CO2-Water-Rock Interactions in Carbonate Formations at the Tazhong Uplift, Tarim Basin, China

Abstract

1. Introduction

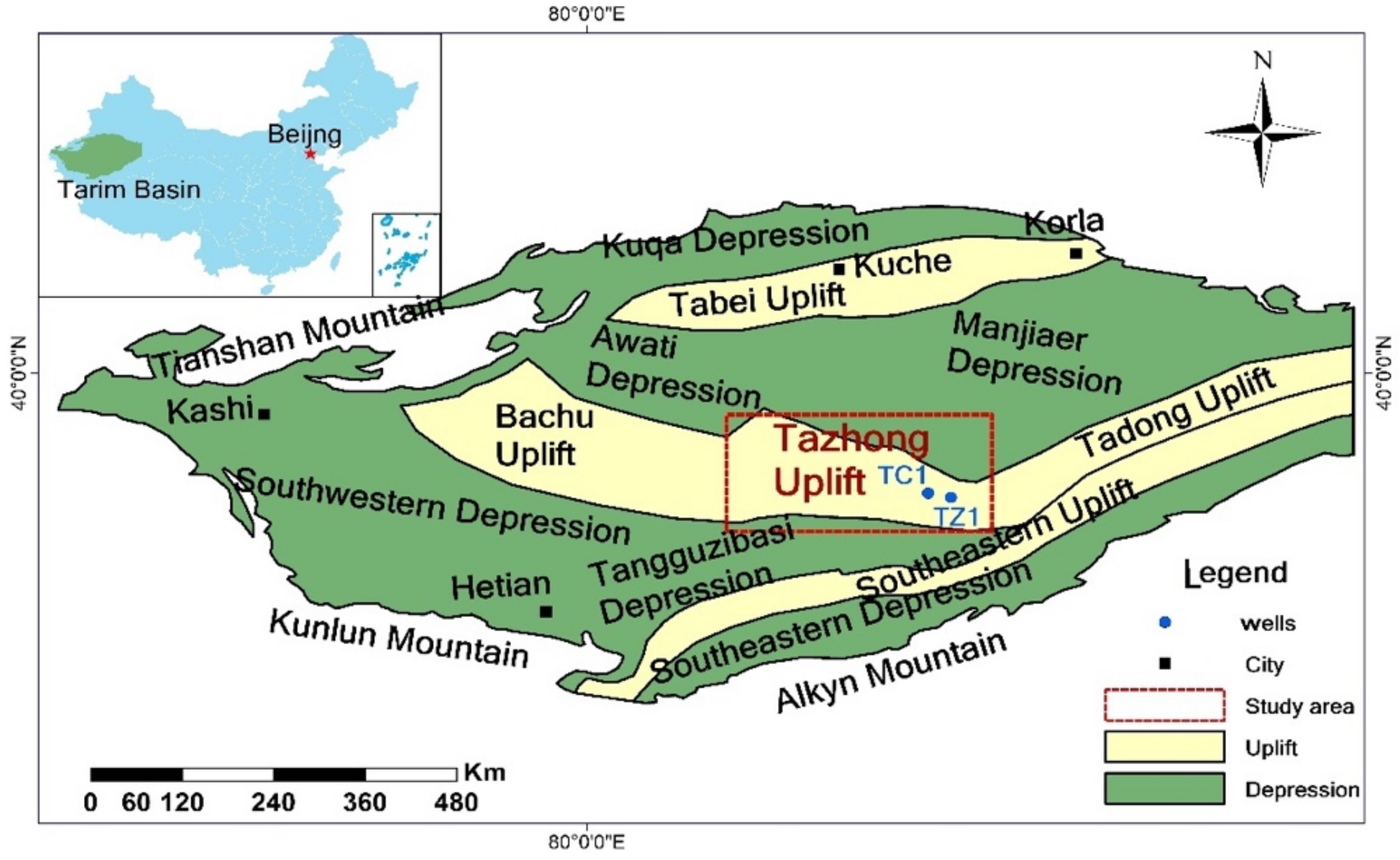

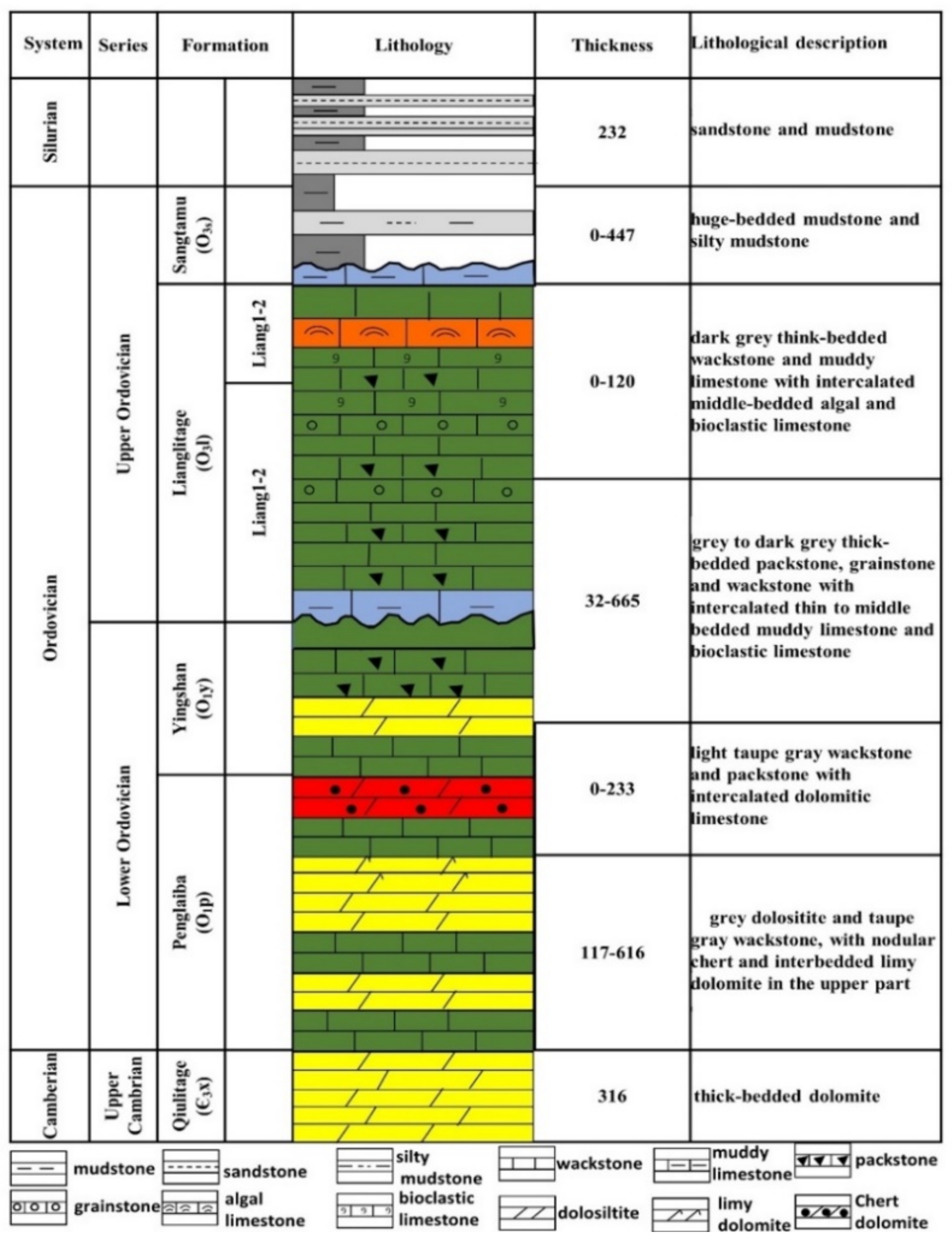

2. Geological Settings

3. Materials and Methods

3.1. Sample Description

3.2. Physical Experimental Conditions

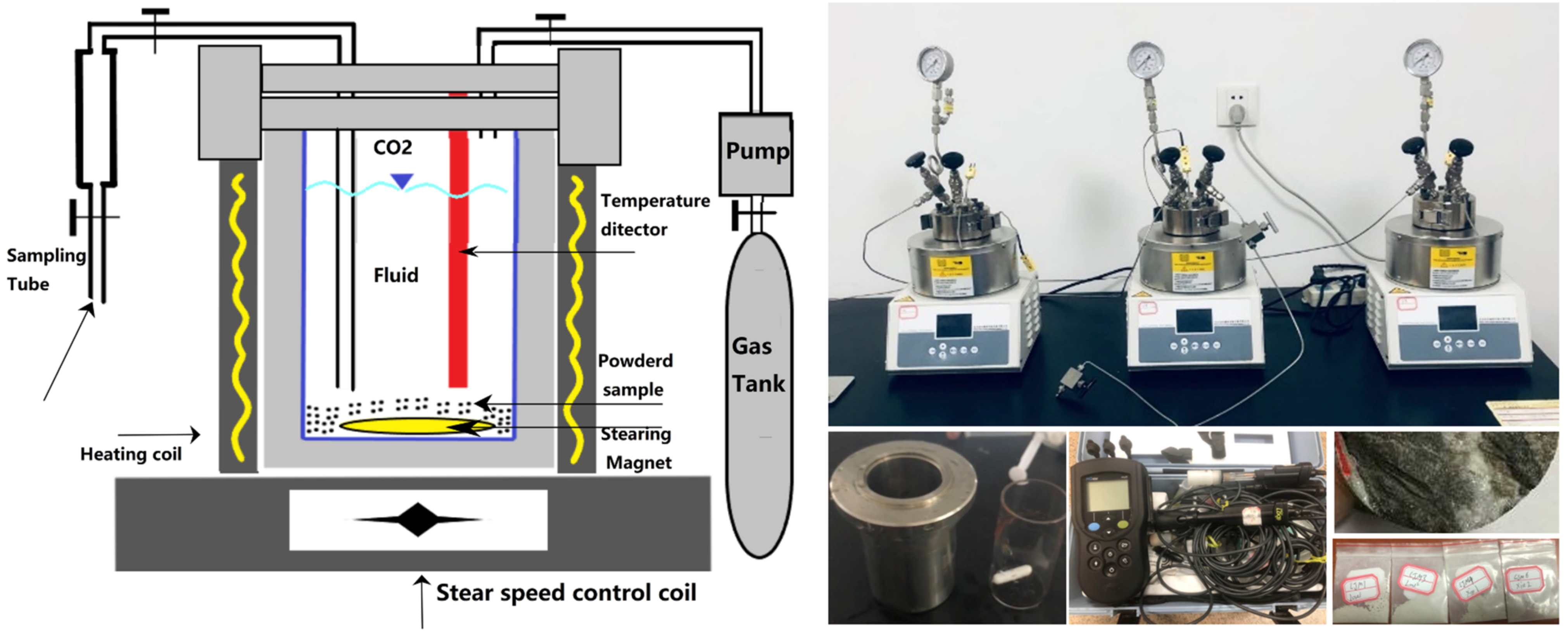

3.3. Experimental Apparatus and Procedures

- Grind 4 g rock sample in an agate bowl into powders, and sieve the powders to approximately 150 µm grain size. Wash and dry the powder sample;

- Place the treated powder sample in a reactor that is filled with 75 mL synthetic brine and then seal the case;

- Make the top space of the reactor into a vacuum state, and heat it to 120 °C. Inject 99.9 wt% CO2 into the reactor until the pressure reaches to 25 MPa;

- Take a 2 mL fluid sample under pressure every 3 days for the measurement of pH and electrical conductivity with Hach HQ40d.

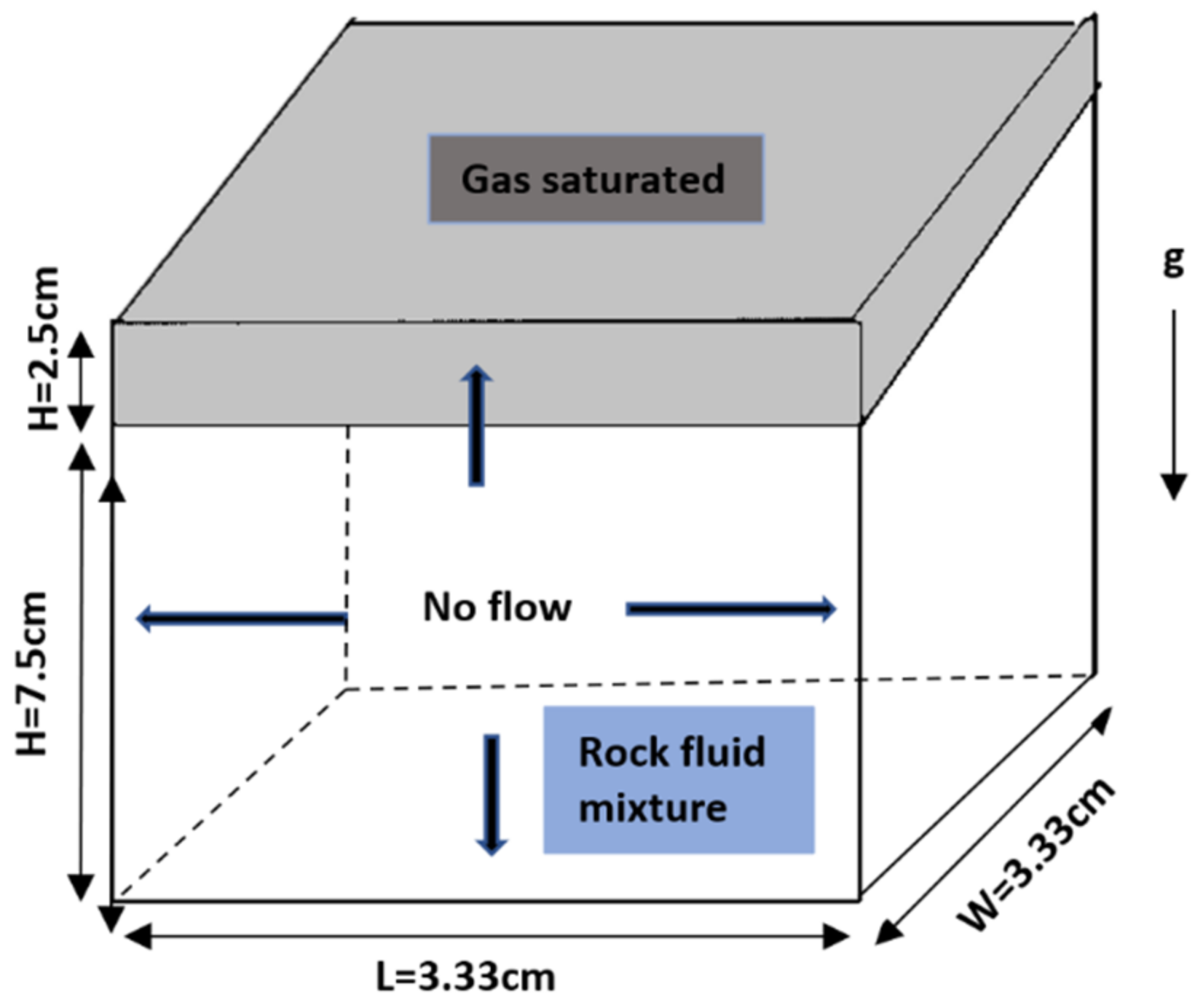

3.4. Numerical Methods

4. Results and Discussion

4.1. Experimental Study on CO2-Water-Rock Interactions

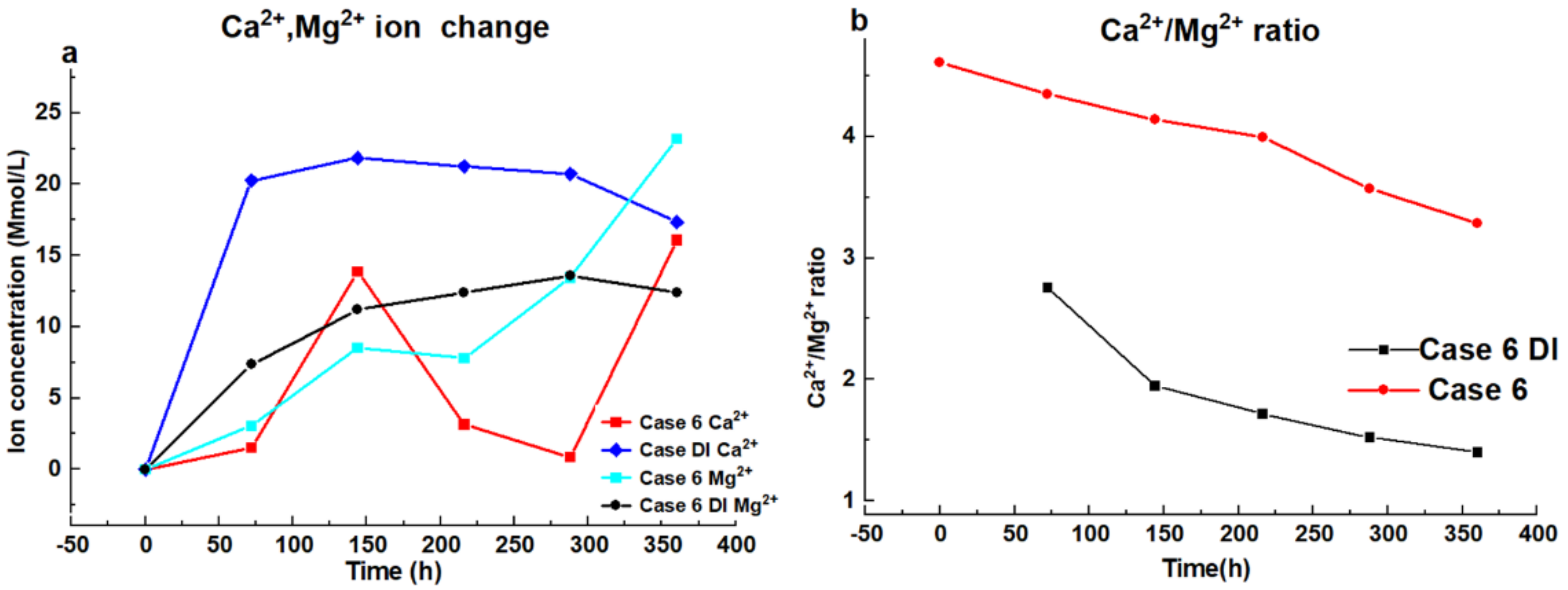

4.1.1. Variation of Water Chemistry

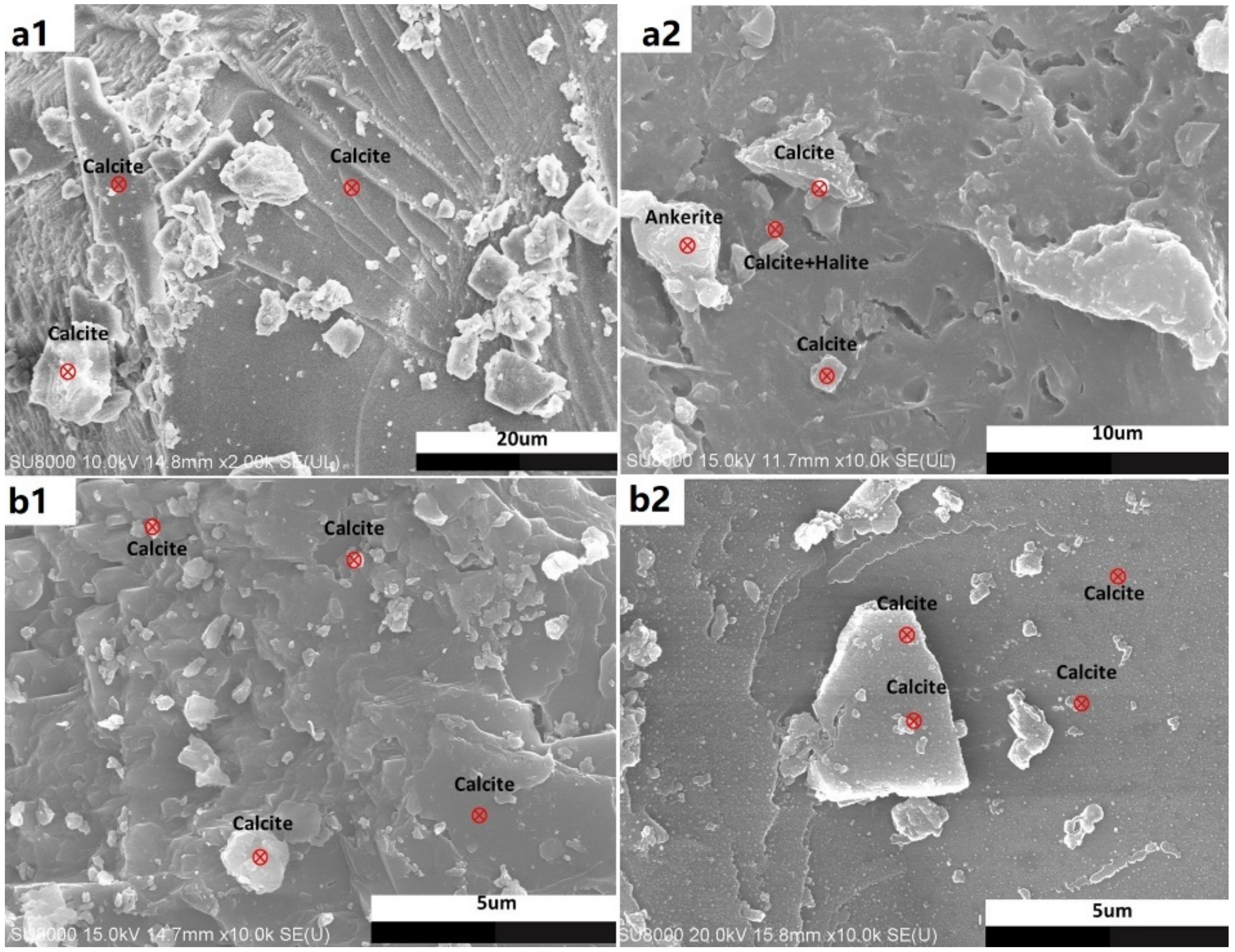

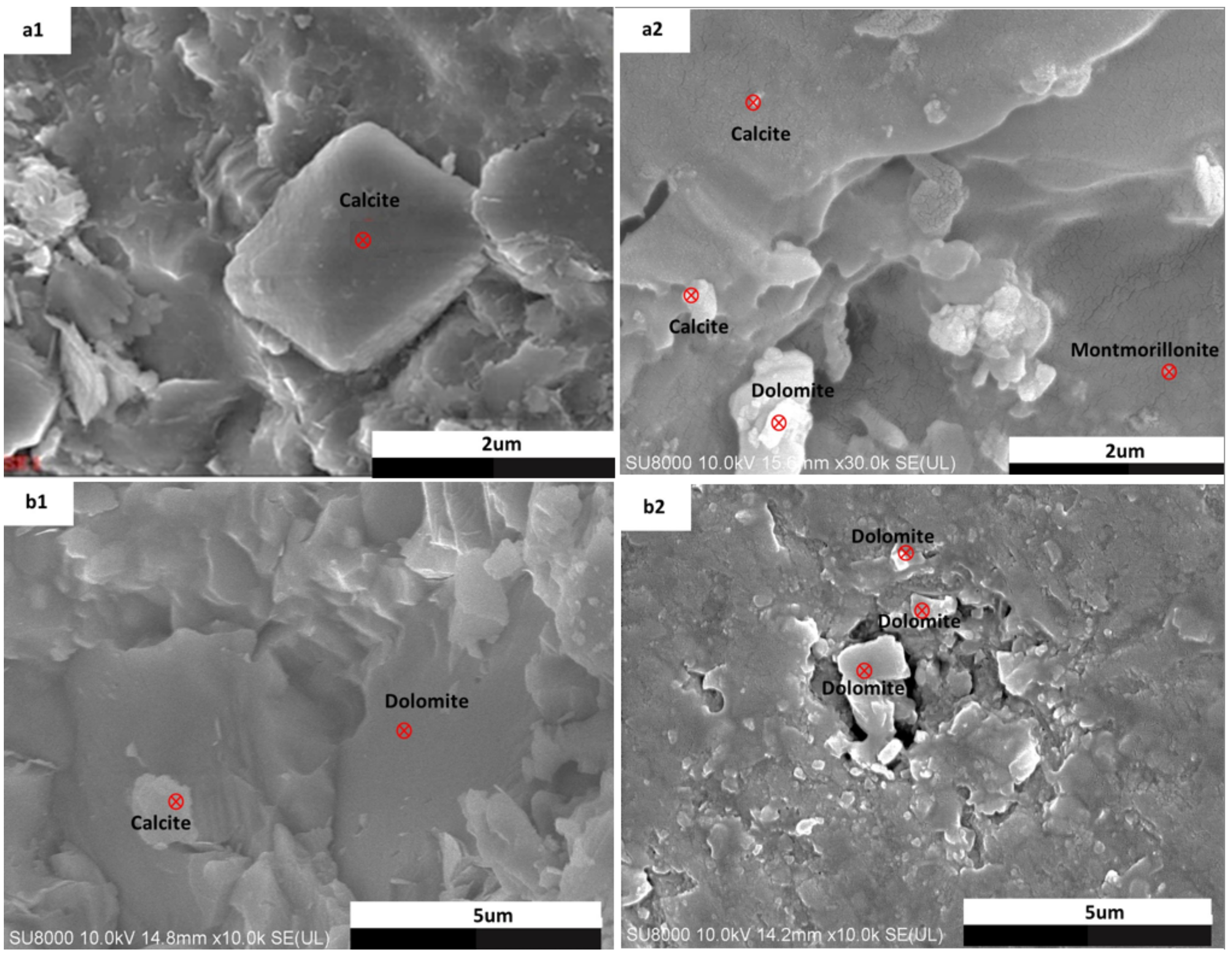

4.1.2. Changes in Mineral Morphology

4.1.3. Transformation between Calcite and Dolomite

4.1.4. Porosity Changes

4.2. Geochemical Modelling of CO2-Water-Rock Interactions

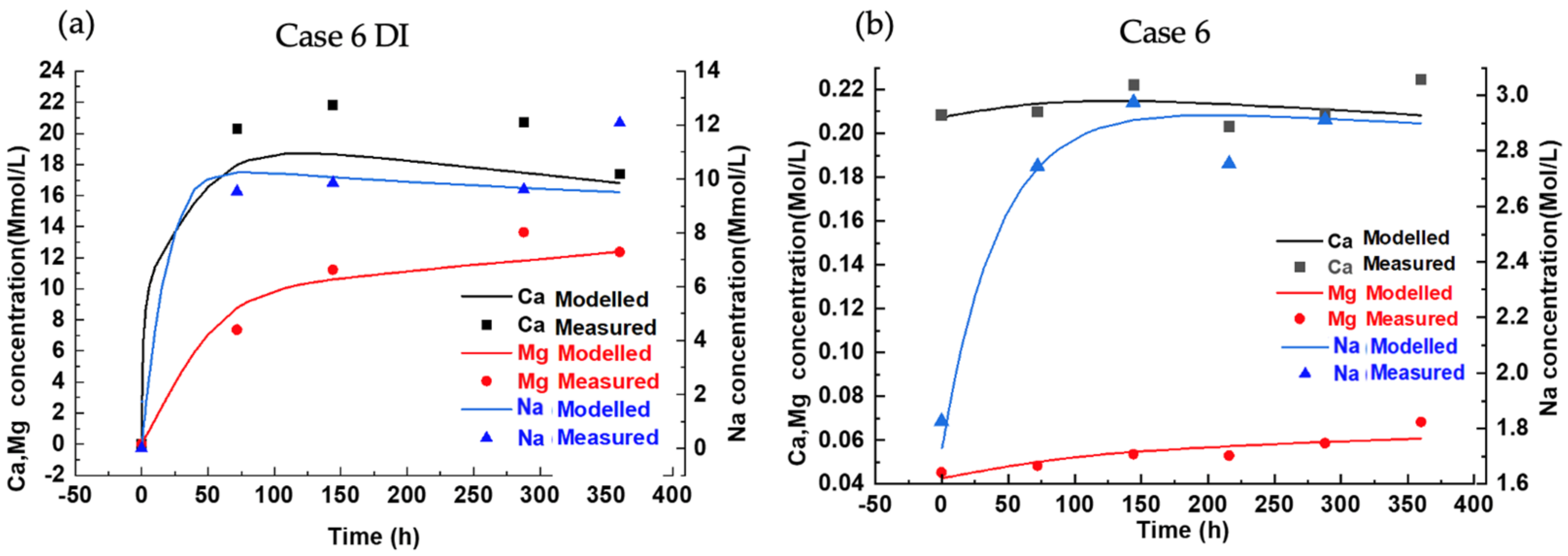

4.2.1. Model Validation

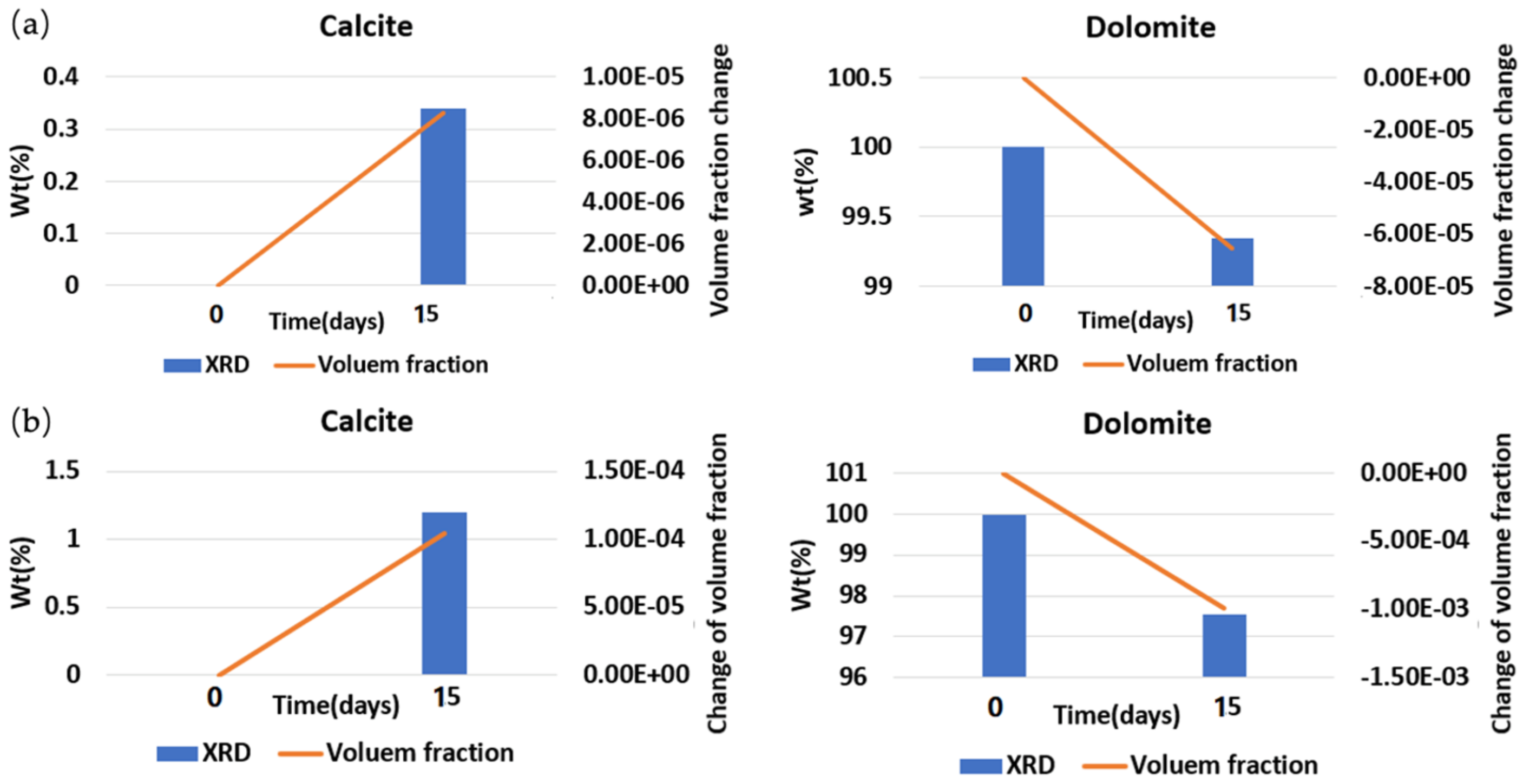

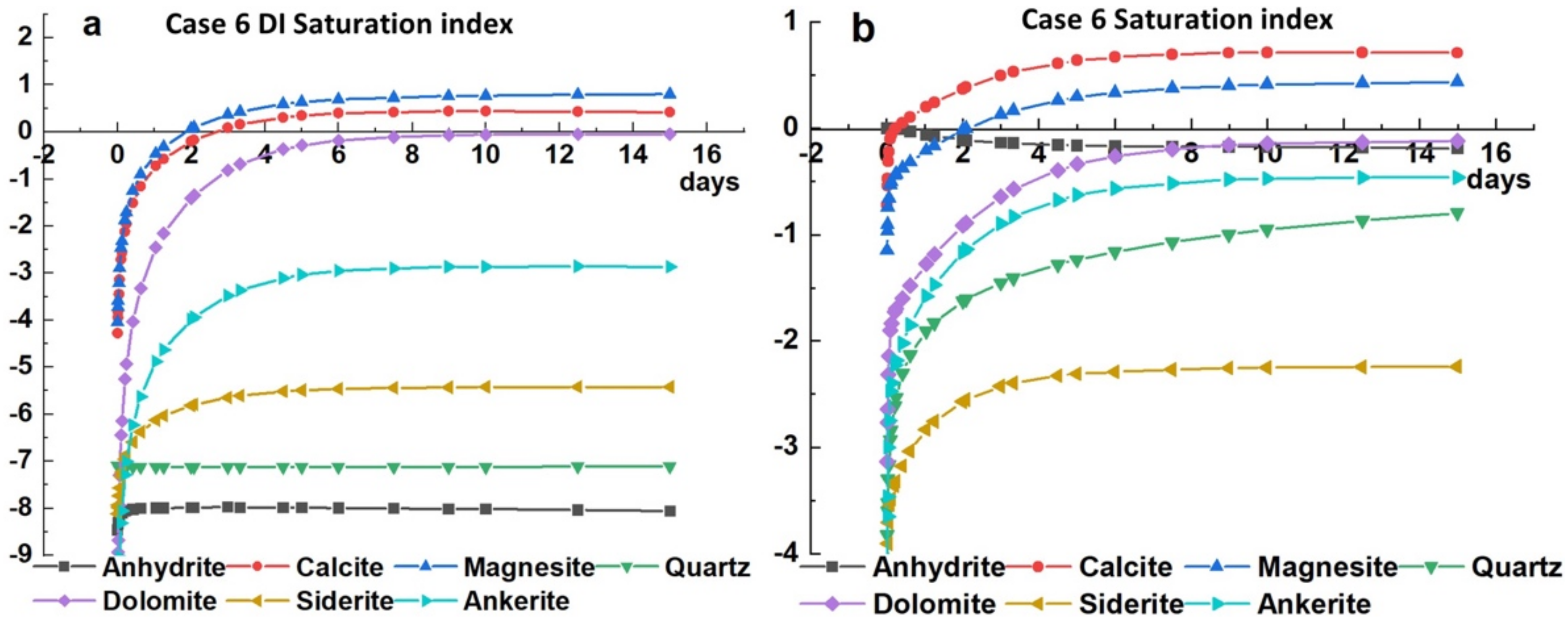

4.2.2. Short-Term Transformation of Minerals

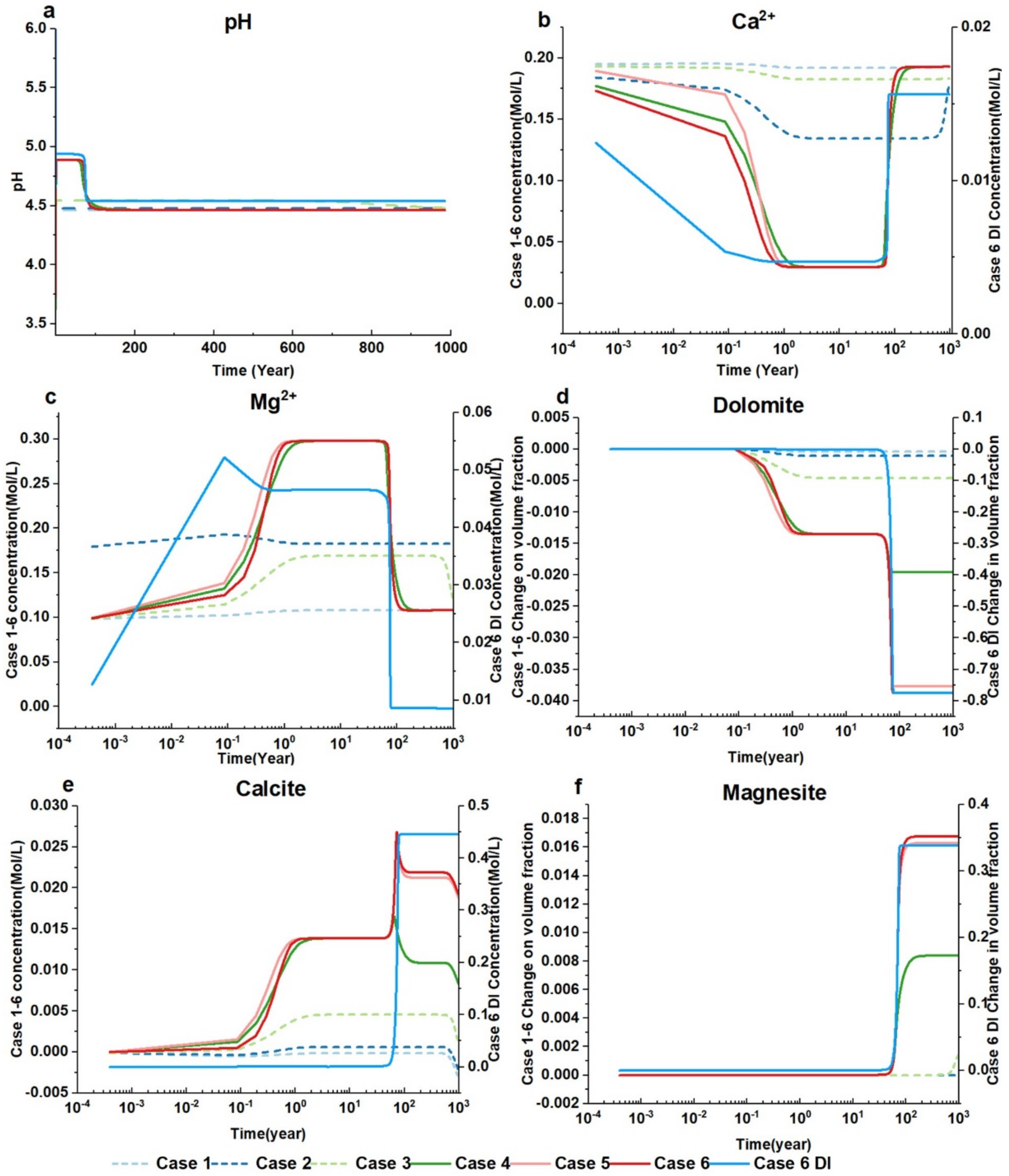

4.2.3. Long-Term Transformation of Minerals

5. Conclusions

- The dissolution of CO2 leads to a rapid decline of pH in the early stage. The pH then rises and becomes stable at the end of the experiments. The dissolution of minerals results in a continuous increase in electrical conductivity until the major secondary minerals reach an equilibrium state and start to precipitate, and then conductivity starts to decrease.

- The SEM analysis demonstrates the dissolution of the calcite and dolomite resulted in a rough surface texture and the formation of dissolution patterns at the edges of the crystals. In addition, some new micropores and pits can be observed. The secondary minerals include ankerite, halite, montmorillonite, calcite, and dolomite. The decreased concentration ratio of Ca2+ to Mg2+ promotes the dolomitization process.

- When the initial calcite content is greater than 90%, or the initial dolomite content is between 50 and 90%, calcite tends to transform to dolomite after the injection of CO2. This dolomitization process increases the rock porosity. When the initial dolomite content is greater than 90%, or the initial calcite content is between 50 and 90%, dolomite transforms to calcite. This dedolomitization process decreases the rock porosity. These can be used for better site selection when considering carbonate reservoirs in CO2 geological storage.

- With the experimental results, corrected reaction rates and surface area are used for the long-term simulations. It was found that in geological time scale, the main secondary minerals that can be observed are calcite, dolomite, magnesite, and hematite. Among them, magnesite and calcite are the main rock-forming minerals, whereas dolomite is the main dissolving mineral. Secondary minerals like ankerite and dawsonite cannot form in the long term mainly due to low iron and aluminum content in the initial system, which limits the CO2 mineral trapping capacity. On the other hand, quartz and kaolinite do not show a significant change in mineral abundance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pachauri, K.; Meyer, A. Climate change 2014 synthesis report. Environ. Policy Collect. 2014, 27, 408. [Google Scholar]

- Metz, B.; Davidson, O.; Coninck, H.D.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage; Cambridge University Press: New York, NY, USA, 2005. [Google Scholar]

- Tollefson, J. IPCC says limiting global warming to 1.5 °C will require drastic action. Nature 2018, 562, 172–173. [Google Scholar] [CrossRef] [PubMed]

- Mi, Z.; Sun, X. Provinces with transitions in industrial structure and energy mix performed best in climate change mitigation in China. Commun. Earth Environ. 2021, 2, 182. [Google Scholar] [CrossRef]

- Bachu, S.; Gunter, W.; Perkins, E. Aquifer disposal of CO2: Hydrodynamic and mineral trapping. Energy Convers. Manag. 1994, 35, 269–279. [Google Scholar] [CrossRef]

- Perkins, E.; Czernichowski-Lauriol, I.; Azaroual, M.; Durst, P. Long term predictions of CO2 storage by mineral and solubility trapping in the Weyburn Midale Reservoir. In Greenhouse Gas Control Technologies 7; Elsevier: Amsterdam, The Netherlands, 2005; pp. 2093–2096. [Google Scholar]

- Snæbjörnsdóttir, S.Ó.; Sigfússon, B.; Marieni, C.; Goldberg, D.; Gislason, S.R.; Oelkers, E.H. Carbon dioxide storage through mineral carbonation. Nat. Rev. Earth Environ. 2020, 1, 90–102. [Google Scholar] [CrossRef]

- Siqueira, T.A.; Iglesias, R.S.; Ketzer, J.M. Carbon dioxide injection in carbonate reservoirs—A review of CO2-water-rock interaction studies. Greenh. Gases Sci. Technol. 2017, 7, 802–816. [Google Scholar] [CrossRef]

- Azin, R.; Mehrabi, N.; Osfouri, S.; Asgari, M. Experimental Study of CO2—Saline Aquifer-Carbonate Rock Interaction during CO2 Sequestration. Procedia Earth Planet. Sci. 2015, 15, 413–420. [Google Scholar] [CrossRef]

- Lu, J.; Mickler, P.J.; Nicot, J.-P.; Yang, C.; Darvari, R. Geochemical impact of O2 impurity in CO2 stream on carbonate carbon-storage reservoirs. Int. J. Greenh. Gas Control. 2016, 47, 159–175. [Google Scholar] [CrossRef]

- Tetteh, J.T.; Pham, A.; Peltier, E.; Hutchison, J.M.; Barati Ghahfarokhi, R. Predicting the electrokinetic properties on an outcrop and reservoir composite carbonate surfaces in modified salinity brines using extended surface complexation models. Fuel 2022, 309, 122078. [Google Scholar] [CrossRef]

- Blunt, M.; Fayers, F.J.; Orr, F.M. Carbon dioxide in enhanced oil recovery. Energy Convers. Manag. 1993, 34, 1197–1204. [Google Scholar] [CrossRef]

- Li, F.; Diao, H.; Li, W. Mineral trapping of CO2: Hydrothermal experimental system and thermodynamic simulation on interaction between CO2–H2O–dawsonite bearing sandstone with the pH of 4–9, temperature of 80–140 °C, and increasing pCO2. Mar. Pet. Geol. 2020, 111, 588–602. [Google Scholar] [CrossRef]

- Crockford, P.; Telmer, K. Dissolution Kinetics of Keg River dolomites and implications for spectra energy’s Fort Nelson CCS project. Energy Procedia 2011, 4, 4472–4479. [Google Scholar] [CrossRef][Green Version]

- Pokrovsky, O.S.; Golubev, S.V.; Schott, J.; Castillo, A. Calcite, dolomite and magnesite dissolution kinetics in aqueous solutions at acid to circumneutral pH, 25 to 150 °C and 1 to 55 atm pCO2: New constraints on CO2 sequestration in sedimentary basins. Chem. Geol. 2009, 265, 20–32. [Google Scholar] [CrossRef]

- Pokrovsky, O.S.; Golubev, S.V.; Schott, J. Dissolution kinetics of calcite, dolomite and magnesite at 25 °C and 0 to 50 atm pCO2. Chem. Geol. 2005, 217, 239–255. [Google Scholar] [CrossRef]

- Andre, L.; Audigane, P.; Azaroual, M.; Menjoz, A. Numerical modeling of fluid-rock chemical interactions at the supercritical CO2-liquid interface during CO2 injection into a carbonate reservoir, the Dogger aquifer (Paris Basin, France). Energy Convers. Manag. 2007, 48, 1782–1797. [Google Scholar] [CrossRef]

- Berrezueta, E.; Kovacs, T.; Luquot, L. Qualitative and quantitative changes of carbonate rocks exposed to SC CO2 (Basque-Cantabrian Basin, Northern Spain). Appl. Sci. 2017, 7, 1124. [Google Scholar] [CrossRef]

- Luquot, L.; Gouze, P. Experimental determination of porosity and permeability changes induced by injection of CO2 into carbonate rocks. Chem. Geol. 2009, 265, 148–159. [Google Scholar] [CrossRef]

- Niemi, A.; Bensabat, J.; Joodaki, S.; Basirat, F.; Hedayati, M.; Yang, Z.; Perez, L.; Levchenko, S.; Shklarnik, A.; Ronen, R.; et al. Characterizing CO2 residual trapping in-situ by means of single-well push-pull experiments at Heletz, Israel, pilot injection site—Experimental procedures and results of the experiments. Int. J. Greenh. Gas Control. 2020, 101, 103129. [Google Scholar] [CrossRef]

- Palandri, J.L.; Rosenbauer, R.J.; Kharaka, Y.K. Ferric iron in sediments as a novel CO2 mineral trap: CO2–SO2 reaction with hematite. Appl. Geochem. 2005, 20, 2038–2048. [Google Scholar] [CrossRef]

- Anbar, S.; Akin, S. Development of a linear predictive model for carbon dioxide sequestration in deep saline carbonate aquifers. Comput. Geosci. 2011, 37, 1802–1815. [Google Scholar] [CrossRef]

- Cunningham, J.A.; Campbell, S.W.; Kumar, R. Effect of Temperature on the Geological Sequestration of CO2 in a Layered Carbonate Formation. J. Energy Resour. Technol. 2020, 142, 070907. [Google Scholar] [CrossRef]

- Izgec, O.; Zhu, D.; Hill, A.D. Numerical and experimental investigation of acid wormholing during acidization of vuggy carbonate rocks. J. Pet. Sci. Eng. 2010, 74, 51–66. [Google Scholar] [CrossRef]

- Izgec, O.; Demiral, B.; Bertin, H.; Akin, S. CO2 injection into saline carbonate aquifer formations I: Laboratory investigation. Transp. Porous Media 2007, 72, 1–24. [Google Scholar] [CrossRef]

- Wang, X.; Alvarado, V.; Swoboda-Colberg, N.; Kaszuba, J.P. Reactivity of dolomite in water-saturated supercritical carbon dioxide: Significance for carbon capture and storage and for enhanced oil and gas recovery. Energy Convers. Manag. 2013, 65, 564–573. [Google Scholar] [CrossRef]

- Grgic, D. Influence of CO2 on the long-term chemomechanical behavior of an oolitic limestone. J. Geophys. Res.-Solid Earth 2011, 116, B07201. [Google Scholar] [CrossRef]

- Ott, H.; Oedai, S. Wormhole formation and compact dissolution in single- and two-phase CO2-brine injections. Geophys. Res. Lett. 2015, 42, 2270–2276. [Google Scholar] [CrossRef]

- Yang, Y.F.; Li, Y.W.; Yao, J.; Iglauer, S.; Luquot, L.; Zhang, K.; Sun, H.; Zhang, L.; Song, W.H.; Wang, Z.Y. Dynamic Pore-Scale Dissolution by CO2-Saturated Brine in Carbonates: Impact of Homogeneous Versus Fractured versus Vuggy Pore Structure. Water Resour. Res. 2020, 56. [Google Scholar] [CrossRef]

- Khather, M.; Saeedi, A.; Myers, M.B.; Verrall, M. An experimental study for carbonate reservoirs on the impact of CO2-EOR on petrophysics and oil recovery. Fuel 2019, 235, 1019–1038. [Google Scholar] [CrossRef]

- Li, B.; Goldberg, K. Diagenesis and reservoir quality of Cambrian carbonates in the Tarim Basin, northwestern China. J. Asian Earth Sci. 2022, 223, 104972. [Google Scholar] [CrossRef]

- Pearce, J.K.; Kirste, D.M.; Dawson, G.K.W.; Farquhar, S.M.; Biddle, D.; Golding, S.D.; Rudolph, V. SO2 impurity impacts on experimental and simulated CO2–water–reservoir rock reactions at carbon storage conditions. Chem. Geol. 2015, 399, 65–86. [Google Scholar] [CrossRef]

- Chen, Y.; Sari, A.; Xie, Q.; Saeedi, A. Insights into the wettability alteration of CO2-assisted EOR in carbonate reservoirs. J. Mol. Liq. 2019, 279, 420–426. [Google Scholar] [CrossRef]

- Chen, Y.; Sari, A.; Xie, Q.; Brady, P.V.; Hossain, M.M.; Saeedi, A. Electrostatic Origins of CO2-Increased Hydrophilicity in Carbonate Reservoirs. Sci. Rep. 2018, 8, 17691. [Google Scholar] [CrossRef] [PubMed]

- Brady, P.V.; Carroll, S.A. Direct effects of CO2 and temperature on silicate weathering: Possible implications for climate control. Geochim. Cosmochim. Acta 1994, 58, 1853–1856. [Google Scholar] [CrossRef]

- Tetteh, J.T.; Barimah, R.; Korsah, P.K. Ionic Interactions at the Crude Oil–Brine–Rock Interfaces Using Different Surface Complexation Models and DLVO Theory: Application to Carbonate Wettability. ACS Omega 2022, 7, 7199–7212. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xie, Q.; Sari, A.; Brady, P.V.; Saeedi, A. Oil/water/rock wettability: Influencing factors and implications for low salinity water flooding in carbonate reservoirs. Fuel 2018, 215, 171–177. [Google Scholar] [CrossRef]

- Gao, D.; Lin, C.; Hu, M.; Yang, H.; Huang, L. Paleokarst of the Lianglitage Formation related to tectonic unconformity at the top of the Ordovician in the eastern Tazhong Uplift, Tarim Basin, NW China. Geol. J. 2018, 53, 458–474. [Google Scholar] [CrossRef]

- He, J.; Ding, W.; Li, A.; Sun, Y.; Dai, P.; Yin, S.; Chen, E.; Gu, Y. Quantitative microporosity evaluation using mercury injection and digital image analysis in tight carbonate rocks: A case study from the Ordovician in the Tazhong Palaeouplift, Tarim Basin, NW China. J. Nat. Gas Sci. Eng. 2016, 34, 627–644. [Google Scholar] [CrossRef]

- Xu, T.; Spycher, N.; Sonnenthal, E.; Zhang, G.; Zheng, L.; Pruess, K. TOUGHREACT Version 2.0: A simulator for subsurface reactive transport under non-isothermal multiphase flow conditions. Comput. Geosci. 2011, 37, 763–774. [Google Scholar] [CrossRef]

- Wan, Y.; Xu, T.; Pruess, K. Impact of fluid-rock interactions on enhanced geothermal systems with CO2 as heat transmission fluid. In Proceedings of the Thirty-Sixth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 31 January–2 February 2011. [Google Scholar]

- Pan, F.; McPherson, B.J.; Lichtner, P.; Karra, S.; Ré, C.L.; Kaszuba, J.P.; Lu, C.; Xu, T. Numerical simulations of interactions between supercritical CO2 and high-temperature fractured rocks in enhanced geothermal systmes. In Proceedings of the Thirty-Seventh Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 30 January–1 February 2012. [Google Scholar]

- Palandri, J.L.; Kharaka, Y.K. A Compilation of Rate Parameters of Water-Mineral Interaction Kinetics for Application to Geochemical Modeling; Geological Survey: Menlo Park, CA, USA, 2004. [Google Scholar]

- Lasaga, A.C.; Soler, J.M.; Ganor, J.; Burch, T.E.; Nagy, K.L. Chemical weathering rate laws and global geochemical cycles. Geochim. Cosmochim. Acta 1994, 58, 2361–2386. [Google Scholar] [CrossRef]

- Wolery, T.J. EQ3/6, a Software Package for Geochemical Modeling of Aqueous Systems: Package Overview and Installation Guide (Version 7.0); Lawrence Livermore National Lab.: Livermore, CA, USA, 1992. [Google Scholar]

- Cai, C.; Franks, S.G.; Aagaard, P. Origin and migration of brines from Paleozoic strata in Central Tarim, China: Constraints from 87Sr/86Sr, δD, δ18O and water chemistry. Appl. Geochem. 2001, 16, 1269–1284. [Google Scholar] [CrossRef]

- Wang, S. Experimental and Simulation Study of Carbon Dioxide Storage in Ordovician Carbonate Formation in Tabei Uplift, Tarim Basin. Master’s Thesis, China University of Geoscience, Wuhan, China, 2020. (In Chinese with English Abstract). [Google Scholar]

- Ma, X. Experiments and Numerical Study of CO2 Storage in Ordovician Carbonate Formations in the Tarim Basin, China. Bachelor’s Thesis, China University of Geoscience, Wuhan, China, 2021. (In Chinese with English Abstract). [Google Scholar]

- Casella, L.A.; Griesshaber, E.; Simonet Roda, M.; Ziegler, A.; Mavromatis, V.; Henkel, D.; Laudien, J.; Häussermann, V.; Neuser, R.D.; Angiolini, L.; et al. Micro- and nanostructures reflect the degree of diagenetic alteration in modern and fossil brachiopod shell calcite: A multi-analytical screening approach (CL, FE-SEM, AFM, EBSD). Palaeogeogr. Palaeoclimatol. Palaeoecol. 2018, 502, 13–30. [Google Scholar] [CrossRef]

- Hemes, S.; Desbois, G.; Urai, J.L.; Schröppel, B.; Schwarz, J.-O. Multi-scale characterization of porosity in Boom Clay (HADES-level, Mol, Belgium) using a combination of X-ray μ-CT, 2D BIB-SEM and FIB-SEM tomography. Microporous Mesoporous Mater. 2015, 208, 1–20. [Google Scholar] [CrossRef]

- Rabbani, A.; Ayatollahi, S. Comparing three image processing algorithms to estimate the grain-size distribution of porous rocks from binary 2d images and sensitivity analysis of the grain overlapping degree. Spec. Top. Rev. Porous Media Int. J. 2015, 6, 71–89. [Google Scholar] [CrossRef]

- Ezeakacha, C.; Rabbani, A.; Salehi, S.; Ghalambor, A. Integrated image processing and computational techniques to characterize formation damage. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 7–9 February 2018. [Google Scholar]

- Montes-Hernandez, G.; Findling, N.; Renard, F. Dissolution-precipitation reactions controlling fast formation of dolomite under hydrothermal conditions. Appl. Geochem. 2016, 73, 169–177. [Google Scholar] [CrossRef]

- Jonas, L.; Müller, T.; Dohmen, R.; Baumgartner, L.; Putlitz, B. Transport-controlled hydrothermal replacement of calcite by Mg-carbonates. Geology 2015, 43, 779–782. [Google Scholar] [CrossRef]

- Weyl, P.K. Porosity through dolomitization—Conservation-of-mass requirements. J. Sediment. Res. 1960, 30, 85–90. [Google Scholar] [CrossRef]

| Cases | Sample Type | Formations | Sampling Depth (m) | Calcite (wt%) | Dolomite (wt%) | Quartz (wt%) | Kaolinite (wt%) |

|---|---|---|---|---|---|---|---|

| Case 1 | Outcrops | YF | 478 | 97.31 | 1.63 | 1.05 | |

| Case 2 | Outcrops | LF | 540 | 95.08 | 3.07 | 1.85 | 2.09 |

| Case 3 | Rock core | LF | 4031.2 | 86.79 | 9.22 | 3.99 | 0.5 |

| Case 4 | Synthetic | 50 | 50 | 0 | 0 | ||

| Case 5 | Rock core | QF | 5100 | 4.12 | 94.39 | 1.49 | |

| Case 6 | Outcrops | QF | 219 | 0 | 100.00 | 0 | |

| Case 6 DI | Outcrops | QF | 219 | 0 | 100.00 | 0 |

| Formation | Depth (m) | pH | Na+ + K+ (g/L) | Mg2+ (g/L) | Ca2+ (g/L) | Cl− (g/L) | SO42+ (g/L) | HCO3− (g/L) | TDS (g/L) |

|---|---|---|---|---|---|---|---|---|---|

| Ordovician | 3853.38–3970.44 | 6.5–7 | 43.27 | 0.82 | 9.02 | 84.50 | 0.593 | 0.21 | 138.42 |

| Mineral | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 6 DI |

|---|---|---|---|---|---|---|---|

| Volume Fraction (%) | |||||||

| Calcite | 97.31 | 95.78 | 83.93 | 50.00 | 4.14 | 0.19 | 0.19 |

| Halite | 0 | 0 | 0 | 0 | 0 | 0.81 | 2.81 |

| Quartz | 1.05 | 1.49 | 3.66 | 0 | 1.49 | 0 | 0 |

| Kaolinite | 0 | 0 | 0.5 | 0 | 0 | 0 | 0 |

| Dolomite | 1.63 | 2.73 | 11.56 | 50.00 | 94.37 | 99.0 | 97.0 |

| Pyrite | 0.8 | ||||||

| Minerals | A (cm2/g) | Neutral | Acidic | Base | |||||

|---|---|---|---|---|---|---|---|---|---|

| k25 (mol/m2·s) | Ea (kJ/mol) | k25 (mol/m2·s) | Ea (kJ/mol) | n (H+) | k25 (mol/m2·s) | Ea (kJ/mol) | n (H+) | ||

| Primary | |||||||||

| Calcite | 0.89 a | 1.55 × 10−6 | 23.50 | 4.012 × 10−2 | 14.40 | 1.00 | 3.310 × 10−4 | 35.40 | 1.0 |

| Halite | 0.101 a | 5.40 × 10−1 | 7.40 | ||||||

| Quartz Kaolinite | 401 | 1.023 × 10−14 | 87.70 | ||||||

| 151.60 | 6.918 × 10−14 | 22.20 | 4.898 × 10−12 | 65.90 | 0.77 | 8.913 × 10−18 | 17.90 | 0.47 | |

| Dolomite | 0.008 a | 2.951 × 10−8 | 52.20 | 6.457 × 10−4 | 36.10 | 0.50 | |||

| Secondary | |||||||||

| Magnesite | 9.80 | 4.571 × 10−10 | 23.5 | 4.169 × 10−7 | 14.40 | 1.00 | |||

| Ankerite | 12.90 | 1.260 × 10−9 | 62.76 | 6.457 × 10−9 | 36.10 | 0.50 | |||

| Hematite | 9.80 | 2.512 × 10−15 | 66.20 | 4.074 × 10−10 | 66.20 | 1.00 | |||

| Montmorillonite | 9.8 | 3.020 × 10−13 | 88.0 | 7.762 × 10−12 | 88.0 | 0.5 | |||

| Smectite-Ca | 151.6 | 1.660 × 10−13 | 35.0 | 1.047 × 10−11 | 23.6 | 0.34 | 3.020 × 10−17 | 58.9 | −0.40 |

| Smectite-Na | 151.6 | 1.660 × 10−13 | 35.0 | 1.047 × 10−11 | 23.6 | 0.34 | 3.020 × 10−17 | 58.9 | −0.40 |

| Pyrite | 12.90 | k25 = 1.260 × 10−9 Ea = 62.76 n(O2(aq)) = 0.5 | k25 = 6.457 × 10−9 Ea = 56.10 n(H+) = −0.50, n(Fe3+) = 0.5 | ||||||

| Source | Primary Aqueous Species | Initial Concentration (mol/kg) |

|---|---|---|

| Measured values | H+ | 1.60 × 10−6 |

| Ca+2 | 2.08 × 10−1 | |

| Mg+2 | 4.52 × 10−2 | |

| Na+ | 1.83 × 10+0 | |

| K+ | 1.60 × 10−2 | |

| HCO3− | 4.80 × 10−3 | |

| SO4−2 | 9.20 × 10+0 | |

| Cl− | 2.33 × 10+0 | |

| H2O | 1.00 × 10+0 | |

| Assumed values | SiO2(aq) | 1.00 × 10−12 |

| AlO2− | 1.00 × 10−12 | |

| O2(aq) | 1.00 × 10−65 | |

| Fe | 1.00 × 10−12 |

| Cases | Samples | Calcite (wt%) | Dolomite (wt%) | Quartz (wt%) | Kaolinite (wt%) | Pyrite (wt%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | Before | After | |||

| Case 1 | YF (outcrop) | 97.83 | 95.21 | 1.10 | 1.71 | 1.05 | 3.08 | - | - | - |

| Case 2 | LF (outcrop) | 95.78 | 88.68 | 2.73 | 7.92 | 1.49 | 1.24 | - | 2.16 | - |

| Case 3 | LF (rock core) | 83.93 | 94.29 | 11.56 | 1.11 | 3.66 | 2.47 | 0.5 | 2.13 | 0.82 (before) |

| Case 4 | Synthetic | 50.0 | 48.13 | 50.0 | 51.24 | 0 | 0.62 | 0 | 0 | - |

| Case 5 | QF (rock core) | 4.14 | 3.4 | 94.37 | 93.34 | 1.49 | 2.41 | - | - | 0.85 (after) |

| Case 6 | QF (outcrop) | 0 | 0.34 | 100 | 99.34 | 0 | 0.32 | 0 | 0 | - |

| Case 6 DI | QF (outcrop) | 0 | 1.20 | 100 | 97.55 | 0 | 1.26 | 0 | 0 | - |

| Category | Cases | Mineral Abundance | Results |

|---|---|---|---|

| 1 | Case 1, Case 2 | Calcite, >90% | Calcite ↓, Dolomite ↑ |

| 2 | Case 3 | Calcite, 50–90% | Calcite ↓, Dolomite ↓ |

| 3 | Case 4 | Dolomite, 50–90% | Calcite ↓, Dolomite ↑ |

| 4 | Case 5, Case 6 | Dolomite, >90% | Calcite ↑, Dolomite ↓ |

| Cases | Porosity (Before) | Standard Deviation Pore Radius | Porosity (After) | Standard Deviation Pore Radius | Porosity Changes |

|---|---|---|---|---|---|

| Case 1 | 0.0592 | 1.48 | 0.082 | 1.904 | 0.023 |

| Case 2 | 0.098 | 1.19 | 0.16 | 1.28 | 0.062 |

| Case 3 | 0.19 | 2.23 | 0.17 | 1.05 | −0.020 |

| Case 4 | 0.139 | 2.82 | 0.175 | 1.903 | 0.036 |

| Case 5 | 0.23 | 2.09 | 0.27 | 0.93 | 0.07 |

| Case 6 | 0.09 | 1.4 | 0.016 | 1.7 | −0.074 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmat, K.; Cheng, J.; Yu, Y.; Zhao, R.; Li, J. CO2-Water-Rock Interactions in Carbonate Formations at the Tazhong Uplift, Tarim Basin, China. Minerals 2022, 12, 635. https://doi.org/10.3390/min12050635

Ahmat K, Cheng J, Yu Y, Zhao R, Li J. CO2-Water-Rock Interactions in Carbonate Formations at the Tazhong Uplift, Tarim Basin, China. Minerals. 2022; 12(5):635. https://doi.org/10.3390/min12050635

Chicago/Turabian StyleAhmat, Kaisar, Jianmei Cheng, Ying Yu, Ruirui Zhao, and Jie Li. 2022. "CO2-Water-Rock Interactions in Carbonate Formations at the Tazhong Uplift, Tarim Basin, China" Minerals 12, no. 5: 635. https://doi.org/10.3390/min12050635

APA StyleAhmat, K., Cheng, J., Yu, Y., Zhao, R., & Li, J. (2022). CO2-Water-Rock Interactions in Carbonate Formations at the Tazhong Uplift, Tarim Basin, China. Minerals, 12(5), 635. https://doi.org/10.3390/min12050635