Study on the Quantitative Characterization and Heterogeneity of Pore Structure in Deep Ultra-High Pressure Tight Glutenite Reservoirs

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Research Region Overview

2.2. Rock Samples and Fluids

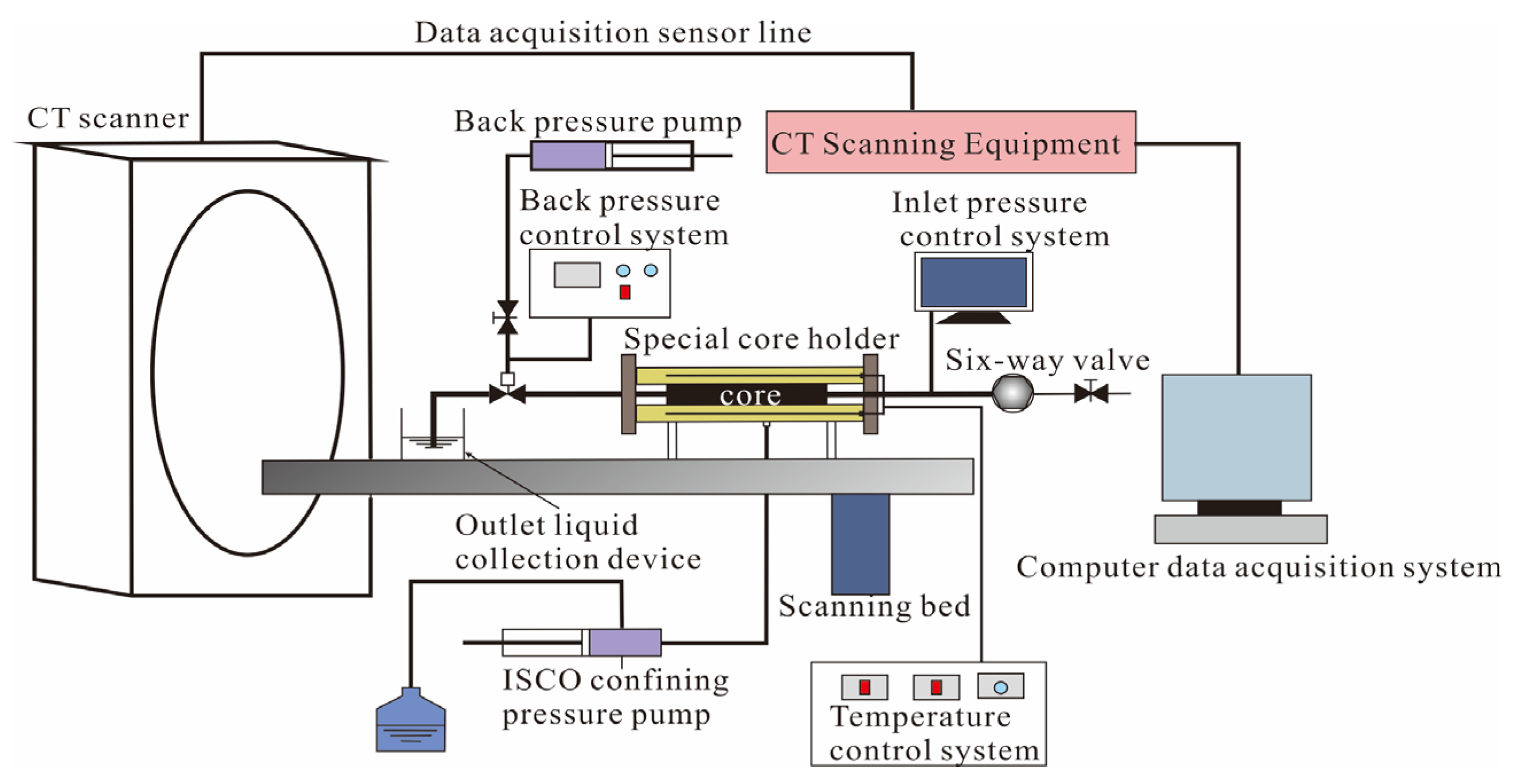

2.3. Experimental Apparatus

2.4. Experimental Procedure

- (1)

- The HPMI experiments were carried out, and the pore throat scale distribution obtained was used as a reference for the digital modeling of the core.

- (2)

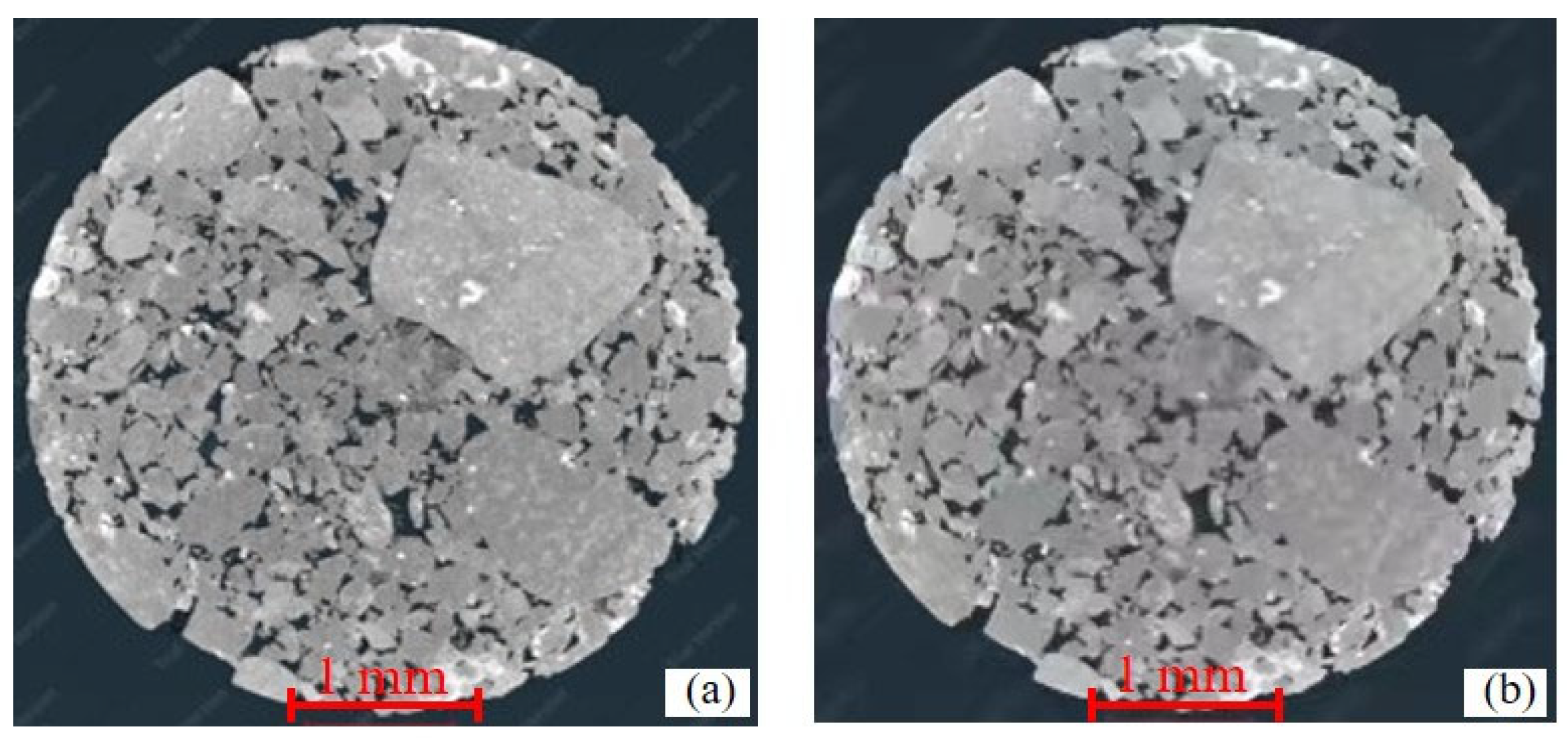

- The plunger sample was scanned using a micro-CT with a spatial resolution of 3.5 μm/pixel, and a two-dimensional section map was obtained to analyze the homogeneity of the core sample. In addition, a small core (2 mm in diameter) was drilled from the plunger sample, and a micro-CT fine scan was carried out at a resolution of 2 μm/pixel.

- (3)

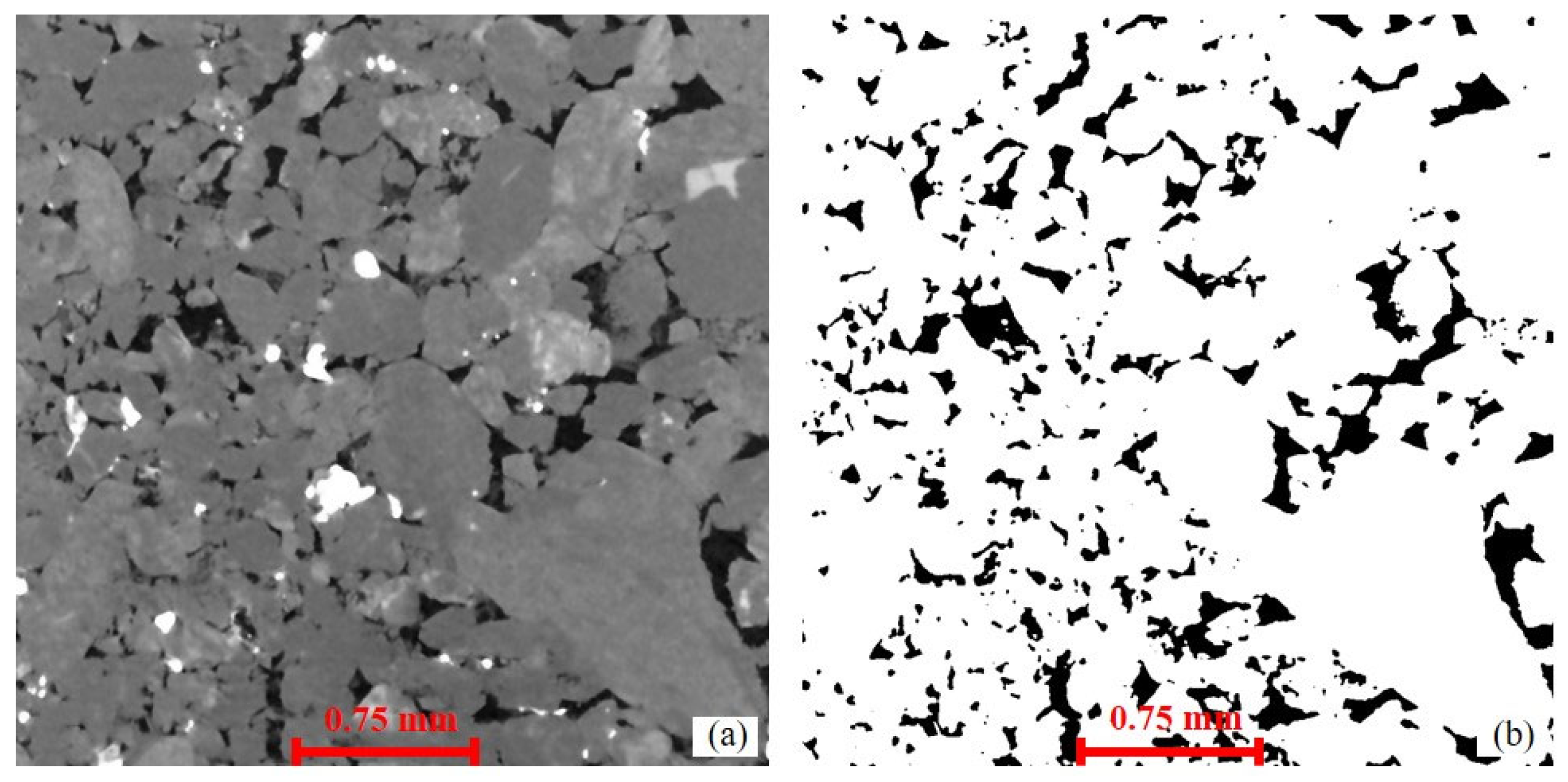

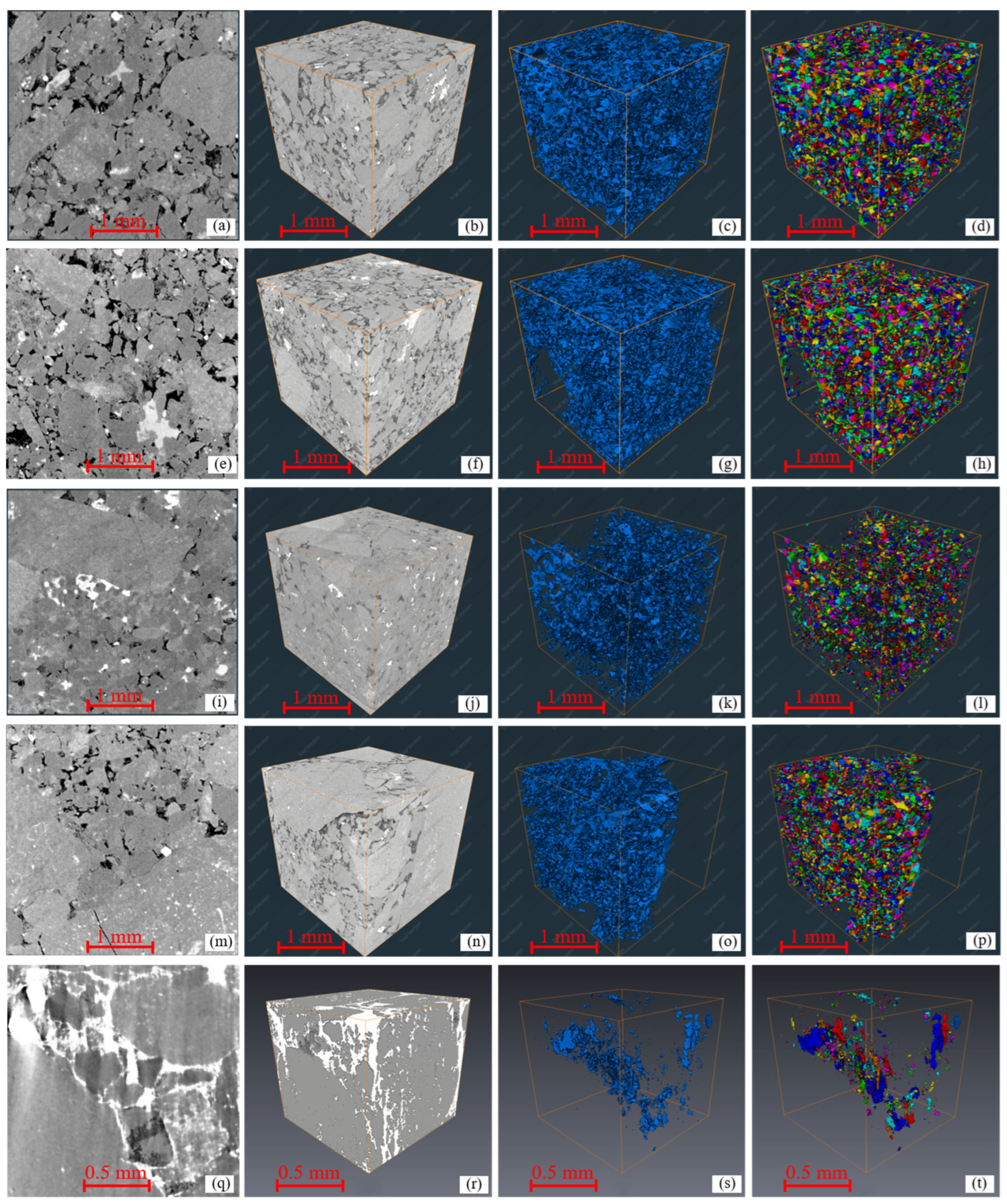

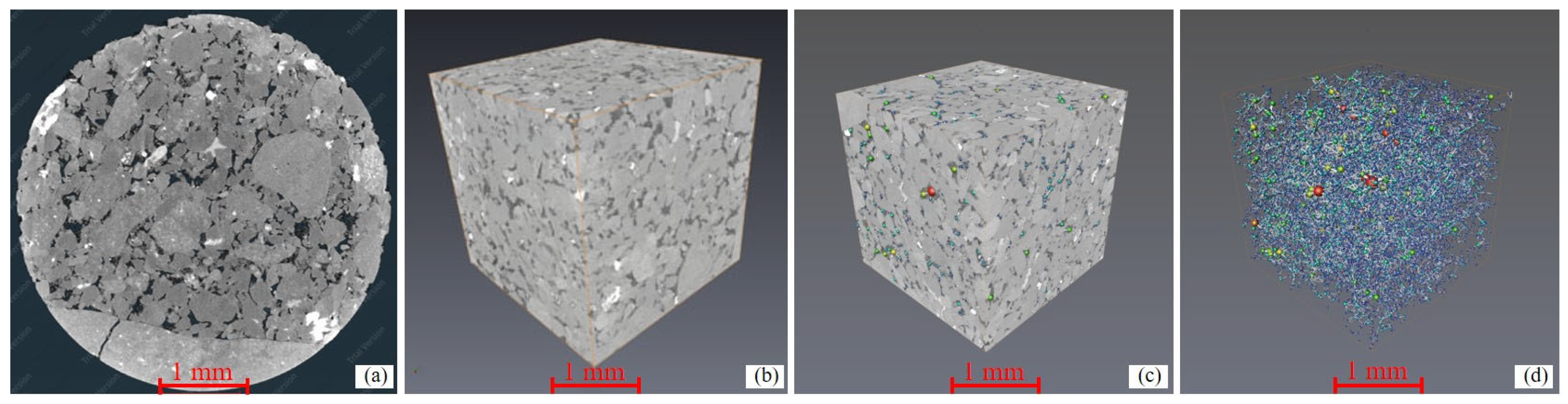

- The ImageJ and AVIZO 8.0 visualization softwares were used to carry out region selection, noise reduction, threshold segmentation, and post-processing of the grayscale images. The pores and framework were separated, the binarized three-dimensional (3D) digital core model was reconstructed, and the pore throat connectivity was analyzed using an image labeling algorithm.

- (4)

- The maximum sphere algorithm was used to extract the pore network model of the core, and the parameters such as the pore radius, throat length, and shape factor were calculated.

3. Experimental Results and Discussion

3.1. Petrophysical Properties and Pore Types

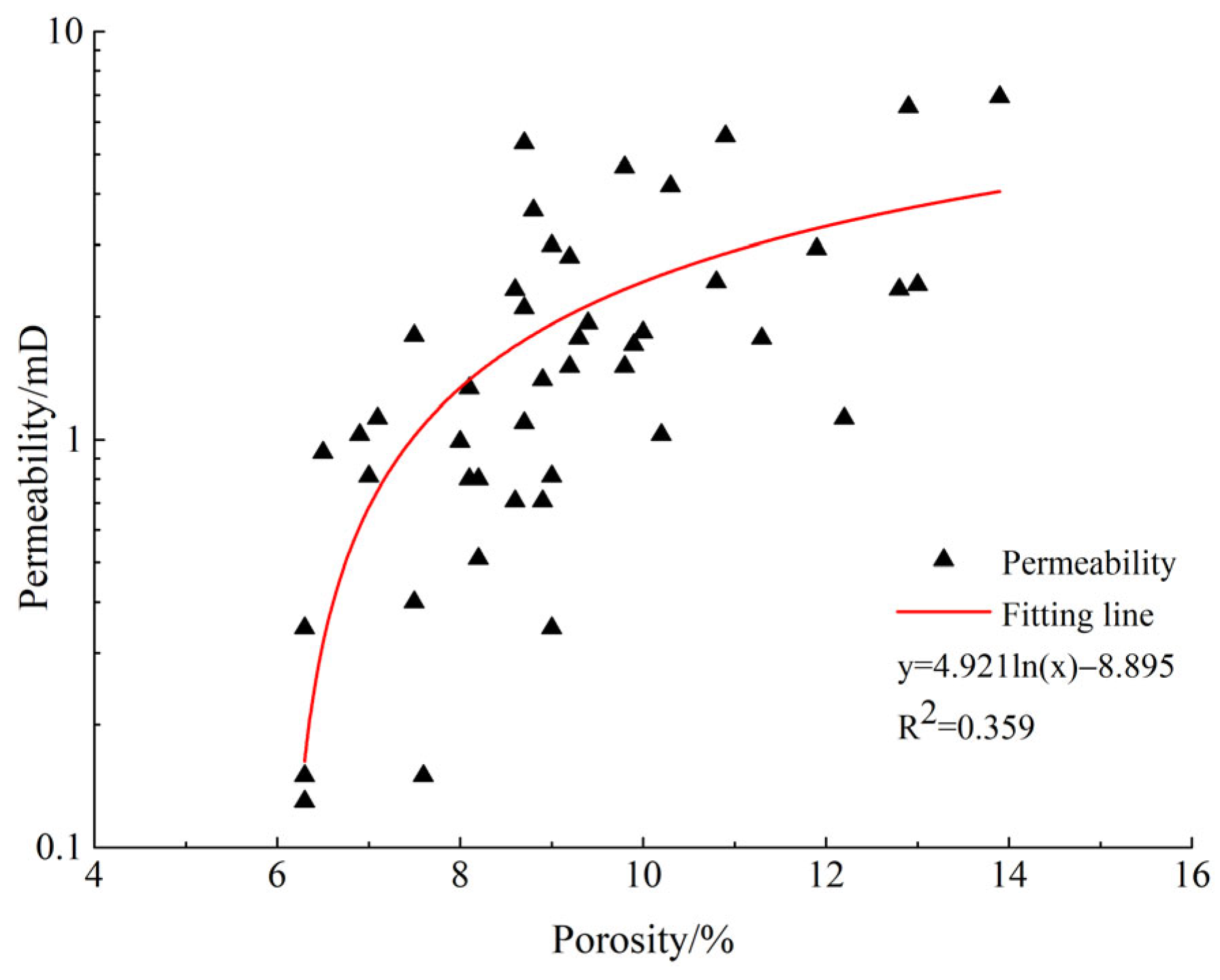

3.1.1. Pore Permeability Intersection Characteristics

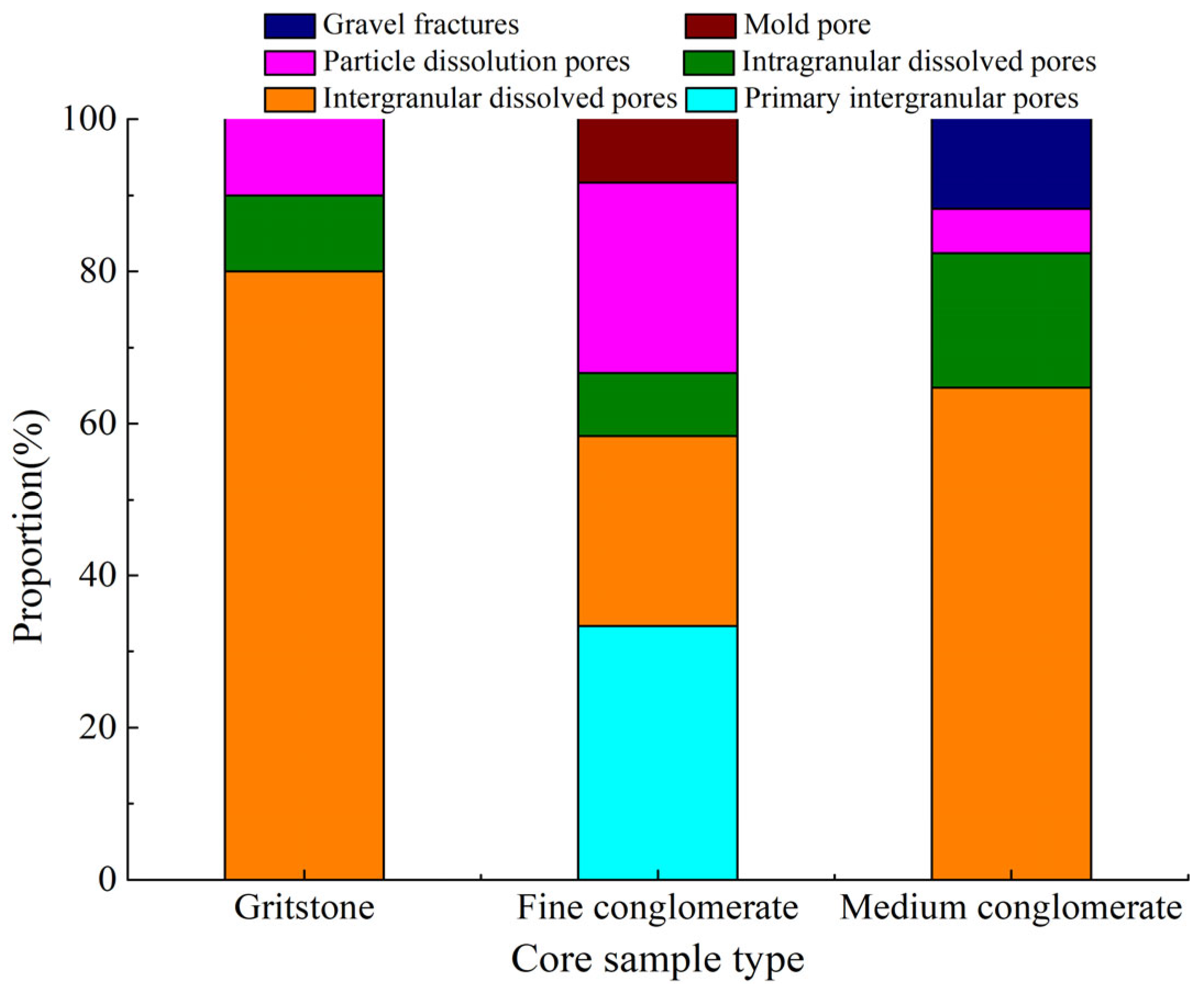

3.1.2. Classification of Pore Types

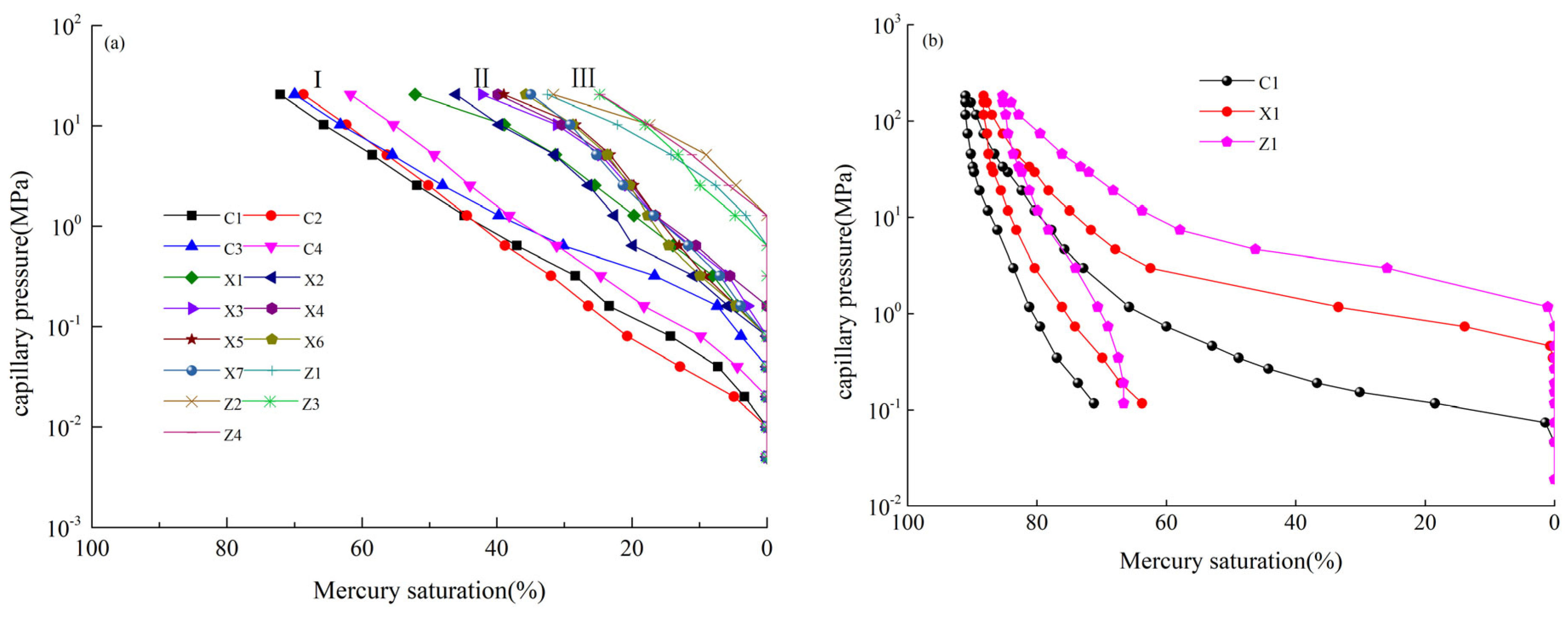

3.2. Pore Structure Characterization Based on HPMI and CSMI

3.3. Quantitative Characterization of Micron Pore Throat Structure

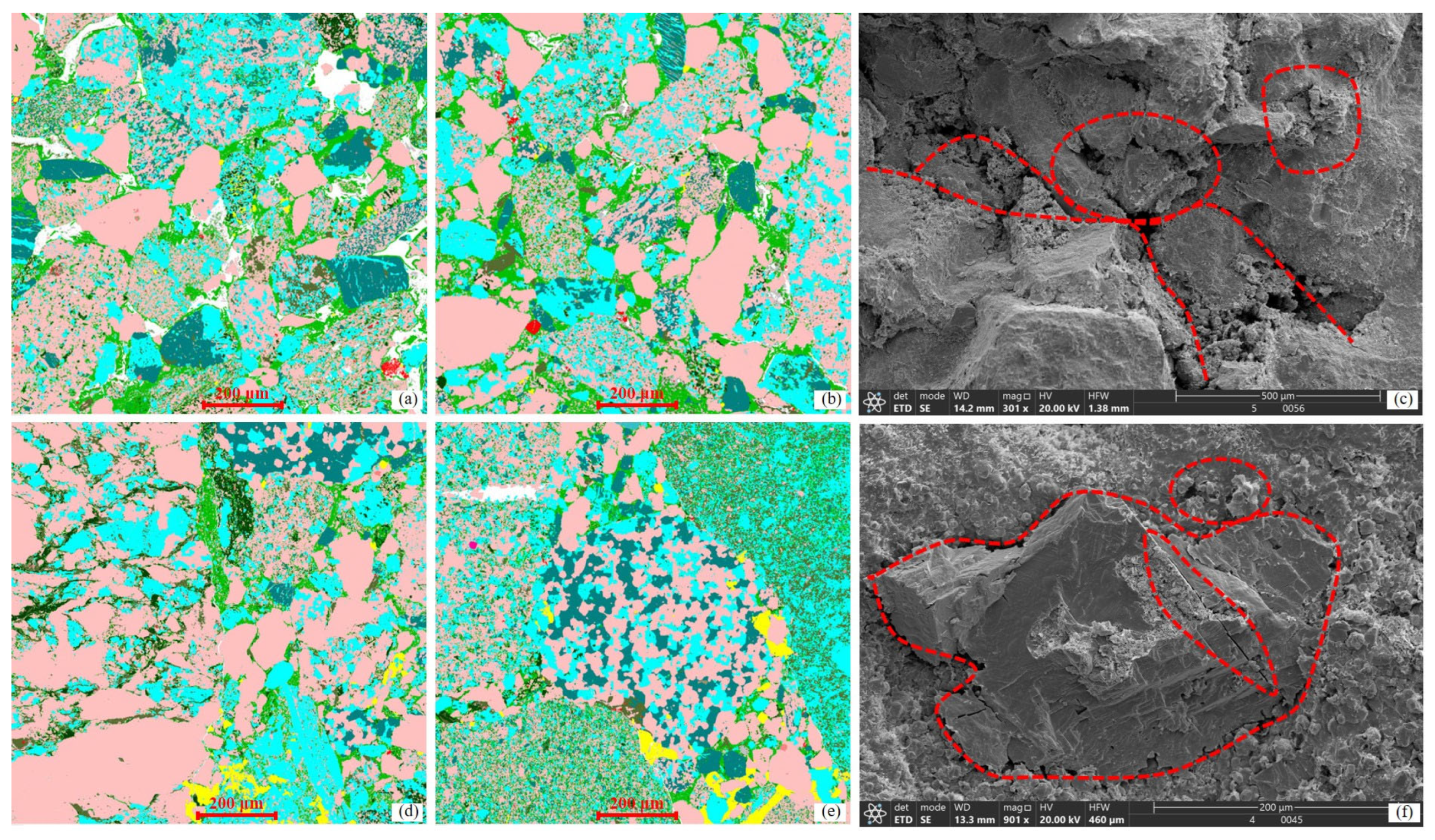

3.3.1. CT Grayscale Image Analysis

3.3.2. Image Processing

3.3.3. Three-Dimensional Digital Core Pore Network Model Reconstruction

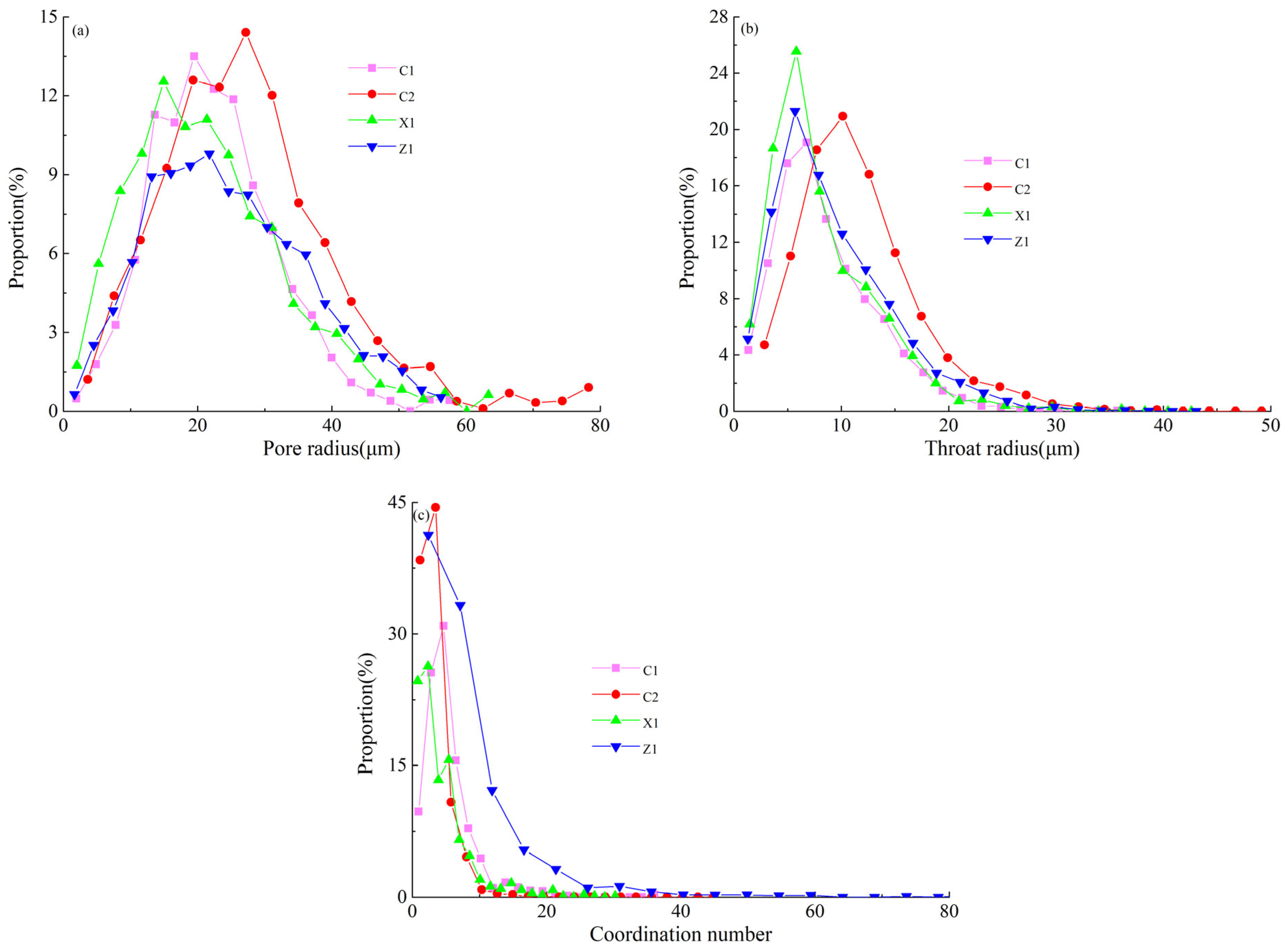

3.3.4. Quantitative Characterization of 3D Pore and Fracture Parameters

3.4. Comprehensive Characterization of Full-Scale Pore Size

3.5. Microscopic Heterogeneity Analysis of Tight Glutenite

3.5.1. Microscopic Heterogeneity of Matrix Mineral Distribution

3.5.2. Influence of Microscopic Heterogeneity on Seepage in Tight Glutenite

4. Conclusions

- (1)

- The mineral distribution and pore structure characteristics of tight glutenite reservoirs at the study site are significantly different. Based on the lithology and capillary pressure curve of the reservoir, three types can be distinguished: The wide and large pore throat and high reservoir quality are characteristics of type I reservoir samples. Type II and type III reservoir samples have medium and low pore throats, and moderate and poor reservoir qualities, respectively. As the permeability decreases, the average and median pore throat radius gradually decrease, which reflects the fact that the connected pores and macropores of tight glutenite play a critical role in seepage.

- (2)

- The various pore throat types and mineral distributions are due to the differences in compaction, dissolution, and cementation. The continuous sheet pores have good connectivity, which is related to the interconnection of primary intergranular pores and strip fractures, while the connectivity of isolated pores is significantly poorer, which is related to the development of intragranular dissolved pores and intercrystalline pores. This demonstrates the deterioration of physical properties and pore throat connectivity, reduced average pore radius, and decreased pore sorting as permeability decreases.

- (3)

- The pore throat scale ranges from nanometers to micrometers. They have a wide size range of between 5 nm to 80 μm, and predominantly exhibit Gaussian and bimodal distribution patterns. The effective pores were found to be attributed to the slowing effect of abnormally high pressure on the vertical stress, and the protective effect was positively correlated with the high pressure strength. Notably, the distribution of reservoir matrix minerals and the pore throat in the study block has strong microscopic heterogeneity. The stronger the heterogeneity of the tight glutenite reservoir, the more easily the injected fluid flows along the preferential seepage channel with pore development and connectivity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aguilera, R. Flow units: From conventional to tight-gas to shale-gas to tight-oil to shale-oil reservoirs. SPE Reserv. Eval. Eng. 2014, 17, 190–208. [Google Scholar] [CrossRef]

- Zou, C.; Zhang, G.; Yang, Z.; Tao, S.; Hou, L.; Zhu, R. Formation, distribution, potential and prediction of global conventional and unconventional hydrocarbon resources. Pet. Explor. Dev. 2015, 42, 13–25. [Google Scholar] [CrossRef]

- Wang, M.; He, J.; Liu, S.; Zeng, C.; Jia, S.; Nie, Z.; Wang, S.; Wang, W.; Zhang, C. Effect of Sedimentary Facies Characteristics on Deep Shale Gas Desserts: A Case from the Longmaxi Formation, South Sichuan Basin, China. Minerals 2023, 13, 476. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, R.; Zhu, K.; Li, D.; Jin, Y.; Guo, W.; Liu, X.; Zhang, X.; Zhang, Q. Probing the Pore Structure of the Berea Sandstone by Using X-ray Micro-CT in Combination with ImageJ Software. Minerals 2023, 13, 360. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, F.; Ullah, A. Integration of the outcrop and subsurface geochemical data, implications for the hydrocarbon source rock evaluation in the Lower Indus Basin, Pakistan. J. Pet. Explor. Prod. Technol. 2019, 9, 937–951. [Google Scholar] [CrossRef]

- Zhao, R.; Xue, H.; Lu, S.; Li, J.; Tian, S.; Wang, M.; Dong, Z. Multi-scale pore structure characterization of lacustrine shale and its coupling relationship with material composition, An integrated study of multiple experiments. Mar. Pet. Geol. 2022, 140, 105648. [Google Scholar] [CrossRef]

- Pang, X.; Jia, C.; Wang, W. Petroleum geology features and research developments of hydrocarbon accumulation in deep petroliferous basins. Pet. Sci. 2015, 12, 1–53. [Google Scholar] [CrossRef]

- Barabasch, J.; Schmatz, J.; Klaver, J.; Schwedt, A.; Klaver, J.; Urai, J. Large grain-size-dependent rheology contrasts of halite at low differential stress: Evidence from microstructural study of naturally deformed gneissic Zechstein 2 rock salt (Kristallbrockensalz) from the northern Netherlands. Solid Earth 2023, 14, 271–291. [Google Scholar] [CrossRef]

- Schmitt, M.; Fernandes, C.P.; Wolf, F.G.; Da Cunha Neto, J.A.B.; Rahner, C.P.; Dos Santos, V.S.S. Characterization of Brazilian tight gas sandstones relating permeability and angstrom-to micron-scale pore structures. J. Nat. Gas Sci. Eng. 2015, 27, 785–807. [Google Scholar] [CrossRef]

- Zhao, H.W.; Ning, Z.F.; Wang, Q.; Zhang, R.; Zhao, T.Y.; Niu, T.F.; Zeng, Y. Petrophysical characterization of tight oil reservoirs using pressure-controlled porosimetry combined with rate-controlled porosimetry. Fuel 2015, 154, 233–242. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Q.M.; Lyu, Q.; Xue, Z.J.; Cao, X.P.; Liu, Z.P. Evaluation technology and practice of continental shale oil development in China. Pet. Explor. Dev. 2022, 49, 1098–1109. [Google Scholar] [CrossRef]

- Afagwu, C.; Alafnan, S.; Mahmoud, M.; Akkutlu, Y.; Mahmoud, M. Modeling of natural gas self-diffusion in the micro-pores of organic-rich shales coupling sorption and geomechanical effects. J. Nat. Gas Sci. Eng. 2022, 106, 104757. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Freeman, M.; He, L.; Agamalian, M.; Melnichenko, Y.; Mastalerz, M.; Bustin, R.; Radliński, A.; Blach, T. Characterization of tight gas reservoir pore structure using USANS/SANS and gas adsorption analysis. Fuel 2012, 95, 371–385. [Google Scholar] [CrossRef]

- Nooruddin, H.A.; Hossain, M.E.; Al-Yousef, H.; Okasha, T. Comparison of permeability models using mercury injection capillary pressure data on carbonate rock samples. J. Petrol. Sci. Eng. 2014, 121, 9–22. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.; Wang, X. Pore throat structure and fractal characteristics of tight oil sandstone: A case study in the Ordos Basin, China. J. Petrol. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Wang, P.; Nie, H.; Liu, Z.; Sun, C.; Cao, Z.; Wang, R.; Li, P. Differences in Pore Type and Pore Structure between Silurian Longmaxi Marine Shale and Jurassic Dongyuemiao Lacustrine Shale and Their Influence on Shale-Gas Enrichment. Minerals 2023, 13, 190. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Cao, J.; Xiao, C.; Wang, S.; Pang, X.; Dai, Q.; He, Z.; Fan, X.; Yang, L. Investigation of pore structure and petrophysical property in tight sandstones. Mar. Petrol. Geol. 2018, 91, 179–189. [Google Scholar] [CrossRef]

- Li, Y.; Di, Q.; Hua, S. Visualization of foam migration characteristics and displacement mechanism in heterogeneous cores. Colloids Surf. A 2020, 607, 125336. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, N.; Sima, L.; Meng, F.; Guo, Y. Pore structure characterization of the tight reservoir: Systematic integration of mercury injection and nuclear magnetic resonance. Energy Fuel 2018, 32, 7471–7484. [Google Scholar] [CrossRef]

- Wei, W.; Gao, Z.; Jiang, Z. The comparative study of shale pore structure between outcrop and core samples of Ziliujing Formation shale from the northeastern Sichuan Basin in China. Energy Rep. 2022, 8, 8618–8629. [Google Scholar] [CrossRef]

- Wennberg, O.; Ramalho, F.; Mafia, M.; Lapponi, F.; Chandler, A.; Cartesio, L.; Hunt, D. The characteristics of natural open fractures in acoustic borehole image logs from the pre-salt Barra Velha formation, Santos Basin, Brazil. J. Struct. Geol. 2023, 165, 104794. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Z.; Jiang, Y.; Wang, A.; Fan, C.; Xiang, B.; Zhou, N. Quantitative evaluation of the transporting capacity of unconformities: A Case Study from the Zhongguai Area, Junggar Basin, NW China. Mar. Pet. Geol. 2020, 114, 104199. [Google Scholar] [CrossRef]

- Forstner, S.; Laubach, S. Scale-dependent fracture networks. J. Struct. Geol. 2022, 165, 104748. [Google Scholar] [CrossRef]

- Wang, G.; Shen, J.; Chu, X.; Cao, C.; Jiang, C.; Zhou, X. Characterization and analysis of pores and fissures of high-rank coal based on CT three dimensional reconstruction. J. China Coal Soc. 2017, 42, 2074–2080. [Google Scholar] [CrossRef]

- Li, W.; Sun, W.; Tang, P.; Yan, T.; Li, Y. A method for rock fracture network characterization based on topological structure. Nat. Gas Ind. 2017, 37, 22–27. [Google Scholar] [CrossRef]

- Bera, B.; Mitra, S.K.; Vick, D. Understanding the micro structure of Berea Sandstone by the simultaneous use of micro-computed tomography (micro-CT) and focused ion beam-scanning electron microscopy (FIB-SEM). Micron 2010, 42, 412–418. [Google Scholar] [CrossRef]

- Golab, A.; Ward, C.R.; Permana, A.; Lennox, P.; Botha, P. High-resolution three-dimensional imaging of coal using microfocus X-ray computed tomography, with special reference to modes of mineral occurrence. Int. J. Coal Geol. 2013, 11, 97–108. [Google Scholar] [CrossRef]

- Lv, W.; Chen, S.; Gao, Y.; Kong, C.; Jia, N.; He, L.; Wang, R.; Li, J. Evaluating seepage radius of tight oil reservoir using digital core modeling approach. J. Pet. Sci. Eng. 2019, 178, 609–615. [Google Scholar] [CrossRef]

- Gasparrini, M.; Sassi, W. Natural sealed fractures in mudrocks: A case study tied to burial history from the Barnett Shale, Fort Worth Basin, Texas, USA. Mar. Pet. Geol. 2019, 55, 122–141. [Google Scholar] [CrossRef]

- Morad, S.; Al-Ramadan, K.; Ketzer, J. The impact of diagenesis on the heterogeneity of sandstone reservoirs: A review of the role of depositional facies and sequence stratigraphy. AAPG Bull. 2019, 94, 1267–1309. [Google Scholar] [CrossRef]

- Hasnan, H.K.; Sheppard, A.; Hassan, M.H.A.; Knackstedt, M.; Abdullah, W.H. Digital core analysis: Improved connectivity and permeability characterization of thin sandstone layers in heterolithic rocks. Mar. Pet. Geol. 2020, 120, 104549. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, Y.; Ning, Z.; Fan, Z.; Wu, X.; Liu, L.; Chen, X. Stress sensitive experiments for abnormal overpressure carbonate reservoirs: A case from the Kenkiyak fractured-porous oil field in the littoral Caspian Basin. Pet. Explor. Dev. 2013, 40, 208–215. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, X.; Li, H.; Lei, Q.; Luo, Y.; Wang, X. Analysis on the influencing factors of imbibition and the effect evaluation of imbibition in tight reservoirs. Pet. Explor. Dev. 2019, 46, 739–745. [Google Scholar] [CrossRef]

- Hu, J.; Sun, R.; Zhang, Y. Investigating the horizontal well performance under the combination of micro-fractures and dynamic capillary pressure in tight oil reservoirs. Fuel 2020, 269, 117375. [Google Scholar] [CrossRef]

- Li, P.; Gong, H.; Jiang, Z.; Zhang, F.; Liang, Z.; Wang, Z.; Wu, Y.; Shao, X. Characteristics and Influencing Factors of Multi-Scale Pore Structure Heterogeneity of Lacustrine Shale in the Gaoyou Sag, Eastern China. Minerals 2023, 13, 359. [Google Scholar] [CrossRef]

| Sample Type | Core Number | Diameter (mm) | Length (mm) | Porosity (%) | Permeability (mD) | Mineral Mass Fraction (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | Plagioclase | K-Feldspar | Calcite | Ankerite | Siderite | Magnetite | Clay Minerals | ||||||

| Gritstone | C1 | 38.23 | 48.21 | 7.1 | 5.83 | 62.97 | 24.41 | 11.66 | 0.05 | 0.03 | 0 | 0 | 0.88 |

| C2 | 38.15 | 49.32 | 7.8 | 6.51 | 55.65 | 26.67 | 12.75 | 1.27 | 1.34 | 0.87 | 0 | 1.45 | |

| Fine conglomerate | X1 | 38.27 | 48.37 | 7.3 | 2.12 | 55.08 | 26.98 | 13.49 | 1.49 | 0.34 | 1.51 | 0.03 | 1.08 |

| X2 | 38.13 | 48.67 | 10.1 | 1.03 | 57.23 | 24.26 | 11.07 | 2.16 | 1.79 | 1.24 | 0.54 | 1.71 | |

| X3 | 38.19 | 45.61 | 9.3 | 1.50 | 76.28 | 12.89 | 8.59 | 1.05 | 0.72 | 0.38 | 0 | 0.09 | |

| X4 | 38.02 | 49.37 | 9.1 | 1.65 | 65.28 | 19.85 | 9.63 | 0.38 | 1.96 | 0.72 | 0.14 | 2.04 | |

| Medium conglomerate | Z1 | 38.11 | 49.35 | 6.9 | 0.59 | 68.31 | 22.44 | 8.55 | 0.04 | 0.02 | 0 | 0 | 0.64 |

| Z2 | 38.07 | 48.17 | 4.2 | 0.28 | 73.93 | 16.02 | 9.61 | 0.03 | 0.02 | 0.03 | 0.01 | 0.35 | |

| Shale | J1 | 38.13 | 49.85 | 7.3 | 0.03 | 22.74 | 51.89 | 9.37 | 0.18 | 7.08 | 0.99 | 0.03 | 7.72 |

| Sample Type | Core Number | Average Pore Volume (10−3 cm3) | Maximum Pore Throat Radius (μm) | Average Pore Throat Radius (μm) | Median Pore Throat Radius (μm) | Mercury Saturation Median Pressure (MPa) | Average Displacement Pressure (MPa) | Starting Pressure (MPa) | Maximum Mercury Saturation (%) | Residual Mercury Saturation (%) | Sorting Coefficient |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gritstone | C1 | 1243 | 9.7814 | 2.343 | 2.001 | 0.375 | 0.077 | 0.015 | 91.06 | 71.18 | 2.025 |

| Fine conglomerate | X1 | 1144 | 1.4181 | 0.292 | 0.370 | 2.025 | 0.529 | 0.073 | 88.24 | 63.75 | 0.229 |

| Medium conglomerate | Z1 | 598 | 0.2393 | 0.066 | 0.094 | 7.989 | 3.135 | 0.874 | 85.29 | 66.58 | 0.038 |

| Sample Type | Core Number | Pore Characteristic Parameters | Throat Characteristic Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum Pore Radius (μm) | Maximum Pore Radius (μm) | Average Pore Radius (μm) | Pore Shape Factor | Minimum Throat Radius (μm) | Maximum Throat Radius (μm) | Average Throat Radius (μm) | Throat Shape Factor | Average Throat Length (μm) | ||

| Gritstone | C1 | 1.91 | 71.26 | 40.09 | 0.0382 | 1.35 | 49.16 | 25.25 | 0.0382 | 3.69 |

| Gritstone | C2 | 1.85 | 79.81 | 41.87 | 0.0397 | 1.73 | 49.86 | 26.89 | 0.03817 | 3.72 |

| Fine conglomerate | X1 | 2.01 | 63.33 | 32.67 | 0.0403 | 1.48 | 42.61 | 22.05 | 0.0394 | 3.41 |

| Medium conglomerate | Z1 | 1.63 | 56.24 | 28.94 | 0.0397 | 1.29 | 40.83 | 21.06 | 0.0387 | 3.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, M.; Yang, Z.; Yang, S.; Feng, C.; Wang, G.; Jia, N.; Li, H.; Shi, X. Study on the Quantitative Characterization and Heterogeneity of Pore Structure in Deep Ultra-High Pressure Tight Glutenite Reservoirs. Minerals 2023, 13, 601. https://doi.org/10.3390/min13050601

Du M, Yang Z, Yang S, Feng C, Wang G, Jia N, Li H, Shi X. Study on the Quantitative Characterization and Heterogeneity of Pore Structure in Deep Ultra-High Pressure Tight Glutenite Reservoirs. Minerals. 2023; 13(5):601. https://doi.org/10.3390/min13050601

Chicago/Turabian StyleDu, Meng, Zhengming Yang, Shuo Yang, Chun Feng, Guofeng Wang, Ninghong Jia, Haibo Li, and Xiaoxing Shi. 2023. "Study on the Quantitative Characterization and Heterogeneity of Pore Structure in Deep Ultra-High Pressure Tight Glutenite Reservoirs" Minerals 13, no. 5: 601. https://doi.org/10.3390/min13050601

APA StyleDu, M., Yang, Z., Yang, S., Feng, C., Wang, G., Jia, N., Li, H., & Shi, X. (2023). Study on the Quantitative Characterization and Heterogeneity of Pore Structure in Deep Ultra-High Pressure Tight Glutenite Reservoirs. Minerals, 13(5), 601. https://doi.org/10.3390/min13050601