Abstract

In this paper, the uniaxial compression tests of coal under different loading rates are carried out by using the MTS rock mechanics loading system and the DS5 acoustic emission instrument, and the mechanical parameters and damage characteristics of coal samples under five loading rates are studied. The conclusions are as follows: The uniaxial compressive strength and the elastic modulus of the sample increase with the increase in the loading rate, whereas the strain at the peak point of stress decreases with the increase in the loading rate; at a low loading rate, the AE ring count of the coal samples is widely distributed, but the maximum AE ring count value is small. At a high loading rate, the AE ring count of the coal samples decreases, whereas the maximum AE ring count value increases significantly. With the increase in the loading rate, the maximum AE ring count and cumulative AE ring count of the sample increase. According to the damage variable curves of the coal samples under different loading rates, the damage evolution process of the samples before the stress peak is roughly divided into three stages: initial damage stage, stable damage development stage and rapid damage development stage. It is found that when the loading rate is low, the deformation time of the coal sample is relatively sufficient, whereas when the loading rate is high, the micro cracks have no time to develop and expand, the sample is destroyed instantly and the destruction of the coal sample is sudden. Therefore, with the increase in the loading rate, the damage variable value at the peak stress of the coal sample generally shows an increasing trend.

1. Introduction

China’s coal mining depth has become deeper and deeper, resulting in many adverse factors such as high ground stress, high gas pressure and high ground temperature. Therefore, China’s mining engineering is facing many new challenges [1,2,3]. The mining process, including the mining of coal seams, causes deformation and damage to the surrounding coal and rock mass, which will change the initial stress state and lead to stress redistribution around the boundary of the excavation [4,5,6,7,8]. In this process, the pores and fractures of the coal and rock masses are expanded and closed repeatedly, resulting in different degrees of damage. At the same time, different advancing speeds will lead to changes in the stress loading rate of the square mass of coal and rock in front of the working face, resulting in different degrees of damage to the coal and rock mass, and the reasonable advancing speed of the working face is helpful to prevent disasters such as a rock burst and coal and gas outbursts [9,10,11,12,13]. With the development of coal mining technology, the advancing speed of the working face is accelerating day by day, and different advancing speeds have a particularly prominent impact on mining space. Therefore, it is very important to study the mechanical properties and damage characteristics of coal samples under different loading rates.

Scholars have conducted substantial research on the loading rate effect and achieved many results, which has made an important contribution to the development of theory and practice. Pan et al. studied the charge induction law of coal, granite and sandstone under different loading rates by using the self-developed coal–rock charge induction uniaxial compression test system [14]. Mao et al. obtained the influence law of loading rate on the mechanical properties of limestone through the uniaxial compression experiment [15].

Li obtained the variation laws of different mechanical indexes of red sandstone through the uniaxial compression experiment at different temperatures [16]. Yin et al. simulated the failure mode of rock under different loading rates by programming, and obtained the failure law of rock [17]. Alam et al. studied the mechanical behavior of sandstone under static and dynamic compressive strain rates [18]. Su and Xu carried out an experimental analysis on the loading rate effect of sandstone and marble under high temperatures [19,20]. Bieniawskiz and Peng carried out experimental research on fine sandstone and tuff under different loading rates [21,22]. In addition, the analysis of the loading rate effect is also reflected in rock permeability [23], acoustic emission fracture [24,25] and impact fracture research [26,27]. Summarizing the current research results, it is found that there are two different views on the analysis of the fracture mode and the degree of coal and rock mass materials when the loading rate increases [28]. Viewpoint 1 holds that under a low loading rate, a few cracks participate in the macro failure of the rock, there are few macro fracture surfaces and the failure degree is light; the rock under a high loading rate is involved in macro failure by multiple cracks, with more macro fracture surfaces and a heavier failure degree [28,29,30,31]. Viewpoint 2 is opposite to viewpoint 1 [32,33].

Therefore, it is found that the research on the loading rate effect in the fracture process of coal mass is still limited. Based on this, the uniaxial compression tests of coal under five loading rates are carried out in this paper. The damage characteristics of coal under different loading rates are studied based on an AE ring count. This research provides an improved characterization of the level of damage sustained by coal samples under different loading rates.

2. Test Process

The test samples were collected from a mine in the Henan province. In order to ensure the consistency of the basic properties of the coal samples taken, the samples were taken from the same roadway of the protected layer from a buried depth of about 700 m. The collected coal samples were wrapped with cling film and packed in a wooden box. The sides of the wooden box were filled with wood chips to prevent the samples from being damaged during transportation.

The sample processing was carried out in accordance with the relevant provisions of the coal industry standard Determination Method of physical and mechanical Properties of Coal and rock [34]. First, a cylindrical sample with a diameter of 50 mm was drilled with a coring drill, and then the coal sample was sawed into a cylinder with a height of 100 mm with a stone saw machine. Finally, the two ends of the coal sample were ground flat with a grinding machine. The non-parallelism of the two ends of the specimen was required to be less than 0.01 mm and the diameter deviation was less than 0.02 mm. The standard samples were wrapped with plastic wrap and placed in a curing box for maintenance.

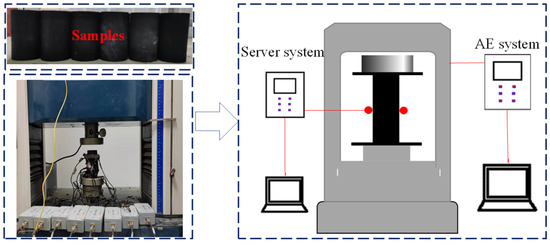

The test loading device was the MTS uniaxial compression testing machine, and the displacement control mode was selected to carry out the test. Five loading rates were set in the test, which are 0.002 mm/s, 0.006 mm/s, 0.01 mm/s, 0.014 mm/s and 0.018 mm/s, respectively; the DS5 acoustic emission parameter acquisition device was adopted.

Under the action of external force, the stress concentration phenomenon occurs in the initial fracture region within the samples, and the micro-fractures generate and propagate continuously inside the samples. In addition, strain energy accumulates in this process, and the release form of strain energy is the elastic wave.

During the test, through the environmental noise test, the threshold value of the acoustic emission system was set to 40 dB and the sampling frequency was set to 1 MHz. Each channel corresponded to an independent acoustic emission probe and preamplifier, and the amplification factor of the signal amplifier was 40 times. After setting the parameters according to the above requirements, the experimental equipment was connected. Test equipment and test samples are shown in Figure 1.

Figure 1.

Test equipment and test samples.

3. Results Analysis

3.1. Analysis of Mechanical Characteristics of Coal under Different Loading Rates

3.1.1. Stress–Strain Curve

Before the test, the diameter, height and mass of the coal was measured and the density was calculated. Finally, the average mass of the coal was 251.32 g and the average density was 1.28 g/cm3.

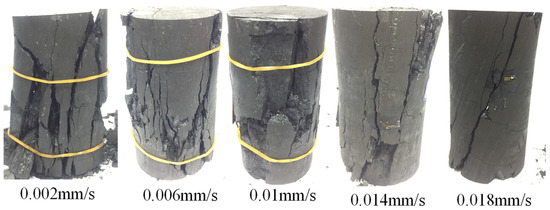

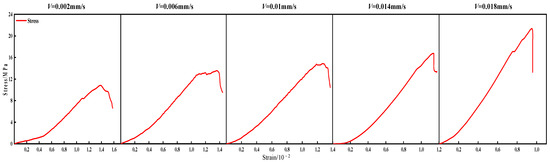

The uniaxial compression test of the coal samples was carried out by the displacement control. Pictures of coal-like destruction are shown in Figure 2; the stress–strain curve of the coal samples is shown in Figure 3.

Figure 2.

Final failure mode of coal sample.

Figure 3.

Stress–strain curve.

According to the change trend of the stress–strain curve of the sample under the five loading rates in Figure 3, it is found that when the loading rate is low, the compaction stage of the coal sample is longer, whereas with the increase in the loading rate, the compaction stage of the sample gradually decreases. By observing the post-peak part of the five curves, it is found that when the loading rate is small, the decline trend of the post-peak curve of the sample is slow, whereas when the loading rate is high, the slope of the post-peak curve of the sample is 90°, that is, the greater the loading rate is, the more obvious the brittle failure characteristics of the sample are.

3.1.2. Analysis of Peak Stress and Strain under Different Loading Rates

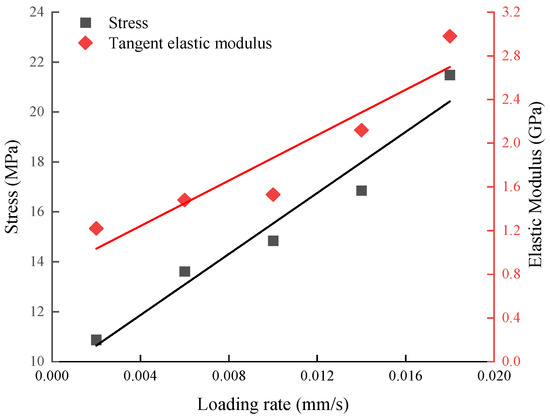

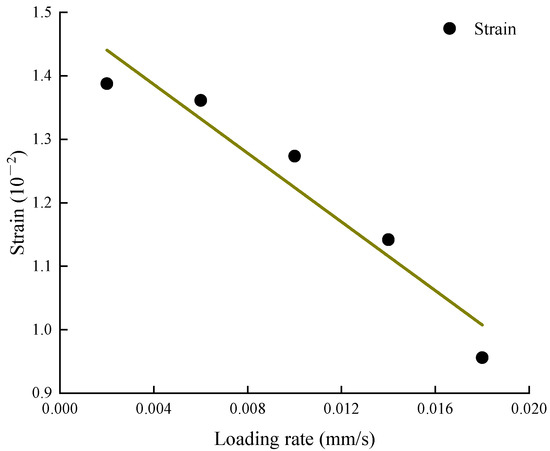

According to the stress and strain data in Figure 3, the uniaxial compressive strength, tangent elastic modulus and the corresponding strain value at the peak stress of the sample are extracted and calculated. The variation trend of the mechanical parameters of the sample under different loading rates is shown in Figure 4 and Figure 5.

Figure 4.

Stress–strain curve.

Figure 5.

Variation Trend of corresponding strain value at stress peak.

The change of the mechanical parameters under different loading rates is shown in Table 1.

Table 1.

Mechanical parameters of coal samples under different loading rates.

It can be seen from Figure 4 and Figure 5 that the uniaxial compressive strength and the elastic modulus of the sample increase with the increase in the loading rate, whereas the peak strain of the sample decreases with the increase in the loading rate. Compared with the coal sample with a loading rate of 0.002 mm/s, the uniaxial compressive strength and the elastic modulus ratio of the sample with a loading rate of 0.006 mm/s are increased by 25.22% and 21.31%, respectively; the uniaxial compressive strength and the elastic modulus ratio of the samples with a loading rate of 0.01 mm/s are increased by 36.51% and 25.41%, respectively; the uniaxial compressive strength and the elastic modulus ratio of the samples with a loading rate of 0.014 mm/s are increased by 55.02% and 73.77%, respectively; the uniaxial compressive strength and the elastic modulus ratio of the specimen with a loading rate of 0.018 mm/s are increased by 97.61% and 144.26%, respectively. As can be seen from Figure 3, the peak strain of the coal sample decreases slowly at a low loading rate, whereas it decreases greatly at a high loading rate.

3.2. Analysis of Acoustic Emission Characteristics of Coal Samples under Different Loading Rates

3.2.1. Variation Characteristics of AE Ringing Counting Curve of Coal Samples

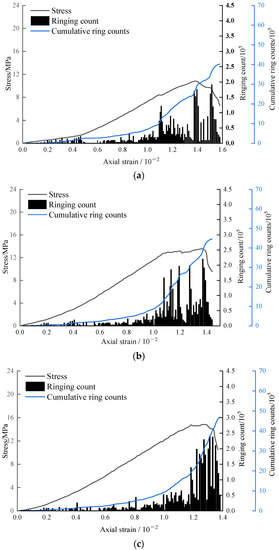

During the uniaxial compression test, the acoustic emission signals were collected synchronously to obtain the AE ring count during the failure of the sample. By accumulating the AE ring count, the cumulative AE ring count during the loading period of the sample was obtained. The relationship curve of the stress–strain AE signal of the coal sample under different loading rates is shown in Figure 6.

Figure 6.

Variation Characteristics of AE parameters of coal samples under different loading rates: (a) V = 0.002 mm/s (b) V = 0.006 mm/s (c) V = 0.01 mm/s (d) V = 0.014 mm/s (e) V = 0.018 mm/s.

It can be seen from Figure 6 that the change trend of the AE ringing count curve of the coal under five loading rates is in good agreement with the change trend of the stress–strain curve of the coal samples. Additionally, it is found that under a low loading rate, the AE ringing count of the coal samples is widely distributed, and the corresponding AE signal appears in each stress stage, but the strongest AE signal value is small. At a high loading rate, the AE ring count of the coal sample decreases, whereas the maximum AE signal value increases significantly.

3.2.2. Variation Characteristics of AE Ringing Count at Peak Stress Point of Coal Sample

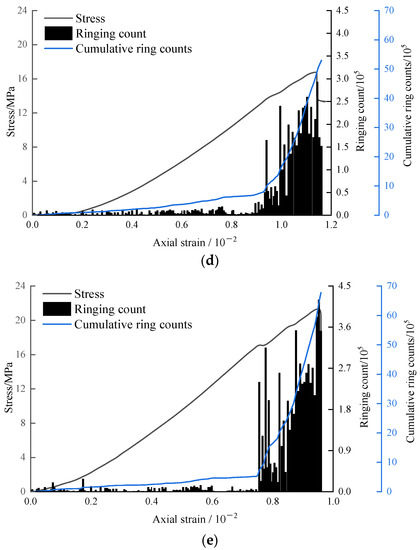

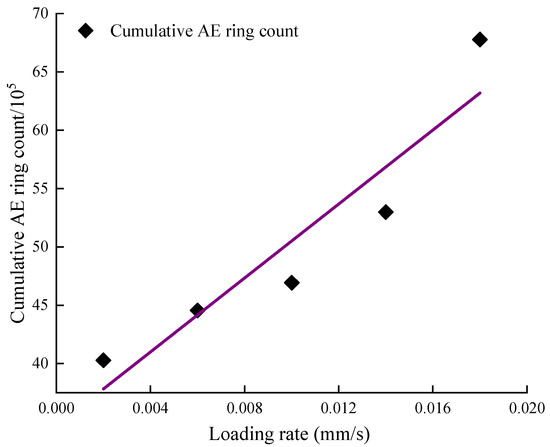

The variation relationship between the maximum AE ring count and the cumulative AE ring count with a loading rate is shown in Figure 7 and Figure 8.

Figure 7.

Variation of maximum AE ring counts with increasing loading rate.

Figure 8.

Variation of cumulative AE ring counts with increasing loading rate.

It can be seen from Figure 7 and Figure 8 that the maximum AE ring count and the cumulative AE ring count of the sample tend to increase with the increase in the loading rate. The reason is that under the low loading rate, the micro cracks in the coal sample develop slowly, and they have sufficient time to expand. When the loading rate increases, the micro cracks have no time to develop and expand. When the stress applied to the sample reaches the compressive strength of coal, the sample is heavily damaged instantly, resulting in a significant increase in the acoustic emission signal. Therefore, the AE peak ringing count of the coal sample increases with the increase in the loading rate. When the loading rate is low, the coal sample experiences a long time of loading damage, and the acoustic emission equipment receives more signals, but the AE signal level strength is low. When the loading rate increases, the coal sample damage time is shortened and the received signals are less, but the AE signal level strength when the sample is damaged is high. Therefore, the cumulative count of the acoustic emission of the coal sample increases with the increase in the loading rate.

3.3. Analysis of Damage Evolution Characteristics of Coal Samples Based on AE Ring Counting

3.3.1. Coal Sample Damage Model Based on AE Ring Counting

Acoustic emission technology has been successfully applied to study the damage and fracture process of materials. AE ring count is one of the characteristic parameters that can better reflect the changes of material properties, because it is proportional to the strain energy released by the dislocation movement of materials, inclusions, stripping and fracture of second phase particles and crack propagation. The damage variable can better reflect the damage degree of samples in different stages. Therefore, the establishment of a sample damage model based on the AE ring count can better analyze the damage process of samples.

The damage variable is calculated as follows:

where is the damage variable of the sample; is all areas of micro defects on the bearing section; is the cross-sectional area without initial damage.

Assuming that the cumulative acoustic emission ring count is when the whole section of the nondestructive material is completely destroyed, the acoustic emission ring count is when the micro element of the unit area is destroyed:

When the damage area of the section reaches the cumulative acoustic emission ring count is :

Namely:

Bring Formula (4) into Formula (1) to obtain the following formula:

3.3.2. Analysis of Loading Rate Effect on Damage Evolution of Coal Samples

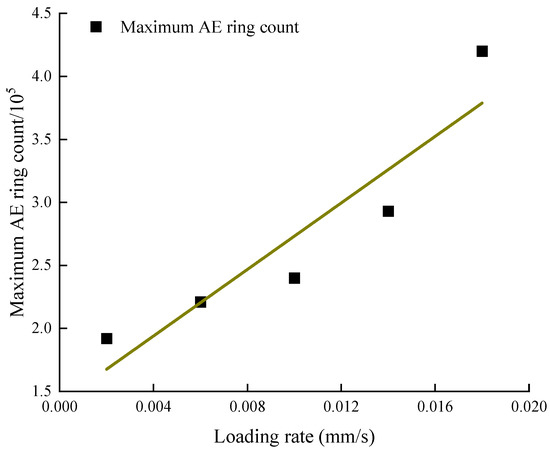

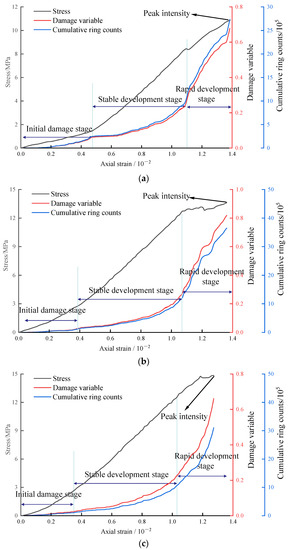

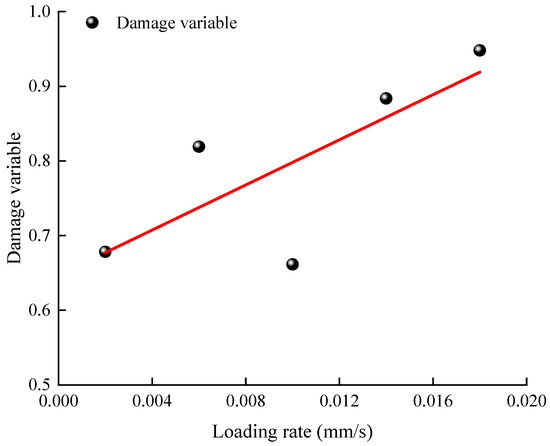

According to the above formula, the damage variable and the strain relationship curve of the sample under different loading rates are obtained, as shown in Figure 9.

Figure 9.

Variation Characteristics of damage variables of coal samples under different loading rates: (a) V = 0.002 mm/s (b) V = 0.006 mm/s (c) V = 0.01 mm/s (d) V = 0.014 mm/s (e) V = 0.018 mm/s.

By analyzing the damage variable curves of the coal samples under different loading rates in Figure 9, it can be seen that the damage evolution process of the samples before the peak can be roughly divided into three stages: initial damage stage, stable development stage of damage and rapid development stage of damage. Initial damage stage: the damage variable in this stage is very small, which is mainly due to the compaction of the original crack in the sample at the initial stage of loading, resulting in a small amount of AE signal. Stable development stage of damage: In this stage, the damage variable begins to grow steadily (damage curve), because this stage is in the linear elastic stage. Under the continuous loading state, the sample begins to produce recoverable deformation. However, the new cracks initiated in this stage are scattered in different positions of the sample, and the amount of new cracks is small, so the growth rate of the damage variable in this stage is relatively slow. Rapid development stage of damage: In this stage, the damage variable increases rapidly and the samples enter the plastic deformation stage, subsequent to the elastic deformation stage. The internal microcracks and micropores produce large-scale new cracks, which expand, converge and connect rapidly. The development of damage in this stage is relatively active.

In Figure 9, the change trend of the cumulative AE ringing count curve and the damage curve of the sample is relatively consistent, which shows that the damage model can better reflect the damage and damage degree of the sample during loading.

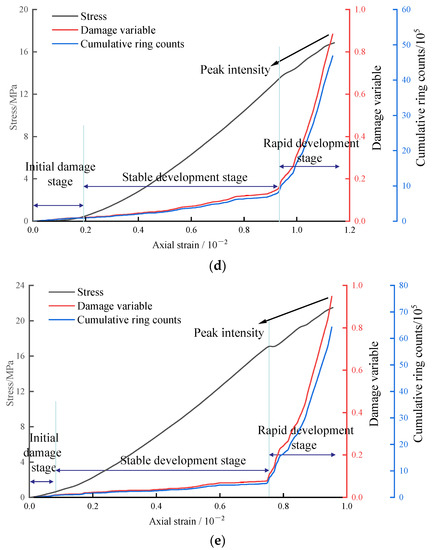

The damage variable value at the peak strength of the coal sample can reflect the severity of damage and the speed of damage evolution. The change characteristics of the damage variable at the peak stress of the coal sample under different loading rates are shown in Figure 10.

Figure 10.

Relationship between damage variable at the peak stress and loading rate.

According to Figure 10, with the increase in the loading rate, the damage variable value at the peak stress of the coal sample generally shows an increasing trend. This is because under the low loading rate, the deformation time of the coal sample under the action of external force is relatively sufficient, and the coal sample is still not directly damaged after reaching its maximum bearing capacity. Therefore, the damage of the coal sample is slow. After the stress peak, the coal sample is still deformed continuously, and the AE ring count is also generated continuously; the damage variable at the peak stress of the coal sample under a low loading rate is small. At the high loading rate, the micro crack has no time to develop and expand. When the coal sample reaches its maximum bearing capacity, the sample is destroyed instantly. The destruction of the coal sample is sudden, so the AE ringing count reaches the maximum at this point. Therefore, the damage variable of the coal sample at the peak stress under the high loading rate is large.

At a low loading rate, the damage curve of the specimen experienced the initial damage stage and the stable growth stage of damage, and then slowly entered the rapid development stage of damage; at a high loading rate, the damage curve of the sample suddenly entered the rapid development stage from the stable growth stage of damage, and after entering the rapid development stage of damage, the damage and failure of the sample was completed in a short time, showing obvious brittle failure characteristics.

Therefore, the failure time of the coal samples under a low loading rate is long and the failure degree is relatively complete; however, the failure of the coal samples under a high loading rate is sudden. This phenomenon shows that in the actual mining process, propulsion speed that is too fast will cause sudden damage to the coal body in front of the working face, resulting in accidents. Therefore, a reasonable propulsion speed must be selected in the actual mining process.

4. Conclusions

In this paper, the uniaxial compression tests of coal under different loading rates are carried out by using the MTS rock mechanics loading system and the DS5 acoustic emission instrument. The damage characteristics of the coal samples under five loading rates are studied based on the damage model of AE ring counting. The conclusions are as follows:

The uniaxial compressive strength and the elastic modulus of the sample increase with the increase in the loading rate, whereas the peak strain decreases with the increase in the loading rate. According to the change trend of the stress–strain curve, the larger the loading rate is, the less the failure surface of the test is, but the failure is sudden, and its brittle failure characteristics are obvious.

At a low loading rate, the AE ring count of the coal samples is widely distributed, but the maximum AE ring count value is small. At a high loading rate, the AE ring count of the coal samples decreases, whereas the maximum AE ring count value increases significantly. With the increase in the loading rate, the maximum AE ring count and the cumulative AE ring count of the sample tend to increase.

According to the damage variable curves of the coal samples under different loading rates, the damage evolution process of the samples before the stress peak is roughly divided into three stages, namely, the initial damage stage, the stable development stage of damage and the rapid development stage of damage.

Under the low loading rate, the deformation time of the coal sample is relatively sufficient, whereas under the high loading rate, the micro crack has no time to develop and expand, the sample is destroyed instantly and the destruction of the coal sample is sudden. Therefore, with the increase in the loading rate, the damage variable value at the peak stress of the coal sample generally shows an increasing trend.

Author Contributions

Conceptualization, J.X.; methodology, S.W.; formal analysis, Z.H.; data curation, Y.D.; writing—original draft preparation, S.W.; writing—review and editing, Q.Y.; funding acquisition, J.X. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Natural Science Foundation of China (5197042023).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- He, M.C.; Xie, H.P.; Peng, S.P.; Jiang, Y.D. Study on rock mechanics in deep mining engineering. Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Xie, H.P.; Gao, F.; Ju, Y.; Gao, M.Z.; Zhang, R.; Gao, Y.N.; Liu, J.F.; Xie, L.Z. Quantitative definition and investigation of deep mining. J. China Coal Soc. 2015, 40, 1–10. [Google Scholar]

- Lan, H.; Chen, D.K.; Mao, D.B. Current status of deep mining and disaster prevention in China. Coal Sci. Technol. 2016, 44, 39–46. [Google Scholar]

- Chen, C.J.; Zhao, Y.J.; Zhang, H.G.; Guo, S.L. Comparative Study on Mechanical and Permeability Characteristics of Raw Coal and Briquettes under Different Loading Rates. Min. Saf. Environ. Prot. 2019, 46, 23–27. [Google Scholar]

- Xie, H.P.; Zhou, H.W.; Liu, J.F.; Gao, F.; Zhang, R.; Xue, D.J.; Zhang, Y. Mining induced mechanical behavior in coal seams under different mining layouts. J. China Coal Soc. 2011, 36, 1067–1074. [Google Scholar]

- Xie, J.; Gao, M.Z.; Zhang, R.; Ren, L.; Peng, G.Y.; Ai, T.; Yang, B.G. Experimental investigation on the gas flow characteristics of coal samples with different fracture network complexities. J. Nat. Gas. Sci. Eng. 2020, 82, 103487. [Google Scholar]

- Bažant, Z.P.; Shang–Ping, B.; Ravindra, G. Fracture of rock: Effect of loading rate. Eng. Fract. Mech. 1993, 45, 393–398. [Google Scholar]

- Oggeri, C.; Oreste, P.; Spagnoli, G. Creep behaviour of two–component grout and interaction with segmental lining in tunnelling. Tunn. Undergr. Space Technol. 2022, 119, 104216. [Google Scholar]

- Ning, J.G.; Wang, J.; Liu, X.S.; Qian, K.; Sun, B. Soft–strong supporting mechanism of gob-side entry retaining in deep coal seams threatened by rockburst. Int. J. Min. Sci. Technol. 2014, 24, 805–810. [Google Scholar]

- Liu, F.; Yu, Y.J.; Cao, L.Z.; Zhang, W. Constitutive model of soft rock disturbance creep based on disturbance factor. J. China Coal Soc. 2018, 43, 2758–2764. [Google Scholar]

- Gao, M.Z.; Xie, J.; Gao, Y.N.; Wang, W.; Li, C.; Yang, B.; Liu, J.; Xie, H.P. Mechanical behavior of coal under different mining rates: A case study from laboratory experiments to field testing. Int. J. Min. Sci. Technol. 2021, 31, 17. [Google Scholar]

- Kan, J.G.; Yang, S.; Zhang, N. Research on influencing factors of excavation disturbance. J. Min. Saf. Eng. 2014, 31, 932–937. [Google Scholar]

- Wang, B.; Gao, C.Y.; Chen, X.X.; Liu, C. Triaxial test system for rock rheological perturbation effect. J. China Coal Soc. 2018, 43, 403–411. [Google Scholar]

- Pan, Y.S.; Tang, Z.; Li, Z.H.; Zhu, L.Y.; Li, G.Z. Research on the charge inducing regularity of coal rock at different loading rate in uniaxial compression tests. Chin. J. Geophys. 2013, 56, 1043–1048. [Google Scholar]

- Mao, X.B.; Liu, R.Y.; Zhang, L.Y. Effect of loading rate on mechanical properties of limestone at different temperature. China Sci. Pap. 2014, 9, 574–577. [Google Scholar]

- Li, Y.S. Experimental analysis on the mechanical effects of loading rates on red sandstone. J. Tongji Univ. 1995, 23, 265–269. [Google Scholar]

- Yin, X.T.; Ge, X.R.; Li, C.G.; Wang, S.L. Influences of loading rates on mechanical behaviors of rock materials. Chin. J. Rock Mech. Eng. 2010, 29, 610–2615. [Google Scholar]

- Alam, M.S.; Chakraborty, T.; Matsagar, V.; Rao, S.K. Characterization of kota sandstone under different strain rates in uniaxial loading. Geo. Geol. Eng. 2015, 33, 143–152. [Google Scholar]

- Su, H.J.; Jing, H.W.; Zhao, H.H. Experimental investigation on loading rate effect of sandstone after high temperature under uniaxial compression. Chin. J. Geo. Eng. 2014, 36, 1064–1071. [Google Scholar]

- Xu, J.Y.; Liu, S. Effect of impact velocity on dynamic mechnaical behaviors of marble after high temperatures. Chin. J. Geo. Eng. 2013, 35, 879–883. [Google Scholar]

- Bieniawski, Z.T. Time–dependent behaviour of fractured rock. Rock Mech. Rock Eng. 1970, 2, 123–137. [Google Scholar]

- Peng, S.S. Time–dependent aspects of rock behavior as measured by a servo controlled hydraulic testing machine. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1973, 10, 235–246. [Google Scholar]

- Gao, F.; Feng, Z.J.; Gao, Y.; Shen, Y.X. Study on evolution laws of sandstone permeability under different loading rates. Min. Res. Dev. 2018, 38, 52–55. [Google Scholar]

- Li, J.H. Study on the acoustic emission and damage characteristics of rock under different unloading rates. Min. Res. Dev. 2018, 38, 91–95. [Google Scholar]

- Ma, D.P. Creep behavior and acoustic emission characteristics of coal samples with different moisture content. Acta Geodyn. Geomater. 2018, 15, 405–412. [Google Scholar]

- Hao, J.W.; Li, Z.J.; Yang, M.H.; Cheng, H.J. Study on the strength constitutive model of magnetite ore under the dynamic loading test. Min. Res. Dev. 2018, 38, 49–53. [Google Scholar]

- Li, Z.J.; Hao, J.W.; Gan, D.Q.; Liu, Z.Y. An experimental study on the failure characteristics of magnetite ore based on dynamic load. J. Vib. Shock. 2019, 38, 231. [Google Scholar]

- Wang, X.D.; Wang, K. Effect of loading rate on mechanical properties and energy conversion mechanism of granite fracture. Saf. Coal Mines 2020, 51, 31–35. [Google Scholar]

- Deng, H.F.; Wang, C.X.J.; Li, J.L.; Zhang, Y.C.; Wang, W.; Zhang, H.B. Influence mechanism of loading rate on tensile strength of sandstone. Rock Soil Mech. 2018, 39, 79–88. [Google Scholar]

- Chen, P.Y. Loading rate effect analysis on rock particle flow model under uniaxial compression. Chin. J. Undergr. Space Eng. 2018, 14, 635. [Google Scholar]

- Pu, C.; Chen, Y.S.; Zhou, C.; Li, G.M. Displacement loading rate of rock–like specimen under uniaxial compress test. J. Water Resour. Archit. Eng. 2018, 16, 161–164. [Google Scholar]

- Luo, K.; Zhao, G.D.; Zeng, J.J.; Zhang, X.X.; Pu, C.Z. Fracture experiments and numerical simulation of cracked body in rock–like materials affected by loading rate. Chin. J. Rock Mech. Eng. 2018, 37, 1833–1842. [Google Scholar]

- Liu, J.X.; Liu, W.; Yang, C.H.; Huo, L. Experimental research on effects of strain rate on mechanical properties of shale. Rock Soil Mech. 2014, 35, 3093. [Google Scholar]

- National Standard Writing Group of the People’s Republic of China. Measurement of Physical Mechanical Mechanical Properties of Coal and Rocks; China Standard Due: Beijing, China, 2009. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).