Abstract

The inclusion of high specific surface materials such as calcined clays in cementitious systems enhances the hydration of clinker products at very early ages, but it may also increase water demand; thus, the pursuit of a flowing concrete may demand an increase in the dosage of superplasticizers. The grinding regime can have a major influence on the properties of the cementitious system and could help mitigate the problem of water demand. This paper discusses the impact of grinding alternatives for the production of a binder consisting of clinker, calcined clay, limestone and gypsum. Two main target products will be discussed: (i) LC3, a binder with a formulation of 50% clinker, 30% calcined clay, 15% limestone and 5% gypsum, co-ground all together, and (ii) LC2, a mineral addition with a formulation of 60% calcined clay, 35% limestone and 5% gypsum, ground separately and further blended with Portland cement on a 1:1 basis (mass). The experimental program is carried out in several stages: (i) the binder, (ii) cement pastes and (iii) standard mortars, and concrete grinding aids from the family TEA are used to enhance grinding, and their impact is also be assessed.

1. Introduction

Cement will continue to be the key material in terms of national and international economic development due to its incidence as a raw material in the construction activity [1,2]. The cement industry is under pressure to assure a preservation of the material and energy resources, as well as to reduce CO2 emissions associated with cement manufacture [3].

In this sense, the substitution of a percentage of clinker through the use of supplementary cement materials (SCM) has been recognized as a way to reduce CO2 emissions and energy costs associated with cement manufacture, while at the same time improving or maintaining its physical, mechanical and chemical properties. Several authors [3,4,5] indicate that energy expenditure in cement production could be reduced by 35% to 40% of the current cost.

On the other hand, the use of calcined clays as SCM is an attractive alternative in cement production, due to their wide availability throughout Earth’s crust [6,7,8], with a relative ease of treatment when activated by thermal processes that require much less energy than that required for clinker production, in addition to their proven pozzolanic properties [9,10,11]. The process is based on the substitution of a large part of the clinker used in its manufacture (30% to 50% substitution) with calcined clay and calcium carbonate, which would reduce CO2 emissions to the atmosphere by 20%–30% compared to other types of cements [3,12].

Based on the above formulations, low carbon cement (LC3), is a new type of cement that can reach 50% clinker substitution using a combination of calcined clay and limestone [11,13,14]. The obvious advantage of calcined clay system with limestone and clinker over traditional blended cements lies in the possibility of increasing the level of clinker substitution without compromising the final properties of the cement [15,16]. This has a direct impact on the reduction of environmental costs associated with CO2 emissions, without implying higher production values, which can even be lower without large investments [17,18].

Grinding, however, could be a potential challenge for these systems. The presence of very hard particles such as clinker and relatively softer materials such as calcined clay and limestone could eventually create trouble in co-grinding. The excess grinding of softer materials could lead to an increase in the demand for water [19]. A separate grinding process could eventually mitigate this problem, in a system where a mineral addition called LC2, consisting of 60% calcined clay, 35% limestone and 5% gypsum, is ground to powder and blended with Portland cement at flexible rates to produce LC3.

The main difference between co-grinding and separate grinding of a multicomponent cement is that during inter grinding the different components interact with each other. The interactions between the components are mainly due to the relative difference in grindability [20,21]. These interactions can help or hinder the grinding process and influence the relative content of each component in different grain size fractions and particle size distributions of the ground products [22,23]. As a result of these interactions, the particle size distribution (PSD) in the co-ground blended cement is different from that of separately ground cement. Schiller and Ellerbrock [20,24] found that the PSD of any constituent is greatly influenced by the grindability of the others. A component that is more difficult to grind concentrates in the coarser fractions, while a component that is easier to grind concentrates in the finer fractions.

Particles play a vital role in relation to rheology and the early hydration process that determines the properties of fresh concrete, such as water demand, heat release, compressive strength and changes in volume at early ages [25,26]. During the co-grinding process of cements with calcined clays, it is not possible to control the fineness of each constituent [27]. As a result of the lower grindability and greater hardness of the clinker, its grinding is insufficient. The finer particles of calcined clay and limestone (softer and more grindable materials) cover the grinding media and the clinker particles, cushioning its grinding, which causes an increase in the content of calcined clay and limestone in the fine fractions and a greater clinker content in coarse fractions [28]. On the other hand, the increase in the proportion of calcined clay causes a lower efficiency in clinker grinding, an increase in the specific surface, deterioration of the rheology and a decrease in compressive strength at early ages.

It should be taken into account that both the LC3 cement and the LC2 mineral addition go through a fragmentation or grinding process, which suffer an agglomeration phenomenon due to the electrostatic charge that affects the fine-grained particles [29]. Grinding aids or grinding intensifiers could eventually mitigate such load. Agglomeration is then avoided and, therefore, less time and resources to obtain the adequate particle size of the final product are required.

The role of grinding aids in LC3 systems is to reduce the agglomeration of cement particles. Their use will also be helpful for the total or partial elimination of the “coating” effect in the grinding media [30], an improvement in efficiency for particle separation due to increased fluidity of fine particles, a decrease in loading problems in storage silos and bulk cement delivery trucks, an increase in quality of bagged storage, as well as, improvements in material handling (blowing in silos, loading trucks, etc.) due to improved fluidity [31,32]. The presence of grinding aids facilitates achieving an adequate specific surface area and a higher grinding capacity index, compared to cements that do not use grinding aids, a fact that is attributed to the elimination or delay of agglomeration phenomena during the grinding process [32,33].

There are different types of grinding aids such as aliphatic amines (triethylenetetramine (TETA)) and tetraethylenepentamine (TEPA)) and alcoholamines (diethanolamine (DEA), triethanolamine (TEA) and triisopropanolamine (TIPA)). Glycol compounds are represented as ethylene glycol (EG) and diethylene glycol (DEG). In addition, there are more complex compounds such as aminoethylethanolamine (AEEA) and diethylenetriamine hydroxyethyl (HEDETA). Phenol and phenol-derivatives are also used as grinding aids [32,33].

This paper presents a study carried out to investigate the impact of grinding on cements containing a blend of calcined clay and limestone.

2. Materials and Methods

This research presents the evaluation of the impact of the grinding regime for LC3 cement and LC2 mineral addition, with and without grinding aids. A commercial grinding intensifier (TEA-A) treated at laboratory scale was used for the analysis. A group of instrumental and analytical research techniques were applied, such as the evaluation and analysis of cement particle size by PSD, its effect on rheology and heat of hydration, as well as on the physical-mechanical properties of pastes, mortars and concretes.

2.1. Materials Used for Pastes and Mortars

Clay: The clay used was obtained from the mining area of the city of Cuenca (see Table 1). In this mining area, a mixture of clay minerals of the 1:1 type is identified. Thermogravimetric analysis (TGA) was used to quantify the kaolinite content of the clay by using the tangent method between 400 °C and 600 °C. A total of 50 mg of powdered sample was analyzed using a Mettler Toledo TGA/SDTA 851 balance with a heating rate of 10 °C/min from 30 °C to 1000 °C under constant dinitrogen flow of 30 mL/min. The content of clay minerals of the kaolinite group was estimated as 55.27%. The Loss on ignition (LOI) of the clay was also quantified by TGA and from the weight loss between 30 °C and 1000 °C. The CaCO3 content in the limestone was calculated from TGA as well, from the weight loss between 600 °C and 800 °C. The experimental protocols for LOI and CaCO3 quantification by TGA were the same as for kaolinite quantification.

Table 1.

Chemical composition of raw materials.

X-ray fluorescence (XRF) measurements were performed by an external company using a Bruker AXS S4 Explorer spectrophotometer (Billerica, MA, US) operating at a power of 1 kW and equipped with a Rh X-ray source. Crystals used were OVO55FC for Na with 0.46° divergence collimator, PET for Al and Si with 0.23° divergence collimator and LiF220, with 0.23° divergence collimator for all other elements.

Table 1 presents the chemical composition of all raw materials used for the experimental program

- Clinker: Mineralogical composition (provided by the clinker supplier) was C3S = 62.04%; C2S = 14.34%; C3A = 7.07%; C4AF = 8.48%

- Limestone: CaCO3 content is higher than 94%, so it could be considered a high-purity limestone.

- Gypsum: SO3 is around 40%, (86.09% of gypsum).

Grinding Aids: a product supplied by the company GCP was used. The active principle is a mixture of alkanolamines and triethanolamine, all designed as Portland cement dispersants which, according to the manufacturer, reduce the attraction forces that occur between the cement particles during the grinding process. Further, it reduces the residence time in the mill and prevent particles from coating mill equipment or re-accumulation, thus helping reduce operating costs. Table 2 presents more details.

Table 2.

Characteristics of grinding aids used.

2.2. Materials Used for Concrete

Cements used: The cements were: cement LC3-50 2:1 (50% clinker and calcined clay–limestone, ratio 2:1) crushed by inter-grinding. Combinations of Portland cements with the mineral addition LC2 2:1 (combination of calcined clay, limestone and gypsum, calcined clay–limestone, ratio 2:1). The combinations used were (Portland cement/LC2) 55%/45%, 70%/30% and 85%/15%, a first reference was a pure Portland cement (OPC) and a second reference was a mixture where the Portland cement was replaced by 10% of a commercial mineral addition (SikaFume). Table 3 shows the physical properties of the cements used, which were ground for 50 min by inter-grinding and 30 min by separate grinding. It is verified that the addition of calcined clays increases the specific surface.

Table 3.

Properties of the binders used.

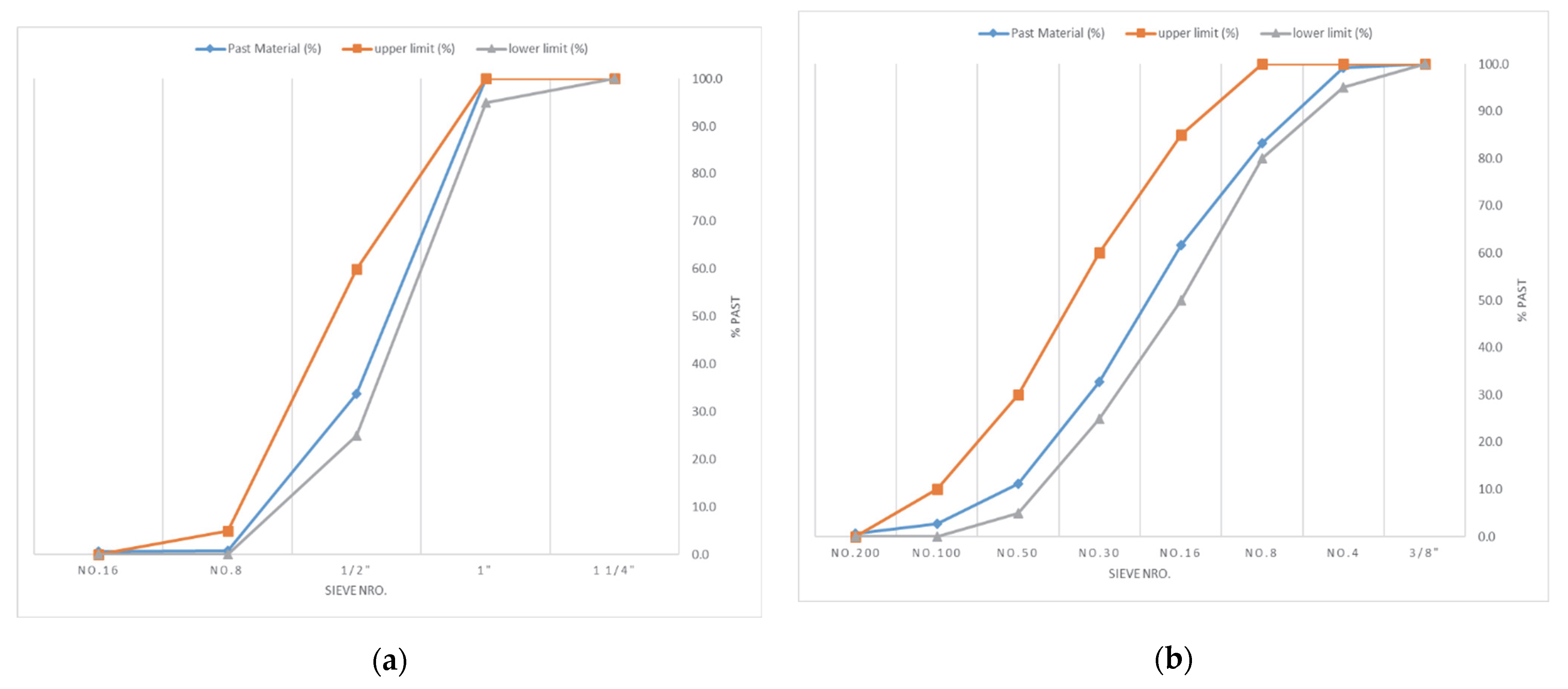

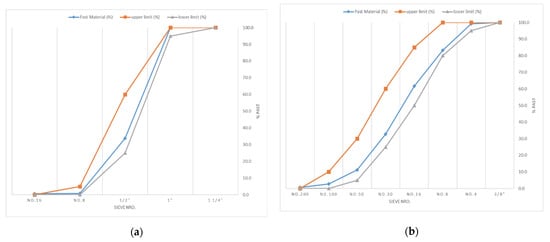

Aggregates: The aggregates used to produce the concrete specimens were provided by the aggregate supplier in the city of Cuenca. They were obtained by crushing pebbles. Figure 1 shows the particle size distribution of the aggregates used in the manufacture of concrete. Both aggregates meet the specifications of Ecuadorian standards [34,35,36,37,38,39].

Figure 1.

Particle size distributions of the aggregates, (a) coarse aggregate (CA), (b) fine aggregate (FA).

SikaFume (SF): Silica fume, also called silica fume or active silica, is an inorganic product consisting of very fine spherical particles that originates from the reduction of quartz with carbon during the processes of obtaining silicon metal and ferrosilicon in electric arc furnaces. The dust is collected in bag filters, consisting of spherical particles of amorphous SiO2 in a variable percentage between 85% and 98%. It is used as additions for high-strength concrete. This product was supplied by the company SIKA

Superplasticizer Admixture (SP): MasterRheobuild® 1050 (company BASF, Ludwigshafen, Germany), which is a high-range water-reducing admixture formulated to produce concrete with a fluid and plastic consistency. This type of admixture makes it possible to obtain concrete with a low water–cement ratio. This admixture complies with ASTM C 494 specifications for type A and F admixtures.

2.3. Experimental Procedure

2.3.1. Impact of Grinding Strategy on the Properties of Cement Pastes

Samples were prepared at laboratory scale; all raw materials underwent a drying process at 200 °C to constant weight. Then, they were weighed and subsequently ground in a ball mill (ball mill, manufacturing in Cuenca, Ecuador). The experimental program at this stage focused on evaluating the impact of grinding with and without grinding aids. The studies were done on LC3 cement and LC2 mineral addition (LC2 2:1) blended with lab-made Portland cement (94% clinker, 6% gypsum). In addition, laboratory tests were carried out in order to assess the physical and mechanical properties of the cements evaluated.

The following materials were produced through separate grinding:

- Pure Portland cement, formulated with Cement ATENAS clinker without limestone.

- Mineral admixture LC2, consisting of 63% calcined clay, 30% limestone and 7% gypsum. A batch was ground for 15 min and another, for 20 min. For each dosage of grinding aid, a batch was produced, following instructions of the supplier.

- The co-grinding was made for:

- LC3-50 cement 2:1 by inter grinding with and without grinding aids. A batch was ground for 15 min and another, for 20 min. For each dosage of grinding aid, a batch was produced, following instructions of the supplier.

The characterization of both materials and the LC3-50 2:1 that result from mixing them is presented in Table 4.

Table 4.

Proportions of the materials that were ground.

The quality of the LC3 cement, as well as the LC2 mineral addition, was verified by using the procedures established by the tests of the standards INEN (Ecuadorian Service of Normalization), ASTM (American Society for Testing and Materials) and NC (Cuban Standards). The tests included in this research were the following:

- Measuring fineness of cement LC3-50 and LC2 + PC (Portland cement) using a laser grain sizer (Dv10%, Dv50% and Dv90%) (Mastersizer 2000, Malvern, United Kingdom). Further, measuring the Blaine specific surface, according to the standard INEN 196. In addition, the compressibility parameter was obtained.

- Assessing the rheology in pastes and mortars following the regulations established in the standard NC 235: 2012. The determination of the normal consistency according to the standard INEN 157 and the fluidity test in mortars according to the standard INEN 2502.

- The determination of physical-mechanical properties, which were carried out taking into account the standard INEN 488 at ages 1, 3, 7 and 28 days.

- Fraction separation aided by an air filter. The following fractions were separated: (i) very fine d < 7 µm, (ii) medium 7 µm < d < 33 µm and (iii) coarse d > 33 µm.

- Determination of the content of cement components in each fraction using quantitative X-ray diffraction (Panalytical Xpert Pro MPD). The focus was to calculate the amount of clinker and calcined clay in each fraction.

- Isothermal calorimetry of cement pastes prepared by both grinding regimes to assess the impact on hydration. A TAM Air calorimeter was used, calibrated at 30 °C.

2.3.2. Impact of Grinding Strategy on the Properties of Concrete

The studies included the evaluation of various concrete mix designs made with LC3 cement and Portland cement + LC2, plus Portland cement and a mixture of Portland cement and 10% of SikaFume as references. A group of instrumental and analytical research techniques were applied, such as the particle size distribution of the aggregates used; for the concrete in the fresh state, the settlement using the Abrams Cone according to the protocol NTE INEN 1578 or the ASTM C143 [27,28], occluded air according to the standard ASTM C231 [29], concrete density according to ASTM C138 for concrete in hardened state and compressive strength at 1, 3, 7 and 28 days [30].

Mix design for the manufacture of concrete.

A certified concrete mix design for 35 MPa was used. Table 5 presents the proportions used, as well as the water-binder ratio and settlement values reached during manufacturing. Each variation of the mix design, such as the use of calcined clay or SikaFume was made based on the original mix design.

Table 5.

Dosage used in the manufacture of concrete (1 m3).

The low water absorption of the aggregates used contributed to achieve relatively low water-cement ratio in all concretes produced, including the ones with calcined clays. The presence of calcined clay, however, increases the water demand and prompts for a higher use of admixtures to make concrete flow.

3. Results

3.1. Impact of Grinding Conditions on Cement Pastes

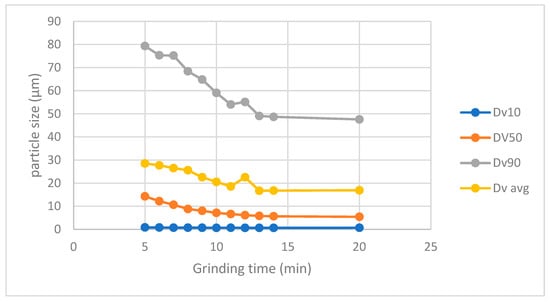

3.1.1. Grinding Calcined Clay Alone

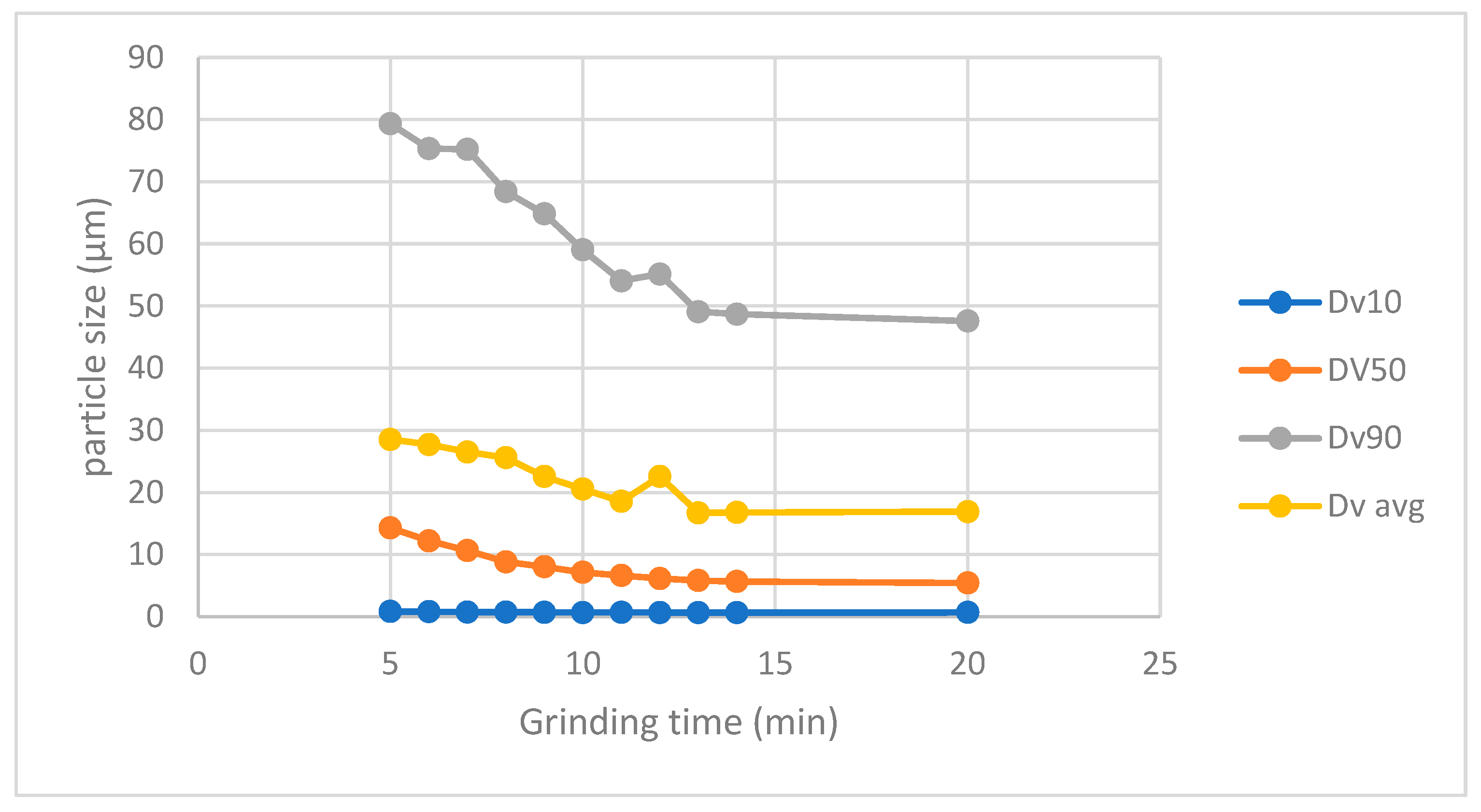

The lab ball milling was studied for every material processed on individual basis. Grinding studies for calcined clay alone show that the increase in grinding time from a certain point do not yield finer product, as described in Figure 2. For grinding times higher than 15 min, there is no evidence of changes in the size in the different fractions analyzed (Dv10%, Dv50% and Dv90%). This limit is possibly imposed by the coating of the steel balls by the calcined clay particles.

Figure 2.

Influence of grinding time on PSD of calcined clay.

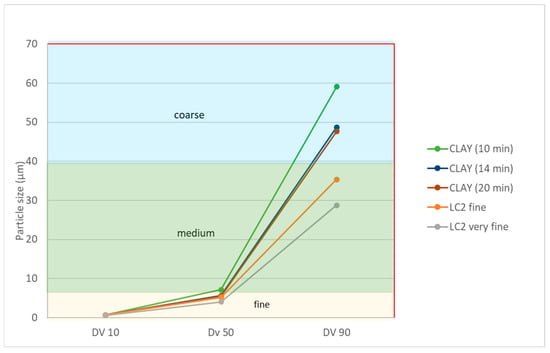

3.1.2. Co-Grinding vs. Separate Grinding

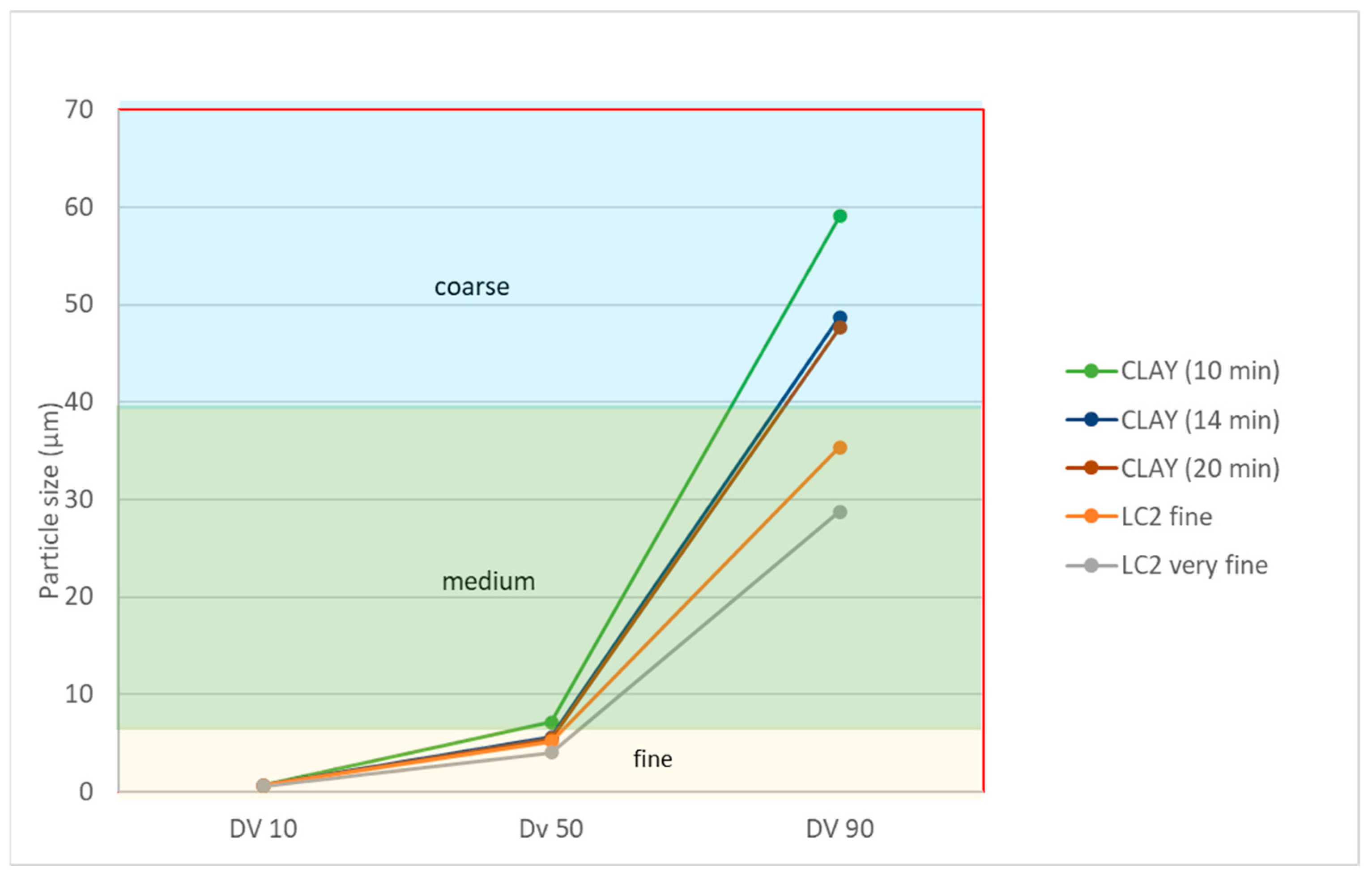

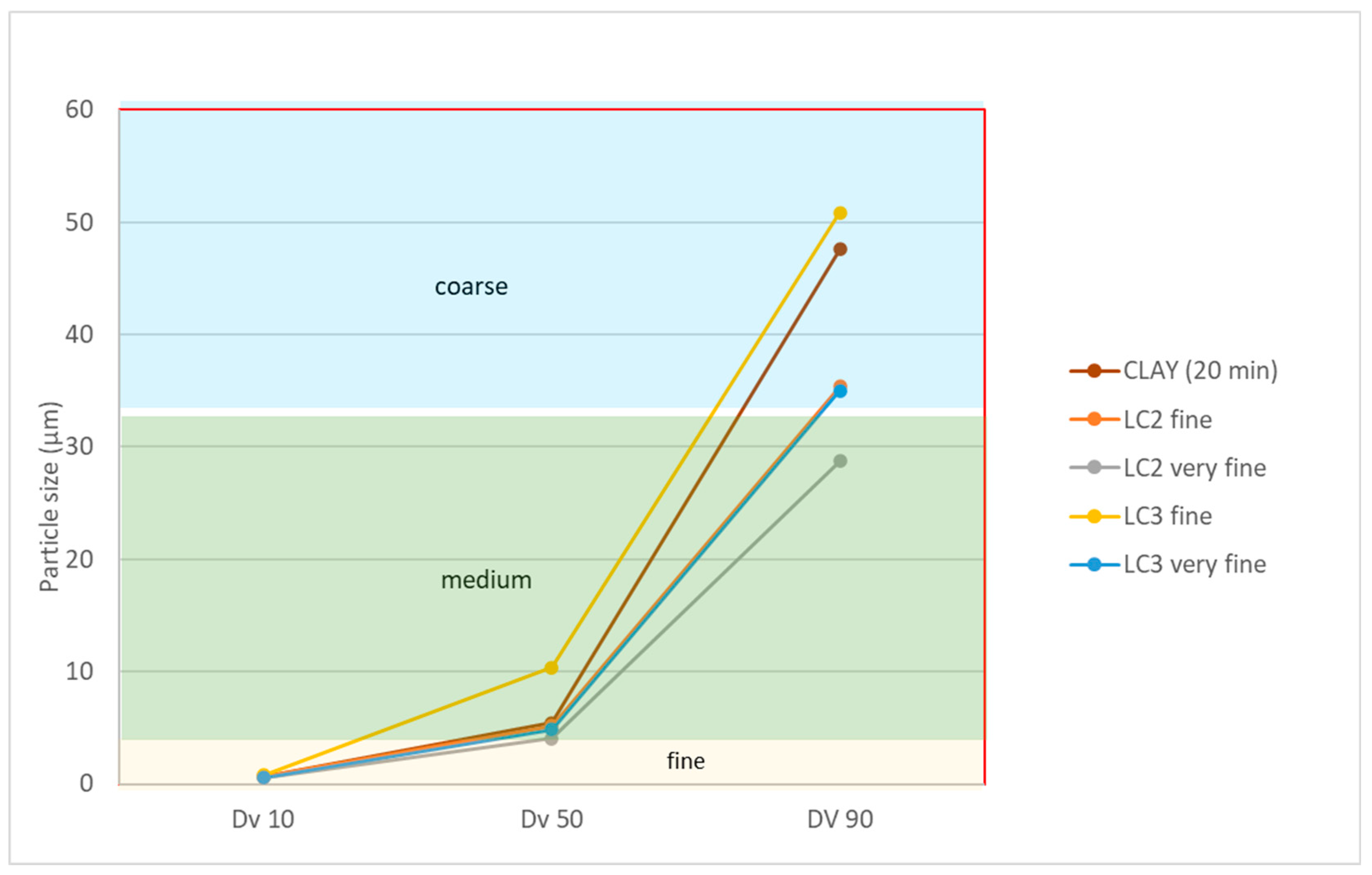

Figure 3 compares the impact of grinding calcined clay alone and incorporating limestone in the system. The main impact is to decrease the amount of coarse particles to medium particles, with an impact on PSD of the entire blend. Further grinding time increases the fineness of the LC2 to values never reached when calcined clay was ground alone. The physical interaction between calcined clay and limestone is possibly responsible for this effect.

Figure 3.

Impact of grinding calcined clay with limestone.

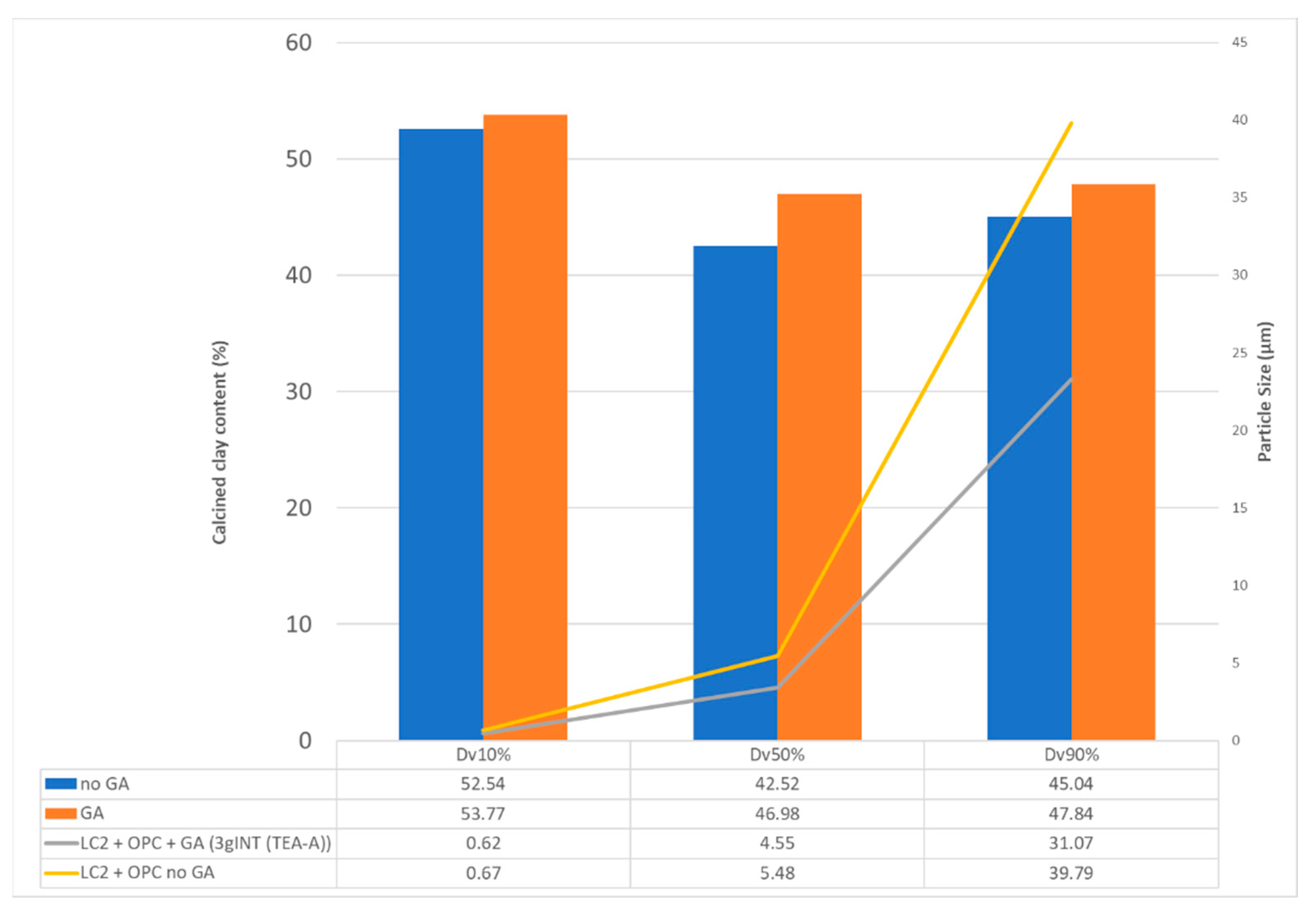

Figure 4 presents the comparison between the results of grinding calcined clay and limestone alone (separate grinding) and clinker, calcined clay, limestone and gypsum (co-grinding). Even excess grinding of LC3 does not yield a fineness lower than that of LC2 fine. This effect is produced by combination of the impact of hard clinker particles and the agglomeration and sticking of the calcined clay particles on the steel balls of the mill. It can be confirmed by the difference in Blaine specific surface observed between the LC3 co-ground and the LC3 produced through a blend of 50% OPC and 50% LC2, see Table 6. It is then expected that co-ground LC3 will have a higher water demand than LC3 produced via separate grinding.

Figure 4.

Comparison of co-grinding LC3 with separate grinding LC2.

Table 6.

Physical parameters separate grinding vs. co-grinding.

The high specific surface brings about an increase in water demand in cement pastes containing calcined clays, as presented in Table 7. The lowest spread in the minicone test was at the paste made with LC3 co-ground, which is the one with the highest specific surface.

Table 7.

Flow of cement pastes assessed by the minicone test.

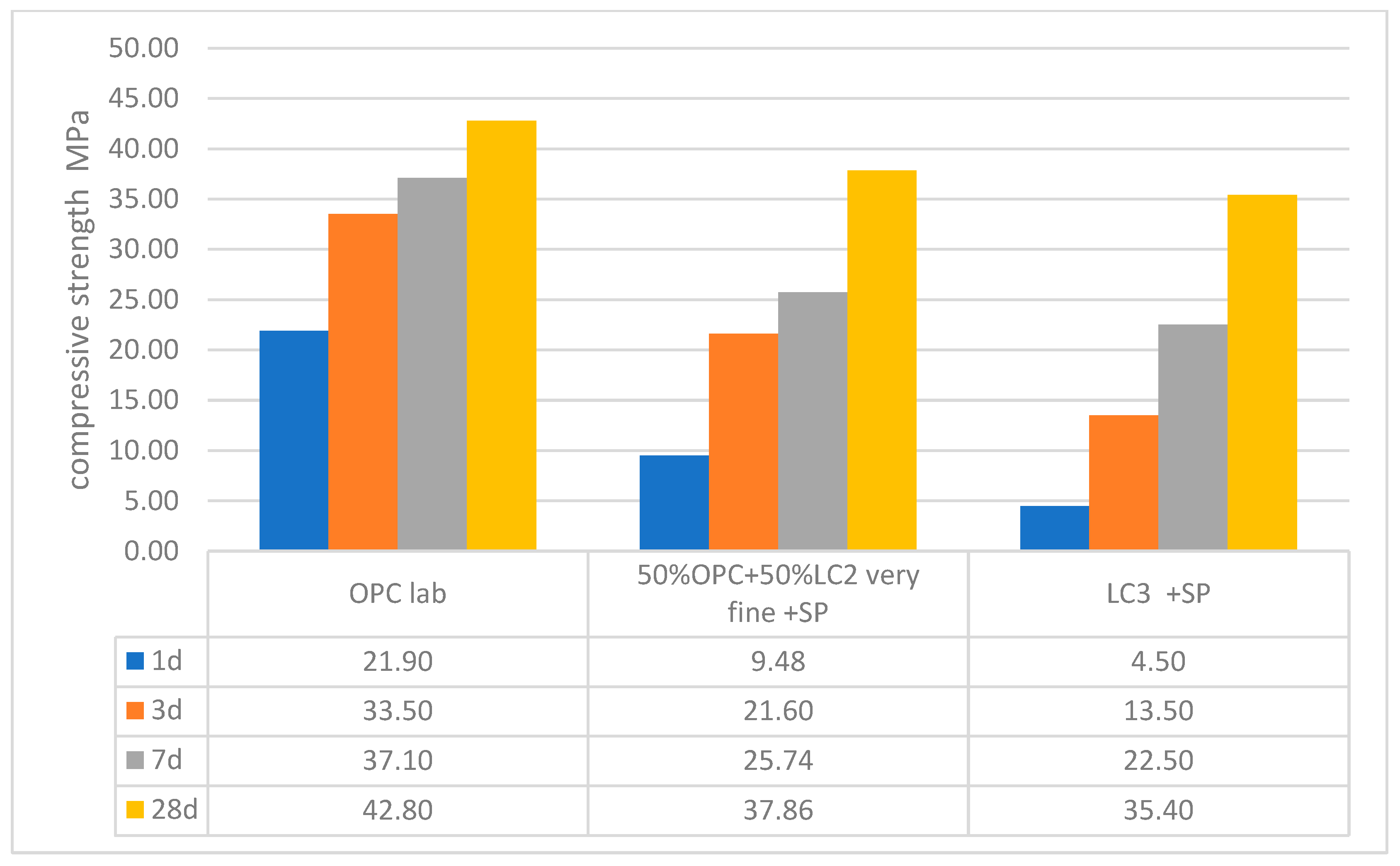

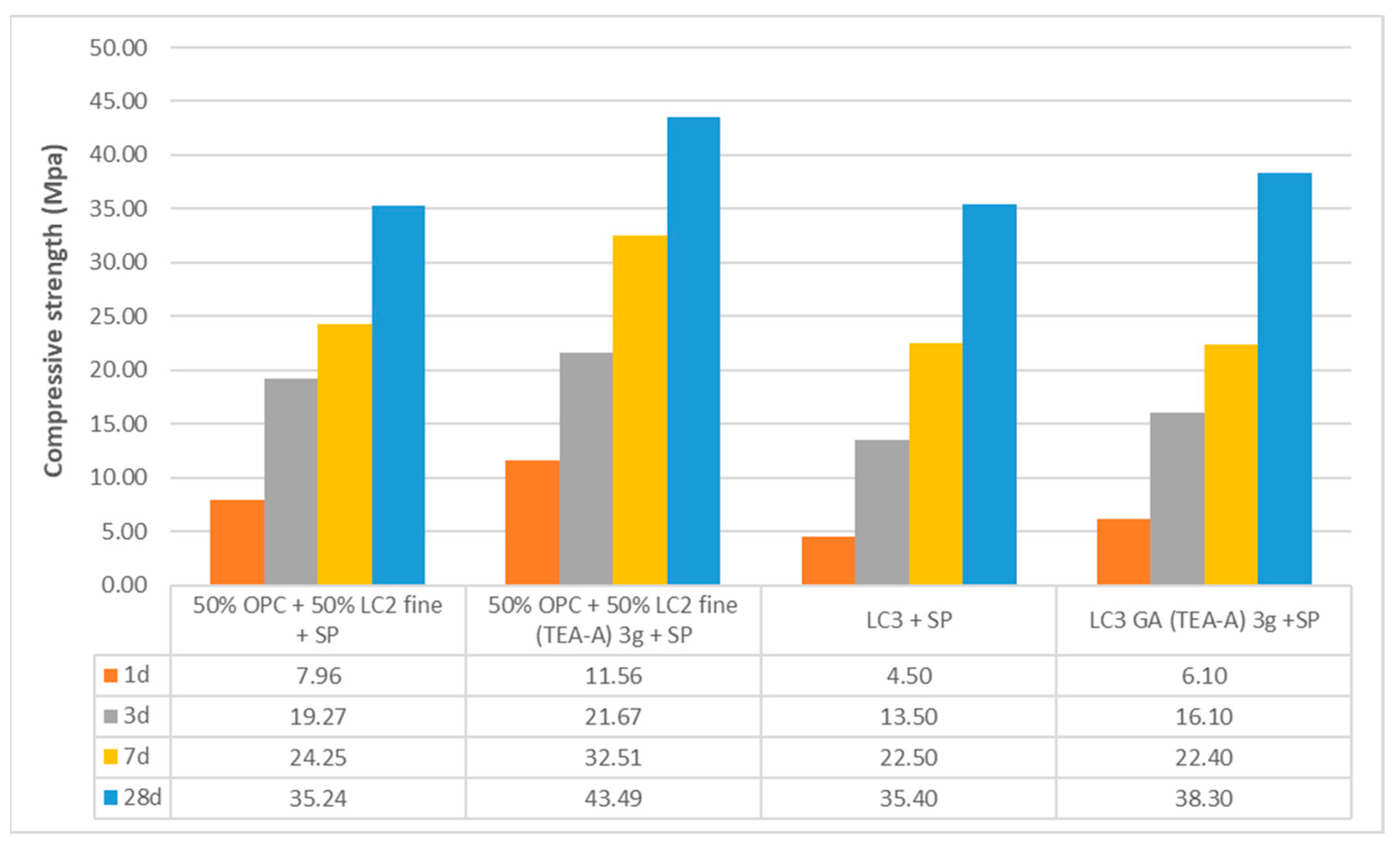

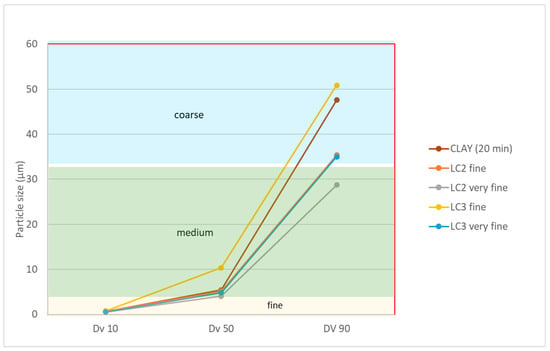

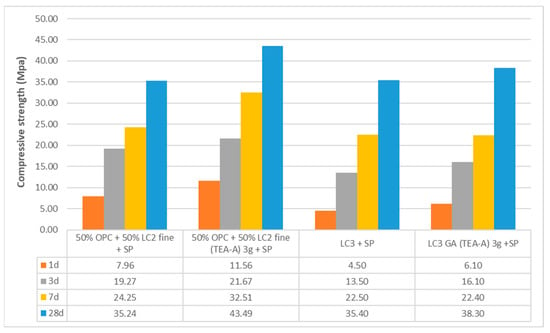

Figure 5 displays the results of compressive strength in standard mortars for a similar flow and water to binder ratio. The combination of 50% OPC + 50% LC2 yields better strength results than the LC3 produced via co-grinding. The major impact is at early age strength, mainly 1d and 3d, and this could indicate a clinker which is poorly ground. [29] The cause could be related to coating of the steel balls which prevent clinker particles to get properly ground.

Figure 5.

Comparison of compressive strength results between co-grinding LC3 with separate grinding LC2.

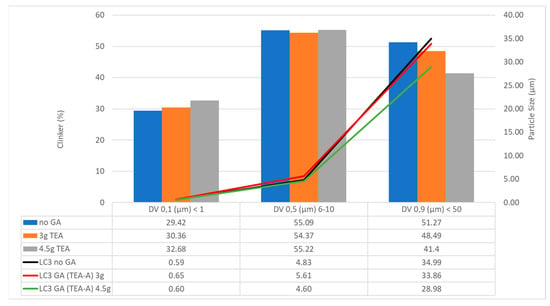

3.1.3. Impact of Grinding Aids

The use of grinding aids could eventually mitigate the negative impact of co-grinding LC3. The grinding aid used in this study was TEA, which is known to enhance the alumina reaction at early ages [27]. Two dosages were used: (i) 3 g of solid/cement, considered the mean dosage proposed by the supplier, and (ii) 4.5 g of solid/cement, which is the highest dosage proposed by the supplier. The main effect of the product would be to disperse the agglomerated particles and clean up the steel balls and the walls of the mill, where fine particles tend to agglomerate.

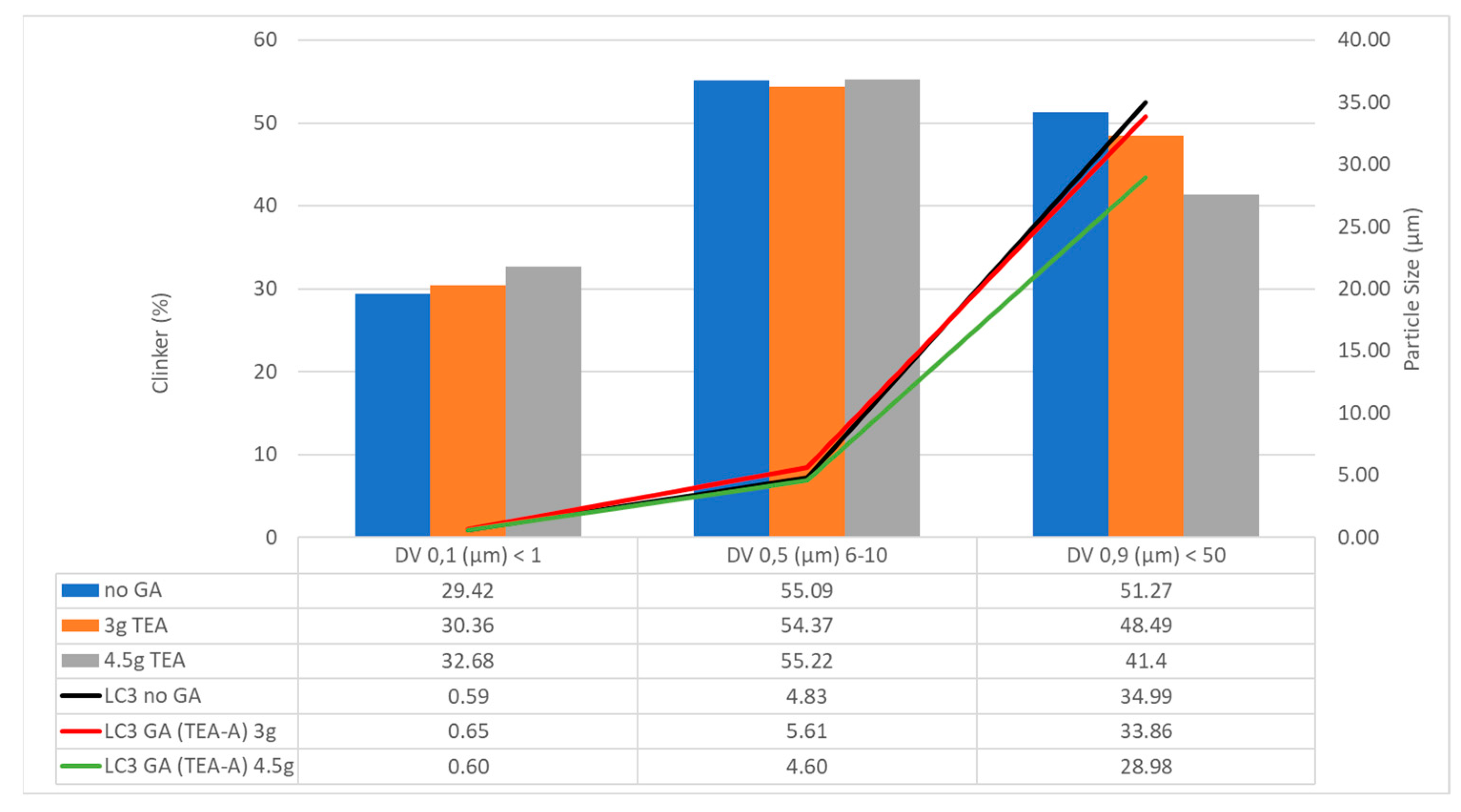

Figure 6 presents an analysis of the clinker content in each fraction for LC3 cement with and without grinding aids. As the dosage of grinding aid increases, the amount of clinker in the very fine fraction increases, at the cost of decreasing the clinker content at the coarse fraction. Having a finer clinker may have a positive impact on the reactivity of the cement in general.

Figure 6.

Impact of the use of grinding aids on co-grinding LC3.

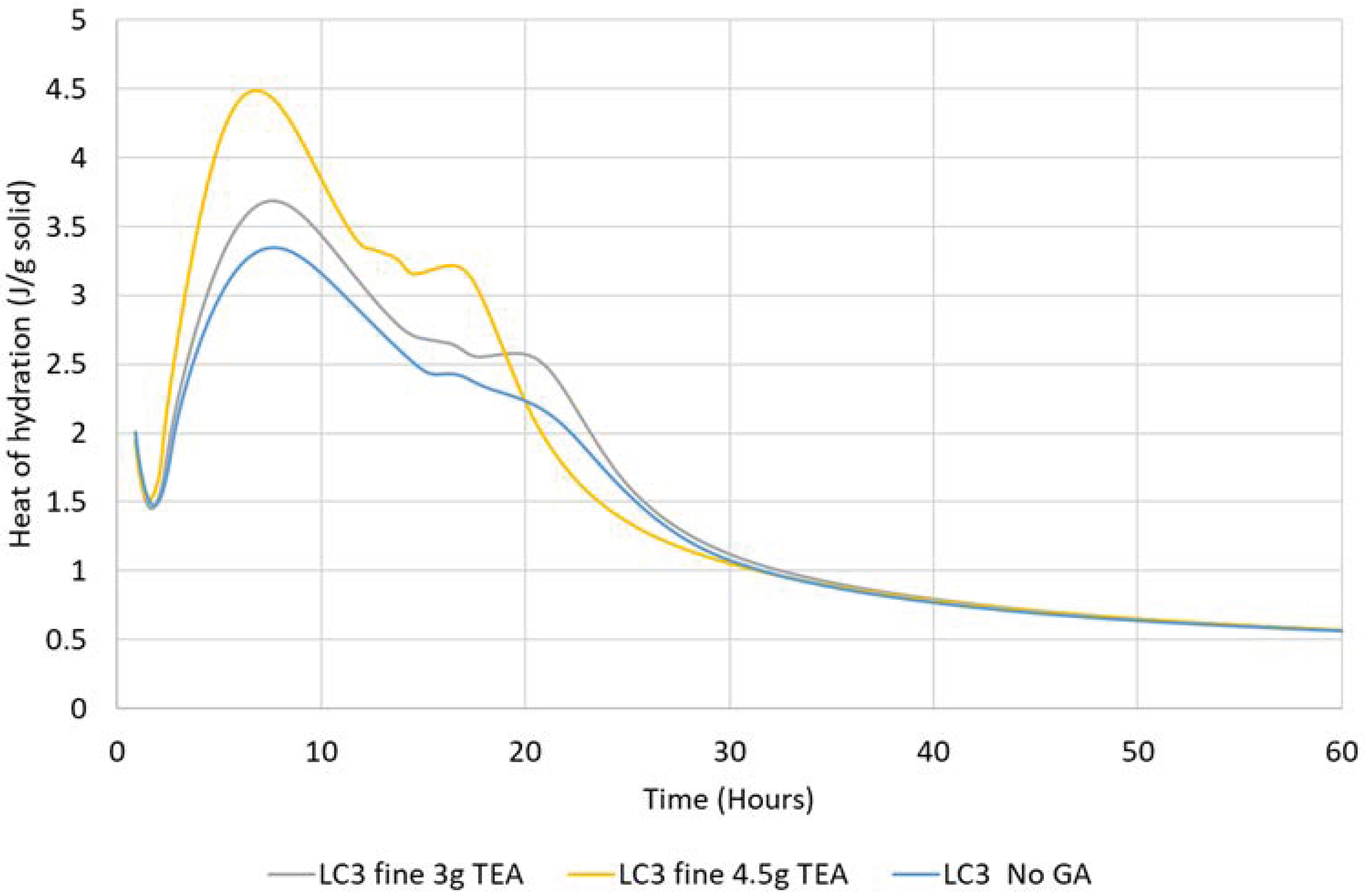

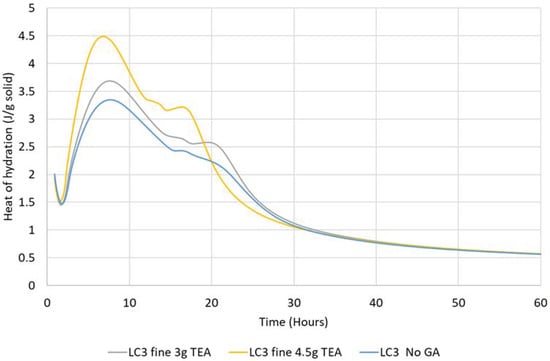

Figure 7 presents the heat of hydration of cement pastes prepared with LC3 with and without grinding aids. The higher the dosage the higher the silicate peak, in correspondence with the higher amount of clinker in the finer and most reactive fraction. As expected, the secondary peak corresponding to the formation of ettringite is also enhanced by the presence of TEA [27], and for the highest dosage the peak appears earlier, probably due to a sulphation problem created by the increase of specific surface during grinding [40].

Figure 7.

Impact of the use of grinding aids on the hydration of LC3.

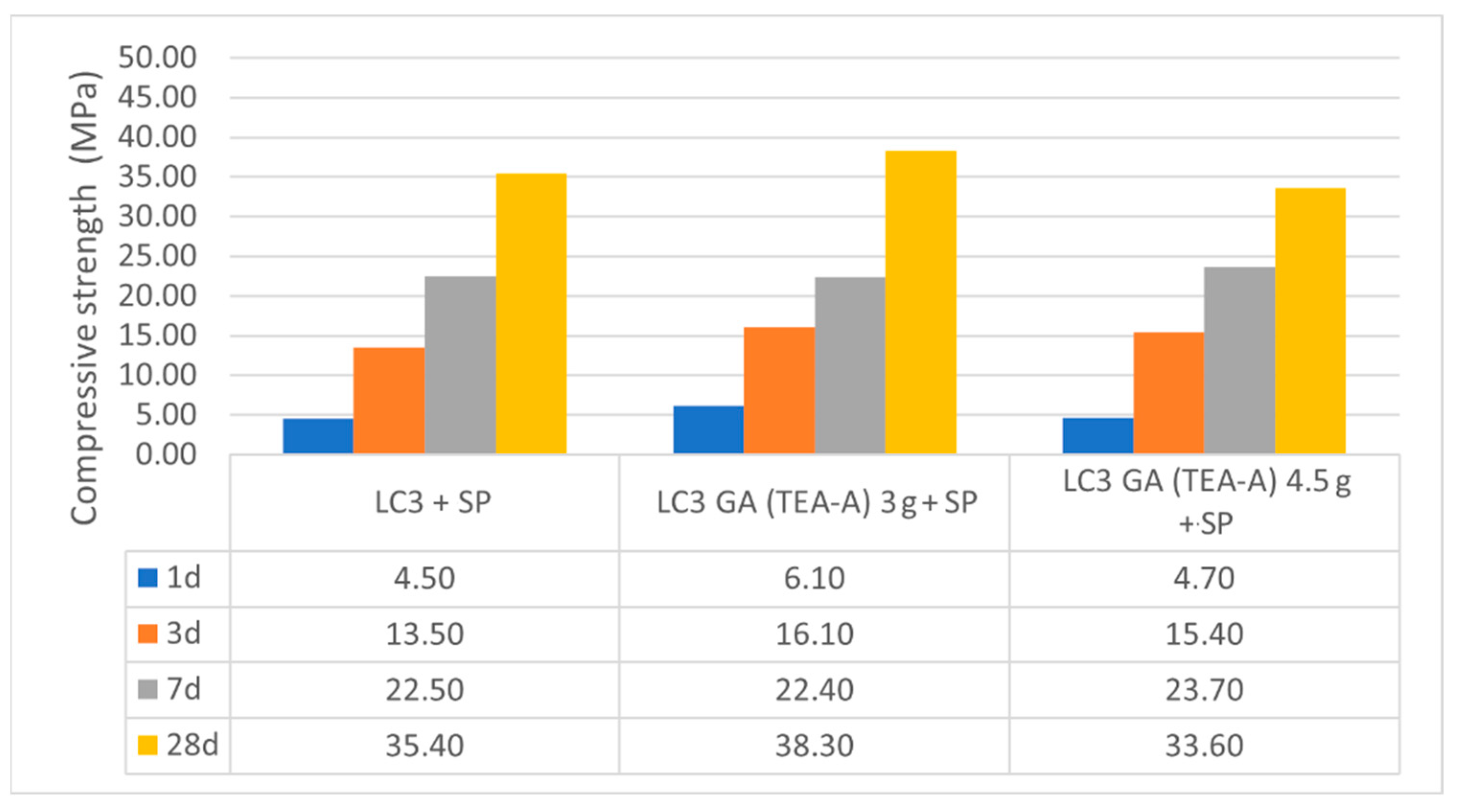

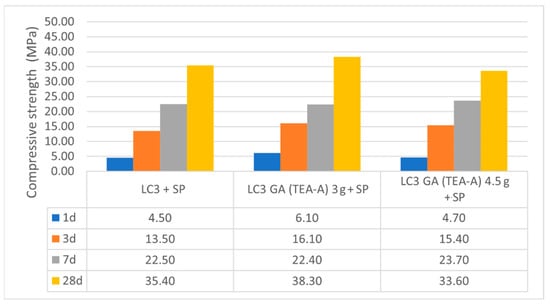

Figure 8 present the results of compressive strength in standard mortars made with LC3 produced with a without grinding aids. As expected, the main impact on compressive strength takes place at early ages, where the hydration of clinker is more important [41,42], and the impact at late ages is less important. It is noted that even the lowest dosage of grinding aid has an impact on strength, so the use of grinding aids should be considered when co-grinding LC3 cements.

Figure 8.

Impact of the use of grinding aids on compressive strength.

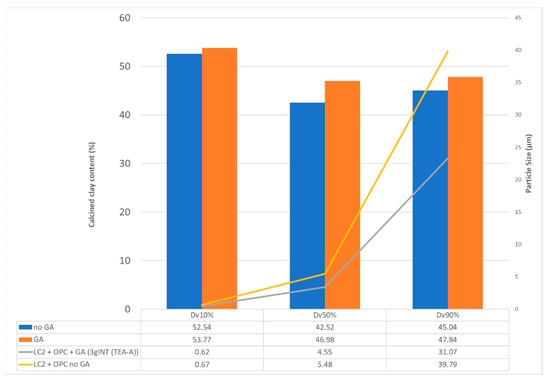

Grinding aids were also tested in separate grinding. The mineral addition LC2 was ground with the same dosage of the grinding aid used for co-grinding. Cement pastes were prepared using 50% OPC and 50% LC2 for further testing. Figure 9 presents the calcined clay content in each of the fractions studied for LC2 ground with and without grinding aid. No significant change is observed in samples ground with grinding aid. This is possibly explained through the role of limestone during grinding, as was displayed in Figure 3.

Figure 9.

Impact of the use of grinding aids on separate grinding LC2.

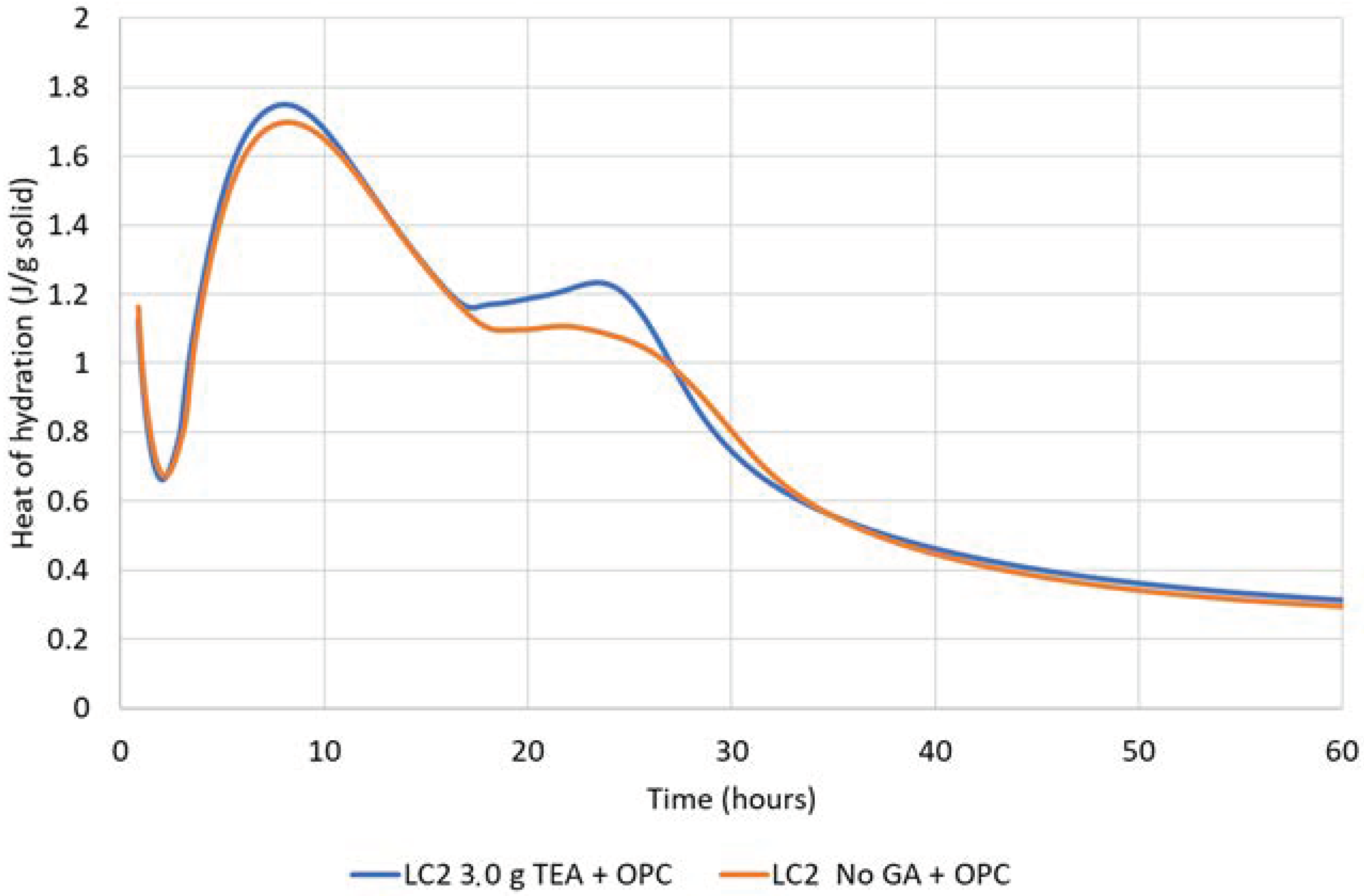

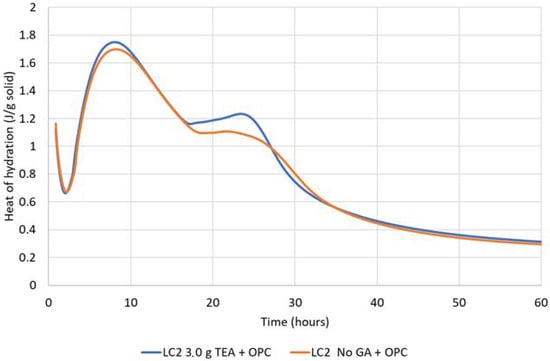

The measurement of the heat of hydration in cement pastes made with a blend of 50% OPC and 50% LC2, depicted in Figure 10, confirm small increase of the peaks of silicates and aluminates. The enhancement of the alumina peak is caused by the interaction with TEA [27], which could have benefits in the performance of cement.

Figure 10.

Impact of the use of grinding aids on the hydration of a blend of 50% OPC + 50% LC2.

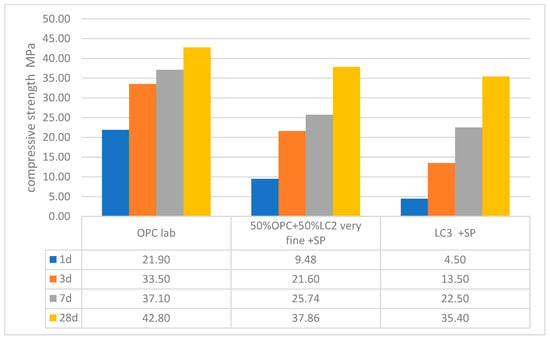

Figure 11 summarizes the impact of the grinding strategy on compressive strength of standard mortars. The best results are obtained for separate grinding using the minimal dosage of grinding aid TEA. The mineral addition LC2 is blended with OPC. The use of grinding aids also brings about benefits in co-grinding, also for a small dosage of TEA. The improvements are associated with a properly good ground clinker and a well-graded blend of calcined clay and limestone [29].

Figure 11.

Summary of the impact of the grinding strategy on strength in standard mortars.

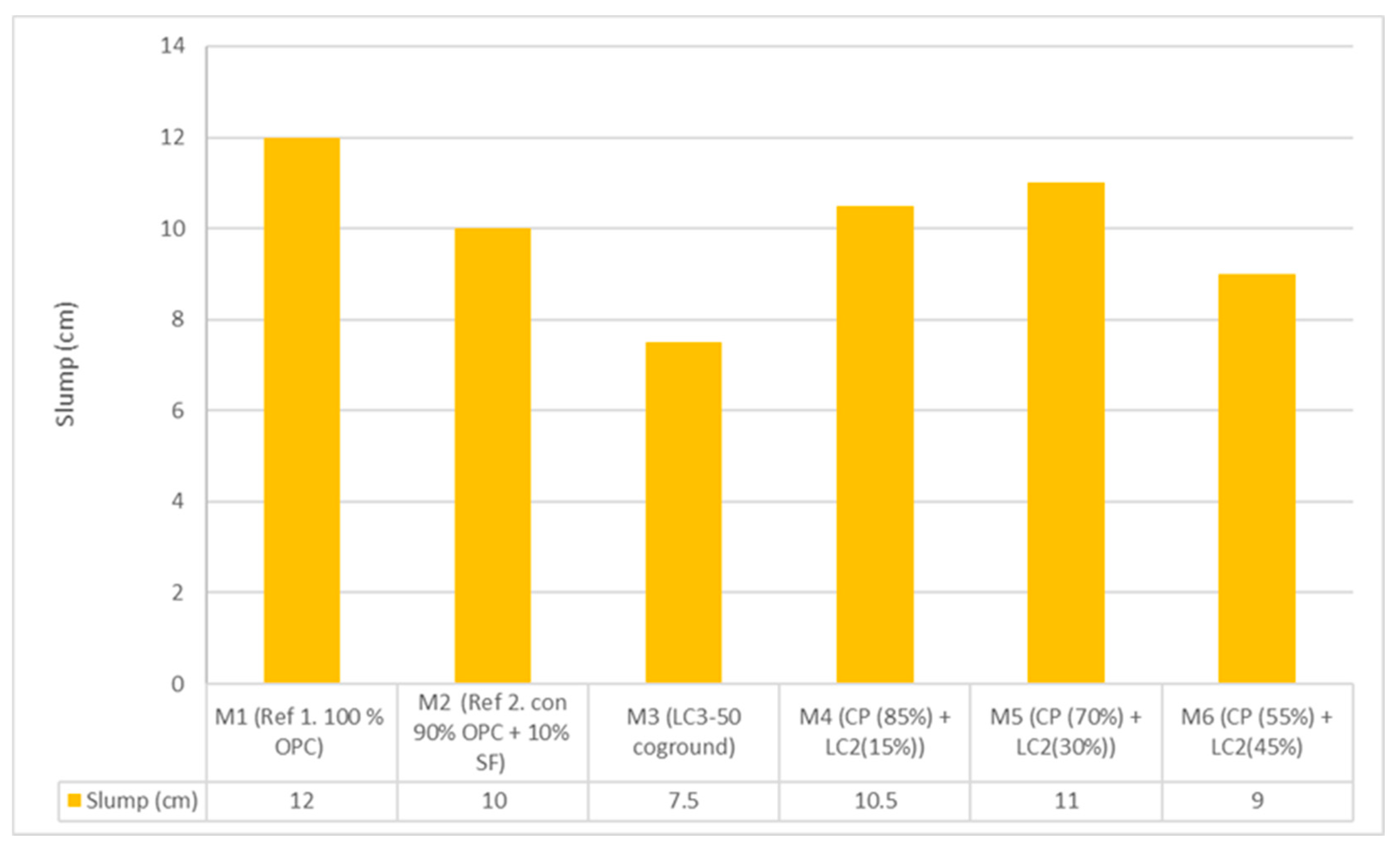

3.2. Impact of Grinding Strategy on Concrete

3.2.1. Properties of Concrete in Fresh State

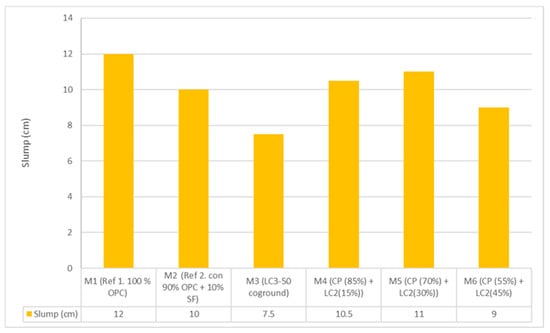

Figure 12 presents the slump in fresh concrete made with the different binders chosen in this study. As expected, water demand increases with the increase on calcined clay content. Samples M3 (co-grinding) and M6 (separate grinding) have a similar calcined clay content, however, water demand is higher in LC3 produced through co-grinding, thus indicating the benefits of separate grinding. Slump values fall within the range specified by the standard NTE INEN 1578 [27] for plastic-consistency concrete. The worst results are those of the concrete produced with the LC3-50 by co-grinding.

Figure 12.

Slump in concrete made for testing.

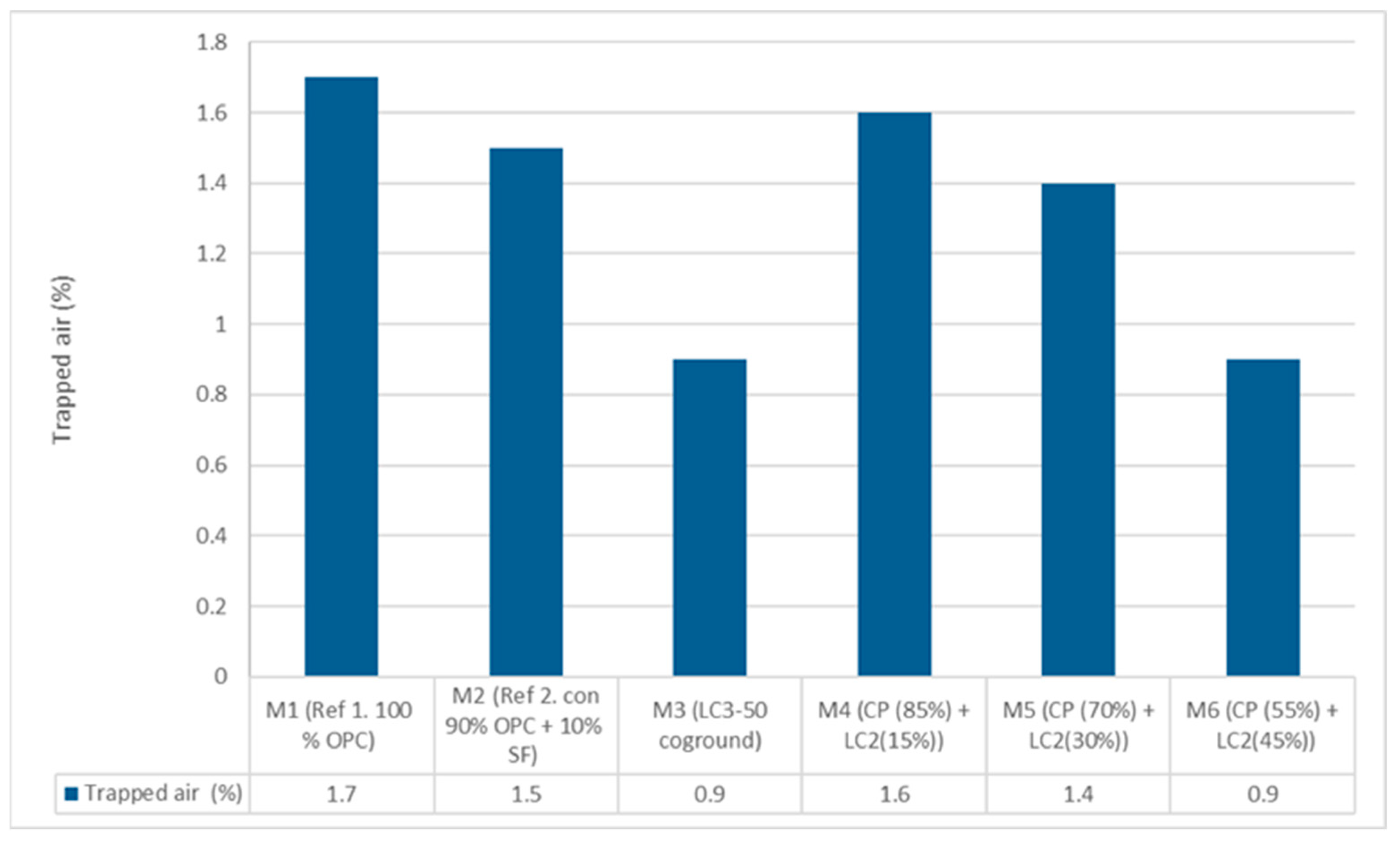

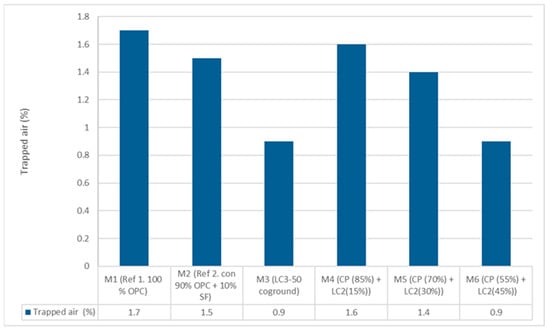

Figure 13 displays the values of trapped air measured in fresh concrete. It is interesting to note that as the calcined clay content increases, the trapped air decreases. This may be related to the ability of calcined clays to retain water in the matrix in addition to their fineness [43,44].

Figure 13.

Measurement of trapped air in the concrete produced.

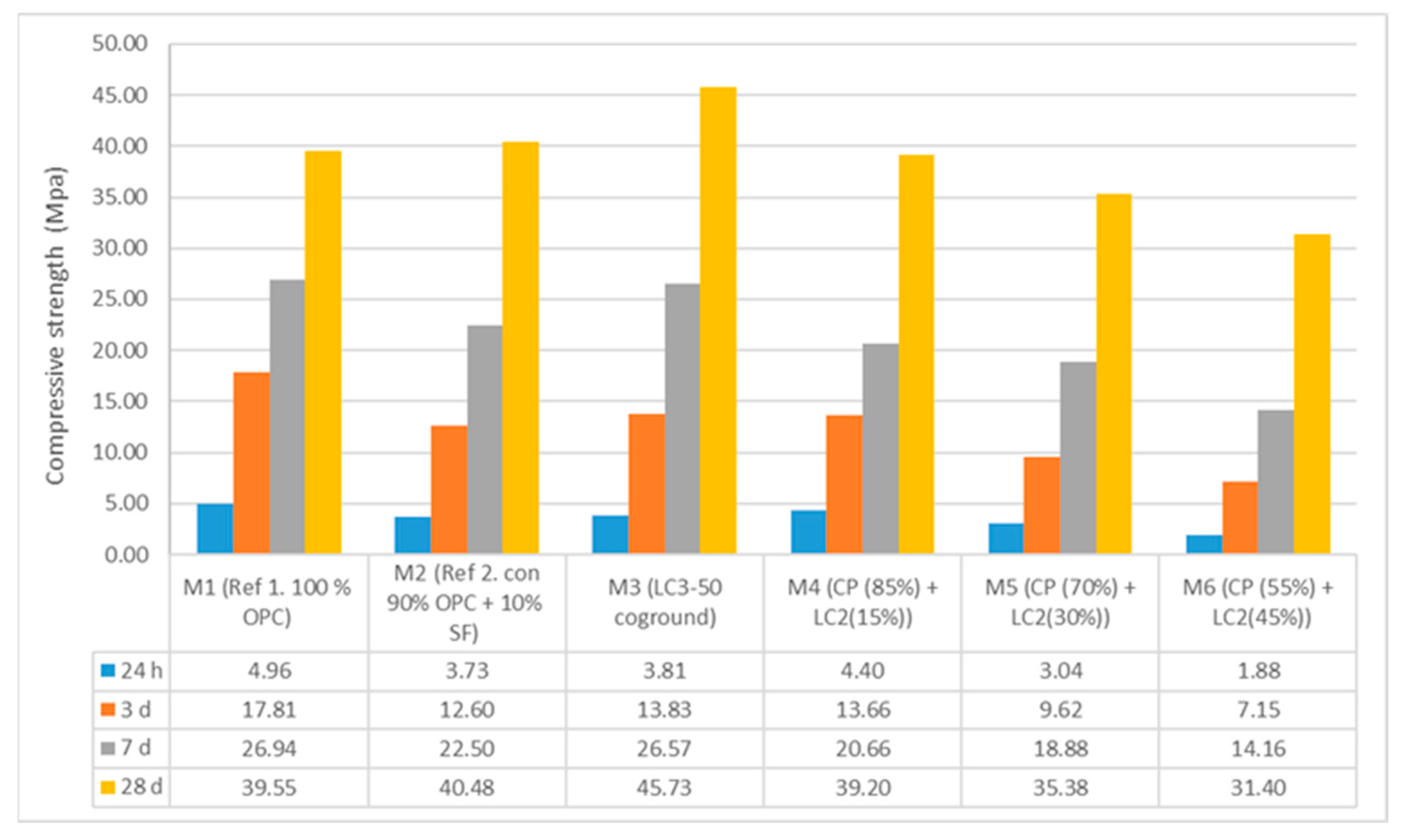

3.2.2. Properties of Concrete in the Hardened State

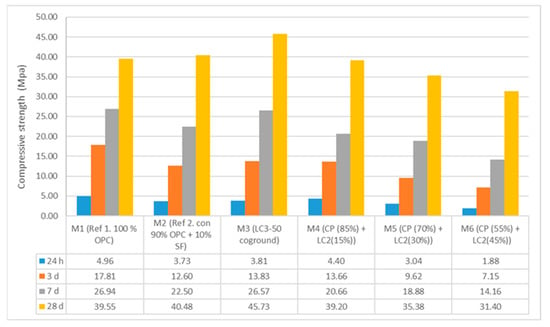

Figure 14 shows the values of compressive strength in concrete at 1, 3, 7 and 28 days, according to the standard NTE INEN 1573 (ASTM C 39M). LC3-50 (coground) achieves the best compressive strength results. This series has the highest calcined clay content of all. Concrete produced with a blend of OPC and LC2, even for the same clinker content (M5) have a lower strength. The explanation is on the difference in calcined clay content. In sample M3, calcined clay is approximately 30% of the weight of the cement whereas in sample M5, clay represents 20% of the weight of the cement, and it also has 20% natural pozzolan. It has been shown that calcined clay is much more reactive than natural pozzolan [14,45], and therefore, it is very possible that the SikaFume in the system is acting as a filler with low reactivity. The compressive resistance values of concrete with SikaFume are similar to those of Portland cement.

Figure 14.

Compressive strength in concrete.

4. Conclusions

Pastes and mortars.

- The use of the laboratory ball mill guarantees an efficient grinding for the study of the impact on material fineness, provided that the grinding time is between 15 and 20 min. Increasing the grinding time above these values does not bring about changes in fineness. Blending calcined clay with limestone will reduce the grinding time to achieve the sought fineness.

- Co-grinding clinker with the blend of calcined clay and limestone increases water demand and lowers strength. The agglomeration and coating by the calcined clay particles prevent clinker grains to be finely ground. Grinding calcined clay and limestone separately brings about better results. The mineral addition LC2 can replace up to 50% of OPC for a similar performance.

- The use of grinding aids of the family TEA brings about improvement in the performance of LC3 cement produced via co-grinding, but also separate grinding. The grinding aid reduces agglomeration and coating and enhances the alumina containing phases reactions. Even a small dosage of the grinding aid has a positive impact.

- The best performance was observed in the blend 50% OPC + 50% LC2, with grinding aids.

Concrete.

- The content of calcined clay brings about a higher water demand at fresh state but favors a higher compressive strength in hardened state. Further, calcined clays increase water retention, and decrease trapped air in concrete, with a direct contribution to reduce total porosity of the matrix.

- If calcined clay is blended with other pozzolans the performance of the system is compromised. It could be since calcined clay consumes all calcium hydroxide in the system at early ages, and there will not be enough Portlandite for the reaction of other pozzolans in the mixture.

- The use of cements with calcined clays in different proportions in the manufacture of concrete ratifies the high water demand and the need to increase the addition of superplasticizers, but the slump obtained in all cases meet the requirements established in the standards. The best options are to produce LC3-50 cement with 50% clinker by inter grinding, or to mix 70% Portland cement with 30% LC2.

- The concretes produced with calcined clay cements reach high compressive strength values at all ages, and exceed the design strength, except for sample M6 with 34% clinker. The best results are obtained with LC3-50 cement with 50% clinker by co-grinding.

Author Contributions

All authors have had a similar participation in the preparation of all sections. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Berriel, S.S.; Favier, A.; Domínguez, E.R.; Machado, I.S.; Heierli, U.; Scrivener, K.; Hernández, F.M.; Habert, G. Assessing the environmental and economic potential of Limestone Calcined Clay Cement in Cuba. J. Clean. Prod. 2016, 124, 361–369. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production-present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Cancio, Y.; Berriel, S.S.; Heierli, U.; Favier, A.R.; Machado, I.R.S.; Scrivener, K.L.; Hernández, J.F.M.; Habert, G. Limestone calcined clay cement as a low-carbon solution to meet expanding cement demand in emerging economies. Dev. Eng. J. 2017, 2, 82–91. [Google Scholar] [CrossRef]

- Gettu, R.; Patel, A.; Rathi, V.; Prakasan, S.; Basavaraj, A.; Maity, S. Sustainability Assessment of Cements and Concretes in the Indian Context: Influence of Supplementary Cementitious Materials. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Nazari, A.; Sanjayan, J.G. Handbook of Low Carbon Concrete; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Badogiannis, E.; Tsivilis, S. Exploitation of poor Greek kaolins: Durability of metakaolin concrete. Cem. Concr. Compos. 2009, 31, 128–133. [Google Scholar] [CrossRef]

- Baghban, M.H.; Mahjoub, R. Natural Kenaf Fiber and LC 3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Appl. Sci. 2020, 10, 357. [Google Scholar] [CrossRef]

- Almenares, R.S.; Vizcaíno, L.M.; Damas, S.; Mathieu, A.; Alujas, A.; Martirena, F. Case Studies in Construction Materials Industrial calcination of kaolinitic clays to make reactive pozzolans. Case Stud. Constr. Mater. 2017, 6, 225–232. [Google Scholar] [CrossRef]

- Ilić, B.; Radonjanin, V.; Malešev, M.; Zdujić, M.; Mitrović, A. Effects of mechanical and thermal activation on pozzolanic activity of kaolin containing mica. Appl. Clay Sci. 2016, 123, 173–181. [Google Scholar] [CrossRef]

- Hollanders, S.; Adriaens, R.; Skibsted, J.; Cizer, Ö.; Elsen, J. Pozzolanic reactivity of pure calcined clays. Appl. Clay Sci. 2016, 132–133, 552–560. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Scrivener, K.L. Options for the future of cement. Indian Concr. J. 2014, 88, 11–21. [Google Scholar]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cement and Concrete Research. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Alujas, A.; Fernández, R.; Quintana, R.; Scrivener, K.L.; Martirena, F. Pozzolanic reactivity of low grade kaolinitic clays: Influence of calcination temperature and impact of calcination products on OPC hydration. Appl. Clay Sci. 2015, 108, 94–101. [Google Scholar] [CrossRef]

- Favier, A.; Zunino, F.; Katrantzis, I.; Scrivener, K. The effect of limestone on the performance of ternary blended cement LC3: Limestone, calcined clays and cement. In Calcined Clays for Sustainable Concrete; RILEM Bookseries; Springer: Berlin/Heidelberg, Germany, 2018; Volume 16, pp. 170–175. [Google Scholar] [CrossRef]

- Bishnoi, S.; Maity, S.; Mallik, A.; Joseph, S.; Krishnan, S. Pilot scale manufacture of limestone calcined clay cement: The Indian experience. Indian Concr. J. 2014, 88, 22–28. [Google Scholar]

- Rocha, D.; Almenares, R.; Sanchez, S.; Alujas, A.; Martirena, F. Standardization strategy of low carbon cement in cuba. Case study for “siguaney” cement factory. In Calcined Clays for Sustainable Concrete; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Martirena, F.; Scrivener, K. Low Carbon Cement LC 3 in Cuba: Ways to Achieve a Sustainable Growth of Cement Production Identification of Suitable Clay Deposits. In Calcined Clays for Sustainable Concrete; Springer: Berlin/Heidelberg, Germany, 2018; pp. 3–6. [Google Scholar]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2019, 7, 3–14. [Google Scholar] [CrossRef]

- Weerdt, K.D. Sintef Report: Advanced Cementing Materials. Separate Grinding Versus Intergringing. 2007, p. 30. Available online: https://www.sintef.no/globalassets/sintef-byggforsk/coin/sintef-reports/sbf-bk-a07022_separate-grinding-versus-intergrinding.pdf (accessed on 5 September 2022).

- Sohoni, S. The effect of grinding aids on the fine grinding of limestone, and Portland cement clinker. Powder Technol. 1991, 67, 277–286. [Google Scholar] [CrossRef]

- Carrasco, M.F.; Menéndez, G.; Bonavetti, V.; Irassar, E.F. Strength optimization of ‘tailor-made cement’ with limestone filler and blast furnace slag. Cem. Concr. Res. 2005, 35, 1324–1331. [Google Scholar] [CrossRef]

- Ghiasvand, E.; Ramezanianpour, A.A.; Ramezanianpour, A.M. Influence of grinding method and particle size distribution on the properties of Portland-limestone cements. Mater. Struct. 2013, 48, 1273–1283. [Google Scholar] [CrossRef]

- Irassar, E.F.; Violini, D.; Rahhal, V.F.; Milanesi, C.; Trezza, M.A.; Bonavetti, V.L. Influence of limestone content, gypsum content and fineness on early age properties of Portland limestone cement produced by inter-grinding. Cem. Concr. Compos. 2011, 33, 192–200. [Google Scholar] [CrossRef]

- Provis, J.L.; Duxson, P.; van Deventer, J.S. The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 2010, 21, 2–7. [Google Scholar] [CrossRef]

- Alonso, M.M.; Martínez-Gaitero, R.; Gismera-Diez, S.; Puertas, F. PCE and BNS admixture adsorption in sands with different composition and particle size distribution. Mater. Construcción 2017, 67, 121. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. Assessing the effect of alkanolamine grinding aids in limestone calcined clay cements hydration. Constr. Build. Mater. 2020, 266, 121293. [Google Scholar] [CrossRef]

- Assaad, J.J.; Issa, C.A. Research Effect of clinker grinding aids on fl ow of cement-based materials. Cem. Concr. Res. 2014, 63, 1–11. [Google Scholar] [CrossRef]

- Andres, L.M.V.; Antoni, M.G.; Hernandez, J.F.M.; Diaz, A.A.; Scrivener, K.L. Effect of fineness in clinker-calcined clays-limestone cements. Adv. Cem. Res. 2015, 27, 546–556. [Google Scholar] [CrossRef]

- Shakhova, L.; Luginina, I.G.; Cherkasov, R. Intensification of Cement Grinding with Apply Grinding Aids with Modify Effect. Mod. Appl. Sci. 2014, 8, 296–305. [Google Scholar] [CrossRef]

- Revuelta, D.; Luco, l.F.; Dorrego, F.; Luxan, M.P. Influencia de los aditivos de molienda de Clinker en las características intrínsecas del cemento y en el comportamiento de morteros. Mater. Construcción 2003, 53, 271–272. [Google Scholar]

- Katsioti, M.; Tsakiridis, P.E.; Giannatos, P.; Tsibouki, Z.; Marinos, J. Characterization of various cement grinding aids and their impact on grindability and cement performance. Constr. Build. Mater. 2009, 23, 1954–1959. [Google Scholar] [CrossRef]

- Schneider, H. Sobre el empleo de aditivos de moliendo en lo molturoción de cemento. Mater. Constr. 1970, 20, 193–201. [Google Scholar] [CrossRef][Green Version]

- NTE INEN 697; Áridos. Determinación del Material más fino que pasa el tamiz con aberturas de 75 um (No. 200), mediante lavado. Instituto ecuatoriano de normalización: Quito, Ecuador, 2010.

- NTE INEN 856; Áridos. Determinación de la densidad, densidad relativa (Gravedad específica) y absorción del árido fino. Instituto ecuatoriano de normalización: Quito, Ecuador, 2010.

- NTE INEN 857; Áridos. Determinación de la densidad, densidad relativa (Gravedad específica) y absorción del árido grueso. Instituto ecuatoriano de normalización: Quito, Eciuador, 2010.

- NTE INEN 858; Áridos. Determinación de la masa unitaria (peso volumétrico) y el porcentaje de vacíos. Instituto ecuatoriano de normalización: Quito, Ecuador, 2010.

- NTE INEN 862; Áridos para hormigón. Determinación del contenido total de humedad. Instituto ecuatoriano de normalización: Quito, Ecuador, 2011.

- NTE INEN-696; Áridos. Análisis granulométrico en los áridos, fino y grueso. Instituto ecuatoriano de normalización: Quito, Ecuado, 2011.

- Zunino, F.; Scrivener, K. The influence of the filler effect on the sulfate requirement of blended cements. Cem. Concr. Res. 2019, 126, 105918. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M. Investigation on the microstructure-related characteristics to elucidate performance of composite cement with limestone-calcined clay combination. Cem. Concr. Res. 2020, 129, 105959. [Google Scholar] [CrossRef]

- Georget, F.; Lothenbach, B.; Wilson, W.; Zunino, F.; Scrivener, K.L. Cement and Concrete Research Stability of hemicarbonate under cement paste-like conditions. Cem. Concr. Res. 2022, 153, 106692. [Google Scholar] [CrossRef]

- Cassagnabère, F.; Diederich, P.; Mouret, M.; Escadeillas, G.; Lachemi, M. Impact of metakaolin characteristics on the rheological properties of mortar in the fresh state. Cem. Concr. Compos. 2013, 37, 95–107. [Google Scholar] [CrossRef]

- Kadri, E.H.; Kenai, S.; Ezziane, K.; Siddique, R.; de Schutter, G. Influence of metakaolin and silica fume on the heat of hydration and compressive strength development of mortar. Appl. Clay Sci. 2011, 53, 704–708. [Google Scholar] [CrossRef]

- Yanguatin, H.; Tobón, J.; Ramírez, J. Pozzolanic reactivity of kaolin clays, a review Pozzolanic reactivity of kaolin clays, a review Reactividad puzolánica de arcillas caoliníticas, una revisión. Ing. Constr. 2017, 21, 13–24. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).