The Power of Characterizing Pore-Fluid Distribution for Microscopic CO2 Injection Studies in Tight Sandstones

Abstract

1. Introduction

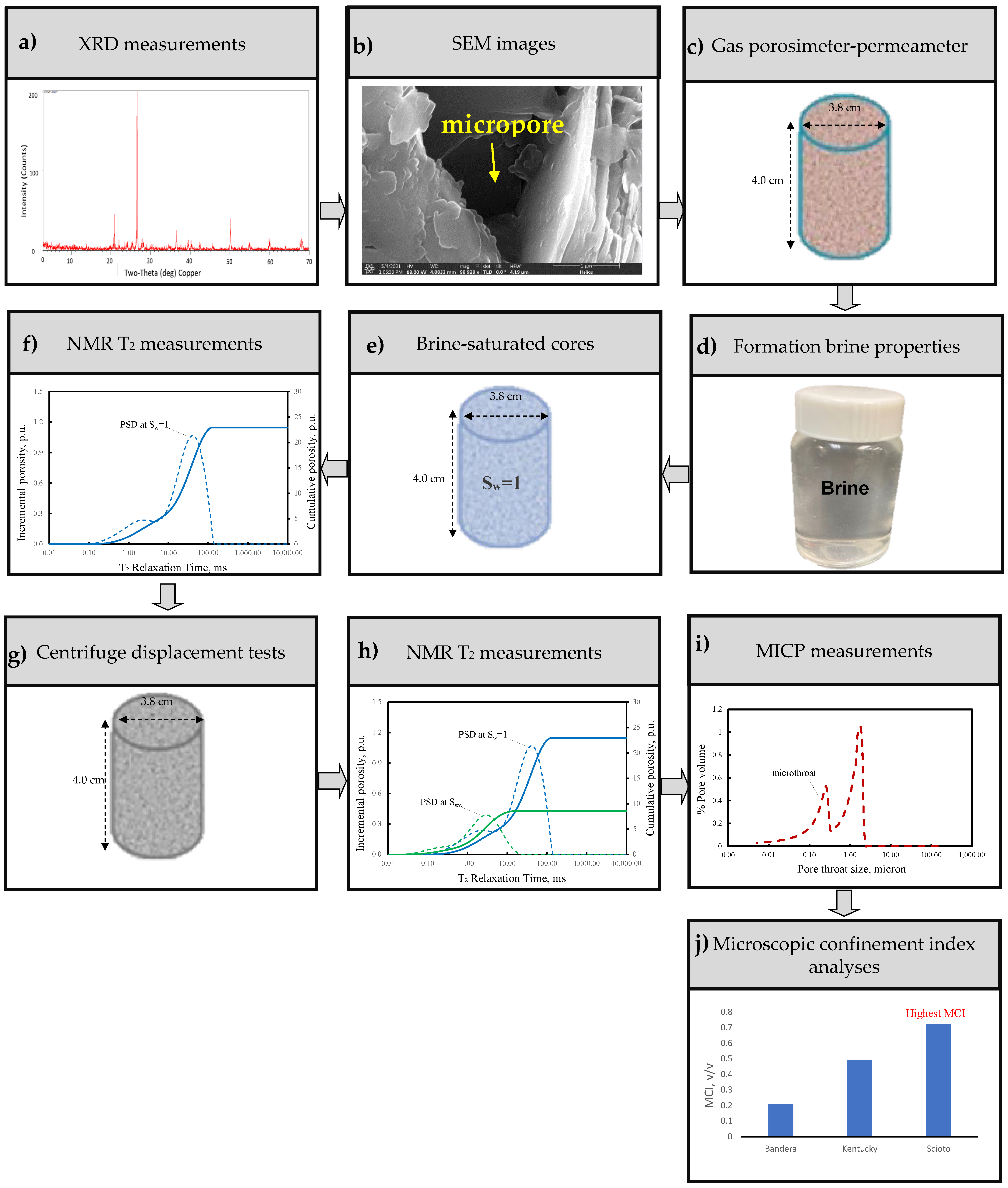

2. Materials and Methods

3. Results

3.1. Mineralogy and Morphology

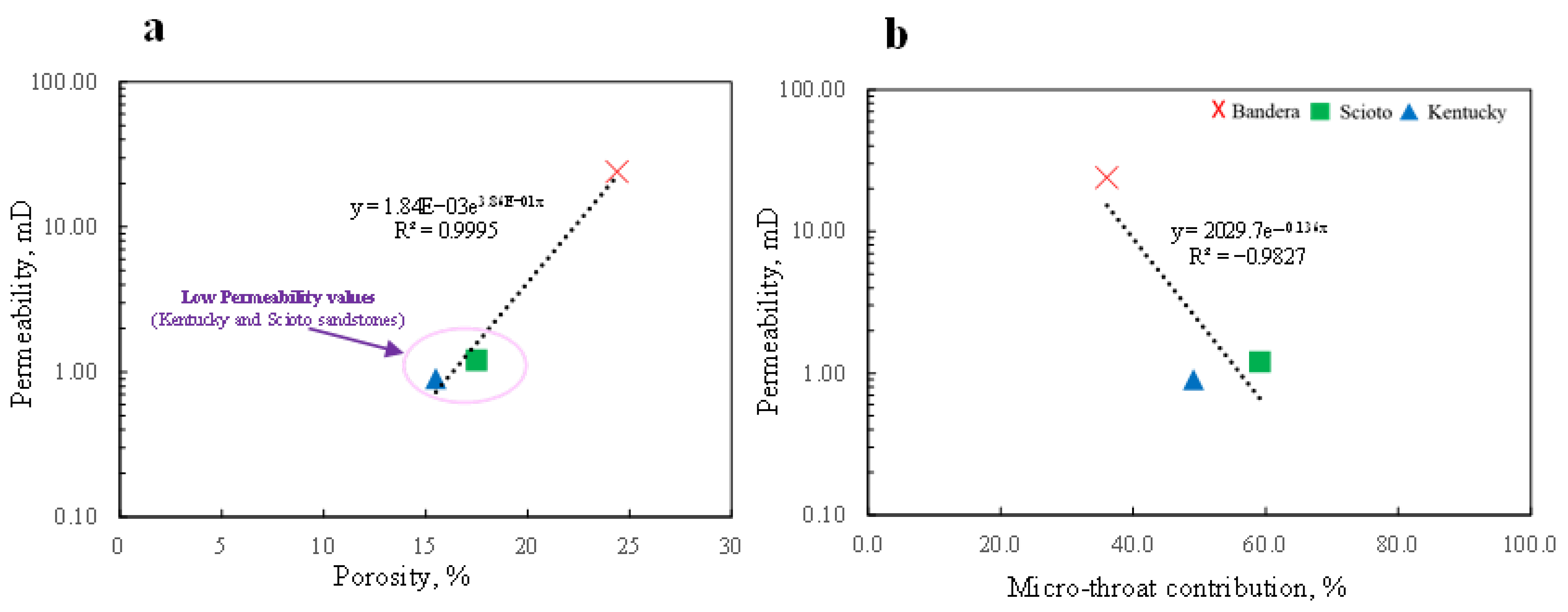

3.2. Porosity and Permeability

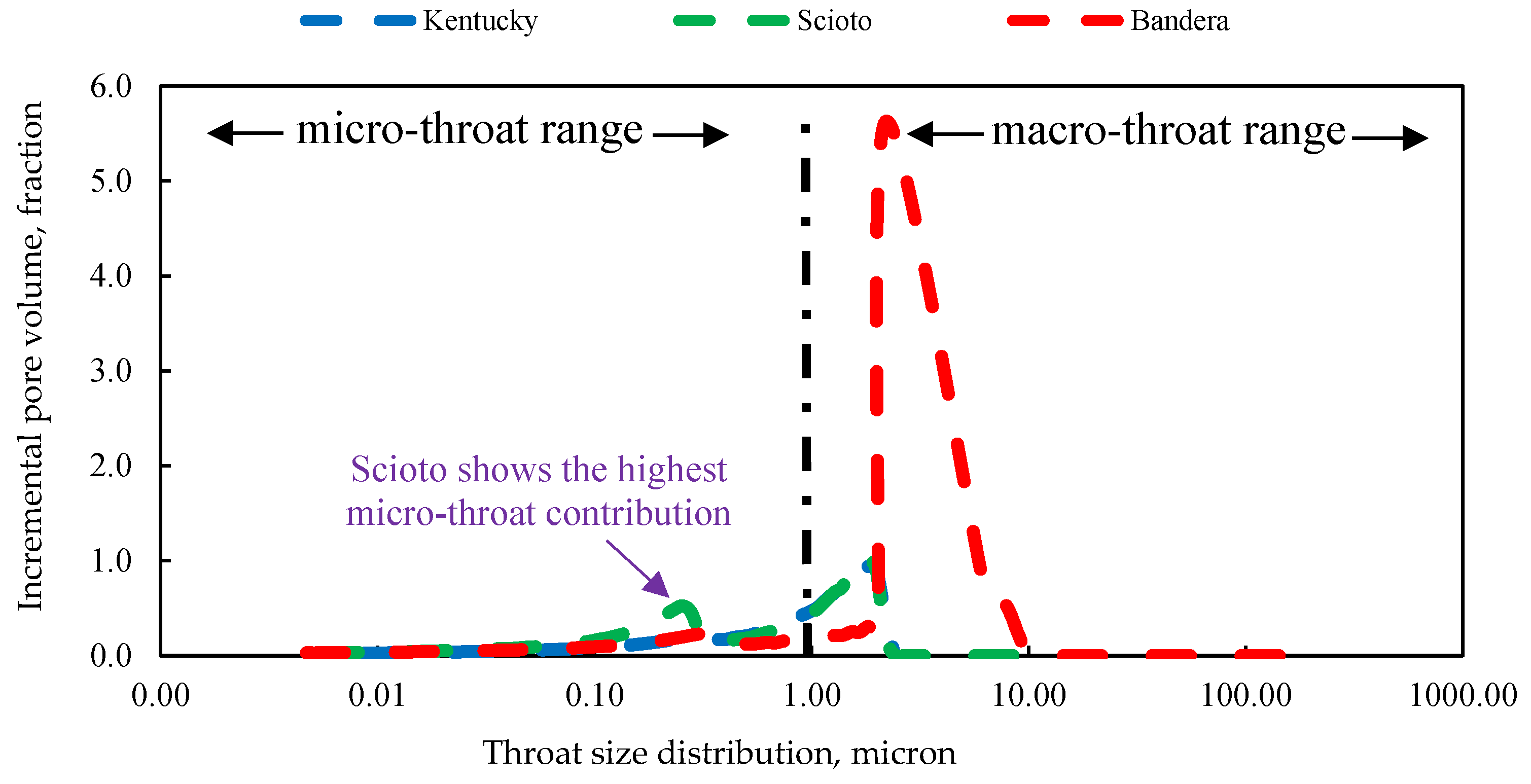

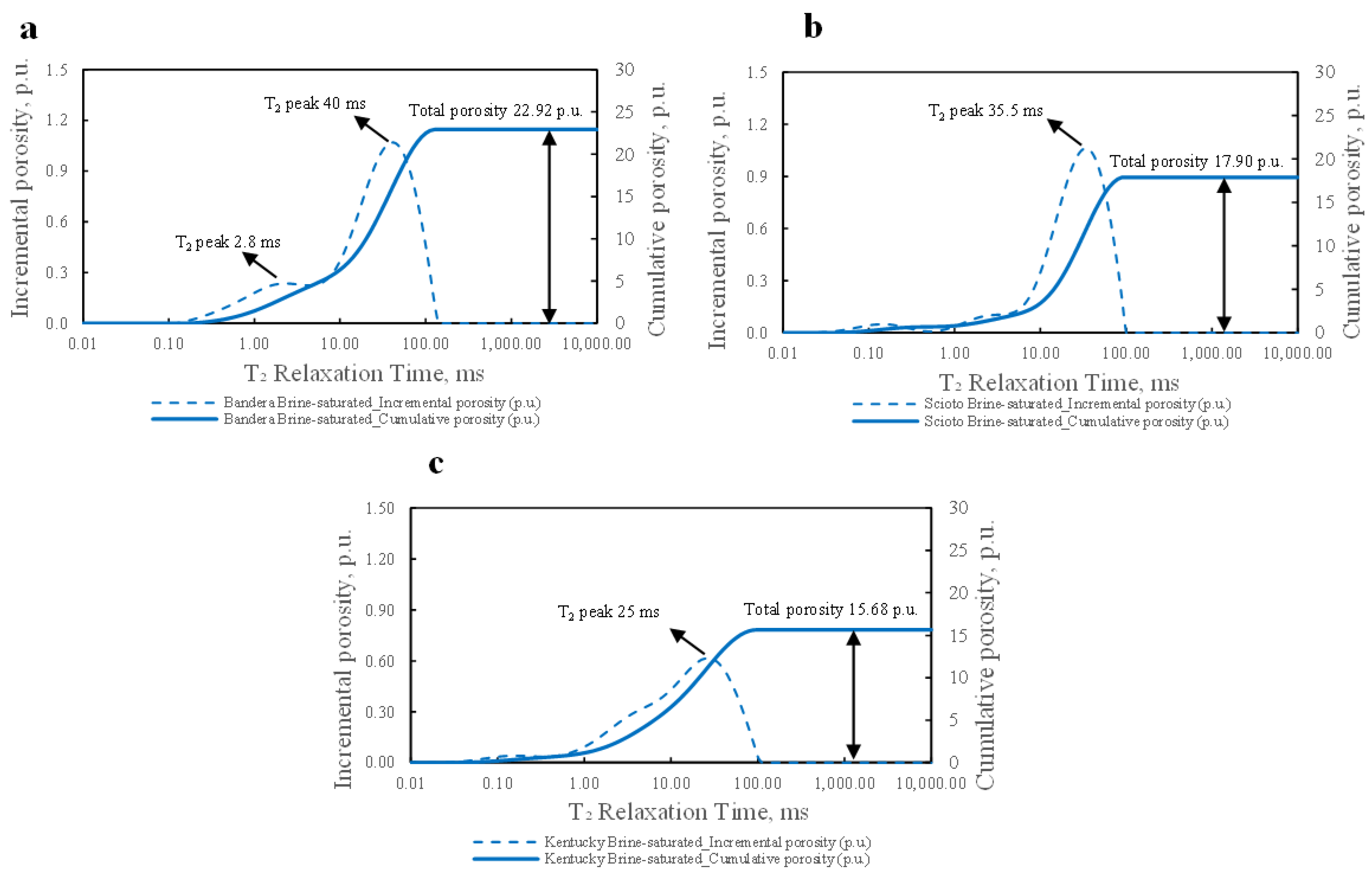

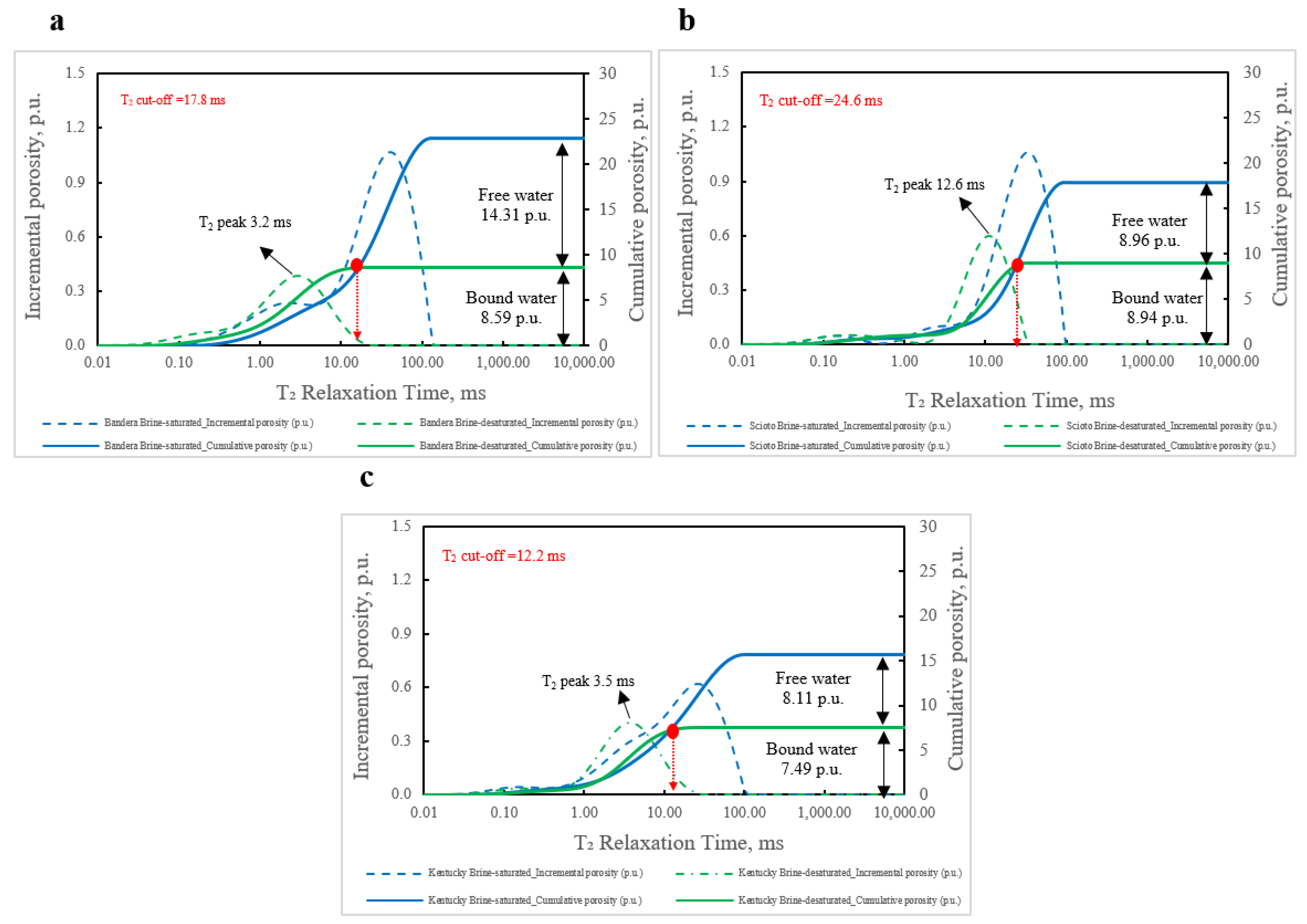

3.3. Pore-Fluid Distribution and Pore Structures

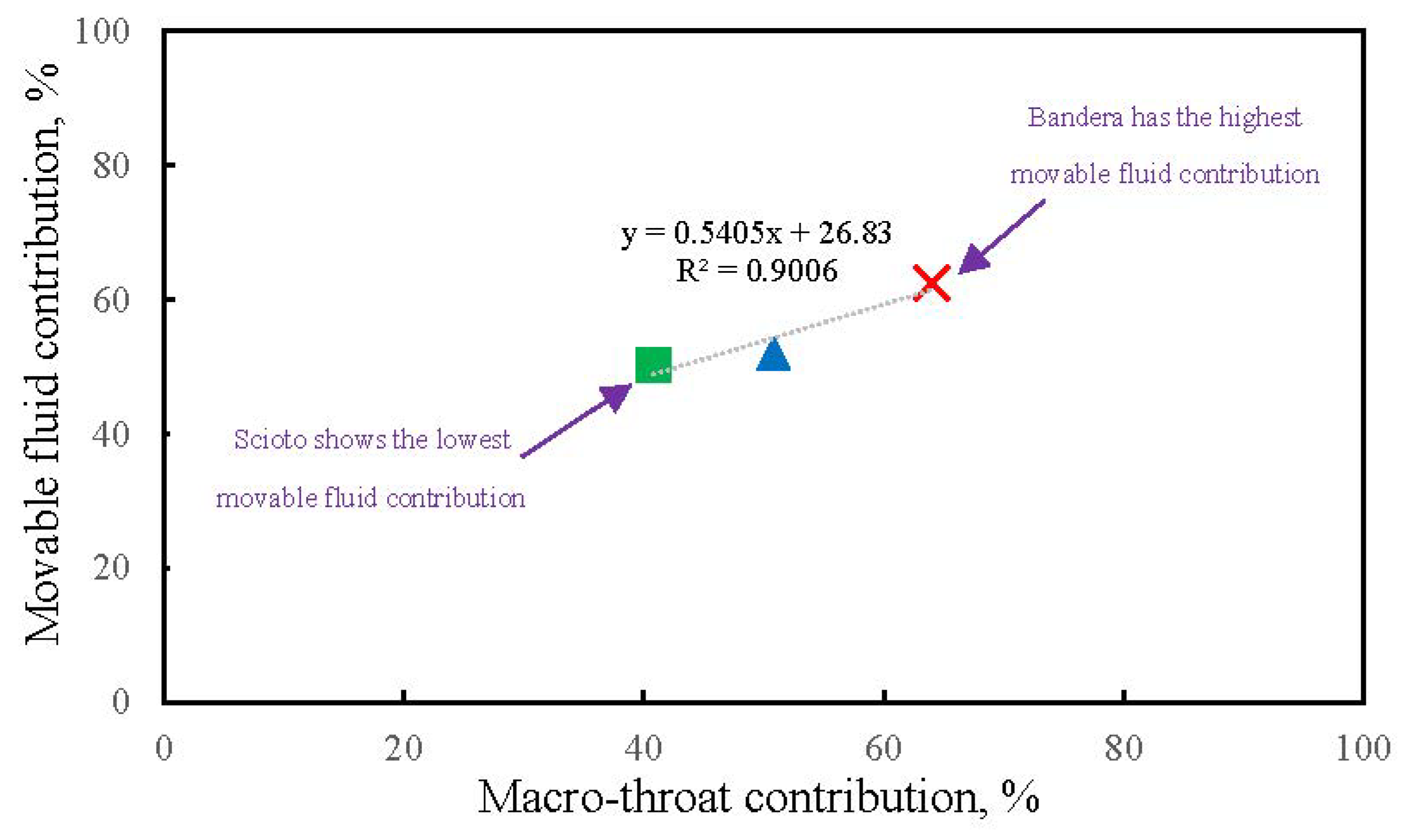

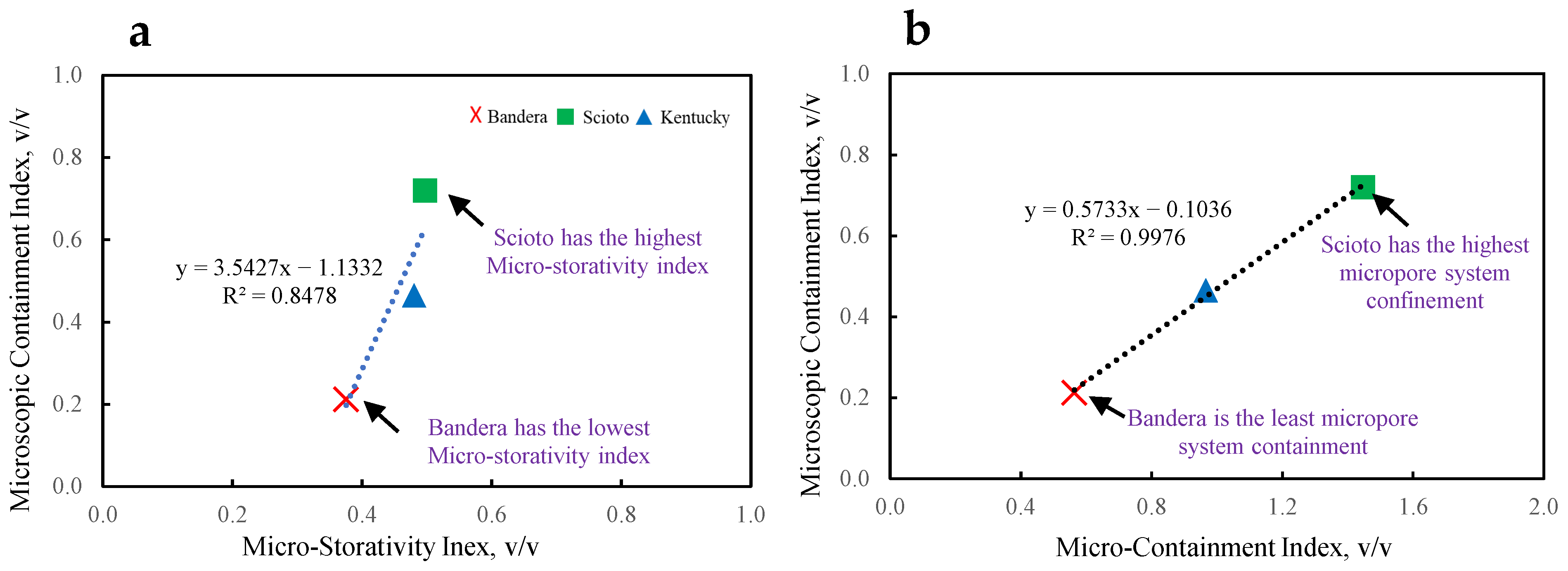

3.4. Microscopic Confinement Index (MCI)

4. Discussion

5. Conclusions

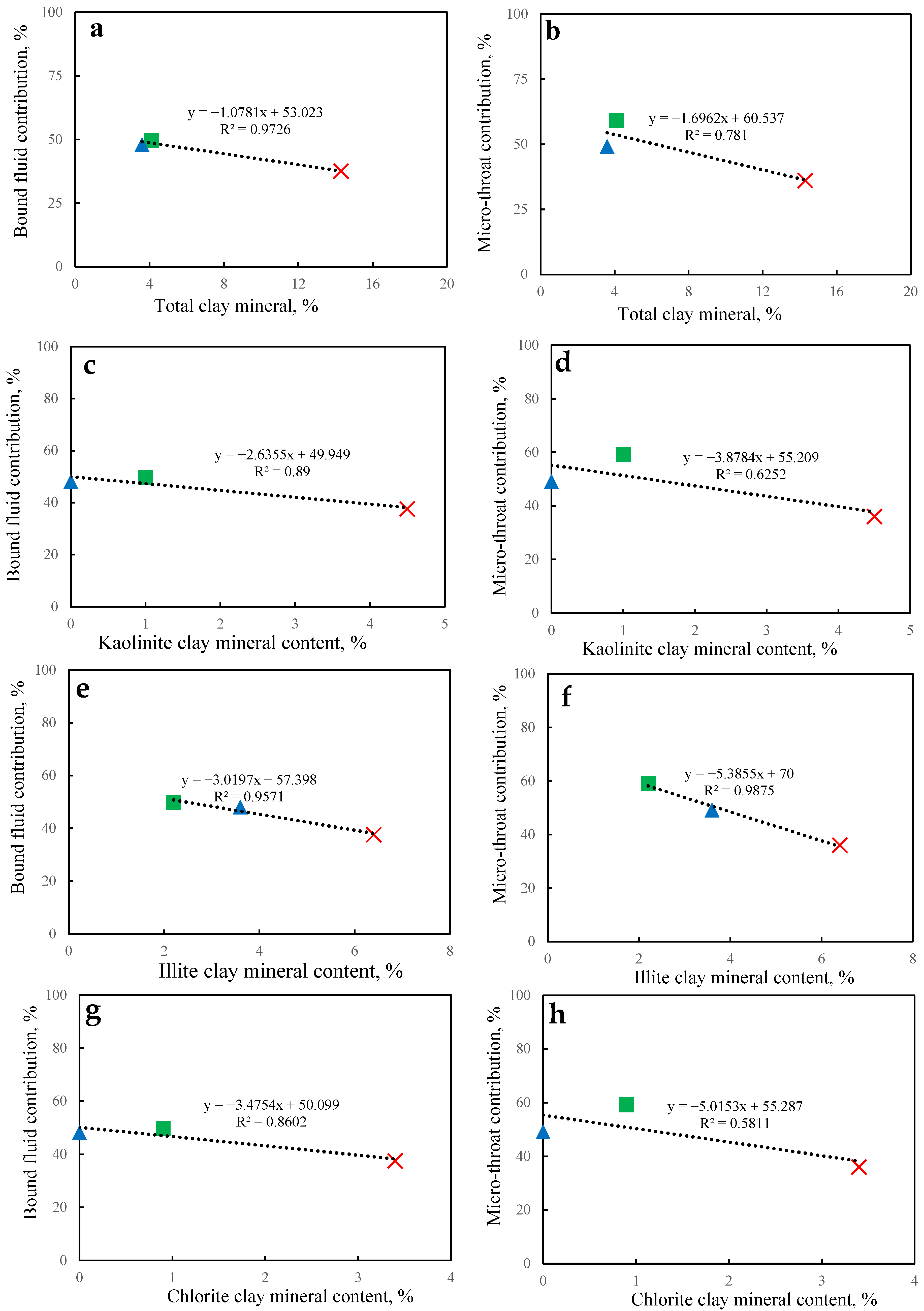

- The findings indicated that the Bandera sandstone sample had the highest clay content, followed by the Scioto and Kentucky sandstone samples. Nevertheless, a routine core analysis indicated that Bandera sandstone had the highest permeability and porosity values followed by Scioto sandstone and, finally, by Kentucky sandstone, which had with the lowest porosity and permeability values.

- SEM analyses indicated Bandera sandstone to be characterized by quartz overgrowths and booklets of kaolinite and filamentous illite overlying the quartz in addition to pore-filling chlorite filling the pores. Scioto sandstone showed visible micropores with pore-lining illite platelets coating the quartz grains, while Kentucky sandstone showed an abundant distribution of booklets of kaolinite.

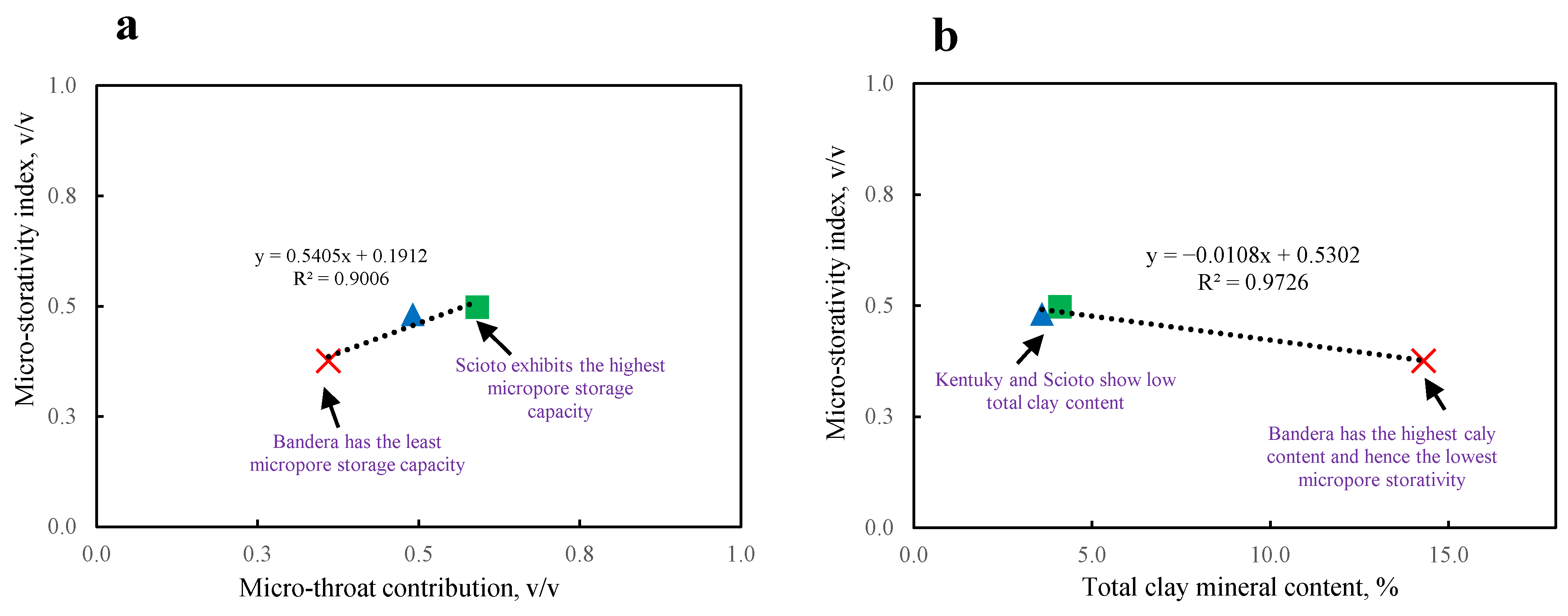

- The MICP results demonstrated that all sandstone samples exhibited a bi-modal pore-throat distribution covering micro- and macropore throat systems. The Bandera sandstone micropore-throat system showed poor contribution, while Scioto sandstone made the largest micropore-throat contribution to the total pore system.

- NMR T2 measurements conducted on partially saturated samples after the displacement tests reveal longer T2 relaxations for Scioto and comparable values for Bandera and Kentucky sandstones, indicating a large contribution from Scioto micropores compared with Kentucky and Bandera sandstones.

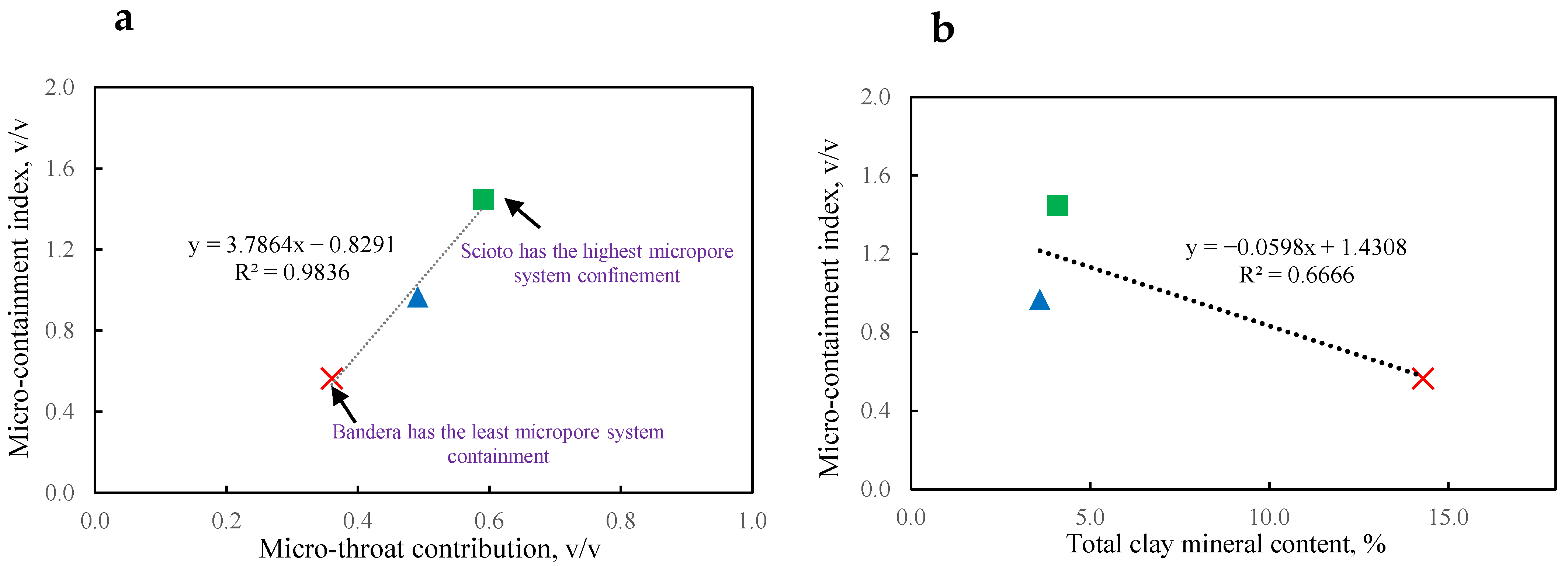

- Bandera sandstone’s micropore system’s ability to store and confine fluid or gas was found to be the weakest among the tested sandstone samples. The low contribution values of the storativity and confinement of the micropore system in Bandera sandstone could be attributed to the presence of clay mineral content. In particular, this could be explained by the presence of pore-filling kaolinite booklets, which significantly reduced the micropore storativity, and the presence of pore-bridging fibrous illite, which reduced the micropore-throat proportion and, hence, reduced the confinement of the micropore system.

- A strong positive correlation was obtained between the micro-throat proportion and the micro-confinement contribution in the tested sandstone samples, indicating that the higher the micro-throat contribution in the pore system was, the more confined the micropore system became.

- The MCI indicated that Scioto sandstone was a suitable candidate for microscopic CO2 injection and storage due to its high contributions of micropore confinement and storativity compared with the other tested samples; these factors will improve CO2 injectivity in the micropore system of tight sandstones.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schmitt, M.; Fernandes, C.P.; Wolf, F.G.; Neto, J.A.B.D.C.; Rahner, C.P.; dos Santos, V.S.S. Characterization of Brazilian tight gas sandstones relating permeability and Angstrom-to micron-scale pore structures. J. Nat. Gas Sci. Eng. 2015, 27, 785–807. [Google Scholar] [CrossRef]

- Zheng, D.; Pang, X.; Jiang, F.; Liu, T.; Shao, X.; Huyan, Y. Characteristics and controlling factors of tight sandstone gas reservoirs in the Upper Paleozoic strata of Linxing area in the Ordos Basin, China. J. Nat. Gas Sci. Eng. 2020, 75, 103135. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (EIA). Monthly Energy Review June 2022; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2022. [Google Scholar]

- McGlade, C.; Speirs, J.; Sorrell, S. Unconventional gas—A review of regional and global resource estimates. Energy 2013, 55, 571–584. [Google Scholar] [CrossRef]

- Wang, J.; Feng, L.; Steve, M.; Tang, X.; Gail, T.E.; Mikael, H. China’s unconventional oil: A review of its resources and outlook for long-term production. Energy 2015, 82, 31–42. [Google Scholar] [CrossRef]

- Gao, H.; Li, H. Determination of movable fluid percentage and movable fluid porosity in ultra-low permeability sandstone using nuclear magnetic resonance (NMR) technique. J. Pet. Sci. Eng. 2015, 133, 258–267. [Google Scholar] [CrossRef]

- Alam, S. Potential of Tight Gas in Pakistan: Productive, Economic and Policy Aspects. In Proceedings of the Annual Technical Conference of Pakistan Association of Petroleum Geoscientists (PAPG), Islamabad, Pakistan, 10–11 November 2010. [Google Scholar]

- Naik, G.C. Tight Gas Reservoir an Unconventional Natural Energy Source for the Future. 2004. Available online: http://www.pinedaleonline.com/socioeconomic/pdfs/tight_gas.pdf (accessed on 10 February 2022).

- U.S. Government Accountability Office (GAO). Impacts of Potential Oil Shale Development on Water Resources; U.S. Government Accountability Office (GAO): Washington, DC, USA, 2011. [Google Scholar]

- National Resources Canada. North American Tight Oil. 2012. Available online: http://www.nrcan.gc.ca/energy/sources/crude/2114#oil1 (accessed on 10 February 2022).

- Holditch, S.A. Tight gas sands. J. Pet. Technol. 2006, 58, 86–93. [Google Scholar] [CrossRef]

- Worden, R.H.; Burley, S.D. Sandstone diagenesis: The evolution of sand to stone. In Sandstone Diagenesis: Recent and Ancient; International Association of Sedimentologists Special Publication 4; Blackwell: Oxford, UK, 2003; pp. 1–44. [Google Scholar]

- Xiao, D.; Lu, Z.; Jiang, S.; Lu, S. Comparison and integration of experimental methods to characterize the full-range pore features of tight gas sandstone—A case study in Songliao Basin of China. J. Nat. Gas Sci. Eng. 2016, 34, 1412–1421. [Google Scholar] [CrossRef]

- Yue, D.; Wu, S.; Xu, Z.; Xiong, L.; Chen, D.; Ji, Y.; Zhou, Y. Reservoir quality, natural fractures, and gas productivity of upper Triassic Xujiahe tight gas sandstones in western Sichuan Basin, China. Mar. Pet. Geol. 2018, 89, 370–386. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, S.; Xiao, D.; Li, B. Pore structure characteristics of tight sandstones in the northern Songliao Basin, China. Mar. Pet. Geol. 2017, 88, 170–180. [Google Scholar] [CrossRef]

- Cao, Y.; Tang, M.; Zhang, Q.; Tang, J.; Lu, S. Dynamic capillary pressure analysis of tight sandstone based on digital rock model. Capillarity 2020, 3, 28–35. [Google Scholar] [CrossRef]

- Nabawy, B.S.; Khalil, H.M.; Fathy, M.S.; Ali, F. Impacts of microfacies type on reservoir quality and pore fabric anisotropy of the Nubia sandstone in the central Eastern Desert, Egypt. Geol. J. 2020, 55, 4507–4524. [Google Scholar] [CrossRef]

- Syed, F.I.; Dahaghi, A.K.; Muther, T. Laboratory to field scale assessment for EOR applicability in tight oil reservoirs. Pet. Sci. 2022, 19, 2131–2149. [Google Scholar] [CrossRef]

- Edwards, A.C. Grain size and sorting in modern beach sands. J. Coast. Res. 2001, 17, 38–52. [Google Scholar]

- Li, L.; Su, Y.; Sheng, J.J.; Hao, Y.; Wang, W.; Lv, Y.; Zhao, Q.; Wang, H. Experimental and numerical study on CO2 sweep volume during CO2 huff-n-puff enhanced oil recovery process in shale oil reservoirs. Energy Fuels 2019, 33, 4017–4032. [Google Scholar] [CrossRef]

- Bjørlykke, K. Relationships between depositional environments, burial history and rock properties. Some principal aspects of diagenetic process in sedimentary basins. Sediment. Geol. 2014, 301, 1–14. [Google Scholar] [CrossRef]

- Bjorlykke, K.; Jahren, J. Open or closed geochemical systems during diagenesis in sedimentary basins: Constraints on mass transfer during diagenesis and the prediction of porosity in sandstone and carbonate reservoirs. AAPG Bull. 2012, 96, 2193–2214. [Google Scholar] [CrossRef]

- Bultreys, T.; De Boever, W.; Cnudde, V. Imaging and image-based fluid transport modeling at the pore scale in geological materials: A practical introduction to the current state-of-the-art. Earth-Science Rev. 2016, 155, 93–128. [Google Scholar] [CrossRef]

- Endres, A.L.; Knight, R. The effects of pore-scale fluid distribution on the physical properties of partially saturated tight sandstones. J. Appl. Phys. 1991, 69, 1091–1098. [Google Scholar] [CrossRef]

- Song, X.; Guo, Y.; Zhang, J.; Sun, N.; Shen, G.; Chang, X.; Yu, W.; Tang, Z.; Chen, W.; Wei, W.; et al. Fracturing with carbon dioxide: From microscopic mechanism to reservoir application. Joule 2019, 3, 1913–1926. [Google Scholar] [CrossRef]

- Holm, L.W.; Josendal, V.A. Mechanisms of oil displacement by carbon dioxide. J. Pet. Technol. 1974, 26, 1427–1438. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Y.; Blunt, M.J.; Yao, J.; Cai, J. Advances in multiscale numerical and experimental approaches for multiphysics problems in porous media. Adv. Geo-Energy Res. 2021, 5, 233–238. [Google Scholar] [CrossRef]

- Juanes, R.; Spiteri, E.J.; Orr, F.M., Jr.; Blunt, M.J. Impact of relative permeability hysteresis on geological CO2 storage. Water Resour. Res. 2006, 42, W12418. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, B.; Shang, J.; Gao, K.; Pu, W.; Xu, X.; Wood, C.; Sun, L. Alterations of geochemical properties of a tight sandstone reservoir caused by supercritical CO2-brine-rock interactions in CO2-EOR and geosequestration. J. CO2 Util. 2018, 28, 408–418. [Google Scholar] [CrossRef]

- Payton, R.L.; Fellgett, M.; Clark, B.L.; Chiarella, D.; Kingdon, A.; Hier-Majumder, S. Pore-scale assessment of subsurface carbon storage potential: Implications for the UK Geoenergy Observatories project. Pet. Geosci. 2021, 27, petgeo2020-092. [Google Scholar] [CrossRef]

- Bjørlykke, K.; Høeg, K. Effects of burial diagenesis on stresses, compaction and fluid flow in sedimentary basins. Mar. Pet. Geol. 1997, 14, 267–276. [Google Scholar] [CrossRef]

- Selley, R.C. Applied Sedimentology; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Pittman, E.D. Porosity, Diagenesis, and Productive Capability of Sandstone Reservoirs; The Society of Economic Paleontologists and Mineralogists (SEPM): Tulsa, OK, USA, 1979. [Google Scholar]

- Worden, R.H.; Griffiths, J.; Wooldridge, L.J.; Utley, J.E.P.; Lawan, A.Y.; Muhammed, D.D.; Simon, N.; Armitage, P. Chlorite in sandstones. Earth-Sci. Rev. 2020, 204, 103105. [Google Scholar] [CrossRef]

- Chang, J.; Fan, X.; Jiang, Z.; Wang, X.; Chen, L.; Li, J.; Zhu, L.; Wan, C.; Chen, Z. Differential impact of clay minerals and organic matter on pore structure and its fractal characteristics of marine and continental shales in China. Appl. Clay Sci. 2022, 216, 106334. [Google Scholar] [CrossRef]

- McLean, R.F.; Kirk, R.M. Relationships between grain size, size-sorting, and foreshore slope on mixed sand-shingle beaches. N. Z. J. Geol. Geophys. 1969, 12, 138–155. [Google Scholar] [CrossRef]

- Keelan, D.K. Core analysis for aid in reservoir description. J. Pet. Technol. 1982, 34, 2483–2491. [Google Scholar] [CrossRef]

- Islam, M.A. Diagenesis and reservoir quality of Bhuban sandstones (Neogene), Titas gas field, Bengal Basin, Bangladesh. J. Asian Earth Sci. 2009, 35, 89–100. [Google Scholar] [CrossRef]

- Hollis, C.; Vahrenkamp, V.; Tull, S.; Mookerjee, A.; Taberner, C.; Huang, Y. Pore system characterisation in heterogeneous carbonates: An alternative approach to widely-used rock-typing methodologies. Mar. Pet. Geol. 2010, 27, 772–793. [Google Scholar] [CrossRef]

- Beard, D.C.; Weyl, P.K. Influence of texture on porosity and permeability of unconsolidated sand. AAPG Bull. 1973, 57, 349–369. [Google Scholar]

- Chima, P.; Baiyegunhi, C.; Liu, K.; Gwavava, O. Diagenesis and rock properties of sandstones from the Stormberg Group, Karoo Supergroup in the Eastern Cape Province of South Africa. Open Geosci. 2018, 10, 740–771. [Google Scholar] [CrossRef]

- Ajdukiewicz, J.M.; Lander, R.H. Sandstone reservoir quality prediction: The state of the art. AAPG Bull. 2010, 94, 1083–1091. [Google Scholar] [CrossRef]

- Makeen, Y.M.; Abdullah, W.H.; Ayinla, H.A.; Hakimi, M.H.; Sia, S.-G. Sedimentology, diagenesis and reservoir quality of the upper Abu Gabra Formation sandstones in the Fula Sub-basin, Muglad Basin, Sudan. Mar. Pet. Geol. 2016, 77, 1227–1242. [Google Scholar] [CrossRef]

- McKinley, J.M.; Atkinson, P.M.; Lloyd, C.D.; Ruffell, A.H.; Worden, R.H. How porosity and permeability vary spatially with grain size, sorting, cement volume, and mineral dissolution in fluvial Triassic sandstones: The value of geostatistics and local regression. J. Sediment. Res. 2011, 81, 844–858. [Google Scholar] [CrossRef]

- Mozley, P.S.; Heath, J.E.; Dewers, T.A.; Bauer, S.J. Origin and heterogeneity of pore sizes in the Mount Simon Sandstone and Eau Claire Formation: Implications for multiphase fluid flow. Geosphere 2016, 12, 1341–1361. [Google Scholar] [CrossRef]

- Kashif, M.; Cao, Y.; Yuan, G.; Asif, M.; Javed, K.; Mendez, J.N.; Khan, D.; Miruo, L. Pore size distribution, their geometry and connectivity in deeply buried Paleogene Es1 sandstone reservoir, Nanpu Sag, East China. Pet. Sci. 2019, 16, 981–1000. [Google Scholar] [CrossRef]

- Zhiyong, G.; Jiarui, F.; Jinggang, C.; Xiaoqi, W.; Chuanmin, Z.; Yuxin, S. Physical simulation and quantitative calculation of increased feldspar dissolution pores in deep reservoirs. Pet. Explor. Dev. 2017, 44, 387–398. [Google Scholar]

- Shao, X.; Pang, X.; Jiang, F.; Li, L.; Li, H.; Zheng, D.; Huyan, Y. Genesis and accumulation of natural gas in the Upper Palaeozoic strata of north-eastern Ordos Basin, China. Geol. J. 2019, 54, 3212–3225. [Google Scholar] [CrossRef]

- Neasham, J.W. The morphology of dispersed clay in sandstone reservoirs and its effect on sandstone shaliness, pore space and fluid flow properties. In SPE Annual Fall Technical Conference and Exhibition; OnePetro: Richardson, TX, USA, 1977. [Google Scholar]

- Schrader, M.E.; Yariv, S. Wettability of clay minerals. J. Colloid Interface Sci. 1990, 136, 85–94. [Google Scholar] [CrossRef]

- Schoonheydt, R.A.; Johnston, C.T. Surface and interface chemistry of clay minerals. Dev. Clay Sci. 2006, 1, 87–113. [Google Scholar]

- Yuan, G.; Gluyas, J.; Cao, Y.; Oxtoby, N.H.; Jia, Z.; Wang, Y.; Xi, K.; Li, X. Diagenesis and reservoir quality evolution of the Eocene sandstones in the northern Dongying Sag, Bohai Bay Basin, East China. Mar. Pet. Geol. 2015, 62, 77–89. [Google Scholar] [CrossRef]

- Kuila, U.; Prasad, M. Specific surface area and pore-size distribution in clays and shales. Geophys. Prospect. 2013, 61, 341–362. [Google Scholar] [CrossRef]

- Wilson, L.; Wilson, M.J.; Green, J.; Patey, I. The influence of clay mineralogy on formation damage in North Sea reservoir sandstones: A review with illustrative examples. Earth-Sci. Rev. 2014, 134, 70–80. [Google Scholar] [CrossRef]

- Kassab, M.A.; Abu Hashish, M.F.; Nabawy, B.S.; Elnaggar, O.M. Effect of kaolinite as a key factor controlling the petrophysical properties of the Nubia sandstone in central Eastern Desert, Egypt. J. Afr. Earth Sci. 2017, 125, 103–117. [Google Scholar] [CrossRef]

- Rosenbrand, E.; Fabricius, I.L.; Fisher, Q.; Grattoni, C. Permeability in Rotliegend gas sandstones to gas and brine as predicted from NMR, mercury injection and image analysis. Mar. Pet. Geol. 2015, 64, 189–202. [Google Scholar] [CrossRef]

- Bjorkum, P.A. How important is pressure in causing dissolution of quartz in sandstones? J. Sediment. Res. 1996, 66, 147–154. [Google Scholar]

- Anovitz, L.M.; Cole, D.R. Characterization and analysis of porosity and pore structures. Rev. Miner. Geochem. 2015, 80, 61–164. [Google Scholar] [CrossRef]

- Al Saadi, F.; Wolf, K.-H.; Van Kruijsdijk, C. Characterization of Fontainebleau sandstone: Quartz overgrowth and its impact on pore-throat framework. J. Pet. Environ. Biotechnol. 2017, 8, 1–12. [Google Scholar] [CrossRef]

- Bloch, S.; Lander, R.H.; Bonnell, L.M. Anomalously high porosity and permeability in deeply buried sandstone reservoirs: Origin and predictability. AAPG Bull. 2002, 86, 301–328. [Google Scholar]

- Freiburg, J.T.; Ritzi, R.W.; Kehoe, K.S. Depositional and diagenetic controls on anomalously high porosity within a deeply buried CO2, storage reservoir—The Cambrian Mt. Simon sandstone, Illinois basin, USA. Int. J. Greenh. Gas Control. 2016, 55, 42–54. [Google Scholar] [CrossRef]

- Wu, Y.; Tahmasebi, P.; Lin, C.; Zahid, M.A.; Dong, C.; Golab, A.N.; Ren, L. A comprehensive study on geometric, topological and fractal characterizations of pore systems in low-permeability reservoirs based on SEM, MICP, NMR, and X-ray CT experiments. Mar. Pet. Geol. 2019, 103, 12–28. [Google Scholar] [CrossRef]

- Wu, K.; Chen, D.; Zhang, W.; Yang, H.; Wu, H.; Cheng, X.; Qu, Y.; He, M. Movable Fluid Distribution Characteristics and Microscopic Mechanism of Tight Reservoir in Yanchang Formation, Ordos Basin. Advances in the Exploration and Development of Unconventional Oil and Gas: From the Integration of Geology and Engineering. Front. Earth Sci. 2022, 10, 840875. [Google Scholar] [CrossRef]

- Kleinberg, R.L.; Kenyon, W.E.; Mitra, P.P. Mechanism of NMR relaxation of fluids in rock. J. Magn. Reson. Ser. A 1994, 108, 206–214. [Google Scholar] [CrossRef]

- Coates, G.R.; Xiao, L.Z.; Prammer, M.G. NMR Logging Principles and Applications; Gulf Publishing Company: Houston, TX, USA, 1999. [Google Scholar]

- Hirasaki, G.J.; Huang, C.C.; Zhang, G.Q. Interpretation of wettability in sandstones with NMR analysis. Petrophys.-SPWLA J. Form. Eval. Reserv. Descr. 2000, 41, 223–233. [Google Scholar]

- Dunn, K.J.; Bergman, D.J.; LaTorraca, G.A. (Eds.) Nuclear Magnetic Resonance: Petrophysical and Logging Applications; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Baban, A.; Al-Yaseri, A.; Keshavarz, A.; Amin, R.; Iglauer, S. CO2—brine—sandstone wettability evaluation at reservoir conditions via Nuclear Magnetic Resonance measurements. Int. J. Greenh. Gas Control. 2021, 111, 103435. [Google Scholar] [CrossRef]

- Dutton, S.P.; Loucks, R.G. Diagenetic controls on evolution of porosity and permeability in lower Tertiary Wilcox sandstones from shallow to ultradeep (200–6700 m) burial, Gulf of Mexico Basin, USA. Mar. Pet. Geol. 2010, 27, 69–81. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Mørk, M.B.E. Diagenesis and quartz cement distribution of low-permeability Upper Triassic–Middle Jurassic reservoir sandstones, Longyearbyen CO2 lab well site in Svalbard, Norway. AAPG Bull. 2013, 97, 577–596. [Google Scholar] [CrossRef]

- Dai, J.; Ni, Y.; Hu, G.; Huang, S.; Liao, F.; Yu, C.; Gong, D.; Wu, W. Stable carbon and hydrogen isotopes of gases from the large tight gas fields in China. Sci. China Earth Sci. 2014, 57, 88–103. [Google Scholar] [CrossRef]

- Pan, B.; Yin, X.; Ju, Y.; Iglauer, S. Underground hydrogen storage: Influencing parameters and future outlook. Adv. Colloid Interface Sci. 2021, 294, 102473. [Google Scholar] [CrossRef]

- Peksa, A.E.; Wolf, K.-H.A.; Zitha, P.L. Bentheimer sandstone revisited for experimental purposes. Mar. Pet. Geol. 2015, 67, 701–719. [Google Scholar] [CrossRef]

- Huyan, Y.; Pang, X.; Jiang, F.; Li, L.; Zheng, D.; Shao, X. Coupling relationship between tight sandstone reservoir and gas charging: An example from lower Permian Taiyuan Formation in Kangning field, northeastern Ordos Basin, China. Mar. Pet. Geol. 2019, 105, 238–250. [Google Scholar] [CrossRef]

- Kenyon, W.E. Petrophysical principles of applications of NMR logging. Log Anal. 1997, 38, 21–43. [Google Scholar]

- Carr, H.Y.; Purcell, E.M. Effects of diffusion on free precession in nuclear magnetic resonance experiments. Phys. Rev. 1954, 94, 630–638. [Google Scholar] [CrossRef]

- Xiao, L.; Liu, X.-P.; Zou, C.-C.; Hu, X.-X.; Mao, Z.-Q.; Shi, Y.-J.; Guo, H.-P.; Li, G.-R. Comparative study of models for predicting permeability from nuclear magnetic resonance (NMR) logs in two Chinese tight sandstone reservoirs. Acta Geophys. 2014, 62, 116–141. [Google Scholar] [CrossRef]

- Song, Y.-Q. Pore sizes and pore connectivity in rocks using the effect of internal field. Magn. Reson. Imaging 2001, 19, 417–421. [Google Scholar] [CrossRef]

- Miller, M.N.; Paltiel, Z.; Gillen, M.E.; Granot, J.; Bouton, J.C. Spin echo magnetic resonance logging: Porosity and free fluid index determination. In SPE Annual Technical Conference and Exhibition; OnePetro: Richardson, TX, USA, 1990. [Google Scholar]

- Looyestijn, W.J. Wettability index determination from NMR logs. Petrophys.-SPWLA J. Form. Eval. Reserv. Descr. 2008, 49, 130–145. [Google Scholar]

- Mitchell, J.; Fordham, E.J. Contributed Review: Nuclear magnetic resonance core analysis at 0.3 T. Rev. Sci. Instrum. 2014, 85, 111502. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, M.; Isah, A.; Hiba, M.; Hassan, A.; Al-Garadi, K.; Mahmoud, M.; El-Husseiny, A.; Radwan, A.E. A review on the applications of nuclear magnetic resonance (NMR) in the oil and gas industry: Laboratory and field-scale measurements. J. Pet. Explor. Prod. Technol. 2022, 12, 2747–2784. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A review on pore structure characterization in tight sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Timur, A. Nuclear magnetic resonance study of carbonate rocks. In Proceedings of the SPWLA 13th Annual Logging Symposium, Tulsa, OK, USA, 7–10 May 1972; OnePetro: Tulsa, OK, USA, 1972. [Google Scholar]

- Chang, D.; Vinegar, H.J.; Morriss, C.; Straley, C. Effective porosity, producible fluid and permeability in carbonates from NMR logging. In Proceedings of the SPWLA 35th Annual Logging Symposium, Tulsa, OK, USA, 19–22 June 1994; OnePetro: Tulsa, OK, USA, 1994. [Google Scholar]

- AlKharraa, H.S.; Wolf, K.-H.A.; Kwak, H.T.; Deshenenkov, I.S.; AlDuhailan, M.A.; Mahmoud, M.A.; Arifi, S.A.; AlQahtani, N.B.; AlQuraishi, A.A.; Zitha, P.L.J. A Characterization of Tight Sandstone: Effect of Clay Mineralogy on Pore-Framework. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 24–26 January 2023; OnePetro: Tulsa, OK, USA, 2023. [Google Scholar]

- Wang, R.; Shi, W.; Xie, X.; Zhang, W.; Qin, S.; Liu, K.; Busbey, A.B. Clay mineral content, type, and their effects on pore throat structure and reservoir properties: Insight from the Permian tight sandstones in the Hangjinqi area, north Ordos Basin, China. Mar. Pet. Geol. 2020, 115, 104281. [Google Scholar] [CrossRef]

- Zou, C.; Zhu, R.; Liu, K.; Su, L.; Bai, B.; Zhang, X.; Yuan, X.; Wang, J. Tight gas sandstone reservoirs in China: Characteristics and recognition criteria. J. Pet. Sci. Eng. 2012, 88–89, 82–91. [Google Scholar] [CrossRef]

- Yang, H.; Li, S.; Liu, X. Characteristics and resource prospects of tight oil and shale oil in Ordos Basin. Acta Pet. Sin. 2013, 34, 1. [Google Scholar]

- Jia, A.; Wei, Y.; Guo, Z.; Wang, G.; Meng, D.; Huang, S. Development status and prospect of tight sandstone gas in China. Nat. Gas Ind. B 2022, 9, 467–476. [Google Scholar] [CrossRef]

- Cook, J.E.; Goodwin, L.B.; Boutt, D.F. Systematic diagenetic changes in the grain-scale morphology and permeability of a quartz-cemented quartz arenite. AAPG Bull. 2011, 95, 1067–1088. [Google Scholar] [CrossRef]

- Blunt, M.J.; Jackson, M.D.; Piri, M.; Valvatne, P.H. Detailed physics, predictive capabilities and macroscopic consequences for pore-network models of multiphase flow. Adv. Water Resour. 2002, 25, 1069–1089. [Google Scholar] [CrossRef]

- Caineng, Z.; Zhang, G.; Zhi, Y.; Shizhen, T.; Lianhua, H.; Rukai, Z.; Xuanjun, Y.; Qiquan, R.; Denghua, L.; Zhiping, W. Concepts, characteristics, potential and technology of unconventional hydrocarbons: On unconventional petroleum geology. Pet. Explor. Dev. 2013, 40, 413–428. [Google Scholar]

| Property | Typical Range | References |

|---|---|---|

| Permeability | <2 mD | [2,7] |

| Porosity | <20% | [15] |

| Pore–throat size | 0.03 µm–2 µm | [16,17] |

| Clay content | 7%–30% | [18] |

| Lithology | shale, sandstone, carbonate | [19] |

| Driving mechanism | poor connectivity | [20] |

| Parameter | Value |

|---|---|

| Larmor frequency | 2 MHz |

| Echo spacing time, TE | 110 µs |

| Signal-to-noise ratio | 150 |

| Total number of scans | 32 |

| Number of echoes | 27,272 |

| Maximum T2 | 300 ms |

| Sample | Quartz | Plagioclase | Orthoclase | Anhydrite | Ilmenite | Siderite | Dolomite | Halite | Hematite | Pyrite | Chlorite | Illite | Kaolinite |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bandera | 64.4 | 12 | 1 | 3 | 1 | 0.5 | 0.4 | 1.4 | 1.2 | 0.8 | 3.4 | 6.4 | 4.5 |

| Kentucky | 77.1 | 10.2 | 2.8 | 3.6 | 0 | 0.7 | 0.9 | 0.8 | 0.3 | 0 | 0 | 3.6 | 0 |

| Scioto | 89.2 | 2.1 | 0.7 | 3 | 0 | 0.2 | 0 | 0.2 | 0.5 | 0 | 0.9 | 2.2 | 1 |

| Sample | Porosity | Permeability |

|---|---|---|

| (vol.%) | (mD) | |

| Bandera | 24.4 ± 0.20 | 24.12 ± 1.50 |

| Kentucky | 15.0 ± 0.11 | 0.98 ± 0.10 |

| Scioto | 17.5 ± 0.13 | 1.21 ± 0.10 |

| Sample | T2 Cut-Off | MSI | Micro-Throat Proportion | MTMR | MCI |

|---|---|---|---|---|---|

| (ms) | (v/v) | (%) | (v/v) | (v/v) | |

| Bandera | 17.8 | 0.38 | 36 | 0.56 | 0.21 |

| Kentucky | 12.2 | 0.48 | 50.9 | 1.03 | 0.49 |

| Scioto | 24.6 | 0.50 | 60 | 1.44 | 0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AlKharraa, H.; Wolf, K.-H.; AlQuraishi, A.; Mahmoud, M.; AlDuhailan, M.; Zitha, P. The Power of Characterizing Pore-Fluid Distribution for Microscopic CO2 Injection Studies in Tight Sandstones. Minerals 2023, 13, 895. https://doi.org/10.3390/min13070895

AlKharraa H, Wolf K-H, AlQuraishi A, Mahmoud M, AlDuhailan M, Zitha P. The Power of Characterizing Pore-Fluid Distribution for Microscopic CO2 Injection Studies in Tight Sandstones. Minerals. 2023; 13(7):895. https://doi.org/10.3390/min13070895

Chicago/Turabian StyleAlKharraa, Hamad, Karl-Heinz Wolf, Abdulrahman AlQuraishi, Mohamed Mahmoud, Mohammed AlDuhailan, and Pacelli Zitha. 2023. "The Power of Characterizing Pore-Fluid Distribution for Microscopic CO2 Injection Studies in Tight Sandstones" Minerals 13, no. 7: 895. https://doi.org/10.3390/min13070895

APA StyleAlKharraa, H., Wolf, K.-H., AlQuraishi, A., Mahmoud, M., AlDuhailan, M., & Zitha, P. (2023). The Power of Characterizing Pore-Fluid Distribution for Microscopic CO2 Injection Studies in Tight Sandstones. Minerals, 13(7), 895. https://doi.org/10.3390/min13070895