Abstract

The stability of mine slopes is an important factor influencing the orderly production of mines and the safety of people’s lives and property. The stability of slopes can be effectively determined by means of three-dimensional simulation analysis. Some 3D simulation analysis methods are based on 2D analysis, and are still essentially 2D analysis methods, whereas this digital simulation analysis uses a true 3D analysis method. This method can reflect the overall slope stability of the mine in a more realistic way, and at the same time, the situation of the selected sections can be observed, making the analysis more scientific and rigorous. This study takes the Shizhuyuan Nonferrous Metal Mine as an example and studies the safety stability of mine slopes through true 3D safety analysis. The results show that the open-pit slopes of the Shizhuyuan mine are stable. The overall model results show that there is only a small amount of tensile damage and no penetration; the section results show that the absolute value of tensile stress is generally small, with a maximum of 1.45 MPa being less than the tensile strength of the material (7.04 MPa). After the model monitoring simulation, it is found that the displacements of each monitoring point are in the process of fluctuation and then stabilisation, which can also indicate that the slope is finally in a stable state. Comparing the above results with the conclusions obtained from the 2D analysis method, the conclusions are found to be in general agreement, indicating that the true 3D simulation analysis method is effective and feasible.

1. Introduction

Open-pit mining is a common mining method. Inevitably, the pits created during the mining process create pit slopes. These slopes can be affected by natural conditions or engineering works and lead to geological hazards [1,2], and these slope-related hazards have a direct impact on people’s lives and property, with some common hazards such as landslides, debris flows, and mountain collapses deserving study and attention [3,4]. Due to the diversity of geological conditions, hydrological conditions, and many other aspects, the problem of slope instability is a systemic problem that combines dynamics and uncertainty. N Valiev et al. [5] confirmed that open pit slopes have a significant impact on the operational efficiency of mining from an economic and ecological point of view. Therefore, it is of crucial importance to ensure the stability of the slope.

In order to ensure the stability of slopes, many scholars have studied their instability mechanisms [6,7,8,9,10]. In recent years, significant progress has been made in the use of numerical techniques to characterise the deformation and damage of complex rock slopes, which can further improve our understanding of the mechanisms/processes involved and the associated risks. Stead, D et al. [11] illustrate how rock slope analyses may be undertaken using three levels of sophistication. Through a series of rock slope analyses, the application of varied numerical methods is discussed. Particular emphasis is given to state-of-the-art developments and the potential use of Level III hybrid techniques. Skempton [12] proposed the idea of progressive slope instability, suggesting that the sliding surface of a slope does not occur simultaneously within the slope, but starts locally first and then gradually spreads outwards until it penetrates after the instability has been damaged. If a failure has already occurred, any subsequent movements on the existing slip surface will be controlled by the residual strength. Sultan, N et al. [13] have focused on the relationship between external mechanisms and the consequence change in the in situ stress state and the physical, mechanical, and elastic properties of the sediment. The primary focus of their study is to identify the relationship between triggering mechanisms and causal factors on one hand and the stress state and geotechnical parameters on the other hand.

With the advancement of technology, many methods have emerged to help determine the stability of slopes to ensure mine safety. These research results cannot be achieved without the continuous efforts and attempts of many scholars concerned [14,15,16,17,18,19]. In open-pit mining, López-Vinielles, J et al. [20] present a methodology that combines digital photogrammetry, satellite radar interferometry, and geomechanical modelling to perform remote analyses of slope instabilities in open-pit mining areas. Wang, W et al. [21] carried out finite element analysis to better understand the effect of the weak layer at the time of the failure. In C. Romer’s study [22], the effect of rock bridges on rock slope stability was investigated by incorporating nonpersistent joint networks in numerical models, and the critical sections of an open pit mine were analysed. Ning YJ [1] extended the numerical manifold method for the stability analysis of lower slopes. Numerical results indicate that the developed program can simulate the opening and sliding along pre-existing discontinuities, fracturing through intact rock, as well as kinematics of the failed slope, and can also reproduce the major failure mechanisms observed in footwall slope collapses. In A. Vyazmensky’s [23] study, the finite element modelling (FEM) approach was utilised in the analysis of block-caving-induced step-path failure development in a large open-pit slope.

However, in recent years, with the development of technology, the method of three-dimensional (3D) slope stability has gradually become popular. K. Zhang et al. [24] compared the results of 2D and 3D analyses and analysed the range of applicability of the two- and three-dimensional methods. J. D. Huang et al. [25] used 2D finite element simulation to more fully examine the effectiveness and potential of the antivibration pavement in the application of vibration absorbing for open-pit mines. Jiang N et al. [26] studied the effect of blast vibrations on overlaying open-pit slopes due to underground mine blast by making a 3D numerical model of the open pit and the underground mine. However, the vast majority of slope stability analyses are performed in two dimensions under the assumption of plane strain conditions [27]. It was found that using a two-dimensional (2D) analysis may lead to significant differences in estimating safety factors. Great care and judgement are required when applying 2D analyses to 3D slope problems [28]. Moreover, many 3D analysis methods are based on 2D analysis methods, which are still essentially 2D analyses. Therefore, it is more scientific and rigorous to use true 3D analysis methods to analyse 3D slope problems [29]. This paper examines the results of a 3D analysis of slope stability using the Shizhuyuan mine as an example.

2. Case Study: The Slopes of Shizhuyuan Nonferrous Metal Mine

2.1. Geological Information and Rock Parameters

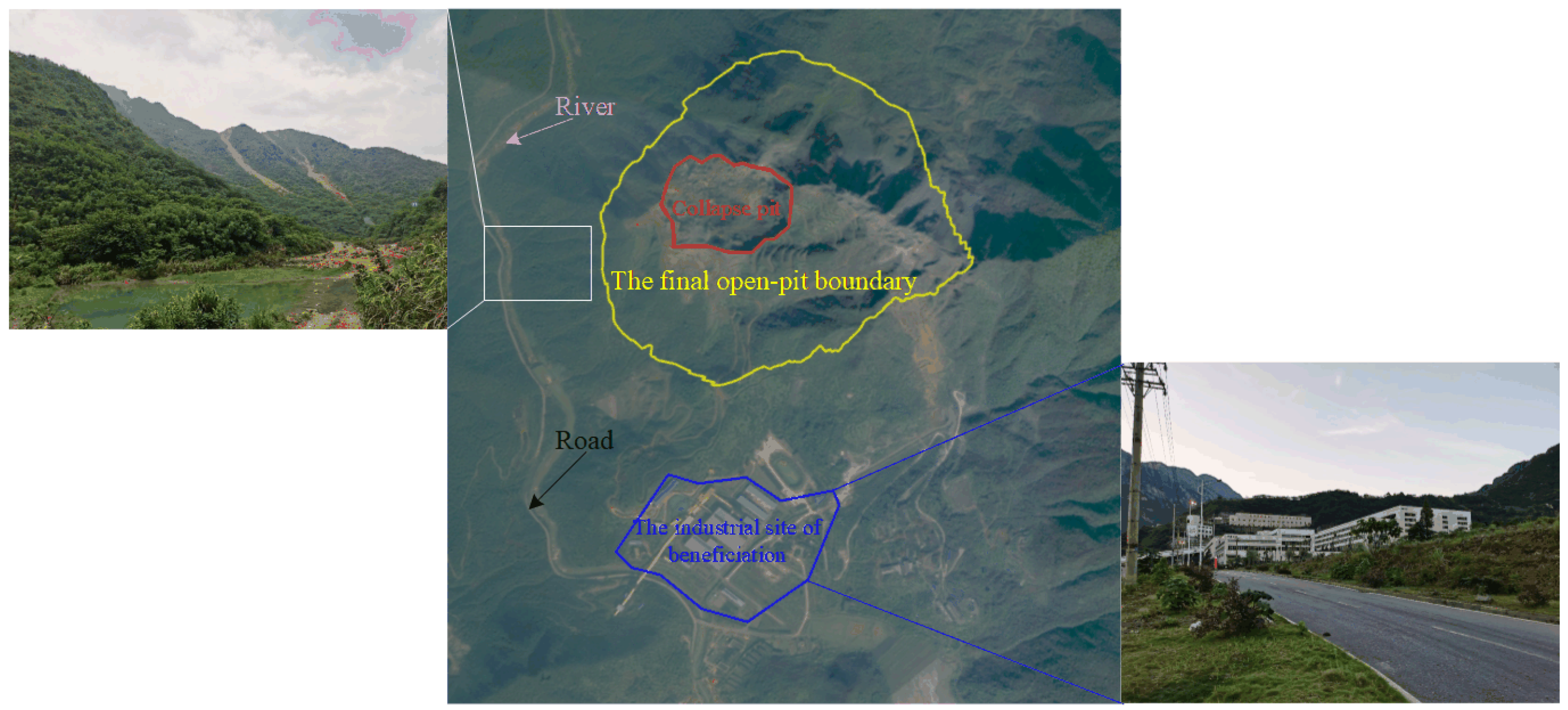

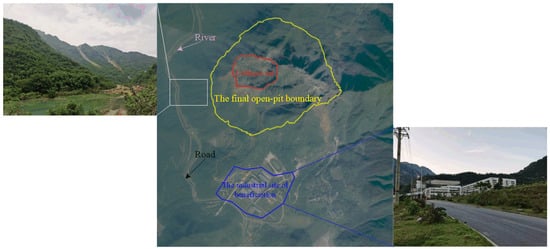

The Shizhuyuan Nonferrous Metal Mine was selected for this study. It is located in Chenzhou City, Hunan Province, China. The mine is stratigraphically simple, mainly consisting of carbonates of the Middle-Upper Devonian Qiziqiao Group and Shetianqiao Group. To the east, there are small areas of shallow metamorphic clastic rocks of the Aurora Series and quartz sandstones of the Middle Devonian Jumping Horse Group. The Upper Devonian She Tian Qiao Formation is the deposit of the ore body, while the Fourth Series is not very well developed. The stratigraphic layers from old to new are as follows: Lower Aurora Group, Devonian Middle Jumajian Formation, Middle Devonian Goziqiao Formation, Upper Devonian Shetianqiao Formation, and Quaternary Strata. The mine site belongs to the subtropical monsoon climate with heavy rainfall [30]. A satellite view of the mine site is shown in Figure 1, where it can be observed that there is a river and road to the west of the final open-pit boundary (yellow contour line) and a beneficiation (blue contour line) to the south. Its collapse pit (red contour line) is close to the above-mentioned locations and has the potential to impact the surrounding area.

Figure 1.

The satellite view of the mine site.

The rock parameters of the mine need to be investigated and measured before the simulation is carried out to ensure the accuracy and scientific validity of the simulation results. Generally speaking, mine rock mechanics tests yield rock mechanics parameters based on ore rock specimens, whereas numerical simulation analysis requires rock mechanics parameters containing structural weaknesses such as joints and fissures, which are much smaller than rock mechanics parameters due to the presence of a large number of structural weaknesses. In this study, the mechanical parameters of the rock mass are obtained based on the results of indoor rock mechanics tests and then after engineering reduction. To simplify the calculation, the model regards granite as a material. The mechanical parameters of the material used in the numerical simulations are shown in Table 1.

Table 1.

The mechanical parameters of the material.

2.2. Engineering Background

Hunan Shizhuyuan Nonferrous Metals Co., Ltd. is a large mining enterprise integrating mining, beneficiation, smelting, and trading. The Shizhuyuan Mine, to which the company belongs, is currently being mined entirely underground.

The ore body of Shizhuyuan Mine is shallow, thick, and concentrated, with a large reserve size, many useful components, and a small stripping ratio suitable for large-scale open-pit mining. However, the mine has been mining high-grade ore using the open-stope method since the mine was built. The mine was developed by adit, ramp, and shaft. It has three major levels: 558 m, 490 m, and 380 m. Among them, 558 m is the return air level, 490 m is the main mining level, and 380 m is the main transportation level. The mining method is sublevel open-stope mining. After more than 20 years of mining, 36 mining rooms have been mined, and the roof is supported by a large number of room pillars. At that time, the total amount of goaf was about 2.6 million m3 and the total exposed area of the roof had reached 35,000 m2. Therefore, the company chose to undertake an underground-to-open-pit mining programme, taking into account the practicalities of the mine to ensure profitability and compliance with environmental requirements. On 21 June 2012, a 419 t charge of large-scale directional layered controlled blasting technology was successfully implemented underground to treat the mining goaf, crumbling 1,186,000 t of ore and causing a large area of the surface to collapse.

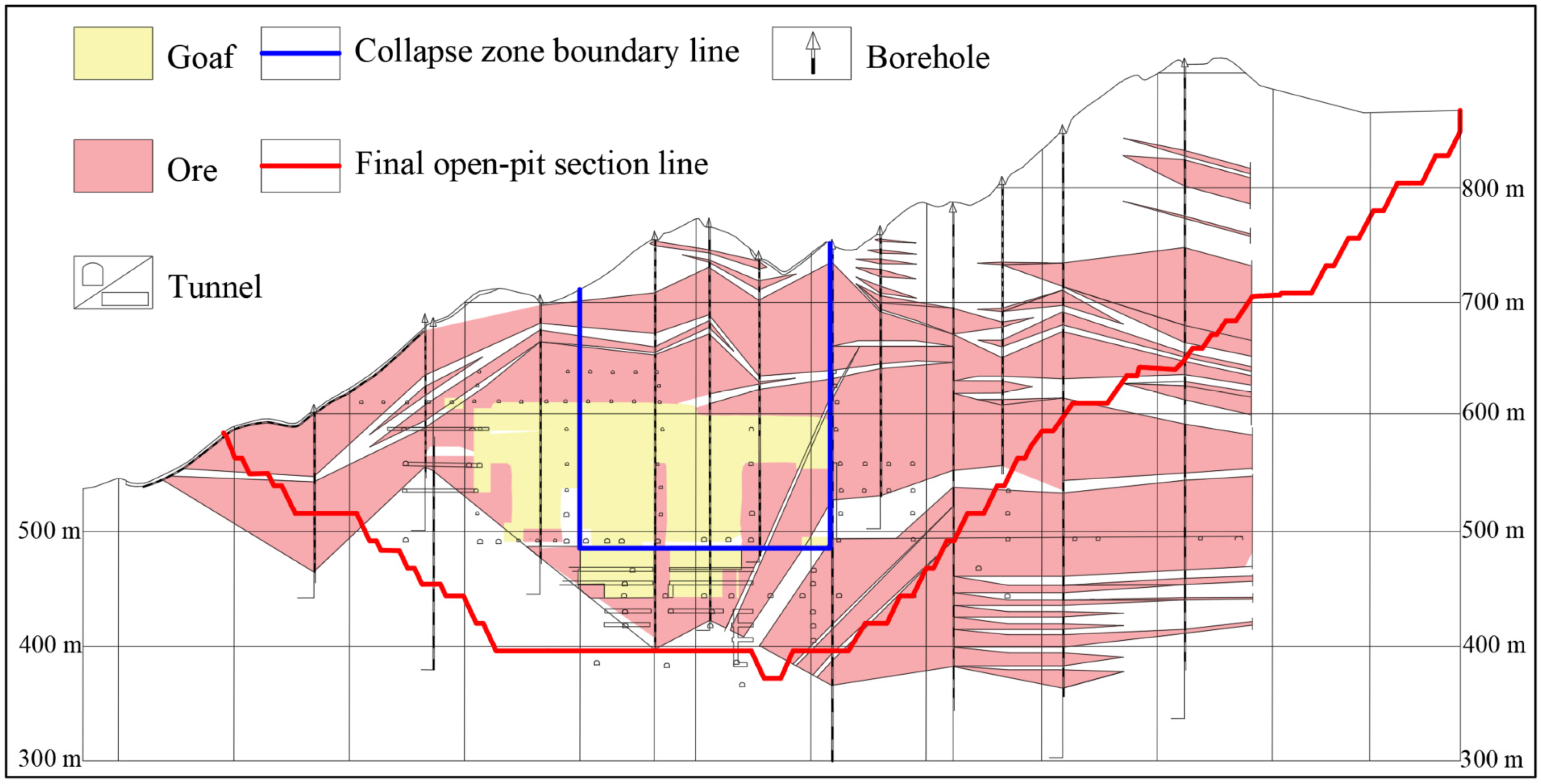

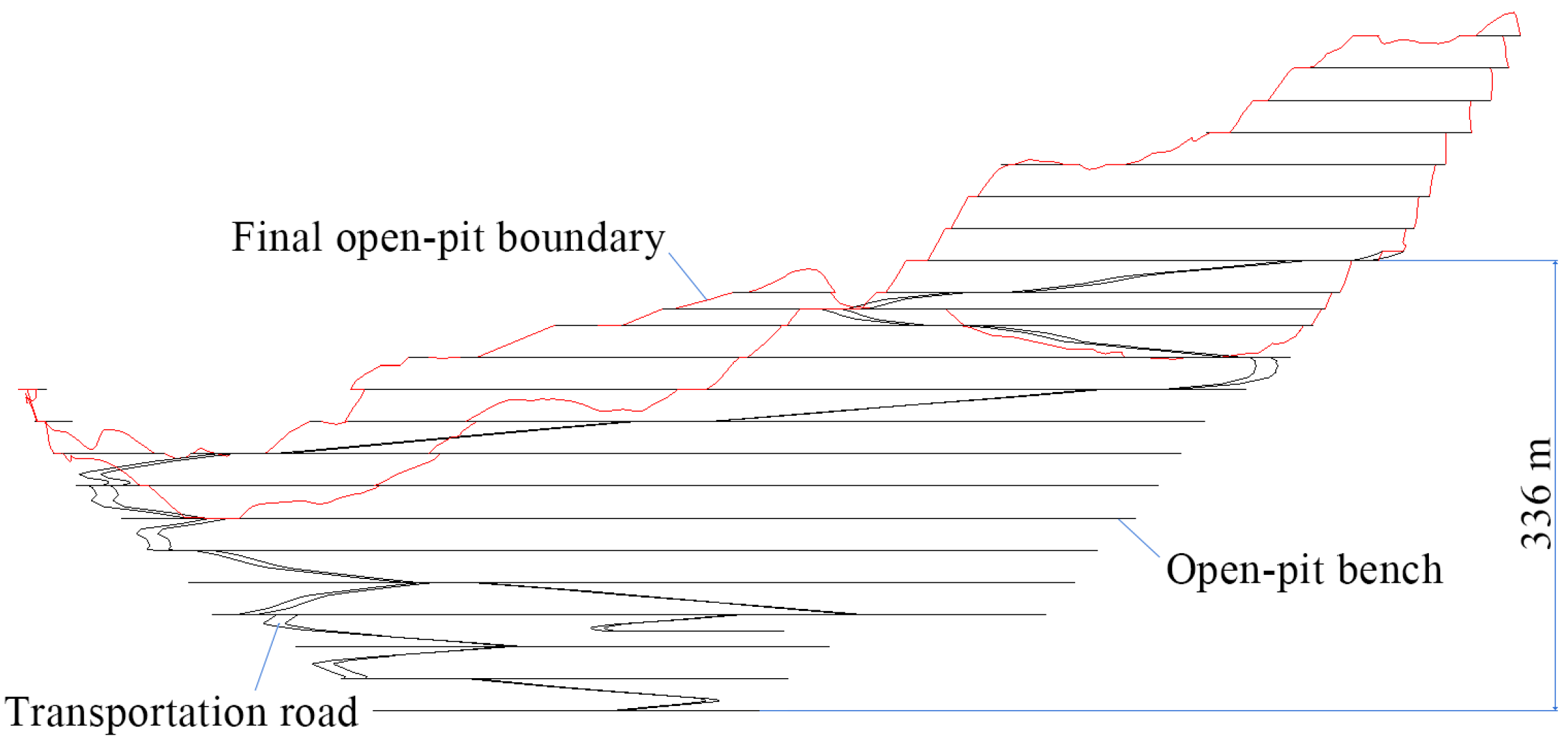

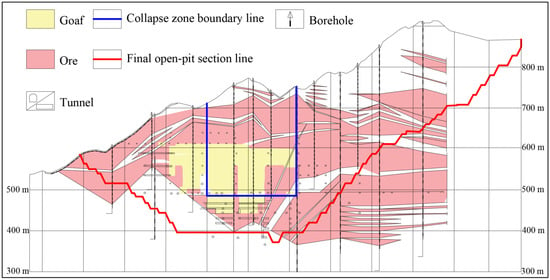

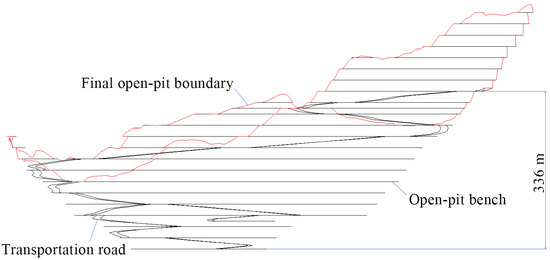

According to the preliminary design requirements, the slope angle of the open-pit step is 70° and the final slope angle is 45°; the area of the final boundary closure circle is 3609.25 m2. The deposit cross section is shown in Figure 2, where the blue line is the boundary line of the collapse zone and the red line is the final open-pit section line. The red line is in the lower part of the extraction zone, so the extraction zone will be stripped after the completion of open-pit mining. In other words, there will be no goaf area at this open pit after final completion. The depth of the open-pit is calculated according to 336 m (as shown in Figure 3), and the total amount of ore rock in the final boundary is about 36,968,000 t. After previous analysis and calculations, it can be concluded that the main hazard classes of this open-pit slope are class II and class III. The safety class of the slope works is mainly class III, and the damage modes are planar, folded line, and wedge [31].

Figure 2.

Cross section of the deposit.

Figure 3.

Schematic diagram of the calculated depth of the open-pit.

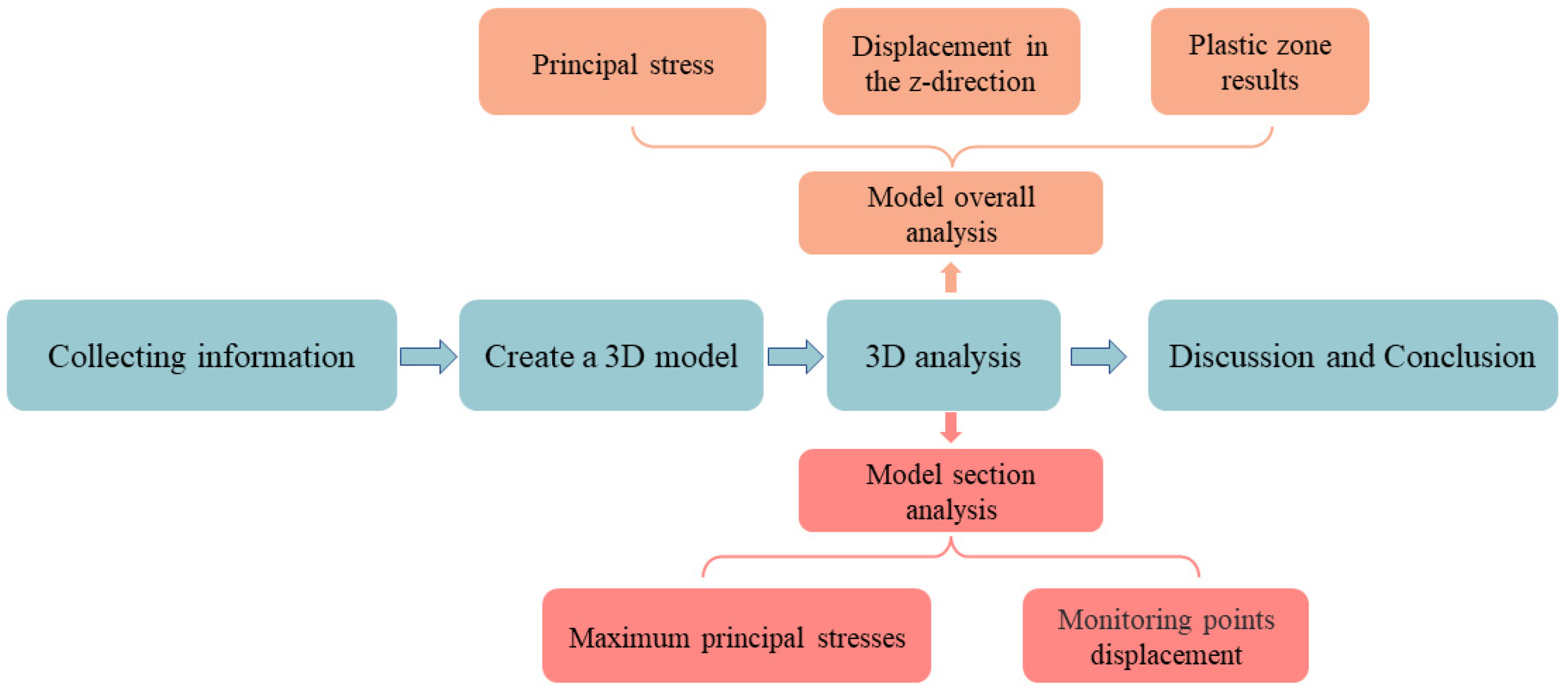

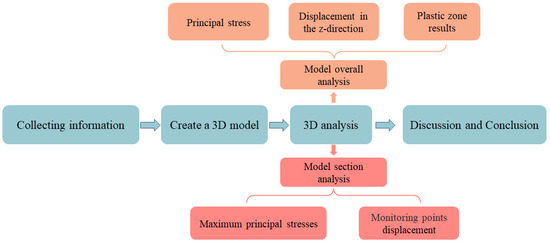

When open-pit mining is used, the safety and stability of the artificially high and steep slopes and the original natural slopes are closely related to the production safety of the mine. Therefore, there is an urgent need to carry out stability analysis and safety evaluation of high and steep slopes in the boundary for open-pit mining and to propose targeted safety management measures for high and steep slopes. It is on this basis that this study examines the safety and stability of the open-pit mine’s slopes. The slopes of the mine are known to be safe and stable from previous studies at the two-dimensional level [31]. The aim of this study is to investigate the overall stability of the mine and to further analyse the selected sections. The analysis process is as follows.

(1) Using the information on the mine slopes, which is previously collected and processed information on the slope elevation of the open pit mine, a 3D model is created in FLAC3D software.

(2) Finite element analysis is carried out to measure the maximum and minimum principal stresses in the model, the displacement in the Z-direction, and the plastic zone results for the overall model.

(3) A suitable slope model section is selected and the maximum principal stresses in the section are analysed.

(4) Observation points are set up on the slope sections selected above to monitor the changes in displacement of the model, resulting in a monitoring graph.

(5) The simulation results obtained are evaluated comprehensively, and recommendations and measures are given according to the slope management method.

The flow chart for the 3D analysis of slope stability is shown in Figure 4.

Figure 4.

Three-dimensional analysis flow chart.

Compared to the Italian study on open-pit-to-underground mining, it can be found that underground-to-open-pit mining focuses more on the stability of the open slope system and the impact on the surrounding environment, while the former focuses more on the impact of structural and static conditions on overall stability, involving stress concentrations, the resistance of the pillars and the room crowns, and the relative orientation of the discontinuities [32].

3. Methodology

From the point of view of its applicability and popularity, the finite element analysis method was used in this study to analyse the stability of the slope. The finite element method allows the differential equation of a problem to be transformed into an integral equation based on appropriate physical field variational principles, and the solution of the integral equation is reduced to an integral over the unit, thus transforming the field problem of solving the differential equation into a unit integral, and ultimately into a problem of solving a finite set of algebraic equations with unknown quantities at the unit nodes. The finite element method is a very effective way to analyse slope stability problems [33].

FLAC3D uses an explicit Lagrangian algorithm and hybrid-discrete partitioning techniques to simulate plastic damage and flow in materials very accurately, and can therefore solve a large range of 3D problems. Consequently, it is scientific and reasonable to use the finite element method to model and solve the stability problems of open-pit slopes in FLAC3D software (version 5.0). Considering the small number of hanging ore bodies in the open pit, the whole model is simplified to use all granite materials for simulation in order to facilitate the modelling analysis. Considering the complexity and variability of the actual mining technical conditions in open pit mines, the following simplifications or assumptions were made in this study to facilitate modelling and analytical calculations:

(1) The ore body is assumed to be an ideal elastic–plastic body, with no change in material strength or volume with the plastic flow after the yield point.

(2) The ore body and the surrounding rock are locally homogeneous and isotropic materials, and plastic flow does not change the material isotropy.

(3) All physical quantities involved in the analysis are independent of time, taking into account the brittleness of the rock.

(4) Strain hardening (or softening) is not considered.

(5) The bottom and four sides of the model are fixed using the FIX command to limit their vertical and horizontal displacements.

(6) The model uses the Mohr–Coulomb yield criterion.

(7) Considering the limitations of the finite element program, it is assumed that there is no influence of tectonic activity in the site, that the primary rock ground stress is of the geodynamic field type, that the rock layers are in integrated contact with each other and are a continuous medium internally, and that the model does not consider the influence of groundwater activity or the presence and influence of structural surfaces, fractures, and weak layers in the rock layers and ore bodies.

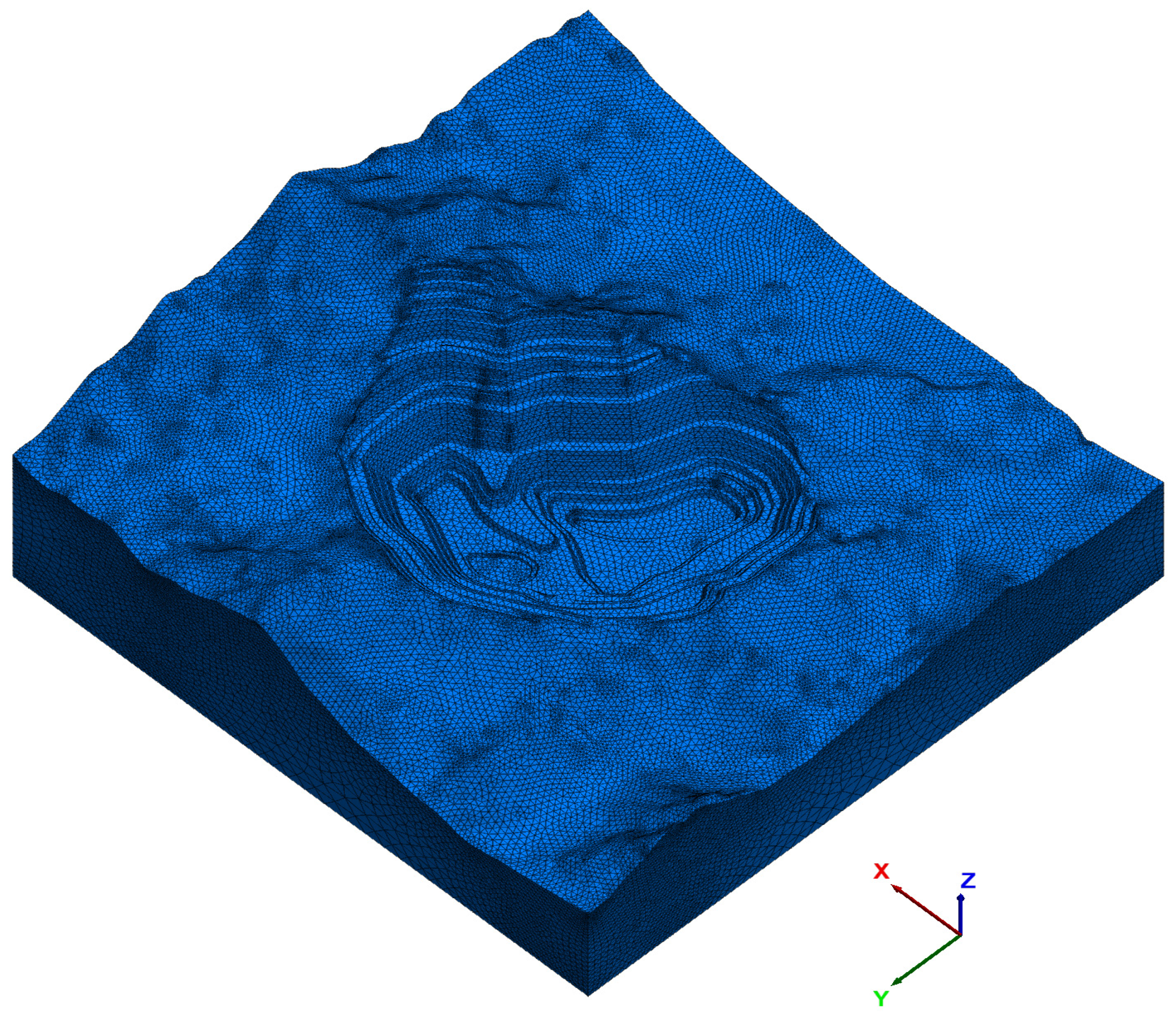

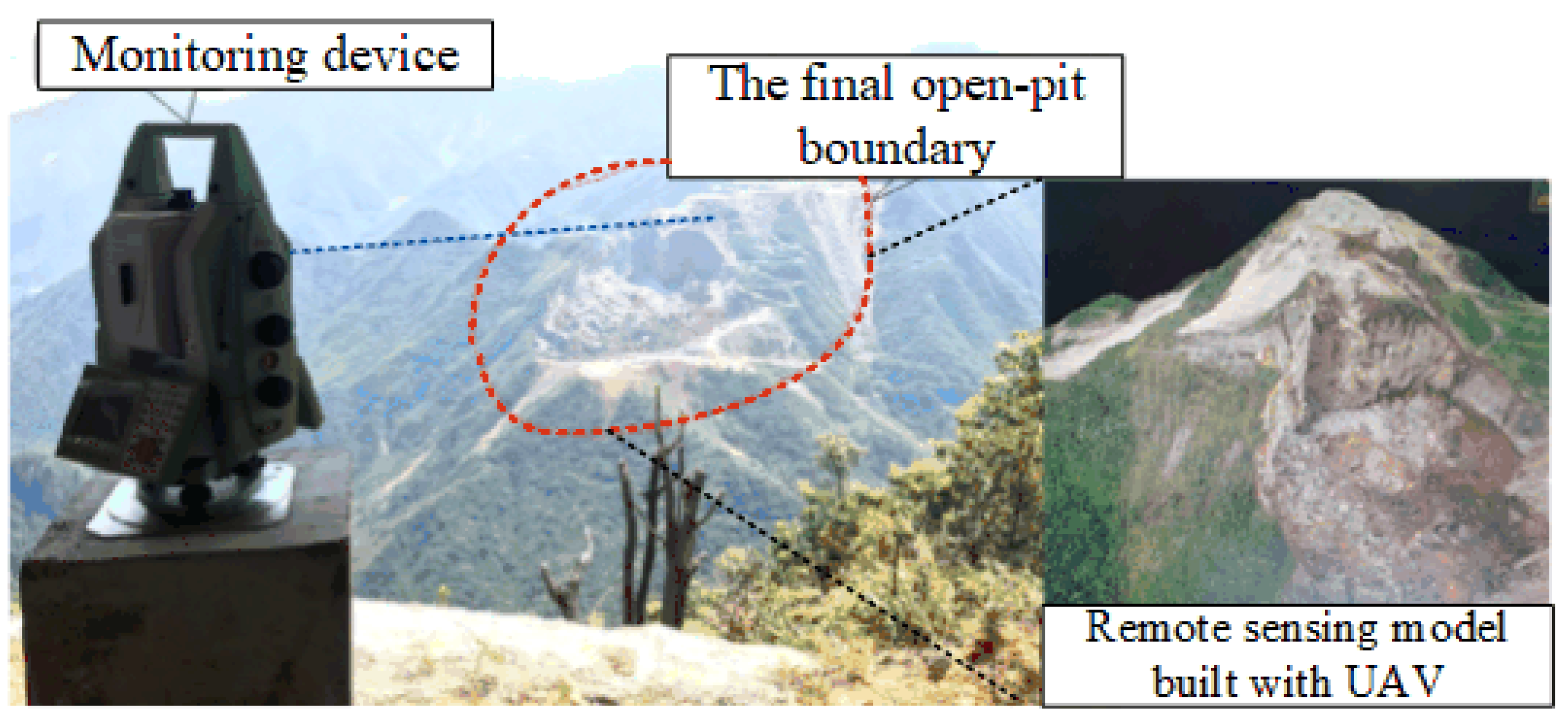

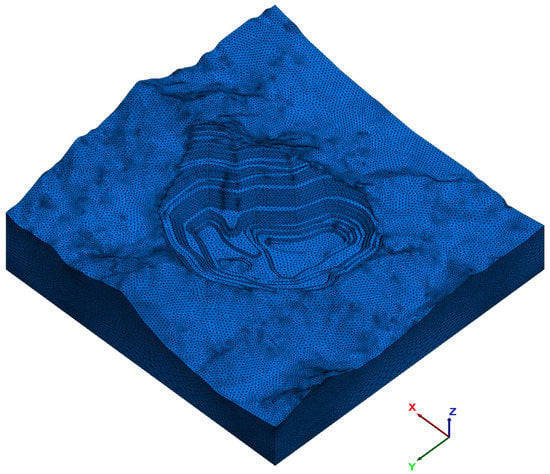

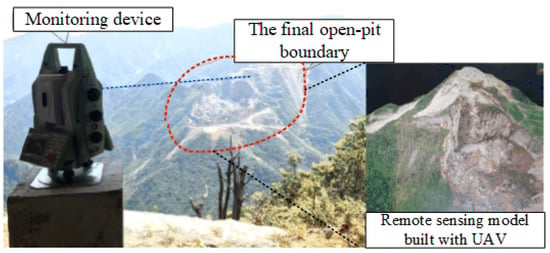

When collecting information on the open-pit slope, UAV remote sensing technology can be used, which can obtain the data and geomorphological features around the current situation of the trap pit and the prebuilt artificial slope, which can help with qualitative analysis and reduce the error of the model built. Then, according to the mine slope data obtained from the construction plan, combined with the UAV remote sensing technology to obtain the open-pit elevation data, the two data establish a 3D model of the Shizhuyuan Mine open-pit boundary. In terms of the division of model elements, theoretically, the finer the division of model elements, the more accurate the calculation results, but too fine a division of elements will consume a lot of calculation time, and the parts far away from the study area do not change much in terms of stress. Therefore, a reasonable grid size should be determined based on the actual conditions of the open pit, taking into account the calculation accuracy and efficiency requirements. The final 3D model created is shown in Figure 5.

Figure 5.

Three-dimensional model of the final realm of open-pit mining.

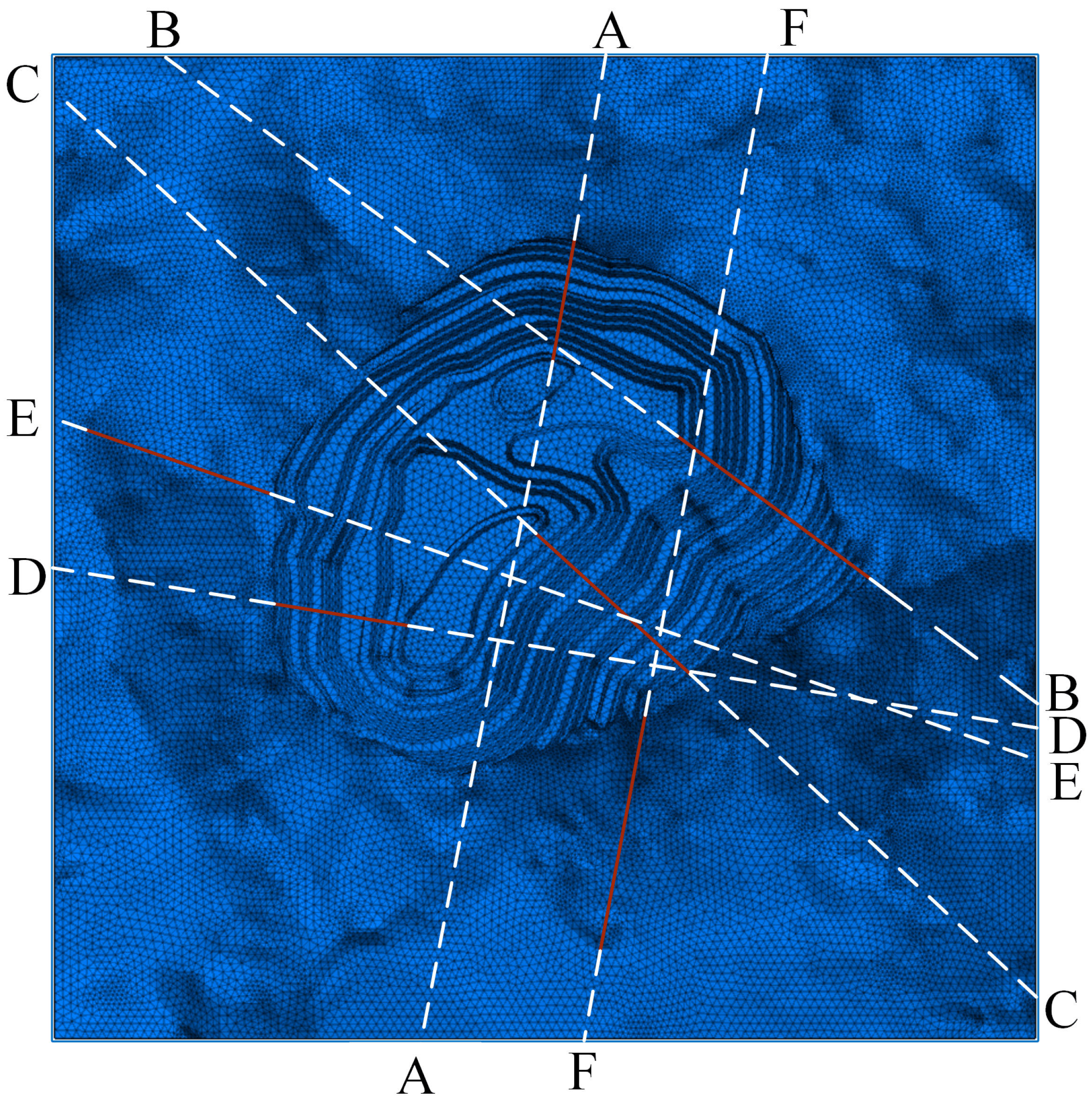

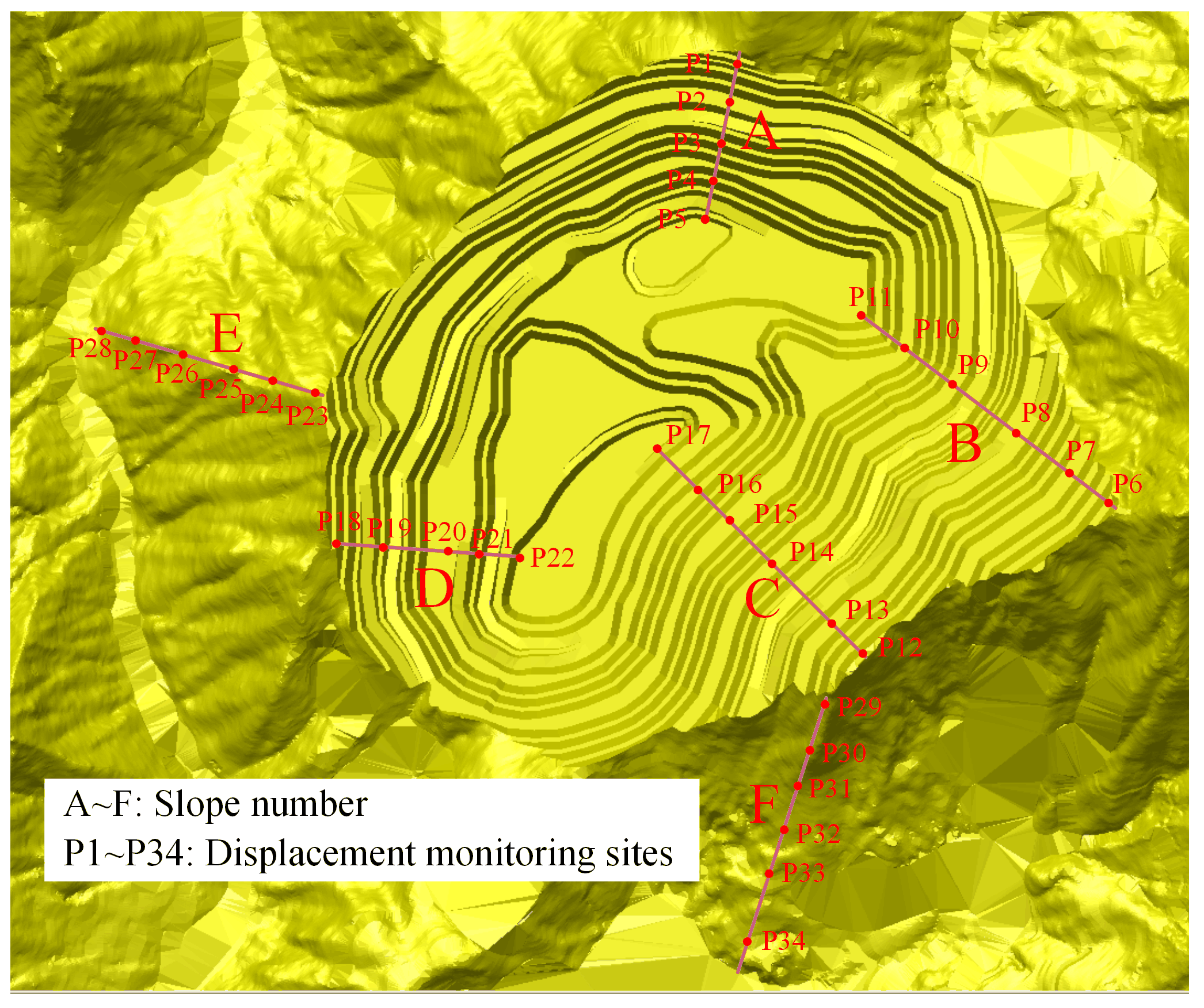

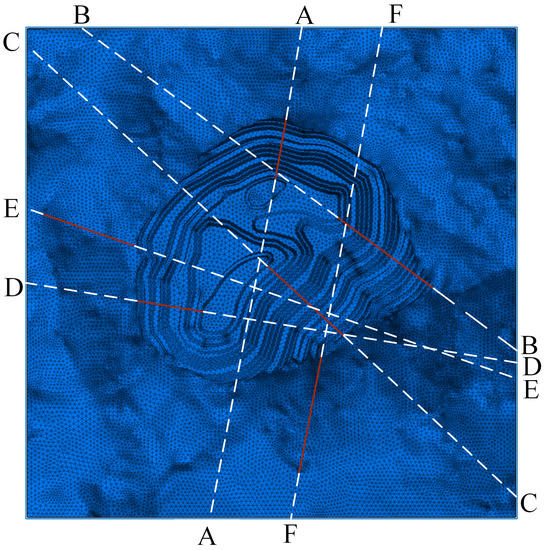

In the section analysis, a representative slope section should also be selected for analysis. Figure 6 shows the top view of the established 3D model. There are six selected slope sections, which are indicated in the figure with red lines as A to F, respectively, where numbers A to D are the subsequent artificially established slopes while E and F are natural slopes.

Figure 6.

Top view of the established 3D model.

4. Results

4.1. Overall Stability Analysis

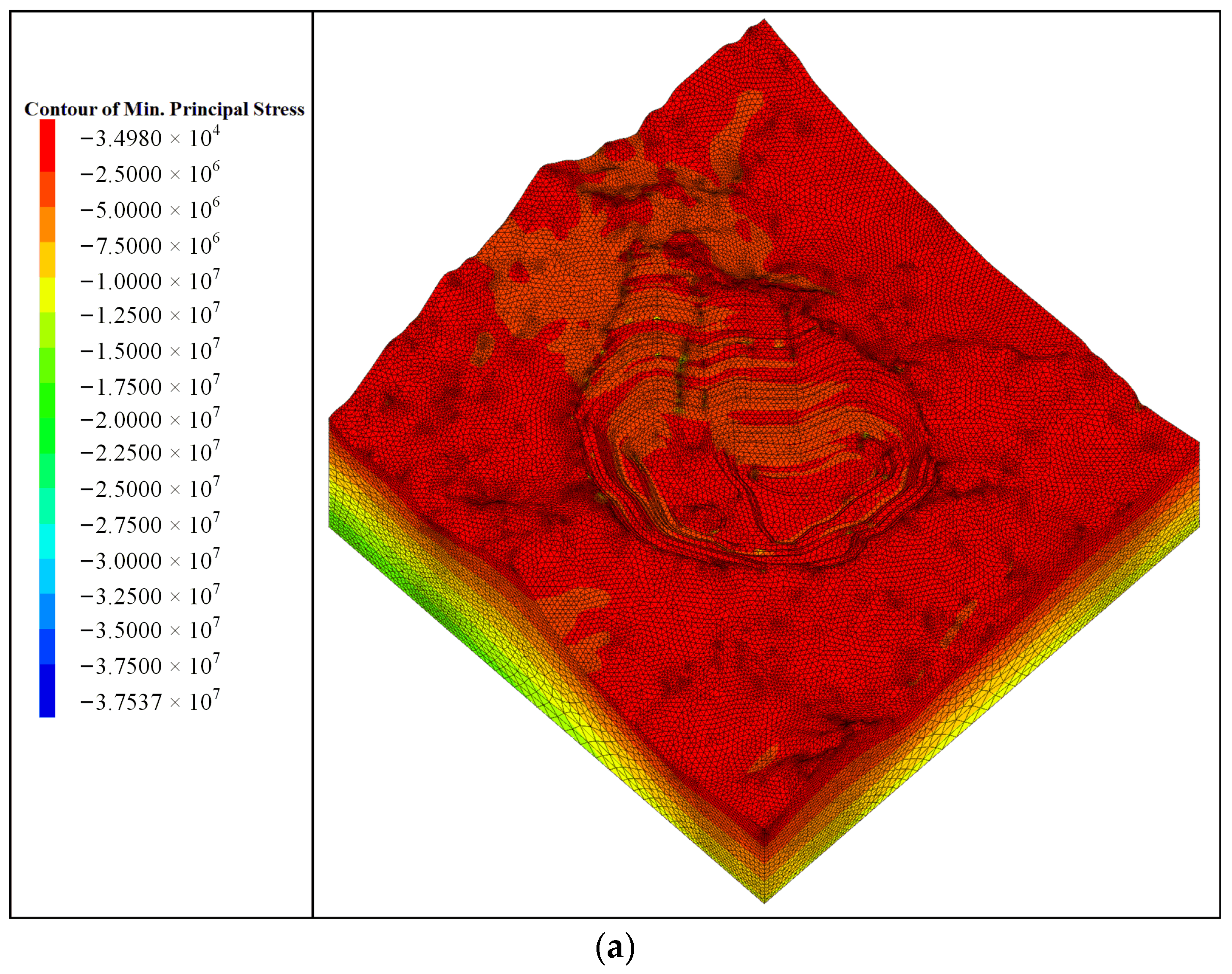

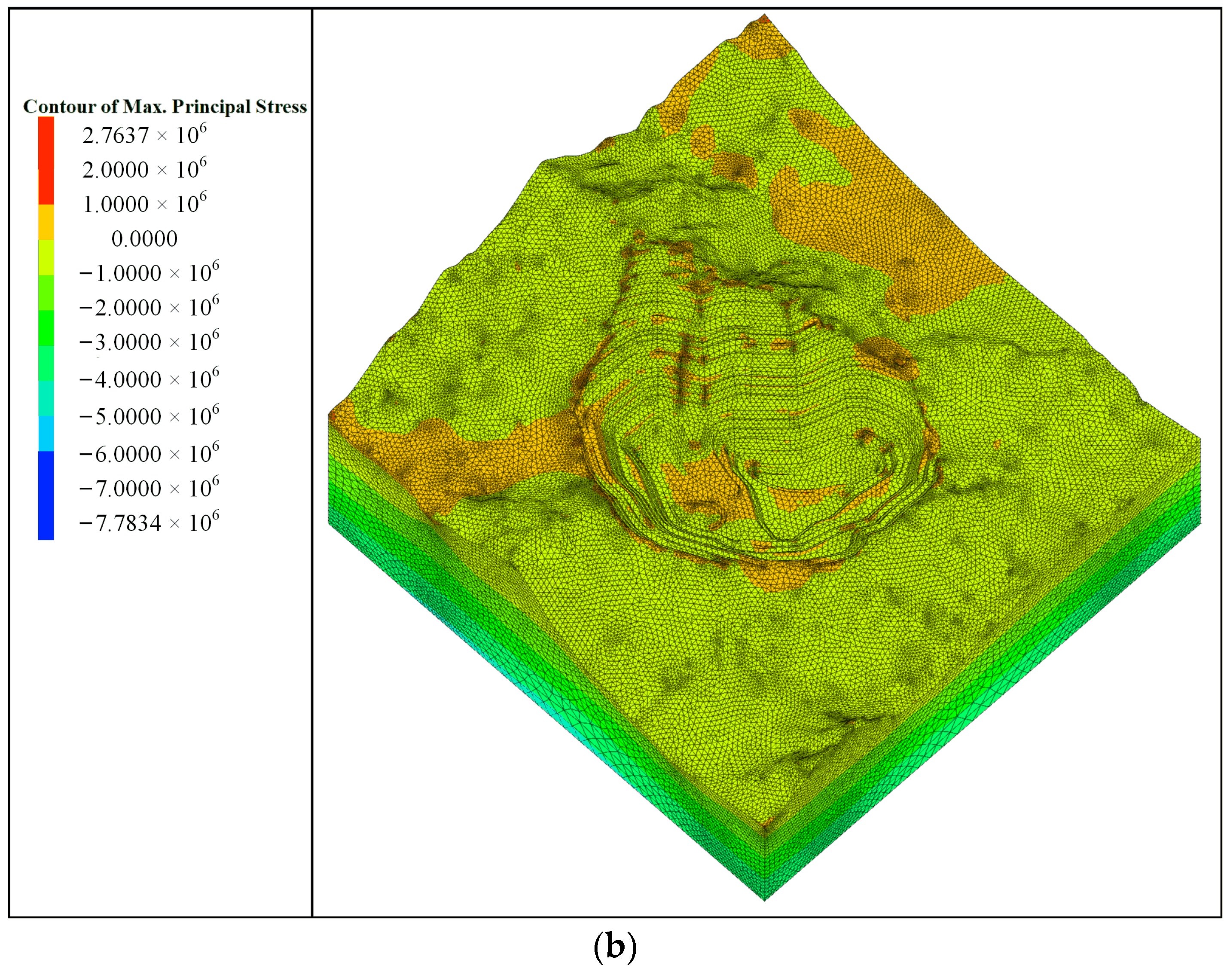

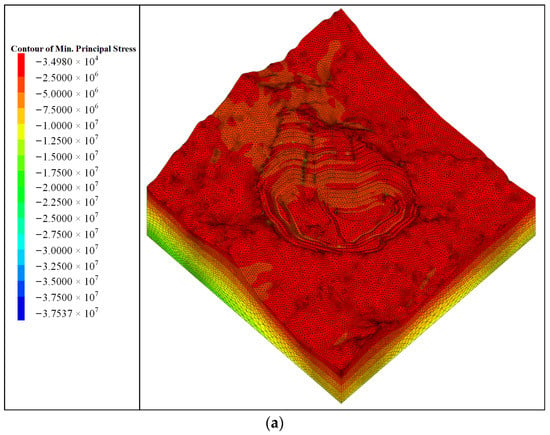

The 3D model is solved under gravity field conditions using the SOLVE command, and the model reaches equilibrium when the maximum unbalanced force is less than 1.0 × 10−5 N. The principal stress contour diagram is shown in Figure 7, where (a) is the minimum principal stress and (b) is the maximum principal stress. The plastic zone results for the overall model are shown in Figure 6. The Z-directional displacement is shown in Figure 7.

Figure 7.

The principal stress diagram of the overall model: (a) minimum principal stress diagram; (b) maximum principal stress diagram.

As can be seen from Figure 7a, the minimum principal stresses at most locations within the open pit are compressive, with the magnitude of the compressive stresses gradually increasing from top to bottom. The minimum principal stresses take values in the range of 37.54 MPa to 0.035 MPa, all of which are less than the compressive strength limit of the material (102.590 MPa), and no significant abrupt changes are found in the simulation results. As can be seen from Figure 7b, the maximum principal stresses within the open pit are mainly compressive (maximum value of 7.78 MPa) but there are also a few tensile stresses (maximum value of 2.76 MPa) present at the surface, all of which are less than the compressive strength limit (102.590 MPa) and tensile strength limit (7.04 MPa) of the material.

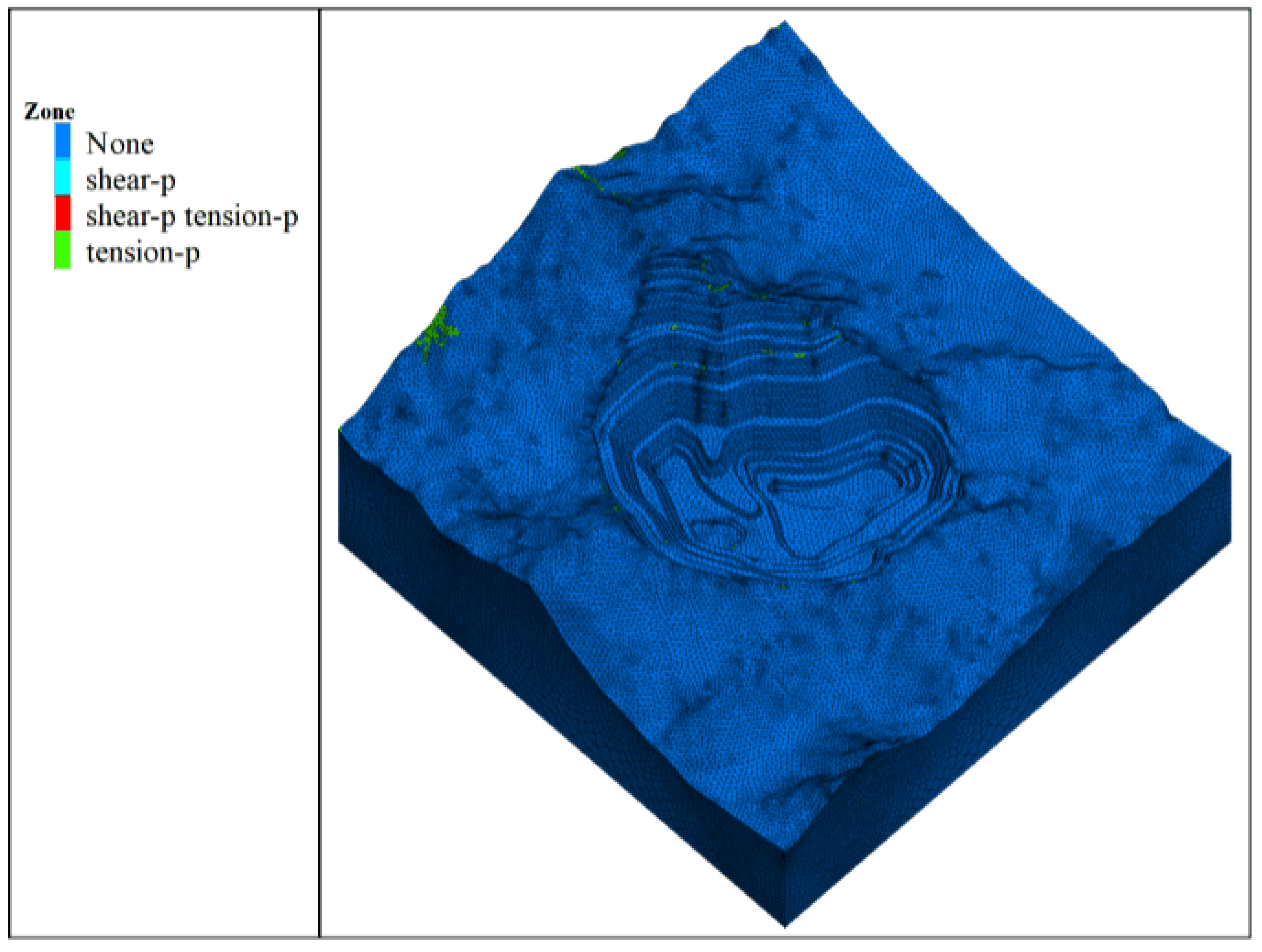

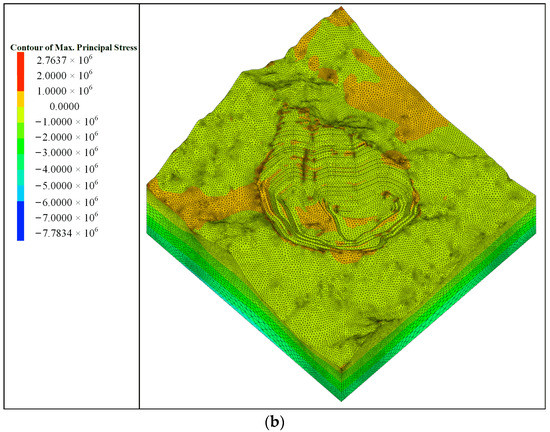

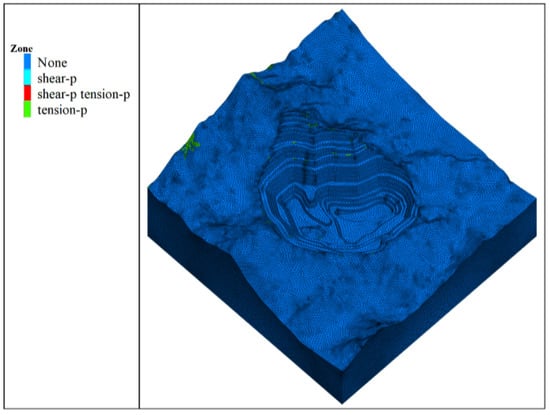

The plastic zone results in a small number of tensile damage cells for the overall mine model in Figure 8. However, the plastic zone has not developed through damage, and therefore the open pit is safe and stable overall.

Figure 8.

Plasticity zone results for the overall model.

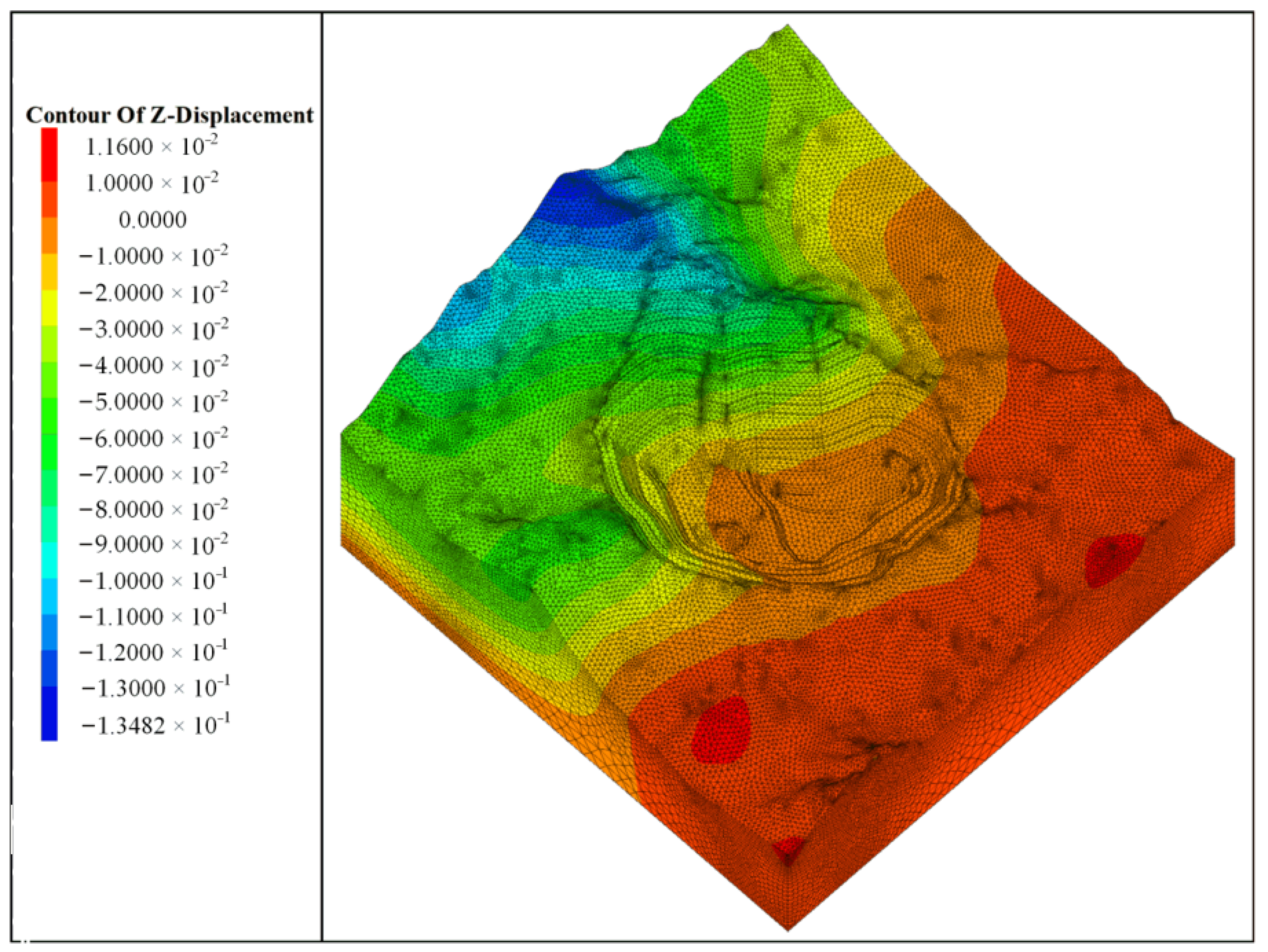

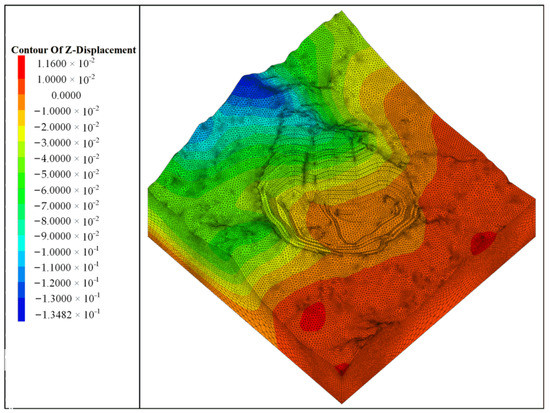

The Z-directional displacement contour in Figure 9 shows that the model settles in the high areas and rebounds in the low areas near the river valley, with a maximum settlement displacement of 13.48 cm for the model as a whole.

Figure 9.

Z-directional displacement diagram of the overall model.

4.2. Slope Section Analysis

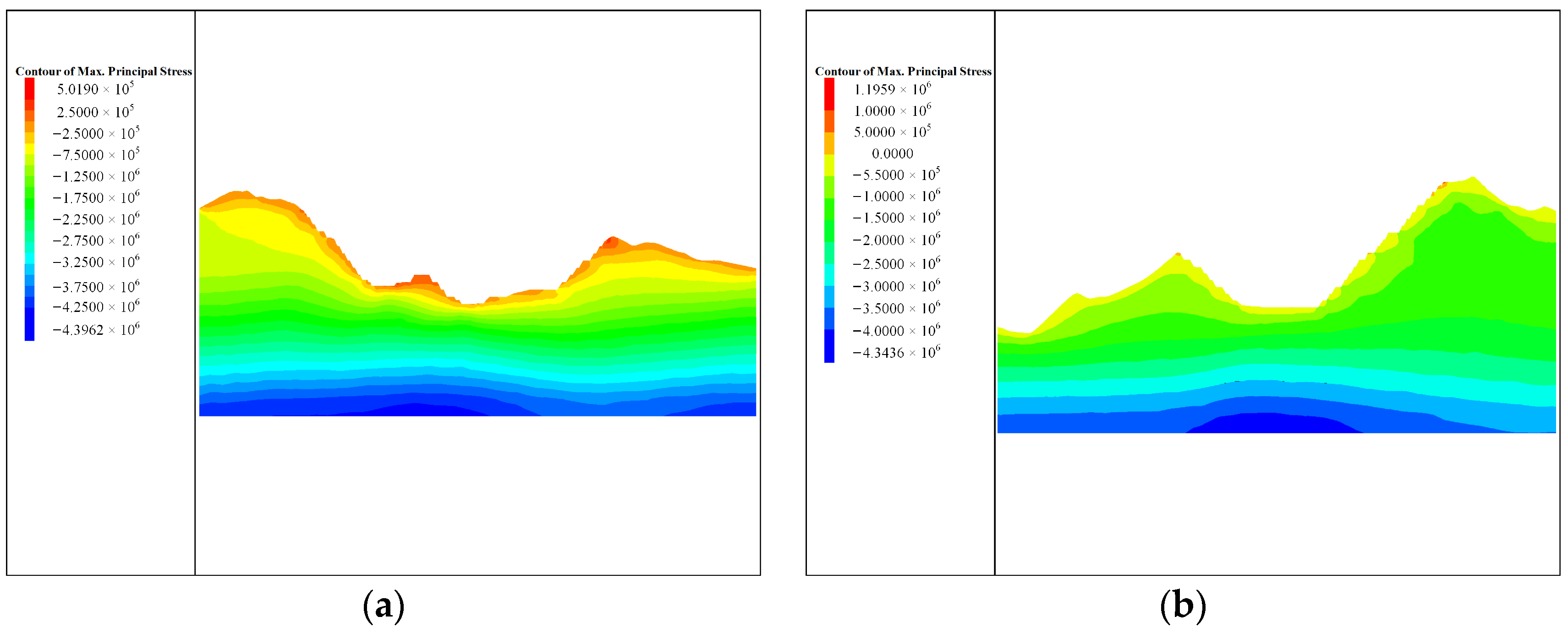

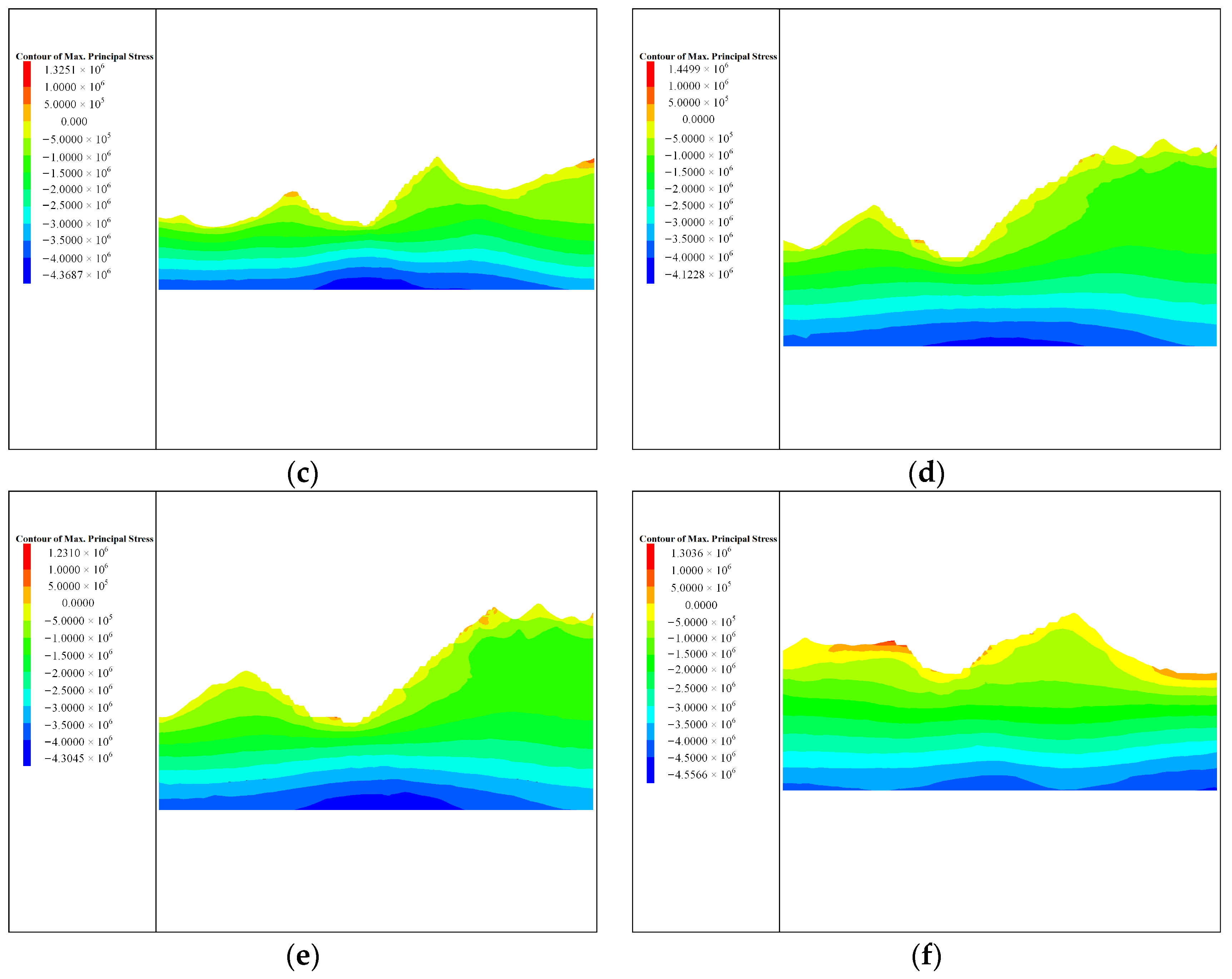

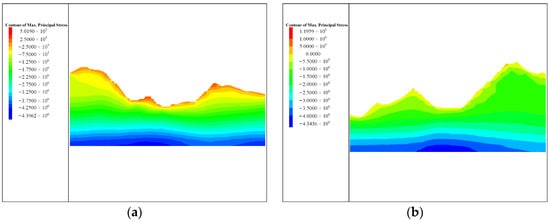

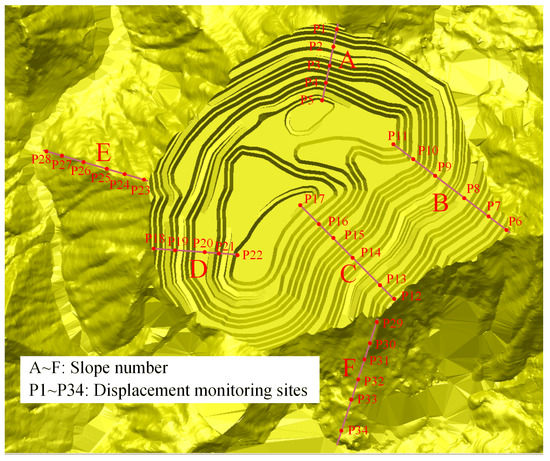

In order to better observe the condition of the slope, the model was cut away from the location of typical A~F sections to show the results of the maximum principal stress contour diagram, as shown in Figure 10. From each figure, it can be seen that there are localised concentrations of tensile stresses in the slope, generally occurring at locations close to the surface, but the absolute values of the tensile stresses are all small, with a maximum of 1.45 MPa, which is less than the tensile strength of the material (7.04 MPa).

Figure 10.

The contour of max. principal stress in sections: (a) section A; (b) section B; (c) section C; (d) section D; (e) section E; (f) section F.

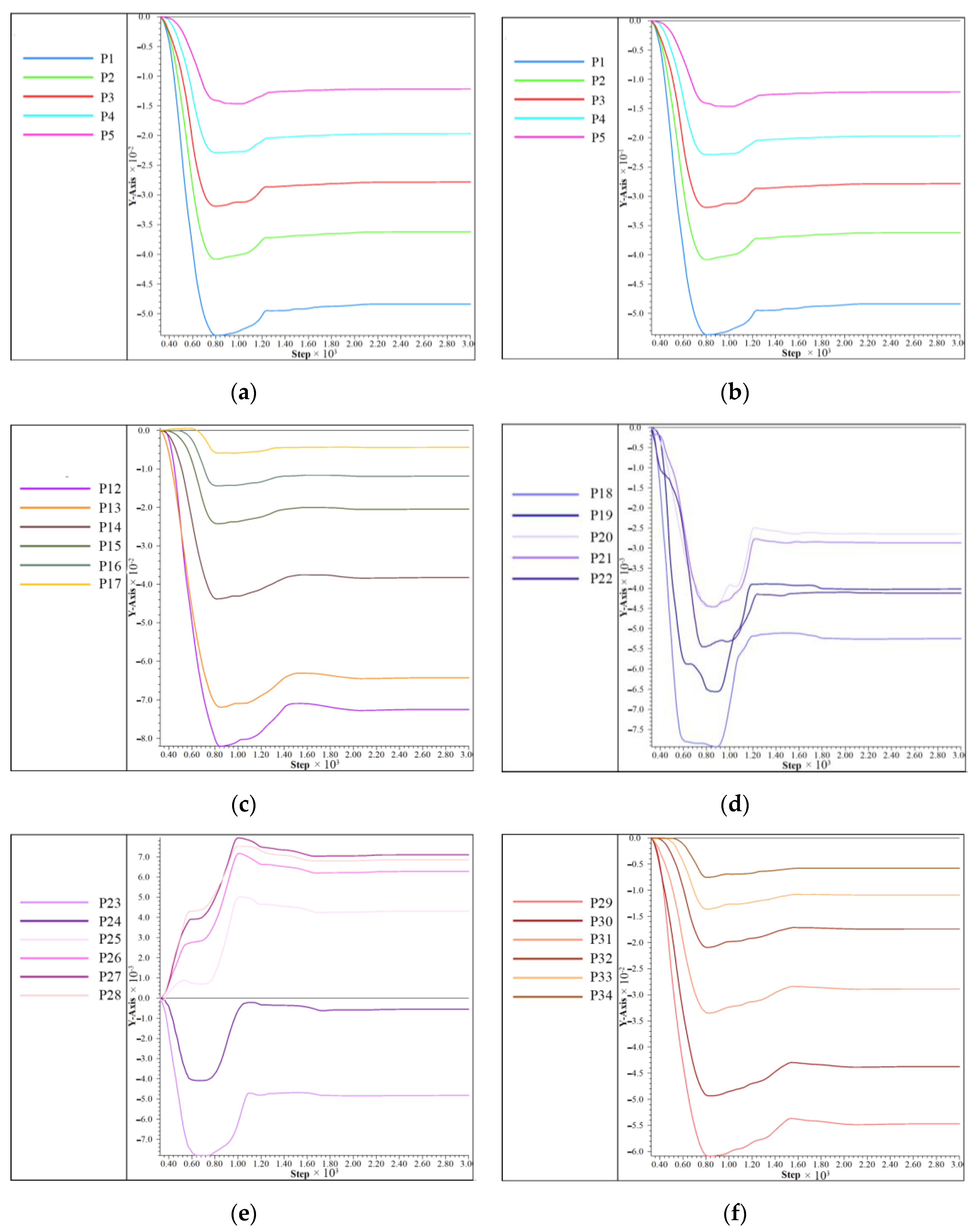

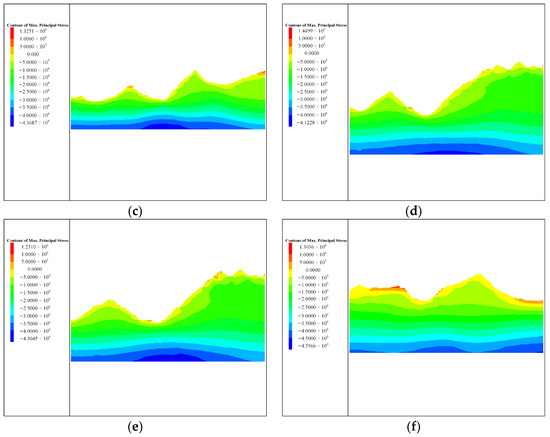

4.3. Displacement Monitoring

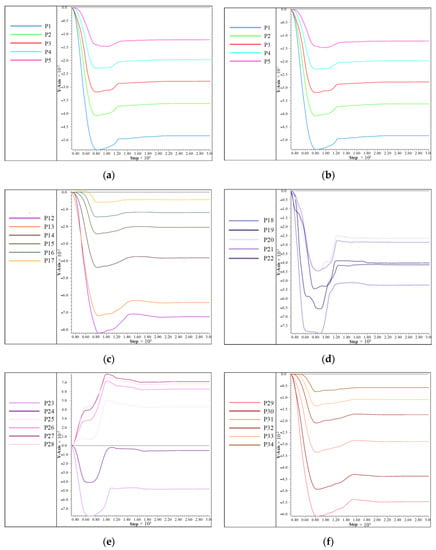

Enhanced geological monitoring can effectively prevent slope hazards [34]. In order to observe the changes in slope displacement, monitoring points were set up in the model and the model was simulated using FLAC3D. The locations of the open-pit boundary slope displacement monitoring points are shown in Figure 11; monitoring points P1~P5 were set at the surface of section A. Similarly, P6~P11 were set at B, P12~P17 at C, P18~P22 at D, P23~P28 at E, and P29~P34 at F. The results of each side’s slope displacement monitoring graphs are shown in Figure 12.

Figure 11.

The locations of the open-pit boundary slope displacement monitoring points.

Figure 12.

The results of each side slope displacement monitoring graphs: (a) slope A; (b) slope B; (c) slope C; (d) slope D; (e) slope E; (f) slope F.

From each figure, it can be seen that, except for the slope of E, the displacement of each monitoring point is a process of settlement followed by a small amount of rebound and then tends to stabilise, which indicates that the slope is finally in a basic stable state. The maximum settlement value is obtained by P6 of B, which is about 12.50 cm, which is consistent with the property that this monitoring point has the maximum elevation, with the exception of P25~P28 of E, where rebound occurs at the beginning, which is consistent with Figure 9. The Z-direction displacement contours of the overall model are consistent.

As can be seen from the contour of the overall stress and displacement results from the model above, the slope of the mine is in an overall stable condition, with only a small amount of tensile damage in some areas, but no penetration. The results for each section show that the displacements and tensile stresses in the slope are small and are consistent with the overall analysis. Therefore, it is clear from the above analysis that the slope of the open pit is stable.

Compared to the results of the 2D analysis [31], it can be found that the conclusions reached by the true 3D analysis method match them, and can show that the method is viable for analysing slope stability.

4.4. Slope Monitoring and Management

The monitoring and management of mine slopes are very important. When mine slopes are about to be damaged, the use of sophisticated monitoring equipment and scientific and reasonable methods can detect the movement of the precursors of slope damage in time, so as to avoid accidents such as property damage and casualties caused by slope damage. Some of the techniques used to monitor slope displacements in mines are laser scanners, total stations, crack meter, visual inspection, sirovision, and lately, monitoring radar. Geological, hydrogeological, and environmental monitoring should be enhanced in various infrastructure projects to prevent geological and engineering hazards if timely monitoring is possible [35].

From the field investigation, we can know that the current slope is relatively steep, the terrain is undulating, and there are a large number of large pieces of rubble that may slide. The staff at Shizhuyuan Mine are highly concerned about the major slope hazards and the subsequent prevention and control work, using the world’s most advanced fully automatic total station (as shown in Figure 13) to monitor the surface deformation around the collapse pit in real time for early warning. On the right side of the figure is the remote sensing model of slope monitoring established by UAV. Together with the microseismic monitoring system, the mine’s slope safety is monitored from different physical perspectives and in synergy with each other.

Figure 13.

The photo of monitoring equipment at Shizhuyuan mine.

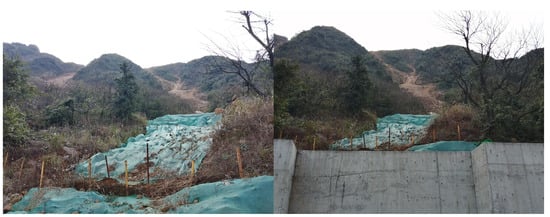

Where the stability of a slope is found to be poor, slope treatment methods can be used to increase stability. Commonly used slope support techniques in slope treatment projects include grouting, prestressed anchor cables, anchor rods, retaining walls, antislip piles, etc. At present, the mine adopts safety nets to prevent falling rocks and dust, while building retaining walls to strengthen protection (as shown in Figure 14).

Figure 14.

Photos of treatment measures.

5. Discussion

In this paper, a series of analyses on the stability of the slope of the Shizhuyuan mine were carried out using the true 3D analysis method, which eventually led to a similar conclusion to the previous 2D analysis method: that the slope of the mine is safe and stable. Compared to the 2D analysis method alone, the true 3D analysis method allows the mine to be seen as a continuous whole and is more realistic when analysing engineering problems. The stability of each slope section is considered not only in terms of its own state of stress and displacement but also in terms of the overall forces acting on the whole, following the principles of systematics.

On the other hand, there are certain limitations in this study. For example, when the finite element method was used to build the mine model, the rock structure in each slope section could not be presented in its entirety as in the traditional two-dimensional method, and the three-dimensional method could only simplify the overall model structure. In addition, the methodology of this study does not investigate the safety and stability of slopes under various working conditions, which still deserves to be improved. The amount of overburden within the open-pit boundary is also an important factor in considering the safety of open-pit mining [36]. Although the results show a high degree of agreement between the 3D and 2D analysis, this is still a direction that we need to continue to work on in the future. Meanwhile, modern back-analysis can be used in the construction process, designed to help people and to guarantee the stability and economic efficiency of the study, for any possible improvements to the original project, as well as for reducing the impact of unforeseen errors arising from the design [37]. Underground to open-pit mining requires the use of a variety of technologies to ensure production safety. For example, the Morenci copper mine in the USA, which converted to open-pit mining in 1937, was the first to use a GPS positioning system and a computer-controlled system to direct the work of the extraction equipment with real-time mine location software monitoring all mining equipment [38].

In summary, the use of three-dimensional analysis to study the stability of mine slopes is of the great reference value, and we hope that more researchers will pay attention to it and improve it in the future.

6. Conclusions

The safety and stability problems of slopes may cause the loss of people and property. This paper explores the stability problems of slopes by taking the Shizhuyuan Multifree Metal Mine as the research object. The underground mine has been subject to blast collapse, and the impact of the resulting collapse pit has required stripping the amount of ore rock and lowering the slope angle to the east of the collapse area, creating a mining system of stripping rock in the upper part of the mine and mining in the lower part. This requires open-pit slope stability analysis for the project. This 3D simulation and analysis were carried out using FLAC3D software (version 5.0), and the following conclusions were drawn.

From the perspective of the overall analysis, it can be seen that the open pit was subjected to compressive stresses of up to 37.54 MPa, less than 102.590 MPa; and tensile stresses of 2.76 MPa, less than 7.04 MPa. Displacement contours in the Z-direction show that the model settles at high points but bounces back at low points near the river valley with a maximum settlement displacement of 13.48 cm, and that the plastic zone is not penetrated. Analysis of the slope sections shows that there are local concentrations of tensile stresses in each slope, but the values are small, with a maximum of 1.45 MPa, which is less than the tensile strength of the material (7.04 MPa). Ultimately, it can be concluded that the open-pit mine is safe and stable overall.

Compared to the 2D analysis method used in the previous analysis, the 3D analysis method used in this study also concluded that the slope is stable, thus supporting the correctness of the true 3D analysis method used in this study. Ultimately, the agreement between the results of the two methods indicates that the open pit slopes of the Shizhuyuan mine are stable and can ensure the orderly conduct of construction and production activities at the mine.

Author Contributions

Data curation, S.L., Z.Z., B.H. and T.Y.; investigation, S.L., Z.Z., B.H. and T.Y.; methodology, S.L., Z.Z. and B.H.; project administration, G.C. (Gong Chen) and G.C. (Guohui Chen); software, Z.Z. and B.H.; supervision, S.L., T.Y., G.C. (Gong Chen) and G.C. (Guohui Chen); writing—original draft, Z.Z.; writing—review and editing, S.L. and B.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Hunan Province (Grant No. 2021JJ40745) and the National Natural Science Foundation of China (Grant No. 51804337).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ning, Y.J.; An, X.M.; Ma, G.W. Footwall slope stability analysis with the numerical manifold method. Int. J. Rock Mech. Min. Sci. 2011, 48, 964–975. [Google Scholar] [CrossRef]

- Abdulai, M.; Sharifzadeh, M. Probability Methods for Stability Design of Open Pit Rock Slopes: An Overview. Geosciences 2021, 11, 319. [Google Scholar] [CrossRef]

- Hungr, O.; Leroueil, S.; Picarelli, L. The Varnes classification of landslide types, an update. Landslides 2014, 11, 167–194. [Google Scholar] [CrossRef]

- Malamud, B.D.; Turcotte, D.L.; Guzzetti, F.; Reichenbach, P. Landslide inventories and their statistical properties. Earth Surf. Process. Landf. 2004, 29, 687–711. [Google Scholar] [CrossRef]

- Valiev, N.; Berkovich, V.; Propp, V.; Kokarev, K. Combined method of opencast and underground mining of valuable ore. E3S Web Conf. 2018, 56, 01023. [Google Scholar] [CrossRef]

- Tiedeu, W.N.; Jiang, D.Y.; Chen, J.; Fan, J.Y. A Review on Rock Slope Stability: Failure Mechanisms, Stabilization Techniques and Implications for Mining Engineering. Geotech. Eng. 2020, 51, 169–180. [Google Scholar]

- Zhu, C.; He, M.C.; Karakus, M.; Cui, X.B.; Tao, Z.G. Investigating Toppling Failure Mechanism of Anti-dip Layered Slope due to Excavation by Physical Modelling. Rock Mech. Rock Eng. 2020, 53, 5029–5050. [Google Scholar] [CrossRef]

- Alejano, L.R.; Gomez-Marquez, I.; Martinez-Alegria, R. Analysis of a complex toppling-circular slope failure. Eng. Geol. 2010, 114, 93–104. [Google Scholar] [CrossRef]

- Zhang, D.M.; Yin, G.Z.; Chen, J.A.; Dai, G.F. Stability Analysis of Multi-step Anti-tilt Slope at Open-pit Mine. Disaster Adv. 2010, 3, 30–34. [Google Scholar]

- Azhari, A.; Ozbay, U. Investigating the effect of earthquakes on open pit mine slopes. Int. J. Rock Mech. Min. Sci. 2017, 100, 218–228. [Google Scholar] [CrossRef]

- Stead, D.; Eberhardt, E.; Coggan, J. Developments in the characterization of complex rock slope deformation and failure using numerical modelling techniques. Eng. Geol. 2006, 83, 217–235. [Google Scholar] [CrossRef]

- Skempton, A. Long-term stability of clay slopes. Geotechnique 1964, 14, 77–102. [Google Scholar] [CrossRef]

- Sultan, N.; Cochonat, P.; Canals, M.; Cattaneo, A.; Dennielou, B.; Haflidason, H.; Laberg, J.S.; Long, D.; Mienert, J.; Trincardi, F.; et al. Triggering mechanisms of slope instability processes and sediment failures on continental margins: A geotechnical approach. Mar. Geol. 2004, 213, 291–321. [Google Scholar] [CrossRef]

- Daftaribesheli, A.; Ataei, M.; Sereshki, F. Assessment of rock slope stability using the Fuzzy Slope Mass Rating (FSMR) system. Appl. Soft Comput. 2011, 11, 4465–4473. [Google Scholar] [CrossRef]

- Bye, A.R.; Bell, F.G. Stability assessment and slope design at Sandsloot open pit, South Africa. Int. J. Rock Mech. Min. Sci. 2001, 38, 449–466. [Google Scholar] [CrossRef]

- Intrieri, E.; Carla, T.; Gigli, G. Forecasting the time of failure of landslides at slope-scale: A literature review. Earth-Sci. Rev. 2019, 193, 333–349. [Google Scholar] [CrossRef]

- Salvoni, M.; Dight, P.M. Rock damage assessment in a large unstable slope from microseismic monitoring—MMG Century mine (Queensland, Australia) case study. Eng. Geol. 2016, 210, 45–56. [Google Scholar] [CrossRef]

- Ding, X.P.; Li, F.M.; Wang, Z.W.; Sang, S.; Cao, M.M. Physical Model Experimental Study on the Coalface Overburden Movement Law on the End Slope of an Open-Pit Mine. Geotech. Geol. Eng. 2022, 40, 4859–4877. [Google Scholar] [CrossRef]

- Nguyen, H.; Drebenstedt, C.; Bui, X.N.; Bui, D.T. Prediction of Blast-Induced Ground Vibration in an Open-Pit Mine by a Novel Hybrid Model Based on Clustering and Artificial Neural Network. Nat. Resour. Res. 2020, 29, 691–709. [Google Scholar] [CrossRef]

- López-Vinielles, J.; Ezquerro, P.; Fernández-Merodo, J.A.; Béjar-Pizarro, M.; Monserrat, O.; Barra, A.; Blanco, P.; García-Robles, J.; Filatov, A.; García-Davalillo, J.C.; et al. Remote analysis of an open-pit slope failure: Las Cruces case study, Spain. Landslides 2020, 17, 2173–2188. [Google Scholar] [CrossRef]

- Wang, W.; Griffiths, D.V. Case study of slope failure during construction of an open pit mine in Indonesia. Can. Geotech. J. 2019, 56, 636–648. [Google Scholar] [CrossRef]

- Romer, C.; Ferentinou, M. Numerical investigations of rock bridge effect on open pit slope stability. J. Rock Mech. Geotech. Eng. 2019, 11, 1184–1200. [Google Scholar] [CrossRef]

- Vyazmensky, A.; Stead, D.; Elmo, D.; Moss, A. Numerical Analysis of Block Caving-Induced Instability in Large Open Pit Slopes: A Finite Element/Discrete Element Approach. Rock Mech. Rock Eng. 2010, 43, 21–39. [Google Scholar] [CrossRef]

- Zhang, K.; Cao, P.; Liu, Z.-Y.; Hu, H.-H.; Gong, D.-P. Simulation analysis on three-dimensional slope failure under different conditions. Trans. Nonferrous Met. Soc. China 2011, 21, 2490–2502. [Google Scholar] [CrossRef]

- Huang, J.; Duan, T.; Lei, Y.; Hasanipanah, M. Finite Element Modeling for the Antivibration Pavement Used to Improve the Slope Stability of the Open-Pit Mine. Shock. Vib. 2020, 2020, 6650780. [Google Scholar] [CrossRef]

- Jiang, N.; Zhou, C.; Lu, S.; Zhang, Z. Effect of Underground Mine Blast Vibrations on Overlaying Open Pit Slopes: A Case Study for Daye Iron Mine in China. Geotech. Geol. Eng. 2018, 36, 1475–1489. [Google Scholar] [CrossRef]

- Griffiths, D.V.; Marquez, R.M. Three-dimensional slope stability analysis by elasto-plastic finite elements. Geotechnique 2007, 57, 537–546. [Google Scholar] [CrossRef]

- Li, A.J.; Merifield, R.S.; Lyamin, A.V. Three-dimensional stability charts for slopes based on limit analysis methods. Can. Geotech. J. 2010, 47, 1316–1334. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, Q.; Li, S.; Yu, H.; Wang, X.; Wang, H. Application of Numerical Simulation Methods in Solving Complex Mining Engineering Problems in Dingxi Mine, China. Minerals 2022, 12, 123. [Google Scholar] [CrossRef]

- Pan, D.W.; Zhong, Q.; Liao, Y.H.; He, B.; Li, W.J.; Jian, H.; He, Z.; Cao, Z.; Xiao, Y. Effects of multi-time scales climate changes on tobacco-planting counties in chenzhou city of hunan province. Bangladesh J. Bot. 2021, 50, 977–985. [Google Scholar] [CrossRef]

- Li, S.; Zhao, Z.M.; Hu, B.Y.; Yin, T.B.; Chen, G.; Chen, G.H. Hazard Classification and Stability Analysis of High and Steep Slopes from Underground to Open-Pit Mining. Int. J. Environ. Res. Public Health 2022, 19, 11679. [Google Scholar] [CrossRef] [PubMed]

- Claudio, O.; Otello, G.; Mauro, F. Underground dimension stone quarrying: Rock mass structure and stability. In Proceedings of the ’99 International Symposium on Mining Science and Technology, Beijing, China, 29 September 1999; pp. 385–396. [Google Scholar]

- Griffiths, D.V.; Lane, P.A. Slope stability analysis by finite elements. Geotechnique 1999, 49, 387–403. [Google Scholar] [CrossRef]

- Liu, D.A.; Yang, Z.F.; Tang, C.H.; Wang, J.; Liu, Y. An automatic monitoring system for the shiplock slope of Wuqiangxi Hydropower Station. Eng. Geol. 2004, 76, 79–91. [Google Scholar] [CrossRef]

- Osasan, K.S.; Afeni, T.B. Review of surface mine slope monitoring techniques. J. Min. Sci. 2010, 46, 177–186. [Google Scholar] [CrossRef]

- Oggeri, C.; Fenoglio, T.M.; Godio, A.; Vinai, R. Overburden management in open pits: Options and limits in large limestone quarries. Int. J. Min. Sci. Technol. 2019, 29, 217–228. [Google Scholar] [CrossRef]

- Oggeri, C.; Oreste, P. Tunnel Static Behavior Assessed by a Probabilistic Approach to the Back-Analysis. Am. J. Appl. Sci. 2012, 9, 1137–1144. [Google Scholar]

- Feihong, S. The world’s largest wet-process copper mine—Morenci Copper. China Met. Bull. 2008, 30, 28. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).