Feasibility of High-Density and Non-Segregable Niobium Ore Tailings

Abstract

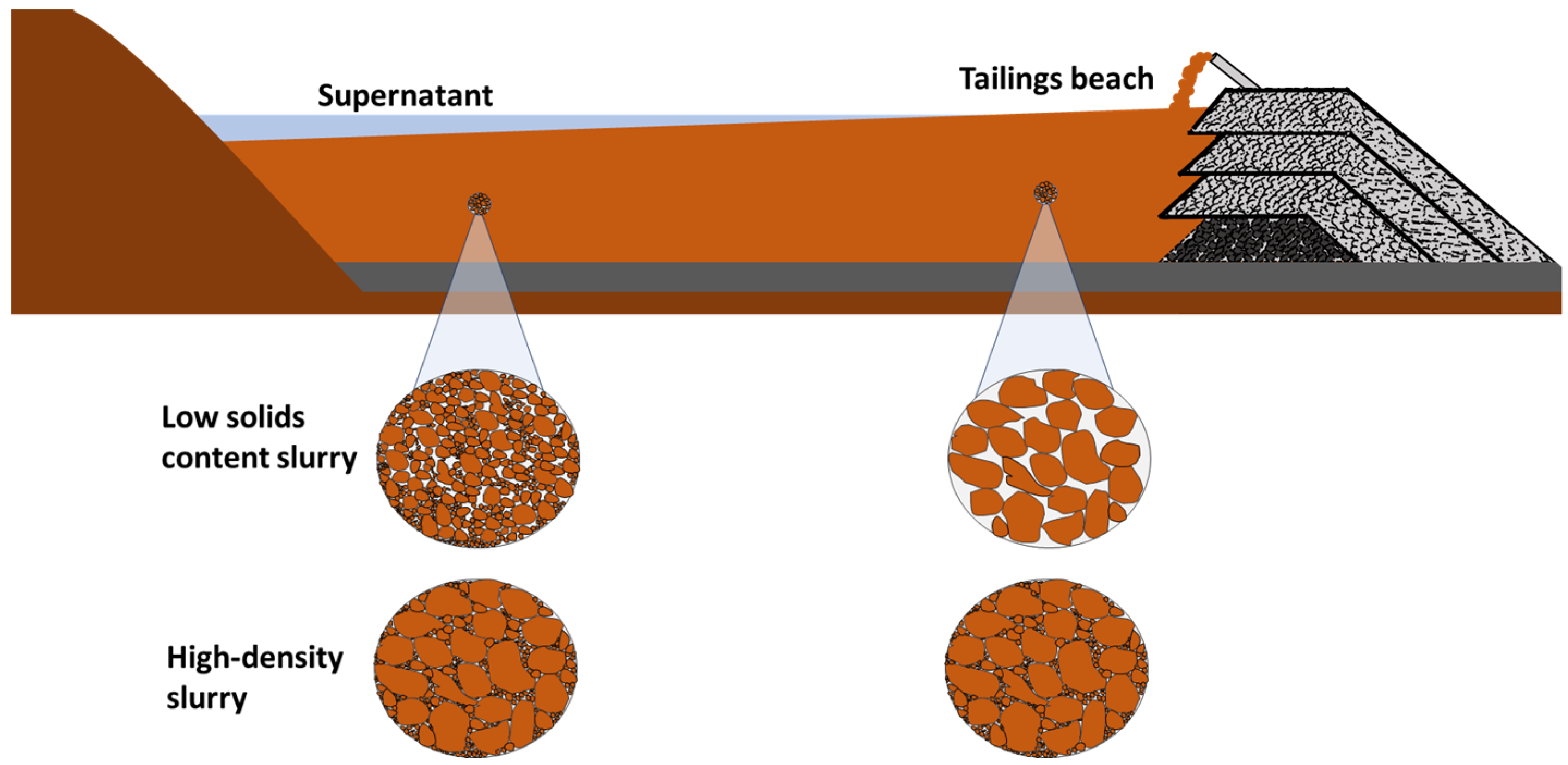

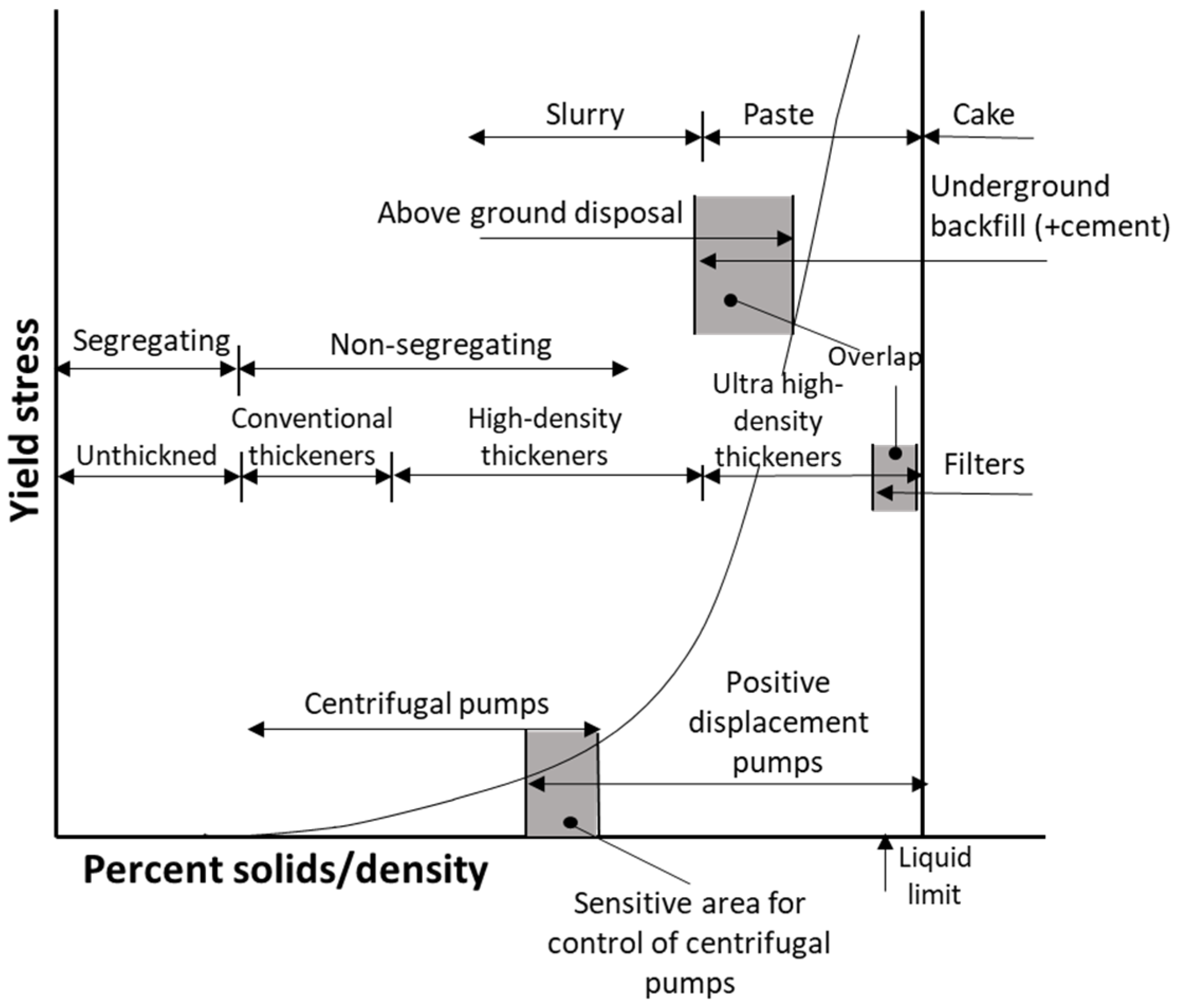

1. Introduction

2. Materials and Methods

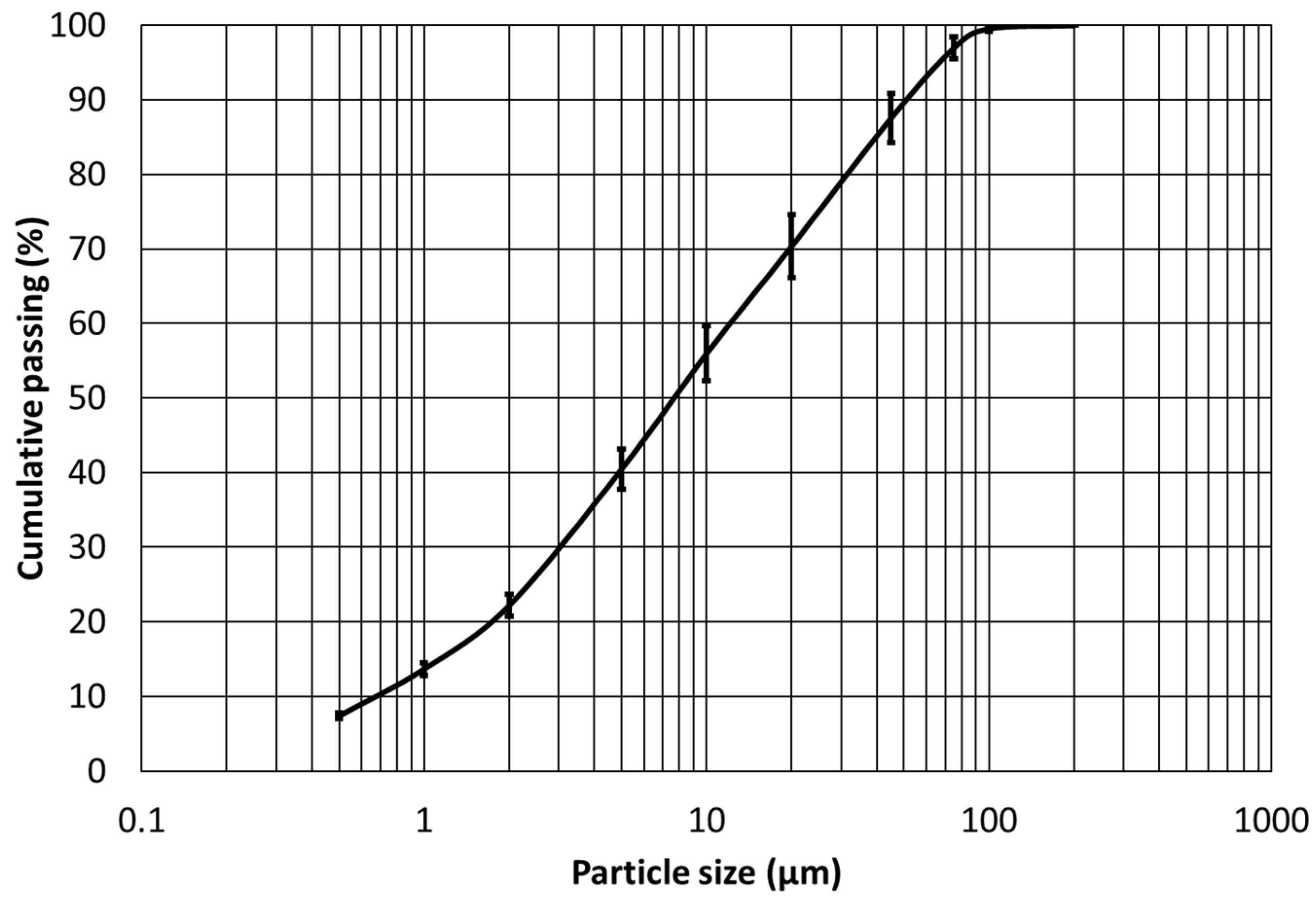

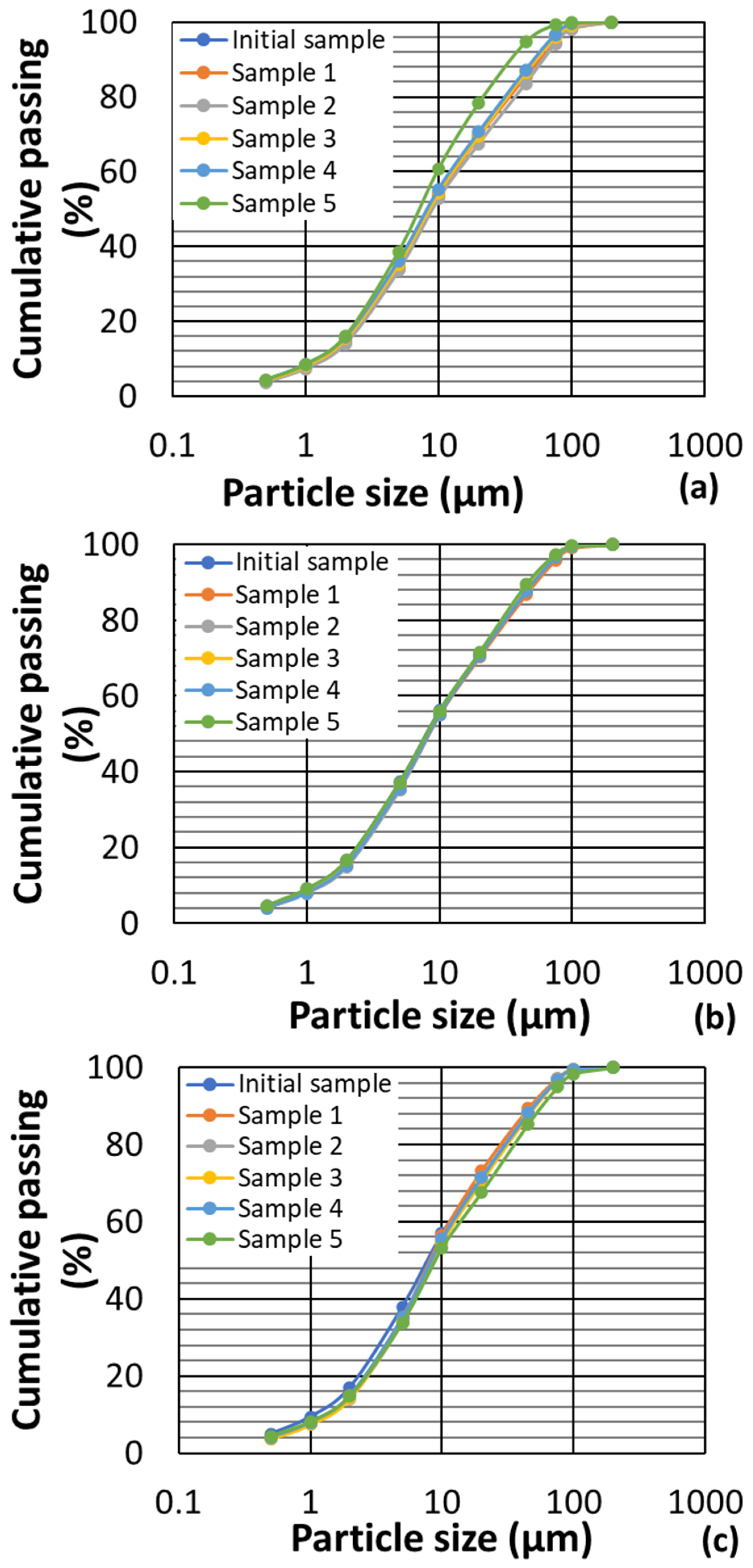

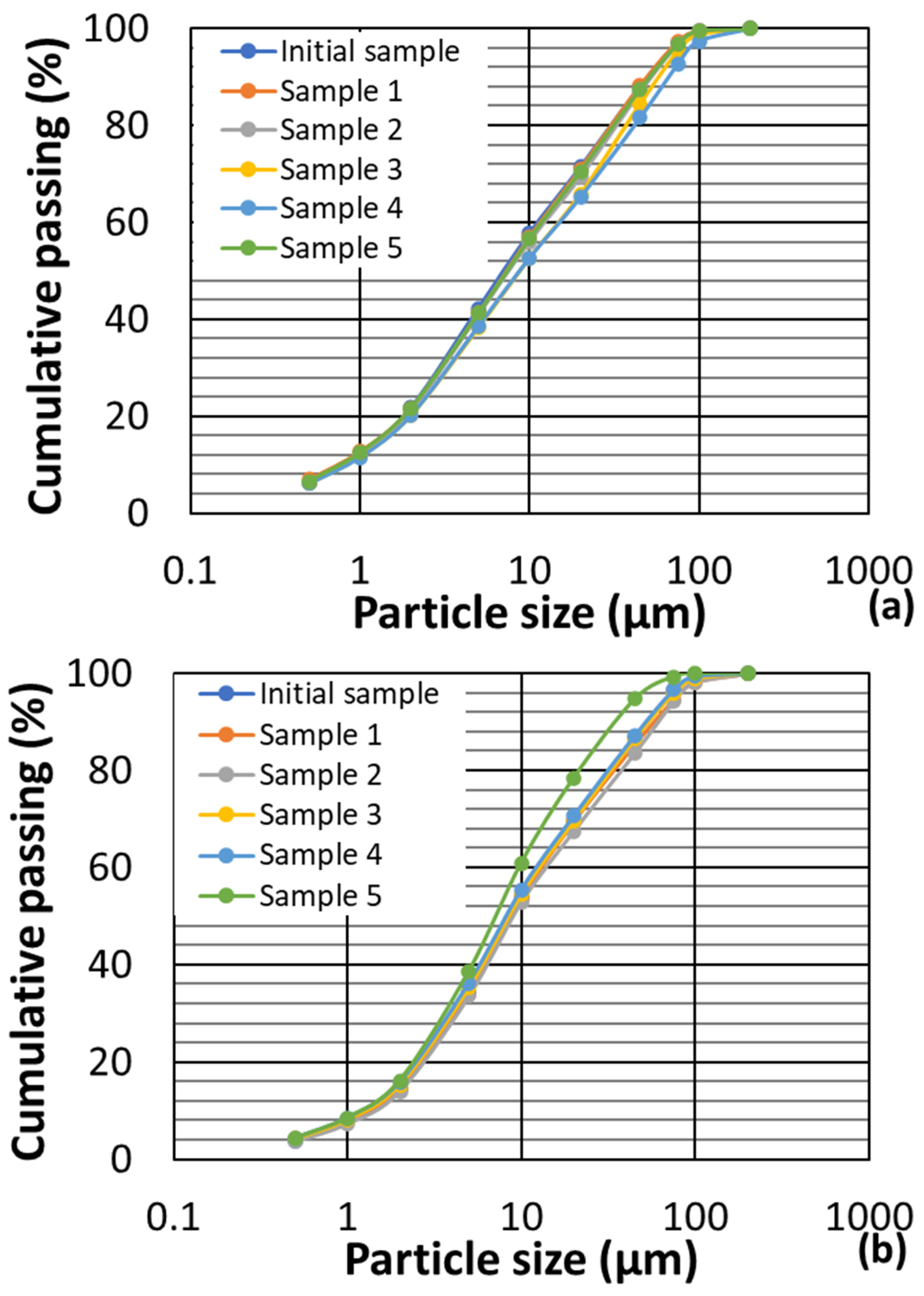

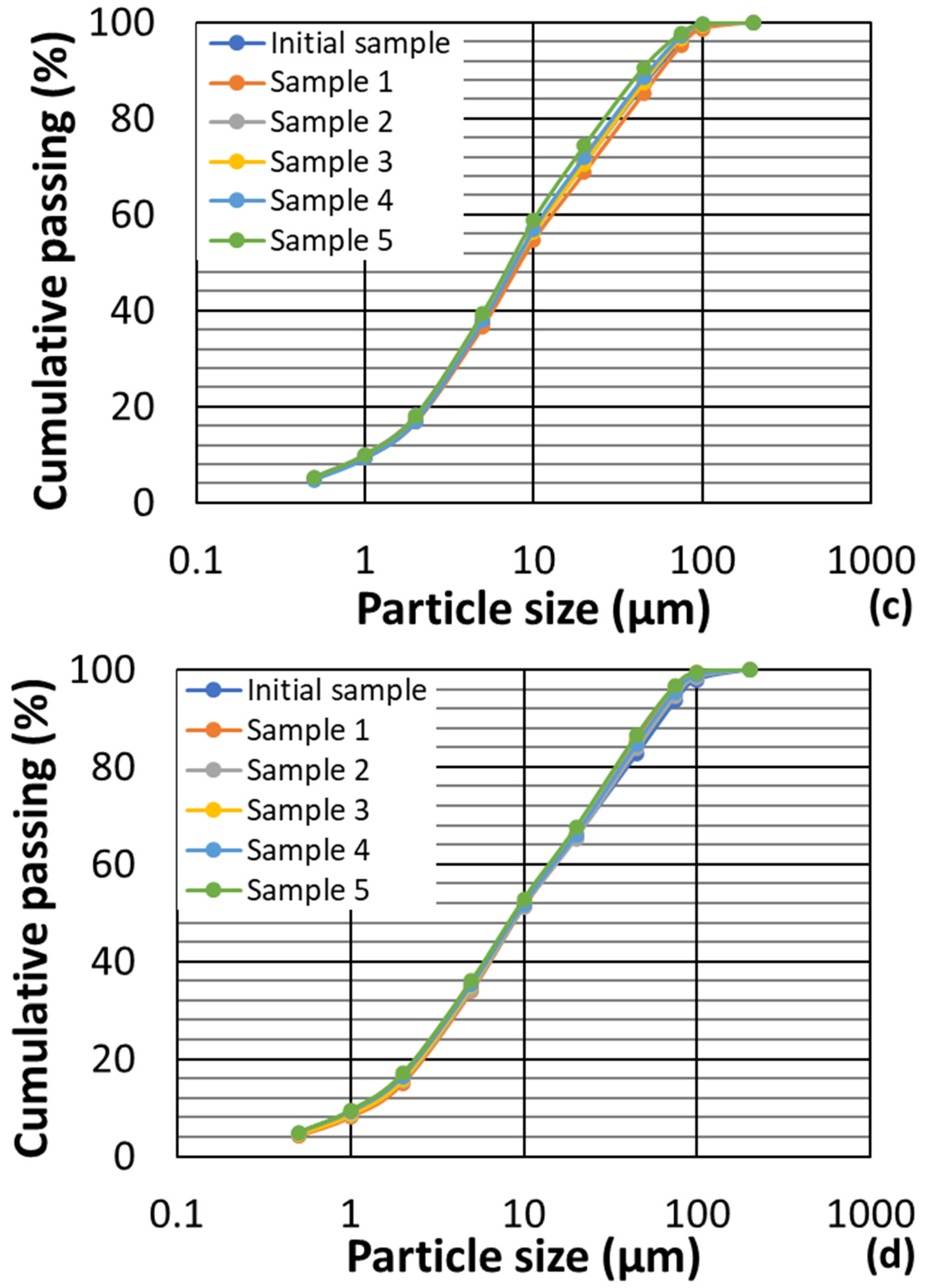

2.1. Solids Characterization

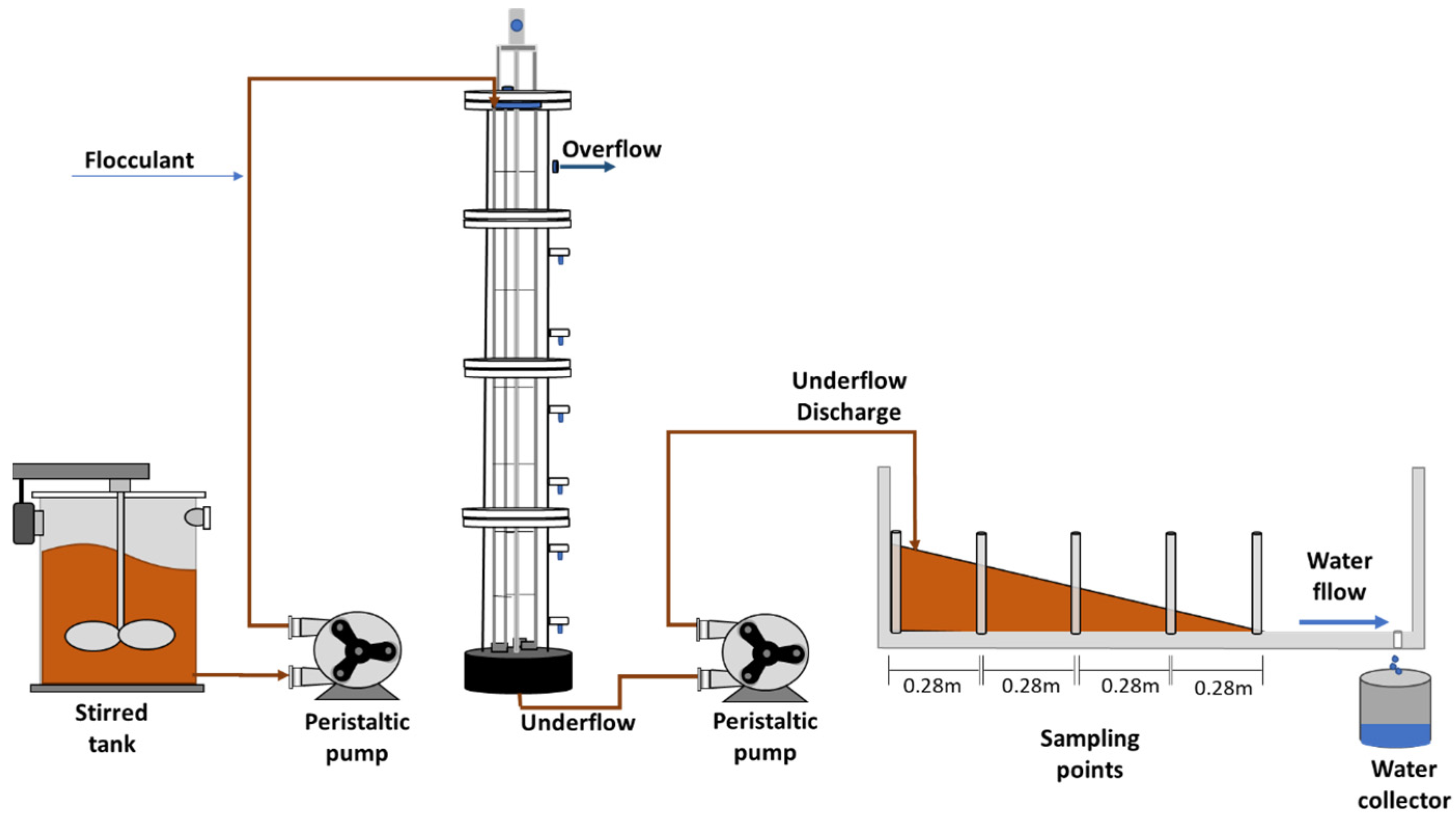

2.2. Thickening Tests

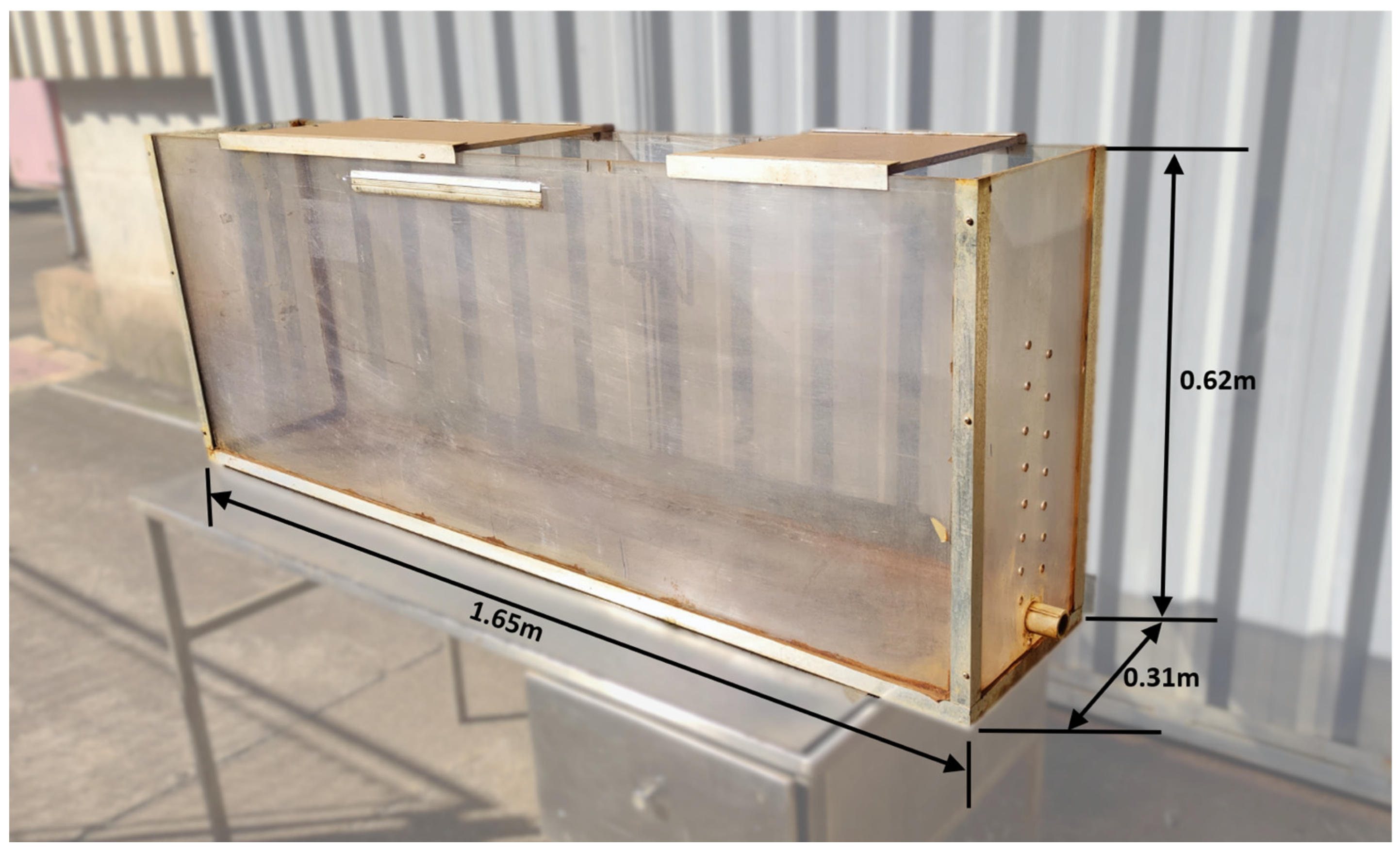

2.3. Underflow Disposal Characteristics

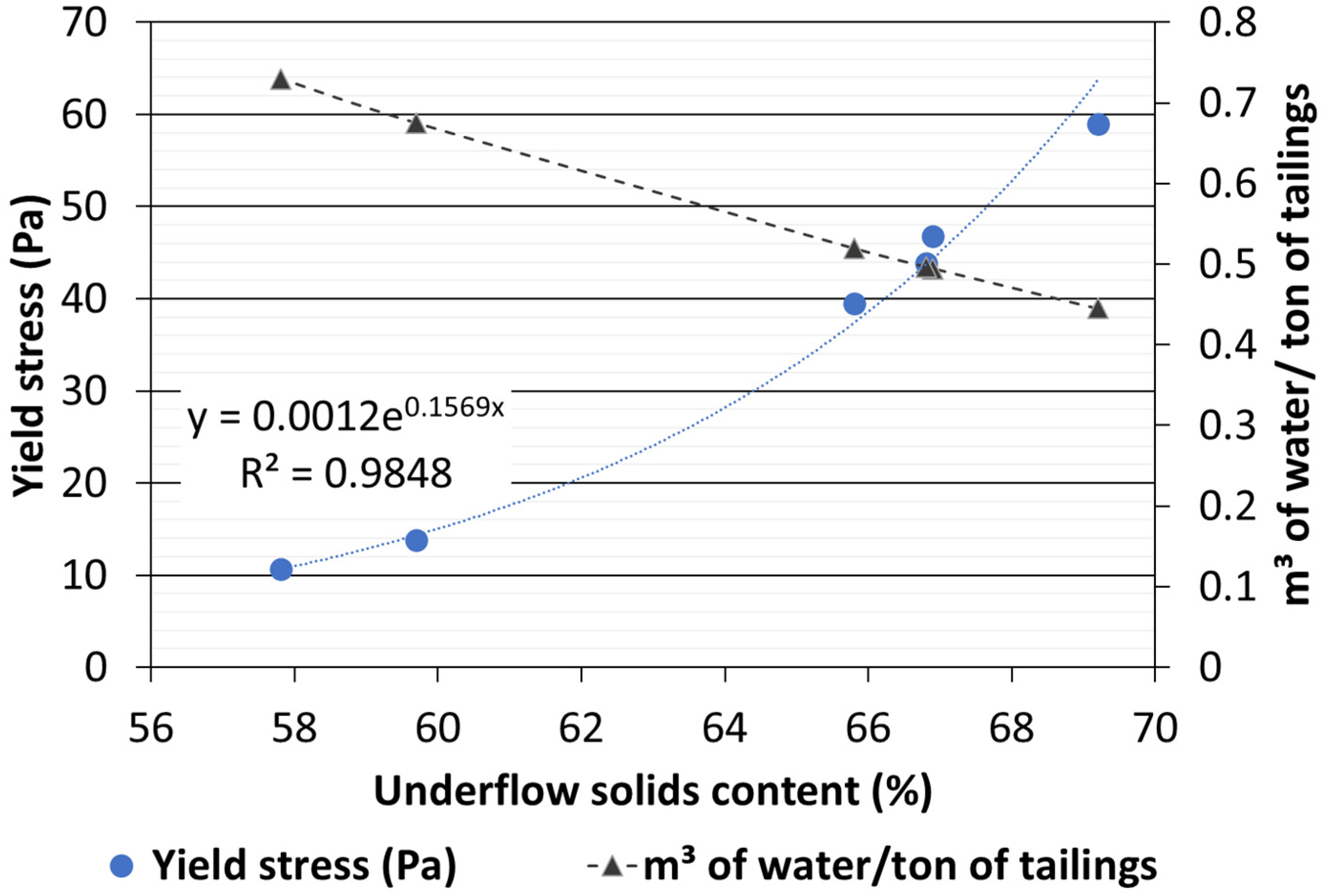

2.3.1. Rheology

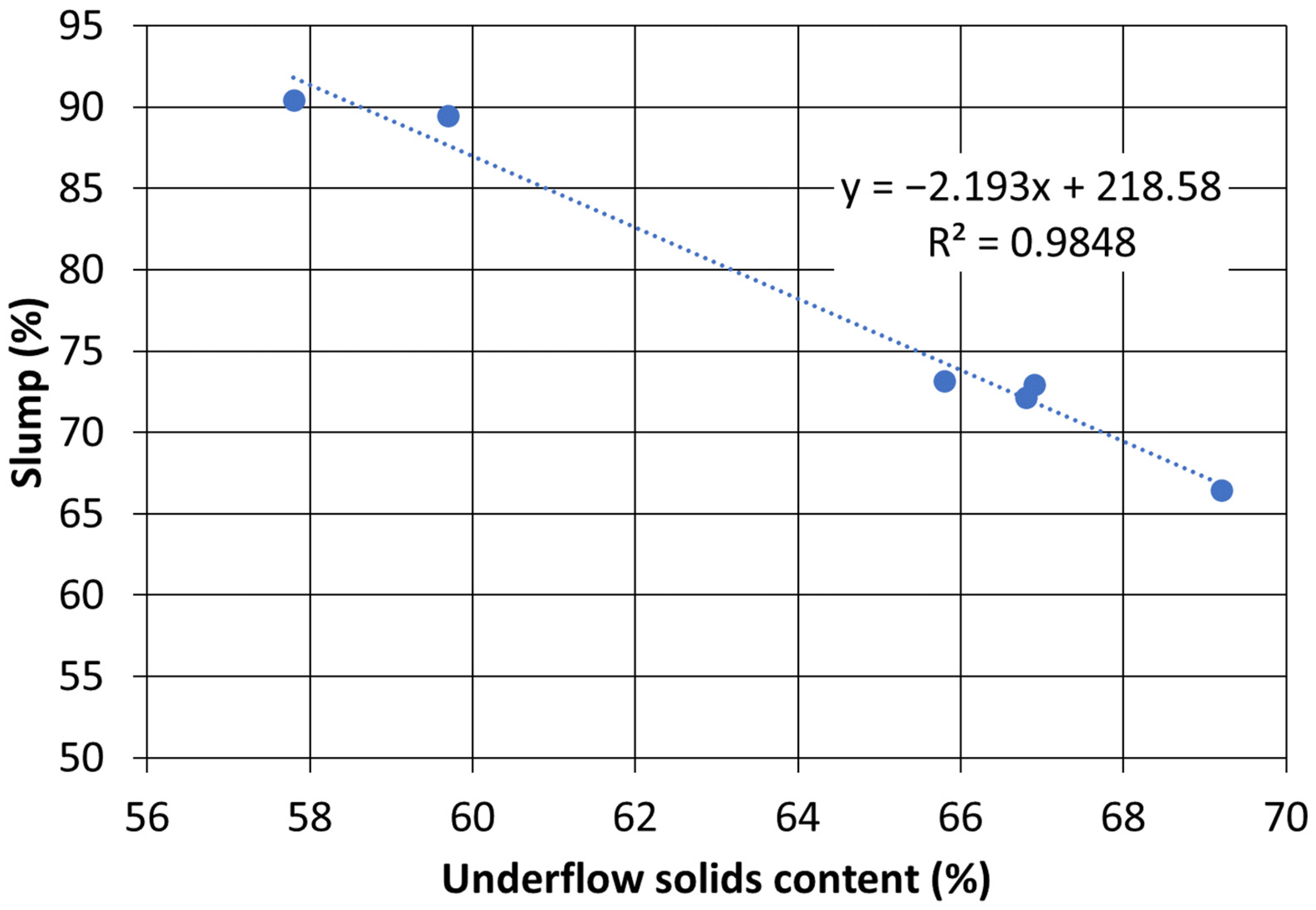

2.3.2. Slump Test

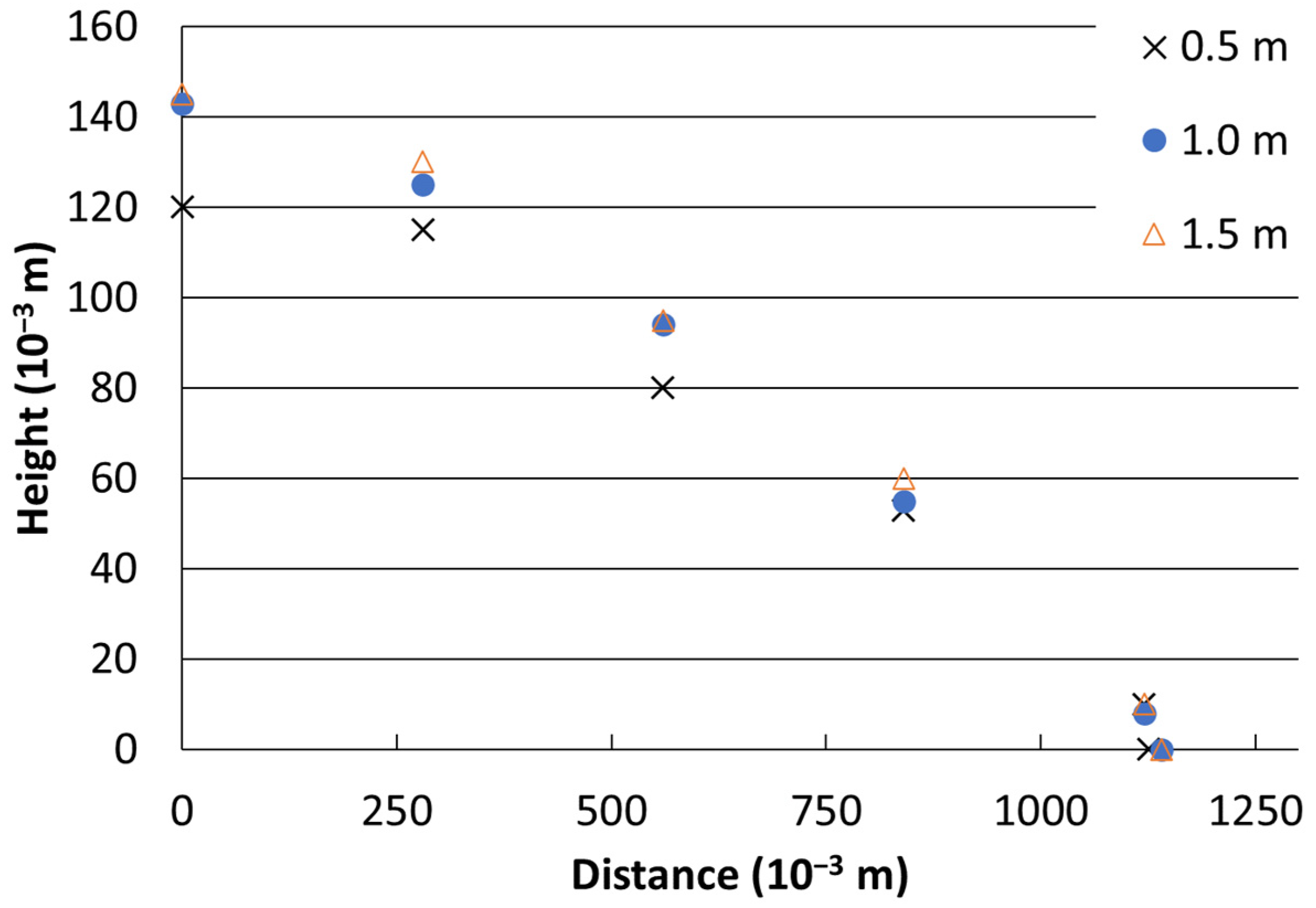

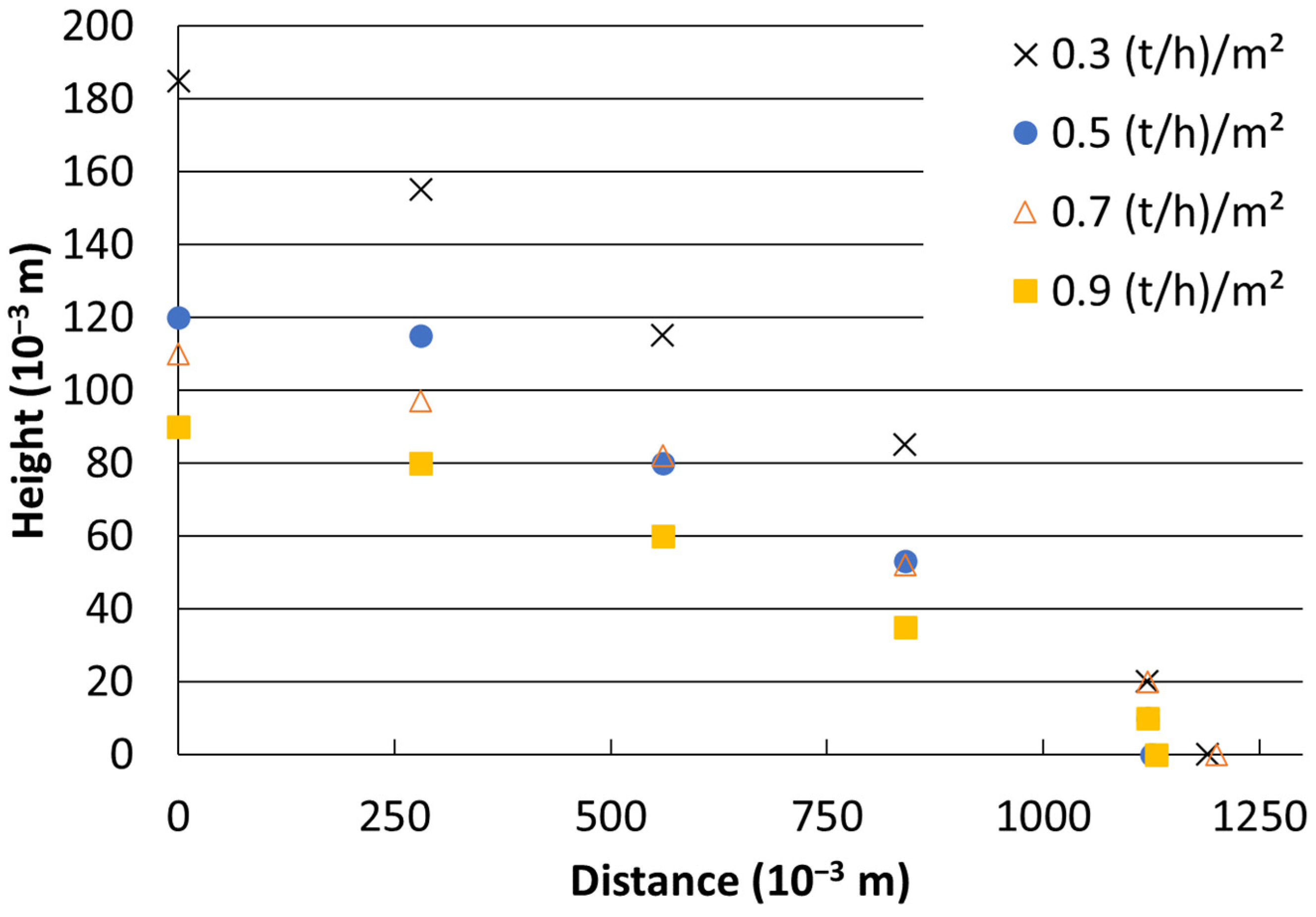

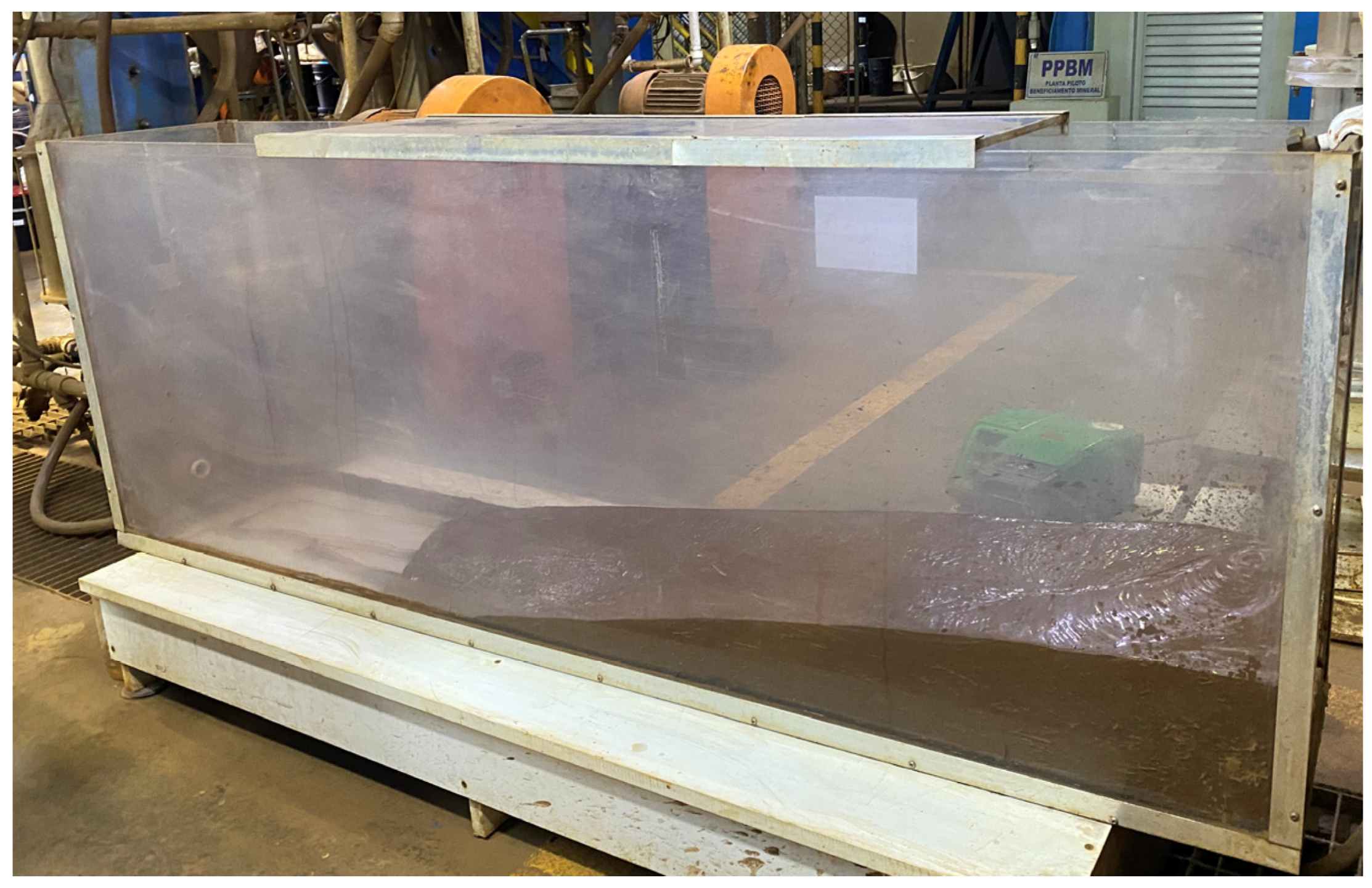

2.3.3. Flume Test

3. Results and Discussion

3.1. Solids Characterization

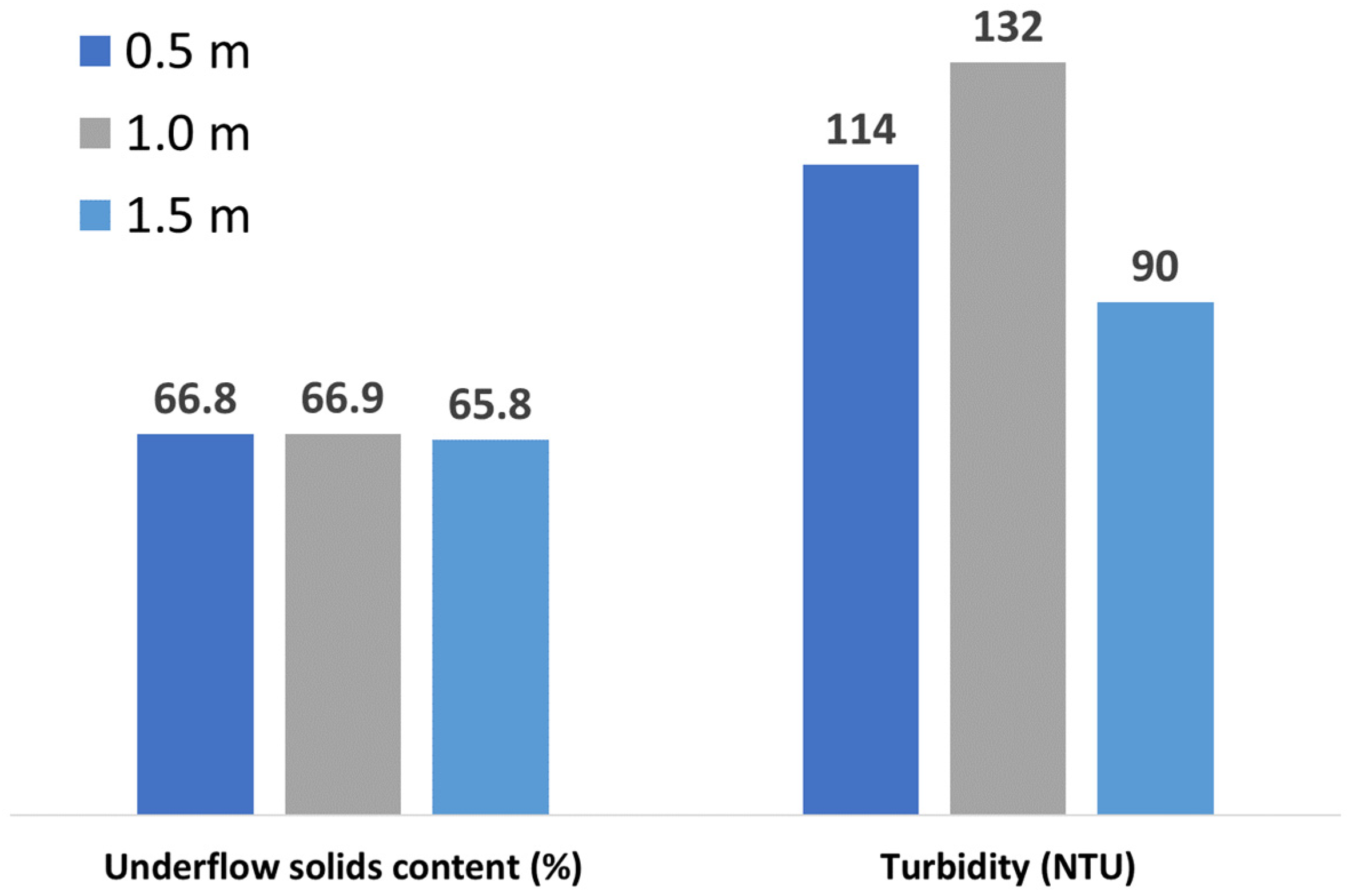

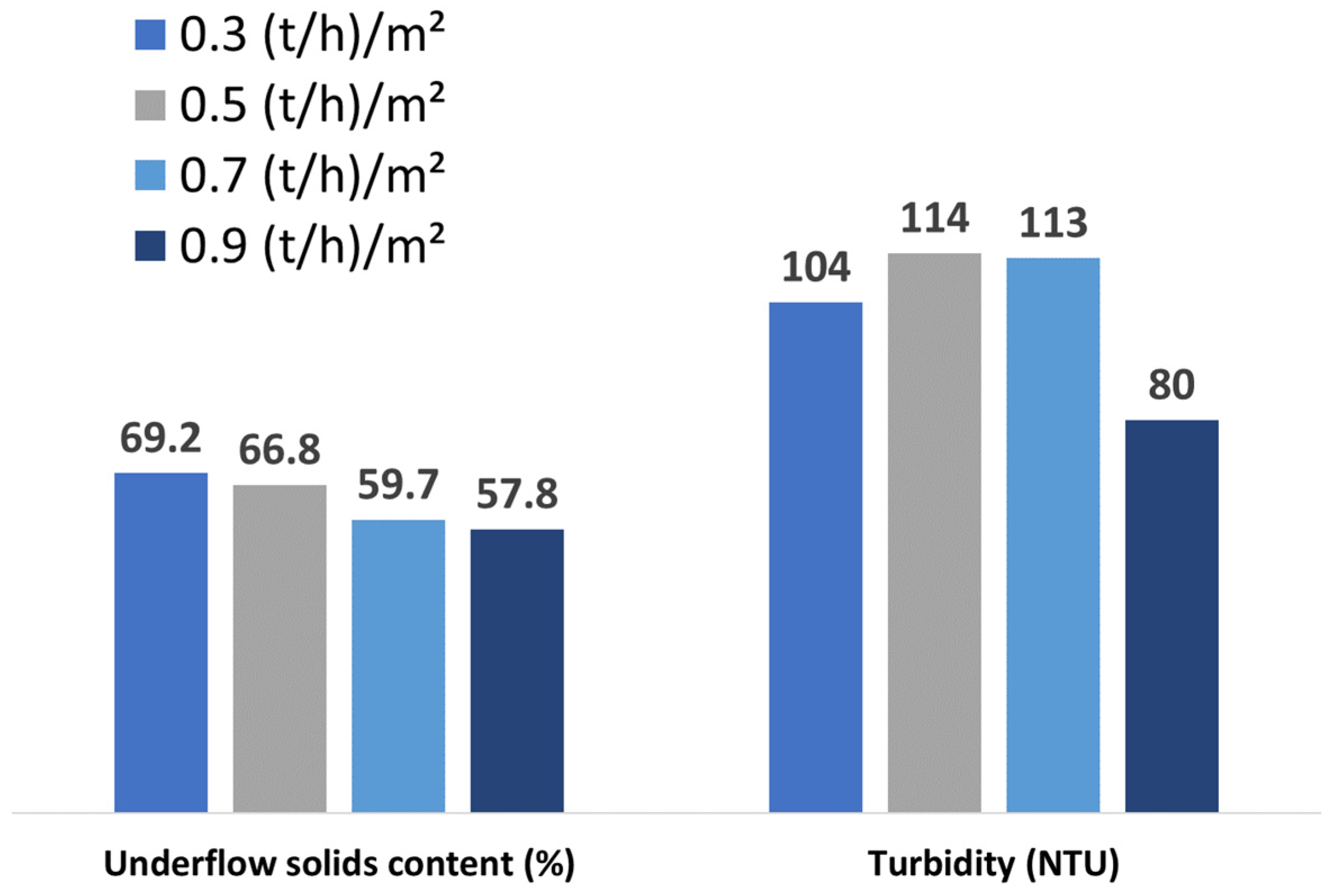

3.2. Thickening Tests

3.3. Underflow Disposal Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fourie, A.B. Perceived and realized benefits of paste and thickened tailings for surface deposition. In Proceedings of the International Seminar on Paste and Thickened Tailings, Sun City, South Africa, 16–19 April 2012. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 114, 106025. [Google Scholar] [CrossRef]

- Davies, M. Filtered Dry Stacked Tailings: The Fundamentals. In Proceedings of the Tailings and Mine Waste Conference, Vancouver, BC, Canada, 6–9 November 2011. [Google Scholar] [CrossRef]

- Franks, D.M.; Boger, D.V.; Cote, C.M.; Mulligan, D.R. Sustainable Development Principles for the Disposal of Mining and Mineral Processing Wastes. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Wang, C.; Harbottle, D.; Liu, Q.; Xu, Z. Current state of fine mineral tailings treatment: A critical review on theory and practice. Miner. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Boger, D.V. Rheology of slurries and environmental impacts in the mining industry. Annu. Rev. Chem. Biomol. Eng. 2013, 4, 239–257. [Google Scholar] [CrossRef] [PubMed]

- Jewell, R. The Evolution of Paste and Thickened Tailings; Australian Centre for Geomechanics: Newsletter, Australia, 2010; Volume 35, pp. 1–3. [Google Scholar]

- Jewell, R.J.; Fourie, A.B. Paste and Thickened Tailings—A Guide, 2nd ed.; Australian Centre for Geomechanics: Perth, Australia, 2006; 242p. [Google Scholar]

- Chaves, A.P. Teoria e Prática do Tratamento de Minérios: Desaguamento, Espessamento e Filtragem, 4th ed.; Oficina de Textos: São Paulo, Brazil, 2013; Volume 2, pp. 1–240. [Google Scholar]

- Cooling, D.J. Improving the Sustainability of Residue Management Practices—Alcoa World Alumina Australia. In Proceedings of the 10th International Seminar on Paste and Thickened Tailings, Perth, Australia, 13–17 March 2007. [Google Scholar]

- Kam, S.; Girard, J.; Hmidi, N.; Mao, Y.; Longo, S. Thickened tailings disposal at Musselwhite Mine. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011. [Google Scholar]

- Mcphail, G.; Noble, A.; Papageorgiou, G.; Wilkinson, D. Development and Implementation of Thickened Tailings Discharge at Osborne Mine, Queensland, Australia. In Proceedings of the International Seminar on Paste and Thickened Tailings, Cape Town, South Africa, 31 March–2 April 2004. [Google Scholar]

- Mudd, G.M.; Boger, D.V. The Ever Growing Case for Paste and Thickened Tailings—Towards More Sustainable Mine Waste Management. J. Aust. Inst. Min. Metall 2013, 2, 56–59. Available online: https://www.researchgate.net/publication/288595659_The_ever_growing_case_for_paste_and_thickened_tailings_-_Towards_more_sustainable_mine_waste_management (accessed on 5 June 2023).

- Xu, W.; Tian, M.; Li, Q. Time-dependent rheological properties and mechanical performance of fresh cementes tailings backfill containing flocculants. Miner. Eng. 2020, 145, 106064. [Google Scholar] [CrossRef]

- Reyes, C.; Álvarez, M.; Ihle, C.F.; Contreras, M.; Kracht, W. The influence of seawater on magnetite tailing rheology. Miner. Eng. 2019, 131, 363–369. [Google Scholar] [CrossRef]

- Fernández-Iglesias, A.; Araujo, A.C.; Goosens, M. Studying feasibility of paste and thickened tailings at laboratory scale—Pilot thickeners. In Proceedings of the 16th International Seminar on Paste and Thickened Tailings, Perth, Australia, 17–20 June 2013. [Google Scholar] [CrossRef]

- Barrera, S.; Engels, J. High-density thickening for large production rates: Main challenges. In Proceedings of the 21st International Seminar on Paste and Thickened Tailings, Perth, Australia, 11–13 April 2018. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.; Jiao, H.; Hu, K.; Wan, L.; Ruan, Z.; Yang, L. Mechanism of Rake Frame Shear Drainage during Gravity De-watering of Ultrafine Unclassified Tailings for Paste Preparation. Minerals 2022, 12, 240. [Google Scholar] [CrossRef]

- Schoenbrunn, F.; Laros, T.; Henriksson, B.; Arbuthnot, I. Solid and Liquid Separation. In Mineral Processing & Extractive Metallurgy Handbook; Kawatra, S.K., Young, C.A., Eds.; Society for Mining, Metallurgy & Exploration: Englewood, CO, USA, 2019; pp. 1069–1107. [Google Scholar]

- Osorio, C.A.H.; de Araujo, A.C.; Valadão, G.E.S. Estudo de Características de Algumas Pastas Minerais. Tecnol. Metal. Mater. Min. 2008, 4, 50–55. [Google Scholar] [CrossRef]

- Sofrà, F.; Boger, D.V. Rheology for thickened tailings and paste—History, state-of-the-art and future directions. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011. [Google Scholar] [CrossRef]

- Usher, S.P.; Scales, P.J. Steady state thickener modelling from the compressive yield stress and hindered settling function. Chem. Eng. J. 2005, 111, 253–261. [Google Scholar] [CrossRef]

- Boger, D.V. A Personal perspective on paste and thickened tailings—A decade on. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011. [Google Scholar] [CrossRef]

- Panchal, S.; Deb, D.; Sreenivas, T. Mill tailings based composites as paste backfill in mines of U-bearing dolomitic limestone ore. J. Rock Mech. Geotech. Eng. 2018, 10, 310–322. [Google Scholar] [CrossRef]

- Yang, L.; Qiu, J.; Jiang, H.; Hu, S.; Li, H.; Li, S. Use of Cemented Super-Fine Unclassified Tailings Backfill for Control of Subsidence. Minerals 2017, 7, 216. [Google Scholar] [CrossRef]

- Fitton, T.G. Some comments on thickened tailings and beach slopes. In Proceedings of the 21st International Seminar on Paste and Thickened Tailings, Perth, Australia, 11–13 April 2018. [Google Scholar] [CrossRef]

- Hernández, C.A.; Pizarro, E.A.; Molina, J.A.; de Araujo, A.C.; Valadão, G.E.S. Mineral Paste Comparison Between Copper and Iron Tails. In Proceedings of the Twelfth International Seminar on Paste and Thickened Tailings, Perth, Australia, 21–24 April 2009. [Google Scholar] [CrossRef]

- Li, A.L.; Been, K.; Ritchie, D.; Welch, D. Stability of Large Thickened, Non-Segregated Tailings Slopes. In Proceedings of the Twelfth International Seminar on Paste and Thickened Tailings, Perth, Australia, 21–24 April 2009. [Google Scholar] [CrossRef]

- Fourie, A.B.; Gawu, S.K.Y. The validity of laboratory flume data for predicting beach slopes of thickened tailings deposits. In Proceedings of the Thirteenth International Seminar on Paste and Thickened Tailings, Toronto, Canada, 3–6 May 2010. [Google Scholar] [CrossRef]

| Bed Height (m) | Underflow Solids Content (%) | Yield Stress (Pa) |

|---|---|---|

| 0.5 | 66.8 | 43.9 |

| 1.0 | 66.9 | 46.8 |

| 1.5 | 65.8 | 39.5 |

| Solids Flux Rate (t/h)/m2 | Underflow Solids Content (%) | Yield Stress (Pa) |

|---|---|---|

| 0.3 | 69.2 | 59 |

| 0.5 | 66.8 | 43.9 |

| 0.7 | 59.7 | 13.8 |

| 0.9 | 57.8 | 10.7 |

| Bed Height (m) | Slump (%) | Image |

|---|---|---|

| 0.5 | 72.2 |  |

| 1.0 | 72.9 |  |

| 1.5 | 73.2 |  |

| Solids Flux Rate (t/h)/m2 | Slump (%) | Image |

|---|---|---|

| 0.3 | 66.4 |  |

| 0.5 | 67.1 |  |

| 0.7 | 89.4 |  |

| 0.9 | 90.5 |  |

| Bed Height (m) | Disposal Angle (°) | Inclination (%) |

|---|---|---|

| 0.5 | 6.0 | 10.7 |

| 1.0 | 7.1 | 12.5 |

| 1.5 | 7.2 | 12.7 |

| Solids Flux Rate (t/h)/m2 | Disposal Angle (°) | Inclination (%) |

|---|---|---|

| 0.3 | 8.8 | 15.5 |

| 0.5 | 6.0 | 10.7 |

| 0.7 | 5.2 | 9.2 |

| 0.9 | 4.6 | 8.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Furtado, R.M.; Chaves, A.P.; Testa, F.G.; de Paula, P.T. Feasibility of High-Density and Non-Segregable Niobium Ore Tailings. Minerals 2023, 13, 820. https://doi.org/10.3390/min13060820

Furtado RM, Chaves AP, Testa FG, de Paula PT. Feasibility of High-Density and Non-Segregable Niobium Ore Tailings. Minerals. 2023; 13(6):820. https://doi.org/10.3390/min13060820

Chicago/Turabian StyleFurtado, Renata Monteiro, Arthur Pinto Chaves, Francisco Gregianin Testa, and Priscila Tavares de Paula. 2023. "Feasibility of High-Density and Non-Segregable Niobium Ore Tailings" Minerals 13, no. 6: 820. https://doi.org/10.3390/min13060820

APA StyleFurtado, R. M., Chaves, A. P., Testa, F. G., & de Paula, P. T. (2023). Feasibility of High-Density and Non-Segregable Niobium Ore Tailings. Minerals, 13(6), 820. https://doi.org/10.3390/min13060820