petrol. Mineral. 2023, 42, 407–416, (In Chinese with English abstract). [Google Scholar]

- Xu, Y.; Yu, X.H.; Zhou, X. Study on process mineralogy of pegmatite-type rare metal Yelonggou deposit in Ke’eryin area of western Sichuan Province. China Min. Mag. 2019, 28, 129–135, (In Chinese with English abstract). [Google Scholar]

- Bates, R.L.; Jackson, J.A. Glossary of Geology; American Geological Institute: Alexandria, VA, USA, 1975; 788p. [Google Scholar]

- Aylmore, G.; Merigot, K.; Quadir, Z.; Rickard, A.; Evans, J.; Mcdonald, J.; Catovic, E.; Spitalny, P. Applications of advanced analytical and mass spectrometry techniques to the characterisation of micaceous lithium-bearing ores. Miner. Eng. 2018, 116, 182–195. [Google Scholar] [CrossRef]

- Charoy, B.; Lhote, F.; Dusausoy, Y. The crystal chemistry of spodumene in some granitic aplite-pegmatite of Northern Portugal. Can. Mineral. 1992, 30, 639–665. [Google Scholar]

- Cerny, P.; Ferguson, R.B. The Tanco Pegmatite at Bernic Lake, Manitoba; IV, Petalite and spodumene relations. Can. Mineral. 1972, 11, 660–678. [Google Scholar]

- Wang, P. Systematic Mineralogy; Geological Publishing House: Beijing, China, 1984; p. 316, (In Chinese with English abstract). [Google Scholar]

- Xu, H.L.; Tian, J.; Wu, H.Q.; Deng, W.; Yi, F.C.; Dong, F.Q. Experimental study on strengthening flotation and comprehensive utilization of pegmatite spodumene ore. Non-Met. Mines 2017, 4, 16–19, (In Chinese with English abstract). [Google Scholar]

| Compositions | LJG-1 | LJG-2 | LJG-3 | LJG-4 | |

|---|---|---|---|---|---|

| TFe | wt% | 0.31 | 1.33 | 0.52 | 0.9 |

| SiO2 | wt% | 76.86 | 69.18 | 74.28 | 71.69 |

| Al2O3 | wt% | 14.42 | 17.42 | 14.83 | 15.87 |

| Na2O | wt% | 3.02 | 3.72 | 3.90 | 4.46 |

| K2O | wt% | 0.70 | 3.11 | 3.26 | 2.60 |

| MgO | wt% | 0.02 | 0.58 | 0.01 | 0.30 |

| CaO | wt% | 0.15 | 0.43 | 0.14 | 0.60 |

| MnO | wt% | 0.07 | 0.09 | 0.31 | 0.12 |

| TiO2 | wt% | 0.03 | 0.25 | 0.02 | 0.03 |

| Nb | ppm | 209 | 175 | 140 | 210 |

| Sn | ppm | - | - | 529 | - |

| TREO | ppm | 10 | 110 | 9 | 53 |

| Li | ppm | 8100 | 2230 | 3500 | 2130 |

| Rb | ppm | 407 | 996 | 1720 | 1090 |

| Cs | ppm | 53 | 121 | 100 | 82 |

| Be | ppm | 72 | 71 | 96 | 82 |

| Li2O | wt% | 1.74 | 0.48 | 0.75 | 0.46 |

| Types | Minerals | wt% | ||

|---|---|---|---|---|

| ore minerals | spodumene | 11.3 | ||

| muscovite | 12.17 | |||

| gangue minerals | felsic minerals | albite, orthoclase, microcline, perthite, quartz, petalite | 74.79 | |

| accessory minerals | metallic minerals | columbite-tantalite, cassiterite, hematite, limonite, rhodochrosite, pyrite | 0.24 | |

| nonmetallic minerals | sericite, tourmaline, sphene, allanite, apatite, garnet, fluorite, chlorite, zircon, beryl | 1.50 | ||

| Phase | Content (wt%) | Distribution (%) |

|---|---|---|

| Silicate | 0.80 | 84.21 |

| Mica | 0.15 | 15.79 |

| Total Li | 0.95 | 100.00 |

| Compositions | Units | Average | Max | Min | SD |

|---|---|---|---|---|---|

| Na2O | wt% | 0.11 | 0.15 | 0.07 | 0.03 |

| MgO | wt% | 0.00 | 0.00 | 0.00 | 0.00 |

| Al2O3 | wt% | 28.24 | 29.49 | 25.39 | 1.28 |

| SiO2 | wt% | 64.86 | 68.32 | 63.60 | 1.50 |

| P2O5 | wt% | 0.02 | 0.04 | 0.00 | 0.01 |

| K2O | wt% | 0.01 | 0.02 | 0.00 | 0.01 |

| CaO | wt% | 0.04 | 0.13 | 0.00 | 0.04 |

| TiO2 | wt% | 0.00 | 0.01 | 0.00 | 0.00 |

| MnO | wt% | 0.08 | 0.12 | 0.04 | 0.03 |

| FeO | wt% | 0.19 | 0.31 | 0.11 | 0.07 |

| Li2O | wt% | 6.40 | 6.81 | 5.97 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, X.; Chen, C.; Chen, X.; Fei, G.; Li, Y.; Wang, J.; Cai, Y. Process Mineralogy Characteristics of Lijiagou Pegmatite Spodumene Deposit, Sichuan, China. Minerals 2023, 13, 1180. https://doi.org/10.3390/min13091180

Lai X, Chen C, Chen X, Fei G, Li Y, Wang J, Cai Y. Process Mineralogy Characteristics of Lijiagou Pegmatite Spodumene Deposit, Sichuan, China. Minerals. 2023; 13(9):1180. https://doi.org/10.3390/min13091180

Chicago/Turabian StyleLai, Xiang, Cuihua Chen, Xiaojie Chen, Guangchun Fei, Yin Li, Jiaxin Wang, and Yunhua Cai. 2023. "Process Mineralogy Characteristics of Lijiagou Pegmatite Spodumene Deposit, Sichuan, China" Minerals 13, no. 9: 1180. https://doi.org/10.3390/min13091180

APA StyleLai, X., Chen, C., Chen, X., Fei, G., Li, Y., Wang, J., & Cai, Y. (2023). Process Mineralogy Characteristics of Lijiagou Pegmatite Spodumene Deposit, Sichuan, China. Minerals, 13(9), 1180. https://doi.org/10.3390/min13091180