Recovery of Hematite from Banded Hematite Quartzite of Southern India by Magnetic Separation and Reverse Flotation

Abstract

1. Introduction

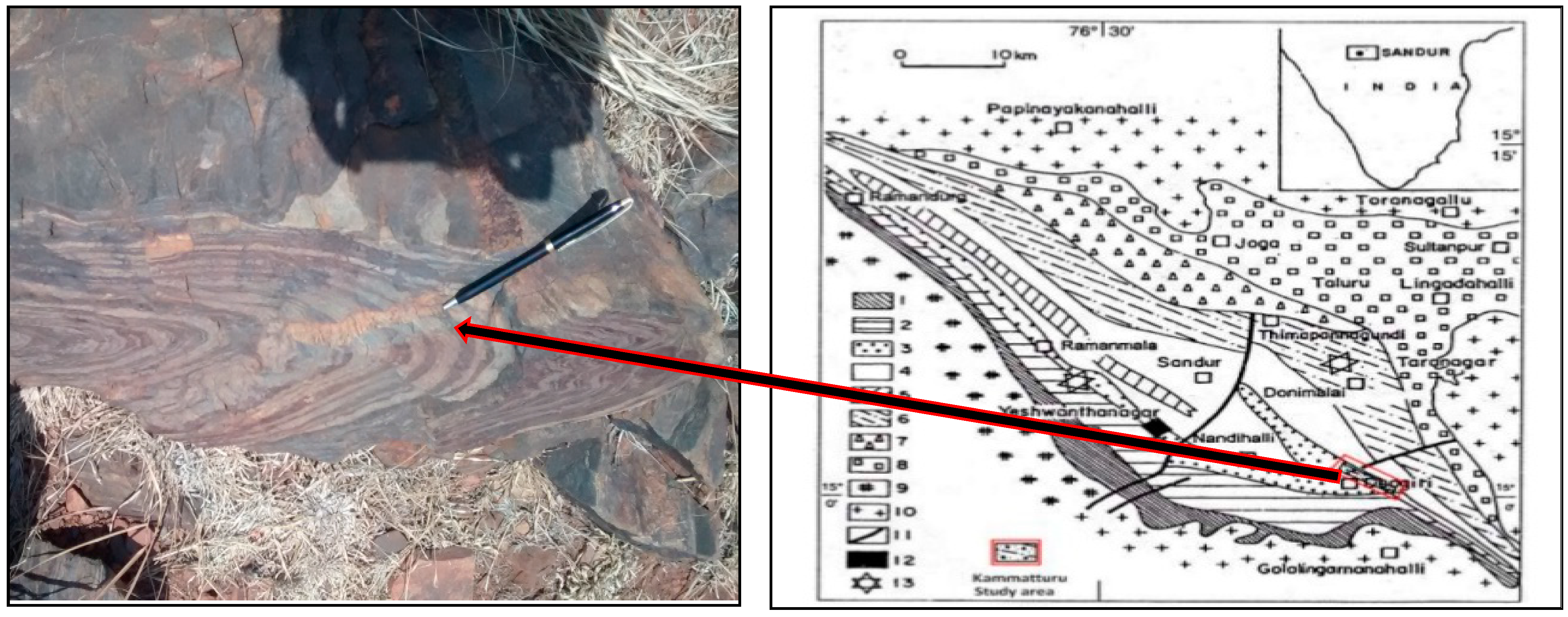

2. Materials

Methods

3. Results and Discussion

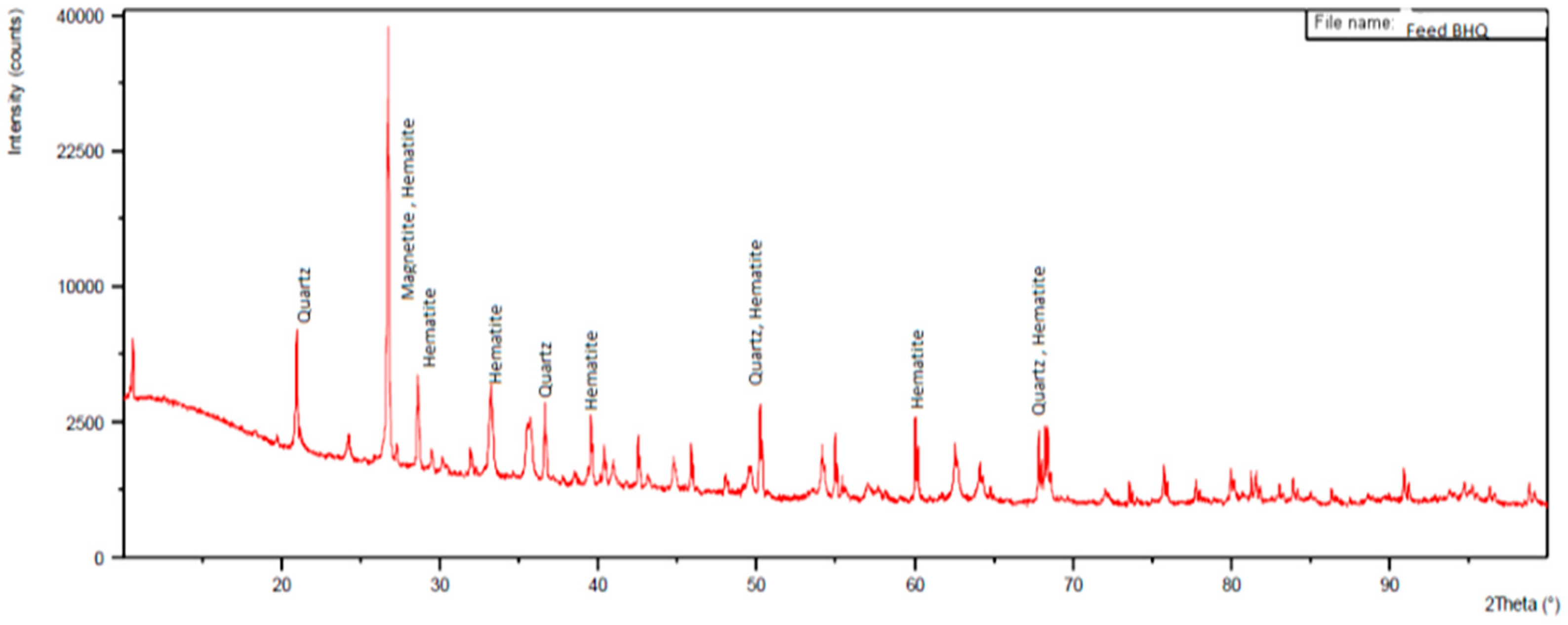

3.1. Feed Material Characterization

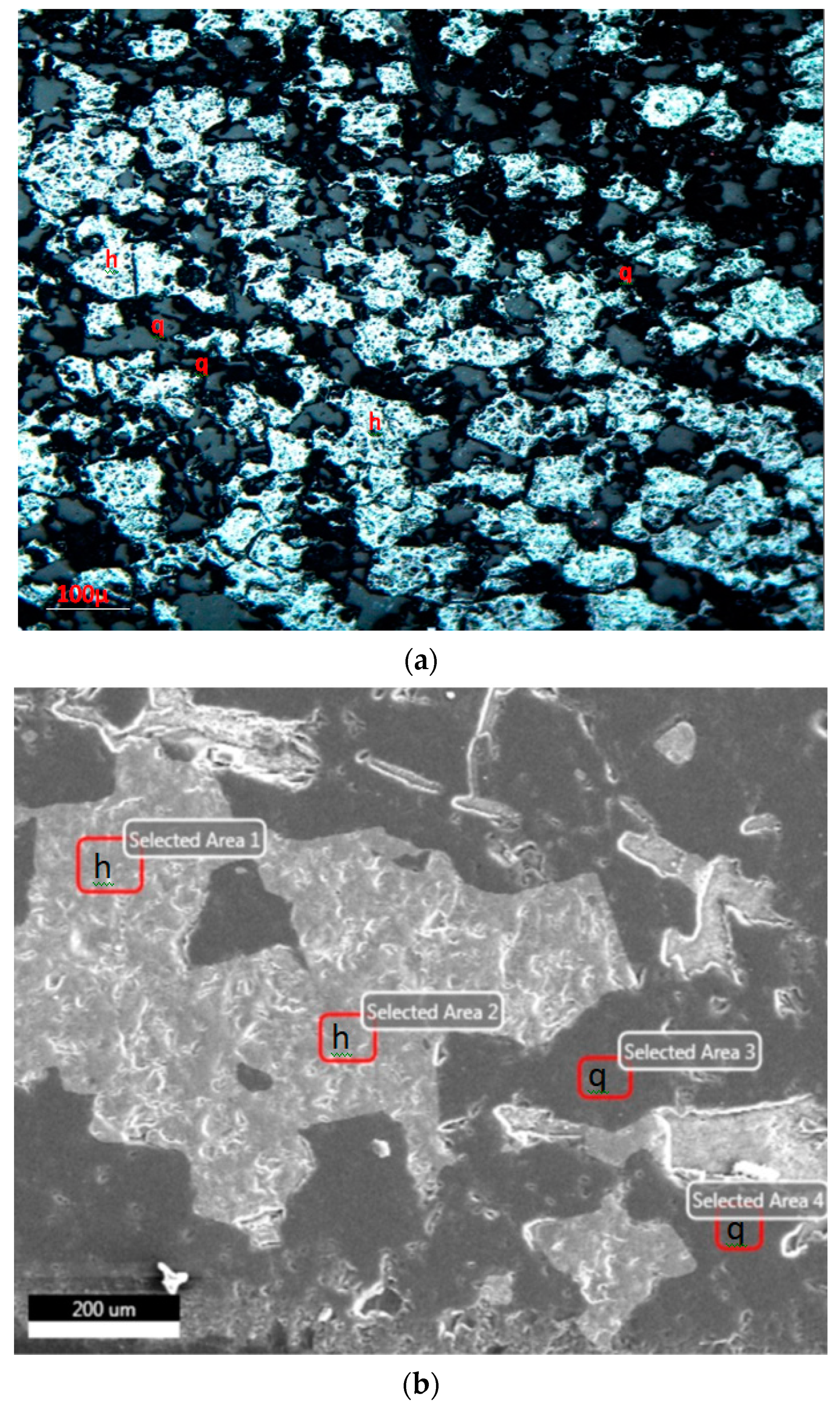

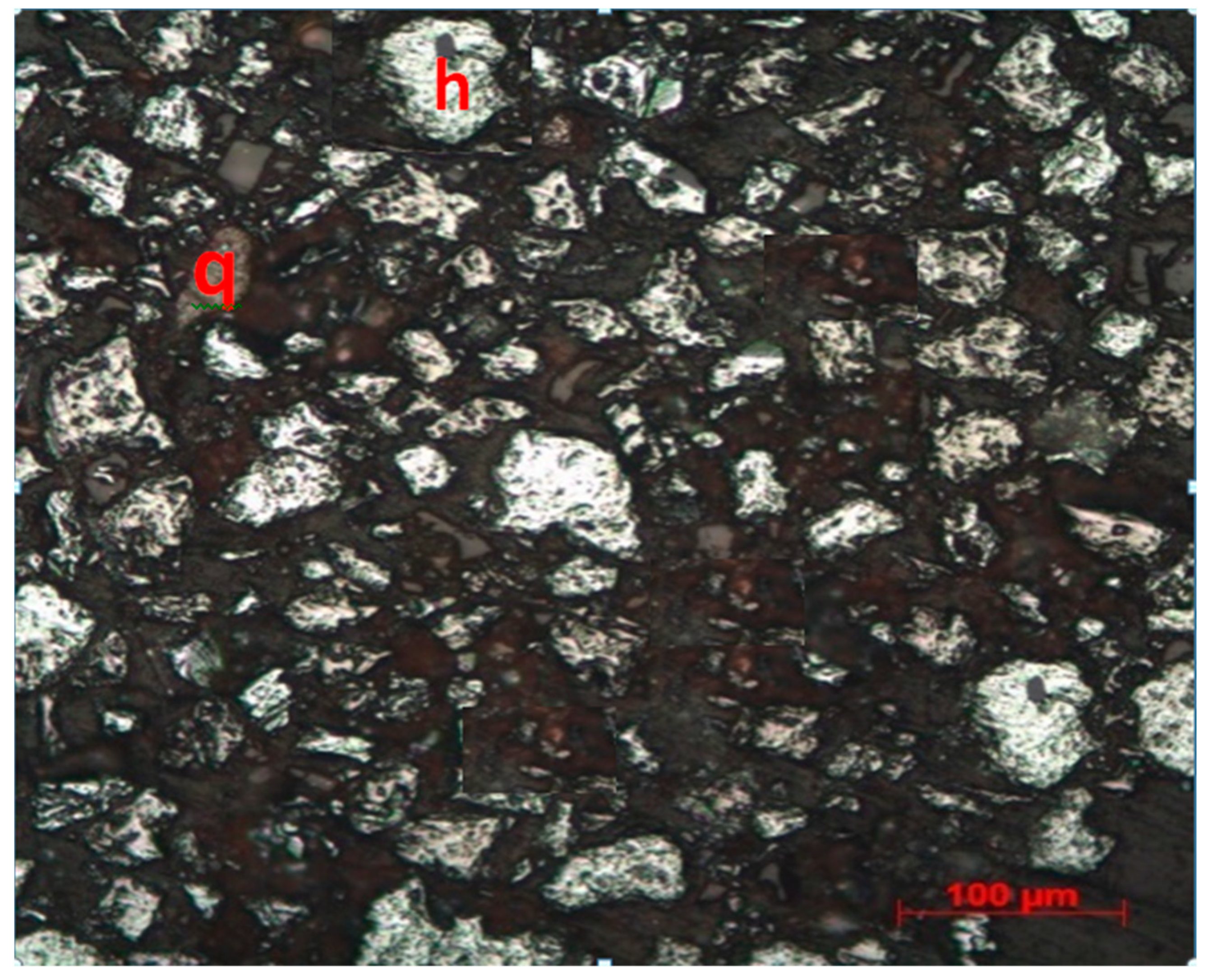

3.2. Mineralogical Studies

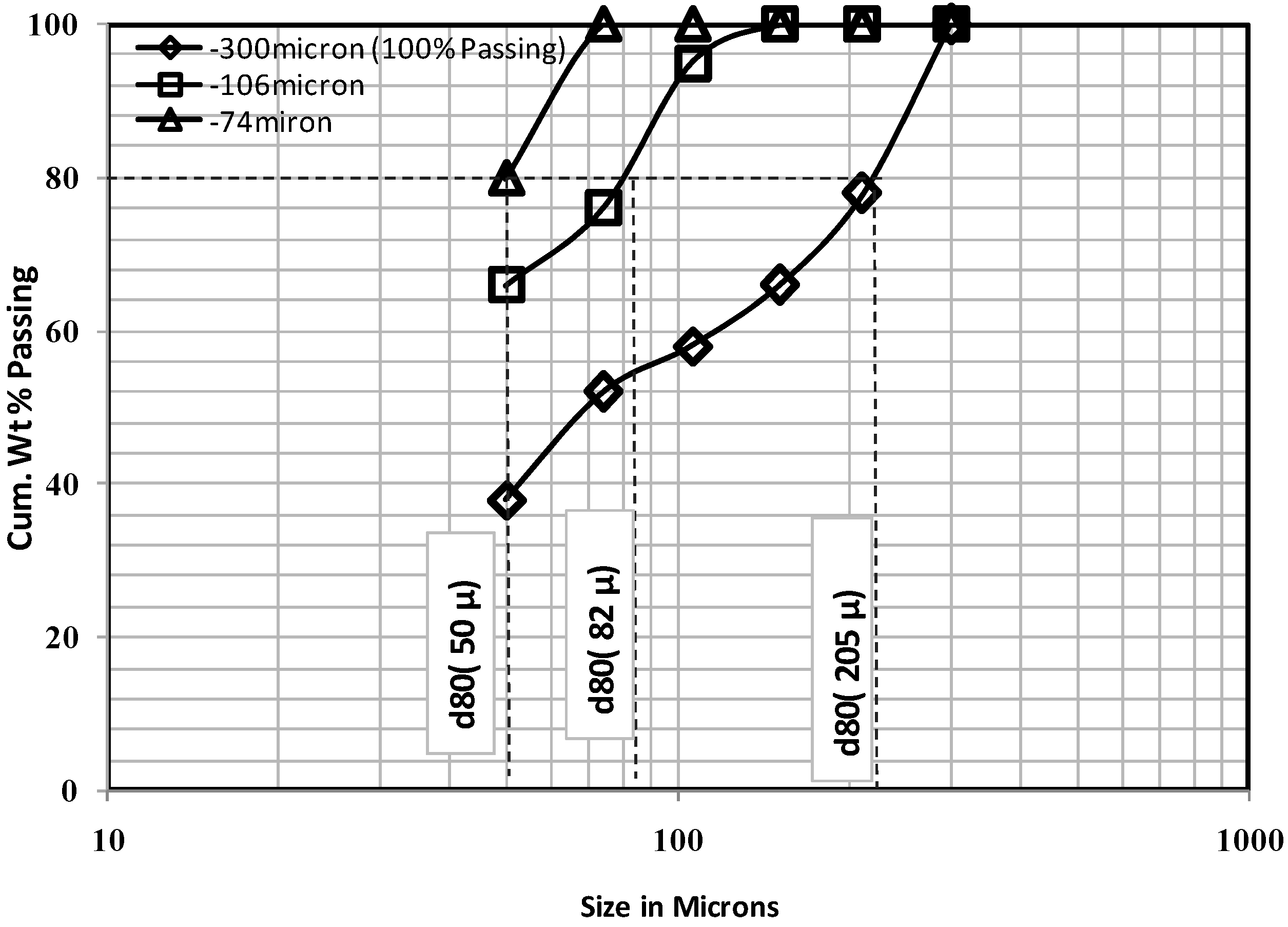

3.3. Process Diagnostic Amenability Tests

3.4. Wet High-Intensity Magnetic Separation Tests

3.5. Reverse Flotation Tests

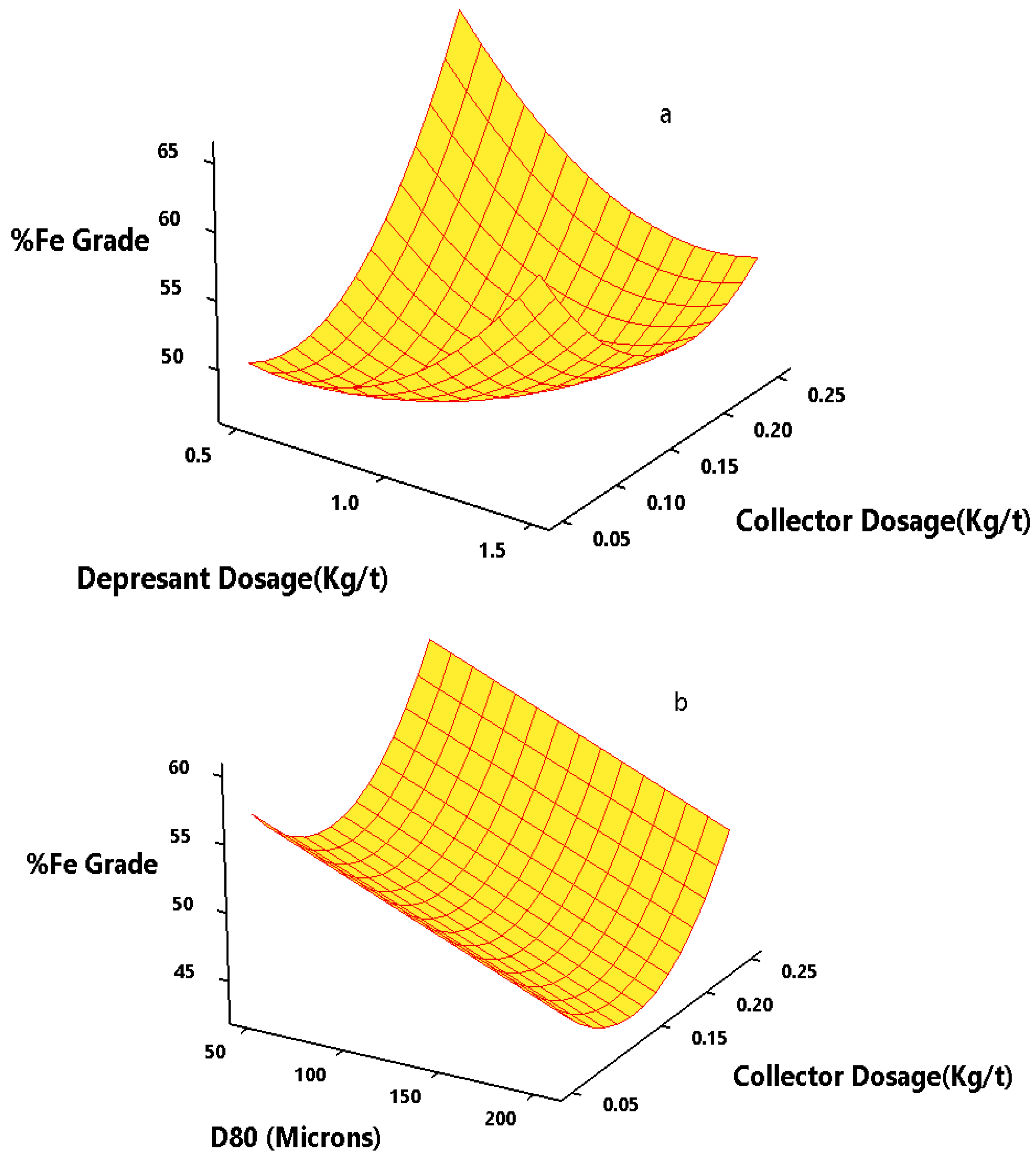

3.5.1. Effect of Flotation Variables on Grade (%Fe) of Concentrate

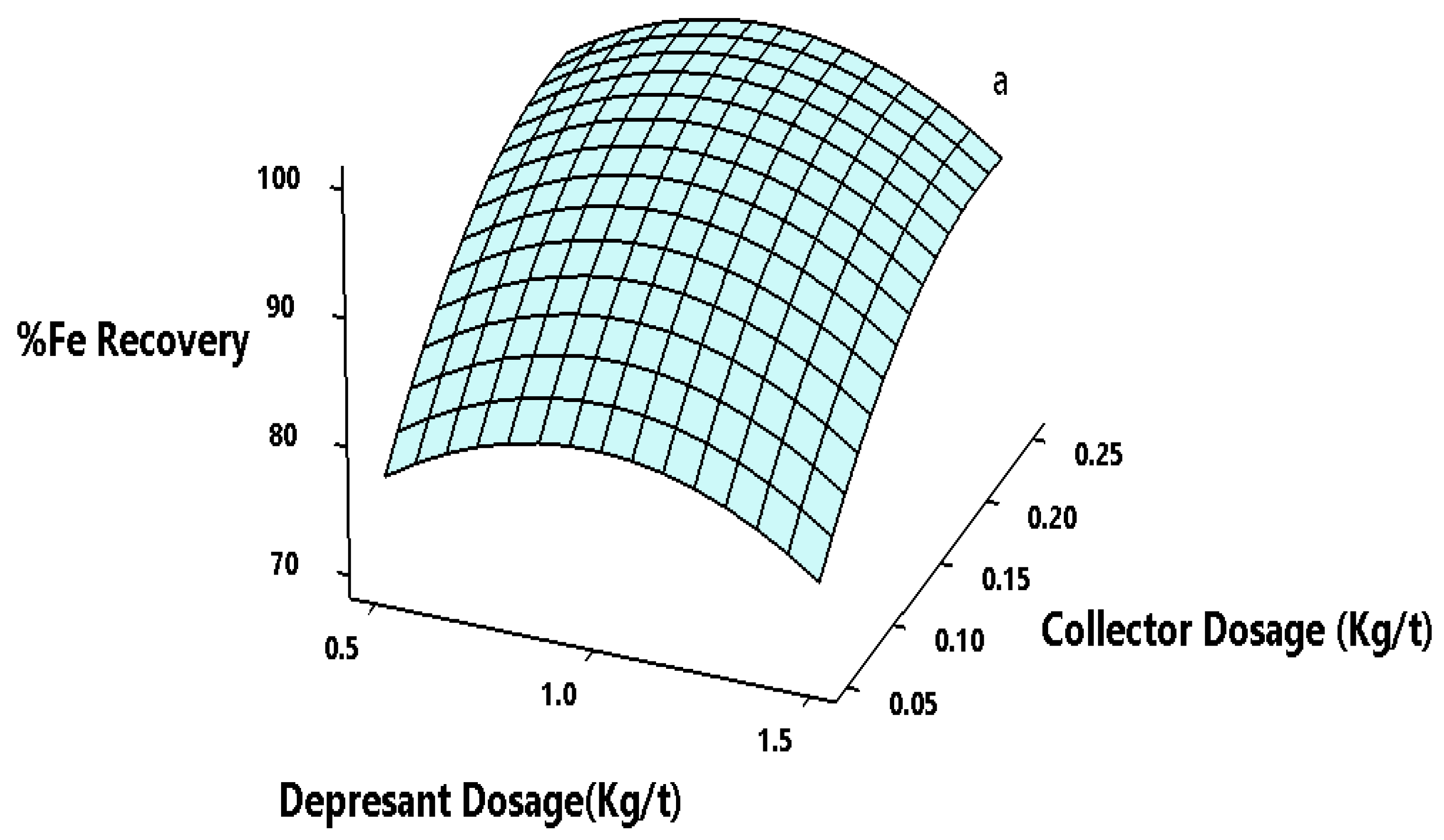

3.5.2. Effect of Flotation Variables on Recovery (%Fe) of Concentrate

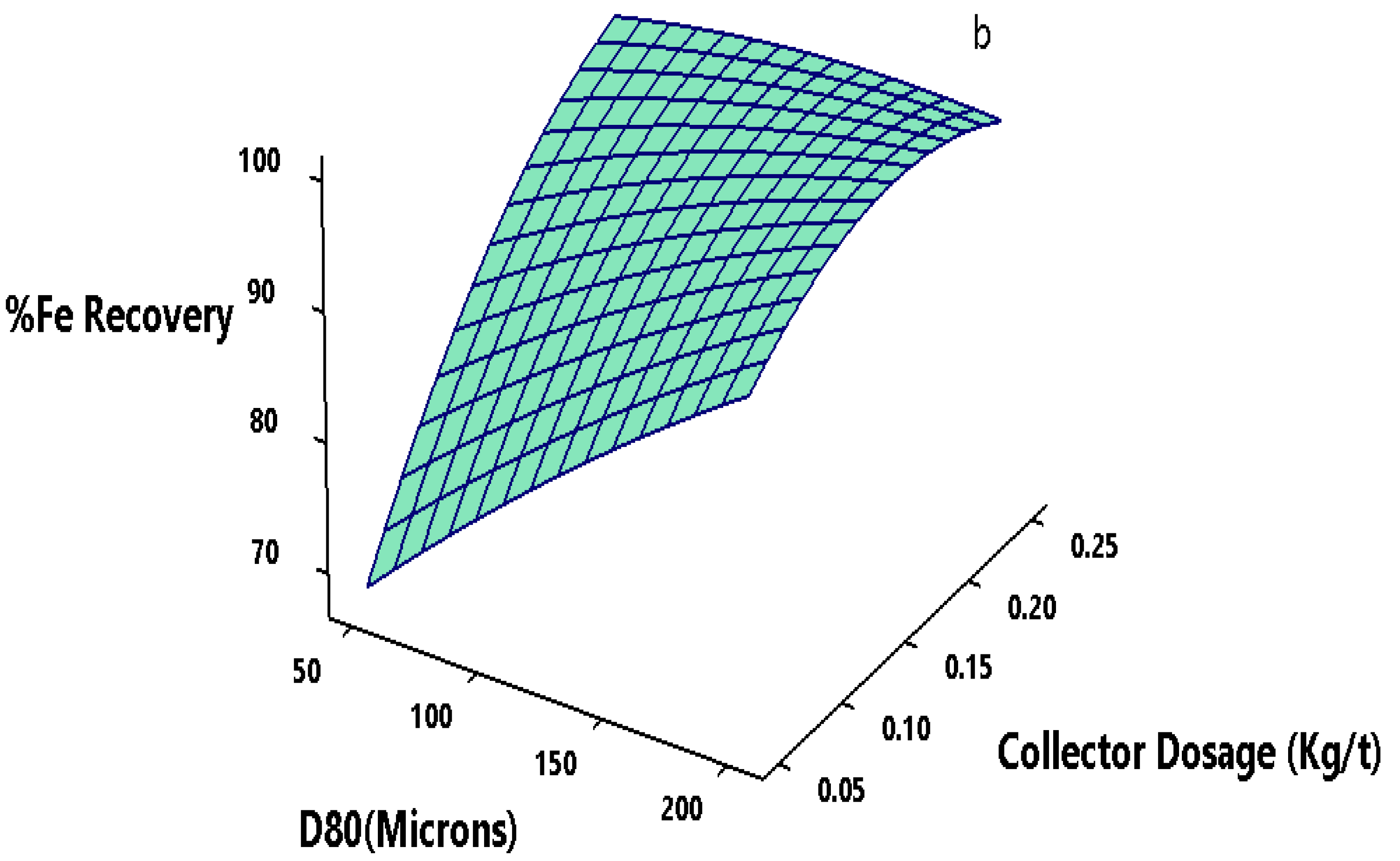

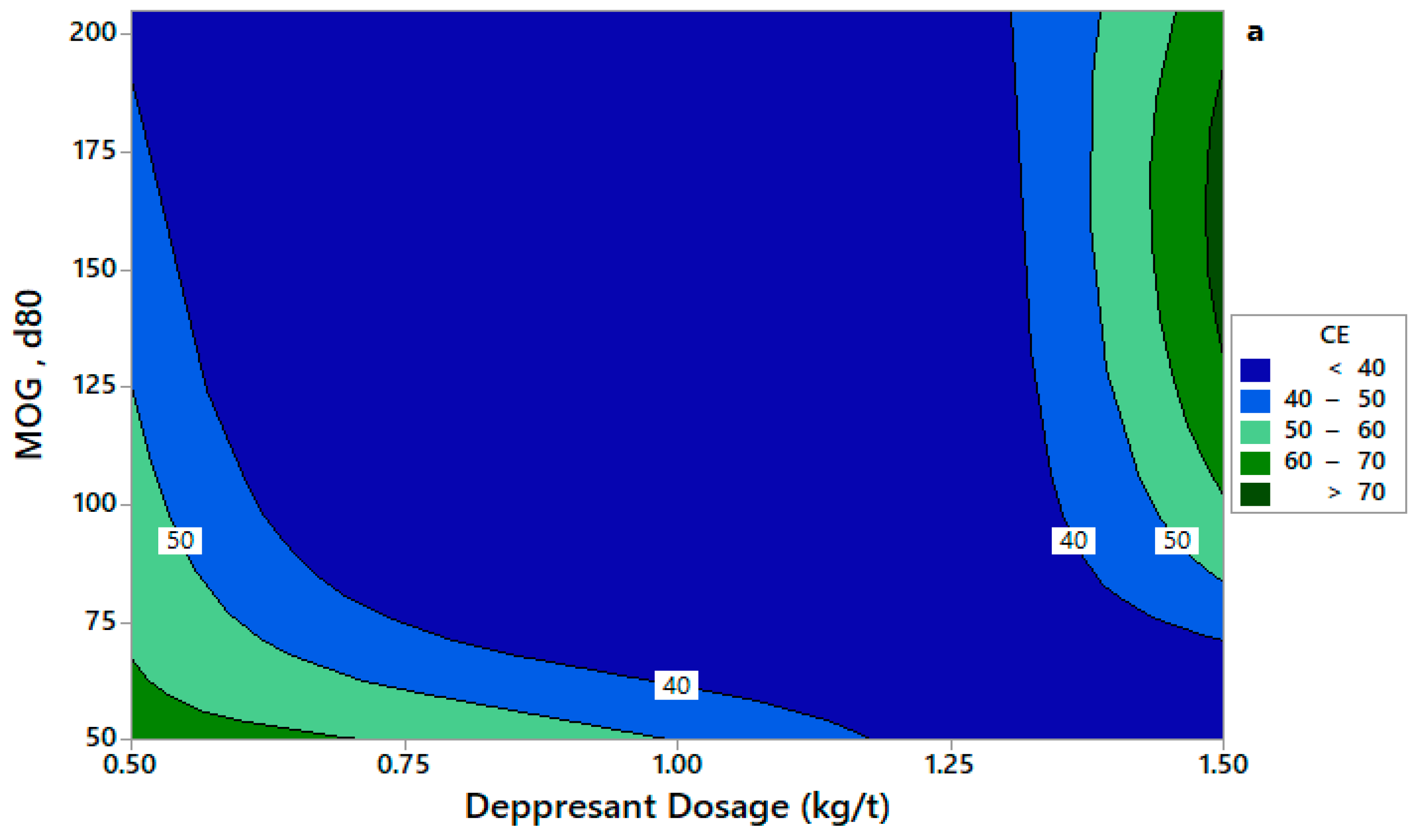

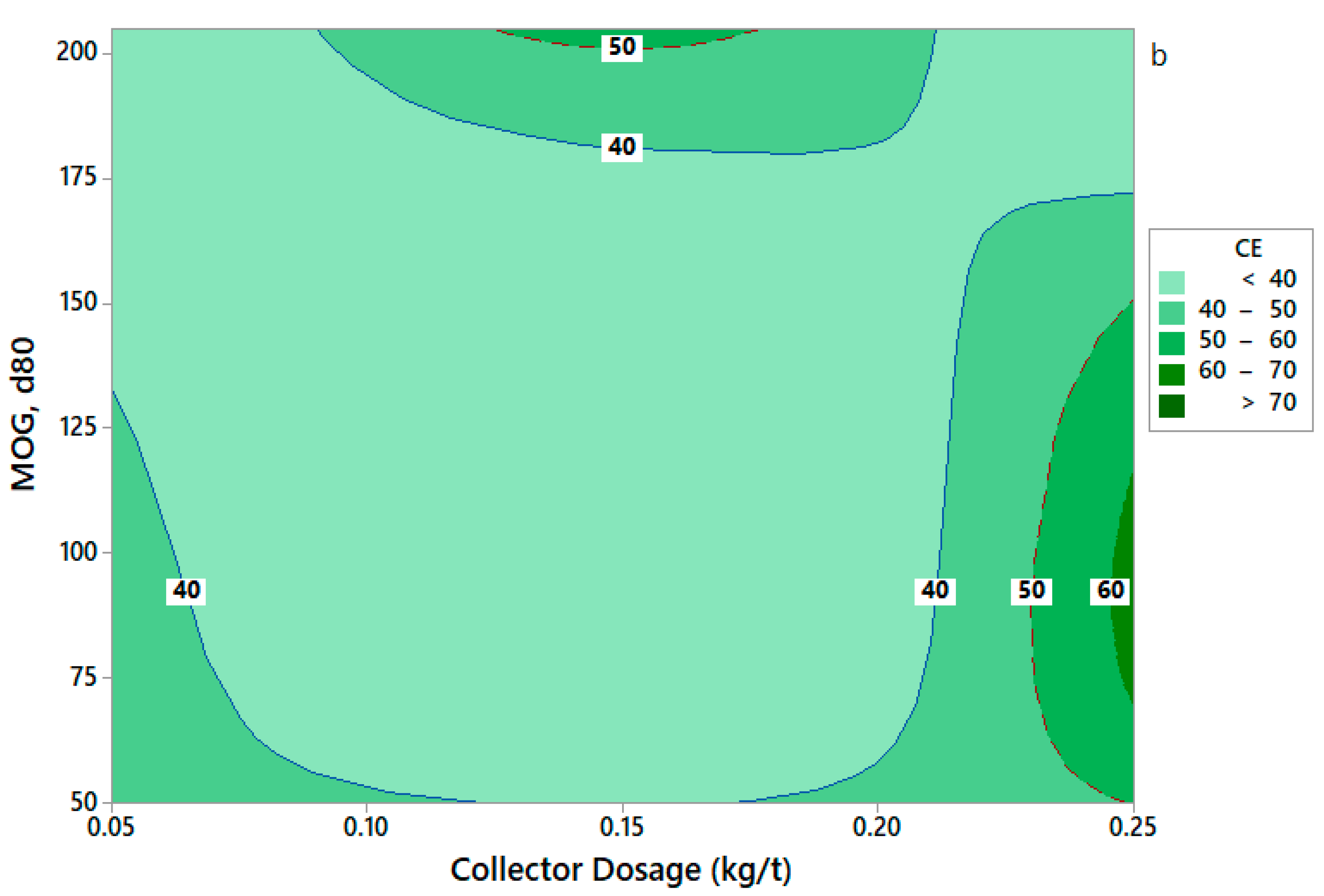

3.5.3. Effect of Flotation Variables on Concentration Efficiency (CE)

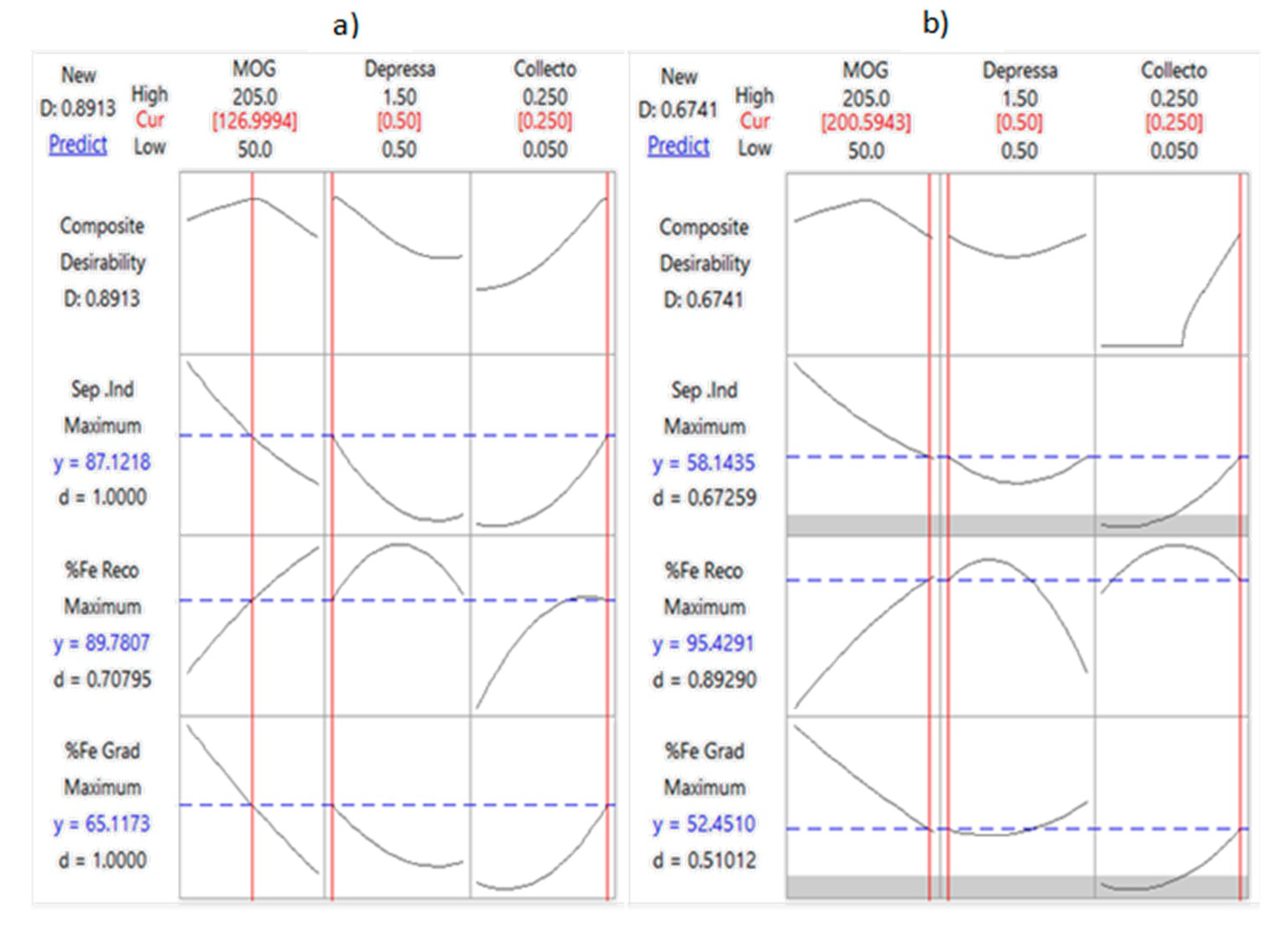

3.5.4. Optimization Studies

- a.

- Obtain the individual desirability (d) for each response;

- b.

- Combine the individual desirability to obtain the combined or composite desirability (D);

- c.

- Maximize the composite desirability and identify the optimal input variable settings.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Swamy, K.; Suresh, N.; Kumar, P.S. Resource Management and Utilization of Lean Grade Iron Ore Resources of Karnataka, India. J. Mines Met. Fuels 2022, 70, 233–241. [Google Scholar] [CrossRef]

- IBM. Iron and Steel Vision 2020; Indian Bureau of Mines: Nagpur, India, 2011. [Google Scholar]

- IBM. Monograph on Iron Ore; Indian Bureau of Mines: Nagpur, India, 1997. [Google Scholar]

- Raj, B. Development of a Process flow sheet for Beneficiation of Indian Banded Hematite Quartz (BHQ) Iron Ore. In Proceedings of the Iron Ore 2007 Conference Perth: AusIMM, Perth, Australia, 20–22 August 2007; pp. 375–380. [Google Scholar]

- Anupam, A.; Singh, G.; Raghav, P.K.; Suresh, N. Studies on beneficiation of BHQ samples by different methods. In Proceedings of the XI International Seminar on Mineral Processing Technology (MPT-2010), Jamshedpur, India, 15–17 December 2010; p. 572. [Google Scholar]

- Das, B.; Rath, S.S.; Reddy, P.S.; Das, S.K.; Mishra, B.K. The flotation response of Banded Iron Ore of Karnataka Region, India. In Proceedings of the 26th International Mineral Processing Congress (IMPC 2012), New Delhi, India, 24–28 September 2012; pp. 1030–1040. [Google Scholar]

- Mohan Rao, A.; Rudramuniyappa, M.V.; Hiremath, M.S.; Naganoor, P.C. Flotation studies on banded hematite quartzite from Sandur Schist belt, Bellary district, Karnataka. In Proceedings of the 26th International Mineral Processing Congress (IMPC 2012), New Delhi, India, 24–28 September 2012; pp. 34–52. [Google Scholar]

- Gurulakshmi, S.N.; Ghosh, T.K.; Mukherjee, A.K. State of Art Characterization Study of Banded Hematite Jasper for Beneficiation. In Proceedings of the XI International Seminar on Mineral Processing Technology (MPT-2010), Jamshedpur, India, 15–17 December 2010; p. 440. [Google Scholar]

- Gurulakshmi, S.N.; John, S.T.; Dixit, T. Flotation studies on Banded Hematite Jasper iron ores. In Proceedings of the 26th International Mineral Processing Congress (IMPC 2012), New Delhi, India, 24–28 September 2012; p. 5181. [Google Scholar]

- Nanda, N.K.; Gopalkrishna, S.J. Development of Process for Beneficiation of low-grade iron ore fins from Karnataka. J. Mines Met. Fuels 2015, 5–9. [Google Scholar]

- IBM. Chemical Analysis of Ores Samples; Indian Bureau of Mines Nagpur: Nagpur, India, 2011. [Google Scholar]

- Menasinakai, V.; Pujar, G.S.; Swami, M.; Asode, A.N. Mineralogy of Banded Iron Formations in and around Kammatturu, Sandur Schist Belt, Karnataka. 2014. Available online: www.semanticscholar.org (accessed on 25 March 2021).

- Krishna, S.J.; Patil, M.R.; Rudrappa, C.; Kumar, S.P.; Ravi, B.P. Characterization and processing of some Iron ores of Indium. J. Inst. Eng. Sec D 2013, 113–120. [Google Scholar] [CrossRef]

- Mishra, B.K.; Reddy, P.S.; Das, B.; Biswal, S.K.; Prakash, S.; Das, S.K. Issues Relating to Characterization and Beneficiation of Low-Grade Iron Ore Fines. December 2007. Available online: www.worldsteel.org (accessed on 15 April 2022).

- Somasundaran, P. Adsorption of starch and oleate and interaction between them on calcite in aqueous solutions. J. Colloid Interface Sci. 1969, 31, 557–565. [Google Scholar] [CrossRef]

- Filippov, L.O.; Filippov, I.V.; Severov, V.V. New technologies for producing hematite concentrate from wastes generated in the processing of iron quartzite. Metallurgist 2010, 54, 268–272. [Google Scholar] [CrossRef]

- Somasundaran, P.; Cleverdon, J. A study of polymer/surfactant interaction at Mineral solution interface. Colloids Surf. 1985, 13, 73–85. [Google Scholar] [CrossRef]

- Houot, R. Beneficiation of iron ore by flotation- review of industrial and potential applications. Int. J. Miner. Processing 1983, 10, 183–204. [Google Scholar] [CrossRef]

- Nummela, W.; Iwasaki, I. Iron ore Flotation. In Advances in Mineral Processing; Somasundaran, P., Ed.; AIME: Mumbai, India, 1986; pp. 308–342. [Google Scholar]

- Wills, B.A.; Napier Munn, T.J. Mineral Processing Technology—An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 7th ed.; Elsevier: Amsterdam, The Netherlands, 2006; p. 18. [Google Scholar]

- Pinto, C.L.L.; Araujo, A.C.; Peres, A.E.C. The effect of starch, amylose, and amylopectin on the depression of oxi-minerals. Miner. Eng. 1992, 5, 469–478. [Google Scholar] [CrossRef]

- Pradip. Beneficiation of alumina rich Indian iron ores limes-Scientific challenges and techno-economic considerations. Met. Mater. Processes. 1994, 6, 179–194. [Google Scholar]

- Su, F.; Rao, K.H.; Forssberg KS, E.; Samskog, P.O. Influence of temperature on the kinetics of apatite flotation from magnetite fines. Int. J. Miner. Processing 1998, 54, 131–145. [Google Scholar] [CrossRef]

- Bhaskar Raju, G.; Prabhakar, S.; Subba Rao, S. Development of indigenous column flotation technology at NML to beneficiate low-grade ores. Met. Mater. Processes 2004, 16, 143–156. [Google Scholar]

- Kumar, P.S.; Ravi, B.P.; Sreedhar, G.E.; Naganoor, P.C. Modeling and Optimization of Vertical Pulsating High Gradient Magnetic Separator for Iron ore Slime Processing Using Response Surface Methodology. Int. J. Miner. Processing Extr. Metallurgy. 2016, 1, 56–63. [Google Scholar] [CrossRef]

- Araujo, A.C.; Amarante, S.C.; Souza, C.C.; Silva, R.R.R. Ore mineralogy and its relevance for selection of concentration methods in processing of Brazilian iron ores. Trans. IMM 2003, 112, C54–C64. [Google Scholar] [CrossRef]

- Lima, N.P.; Valadão, G.E.; Peres, A.E. Effect of amine and starch dosages on the reverse cationic flotation of iron ore. Miner. Eng. 2013, 45, 180–184. [Google Scholar] [CrossRef]

- Nanda, S.K.; Pani, S.; Beura, D. Recovery of iron values through conventional beneficiation techniques fromBHJ of eastern India with reference to mineralogical and chemical characterization. Ind. J. Sci. Tech. 2020, 13, 3960–3969. [Google Scholar] [CrossRef]

- Ravi, B.P.; Kumar, G.S.; Ananth, B.D.; Hussain, M.I.; Kristappa, M.G. Process Characterization of some Iron ores of India. Indian Mineral. 2013, 25–134. [Google Scholar]

- Nayak, N.; Das, A.; Paul, B.K. Feasibility of beneficiation of BHJ of eastern India. IJERT 2012, 1, 1–11. [Google Scholar]

- Ravishankar, S.A.; Sankar, T.A.P.; Khosla, N.K. Beneficiation studies on alumina–rich Indian iron ore slimes using selective dispersants, flocculants and flotation collectors. In Proceedings of the XVIII International Mineral Processing Congress, Sydney, Australia, 23–28 May 1993; AusIMM: Carlton, Australia; pp. 1289–1294. [Google Scholar]

| Ingredient | Specification in Percentage | |

|---|---|---|

| BF Grade | DRI Grade | |

| Fe | >63.0 | >65.0 |

| SiO2 + Al2O3 | <6.00 | <2.00 |

| S and P | <0.05 (each) | <0.05 |

| (Al2O3/SiO2) Ratio | <0.5 | <0.5 |

| MOG/# D80 µm | Products | Wt% | %Fe | |

|---|---|---|---|---|

| Assay | Distribution | |||

| −50# 205 µm | Mag Conc. | 34.7 | 44.07 | 36.4 |

| Non-Mag tails | 65.3 | 27.10 | 63.6 | |

| Head Cal | 100.0 | 42.01 | 100.0 | |

| 150# 82 µm | Mag Conc. | 56.0 | 45.00 | 63.6 |

| Non-Mag tails | 44.0 | 32.79 | 36.4 | |

| Head Cal | 100.0 | 40.00 | 100.0 | |

| 200# 50 µm | Mag Conc. | 41.0 | 47.30 | 47.3 |

| Non-Mag tails | 59.0 | 36.60 | 52.7 | |

| Head Cal | 100.0 | 41.05 | 100.0 | |

| Variables Varied | Units | Real Values of Coded Levels | ||

|---|---|---|---|---|

| Low (−1) | Centre (0) | High (+1) | ||

| D80, D100 % passing feed sizes | µm | 50, −74 | 82, −106 | 205, –300 |

| Collector dosage | kg/t | 0.05 | 0.15 | 0.25 |

| Depressant dosage | kg/t | 0.5 | 1.0 | 1.5 |

| Run Order | MOG | Depressant Dosage (kg/t) | Collector Dosage (kg/t) | Wt% | %Fe Grade | %Fe Recovery wrt Mag conc | % Concentration EfficiencywrtFeed | |||

|---|---|---|---|---|---|---|---|---|---|---|

| No | A | B | C | Y | Observed | Predicted | Observed | Predicted | Observed | Predicted |

| 1 | 50 | 0.5 | 0.15 | 49.65 | 63.6 | 65.55 | 74.49 | 72.3 | 63.35 | 72.06 |

| 2 | 205 | 0.5 | 0.15 | 83.68 | 49.8 | 37.15 | 98.7 | 97.7 | 37.86 | 24.62 |

| 3 | 50 | 1.5 | 0.15 | 79.24 | 45.5 | 47.23 | 85.4 | 82.4 | 15.51 | 28.75 |

| 4 | 205 | 1.5 | 0.15 | 60.89 | 60.6 | 57.67 | 87.4 | 85.6 | 66.79 | 58.09 |

| 5 | 50 | 1 | 0.05 | 48.69 | 59.1 | 56.95 | 68.16 | 71.8 | 49.05 | 34.47 |

| 6 | 205 | 1 | 0.05 | 87.77 | 45.7 | 47.97 | 95 | 97.4 | 18.23 | 25.59 |

| 7 | 50 | 1 | 0.25 | 39.97 | 63.3 | 59.93 | 92.6 | 86 | 50.29 | 42.93 |

| 8 | 205 | 1 | 0.25 | 43.39 | 49.6 | 50.98 | 96.8 | 89 | 19.11 | 33.70 |

| 9 | 82 | 0.5 | 0.05 | 65.11 | 50.5 | 50.31 | 77.88 | 80.1 | 32.18 | 38.05 |

| 10 | 82 | 1.5 | 0.05 | 49.45 | 63.6 | 63.64 | 74.49 | 79.2 | 63.10 | 64.45 |

| 11 | 82 | 0.5 | 0.25 | 59.15 | 64.6 | 65.49 | 90.5 | 83.1 | 79.01 | 77.66 |

| 12 | 82 | 1.5 | 0.25 | 71.51 | 53.3 | 54.41 | 90.28 | 82.2 | 47.29 | 41.41 |

| 13 | 82 | 1 | 0.15 | 84.53 | 46.8 | 47.42 | 93.7 | 91.6 | 23.11 | 23.11 |

| 14 | 82 | 1 | 0.15 | 84.53 | 46.8 | 47.42 | 93.7 | 91.6 | 23.11 | 23.11 |

| 15 | 82 | 1 | 0.15 | 84.53 | 46.8 | 47.42 | 93.7 | 91.6 | 23.11 | 23.11 |

| Products | Wt% | %Fe | |

|---|---|---|---|

| Assay | Distn. | ||

| Reverse Flotation Conc | 37.4 | 64.60 | 60.4 |

| Silica float | 18.6 | 6.90 | 3.2 |

| WHIMS non-mag | 44.0 | 32.79 | 36.4 |

| Head-cal | 100.0 | 40.00 | 100.0 |

| Fe | 64.60% | SiO2 + Al2O3 | 4.12% |

| SiO2 | 3.12% | Al2O3 to SiO2 ratio | 0.32 |

| Al2O3 | 1.00% | LOI | 1.06% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Swamy, A.K.; Nikkam, S.; Palthur, S.K. Recovery of Hematite from Banded Hematite Quartzite of Southern India by Magnetic Separation and Reverse Flotation. Minerals 2022, 12, 1095. https://doi.org/10.3390/min12091095

Swamy AK, Nikkam S, Palthur SK. Recovery of Hematite from Banded Hematite Quartzite of Southern India by Magnetic Separation and Reverse Flotation. Minerals. 2022; 12(9):1095. https://doi.org/10.3390/min12091095

Chicago/Turabian StyleSwamy, Aspari Kumara, Suresh Nikkam, and Sharath Kumar Palthur. 2022. "Recovery of Hematite from Banded Hematite Quartzite of Southern India by Magnetic Separation and Reverse Flotation" Minerals 12, no. 9: 1095. https://doi.org/10.3390/min12091095

APA StyleSwamy, A. K., Nikkam, S., & Palthur, S. K. (2022). Recovery of Hematite from Banded Hematite Quartzite of Southern India by Magnetic Separation and Reverse Flotation. Minerals, 12(9), 1095. https://doi.org/10.3390/min12091095