Study on the Stress Field and Crack Propagation of Coal Mass Induced by High-Pressure Air Blasting

Abstract

:1. Introduction

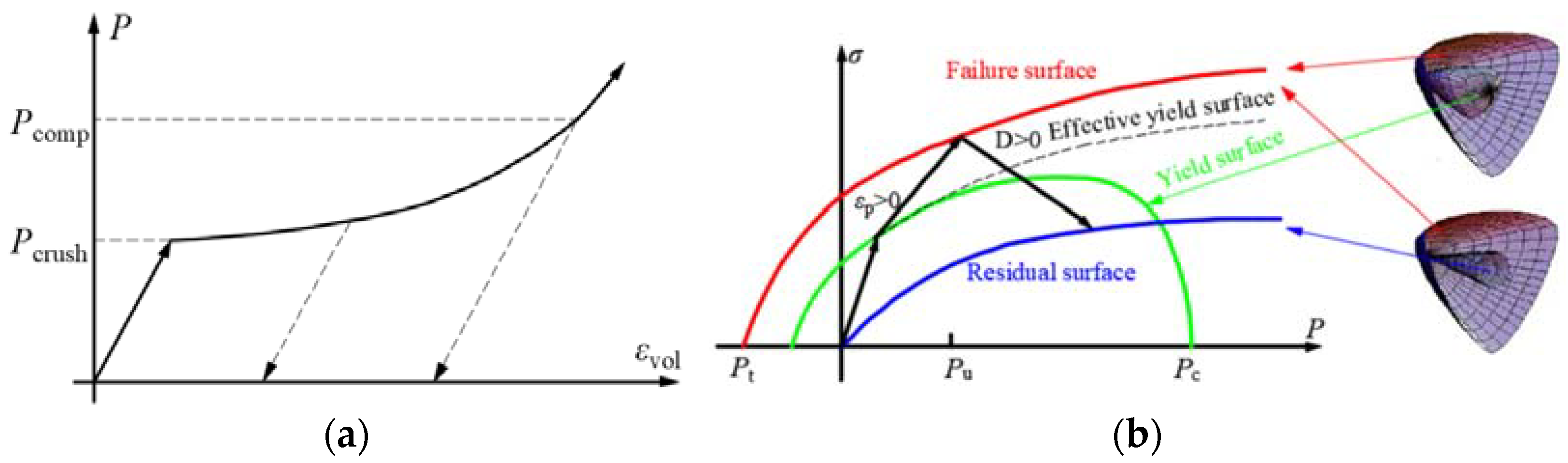

2. Constitutive Model and Parameters for Coal Mass

2.1. RHT Constitutive Model for Coal Mass

2.2. Determination of RHT Model Parameters

2.2.1. Determination of the Parameters of the p-α Equation of State

2.2.2. Determination of the Residual Parameters of the RHT Model

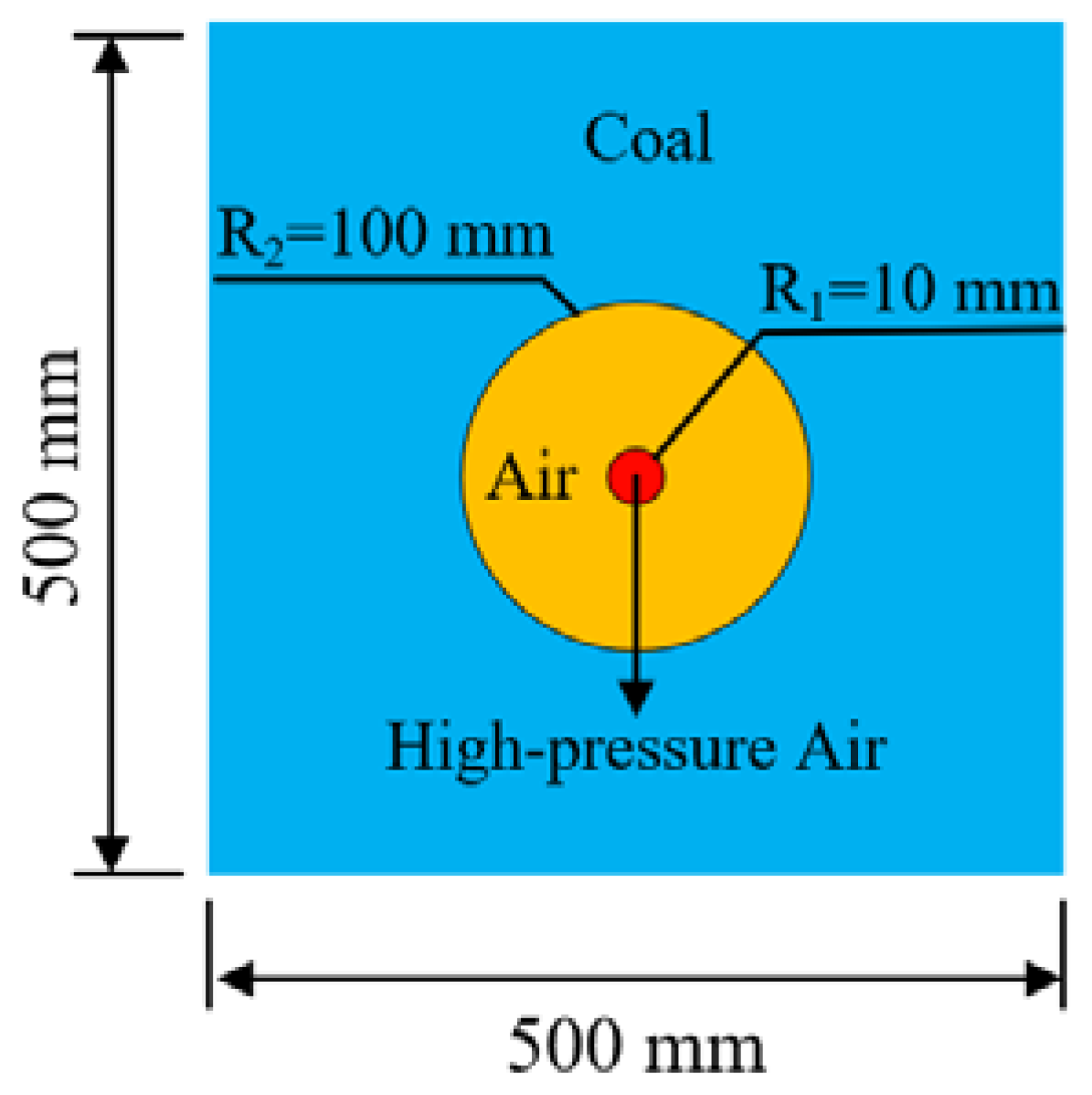

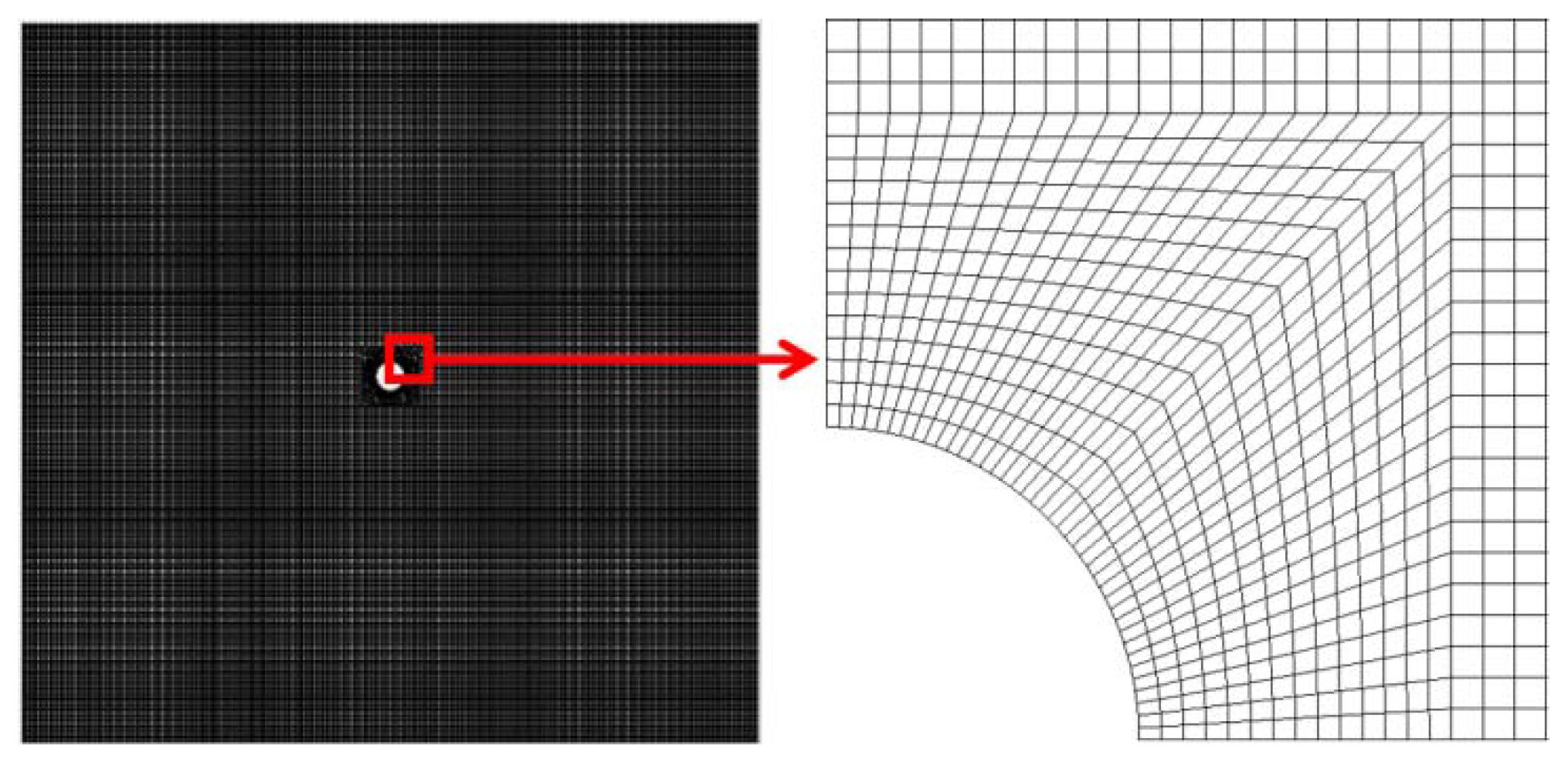

3. Numerical Simulation of High-Pressure Gas Impact on Coal Mass

3.1. Numerical Modeling of HPAB

3.2. Calculation of Explosive Equivalents

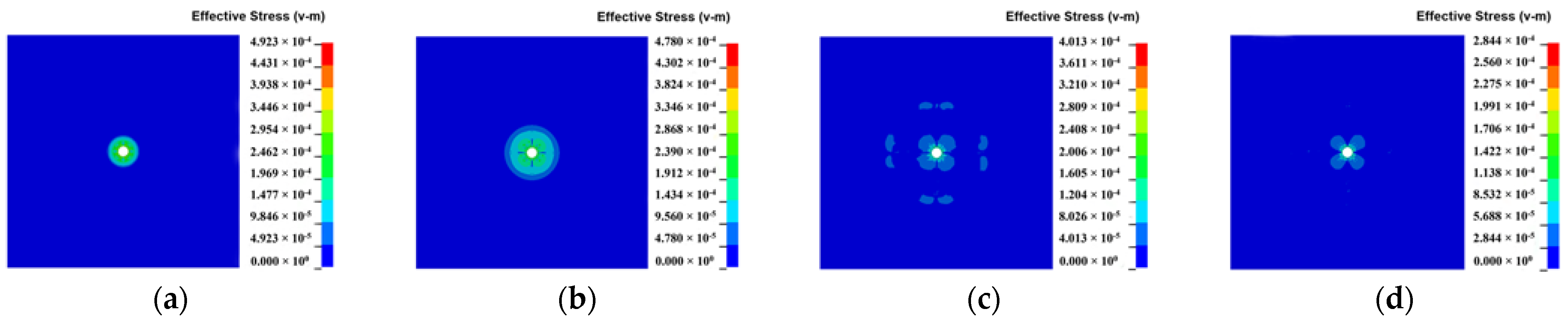

4. Analysis of Crack Propagation Process of Coal Mass Induced by HPAB

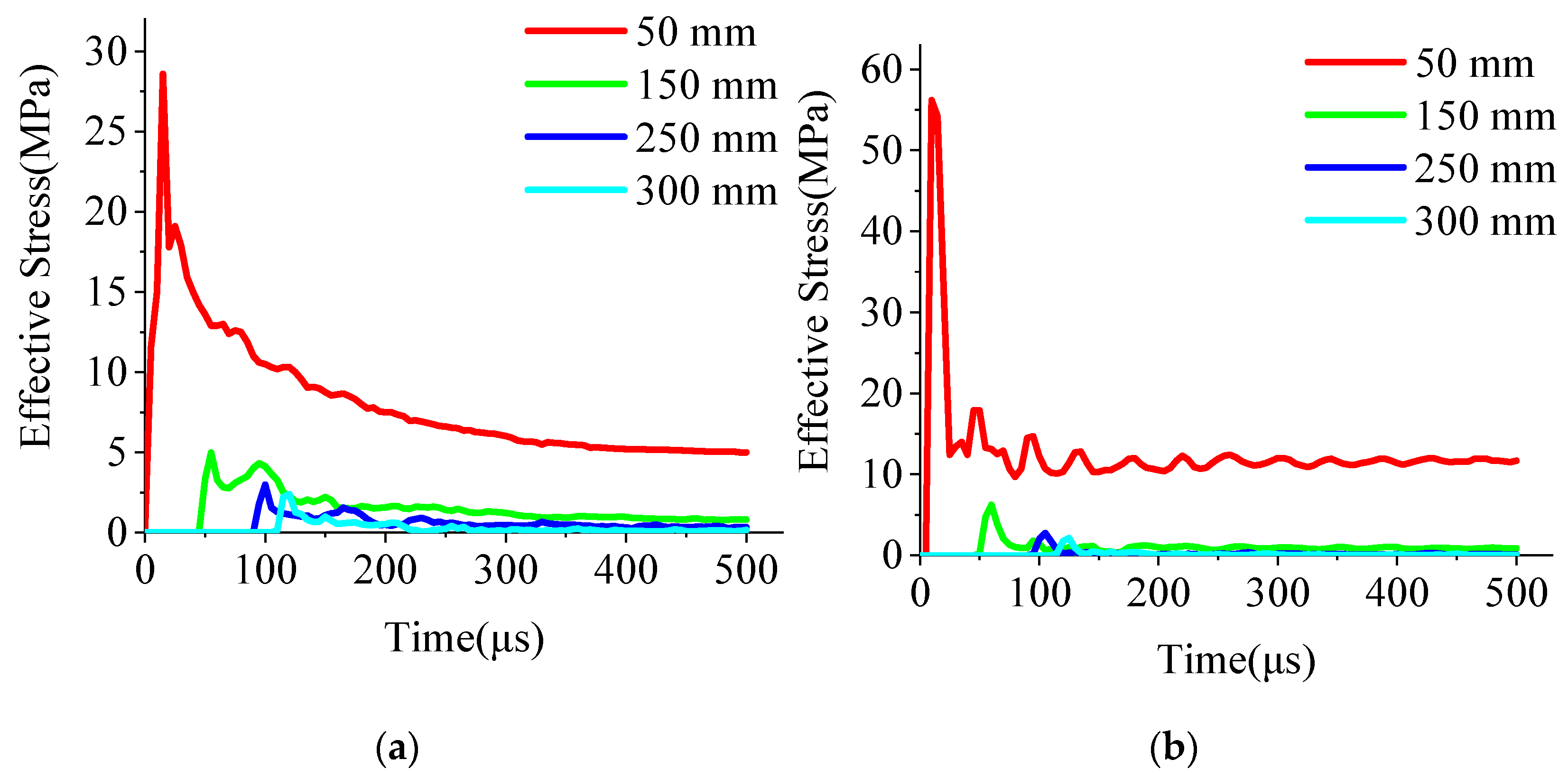

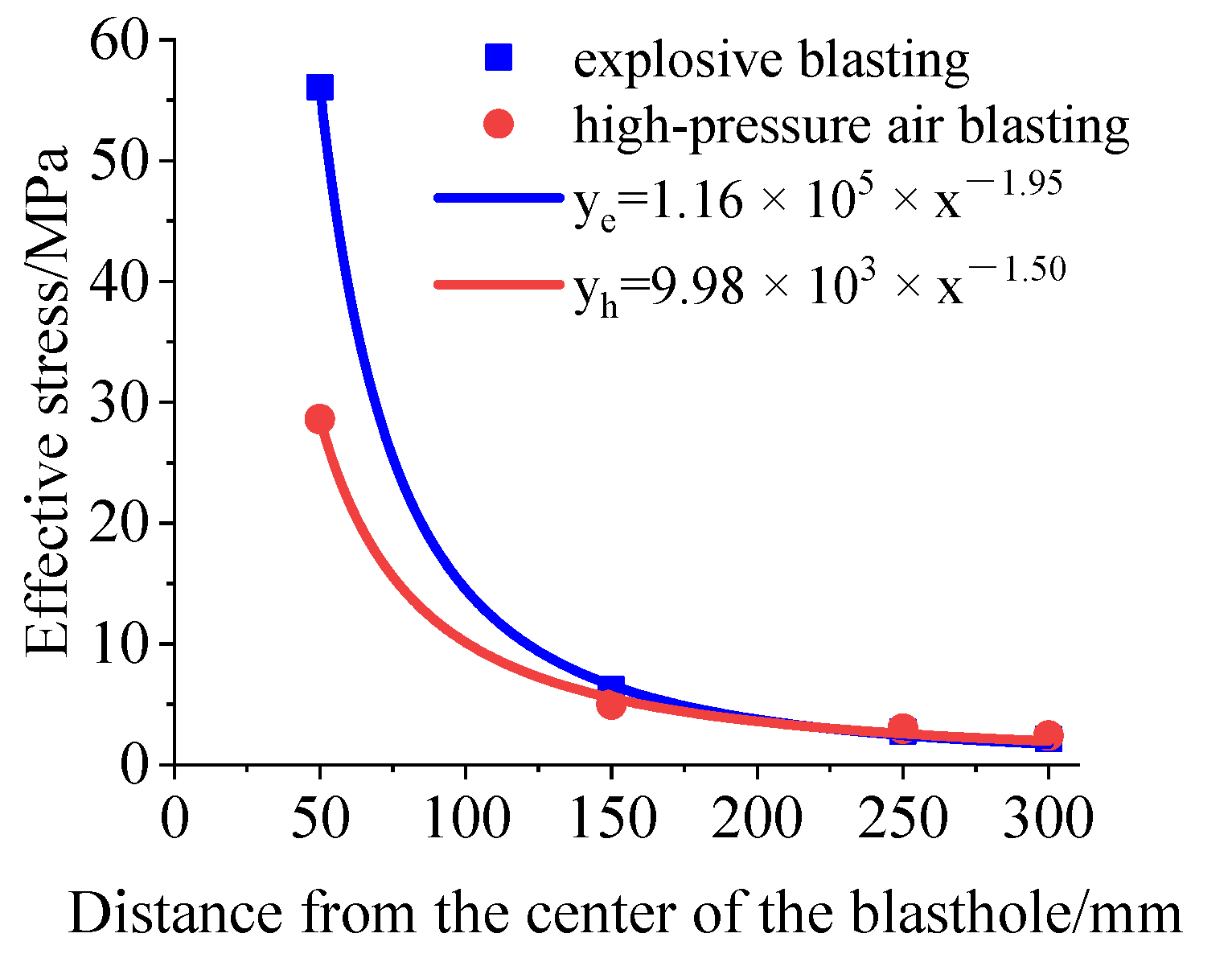

4.1. Stress Field in Coal Mass Induced by HPAB

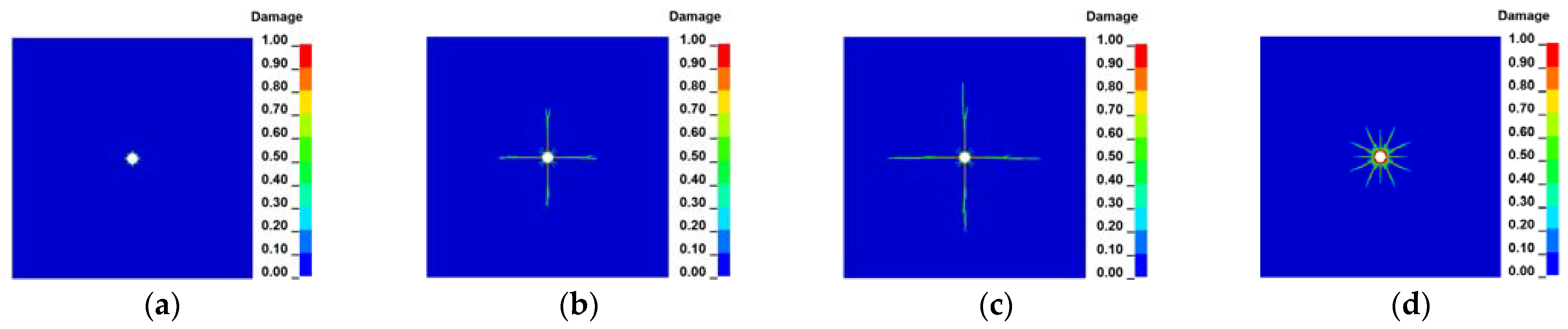

4.2. Propagation of Cracks in Coal Mass Induced by HPAB

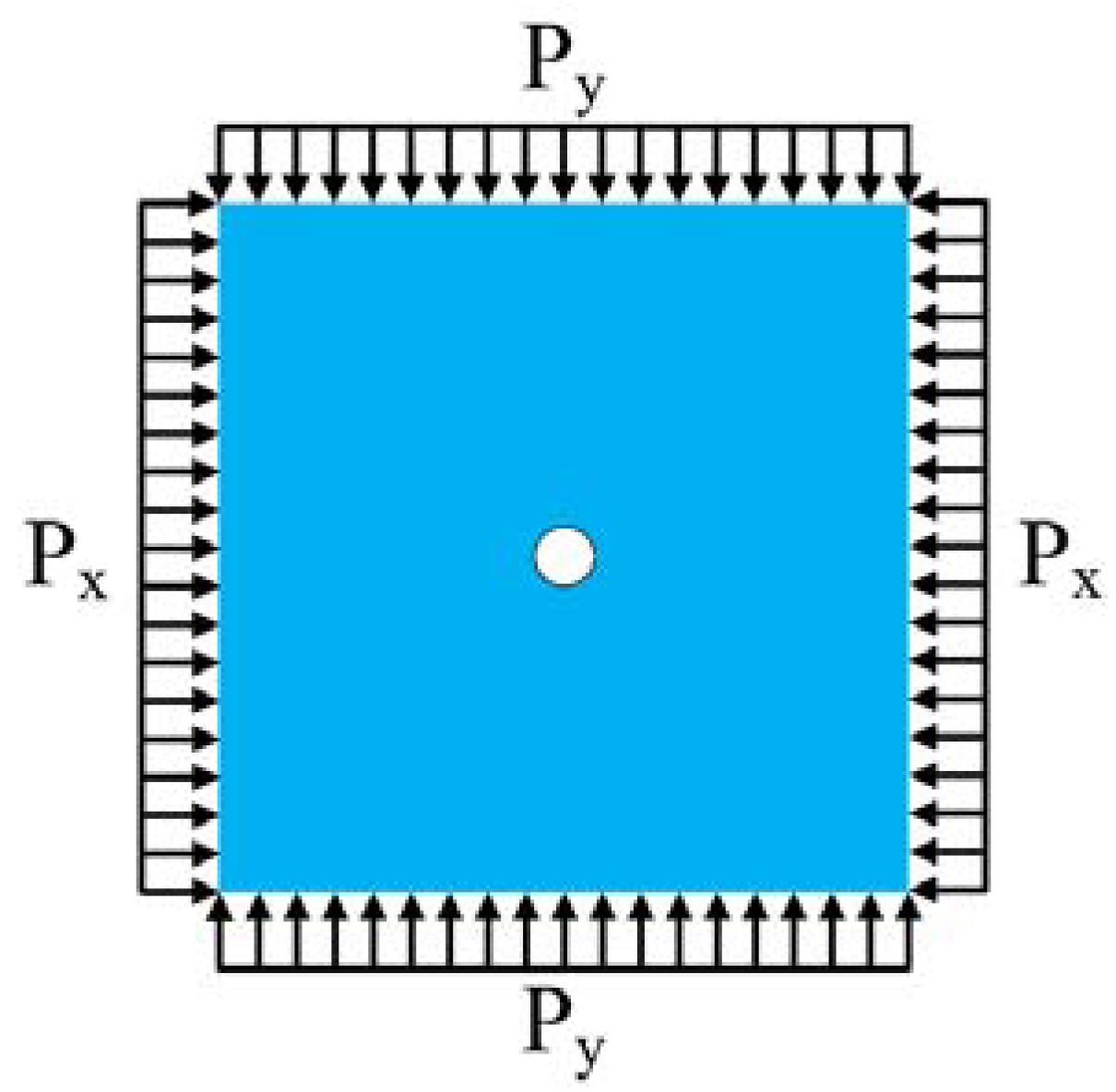

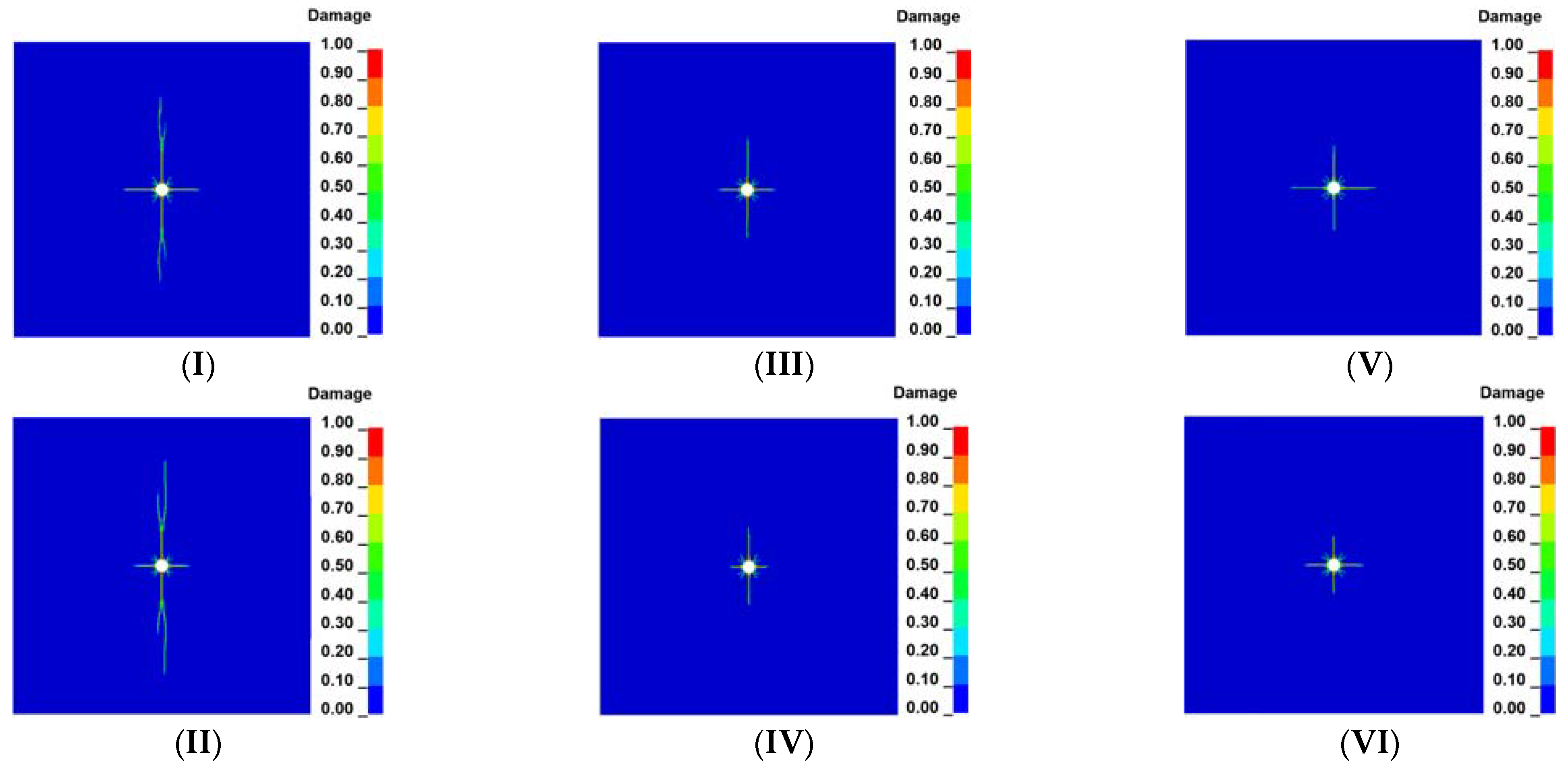

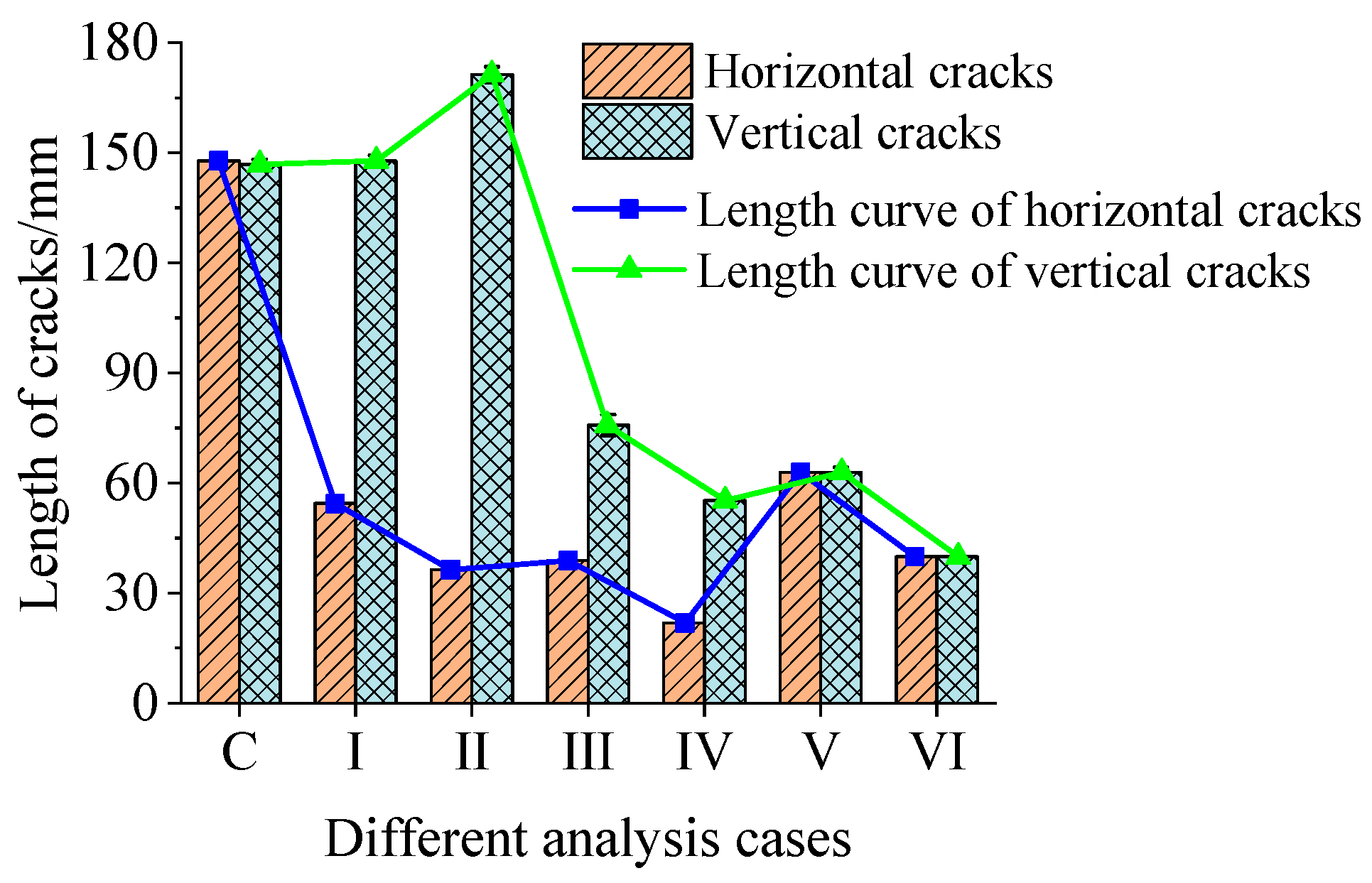

4.3. Effect of In-Situ Stresses on the Crack Propagation

5. Experimental Study on HPAB on Coal Mass Specimen

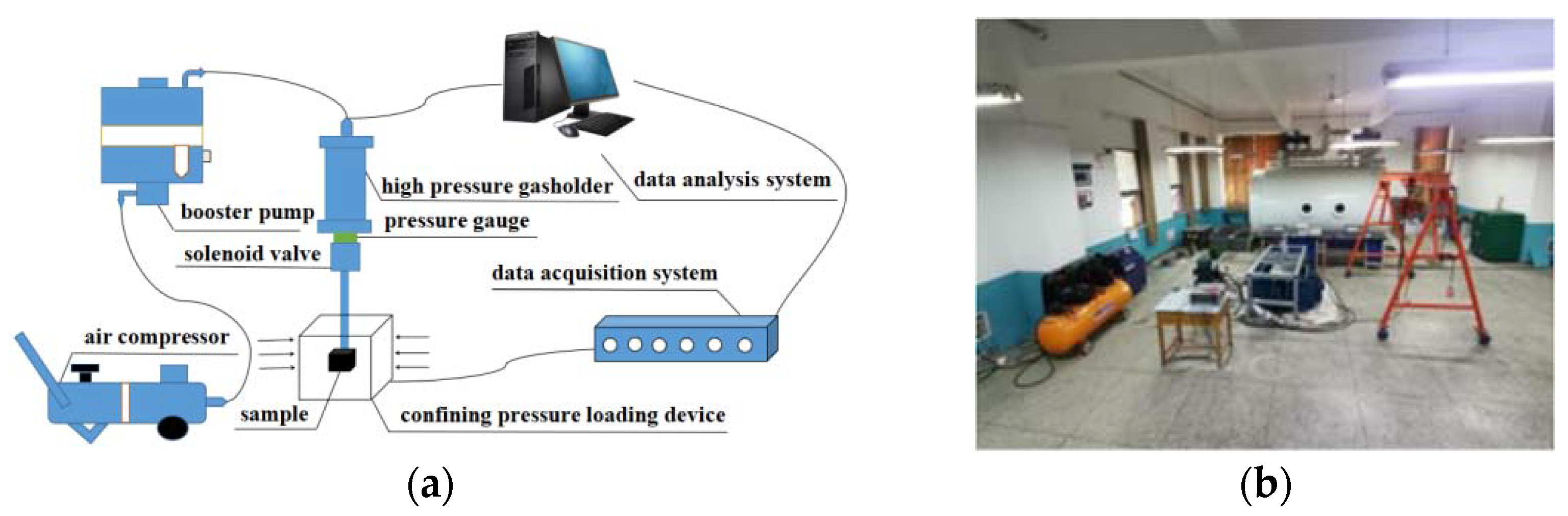

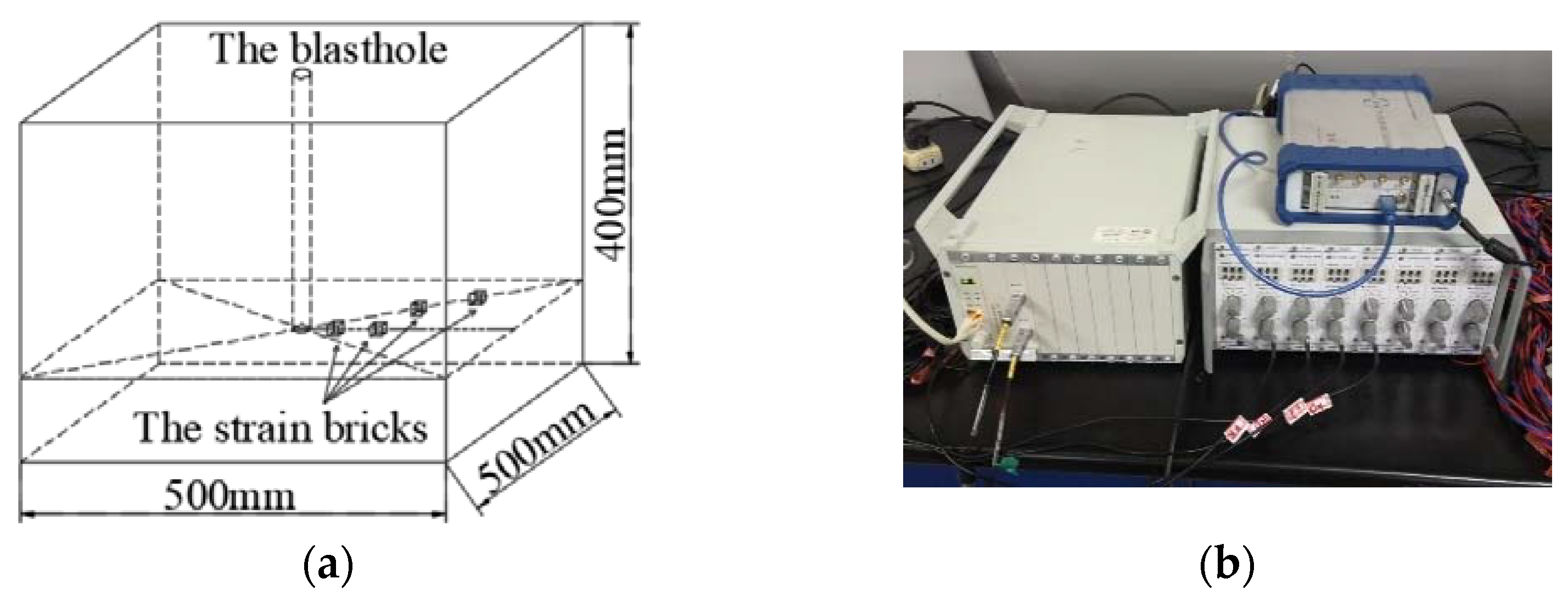

5.1. Simulation Experiment Scheme of HPAB Coal Mass Specimen

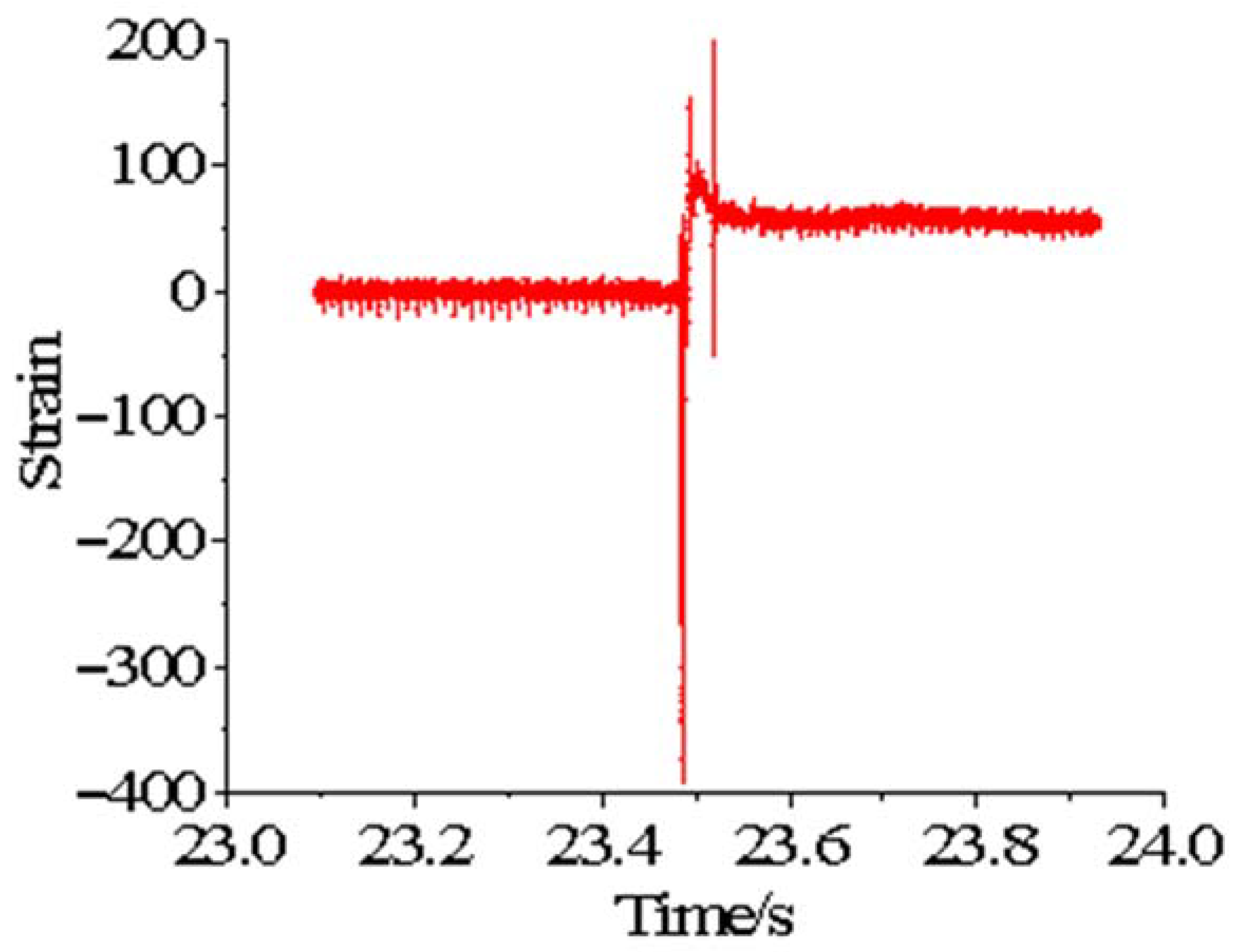

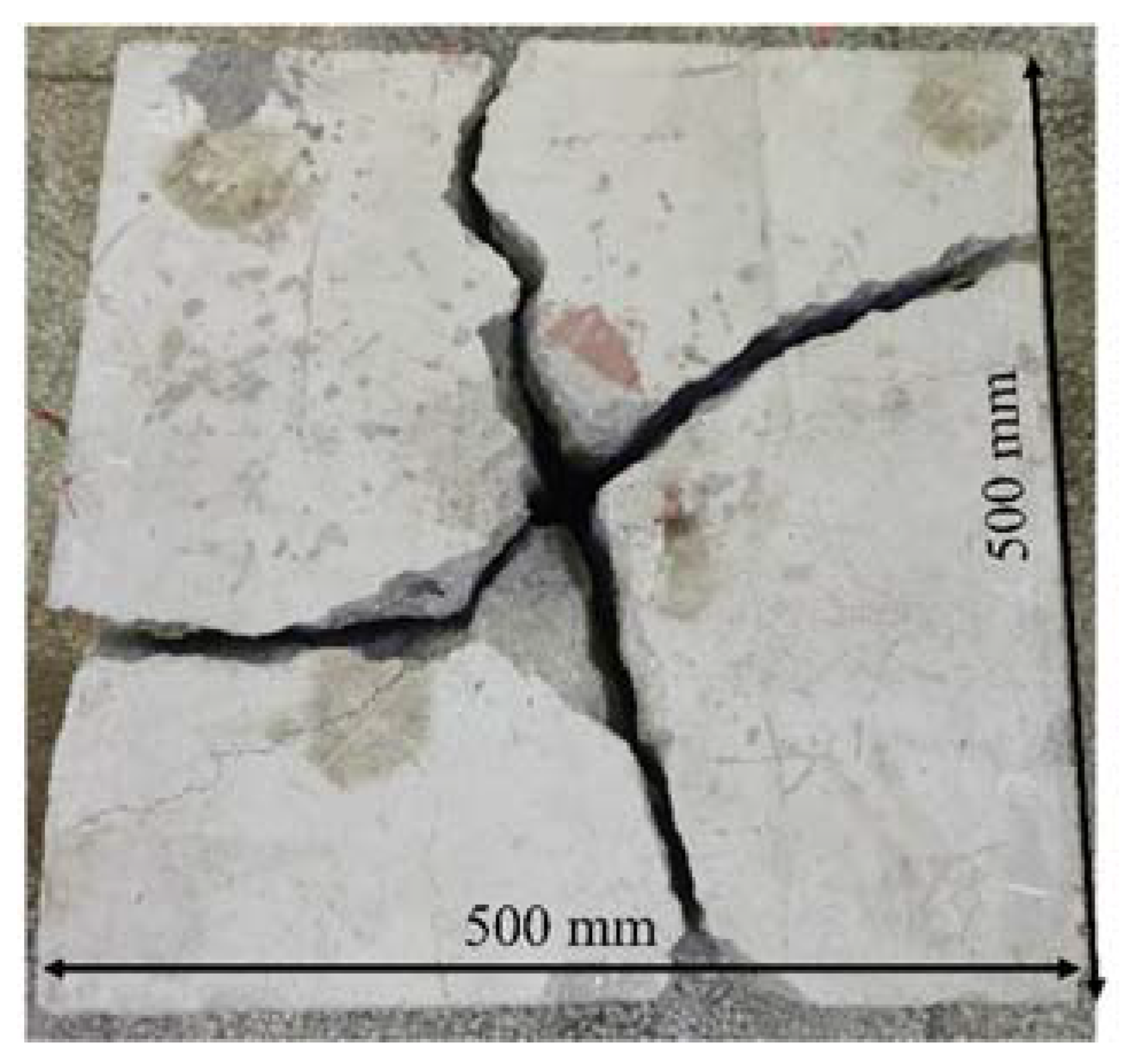

5.2. Strain Wave and Crack Propagation in Coal Mass Specimen Induced by HPAB

5.3. Comparison of Simulated Experiment and Numerical Simulation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, J.; Qu, J.; Wang, Q. Research status and development direction in combustion and explosion of gas and coal dust in coal mine. Coal Mine Mod. 2014, 96–99. [Google Scholar] [CrossRef]

- Li, R.; Si, R.; Wang, l.; Jia, Q. Experimental study on starting condition and effect of active explosion proof for gas and coal dust explosion. J. China Coal Soc. 2021, 1–8. [Google Scholar] [CrossRef]

- Lin, B.Q.; Yan, F.Z.; Zhu, C.J.; Zhou, Y.; Zou, Q.L.; Guo, C.; Liu, T. Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation. J. Nat. Gas Sci. Eng. 2015, 26, 518–525. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, E.; Xu, J.; Peng, S. A new method for coal and gas outburst prediction and prevention based on the fragmentation of ejected coal. Fuel 2021, 287, 119493. [Google Scholar] [CrossRef]

- Al-Anazi, H.A.; Pope, G.A.; Sharma, M.M.; Metcalfe, R.S. Laboratory measurements of condensate blocking and treatment for both low and high permeability rocks SPE Annual Technical Conference and Exhibition. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September 2002. [Google Scholar] [CrossRef]

- Mahadevan, J.; Sharma, M.M.; Yortsos, Y.C. Capillary wicking in gas wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24 September 2006. [Google Scholar]

- Zeng, F.; Li, C.; Sun, K.; Song, W.; Li, Z. Influence of gas explosion on permeability of coal body. Coal Geol. Explor. 2012, 40, 35–38. [Google Scholar]

- Wang, B.; Li, H.; Shao, Z.; Chen, S.; Li, X. Investigating the mechanism of rock fracturing induced by high-pressure gas blasting with a hybrid continuum-discontinuum method. Comput. Geotech. 2021, 140, 104445. [Google Scholar] [CrossRef]

- Zhu, Z.; Mohanty, B.; Xie, H. Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 412–424. [Google Scholar] [CrossRef]

- Hajibagherpour, A.R.; Mansouri, H.; Bahaaddini, M. Numerical modeling of the fractured zones around a blasthole. Comput. Geotech. 2020, 123, 103535. [Google Scholar] [CrossRef]

- Pu, C.; Yang, X.; Zhao, H.; Chen, Z.; Xiao, D. Numerical investigation on crack propagation and coalescence induced by dual-borehole blasting. Int. J. Impact Eng. 2021, 157, 103983. [Google Scholar] [CrossRef]

- Zhu, W.C.; Gai, D.; Wei, C.H.; Li, S.G. High-pressure air blasting experiments on concrete and implications for enhanced coal gas drainage. J. Nat. Gas Sci. Eng. 2016, 36, 1253–1263. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Zhang, Y.; Ranjith, P.G. Numerical simulation of blasting-induced fracture expansion in coal masses. Int. J. Rock Mech. Min. Sci. 2017, 100, 28–39. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H.; Wang, J.; Tian, N. Finite element analyses of constitutive models performance in the simulation of blast-induced rock cracks. Comput. Geotech. 2021, 135, 104172. [Google Scholar] [CrossRef]

- Ma, G.W.; An, X.M. Numerical simulation of blasting-induced rock fractures. Int. J. Rock Mech. Min. Sci. 2008, 45, 966–975. [Google Scholar] [CrossRef]

- Kutter, H.; Fairhurst, C. On the fracture process in blasting. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1971, 8, 181–202. [Google Scholar] [CrossRef]

- Chu, H.; Yang, X.; Wang, C.; Liang, W. Study on the coal damage and fracture mechanism under multiple actions of blasting stress wave. Arab. J. Sci. Eng. 2021, 46, 10847–10854. [Google Scholar] [CrossRef]

- Yi, C.; Johansson, D.; Greberg, J. Effects of in-situ stresses on the fracturing of rock by blasting. Comput. Geotech. 2018, 104, 321–330. [Google Scholar] [CrossRef]

- Jayasinghe, L.B.; Shang, J.; Zhao, Z.; Goh, A.T.C. Numerical investigation into the blasting-induced damage characteristics of rocks considering the role of in-situ stresses and discontinuity persistence. Comput. Geotech. 2019, 116, 103207. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Wang, J.; Wang, S.; Wang, H.; Yin, Y.; Li, F. Effect of confining pressure on damage accumulation of rock under repeated blast loading. Int. J. Impact Eng. 2021, 156, 103961. [Google Scholar] [CrossRef]

- Riedel, W.; Thoma, K.; Hiermaier, S. Penetration of reinforced concrete by BETA-B-500 numerical analysis using a new macroscopic concrete model for hydrocodes. In Proceedings of the Internationales Symposium, Interaction of the Effects of Munitions with Structures, Berlin/Strausberg, Germany, 3 May 1999. [Google Scholar]

- Borrvall, T.; Riedel, W. The RHT concrete model in LS-DYNA. In Proceedings of the 8th European LS-DYNA User Conference, Strasbourg, France, 23 May 2011. [Google Scholar]

- Chu, H.; Yang, X.; Yu, Y.; Liang, W. Test and research on similar material selection for coal blasting. Coal Sci. Technol. 2010, 38, 31–33. [Google Scholar]

- Malvar, L.J.; Crawford, J.E.; Wesevich, J.W.; Simons, D. A plasticity concrete material model for DYNA3D. Int. J. Impact Eng. 1997, 19, 847–873. [Google Scholar] [CrossRef]

- Li, H. The Study of the Rock RHT Model and to Determine the Values of Main Parameters; China University of Mining & Technology-Beijing: Beijing, China, 2016. [Google Scholar]

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons: Manhattan, NY, USA, 1994. [Google Scholar]

- Ning, J.; Wang, C.; Ma, T. Explosion and Shock Dynamics; National Defense Industry Press: Beijing, China, 2010. [Google Scholar]

- Yang, M. Calculation and measurement of concrete impact insulation line. In Proceedings of the Material Penetration Symposium, Sanya, China, 1 December 2001. [Google Scholar]

- Holmquist, T.J.; Johnson, G.R. A computational constitutive model for concrete subjected to large strains, high strain rates, and high pressures. In Proceedings of the 14th International Symposium on Ballistics, Quebec City, QC, Canada, 26–29 September 1993. [Google Scholar]

- Zhao, J. Failure Mechanism of Hard Thick Coal under Various Types of Disturbance at the Front of Mining Face; China University of Mining & Technology-Beijing: Beijing, China, 2018. [Google Scholar]

- Huang, Y. Numerical Simulation of Rock Blasting Damage Evolution Based on HJC Constitutive Model; Hefei University of Technology: Hefei, China, 2020. [Google Scholar]

- Bi, C.; Wang, Z.; Shi, G.; Hao, S. The application of initial volume fraction method in explosion simulation. Eng. Blast. 2017, 23, 26–33+38. [Google Scholar]

- Li, W.; Di, G.; Wang, R. Analysis of a liquid CO2 tank explosion on a ship. Saf. Environ. Eng. 2010, 17, 95–98. [Google Scholar]

- Chu, H.; Yang, X.; Hou, A.; Yu, Y.; Liang, W. A simulation-based experimental study on explosion stress wave propagation and attenuation in coal. Explos. Shock Waves 2012, 32, 185–189. [Google Scholar]

- Chu, H.; Yang, X.; Yu, Y.; Liang, W. Study on the damage-fracture process and mechanism of blasting. J. Min. Saf. Eng. 2018, 35, 410–414. [Google Scholar]

- Chu, H.; Yang, X.; Liang, W.; Yu, Y. Simulation experimental study on coal blast mechanism. J. China Coal Soc. 2011, 36, 1451–1456. [Google Scholar]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| ρ0(kg/m3) | 1820 | Fc(MPa) | 30 | α0 | 1.6 |

| Pel(MPa) | 10 | βc | 0.03636 | βt | 0.04 |

| A1(GPa) | 11.19 | A2(GPa) | 13.65 | A3(GPa) | 6.548 |

| B0 | 1.22 | B1 | 1.22 | T1(GPa) | 11.19 |

| T2 | 0 | G(GPa) | 3.79 | EOC(s−1) | 3.0 × 10−5 |

| EOT(s−1) | 3.0 × 10−6 | EC(s−1) | 3.0 × 1025 | ET(s−1) | 3.0 × 1025 |

| B | 0.0105 | A | 1.60 | N | 0.61 |

| Fs* | 0.2 | Ft* | 0.1 | Q0 | 0.6805 |

| Gc* | 0.53 | Gt* | 0.7 | XI | 0.5 |

| Af | 1.6 | Nf | 0.61 | Np | 4 |

| ρ(g·cm−3) | D(m·s−1) | A(GPa) | B(GPa) | R1 | R2 | ω | Pcj(GPa) | E0(GPa) |

|---|---|---|---|---|---|---|---|---|

| 0.95 | 3600 | 347 | 0.733 | 4.15 | 0.95 | 0.3 | 9.0 | 1.0 |

| Case | Px(MPa) | Py(MPa) | λ |

|---|---|---|---|

| Comparative case | 0 | 0 | / |

| I | 0 | 2 | 0 |

| II | 0 | 4 | |

| III | 2 | 4 | 0.5 |

| IV | 3 | 6 | |

| V | 2 | 2 | 1 |

| VI | 4 | 4 |

| No. | The Material Mass Ratio | Density (g/cm3) | Wave Velocity(m/s) | Porosity(%) | Testing Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|

| Cement: Sand: Gypsum: Water: Perlite: Foaming Agent: Mica Scraps | ||||||

| I | 1.7: 4.1: 0.3: 0.55: 0.0203: 0.055: 0.03 | 1.82 | 2480 | 1.6 | 30.0 | 9.10 |

| Monitoring Point | The Peak Strains/μs | |||

|---|---|---|---|---|

| Samples | 50 mm | 150 mm | 250 mm | 300 mm |

| I | 4754 | 927 | / | / |

| II | 5220 | / | / | 305 |

| III | 4829 | 934 | 311 | 275 |

| IV | / | 1135 | 342 | / |

| V | 4814 | / | / | / |

| Average value | 4904 | 999 | 327 | 290 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Wang, C.; Chu, H.; Yan, S.; Wei, H.; Yu, M. Study on the Stress Field and Crack Propagation of Coal Mass Induced by High-Pressure Air Blasting. Minerals 2022, 12, 300. https://doi.org/10.3390/min12030300

Yang X, Wang C, Chu H, Yan S, Wei H, Yu M. Study on the Stress Field and Crack Propagation of Coal Mass Induced by High-Pressure Air Blasting. Minerals. 2022; 12(3):300. https://doi.org/10.3390/min12030300

Chicago/Turabian StyleYang, Xiaolin, Chang Wang, Huaibao Chu, Shaoyang Yan, Haixia Wei, and Mengfei Yu. 2022. "Study on the Stress Field and Crack Propagation of Coal Mass Induced by High-Pressure Air Blasting" Minerals 12, no. 3: 300. https://doi.org/10.3390/min12030300

APA StyleYang, X., Wang, C., Chu, H., Yan, S., Wei, H., & Yu, M. (2022). Study on the Stress Field and Crack Propagation of Coal Mass Induced by High-Pressure Air Blasting. Minerals, 12(3), 300. https://doi.org/10.3390/min12030300